M06K40A18-00

CKN-XHE2i 7.1-14.2

High eciency “Roof Top” air cooled heat pump

Installation and

operating manual

08-05-18

Dear Customer,

We congratulate you on choosing this product

For many years Clivet has been oering systems that provide maximum comfort, together with high

reliability, eciency, quality and safety.

The aim of the company is to oer advanced systems, that assure the best comfort, reduce energy

consumption and the installation and maintenance cost for the life cycle of the system.

The purpose of this manual is to provide you with information that is useful from reception of

the equipment, through installation, operational usage and nally disposal so that this advanced

system oers the beat solution.

Yours faithfully.

CLIVET Spa

The data contained in this manual is not binding and may be changed by the manufacturer without

prior notice.

Reproduction, even is part, is FORBIDDEN © Copyright - CLIVET S.p.A. - Feltre (BL) - Italia

Index of contents

1 General description

2 Reception

3 Positioning

4 Water connections

5 Aeraulic connections

6 Electrical connections

7 Start-up

8 Control

9 Maintenance

10 Accessories

11 Decommissioning

12 Residual risks

13 Technical information

4

6

9

13

14

15

20

26

4

5

54

5

M06K40A18-00 CKN-XHE2i 7.1-14.2 3

1 General description

1.1 Manual

The manual provides correct unit installation, use and maintenance.

Pay particular attention to:

Warning, identies particularly important operations or information.

Prohibited operations that must not be carried out, that compromise the operating of the unit or may cause damage to persons or things.

It is advisable to read it carefully so you will save time during operations.

•

Follow the written indications so you will not cause damages to things and injuries people.

•

1.2 Preliminaries

Only qualied personnel can operate on the unit, as required by the regulation in force.

1.3 Risk situations

The unit has been designed and created to prevent injures to people.

During designing it is not possible to plane and operate on all risk situation.

Read carefully “Residual risk” section where all situation which may cause damages to things and injuries to people are reported.

Installation, starting, maintenance and repair required specic knowledge; if they are carried out by inexperienced personnel, they may cause

damages to things and injuries people.

1.4 Intended use

Use the unit only:

civil air-conditioning

•

keep to the limits foreseen in the technical schedule and in this manual

•

The manufacturer accepts no responsibility if the equipment is used for any purpose other than the intended use.

1.5 Installation

Outdoor installation

The positioning, hydraulic system, refrigerating, electrics and the ducting of the air must be determined by the system designer in accordance

with local regulations in force.

Follow local safety regulations.

Verify that the electrical line characteristics are in compliance with data quotes on the unit serial number label.

1.6 Maintenance

Plan periodic inspection and maintenance in order to avoid or reduce repairing costs.

Turn the unit o before any operation.

1.7 Modication

All unit modications will end the warranty coverage and the manufacturer responsibility.

1.8 Breakdown/Malfuction

Disable the unit immediately in case of breakdown or malfunction.

Contact a certied service agent.

Use original spares parts only.

Using the unit in case of breakdown or malfunction:

voids the warranty

•

it may compromise the safety of the unit

•

may increase time and repair costs

•

4 CKN-XHE2i 7.1-14.2 M06K40A18-00

1.9 User training

The installer has to train the user on:

Start-up/shutdown

•

Set points change

•

Standby mode

•

Maintenance

•

What to do / what not to do in case of breakdown

•

1.10 Data update

Continual product improvements may imply manual data changes.

Visit manufacturer web site for updated data.

1.11 Indications for the User

Keep this manual with the wiring diagram in an accessible place for the operator.

Note the unit data label so you can provide them to the assistance centre in case of intervention (see “Unit identication” section).

Provide a unit notebook that allows any interventions carried out on the unit to be noted and tracked making it easier to suitably note the

various interventions and aids the search for any breakdowns.

In case of breakdown or malfunction:

Immediately deactivate the unit

•

Contact a service centre authorized by the manufacturer

•

The installer must train the user, particularly on:

Start-up/shutdown

•

Set points change

•

Standby mode

•

Maintenance

•

What to do / what not to do in case of breakdown

•

1.12 Unit indentication

The serial number label is positioned on the unit and allows to indentify all the unit features.

The matriculation plate shows the indications foreseen by the standards, in particular:

unit type

•

serial number (12 characters)

•

year of manufacture

•

wiring diagram number

•

electrical data

•

type of refrigerant

•

refrigerant charge

•

manufacturer logo and address

•

The matriculation plate must never be removed.

It contains uorinated greenhouse gases

Type of refrigerant: R410A

1.13 Serial number

It identies uniquely each unit.

Must be quoted when ordering spare parts.

1.14 Assistance request

Note data from the serial number label and write them in the chart on side, so you will nd them easily when needed.

Series

Size

Serial number

Year of manufacture

Electrical wiringdiagram

M06K40A18-00 CKN-XHE2i 7.1-14.2 5

2 Reception

You have to check before accepting the delivery:

That the unit hasn’t been damaged during transport

•

That the materials delivered correspond with that indicated on the transport document comparing the data with the identication label

•

positioned on the packaging.

In case of damage or anomaly:

Write down on the transport document the damage you found and quote this sentence: “Conditional acceptance clear evidence of

•

deciencies/damages during transport”

Contact by fax and registered mail with advice of receipt to supplier and the carrier.

•

Any disputes must be made within 8 days from the date of the delivery. Complaints after this period are invalid.

2.1 Storage

Observe external packaging instructions.

2.2 Handling

1. Verify unit weight and handling equipment lifting capacity.

2. Identify critical points during handling (disconnected routes, ights, steps, doors).

3. Suitably protect the unit to prevent damage.

4. lifting brackets

5. Lifting with balance

6. Lifting with spacer bar

7. Align the barycenter to the lifting point

8. Use all the lifting brackets (see the dimensional section)

9. Gradually bring the lifting belts under tension, making sure they are positioned correctly.

10. Before starting the handling, make sure that the unit is stable.

6 CKN-XHE2i 7.1-14.2 M06K40A18-00

M06K40A18-00 CKN-XHE2i 7.1-14.2 7

2.3 Packaging removing

Be careful not to damage the unit.

Keep packing material out of children’s reach it may be dangerous.

Recycle and dispose of the packaging material in conformity with local regulations.

8 CKN-XHE2i 7.1-14.2 M06K40A18-00

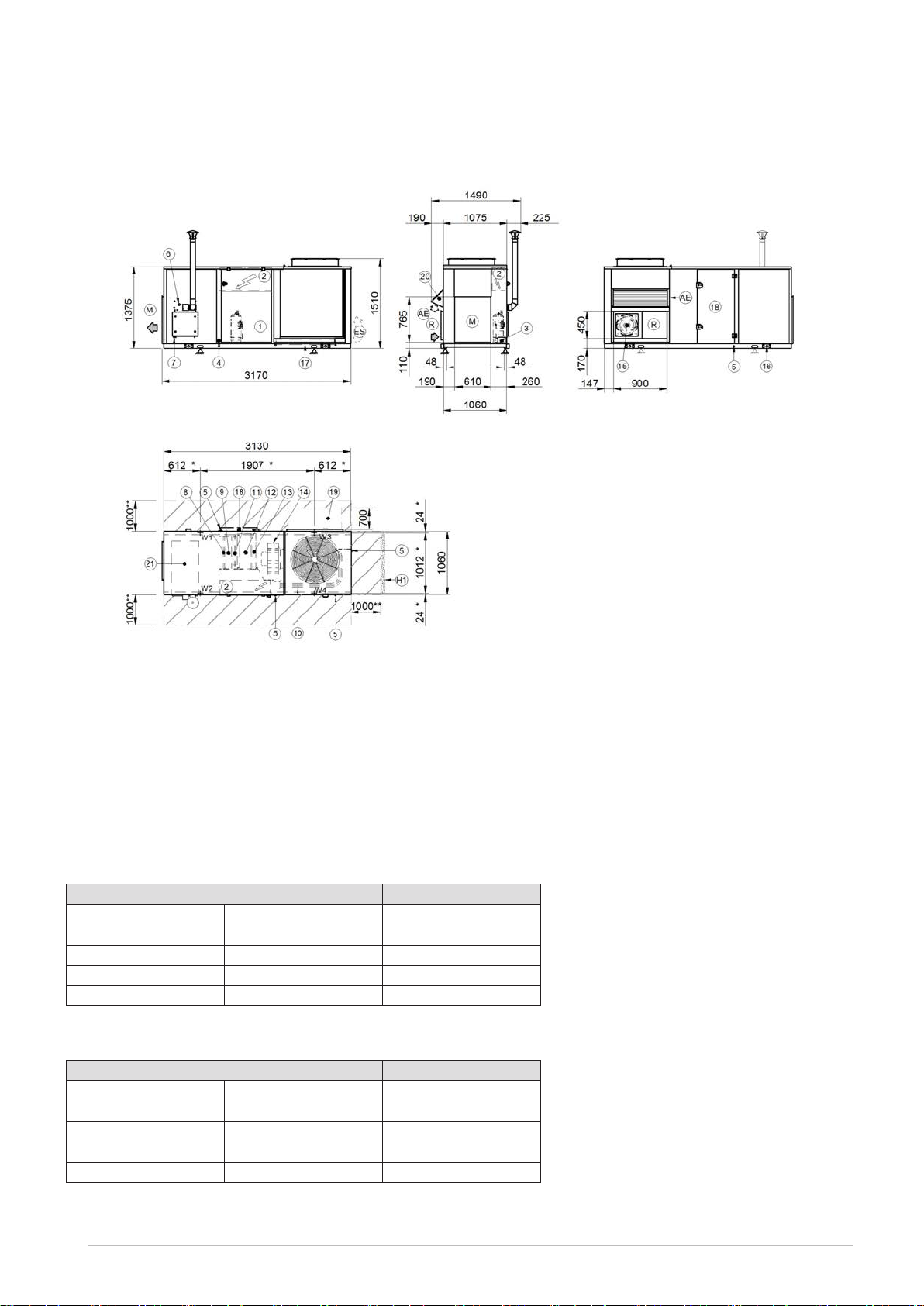

3 Positioning

During positioning consider these elements:

Technical spaces requested by the unit

•

Electrical connections

•

Water connections

•

Spaces for air exhaust and intake

•

3.1 Functional spaces

Functional spaces are designed to:

guarantee good unit operation

•

carry out maintenance operations

•

protect authorized operators and exposed people

•

Respect all functional spaces indicated in the DIMENSIONS section.

Double all functional spaces if two or more unit are aligned.

3.2 Positioning

Units are designed to be installed:

EXTERNAL

•

in xed positions

•

Limit vibration transmission:

use anti-vibration devices or neoprene strips on the unit support points

•

install exible joints on the hydraulic connections

•

install exible joints on the hydraulic connections

•

Choose the installation place according to the following criteria:

Customer approval

•

safe accessible position

•

technical spaces requested by the unit

•

spaces for the air intake/exhaust

•

max. distance allowed by the electrical connections

•

install the unit raised from the ground

•

verify unit weight and bearing point capacity

•

verify that all bearing points are aligned and leveled

•

condensate water draining

•

consider the maximum possible snow level

•

Avoid installations in places subject to ooding

•

Protect the unit with suitable fence in order to avoid access to unauthorised personnel (children, vandals, etc.)

A correct circulation of the air is mandatory to guarantee the good unit operating.

Avoid therefore:

obstacles to the airow

•

diculty of air exchange

•

leaves or other foreign bodies that can obstruct the air coil

•

winds that hinder or favour the airow

•

heat or pollution sources close to the unit (chimneys, extractors etc..)

•

stratication (cold air that stagnates at the bottom)

•

recirculation (expelled air that is sucked in again)

•

incorrect positioning, close to very high walls, attics or in angles that could give rise to stratication or recirculation phenomenons

•

Ignoring the previous indications could:

reduce energy eciency

•

alarm lockout due to HIGH PRESSURE (in summer) or LOW PRESSURE (in winter)

•

M06K40A18-00 CKN-XHE2i 7.1-14.2 9

1

5

2

3

4

1 Positioning on concrete oor 5 Positioning on steel structure

2 2 cm thick neoprene strips 6 antivibration mounts

3 concrete oor 7 steel structure

4 insulation 8 steel structure

Avoid the accumulation of snow and ice in front of the exhaust air outlet

6

7

8

3.3 Saftey valve gas side

The installer is responsible for evaluating the opportunity of installing drain tubes, in conformity with the local regulations in force (EN 378).

3.4 Condensate water

When a heat pump is running it produces a considerable amount of water due to the defrosting cycles of the external coil.

The condensate must be disposed in order to avoid damages to people and things.

10 CKN-XHE2i 7.1-14.2 M06K40A18-00

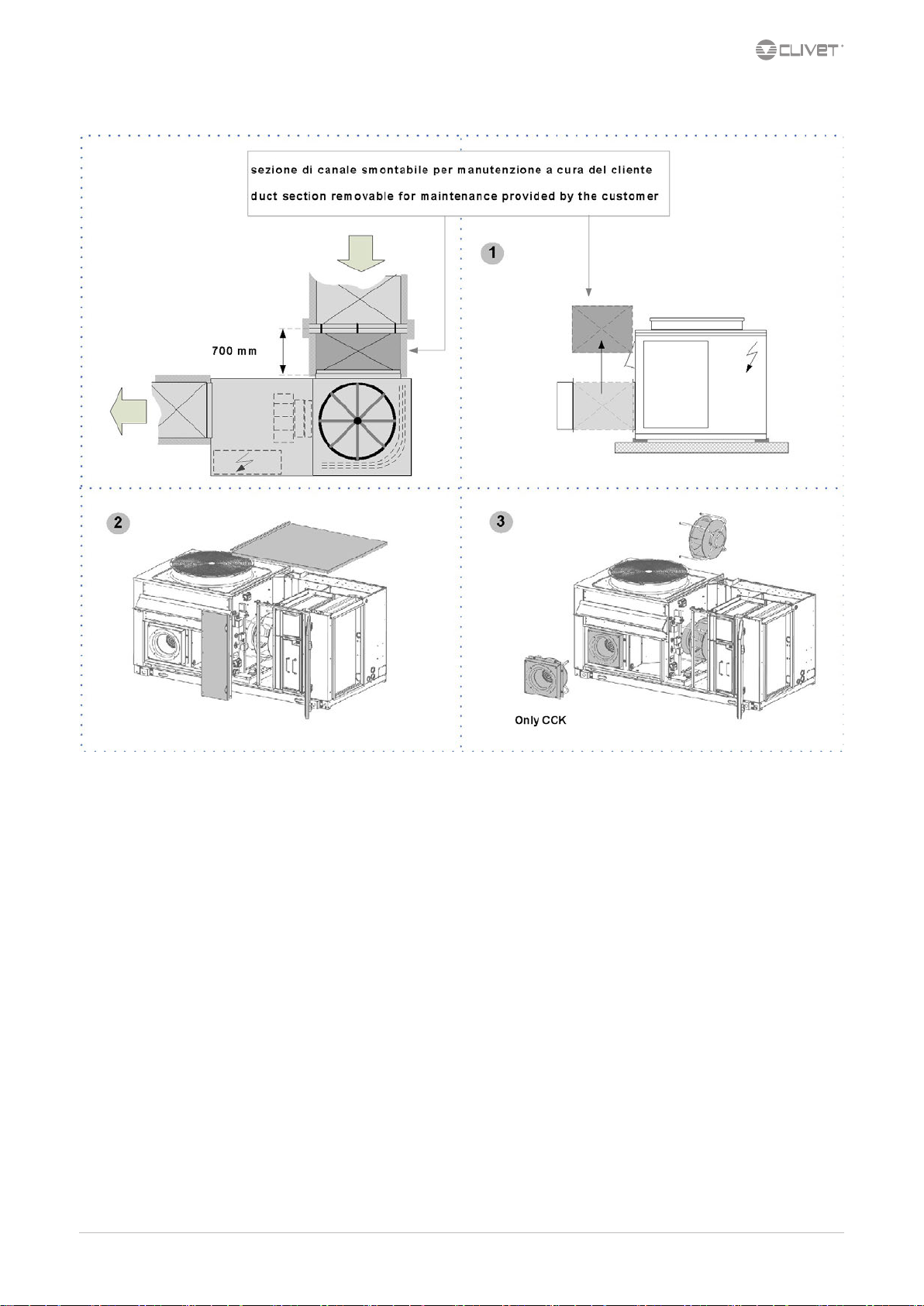

3.5 Congurations CBK, CCK

CUFFIA ARIA ESTERNA - EXTERNAL AIR HOOD

1 - APRIRE CUFFIA ARIA ESTERNA – All’interno ci sono le finiture DX e SX, rete AE + viti di fissaggio

1 – OPEN THE EXTERNAL AIR HOOD – Inside there are right and left parts, grid EA + fixing screws

Togliere viti e

staffa di fissaggio

Remove screws

and

mounting bracket

2 - FISSARE LE FINITURE DX E SX - Esternamente e internamente, sugli appositi fori con le viti in dotazione.

2 – FIX RIGHT and LEFT PARTS - With screws supplied, on the appropriate holes internal and external side.

FISSAGGI ESTERNI - EXTERNAL FIXING FISSAGGI INTERNI - INTERNAL FIXING

Le pieghe in basso devono andare verso l’esterno della cuffia !

The folds on the bottom must be installed on the external side of the air hood !

M06K40A18-00 CKN-XHE2i 7.1-14.2 11

3 - FISSARE LA RETE ARIA ESTERNA ( AE )- Sugli appositi fori con le viti in dotazione.

3 – FIX GRID EXTERNAL AIR ( EA )- With screws supplied, on the appropriate holes.

La piega deve andare verso l’esterno della cuffia

The fold must be installed on the external side of the air hood

3.6 Electronic lter

For details see:

10.1 Electronic ltersp.47

3.7 Gas module

For details see:

10.4 Modulating condensation gas heating modulep.51

12 CKN-XHE2i 7.1-14.2 M06K40A18-00

4 Water connections

4.1 Condensate drain

The condensate must be disposed in order to avoid damages to people and things.

Unit discharge tting: the connection must not transmit mechanical stresses and must be performed taking care not to damage the unit

•

discharge tting.

Provide a siphon that, eliminating the negative pressure caused by the fan, prevents the air intake from the discharge duct.

•

The ducting must have a min. slope of 3% to allow the runo.

•

Anchor the ducting with an adequate number of supports.

•

Insulate the duct and the siphon to avoid the condensate drippings.

•

Connect the condensate discharge to a sewerage drainage network.

•

DO NOT use white water or drainage networks to avoid the aspiration of odours in the case of evaporation of water contained in the siphon.

Check at the end of the work, the regular condensate runo pouring some water in the tray.

4.2 Risk of freezing

If the unit or the relative water connections are subject to temperatures close to 0°C:

mix water with glycol, or

•

safeguard the pipes with heating cables placed under the insulation, or

•

empty the system in cases of long non-use

•

4.3 Anti-freeze solution

The use of an anti-freeze solution results in an increase in pressure drop.

Make sure that the glycol type utilized is inhibited (not corrosive) and compatible with the water circuit components.

Do not use dierent glicol mixture (i.e. ethylene with propylene).

4.4 Humidier

For details see:

10.3 Immersed electrode humidierp.49

M06K40A18-00 CKN-XHE2i 7.1-14.2 13

5 Aeraulic connections

The dimensioning and correct execution of the aeraulic connections are fundamental to guarantee good unit operation and adequate level

of silence in the room.

When designing and manufacturing the ducting, consider LOAD LOSSES, AIR FLOW AND SPEED that must be consistent with the unit features.

Particularly consider that load losses higher than the unit useful prevalence, lead to reduction in ow rate, with consequent unit blocks.

the weight of the channels must not burden on the connection anges

•

place anti-vibration joints between channels and unit

•

connection to the anges and between the various sections of the channels must guarantee air seal, avoiding dispersions penalising the

•

overall eciency of the system

limit the load losses by optimising the path, the type and number of bends and junctions

•

use wide bends evaluating the opportunity of equipping them with deectors (in particular with high air speed or bends with reduced

•

radius)

5.1 Treated air channelling

The internal surface of the channel must be smooth, enable its washing and must not contaminate the air.

Thermally isolate the channels and the anges to avoid energy losses and forming of condensation.

DIFFUSERS INLETS GRILLES

A correct diusion of the air in the room is determining for the level of comfort.

When choosing and positioning the grilles, inlets and diusers, avoid:

excessive air speed

•

forming of stagnant and stratication areas

•

cold air delivery in room

•

forming of localised currents (also due to uneven distribution of air)

•

excessive room temperature variations, vertically and horizontally

•

short circuits of the supply air towards the return air

•

For sound comfort, consider that:

the air diusers must be chosen verifying the sound power generated at nominal ow rate conditions

•

the cut-o to diusers must be carried out with exible elements

•

the return grilles must be widely dimensioned

•

Thermally isolate the channels and the anges to avoid energy losses and forming of condensation.

14 CKN-XHE2i 7.1-14.2 M06K40A18-00

6 Electrical connections

The characteristics of the electrical lines must be determined by qualied electrica personnel able to design electrical installations; moreover,

the lines must be in conformity with regulations in force.

The protection devices of the unit power line must be able to stop all short circuit current, the value must be determined in accordance with

system features.

The power cables and the protection cable section must be dened in accordance with the characteristics of the protections adopted.

All electrical operations should be performed by trained personnel having the necessary qualications required by the regulations in force

and being informed about the risks relevant to these activities.

Operate in compliance with safety regulations in force.

6.1 Electrical data

The serial number label reports the unit specic electrical data, included any electrical accessories.

The electrical data indicated in the technical bulletin and in the manual refer to the standard unit, accessories excluded.

The matriculation plate shows the indications foreseen by the standards, in particular:

Voltage

•

F.L.A.: full load ampere, absorbed current at maximum admitted conditions

•

F.L.I.: full load input, full load power input at max. admissible condition

•

Electrical wiringdiagram Nr.

•

6.2 Connections

1. Refer to the unit electrical diagram (the number of the diagram is shown on the serial number label).

2. Verify that the electrical supply has characteristics conforming to the data shown on the serial number label.

3. Before starting work, ensure the unit is isolated, unable to be turned on and a safety sign used.

4. Ensure correct earth connection.

5. Ensure cables are suitably protected.

6. Respect the indicated phase sequence

7. Before powering up the unit, make sure that all the protections that were removed during the electrical connection work have been

restored.

6.3 Signals / data lines

Do not exceed the maximum power allowed, which varies, according to the type of signal.

Lay the cables far from power cables or cables having a dierent tension and that are able to emit electromagnetic disturbances.

Do not lay the cable near devices which can generate electromagnetic interferences.

Do not lay the cables parallel to other cables, cable crossings are possible, only if laid at 90°.

Connect the screen to the ground, only if there aren’t disturbances.

Guarantee the continuity of the screen during the entire extension of the cable.

Respect impendency, capacity and attenuation indications.

6.4 Power input

Fix the cables: if vacated may be subject to tearing.

The cable must not touch the compressor and the refrigerant piping (they reach high temparatures).

M06K40A18-00 CKN-XHE2i 7.1-14.2 15

6.5 Connections performer by customer

16 CKN-XHE2i 7.1-14.2 M06K40A18-00

6.6 Remote ON-OFF

Do not perform short On O cycles

Do not use the remote On O with thermoregulation function.

YES NO !

A B

B

A B

6.7 Wall mounted electronic room control

Before proceeding, make sure you have:

Name Quantity Notes

Controller 1 KJRH-120H/BMKO-E

Half-round Phillips head mounting screw 3 GB950-86 M4X20 For mounting on wall

Half-round Phillips head mounting screw 2 M4X25 GB823-88 For mounting on electrical junction box

Plastic bolt 2 To install the controller inside the switch box

Plastic expansion plug 3 For mounting on wall

Do not install in a place subject to ammable gas leaks. Once the ammable gases have leaked and spread around the controller, they could

trigger a re.

Do not place the controller near lamps, in order to prevent potential interferences with the controller signal

Do not install the unit in a place subject to excessive amounts of oil, vapour, sulphide gases. Exposure to these substances may cause the

product to deform and stop working.

The wiring must be suited to the controller’s current rating. If not, electrical dispersions or overheating may occur, which could trigger a re.

The controller operates with a low-voltage circuit. Never connect it to a standard 220 V/380 V circuit or insert it through the same cable

grommet of the circuit.

The shielded cable must be stably grounded, or the transmission might fail.

After making the connections, do not use the insulation tester to check the signal cable’s insulation.

Do not apply any external force on the terminal. This may cause the wires to break or overheating, which could trigger a re.

A

B

M06K40A18-00 CKN-XHE2i 7.1-14.2 17

Take a slotted-head screwdriver and insert it into the recess on the lower part of the controller, then turn the screwdriver to lower the back

cover. (Pay attention to the rotation direction, or the back cover may get damaged!)

Use three GB950-86 M4X20 screws to install the back cover directly onto the wall.

Use two GB823-88 M4X25 screws to install the back cover in the electrical junction box 86 and use one GB950-86 M4X20 screw to install it

directly onto the wall.

Adjust the length of the two plastic plugs to the standard distance from the threaded bar of the wall-mounted switch box. When inserting the

plastic plugs into the wall, make sure that the lie ush with the wall.

Use Phillips-head screws to fasten the back cover of the controller to the wall using the plastic plug. Make sure that the back cover of the

controller lies at the same level after installation and mount the controller back onto the rear cover.

Install the back cover correctly and securely fasten both the front and back covers, otherwise the front cover could fall.

18 CKN-XHE2i 7.1-14.2 M06K40A18-00

Make sure that no water penetrates inside the controller; use mastic and other contraptions to seal the cable connectors during installation.

Adjust the front cover then fasten it; avoid blocking the cables during installation.

The sensor must not be subject to humidity.

M06K40A18-00 CKN-XHE2i 7.1-14.2 19

7 Start-up

7.1 General description

The indicated operations should be done by qualied technician with specic training on the product.

Upon request, the service centres performing the start-up.

The electrical, water connections and the other system works are by the installer.

Agree upon in advance the star-up data with the service centre.

Before checking, please verify the following:

the unit should be installed properly and in conformity with this manual

•

the electrical power supply line should be isolated at the beginning

•

the unit isolator is open, locked and equipped with the suitable warning

•

make sure no tension is present

•

After turning o the power, wait at least 5 minutes before accessing to the electrical panel or any other electrical component.

Before accessing check with a multimeter that there are no residual stresses.

7.2 Preliminary checks

For details refer to the dierent manual sections.

Unit OFF power supply

1. safety access

2. functional spaces

3. air ow: correct return and supply (no bypass, no stratication)

4. structure integrity

5. fans run freely

6. unit on vibration isolators

7. air lters present and clean

8. completed aeraulic system

9. refrigerant circuit visual check

10. earthing connection

11. power supply features

12. electrical connections provided by the customer

7.3 Start-up sequence

For details refer to the dierent manual sections.

Unit ON power supply

1. the compressor crankcase heating elements have been running for at least 12 hours

2. o-load voltage measure

3. phase sequence check

4. shut-o valve refrigerant circuit open

5. unit ON

6. load voltage measure and absorptions

7. check all fan operating

8. check air ow on outer coil (no by-pass, no stratication)

9. air ow rate measurement

10. supply, return and outdoor air temperature measurement

11. measure super-heating and sub-cooling

12. check no anomalous vibrations are present

13. climatic curve personalization

14. climatic curve personalization

15. scheduling personalization

16. re alarm conguration *

17. complete and available unit documentation

* only if present

20 CKN-XHE2i 7.1-14.2 M06K40A18-00

7.4 Refrigeration circuit

1. Check carefully the refrigerating circuit: the presence of oil stains can mean leakage caused by transportation, movements or other).

2. Verify that the refrigerating circuit is in pressure: Using the unit manometers, if present, or service manometers.

3. Make sure that all the service outlets are closed with proper caps; if caps are not present a leak of refrigerant can be possible.

4. Open the valves of the refrigerant circuit, if there are any.

7.5 Water circuit

1. Before realizing the unit connection make sure that the hydraulic system has been cleaned up and the cleaning water has been drained.

2. Check that the water circuit has been lled and pressurized.

3. Check that the shut-o valves in the circuit are in the “OPEN” position.

4. Check that there isn’t air in the circuit, if required, evacuate it using the air bleed valve placed in the system high points.

5. When using antifreeze solutions, make sure the glycol percentage is suitable for the type of use envisaged.

Neglecting the washing will lead to several lter cleaning interventions and at worst cases can cause damages to the exchangers and the

other parts.

Weight of glycol (%) 10 20 30 40

Freezing temperature (°C) -3.9 -8.9 -15.6 -23.4

Safety temperature (°C) -1 -4 -10 -19

7.6 Electric Circuit

Verify that the unit is connected to the ground plant.

Check the conductors are tightened as: the vibrations caused by handling and transport might cause these to come loose.

Connect the unit by closing the sectioning device, but leave it on OFF.

Check the voltage and line frequency values which must be within the limits: 400/3/50 +/- 10%

Check and adjust the phase balance as necessary: it must be lower than 2%

Example

Working outside of these limits can cause irreversible damages and voids the warranty.

7.7 Compressor crankcase heaters

Power the heating elements of the compressor oil for at least 12 hours before the compressor starts:

at the rst unit start-up

•

after each prolonged period of inactivity

•

1. Supply the resistances switching o the unit isolator switch.

2. The heating elements activate with an outdoor temperature below 3°C.

3. To make sure that heaters are working, check the power input.

4. At start-up the compressor crank-case temperature on the lower side must be higher at least of 10°C than the outside temperature.

Do not start the compressor with the crankcase oil below operating temperature.

M06K40A18-00 CKN-XHE2i 7.1-14.2 21

7.8 Voltages

Check that the air and water temperatures are within in the operating limits.

Start-up the unit.

With unit operating in stable conditions, check:

Voltage

•

Total absorption of the unit

•

Absorption of the single electric loads

•

7.9 Remote controls

Check that the remote controls (ON-OFF etc) are connected and, if necessary, enabled with the respective parameters as indicated in the

“electrical connections” section.

Check that probes and optional components are connected and enabled with the respective parameters (“electrical connections” section and

following pages).

7.10 Air ow management

Standard mode

The delivery air ow stays constant as the thermal load varies.

The ventilation remains active even when the setpoint is fullled.

Constant air ow rate

Option

The delivery air ow rate stays constant during variations in the thermal load and head losses of the unit and system.

The ventilation remains active even when the setpoint is fullled.

Variable airow

Option

The air ow supply varies depending on the heat load, up to a minimum value compatible with the distribution system and the chosen air

diusion.

The ventilation remains active even when the setpoint is fullled.

7.11 Air ow setting

Standard mode

The real unit ow is according to the aeraulic system features.

Before checking, make sure that the system has been completed in all its parts (shunts, dampers, grilles, diusers etc.).

Check the doors and windows of the serviced room are closed.

The unit must be calibrated while full recirculation has been running for at least 30 minutes.

The unit is in full recirculation during the rst 60 minutes of operation.

Set the fan’s percentage of operation:

FanSpeedOutMand

22 CKN-XHE2i 7.1-14.2 M06K40A18-00

7.12 ECO mode

The air

ow supply remains constant at varied heat loads and is shutdown when setpoint is fullled.

To further increase the energy savings in this condition, it is also possible to set less demanding operation setpoints for the unit in respect to

the standard mode.

This function is indicated for the thermal maintenance of the served area in case it is temporarily not used, which can for example occur

at night.

In ECO mode, the renewal air is not managed.

The ECO mode can be activated:

Manually: P04 Enable EcoMode = 1

•

Automatically by means supervision system

•

Example in cooling mode:

7.13 Operating mode

The set point can be xed (1) or variable depending on the outdoor temperature (2).

Menu: Auto Temp. Setting

The HEAT/COOL mode can be modied:

manually through the SA5 contact, from the keypad or through the BMS

•

automatically depending on the return temperature

•

To choose, set 1.06 EnMode.

Entonces será posible elegir entre 4 tipos de funcionamiento:

1. Fixed set point - Manual mode

2. Fixed set point - Automatic mode

3. Variable set point - Manual mode

4. Automatic set point - Automatic mode

M06K40A18-00 CKN-XHE2i 7.1-14.2 23

Fixed set point - Manual mode

Fixed set point - Automatic mode

Variable set point - Manual mode

Automatic set point - Automatic mode

24 CKN-XHE2i 7.1-14.2 M06K40A18-00

7.14 Fire alarm: conguration

It is possible to congure the unit behaviour in presence of alarm signal.

Par 1.11 TypeFireMode

The unit cannot be used as smoke extractor.

Any re detection devices built-in the unit must be considered as an auxiliary safety system, and, accordingly, must not be a replacement for

any re detection devices in the room.

7.15 Room pressure calibration

CCK congurations

1. check the doors and windows of the serviced room are closed

2. calibration must be carried out with unit all in recirculation

3. view the status on the display: Pf2 RETURN AIR PRE

4. wait for the pressure value to stabilise and take note of the value

5. to keep the room at neutral pressure, memorise the value of the read pressure in 5.07 SetPAmb

6. to maintain the room in overpressure, memorise a higher value respect to that detected

7. to maintain the room in depression, memorise a lower value

7.16 Start-up report

Identifying the operating objective conditions is useful to control the unit over time.

With unit at steady state, i.e. in stable and close-to-work conditions, identify the following data:

total voltages and absorptions with unit at full load

•

absorptions of the dierent electric loads (compressors, fans, pumps etc)

•

temperatures and ows of the dierent uids (water, air) both in input and in output from the unit

•

temperature and pressures on the characteristic points of the refrigerating circuit (compressor discharge, liquid, intake)

•

The measurements must be kept and made available during maintenance interventions.

7.17 2014/68/UE PED directive

DIRECTIVE 2014/68/UE PED gives instructions for installers, users and maintenance technicians as well.

Refer to local regulations; briey and as an example, see the following:

Compulsory verication of the rst installation:

only for units assembled on the installer’s building site (for ex. Condensing circuit + direct expansion unit)

•

Certication of setting in service:

for all the units

•

Periodical verications:

to be executed with the frequency indicated by the Manufacturer (see the “maintenance inspections” paragraph)

•

M06K40A18-00 CKN-XHE2i 7.1-14.2 25

MENU

26

To access the various menus of the HOME page.

▲ up, ▼ down, ◄ left, ► right

▲, ▼, ◄ ►

OK

ON/OFF

BACK

UNLOCK

To shift the cursor, modify the selection or modify the set value.

The parameter can be rapidly modified by pressing it extendedly..

To confirm an operation

To set the ON / OFF function

To return to the previous level.

Press to exit the current page and return to the previous page.

Press extendedly to return to the home page directly.

To lock/unlock.

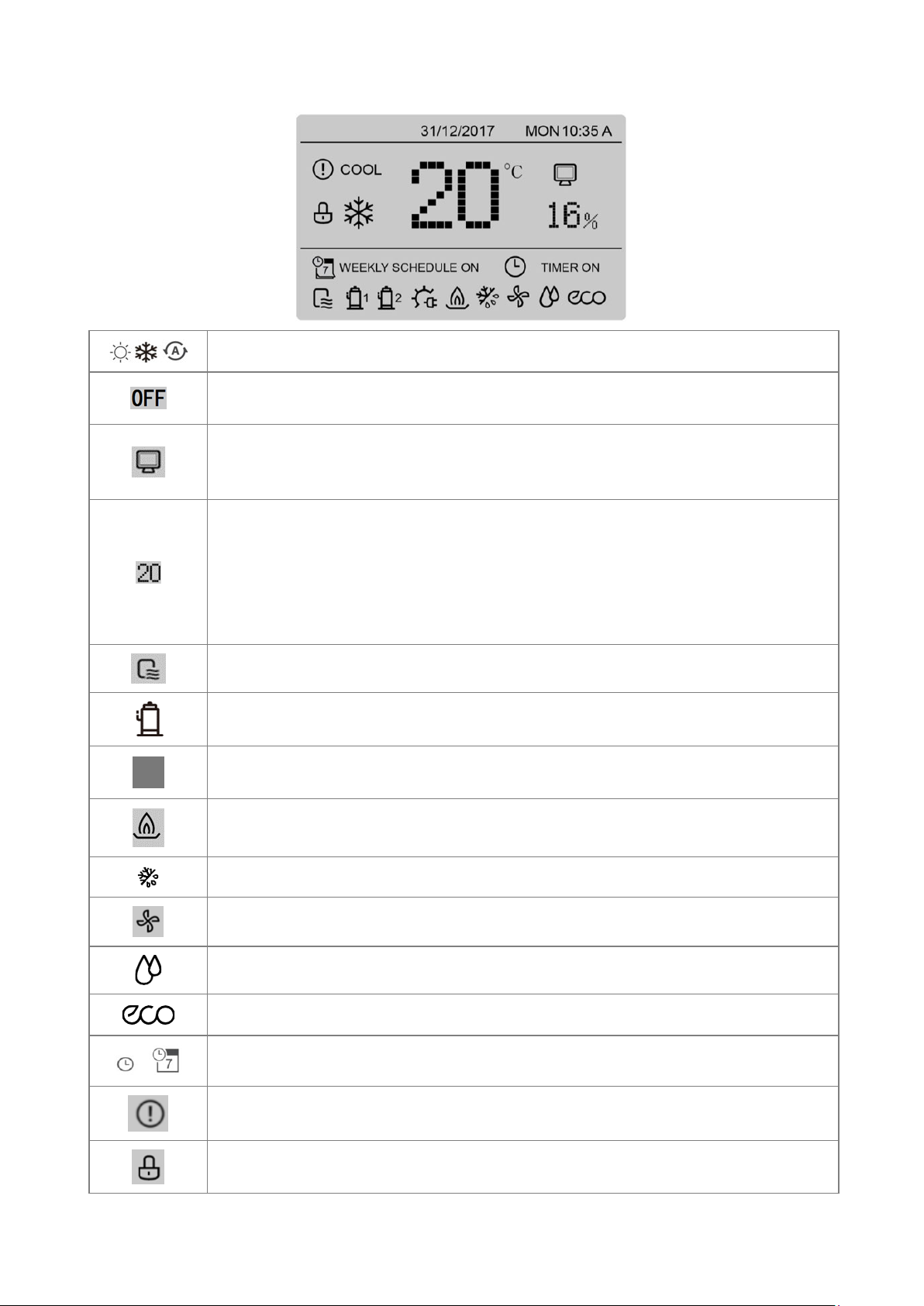

Mode: indicates, respectively, heat, cool and auto

27

Controller deactivated (off)

Remotely controlled controller

Appears when the unit is set from the keypad for being controlled from a remote terminal

or a remote switch.

Return air temperature.

16: value of the return air humidity (indicator on only when humidity check is enabled)

Generally, this area displays the actual temperature of the return air and the relative

humidity of the return air; when the set value is modified, it displays the modified

temperature and the relative humidity.

Unit status: indicator on when the unit is running.

Compressor: indicator on when the compressor is running.

Auxiliary electric heater: indicator on when the auxiliary electric heater

or H2O coil is running.

Gas module: indicator on when the gas module is running.

Defrosting: indicator on when the unit is defrosting the outdoor coil

Internal fan: indicator on when the internal fan is running.

Humidifier: indicator on when the humidifier is running.

Eco running: indicator on when the ECO function is set to ON

Timer: indicator on when a valid timer has been set (weekly schedule).

Alarm: indicator on when a fault occurs or a protection device intervenes.

Lock: indicator on when the controller’s keypad is locked.

Lock/unlock

28

To lock/unlock the screen, press UNLOCK for 3 sec.

Switch-on/off

To switch it on/off, press ON/OFF.

Temperature/humidity adjustment

Press ◄ ► to adjust the temperature

Press ▲▼to select

Press◄ ► to adjust the temperature (if the sensor is enabled)

Press OK to confirm

If no operations are made for more than 10 sec, the system automatically

memorises the settings and returns to the home page

Alarms

If an alarm intervenes, the “!” symbol flashes and the error code appears.

The beeper sounds 3 times for 180 sec.

Press OK: the buzzer can be silenced. Select using ◄ ► and press OK.

Settings menu

29

Press ▲▼ to select each menu option.

Press OK to access the corresponding sub-menu

Press BACK to return to the home page .

If ENMode=0 or =2 (in the ASSISTANCE menu), the mode operation is disabled

If ENMode=3 (in the ASSISTANCE menu), the mode and eco mode operations are

disabled

Operating mode

Choose the mode with

▲▼. Confirm with OK.

After 10 sec, without any operation, the mode is memorised automatically

Timer

30

Select TIMER using ◄ ► and press OK.

Press ◄ ► to select the value of the password Press ▲ ▼

to enter the value of the password.

The password is 123 and cannot be modified.

If the password is incorrect, the display will appear as follows:

After entering the correct password, the display will appear as follows:

Daily timer

Select DAILY TIMER using ▲▼ and press OK .

Press ▲ ▼ to choose timer T1 - T5.

31

Press ON/OFF to enable/disable the selected timer.

Press ▲▼ to select each option to be set

Press ▲ ▼ to adjust the temperature and start/end time parameters.

Press OK to confirm the setting and return to the previous page, or press

BACK to delete the setting and return to the previous page .

Weekly timer

Select DAILY TIMER using ▲▼ and press OK

Press ◄ ► ▲ ▼ to select the days.

Press ON/OFF to confirm/delete the selected days

After the selection, press OK to view the next page

Press ▲ ▼ to choose timer T1 - T5.

Press ON/OFF to enable/disable the selected timer.

Press ON/OFF to enable/disable ECO function

Press ▲▼ to select each option to be set

Press ▲ ▼ to adjust the temperature and start/end time parameters.

Press OK to confirm the setting and return to the previous page,

or press BACK to delete the setting and return to the previous page.

Verification of the weekly schedule

Select WEEKLY SCHEDULE CHECK in the TIMER menu

The WEEKLY CHECK allows for viewing, but not modifying, the weekly

schedule.

Press ▲ ▼ to shift from one day of the week to another.

Verification of the weekly schedule

32

Select CANCEL TIMER in the TIMER menu

Press ◄ ► to select YES.

Press OK to cancel all the settings of the daily and weekly timers.

AUTOMATIC TEMPERATURE

Press ON/OFF to enable/disable the function.

Press OK to confirm or BACK to cancel the operation and return to the previous

page .

When AUTO TEMP. SETTING = ON, manual adjustment of the temperature is

disabled.

Shown to the side is the page that appears when the user attempts to modify

the temperature manually.

Press ◄ ► to select YES.

Press OK to disable the AUTO TEMP. function and return to the previous page

ECO RUNNING

When ECO RUNNING is set to ON, the unit operates in the energy saving

mode..

When ECO RUNNING is set to ON, the set point cannot be modified from the

33

HOME page; if the user attempts to modify it, the following page appears:

If YES is selected, the ECO RUNNING function is disabled; if NO is selected,

ECO RUNNING is still active .

MAIN PARAMETERS

Press ▲ ▼ to select the parameter.

Press ◄ ► to set the value.

Press OK to confirm the value or press BACK to cancel it and return to the

previous page.

If EnURCool = 0 and EnURHeat = 0 are set on the controller, SetUR is

disabled; SetUR and URin are displayed as "--".

If EnDiffMand = 0 is set on the controller, QSetMand is disabled; QSetMand

and QAir are displayed as "--".

If EnProbe = 0 is set on the controller, SetCO2 is disabled; SetCO2 and VOC

are displayed as "--".

If the sensor does not work, the current value is displayed as "--".

ALARM LOG

Press ▲ ▼ to select ERROR CODE.

The time of the error code is that at which the corresponding protection

device intervenes or the error occurs.

Press▲ ▼ to skip to the log pages.

Up to maximum 24 errors can be displayed (when 25 faults occur or

protection devices intervene, the error that occurs first will be cancelled)

Select an error code and press OK to access the page with the details.

If an error occurs, the same page appears

Codice Description

34

E0 Main board EPROM fault

E1 Main board phase error

E2 Communication error between the main board and the keypad/controller

E3 T2 probe fault

E4 Tw probe fault

E5 T3 probe fault

E6 T1 probe fault

E7 T4 probe fault

E8 Power phase protection fault

E9 Compressor type error

Eb T2B probe fault

Ed Tp probe fault

EP Fire alarm

EU Room fan alarm

H0 IPM module communication error

H1 Low-voltage protection

H4 10 interventions of the protection module in 120 minutes

H9 Outdoor fan fault

HE EXV disconnection alarm

F8 Expulsion fan

F9 TF probe fault

C0 Heating elements high temperature alarm

C1 Humidifier alarm

C3 Filter alarm

C4 Electric filter alarm

C6 URin probe fault

C7 URout probe fault

C8 Pf1 probe fault

C9 Pf2 probe fault

CA CO2 probe fault

P0 High discharge temperature or high-pressure protection

P1 Low pressure

P4 High current

P6 L0-L9 module fault

P7 T3 high-temperature protection in cool mode

P9 DC fan outdoor DC protection

Pb Water coil anti-frost protection

PL TF high-temperature alarm

KEYPAD SETTINGS

35

Select INTERFACE SETTING

To shift the cursor, press ▲ ▼;

select ON or OFF

To adjust the value, press ◄ ►.

To select the language, press ▲ ▼.

SERVICE INFORMATION

Select SERVICE INFORMATION

To shift the cursor, press ▲ ▼

MODBUS

Function Code

03

Read Holding Registers

06

Write Single Register

16

Write Multiple Registers

36

1、Summary

The communication protocol is between the wired controller and the unit, adopt Modbus RTU,

wired controller is Master, Unit is Slave.

2 Enabling

Menu > Assistance setting > password > operation parameter :

05 EnOnOff = 2

06 EnMode = 2

3 Communication spec:RS-485:

Protocol :ModbusRTU:9600,8,N,1

Baud rate : 9600bps

Data bits: 8 Data bits

Parity bit:None Parity

Stop bit: 1 stop bit

4 Function code

Unit address is setted by the encoder called “NET ADRESS”. The unit address is corresponding with

Encoder setting+1 (eg, if it is setted to 0, the corresponding unit address is 1). The unit address is shown

in the main borad in the display called “DSP1”.

The default encoder setting is 0. The default address is 1

It should power on the unit after set the dipswitch.

Error code:

Exception Code)

01

Illegal function code

Unsupported function code.

02

illegal data address

The address that is sent when query or set, undefined in the online

controller.

03

illegal data value

The parameters set are illegal, beyond the reasonable range or not

the valid parameter for current state of the wired controller.

Customer's BMS registers

Register

number

Register content

Note

0

Mode setting

8=OFF; 0=Stanby; 1=Cooling mode;

2=Heating mode

1

Temperature setpoint

16°C -- 28°C

2

Ur% setpoint

0% -- 100%

3

Constant airflow setpoint

set [m3/h]

4

Enable Auto Temperature

0=OFF; 1=ON

5

Enable ECO Mode

0=OFF; 1=ON

6

Air quality setpoint

set [ppm]

7

void

8

void

9

void

10

void

Status

Register

number

Register content

Note

200

Host address

-

201

PCB swithches setting

-

202

Encoder setting

7 = size 7.1; 11 = size 10.1; 18 = size 14.2

203

Operation mode

8=OFF; 0=Stanby; 1=Cooling mode;

2=Heating mode

204

HMI visualization

1 = ON

0 = OFF

BIT0 = Unit running

BIT1 = Compressor 1 running

BIT2 = Compressor 2 running

BIT3 = Electric air heater

BIT4 = Gas Burner or Water coil

BIT5 = Defrost Logo

BIT6 = Indoor fan state

BIT7 = Humidifier state

BIT8 = ECO running

BIT9 = Fault state

205

Current compressor

Current [A] Compressor A

37

206

Current compressor

Current [A] Compressor B

207

Frequency compressor

Frequency [Hz] Compressor A

208

Frequency compressor

Frequency [Hz] Compressor B

209

EXV step

step

210

Outdoor fan speed

RPM

211

Supply fan output

%

212

Airflow

2000~2000 m3/h

213

Exhaust fan output

%

214

Damper output

%

215

Fault code

See below

216

Ai setpoint

0 ~ 65535 m3/h

217

T1

-25 °C ~ 70 °C

218

Tc

-25 °C ~ 70 °C

219

T2

-25 °C ~ 70 °C

220

T3

-25 °C ~ 70 °C

221

T4

-25 °C ~ 70 °C

222

TP1

-25 °C ~ 70 °C

223

TP2

-25 °C ~ 70 °C

224

TF1

0 °C ~ 140 °C

225

TF2

0 °C ~ 140 °C

226

T2B

-25 °C ~ 7 0°C

227

Tw

-25 °C ~ 70 °C

228

Pfin

0 Pa ~ 2000 Pa

229

Pfout

0 Pa ~ 2000 Pa

230

URin

0% ~ 100%

231

URout

0% ~ 100%

232

CO2 concentration

0 ppm ~ 2000 ppm

233

Exhaust fan output

%

234

Auxiliary heating source output

%

235

Humidifier output

%

236

Factory test mode output

step

In BMS reading, register 215 displays one of the following "Fault codes" in hexadecimal format (hex),

38

considering only the LOW BYTE.

Consider only the last two alphanumeric digits of the code.

Fault code

A0

A1

A2

A3

A4

A5

A6

A7

A8

A9

AA

AB

AC

AD

AE

AF

AH

AL

AP

AU

LOW BYTE [Hex]

01

02

03

04

05

06

07

08

09

0A

0B

0C

0D

0E

0F

10

11

12

13

14

Fault code

B0

B1

B2

B3

B4

B5

B6

B7

B8

B9

BA

BB

BC

BD

BE

BF

BH

BL

BP

BU

LOW BYTE [Hex]

15

16

17

18

19

1A

1B

1C

1D

1E

1F

20

21

22

23

24

25

26

27

28

Fault code

C0

C1

C2

C3

C4

C5

C6

C7

C8

C9

CA

CB

CC

CD

CE

CF

CH

CL

CP

CU

LOW BYTE [Hex]

29

2A

2B

2C

2D

2E

2F

30

31

32

33

34

35

36

37

38

39

3A

3B

3C

Fault code

E0

E1

E2

E3

E4

E5

E6

E7

E8

E9

EA

EB

EC

ED

EE

EF

EH

EL

EP

EU

LOW BYTE [Hex]

3D

3E

3F

40

41

42

43

44

45

46

47

48

49

4A

4B

4C

4D

4E

4F

50

Fault code

F0

F1

F2

F3

F4

F5

F6

F7

F8

F9

FA

FB

FC

FD

FE

FF

FH

FL

FP

FU

LOW BYTE [Hex]

51

52

53

54

55

56

57

58

59

5A

5B

5C

5D

5E

5F

60

61

62

63

64

Fault code

H0

H1

H2

H3

H4

H5

H6

H7

H8

H9

HA

HB

HC

HD

HE

HF

HH

HL

HP

HU

LOW BYTE [Hex]

65

66

67

68

69

6A

6B

6C

6D

6E

6F

70

71

72

73

74

75

76

77

78

Fault code

L0

L1

L2

L3

L4

L5

L6

L7

L8

L9

LA

LB

LC

LD

LE

LF

LH

LL

LP

LU

LOW BYTE [Hex]

79

7A

7B

7C

7D

7E

7F

80

81

82

83

84

85

86

87

88

89

8A

8B

8C

Fault code

J0

J1

J2

J3

J4

J5

J6

J7

J8

J9

JA

JB

JC

JD

JE

JF

JH

JL

JP

JU

LOW BYTE [Hex]

8D

8E

8F

90

91

92

93

94

95

96

97

98

99

9A

9B

9C

9D

9E

9F

A0

Fault code

N0

N1

N2

N3

N4

N5

N6

N7

N8

N9

NA

NB

NC

ND

NE

NF

NH

NL

NP

NU

LOW BYTE [Hex]

A1

A2

A3

A4

A5

A6

A7

A8

A9

AA

AB

AC

AD

AE

AF

B0

B1

B2

B3

B4

Fault code

P0

P1

P2

P3

P4

P5

P6

P7

P8

P9

PA

PB

PC

PD

PE

PF

PH

PL

PP

PU

LOW BYTE [Hex]

B5

B6

B7

B8

B9

BA

BB

BC

BD

BE

BF

C0

C1

C2

C3

C4

C5

C6

C7

C8

Fault code

R0

R1

R2

R3

R4

R5

R6

R7

R8

R9

RA

RB

RC

RD

RE

RF

RH

RL

RP

RU

LOW BYTE [Hex]

C9

CA

CB

CC

CD

CE

CF

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

DA

DB

DC

Fault code

T0

T1

T2

T3

T4

T5

T6

T7

T8

T9

TA

TB

TC

TD

TE

TF

TH

TL

TP

TU

LOW BYTE [Hex]

DD

DE

DF

E0

E1

E2

E3

E4

E5

E6

E7

E8

E9

EA

EB

EC

ED

EE

EF

F0

Fault code

U0

U1

U2

U3

U4

U5

U6

U7

U8

U9

UA

UB

UC

UD

UE

UF

UH

UL

UP

UU

LOW BYTE [Hex]

F1

F2

F3

F4

F5

F6

F7

F8

F9

FA

FB

FC

FD

FE

FF

39

9 Maintenance

9.1 General description

Maintenance must be done by authorized centres or by qualied personnel.

The maintenance allows to:

maintain the unit eciency

•

increase the life span of the equipment

•

assemble information and data to understand the state of the unit eciency and avoid possible damages

•

Before checking, please verify the following:

the electrical power supply line should be isolated at the beginning

•

the unit isolator is open, locked and equipped with the suitable warning

•

make sure no tension is present

•

After turning o the power, wait at least 5 minutes before accessing to the electrical panel or any other electrical component.

Before accessing check with a multimeter that there are no residual stresses.

9.2 Inspections frequency

Perform an inspection every 6 months minimum.

The frequency, however, depends on the use.

In the event of frequent use it is recommended to plan inspections at shorter intervals:

frequent use (continuous or very intermittent use, near the operating limits, etc)

•

critical use (service necessary)

•

√ intervention frequency (months) 1 6 12

1 presence corrosion X

2 panel xing X

3 fan xing X

4 coil cleaning X

5 bowl cleaning + sanitisation X

6 outow test X

7 air lters cleaning / inspection X

8 check of the xing and the insulation of the power lead X

9 check of the earthing cable X

10 electric panel cleaning X

11 capacity contactor status X

12 termina closing, cable insulation integrity X

13 voltage and phase unbalancing (no load and on-load) X

14 absorptions of the single electrical loads X

15 test of the compressor crankcase heaters X

16 Checking for leaks *

17 survey of the refrigerant circuit operating parameters X

18 safety valve *

19 protective device test: pressure switches, thermostats, ow switches etc.. X

20 control system test: setpoint, climatic compensations, capacity stepping, water / air ow-rate variations X

21 control device test: alarm signalling, thermometers, probes, pressure gauges etc.. X

* Refer to the local regulations; and ensure correct adherance. Companies and technicians that eect interventions of installation, maintenance/re-

pairs, leak control and recovery must be CERTIFIED as expected by the local regulations. The leak control must be eected with annual renewal.

M06K40A18-00 CKN-XHE2i 7.1-14.2 4

9.3 Unit booklet

It’s advisable to create a unit booklet to take notes of the unit interventions.

In this way it will be easier to adequately note the various interventions and aid any troubleshooting.

Report on the booklet:

date

•

intervention description

•

carried out measures etc.

•

9.4 Standby mode

If a long period of inactivity is foreseen:

turn o the power

•

avoid the risk of frost (empty the system or add glycol)

•

Turn o the power to avoid electrical risks or damages by lightning strikes.

With lower temperatures keep heaters turned on in of the electrical panel (option).

It’s recommended that the re-start after the stopping period is performed by a qualied technician, especially after seasonal stops or seasonal

switching.

When restarting, refer to what is indicated in the “start-up” section.

Schedule technical assistance in advance to avoid hitches and to guarantee that the system can be used when required.

9.5 Outdoor air coil

Contact with the exchanger ns can cause cuts: wear protective gloves to perform the above described operations.

It is extremely important that the battery gives the maximum thermal exchange; therefore, its surface must be cleaned from dust and deposits.

Remove all impurities from the surface.

Using an air pressure gun, clean the aluminum surface of the battery; be careful to direct the air in the opposite direction of the fan air

movement.

Hold the gun parallel to the ns to avoid damages.

As an alternative, vacumn cleaner can be used to suck impurities from the air input side.

Verify that the aluminum ns are not bent or damaged, in the event of damages contact the authorized assistance center and get the ns

straightened in order to restore the initial condition for an optimal air ow.

4 CKN-XHE2i 7.1-14.2 M06K40A18-00

9.6 Indoor air coil

Contact with the exchanger ns can cause cuts: wear protective gloves to perform the above described operations.

The nned surfaces of the cooling coils and, in particular, the condense collection bowls constitute places where microorganisms and moulds

greatly ourish.

It is very important to foresee periodical cleaning with suitable detergents and, eventually, disinfect with sanitising products.

9.7 Electric fans

Check:

the fans and the relative protection gridsare well xed

•

the fan bearings (evident by noise and anomalous vibrations)

•

the terminal protection covers are closed and the cable holders are properly positioned

•

9.8 Condensation collection basin

Dirt or scale can give rise to clogging.

Also, microorganisms and mould can ourish in the bowl.

It is very important to foresee periodical cleaning with suitable detergents and, eventually, disinfect with sanitising products.

Once cleaning is completed, pour water inside the bowl to check the regular outow.

9.9 crankcase heather

Check:

closure

•

Operation

•

9.10 G4 Folded air lters

It is very important for the air treatment coil to oer maximum thermal exchange: the unit must always work with clean and installed lters.

Cleaning and replacement of lters are very important from an hygienic-sanitary point of view.

Operation with clogged lters leads to a reduction in the air ow rate with malfunctionings and block, up to possible breaks in the unit.

The frequency with which the lters must be checked depends on the quality of the air, the unit operation hours, the dustiness and crowding

of rooms.

Frequency can indicatively vary from WEEKLY to MONTHLY.

It is advised to start with frequent checks, subsequently adjusting frequency to degree of detected dirt.

1. Remove the closing panels

2. Delicately remove the lter avoiding dirtying the area below

3. Wash the ltering jacket in warm water with common detergent

4. Accurately rinse in running water avoiding spilling in the room

5. Dry the lter

6. Insert it back in its seat

7. Remount the closing panels

Old lters, washing wastewater and residues must be disposed of according to the current standards.

M06K40A18-00 CKN-XHE2i 7.1-14.2 4

9.11 F7 Highly ecient lters

Accessory

For details see:

10.2 F7 Highly ecient ltersp.48

9.12 Electronic lters

Accessory

For details see:

10.1 Electronic ltersp.47

9.13 Electric heaters

Accessory

Check:

cleaning state

•

fastening

•

presence of corrosion

•

9.14 Immersed electrode humidier

Accessory

For details see:

10.3 Immersed electrode humidierp.49

9.15 access to the components

Probes and transducers

1. Outdoor / return air pressure transducers

2. Outdoor air humidity probe

3. Outdoor air shutter actuator

4. Return humidity probe

5. Return air quality probe

6. Return temperature probe

7. Delivery pressure transducer

8. Filter dierential pressure switch

4 CKN-XHE2i 7.1-14.2 M06K40A18-00

Fans

M06K40A18-00 CKN-XHE2i 7.1-14.2 44

VALVES

Only value 14.2

4 CKN-XHE2i 7.1-14.2 M06K40A18-00

10 Accessories

10.1 Electronic lters

The most common contaminants for which the lter is designed, are: air pollution by PM10, PM 2,5 and PM1

Contaminants that can be ltered:

dry smokes

•

powder (up to 0,3 microns)

•

smoke electrostatically charged

•

Contaminants that can NOT be ltered:

water vapors also in low concentration

•

oil vapors

•

large amounts of dust

•

metal shavings,iron ling dusts and waste generally

•

Gas

•

Absolutely to avoid:

metal dusts also ne

•

fumes produced by combustion of organic and not materials (wood, coal, gasoline, etc.)

•

MATERIALS NECESSARY FOR MAINTENANCE

Plastic or steel tank (750x750x310 mm) with settling bottom

•

Acid detergent B01212 (code CLIVET C6460316)

•

Protective gloves and goggles

•

Graduated jug

•

Pump for manual or pneumatic spraying

•

Do not use aluminum tanks or galvanized

Foresee a stainless steel frame that keeps the lters lifted from the tank base to have a settling bottom for the muds.

The electronic adjustment is integrated in the lter; maintenance can be carried out without removing it.

Remove the pre-lter by lifting it of about 1 cm and remove it as shown in gure.

1. Position the lter to be washed on a support to facilitate work.

2. Prepare a tank with a solution of B01212 detergent and water at 1÷20.

3. Immerse the lter in this solution.

4. Ensure the solution covers the entire lter.

5. A slight chemical reaction is noticed within 2÷3 minutes with the development of foam. Wait 3 or 4 minutes.

6. Rinse the lter with a jet of water or using a low-pressure water jet machine.

7. Leave the electrostatic cells to dry in a hot room or directly in the sun for a few hours. Keep the cells lifted from the ground using two

metal or wooden laths.

8. Check the ionisation wires before remounting the lter.

The cleaner can be used to clean about 20 lters.

Can be recovered and placed in plastic containers closed; the air oxidizes the cleaner and reduces its eectiveness.

IONISATION WIRES

The impurities can determine oxidation or scaling on the wires, which can be removed using a cloth soaked in alcohol or an abrasive scourer

with very ne grain.

Due to the high voltage powering them, the ionisation wires are subject to wear.

To foresee a yearly replacement OF ALL WIRES avoids unexpected breaks.

In case of break:

1. remove all wire pieces present in the cell and remove the springs stretching the wire

2. hook the spring to the wire eyelet

3. grip the ionisation wire with curved beaks pliers

4. hook the top of the spring with the open eyelet to the wire stretcher rod of the electrostatic cell

5. keeping the ionisation wire stretched, with the other hand hook it to the other wire stretching rod, always by means of the curved beaks

pliers

M06K40A18-00 CKN-XHE2i 7.1-14.2 46

10.2 F7 Highly ecient lters

The pocket lters are not renewable, once dirty they must be replaced

1. Open the access panel

2. Delicately remove the lter avoiding dirtying the area below

3. Insert the new lters, with the pockets vertically

4. Close the panel

5. Dispose of the old lters sending them to specialised recycling or collection centres (keep to the standards in force)

4 CKN-XHE2i 7.1-14.2 M06K40A18-00

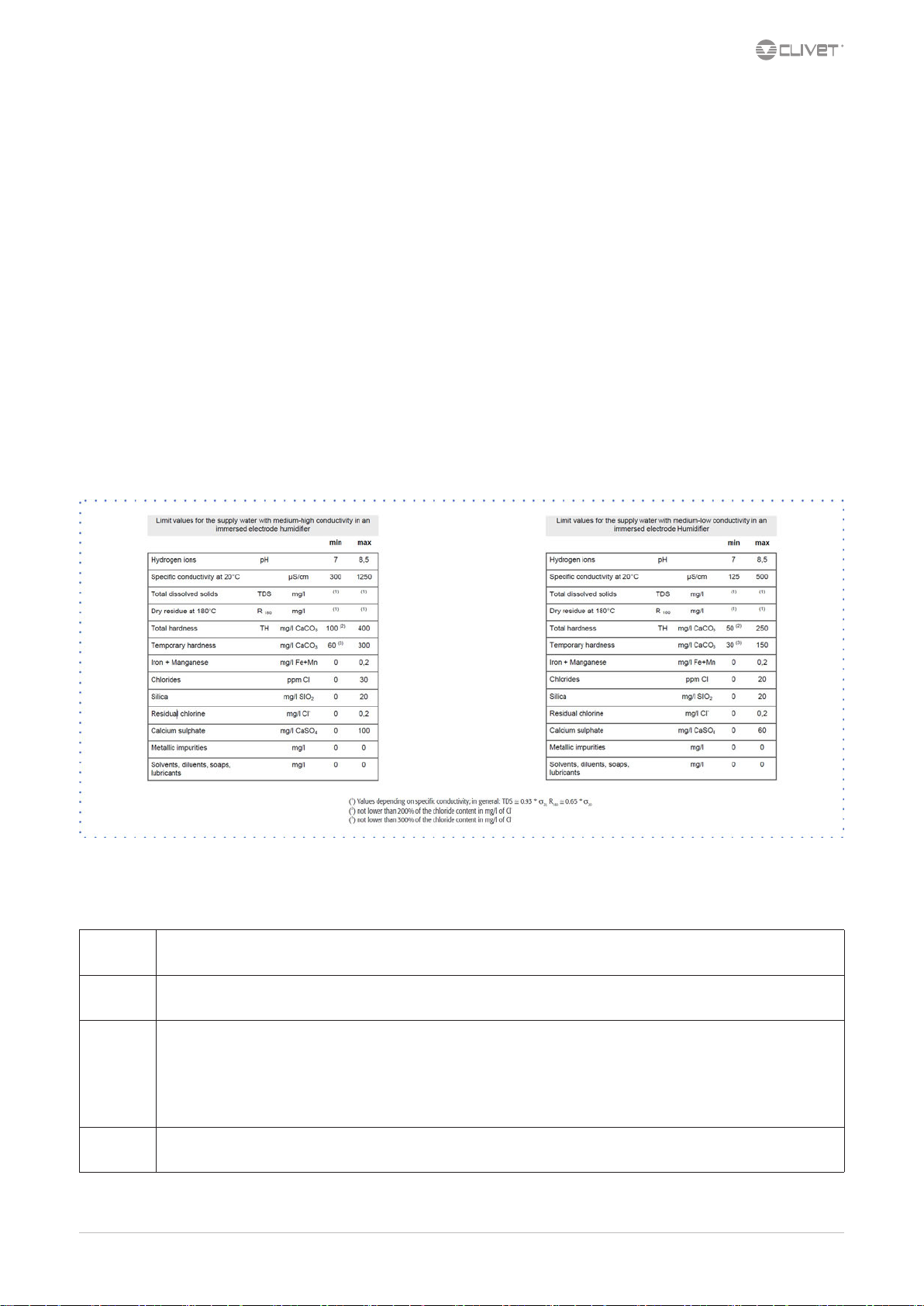

10.3 Immersed electrode humidier

SUPPLY WATER

The humidier must be supplied with mains water having the following features:

pressure between 0.1 and 0.8 Mpa (1 – 8 bar)

•

temperature between 1 and 40°C

•

Do not use:

water treated with softeners: it can corrode the electrodes and form foam with possible faults/malfunctionings

•

pit, industrial or potentially polluted (chemically or bacteriologically) water

•

disinfectants or anti-corrosive substances mixed with water, as potentially irritating

•

Supplying the humidier with water treated with reverse osmosis ltering system gives the following advantages:

reduces limescale deposits

•

reduces energy consumptions

•

reduces maintenance costs

•

increases the humidier’s duration

•

Check that the lter guarantees a water ow rate higher than the ow rate of the installed humidier.

DRAINAGE WATER

It can reach a temperature of 100°C

It contains the same substances of the supply water but in higher concentration.

As it is not toxic, it can be disposed of with white waters.

Periodical checks

Do not use solvents or detergents to clean the plastic components.

For descaling use a vinegar or acetic acid solution at 20%, subsequently rinsing with water.

15 days

90 days

1 year

5 years

M06K40A18-00 CKN-XHE2i 7.1-14.2 4

Cylinder:

not over 300 hours of work

checking operation, general state, no leaks

Cylinder:

not over 1000 hours of work

checking operation, general state, no leaks, any replacement

Cylinder:

not over 2500 hours of work (disposable cylinders)

Load solenoid valve replacement:

disconnect electric power supply, dismantle valve, clean the lter

Drain solenoid valve:

disconnect electric power supply, remove reel and dismantle valve body and any impurity and rinse

The power supply bowl, piping:

check they are free and without impurities

Cylinder:

not over 10000 hours of work (inspectional cylinders)

replacement

Humidier cylinder drainage

Cylinder must be drained in these situations:

cleaning of the cylinder

•

emptying of the cylinder to avoid ice forming

•

replacement of the cylinder

•

The manual drainage is carried out by means of selector SA7: see ELECTRIC CONNECTIONS chapter.

Replacement of the cylinder

To remove the cylinder:

completely drain the water

•

interrupt power supply voltage of humidier by means of the unit isolator

•

remove the vapour pipe from the cylinder

•

disconnect the electric connections of the electrodes and remove the pins from the high level electrodes

•

loosen the ring nut to remove the pipe unions and the lter (when lter is outside the cylinder)

•

lift the cylinder to remove it

•

Before mounting it:

the lter body does not require replacing, wash it with water and remount it on the new cylinder, using the new gasket provided with

•

the latter

check the seal gasket between the cylinder and the drain unit

•

remount the cylinder repeating the operations in reverse order

•

4 CKN-XHE2i 7.1-14.2 M06K40A18-00

10.4 Modulating condensation gas heating module

System maintenance booklet

It must be kept in the place of installation of the unit

•

It must be lled-in upon commissioning

•

It must be updated with the results of the periodical checks, of the routine and extraordinary maintenance interventions.

•

Gas connection

Read the gas heating module manual.

•

Connection must be carried out by qualied personnel.

•

use certied components and comply with the local standards in force

•

install on the gas connection: tap, large section lter and anti-vibration joint

•

check the supply pressure is correct and stable, in particular where more uses are inserted on the same line.

•

The heating module includes:

hot air generator with condensation and integrated modulating adjustment, powered with methane gas

•

kit for transformation of power with liqueed petroleum gas (LPG)

•

kit of steel chimney for exhaust fumes

•

All the control and safety devices

•

1. GAS COCK

2. GAS FILTER (LARGE SECTION)

3. ANTI-VIBRATION JOINT

4. GAS FILTER (SMALL SECTION)

5. SAFET GAS SOLENOID VLAVE

6. PRESSURE STABILISER

7. MAIN GAS BURNER SOLENOID VALVE

8. PILOT BURNER GAS SOLENOID VALVE

M06K40A18-00 CKN-XHE2i 7.1-14.2 5

Flue stack assembly

5 CKN-XHE2i 7.1-14.2 M06K40A18-00

10.5 Gas heating module with 2-stage control

System maintenance booklet

It must be kept in the place of installation of the unit

•

It must be lled-in upon commissioning

•

It must be updated with the results of the periodical checks, of the routine and extraordinary maintenance interventions.

•

Gas connection

Read the gas heating module manual.

•

Connection must be carried out by qualied personnel.

•

use certied components and comply with the local standards in force

•

install on the gas connection: tap, large section lter and anti-vibration joint

•

check the supply pressure is correct and stable, in particular where more uses are inserted on the same line.

•

The heating module includes:

hot air generator with condensation and integrated modulating adjustment, power with methane gas

•

kit for transformation of power with liqueed petroleum gas (LPG)

•

kit of steel chimney for exhaust fumes

•

All the control and safety devices

•

1. GAS COCK

2. GAS FILTER (LARGE SECTION)

3. ANTI-VIBRATION JOINT

4. GAS FILTER (SMALL SECTION)

5. SAFET GAS SOLENOID VLAVE

6. PRESSURE STABILISER

7. MAIN GAS BURNER SOLENOID VALVE

8. PILOT BURNER GAS SOLENOID VALVE

M06K40A18-00 CKN-XHE2i 7.1-14.2 5

10.6 Hot water coil

5 CKN-XHE2i 7.1-14.2 M06K40A18-00

11 Decommissioning

11.1 Disconnecting

Only authorised personnel must disconnect the unit.

Avoid leak or spills into the environment.

Before disconnecting the unit, the following must be recovered, if present:

refrigerant gas

•

anti-freeze solutions in the water circuit

•

Awaiting dismantling and disposal, the unit can also be stored outdoors, if the electrical, cooling and water circuits of the unit have 100%

integrity and are isolated, bad weather and rapid change in temperature will not result in any environmental impact.

11.2 Dismantling and disposal

The unit must always be sent to authorised centres for dismantling and disposal.

When dismantling the unit, the fan, the motor and the coil, if operating, may be recovered by the specialist centres for reuse.

All the materials must be recovered or disposed of in compliance with the corresponding national standards in force.

For further information on the decommissioning of the unit, contact the manufacturer.

11.3 Directive EC RAEE

The units covered by the legislation in question are marked with the symbol on the side.

With the aim of protecting the environment, all of our units are produced in compliance with Directive EC on waste electrical and electronic

equipment (RAEE).

The potential eects on the environment and on human health due to the presence of hazardous substances are shown in the use and

maintenance manual in the section on residual risks.

Information in addition to that indicated below, if required, can be obtained from the manufacturer/distributor/importer, who are responsible

for the collection/handling of waste originating from equipment covered by EC-RAEE. This information is also available from the retailer who

sold this appliance or from the local authorities who handle waste.

Directive EC-RAEE requires disposal and recycling of electrical and electronic equipment as described therein to be handled through

appropriate collection, in suitable centres, separate from collection for the disposal of mixed urban waste.

The user must not dispose of the unit at the end of its life cycle as urban waste, it must instead be handed over to appropriate collection

centres as set forth by current standards or as instructed by the distributor.

M06K40A18-00 CKN-XHE2i 7.1-14.2 54

12 Residual risks

General description

In this section the most common situations are indicated,as these cannot be

controlled by the manufacturer and could be a source of risk situations for

people or things.

Danger zone

This is an area in which only an authorised operator may work.

The danger zone is the area inside the unit which is accessible only with the

deliberate removal of protections or parts thereof.

Handling

The handling operations, if implemented without all of the protection

necesssary and without due caution, may cause the drop or the tipping of

the unit with the consequent damage, even serious, to persons, things or the

unit itself.

Handle the unit following the instructions provided in the present manual regarding the packaging and in compliance with the local regulations in force.

Should the refrigerant leak please refer to the refrigerant “Safety sheet”.

Installation

The incorrect installation of the unit could cause water leaks, condensate

accumulation, leaking of the refrigerant, electric shock, poor operation or

damage to the unit itself.

Check that the installation has been implemented by qualied technical

personnel only and that the instructions contained in the present manual

and the local regulations in force have been adhered to.

The installation of the unit in a place where even infrequent leaks of inammable gas and the accumulation of this gas in the area surrounding the area

occur could cause explosions or res.

Carefully check the positioning of the unit.

The installation of the unit in a place unsuited to support its weight and/or

guarantee adequate anchorage may result in consequent damage to things,

people or the unit itself.

Carefully check the positioning and the anchoring of the unit.

Easy access to the unit by children, unauthorised persons or animals may be

the source of accidents, some serious.

Install the unit in areas which are only accessible to authorised person and/or

provide protection against intrusion into the danger zone.

General risks

Smell of burning, smoke or other signals of serious anomalies may indicate a

situation which could cause damage to people, things or the unit itself.

Electrically isolate the unit (yellow-red isolator).

Contact the authorised service centre to identify and resolve the problem at

the source of the anomaly.

Accidental contact with exchange batteries, compressors, air delivery tubes

or other components may cause injuries and/or burns.

Always wear suitable clothing including protective gloves to work inside the

danger zone.

Maintenance and repair operations carried out by non-qualied personnel

may cause damage to persons, things or the unit itself.

Always contact the qualied assistance centre.

Failing to close the unit panels or failure to check the correct tightening of all

of the panelling xing screws may cause damage to persons, things or the

unit itself.

Periodically check that all of the panels are correctly closed and xed.

If there is a re the temperature of the refrigerant could reach values that increase the pressure to beyond the safety valve with the consequent possible

projection of the refrigerant itself or explosion of the circuit parts that remain

isolated by the closure of the tap.

Do not remain in the vicinity of the safety valve and never leave the refrigerating system taps closed.

Electric parts

An incomplete attachment line to the electric network or with incorrectly

sized cables and/or unsuitable protective devices can cause electric shocks,

intoxication, damage to the unit or res.

Carry out all of the work on the electric system referring to the electric layout

and the present manual ensuring the use of a system thereto dedicated.

An incorrect xing of the electric components cover may lead to the entry of

dust, water etc inside and may consequently electric shocks, damage to the

unit or res.

Always x the unit cover properly.

When the metallic mass of the unit is under voltage and is not correctly

connected to the earthing system it may be as source of electric shock and

electrocution.

Always pay particular attention to the implementation of the earthing

system connections.

Contact with parts under voltage accessible inside the unit after the removal

of the guards can cause electric shocks, burns and electrocution.

Open and padlock the general isolator prior to removing the guards and

signal work in progress with the appropriate sign.

Contact with parts that could be under voltage due to the start up of the unit

may cause electric shocks, burns and electrocution.

When voltage is necessary for the circuit open the isolator on the attachment

line of the unit itself, padlock it and display the appropriate warning sign.

Moving parts

Contact with the transmissions or with the fan aspiration can cause injuries.

Prior to entering the inside of the unit open the isolater situated on the connection line of the unit itself, padlock and display the appropriate warning

sign.

Contact with the fans can cause injury.

Prior to removing the protective grill or the fans, open the isolator on the

attachment line of the unit itself, padlock it and display the appropriate

warning sign.

Refrigerant