CLIVET AQUA SWAN 190, AQUA SWAN 190S, AQUA SWAN 300, AQUA SWAN 300S Installation And Operating Manual

INSTALLATION AND

OPERATING MANUAL

AQUA SWAN 190-300

Heat pumps for domentic hot water

M0MR40E17-00

15-11-2017

Dear Customer,

We congratulate you on choosing this product

For many years Clivet has been offering systems that provide maximum

comfort, together with high reliability, efficiency, quality and safety.

The aim of the company is to offer advanced systems, that assure the best

comfort, reduce energy consumption and the installation and maintenance

cost for the life cycle of the system.

The purpose of this manual is to provide you with information that is useful

from reception of the equipment, through installation, operational usage and

finally disposal so that this advanced system offers the beat solution.

Yours faithfully.

CLIVET Spa

INDEX

Before any operation carefully read the GENERAL WARNINGS

1 General instructions

2 Residual risks / Disposal

3 General

4 Reception

5 Installation

6 Water connections

7 Aeraulic connections

8 Electrical connections

4

8

11

14

16

18

22

25

9 Start - up

10 Control

11 Maintenance

12 Technical data

Pay particular attention to:

INSTALLER use

USER use

WARNING, identifies particularly important operations or information

PROHIBITIONS, identifies operations that must not be carried out, that compromises the

operating of the unit or may cause damages to persons or things.

29

35

46

51

The data contained in this manual is not binding and may be modified by the manufacturer without prior notice. preliminary

3

1 - GENERAL INSTRUCTIONS

USER

This appliance can be used by children

aged from 8 years and above and

persons with reduced physical, sensory

or mental capabilities or lack of

experience and knowledge if they have

been given supervision or instruction

concerning use of the appliance in a

safe way and understand the hazards

involved. Children shall not play with the

appliance. Cleaning and user

maintenance shall not be made by

children without supervision.

Before cleaning, be sure to stop the

operation and turn the breaker off or pull

out the power plug.

Otherwise, an electric shock and injury

may be caused.

Do not insert fingers, rods or other

objects into the air inlet or outlet.

When the fan is rotating at high speed, it

will cause injury.

Do not touch the inner parts of the

controller.

Do not remove the front panel.

Some parts inside are dangerous to

touch, otherwise a machine malfunction

may be caused.

Never use a flammable spray such as

hair spray, lacquer paint near the unit, it

may cause a fire.

Do not remove, cover or deface any

permanent instructions, lables, or the

data label from either the outside of the

unit or inside of unit panels.

It is forbidden the use of the device to

children and unassisted disables .

It is forbidden to touch the device if you

are barefoot and with wet body parts .

It is forbidden any cleaning, before

having disconnected the device

positioning the system main switch on

“off”.

It is forbidden to pull, remove, twist the

electric cables that come out from the

device even if it is disconnected from the

mains supply.

It is forbidden to trample on the device

and/or to put on it any type of object.

It is forbidden to throw or spray water

directly on the device.

It is forbidden to insert sharpened

objects by the air return and supply

grilles.

It is vorbidden to open the lids of access

to the internal device parts, without

having before positioned the main switch

of the system on “off”.

Do not turn off the power supply.

If the supply cord is damaged, it must be

replaced by the manufacturer or its

service agent or a similarly qualified

person.

The wiring must be performed by

professional technicians in accordance

with national wiring regulations.

A disconnect device for all poles having

a separation distance of at least 3 mm

across all poles and that a residual

current device (RCD) with a power

greater than 10mA is incorporated into

fixed wiring.

System will stop or restart heating

automatically.

A continuous power supply for water

heating is necessary, except service and

maintenance.

Keep this manual with the wiring

diagram in an accessible place for the

operator.

Children should be supervised to ensure

that they do not play with the unit.

Note the unit lable data so you can

provide them at the assistance centre in

case of intervention (see "Unit

identification" section)

Provide a unit notebook that allows any

interventions carried out on the unit to

be noted and tracked making it easier to

suitably note the various interventions

and aids the search for any breakdowns.

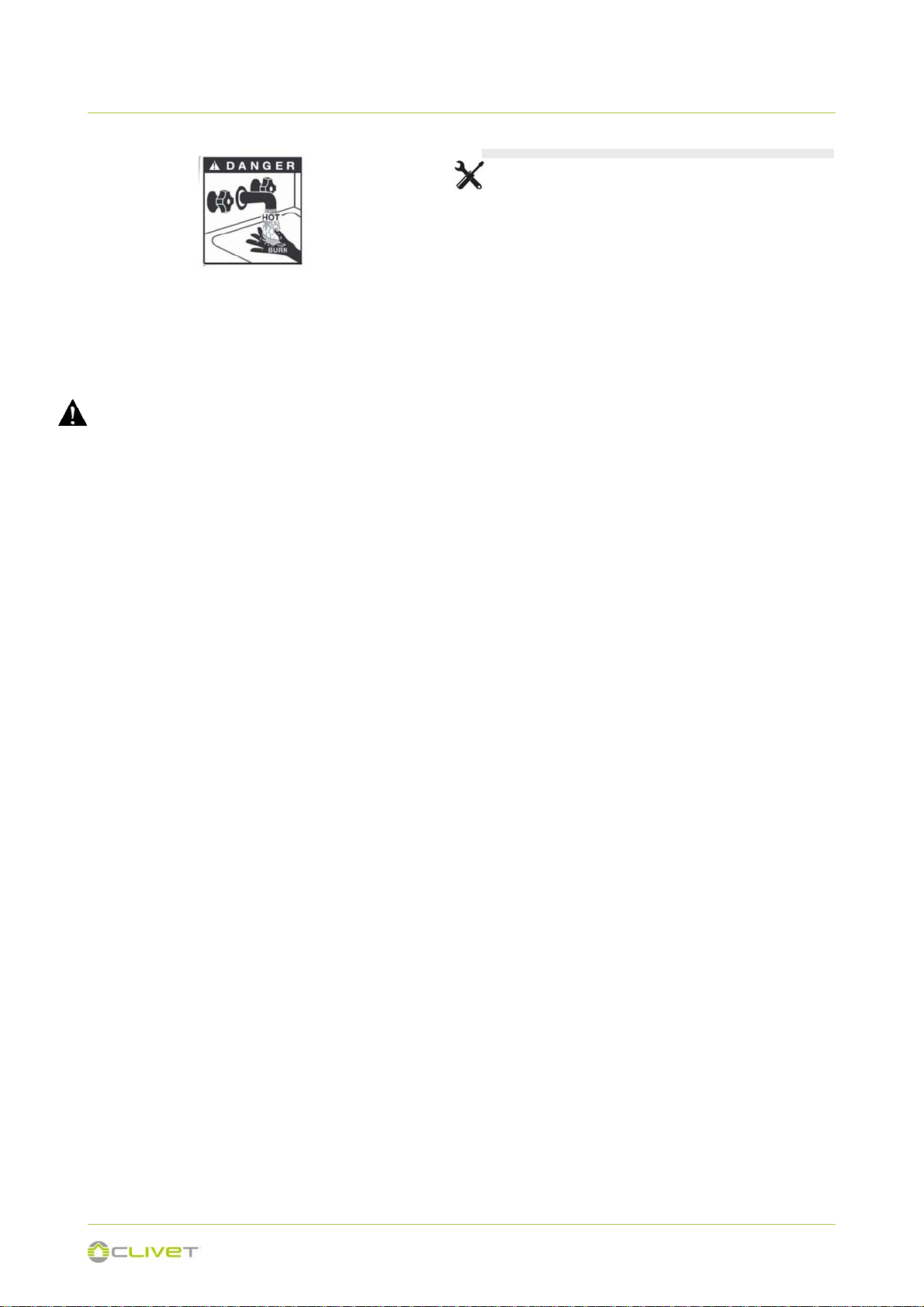

Water temperature over 50°C can cause

severe burns instantly or death from

scalds.

4

1 - GENERAL INSTRUCTIONS

Children, disabled and elderly are at

highest risk of being scalded.

Feel water before bathing or showering.

Water temperature limiting valves are

recommended.

If the unit has not been used for a long

period of time(2 weeks or more),

hydrogen gas will be produced in the

water piping system.

Hydrogen gas is extremely flammable.

To reduce the risk of injury under these

conditions, it is recommended that open

the hot water tap for several minutes at

the kitchen sink before using any

electrical appliance connected to the hot

water system. When hydrogen is

present, there will probably be an

unusual sound such as air escaping

through the pipe as the water begins to

flow.

There should be no smoking or open

flame near the tap at the time it is open.

Ask qualified person for relocating,

repairing and maintaining the unit

instead of doing by yourself.

In case of breakdown or malfunction:

- immediately deactivate the unit

- Contact a constructor certified

assistance service.

- Use original spares parts only

Ask the installer to be trained on:

- start-up / shutdown

- set points change

- standby mode

- maintenance

- what to do / what not to do in case

of breakdown

GENERAL INSTRUCTIONS

Preliminaries

Read carefully the IOM and use the unit

strictly according to the instructions in

order to avoid personal injuries, damages

to the unit, damages to property and

litigations.

Our company does not assume any legal

liability for any damage caused by

improper use of the unit.

The positioning, hydraulic system,

refrigerating, electrics and the air duct

must be determined by the system

designer or by experts and must take into

consideration both the decidedly

technical requirements as well as any

local regulations in act regarding specific

authorisations.

Only qualified personnel can operate on

the unit, as required by the regulation in

force.

Using the unit in case of breakdown or

malfunction :

voids the warranty

may compromise the safety of the

unit

may increase time and repair costs.

Follow local safety regulations.

Keep packing material out of children’s

reach it may be dangerous.

Recycle and dispose of packing material

in conformity with local regulations.

Risk situations

The unit has been designed and created

to prevent injures to people. During

designing it is not possible to plane and

operate on all risk situation. Read

carefully "Residual risk" section where all

situation which may cause damages to

things and injuries to people are

reported. Installation, starting,

maintenance and repair required specific

knowledge; if they are carried out by

inexperienced personnel, they may

cause damages to things and injuries

people.

Intended use

Use the unit for cooling/heating air only

5

1 - GENERAL INSTRUCTIONS

and domestic hot water, within limits

defined in the technical bulletin and on

this manual.

Any use other than intended does not

involve the manufacturer in any

commitment or obligation.

HYDRAULIC SYSTEM

Components

Selection and installation of system

components must be carry out by

installer.

Water quality

The water quality is determined by the

following factors, avoid therefore:

- Inorganic salts

- pH

- Biological load (seaweeds etc)

- Suspended solids

- Dissolved oxygen

Water with inadequate characteristics

can cause:

- pressure drop increase

- energy efficiency decrease

- corrosive symptom increase

Risk of freeze

If the unit or the relative water

connections can be subject to

temperatures close to 0°C adopt

measures for prevent risk of freeze.

The appliance is intended to be

permanently connected to the water

mains and not connected by a hose-set .

The water may drip from the discharge

pipe of the pressure-relief device and

that this pipe must be left open to the

atmosphere.

The pressure-relief device is to be

operated regularly to remove lime

deposits and to verify that is not blocked.

A discharge pipe connected to the

pressure-relief device is to be installed in

a continuously downward direction and

in a frost-free environment.

ELETTRIC SYSTEM

This unit is required reliable earthing

before usage, otherwise might cause

death or injury.

General

The characteristics of the electrical lines

must be determined by specialized

personnel able to design electrical

installations; moreover, the lines must be

in conformity with regulations in force.

Operate in compliance with safety

regulations in force .

This unit is required reliable earthing

before usage, otherwise might cause

death or injury.

If you can't make sure that your house

power supply is earthed well, please

don't install the unit if it does not in

conformity with regulations in force.

The power supply should be an

independent circuit with rated voltage.

Power supply circuit should be earthed

effectively.

Do not use water pipes to earthing

connection of the unit

Use single protection devices : gloves,

glasses ecc.

The power cables and the protection

cable section must be defined in

accordance with the characteristics of the

protections adopted. The serial number

label reports the unit specific electrical

data, included any electrical accessories.

Connection

All electrical operations should be

performed by trained personnel having

the necessary requirements by the

regulations in force and being informed

about the risks relevant to these

activities. Refer to the unit electrical

diagram (the number of the diagram is

6

1 - GENERAL INSTRUCTIONS

shown on the serial number label). Verify

that the network has characteristics

conforming to the data shown on the

serial number label .

Make sure that the unit supply line is

selected at start.

Shelter the cables using adequate

measure fairleads.

Before starting work, verify that the

sectioning device at the start of the unit

power line is open, blocked and equipped

with sign warning.

First create the earthing connection.

After wire connection, check it again and

make sure the correctness before power

on.

Prior to powering the unit ensure that all

the protections that were removed during

the electrical connection work have been

restored.

Signal lines/data-lay

Do not overpass the maximum power

allowed, which varies, according to the

type of signal.

Lay the cables far from power cables or

cables having a different voltage and that

are able to emit electromagnetic

disturbances. Do not lay the cable near

devices which can generate

electromagnetic interferences.

Do not lay the cables parallel to other

cables; cable crossings are possible, only

if laid at 90°.

Connect the screen to the ground, only if

there aren’t disturbances .

Guarantee the continuity of the screen for

the entire extension of the cable.

Respect impendency, capacity and

attenuation indications.

MODIFICATION

All unit modifications will end the

warranty coverage and the manufacturer

responsibility.

BREAKDOWN/MALFUCTION

Disable the unit immediately in case of

breakdown or malfunction.

Contact a constructor certified assistance

service.

Use original spares parts only.

USER TRAINING

The installer has to train the user on :

- ON / OFF

- set points change;

- standby mode;

- Maintenance;

- what to do / what not to do in case of breakdown.

DATA UPDATE

Continual product improvements may

imply manual data changes

Visit manufacturer web site for updated

data.

7

2 - RESIDUAL RISKS / DISPOSAL

RESIDUAL RISKS

General

In this section the most common

situations are signalled. As these cannot

be controlled by the manufacturer these

could be a source of risk situations for

people or things.

Danger zone

This is an area in which only an

authorised operator may work. The

danger zone is the area inside the unit

which is accessible only with the

deliberate removal of protections or parts

thereof.

Handling

The handling operations, if implemented

without all of the protection necesssary

and without due caution, may cause the

fall or the tipping of the unit with the

consequent damage, even serious, to

persons, things or the unit itself. Handle

the unit following the instructions

provided in the present manual regarding

the packaging and in compliance with the

local regulations in force.

Should the gas refrigerant leak please

refer to the refrigerant "Safety sheet".

Installation

An incorrect installation of the unit could

cause water leaks, condensate

accumulation, leaking of the refrigerant,

electric shock, bad functioning or

damage to the unit itself.

Check that the installation has been

implemented by qualified technical

personnel only and that the instructions

contained in the present manual and the

local regulations in force have been

adhered to. The installation of the unit in

a place where even infrequent leaks of

inflammable gas and the accumulation of

this gas in the area surrounding the area

occur could cause explosions or fires.

Carefully check the positioning of the

unit. The installation of the unit in a place

unsuited to support its weight and/or

guarantee adequate anchorage may

cause the fall or the tipping of the unit

with the consequent damage to things,

people or the unit itself. Carefully check

the positioning and the anchoring of the

unit.

Easy access to the unit by children,

unauthorised persons or animals may be

the source of accidents, some serious.

Install the unit in areas which are only

accessible to authorised person and/or

provide protection against intrusion into

the danger zone .

General risks

Smell of burning, smoke or other signals

of serious anomalies may indicate a

situation which could cause damage to

people, things or the unit itself.

Electrically isolate the unit (yellow-red

isolator).

Contact the authorised service centre to

identify and resolve the problem at the

source of the anomaly.

Accidental contact with exchange

batteries, compressors, air delivery pipes

or other components may cause injuries

and/or burns. Always wear suitable

clothing including protective gloves to

work inside the danger zone.

Maintenance and repair operations

carried out by non-qualified personnel

may cause damage to persons, things or

the unit itself.

Always contact the qualified assistance

centre.

Failing to close the unit panels or failure

to check the correct tightening of all of

the panelling fixing screws may cause

damage to persons, things or the unit

itself. Periodically check that all of the

panels are correctly closed and fixed. If

there is a fire the temperature of the

8

2 - RESIDUAL RISKS / DISPOSAL

refrigerant could reach values that

increase the pressure to beyond the

safety valve with the consequent possible

projection of the refrigerant itself or

explosion of the circuit parts that remain

isolated by the closure of the tap. Do not

remain in the proximity of the safety valve

and never leave the refrigerating system

taps closed.

Electric parts

An incomplete attachment line to the

electric network or with incorrectly sized

cables and/or unsuitable protective

devices can cause electric shocks,

intoxication, damage to the unit or fires.

Carry out all of the work on the electric

system referring to the electric layout and

the present manual ensuring the use of a

system thereto dedicated. An incorrect

fixing of the electric components cover

may favour the entry of dust, water etc

inside and may consequently can electric

shocks, damage to the unit or fires.

Always fix the unit cover properly. When

the metallic mass of the unit is under

voltage and is not correctly connected to

the earthing system it may be as source

of electric shock and electrocution.

Always pay particular attention to the

implementation of the earthing system

connections. Contact with parts under

voltage accessible inside the unit after

the removal of the guards can cause

electric shocks, burns and electrocution.

Open and padlock the general isolator

prior to removing the guards and signal

work in progress with the appropriate

shield.

Contact with parts that could be under

voltage due to the start up of the unit may

cause electric shocks, burns and

electrocution.

When voltage is necessary for the circuit

open the isolator on the attachment line

of the unit itself, padlock it and display

the appropriate warning shield.

Moving parts

Contact with the transmissions or with

the fan aspiration can cause injuries.

Prior to entering the inside of the unit

open the isolater situated on the

connection line of the unit itself, padlock

and display the suitable sign.

Contact with the fans can cause incurie.

to removing the protective grill or the

fans, open the isolator on the attachment

line of the unit itself, padlock it and

display the appropriate warning sign.

Refrigerant

The intervention of the safety valve and

the consequent expulsion of the gas

refrigerant may cause injuries and

intoxication. Always wear suitable

clothing including protective gloves and

eyeglasses for operations inside the

danger zone.

Should the gas refrigerant leak please

refer to the refrigerant "Safety sheet".

Contact between open flames or heat

sources with the refrigerant or the

heating of the gas circuit under pressure

(e.g. during welding operations) may

cause explosions or fires.

Do not place any heat source inside the

danger zone.

The maintenance or repair interventions

which include welding must be carried

out with the system off.

Hydraulic parts

Defects in ducting , the attachments or

the cut-off parts may cause a leak or

water projection with the consequent

damages to people, things or shortcircuit

the unit.

9

2 - RESIDUAL RISKS / DISPOSAL

DISCONNECTION

Only authorised personnel must

disconnect the unit.

Avoid leak or spills into the environment.

Before disconnecting the unit, the

following must be recovered, if present:

- refrigerant gas

When awaiting dismantling and disposal,

the unit can also be stored outdoors, as

bad weather and rapid changes in

temperature will not cause damage to the

environment, if the unit's electric, cooling

and hydraulic circuits are integral and

closed.

DISPOSAL

CE WEEE DIRECTIVE

The units covered by the legislation in

question are marked with the symbol on

the side.

With the aim of protecting the

environment, all of our units are

produced in compliance with CE

Directive on waste electrical and

electronic equipment (WEEE).

The potential effects on the environment

and on human health due to the

CE-WEEE directive requires disposal

and recycling of electrical and electronic

equipment as described therein to be

handled through appropriate collection, in

suitable centres, separate from collection

for the disposal of mixed urban waste.

The user must not dispose of the unit at

the end of its life cycle as urban waste. It

must instead be handed over to

appropriate collection centres as set forth

by current standards or as instructed by

the distributor.

If disposal takes places at the same time

as delivery of a new electrical or

electronic equipment for the same family,

the product may be collected directly by

the distributor.

Dismantling and disposal

THE UNIT MUST ALWAYS BE SENT TO

AUTHORISED CENTRES FOR

DISMANTLING AND DISPOSAL.

When dismantling the unit, the fan, the

motor and the coil, if operating, may be

recovered by the specialist centres for

reuse. All the materials must be

presence of hazardous substances are

shown in the use and maintenance

manual in the section on residual risks.

Information in addition to that indicated

below, if required, can be obtained from

the manufacturer/distributor/importer,

who are responsible for the collection/

handling of waste originating from

equipment covered by CE-WEEE. This

information is also available from the

retailer who sold this appliance or from

the local authorities who handle waste.

10

3 - GENERAL

UNIT INDENTIFICATION

Serial number label

The serial number label is positioned on the unit and allows to

indentify all the unit features.

It has not to be removed for any reason.

It reports the regulations indications such as:

machine type, exmple:

Series SWAN

Size 190-190S-300-300S

serial number

12 characters Axxxxxxxxxxx

year of manufacture

wiring diagram number

electrical data

manufacturer logo and address .

Serial number

It identifies uniquely each machine.

It identifies specific spare parts for the machine.

Assistance request

Note data from the serial number label and write them in the

chart on side, so you will find them easily when needed.

In case of intervention you have to provide data.

Serie

Size

Serial number

Year of manufacture

Wiring diagram

PRELIMINARY INFORMATION

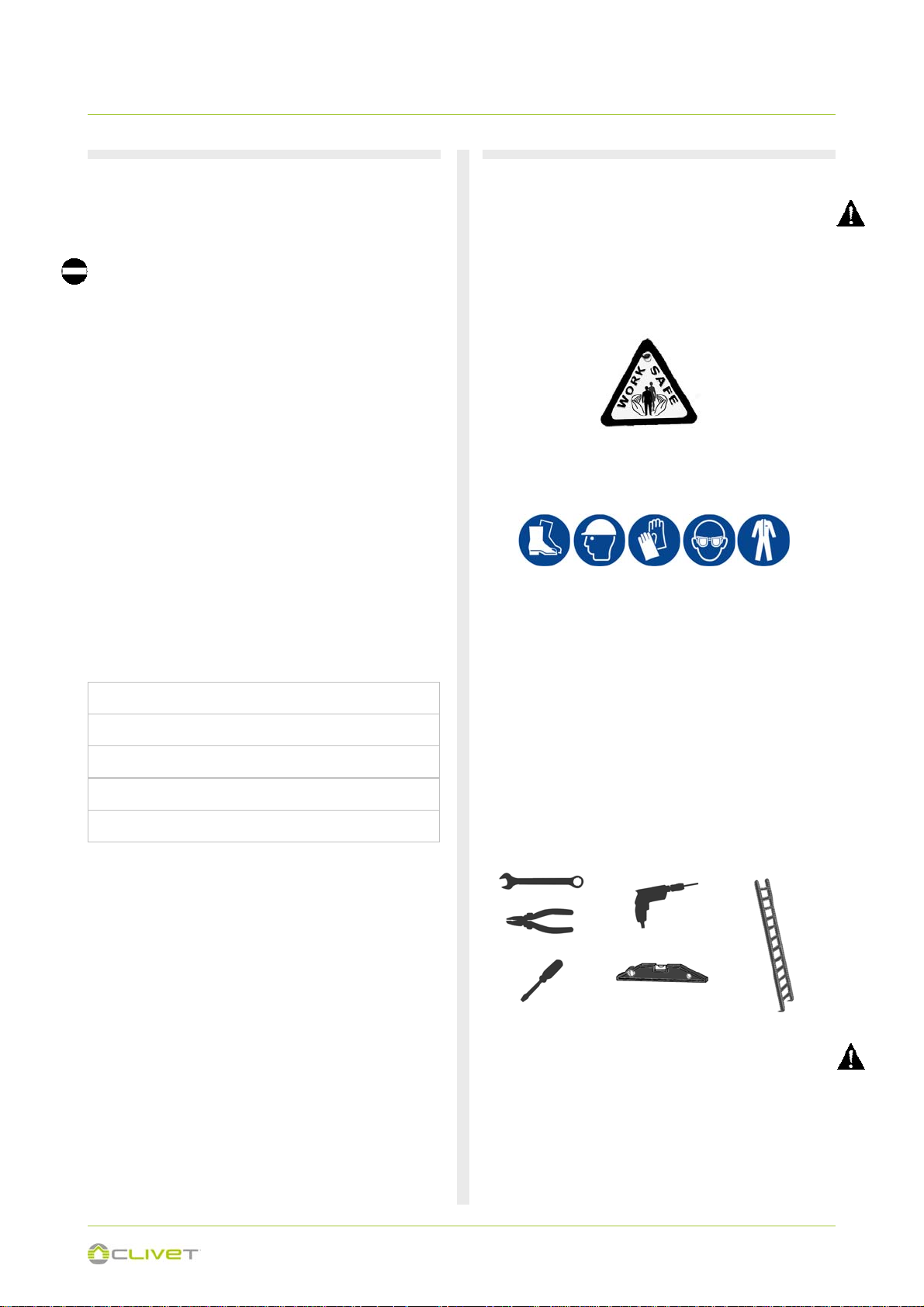

Before beginning the work, ensure you that have the final

project for installing the aeraulic, hydraulic, electric,drains and

positioning the units.

Operate in compliance with safety regulations in force .

Use single protection devices.

Recommended instruments

Set of Philips and flathead screwdrivers;

Cutters;

Drill;

Scissors;

Set of open spanners or pipe wrenches;

Range;

Hydraulic material for the sealing of the threads;

Electrical equipment for the connections;

Cut prevention gloves;

Tester and amperometric pliers.

BEFORE REQUESTING START-UP

Completed aeraulic system and free of dirt

Completed water system, circuit loading and venting

Discharges unit connected

Electric connections

11

3 - GENERAL

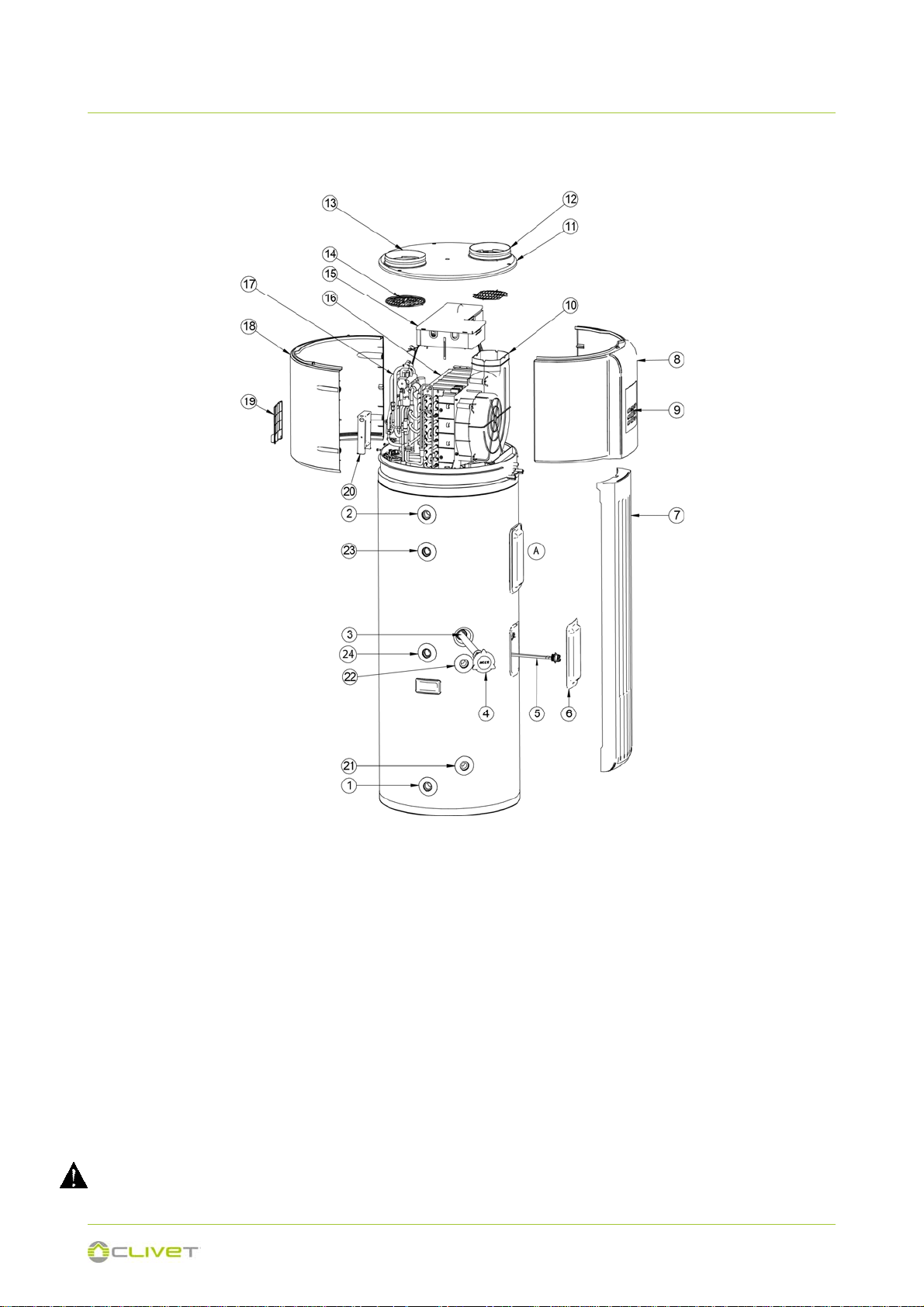

PARTS NAMES - 190 LITRES

1) Water inlet 3/4” F

2) Domestic hot water outlet 3/4” F (ACS)

3) Sacrificial anode

4) Anode cap

5) Electric heater

6) Heating element cap

7) Front mask

8) Front cover

9) Unit control keypad

10) Fan

11) Top cover

12) Air outlet flange

13) Air inlet flange

When ordering repair parts please always give the following information:

Model, serial and product number.

Parts name.

All the picture in this manual are for explanation purpose only. They may be slightly different from the unit you purchased (depand on

model). Please refer to the real sample instead of the picture of this manual.

14) Air filter

15) Electric panel

16) Evaporator

17) Compressor

18) Rear closure

19) Electrical connector cover

20) Electrical connections box

21) Solar inlet 3/4” F (Solar version only)

22) Solar outlet 3/4” F (Solar version only)

23) DHW recirculation (Solar version only)

24) Probe sump for solar

A - ATCO (automatic temperature Switch)

TCO (temperature Switch)

12

3 - GENERAL

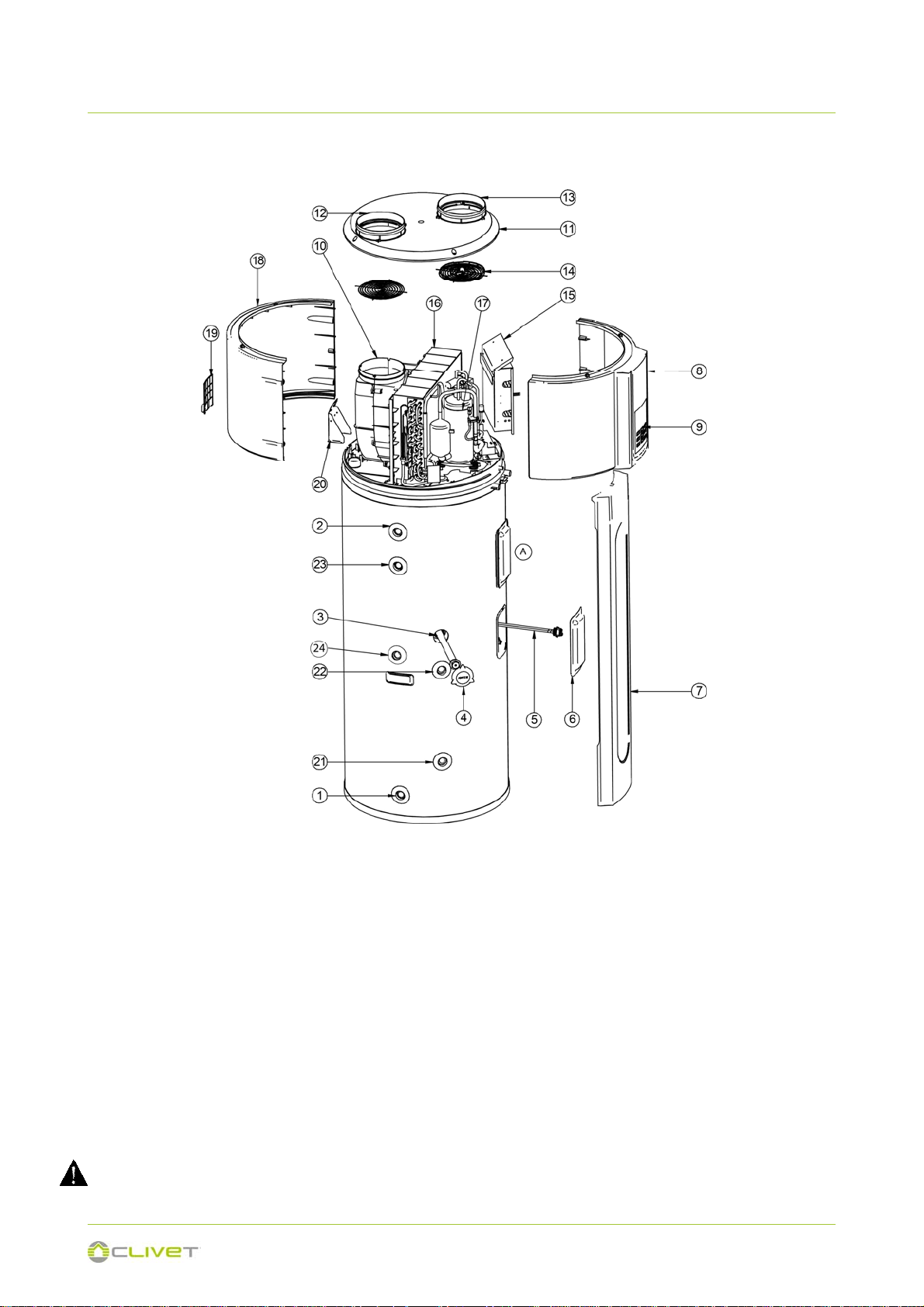

PARTS NAMES - 300 LITRES

1) Water inlet 3/4” F

2) Domestic hot water outlet 3/4” F (ACS)

3) Sacrificial anode

4) Anode cap

5) Electric heater

6) Heating element cap

7) Front mask

8) Front cover

9) Unit control keypad

10) Fan

11) Top cover

12) Air outlet flange

13) Air inlet flange

When ordering repair parts please always give the following information:

Model, serial and product number.

Parts name.

All the picture in this manual are for explanation purpose only. They may be slightly different from the unit you purchased (depand on

model). Please refer to the real sample instead of the picture of this manual.

14) Air filter

15) Electric panel

16) Evaporator

17) Compressor

18) Rear closure

19) Electrical connector cover

20) Electrical connections box

21) Solar inlet 3/4” F (Solar version only)

22) Solar outlet 3/4” F (Solar version only)

23) DHW recirculation (Solar version only)

24) Probe sump for solar

A - ATCO (automatic temperature Switch)

TCO (temperature Switch)

13

4 - RECEPTION

4.1 - DELIVERY CONTROL

Before accepting the delivery you have to check:

that the unit hasn’t been damaged during transport.

Check that the materials delivered correspond with that

indicated on the transport document comparing the data

with the identification label ‘A’ positioned on the packa-

ging.

In case of damage or anomaly:

Write down on the transport document the damage you

found and quote this sentence: "Conditional acceptance

clear evidence of deficiencies/damages during transport".

Contact supplier and the carrier by fax and registered mail

with advice of receipt.

Any disputes must be made within the 8 days following the

delivery. Complaints after this period are invalid.

Use protection (A) to avoid the unit damaging

Stair climbing trolley.

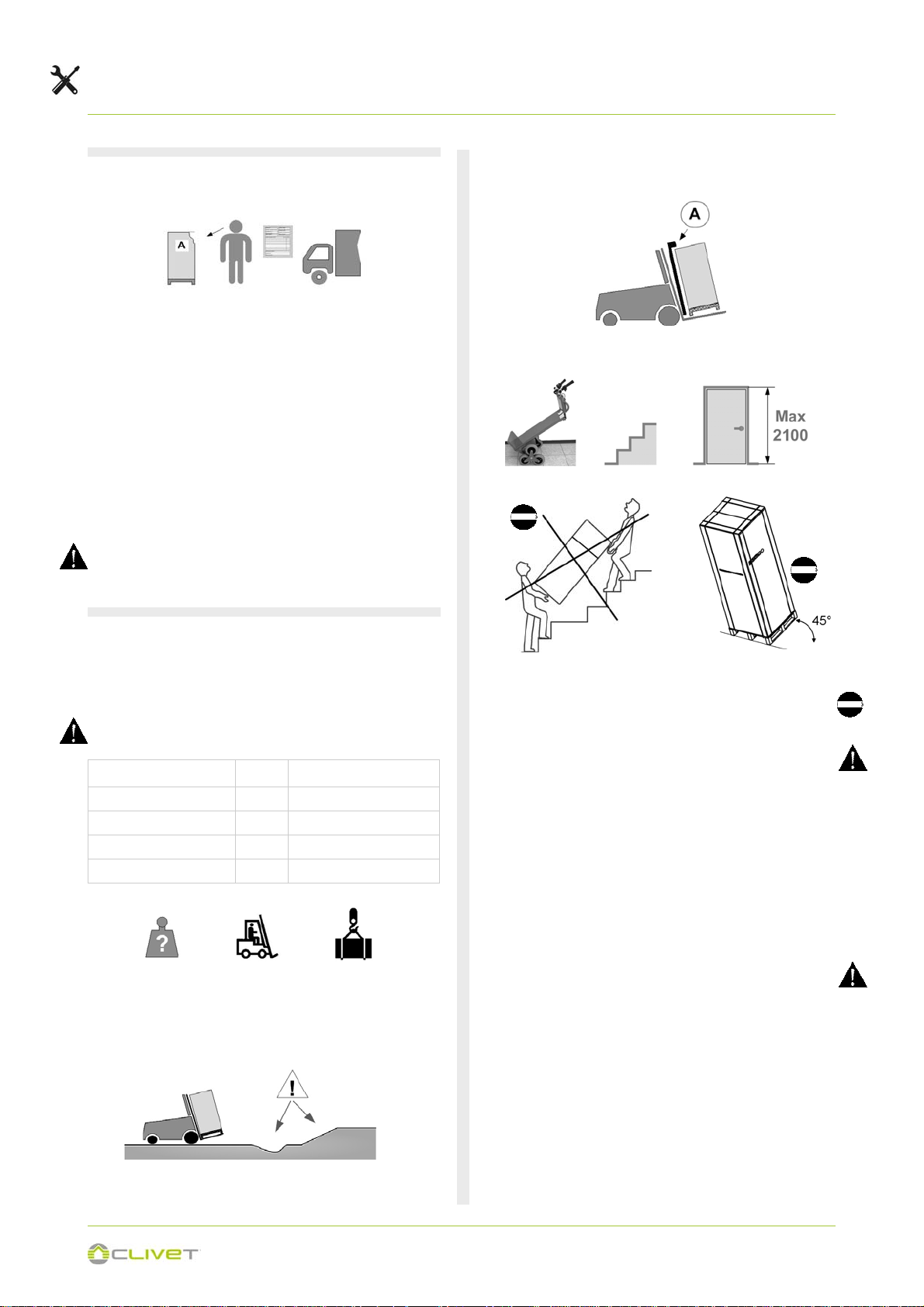

4.2 - HANDLING

The following examples are indications the choice of the

means and of the handling modes will depend on factors.

Verify the lifting equipment's load-bearing capacity: the shipped unit weighs

Unit

190 litres kg 126

190 litres (with solar) kg 149

300 litres kg 149

300 litres (with solar) kg 171

Identify critical points during handling (disconnected routes,

flights, steps, doors).

Shipping weight

Maximum inclination

When transporting the unit, do not carry it by holding on to the

top part of the circuit.

This unit is heavy, it need to be carried by two or more persons, otherwise might cause injury and damage.

In order to avoid scratch or deformation of the unit surface,

apply guard boards to the contacting surface.

No contact of fingers and other things with the vanes.

While moving it, do not tip the unit to an angle less than 45°

and keep it in a vertical position during installation.

If the unit has been tipped during transport, wait at least 2

hours before starting it up

14

4 - RECEPTION

4.3 - PACKAGING REMOVING

Be careful not to damage the unit.

Keep packing material out of children’s reach it may be dangerous.

Recycle and dispose of the packaging material in conformity

with local regulations.

Cut the hoops

1

Front

Cut along the joint (A)

2

Rear

3

A

15

5 - POSITIONING

5.1 - INSTALLATION REQUIREMENTS

The installation has been implemented by qualified technical

personnel only and that the instructions contained in the

present manual and the local regulations in force have been

adhered to.

Choose the installation place according to the following

criteria:

customer approval

Internal

in a dry room/compartment where the temperature cannot

fall below 0 degrees

guarantee good unit operation

safe accessible position

enough space for installation and maintenance shall be

preserved.

the air inlet and outlet should be free from obstacles and

strong wind.

the base surface should be flat, surface should be inclined

no more than 2°and able to bear the weight of the unit and

suitable for installing the unit without increasing noise or

vibration.

the operation noise and air flow expelled shall not affect

neighbors.

If the unit has to be installed on a metal part of building,

make sure the well electric insulation which should meet

the relevant local electric standard.

use of air from heated rooms could penalise the heating

performance of the building

The unit must be securely fixed, elsewise, noise and

shaking may be resulted.

Make sure that there’s no obstacle around the unit.

The external air temperature must also be considered when

installing this unit, in heat pump mode the external air

temperature must be above -7°C and below 43°CIf the

externalair temperature falls outside these upper and lower

limits, the electrical elements will activated to meet the hot

water demand and the heat pump does not operate.

The unit should be located in an area not subject to freezing

temperatures. The unit located in unconditioned spaces(i.e.,

garages, basements, etc.) may require the water piping,

condensate piping, and drain piping to be insulated to shelter

against freezing.

Installing the unit in any of the following places may lead to

malfunction:

The site contains mineral oils such as cutting lubricant

Seaside where the air contains much salt.

Hot spring area where corrosive gases exist, e.g., sulfide

gas.

Factories where the power voltage fluctuates seriously.

Inside a car or cabin.

The place with direct sunlight and other heat supplies. If

there’s no way to avoid these, please install a covering.

Place like kitchen where oil permeates.

Place where strong electromagnetic waves exist.

Place where flammable gases or materials exist.

Place where acid or alkali gases evaporate.

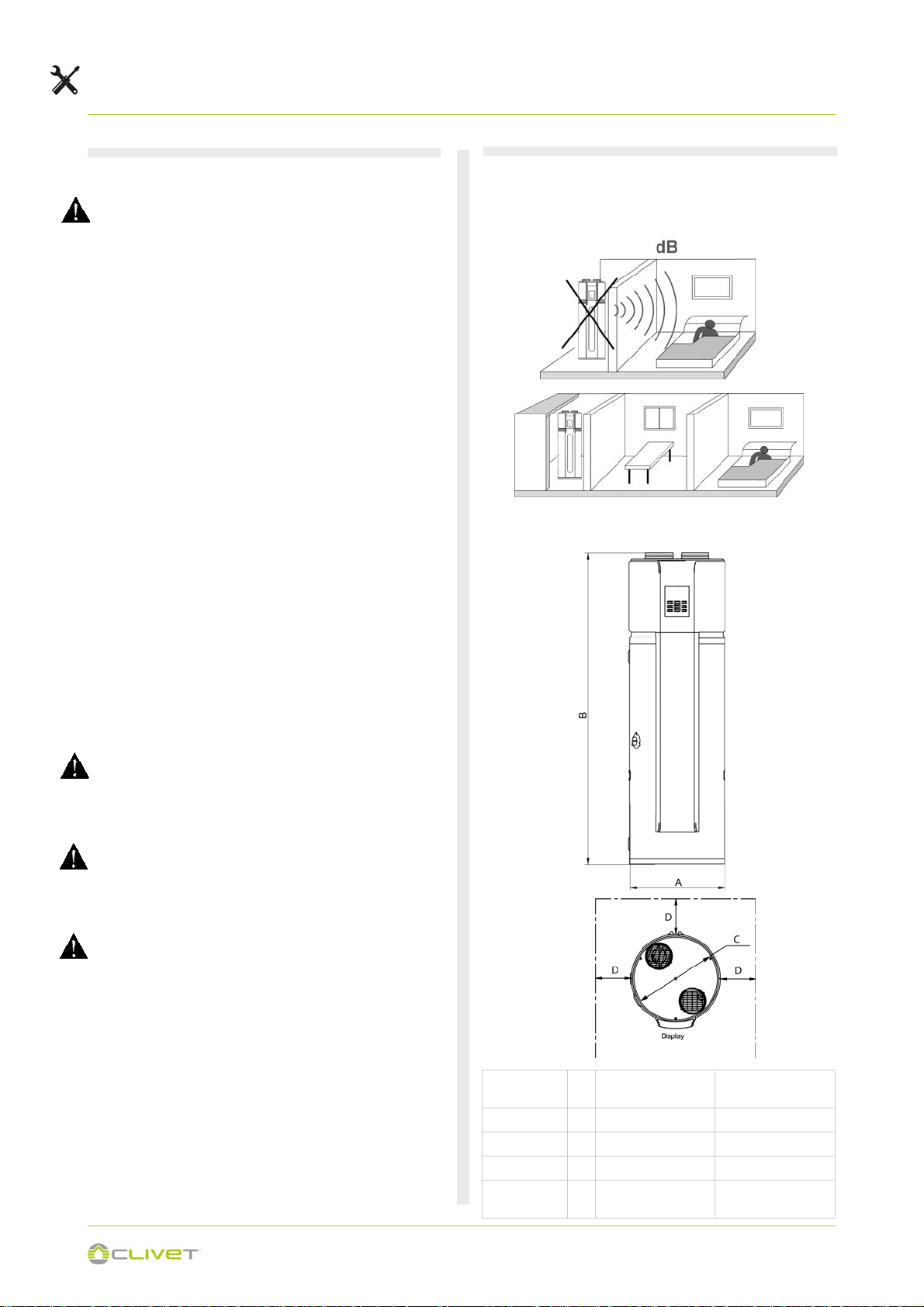

5.2 - CONSIDER SOUND EMISSIONS

Noise levels could represent an inconvenience if installed in

areas that require extreme silence, exsample near bedrooms.

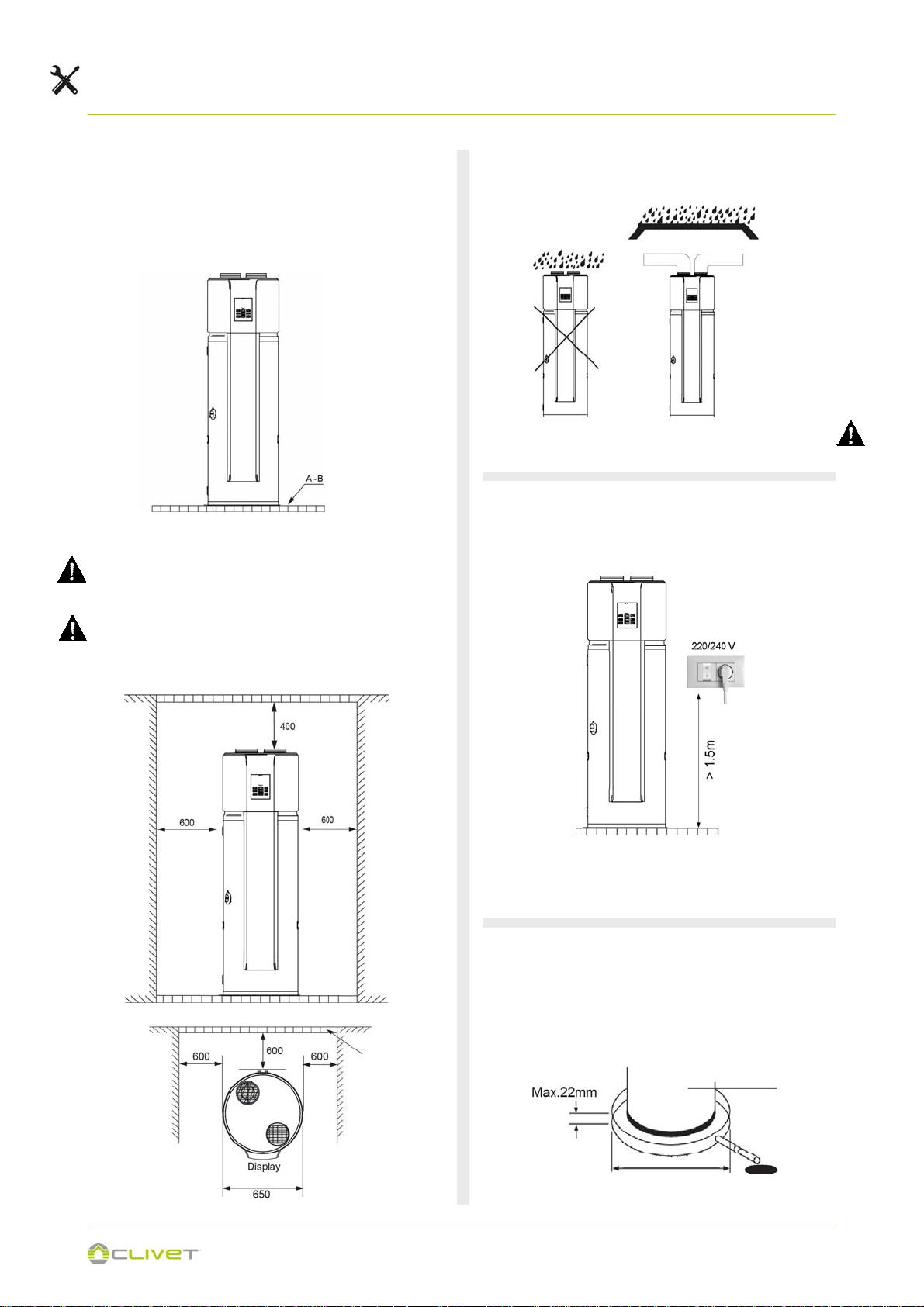

Unit dimension / Functional spaces

Unit 190L

Width A 560 650

Height B 1830 1930

Diameter C 560 650

Functional

spaces

190L (with solar)

D = 600 = 600

300L

300L (with solar)

16

5 - POSITIONING

Check that the floor can support the weight of the unit in

operation:

A - > 287 Kg/m

> 310 Kg/m

B - > 412 Kg/m

> 435 Kg/m

2

(190L)

2

(190S with solar)

2

(300L)

2

(300S with solar)

If installed in inclosed space

The unit must be located in a space >15m³, and must have

unrestricted air flow.

Make sure there is enough Installation space.

For optimal efficiency and serviceability, the following

clearances should be maintained: 400mm on the air inlet

side, 400mm on the air outlet side, 600mm in the back, and

600mm in the front.

Install the unit in the indoor space, it is not allow to install the

unit at the rainy space

In case of rain entering to internal components of the unit, the

component might be damaged or causing physical danger.

5.5 ELECTRICAL OUTLET

The installation height of power supply should be over 1.5m, if

separate the power supply from water.

Barrier

Configuration for electric power socket (schuko + On/Off

switch) close to the unit

The plug must be accessible at all moment.

5.6 - CONDENSATE DRAIN

Condensate may be leaked from unit if drainage pipe is

blocked, a drainage pan is recommended as shown as

following figure.

Heat pump

50mm larger than the diameter of

unit

17

Loading...

Loading...