Clinton 8890BH Service Manual

ML8890BH-7

CLINT ON

MODEL 8890BH

PROGRAMMABLE CONTROLLER

DRIVE SYSTEM

FOR

DURKOPP 558

BUTTONHOLE MACHINE

SERVICE MANUAL

Para Español vea el reverso del libro

40-0240-01

ML8890BH-8

TABLE OF CONTENTS

SECTION I - DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

SECTION II - INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DRIVE PULLEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.

SYNCHRONIZER & SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . .

B.

SEWING HEAD DRIVE PULLEY . . . . . . . . . . . . . . . . . . . . . . . .

C.

START SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.

AIR CYLINDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.

UPPER MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

F.

EMERGENCY STOP SWITCH . . . . . . . . . . . . . . . . . . . . . . . . .

G.

SECTION III - ADJUSTMENTS INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

HOME POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.

FIRST STITCH POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.

NEEDLE UP POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.

MOTOR FUNCTION & SENSOR TEST . . . . . . . . . . . . . . . . . .

D.

TENSION RELEASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.

SWING KNIFE & LOOPER THREAD TRAPPER . . . . . . . . . . . .

F.

THREAD NIPPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

G.

SECTION IV - MODES OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

FULL CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.

SINGLE STEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B.

MOVE TABLE ONLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.

REPAIR CYCLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.

2-1

2-2

2-3

2-4

2-4

2-5

2-5

3-1

3-1

3-1

3-2

3-2

3-2

3-3

4-1

4-2

4-2

4-2

SECTION V - PROGRAMMING MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

HOW TO PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.

ACCESS TO HIDDEN PARAMETERS . . . . . . . . . . . . . . . . . . .

B.

MASTER RESET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C.

EXPLANATION OF PARAMETERS . . . . . . . . . . . . . . . . . . . . .

D.

1.

2.

3.

4.

5.

E. PARAMETER LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

SECTION VI - TEST MODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

BUILT-IN TEST PROGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . .

A.

TESTING THE HOME AND SEW SENSORS . . . . . . . . . . . . .

B.

TESTING THE CLAMP DOWN AND START SWITCHES . . . .

C.

TESTING THE MOTORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D.

EXITING THE TEST MODE . . . . . . . . . . . . . . . . . . . . . . . . . . .

E.

DESCRIPTION OF THE HOME AND SEW SENSOR BLOCKS

F.

USING THE EMERGENCY STOP BUTTON . . . . . . . . . . . . . .

G.

AIR PRESSURE SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

H.

PARAMETERS WITH DIRECT ACCESS . . . . . . . . . . . . .

TIMERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

COUNTERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOGGLE SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIDDEN PARAMETERS . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1

5-1

5-2

5-2

5-2

5-2

5-3

5-3

5-4

6-1

6-1

6-1

6-1

6-2

6-2

6-3

6-3

ML8890BH-9B

SECTION I

DESCRIPTION

The Clinton Model 8890BH is a Micro Computer Controlled Electro / Mechanized / Pneumatic

system designed to enhance the performance and drastically reduce the maintenance required

to operate a Durkopp Buttonhole machine.

Two DC Servo Motors are used to replace the complete mechanized stop motion components

including the clutch, brake, spur gears and shafts.

State of the art sensors are used to communicate position and speed data to the single micro

computer control system. By use of the LCD Programmable Display, both the machine speed

and buttonhole "Eye" speed can be precisely entered and controlled. The LCD can also be used

to command repair cycles or 3 step cycles to assist in machine maintenance.

Figure 1-1 shows the major components of the system.

STOP

SWITCH

START

SWITCH

UPPER MOTOR

NEEDLE-UPSENSOR

SENSOR

ASSEMBL Y

LCD DISPLA Y

FIG. 1-1

1-1

LCD POST

ASSEMBLY

ML8890BH-10

SECTION II

INSTALLATION

Insure that the machine is in working order.

Mark the home position.

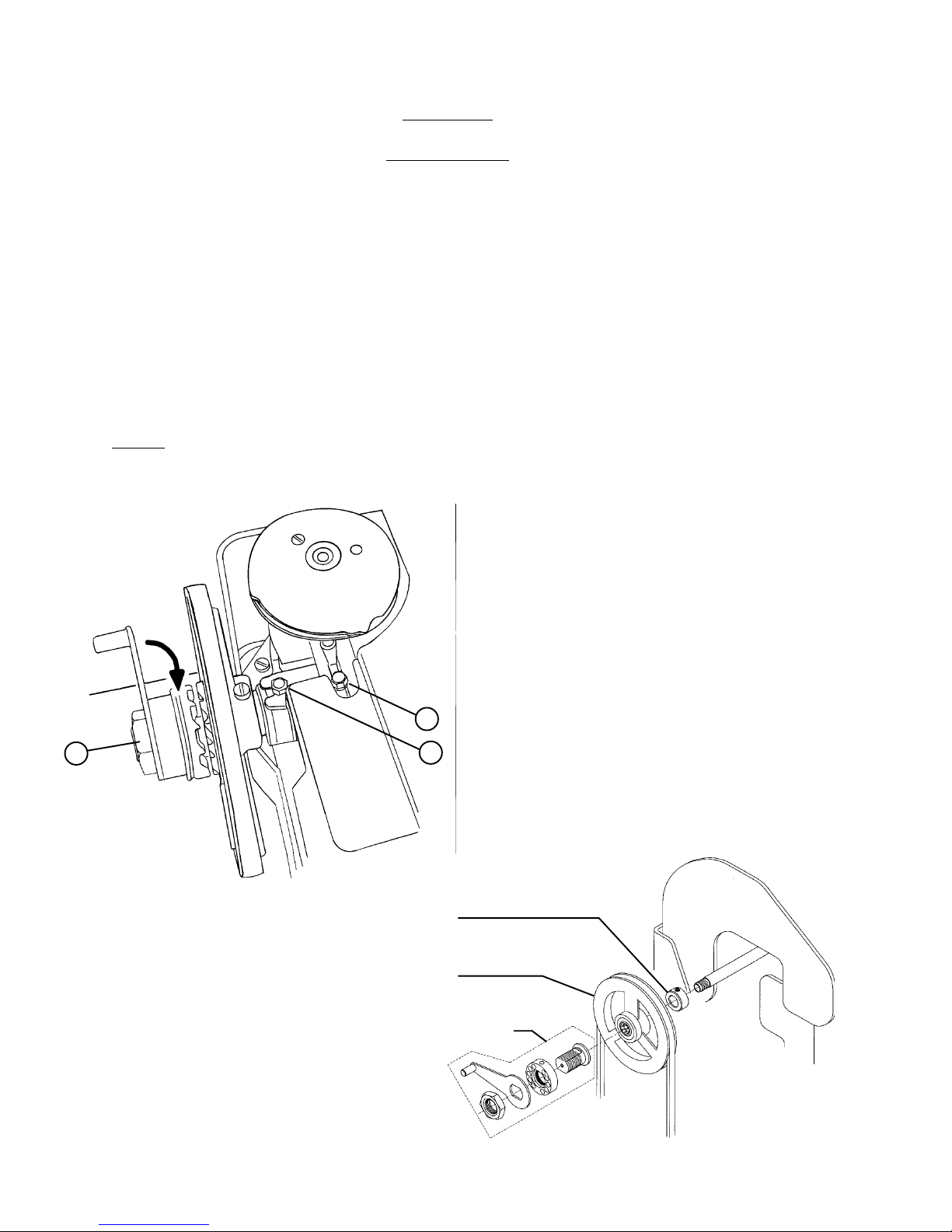

A. To install the drive pulley assembly. Remove the manual crank mechanism by rotating the crank

in the clockwise direction (See Fig. 2-1). Remove the pulley carrier assembly by loosening the hex

nut which attaches it to the reversing lever (Fig. 2-1, Item 1) and sliding the entire assembly off the

end of the cross shaft. Remove the large hex nut which holds the manual crank onto the crank hub

(Fig. 2-1, Item 2). Remove all parts from the crank hub. Loosen hex head screw (Fig. 2-1, Item 3)

and slide it toward the operator as far as it will travel in it’s adjusting slot. Place collar (02-4007-01)

and pulley assembly (10-1457-01) on the end of the cross shaft (See Fig. 2-2).

NOTE: The pulley assembly contains a locking bearing, insure that the bearing locks and drives

the shaft in the counterclockwise direction and free-wheels in the clockwise direction. Replace

the crank hub, spring holding device, manual crank and retaining nut (Fig. 2-2).

ROTATE

CLOCKWISE

TO REMOVE

2

3

1

FIG. 2-1

02-4007-01

COLLAR

10-1457-01

PULLEY ASS'Y

EXISTING

CRANK

FIG. 2-2

2-1

ML8890BH-11A

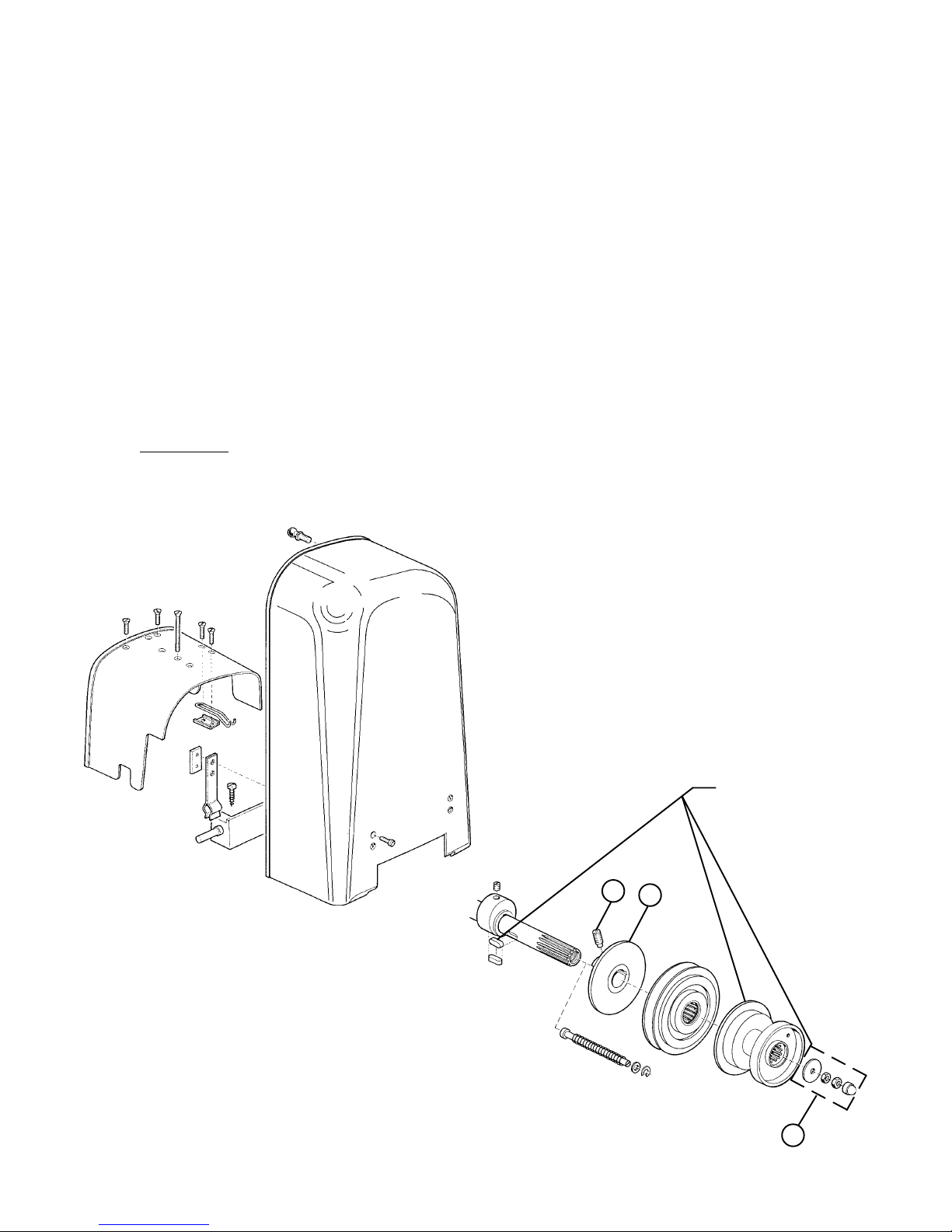

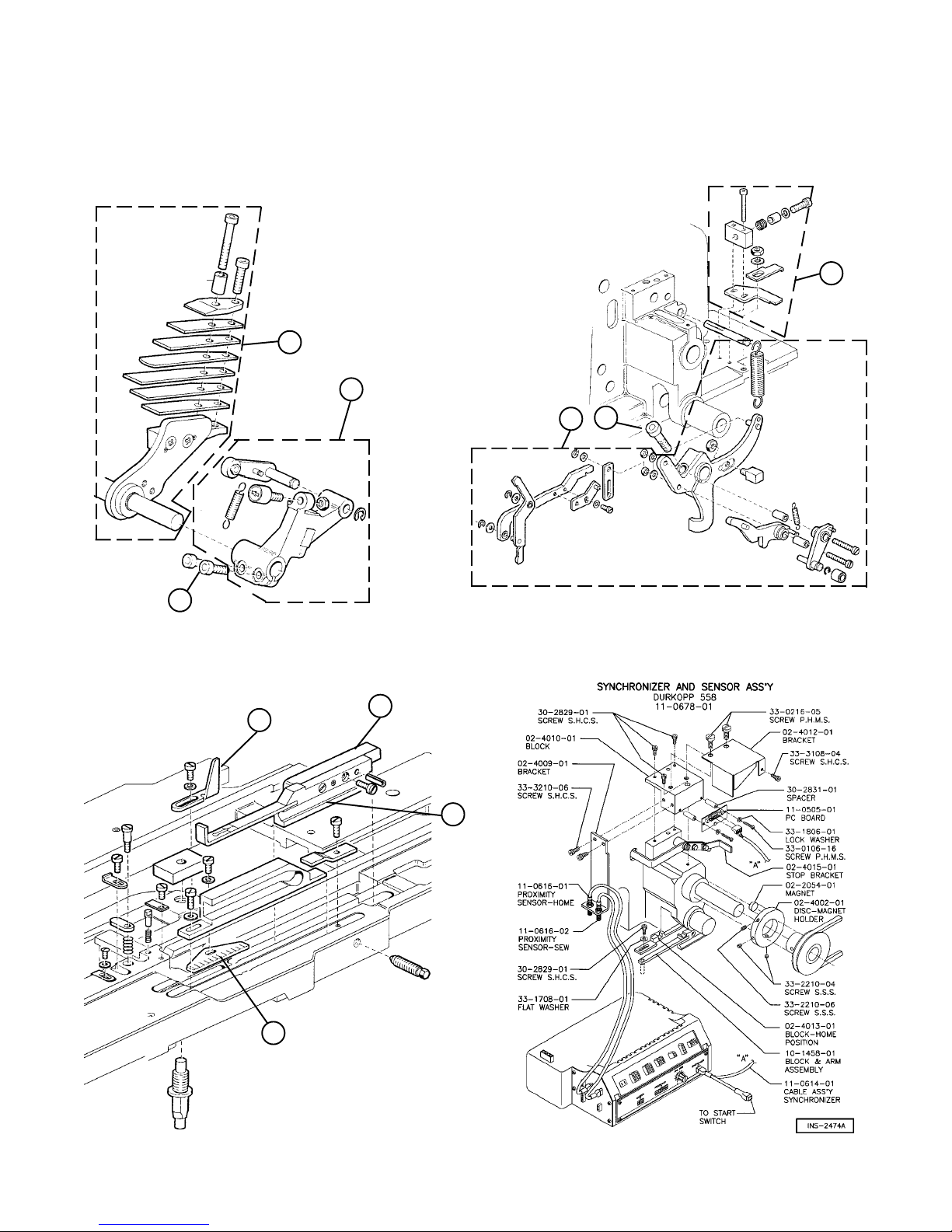

B. To install the synchronizer and sensor assemblies. Remove cover assemblies (Fig. 2-3).

Remove the hand wheel and sewing head pulley by removing the two locking nuts (Fig. 2-4,

Item 1). Remove the stop motion eccentric (Fig. 2-4, Item 2) by removing the threaded stud

(Fig. 2-4, Item 3). Retain thehand wheel, washer and locking nuts so that they may be put back

on at a later time. Remove the stop motion roller assembly (Fig. 2-5, Item 1) by loosening the two

clamp screws (Fig. 2-5 , Item 2). Manually rotate the machine to it’s furthest foreword point (half

way around the eye). Remove the stop motion leaf spring assembly (Fig. 2-5, Item 3) and three

forks lever by loosening the clamp screw (Fig. 2-6, Item 2) and sliding the leaf spring shaft out of

the casting. Remove torsion spring assembly (Fig. 2-6, Item 1). Remove the length adjusting slide,

stop and gauge plate (Fig. 2-7, Items 1, 2, & 3). Remove the tension release block (Fig. 2-7,

Item 4)from the length adjusting slide and attach it to the first stitch sensor block (Fig. 2-8,

10-1458-01). Replace the length adjusting slide with the first stitch sensor block. Using the screw

provided install the home position sensor block (Fig. 2-8, 02-4008-01) and stop bracket (Fig. 2-8,

02-4015-01). Using the screws provided install the sensor block assembly (Fig. 2-8).

WARNING: Insure that there is at least 1/16th of an inch clearance between bottom of

thehome and sew sensors and the home position and first stitch blocks

(Fig. 2-9) so that no damage is caused to the sensors when the machine is

cycled.

FIG. 2-3

2-2

3

FIG. 2-4

RETAIN FOR

REINSTALLATION

2

1

ML8890BH-12A

C. To install the sewing head drive pulley assembly. Attach the magnet disk holder to the sewing

head pulley (Fig. 2-8). Slide the pulley onto the arm shaft. Replace the hand wheel, washer and

locking nuts (Fig. 2-4).

3

3

1

2

1

2

FIG. 2-5

FIG. 2-6

4

2

1

3

FIG. 2-7 FIG. 2-8

2-3

ML8890BH-13A

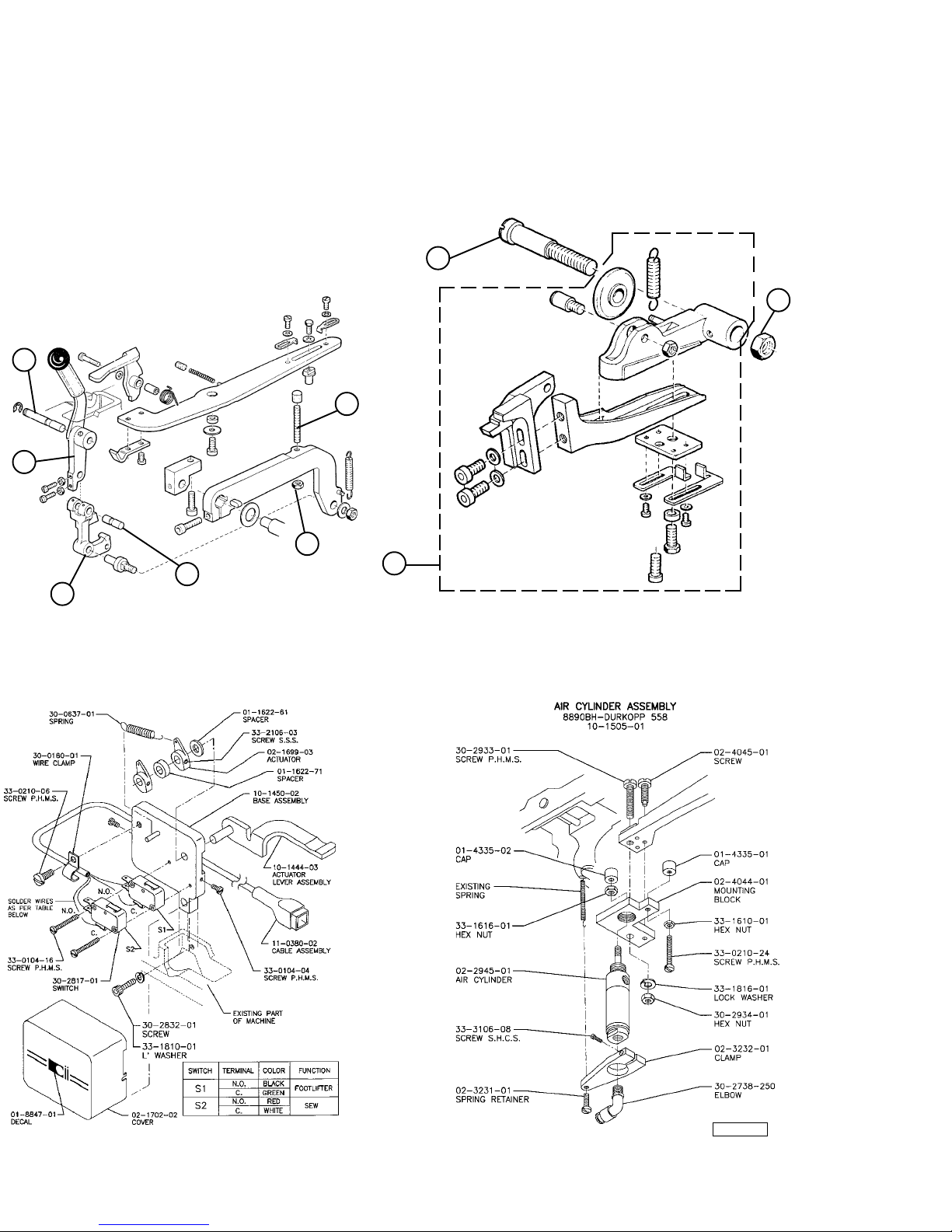

D. To install the start switch assembly. Remove the hand lever and clamping angle

(Fig. 2-9, Item 1 & 2) by removing the two pivot pins (Fig. 2-9, Item 3 & 4). Remove the manual

start switch (Fig. 2-9, Item 5). Remove the stop stud and locking nut (Fig. 2-9, Item 6 & 7).

Remove the clamping lever (Fig. 2-10, Item 1) by removing the lock nut and pivot bolt (Fig. 2-10,

Item 2 & 3). Install the start switch. (See Fig. 2-12).

3

3

6

1

2

7

4

1

2

FIG. 2-9

E. To install the air cylinder assembly. See Fig. 2-12.

FIG. 2-10

FIG. 2-11

INS-2594

FIG. 2-12

2-4

ML8890BH-14

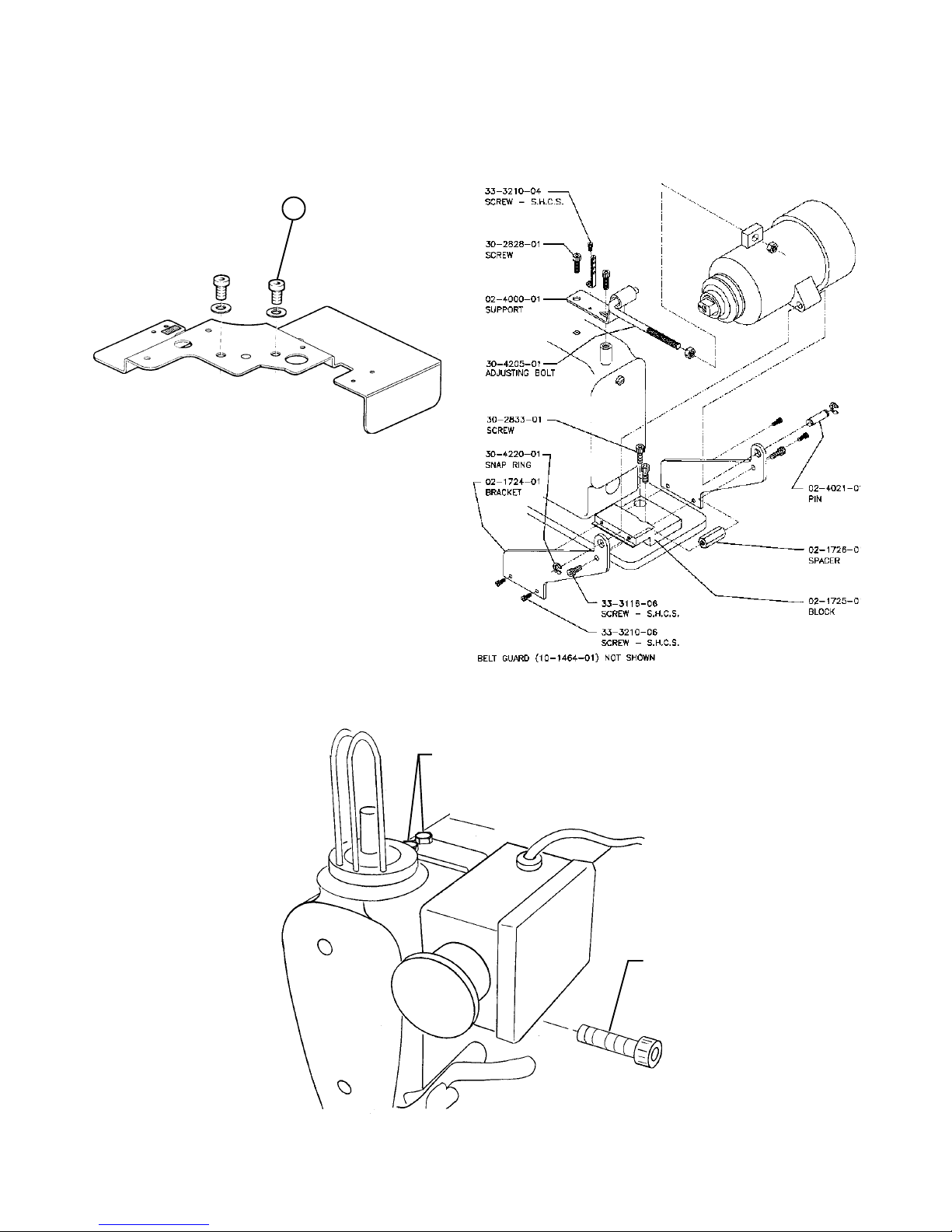

F. To install the Upper Motor. Remove the two cover retaining screws (Fig. 2-13, Item 1), and using

the screws provided install the upper motor (See Fig. 2-14).

1

FIG. 2-13

FIG. 2-14

G. To install the Emergency Stop Switch. Use the screws provided and install as shown

(See Fig. 2-15).

MOUNTING

SCREWS

MOUNTING

SCREW

FIG. 2-15

2-5

ML8890BH-15

SECTION III

ADJUSTMENT INSTRUCTIONS

Remove the needle.

A. T o set the Home Position. Return the machine to the home position by rotating the

manual crank until the arrows on the home position labels are aligned. Making sure that

the air supply is disconnected turn the power on. Loosening the home position block

retaining screw (Fig. 2-8) and slide the home position block toward the rear of the machine

as far as the adjusting slot will allow. Slowly pull the home position block toward the

operator until the indicator light on the home position sensor goes out. Gently push the

home position block toward the rear of the machine until the indicator light again comes on.

Tighten the retaining screw .

B. T o s e t the first stitch position. Rotate the machine with the manual crank until the leading

edge of the material clamp is aligned with the needle. Loosen the first stitch sensor block

retain screw and push the stitch sensor block toward the rear of the machine as far as it will

travel. Pull the first stitch sensor block toward the operator until the indicator light on the

first stitch sensor comes on. Tighten the retaining screw . Return the machine to the home

position.

C. T o set the needle up position. Rotate the hand wheel until the needle bar is at to dead

center with the left hand looper at the extreme left hand end of it’s stroke. With the

machine in this position loosen the set screws on the magnet disk. Rotate the magnet disk

until the magnet is aligned with the magnet sensor on the synchronizer board and as close

as possible to it without touching. Tighten the set screws.

Connect the air supply .

CAUTION: With the air supply now connected the machine will cycle if the start

switch is depressed.

3-1

Loading...

Loading...