Clinton 323A Instruction Manual And Parts List

CLIITTOII

CHI1INSf,IUS

REPTACEMENT

ENGINE

..$,

Port No.

A40t t69

PART DESCRIPTION

Power

Heod

Atst

92

-

IYPE

16

l7/a" Bore

*

GL[N$T@N$

*

GHAINSAW

Pqrf No. 40ll74

INSTRUCTION

TJIANUAL

0nd

PARTS tIST

/

By

following the

instructions in this

manual

you

can

look forward

to de-

pendable

service from

your

Chainsaw.

Quality

made, time tested Clinton

Chainsaws are

designed to

provide

ef-

ficient cutting on a

great

variety

of

jobs.

They

are

checked for high stand-

ards during all

phases

of

production

and assembly.

Treat

your

Chainsaw

right, and it will become the most valu-

able

tool

you

own.

For

periodic

servicing

and all

major

repairs,

you

should consult the Author-

ized

Clinton

Service Station

in

your

area. Here

you

will

find

factory-trained

mechanics,

genuine

Clinton

parts

and

prompt,

efficient service at

your

dis-

posal.

There

are Clinton

Service Sta-

tions

throughout the United States,

Canada and

many foreign countries.

Consult

the

yellow

pages

of

your

tele-

phone

directory for list

of Authorized

Clinton Service Stations.

For additional information about

your

Clinton Chainsaw

please

feel free

to write directly

to the factbry.

INTRODUCTION

AND

GENERAT

INFORMATION

lntroduction

SERVICE DEPARTMENT

CHAINSAW DIVISION

CTINTON MACHINE

COMPANY

CLINTON, MICHIGAN

Specif

ications

Princip.le

of

2-Cycle

Engine

Operation

Assembly

of

Guide

Bar

and

ihipper

Chain.

.

3

3

4

5

6

6

Fuel

Preparation

and

Lubrication

Chain

and

Guide

Bar

Lubrication

STARTING

AND

OPERATING

PROCEDURE

Sofety.

Precoutions

Controls

Storting

Procedure

Corburetor

(Floot

Type)

Break-ln

Period

Bucking

Cut-Small

Logs

N.otching

and

Felling

Cut

SERV!CE

AND

ADJUSTMENTS

Fuel

System

Cleaning

Valve

Ports-Exhaust

Maintenance

ACCESSORY

ITEMS

Bow

Sow

Attochment

Helpers

Handle

Assembly

ENGINE-Clinton two

cycle,

one

cylin-

der, air-cooled.

BORE-I7e

STROKE-15/e inches.

FUEt-Oil and Gasoline mixed.

SPARKPTUG-Champion Hll

or

equal,

Gap .025 inches.

POINT GAP-.020 inches,

nominal set-

ting.

IGNITION TIMING-Fixed.

IYPE OF VALVE*Reed.

OPERATING

SPEED

-

Approximalely

4500 R.P.M.

lDLlNG

SPEED

-

Approximotely

1500

to 1800 R.P.M.

TYPE OF

BEARINGS-Bo||

ond needle

beorings

lhroughout.

TYPE OF

CARBUREIOR

-

Floot.

FUEL

TANK CAPACITY

-

I

quort.

FUEI R.AIIO-3/a

pint

of SAE

#30

to I

gal. gasoline.

RECOMMENDED

GASOLINE

-

Any

good grode

(non-leoded).

RECOMMENDED OIt GRADE

-

SAE

#30

(non-detergent).

TYPE OF

IGNITION

-

Clinlon high

tension fly-wheel mognelo.

TYPE

OF

STARTER-CIinton recoil.

TYPE OF C[UTCH-Automatic

Centri-

f ugal.

CHAIN

OIIER CAPACIIY

-

7z

pint

SAE

#30.

GUIDE

BAR TENGTHS-From l6

inches

to 30 inches

(stroight

guide

bors);

14 & 18

inch

Bow Sow Attqch-

ments ovoiloble.

6

7

8

8,9

8

t0

l0

l0

11,12

l3

r3

l3

I3

t4

r5

currTolt

'cHAtilsAw

INTRODUCT!ON

w

SPECIFICATIONS

In a

two

cycle

engine,

intake,

com-

pression,

power

and

exhaust

are

com-

pleted

in

two

strokes

of

the piston.

A

power-stroke

results

with

every

revolu_

tion

of

the

crankshaft.

On the

Lrpward

stroke

of

the piston,

a

partial

vacuum

is

created

in

the

crankcase. (See

Figure

No. l)

First,

the

vacuunt

and

outside

air

pressure

cause

the

reed

valve

between

the

crankcase

and

the

carburetor

to

open.

The

air-fuel

mixture

from

the

carburetor

flows

in

to

the

ensine

crankcase.

Then,

the

downward

m6u"-

ment

of

the piston

causes

the

reed

valve

to

close

while

continued

down-

ward

movement

of

the

piston

com_

presses

the

fuel

charge

in

the

crank_

case.

Near

the

bottom

of its

stroke

the

piston

uncovers

the

intake

by-pass

port,

which

connects

the

combirsiion

chamber

and

the

crankcase.

As

the piston

moves

upward

on

its

stroke,

it passes

the

intake

port,

closins

the

port

opening.

Its

continued

,p*arj

movement

causes

the

fuel

mixture

in

the

cylinder

to

be

compressed.

At

the

same

time

a new

fuel

iharge

is

drawn

into

the

crankcase.

As

the

iiston

nears

the

top

of

the

compression

stroke,

the

fuel

nrixture

in

the-combustion

cham_

ber

is

ignited

by the

spark.

The

explo_

sron

and

expansion

of

gases

forces'the

piston

down

on

its

-power

stroke.

Power

is

not

delivered

for

the

full

length

of

the

stroke.

Some

time

is re_

quired

to

rid

the

cylinder

of

burned

gases,

so

that

it

may

receive

a fresh

fuel

charge

l'ronr

the-

crankcase.

'

As the

piston

nears

the

bottom

of its

stroke,

it

uncovers

the

exhaust

oort

opening

slightly

ahead

of

the

iniake

port.

This permits

taking

advantage

of

the. pressure

of

the

exharlst

gases

ii

the

cylinder,

which

are

still

coirparatively

high,

and

allows

them

to

start

escaoins.

Further

downward

travel

of the pisto"n

uncovers

the

intake

by-pass

port.

The

incoming

charge

assists

in

forcing

the

exhaust

gases

out

of

the

cylindei,

to

contplete

the

cycle.

'The

chief

atfributes

of

the

two

cvcle

engine-

are

its

lightweight,

low

cost

ind

powerful

but

simple

operation.

With

only

three

basic

moving

parts (crank_

shaft,

piston

and

rod)],'muirteninc"

costs

are

at

a minimum

while

efficiency

is

at

a

maximum.

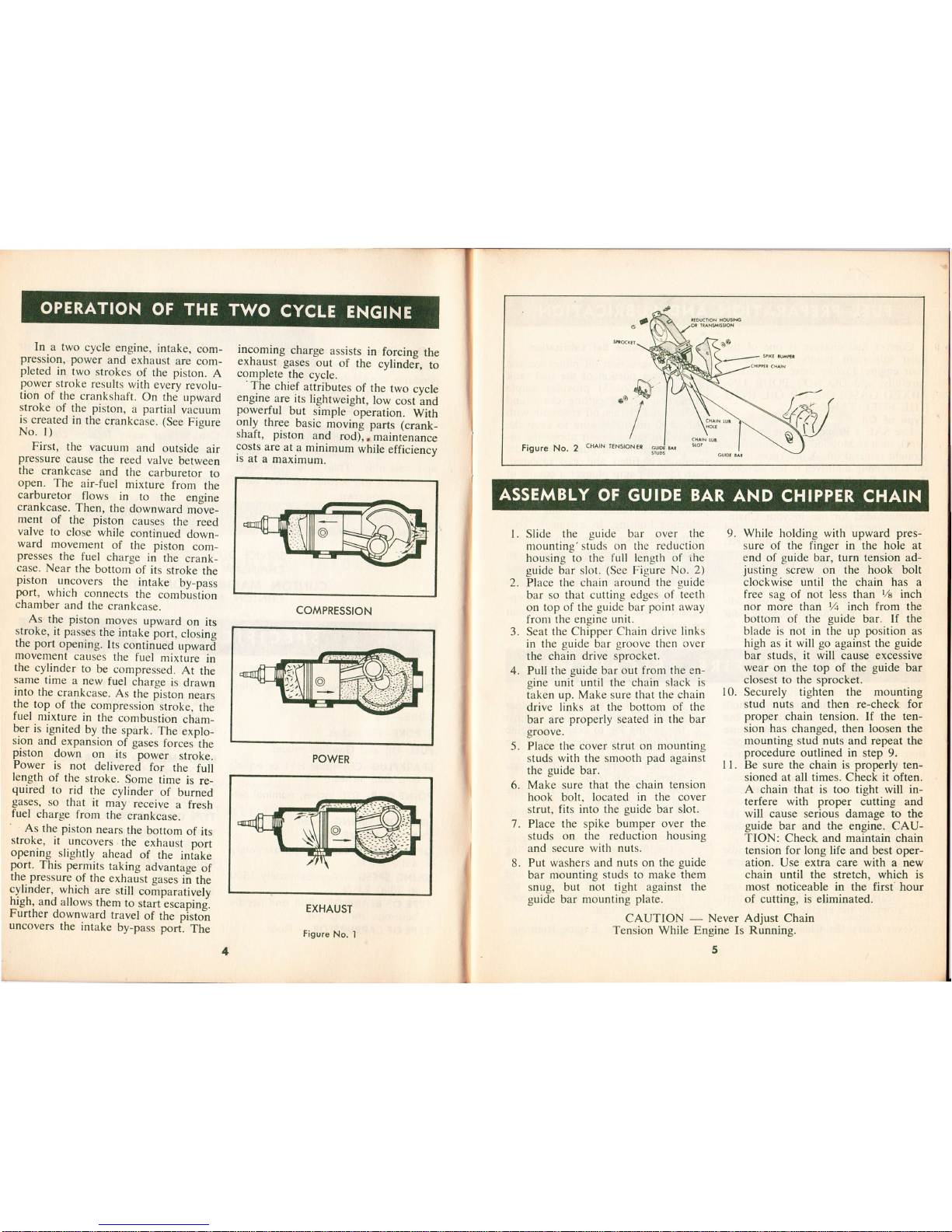

Figure

No. 2

cHArN

l Slide the

guide bar over the

mounting'studs

on the reduction

housing

to the full

length of the

guide

bar slot.

(See

Figure No.

2)

Place

the chain around

the

guide

bar so that cutting

edges of teeth

on

top of the

guide

bar

point away

fronr

the engine unit.

Seat

the Chipper

Chain drive links

in the

guide

bar

groove

then over

the chain drive

sprocket.

Pull

the

guide

bar out

from the en-

gine unit until the chain

slack is

taken

up. Make sure that the chain

drive links at the bottom of the

bar are

properly

seated

in

the bar

groove.

Place the cover

strut on mounting

studs

with the smooth

pad

against

the

guide

bar,

Make sure that the chain tension

hook

bolt.

located in

the

cover

strut,

fits into the

guide

bar slot.

7. Place

the

spike

bumper over the

studs on the reduction

housing

and

secure with nuts.

8.

Put washers and

nuts on the

guide

bar mounting

studs to make them

snug,

but not tight against

the

guide bar mounting

plate.

While holding with upward

pres-

sure of the finger

in

the hole

at

end

of guide

bar, turn tension ad-

justing

screw on the hook bolt

clockwise until the chain

has a

free sag of not less than

7e

inch

nor more

lhan

Vt inch from the

bottom of the

guide

bar. lf

the

blade is not in the up

position

as

high as it will go

against

the

guide

bar studs, it

will

cause excessive

wear on the top of the guide bar

closest to the sprocket.

Securely tighten the mounting

stud

nuts

and then re-check for

proper

chain tension.

If the

ten-

sion has

changed,

then

loosen

the

mounting stud nuts and repeat the

procedure

outlined

in

step 9.

Be sure the chain

is properly

ten-

sioned

at all

times.

Check

it

often.

A chain that is

too

tight

rvill

in-

terfere with

proper

cuttin,s

and

rvill

cause serious damage to the

guide

bar and the engine. CAU-

TION:

Check and

maintain

chain

tension for

long life and best oper-

ation. Use extra care with a new

chain until the stretch, which

is

most noticeable in the

first' hour

of

cutting,

is eliminated.

9.

COMPRESSION

POWER

EXHAUST

Figure

No.

I

2.

3.

4.

10.

I l.

5.

6.

CAUTION

-

]rlsysl

Adjust

Chain

Tension While

Engine

Is Running.

5

4

ASSEMBLY

OF GUIDE BAR

AND

CHIPPER

CHAIN

Correct

fuel mixture

is

one

of the

most important

points

in operating

your

engine.

Follow

these

instructions

carefully,

and

DO NOT

POUR

UN-

MIXED

GASOLINE

OR

OIL INTO

THE

FUEL

TANK.

Type

of Oil

Use SAE

#30 motor

oil

(non-deter-

gent),

such

as

Mobiloil

or a

comparable

straight

mineral

oil. A

detergent

oil

or

oil

containing

additives

is

not advised.

Type

of Gasoline

A

good

grade

of

regular gasoline,

available

at

your

local

filling

station,

is

recommended

for use

in your

Chain-

saw engine.

High

octane

or

Ieaded

fuels

offer

no advantages

and ARE,

NOT

advised.

Mixing

Ratio

of

Oil to

Gasoline

Thoroughly

ntix

3/+

pint

of oil

with

each gallon

of gasoline.

This

rich

oil

mixture

may

cause

difficulty

with

idl-

ing,

but it is

necessary

to properly

wear

in the

various parts

of the

engine.

Chain

and

Guide

Bar

Lubrication

A

positive

action oil

pump

located

in the

upper portion

of

the fuel

tank

(See

Figure

No. 3)

provides

ample

Iubrication

to the

cutting

chain

and

guide

bar. FiU

this oil

reservoir

with

SAE

#30 oil, being

sure

to keep

the

oil level

in

the reservoir

4bove

the

in-

take

tube

of the

oil

pump.

When

the

reservoir

is

filled

and

cap replaced,

push

the

oil

pump

plunger

a couple

of

times

until

pressure

is felt,

or until you

see oil

appearing

on

the

guide

bar op-

posite

the

convenient

oil

fitting in

the

reduction

housing.

In

extremely

cold

weather,

or

when

cutting

wood

which

contains

a lot

of

pitch,

sap or

resin,

use

a 50-50

mixture

of

kerosene

and

oil

in the

oil

reservoir.

This

will

pro-

vide good

lubrication

as

well as

keep-

ing

the

guide

bar g,roove

and

chain

comparatively

clean.

Be

sure

that

the

spike

bumper

(abutment

strut)

is

flush

against

the sawing

log

to keep

the

engine

unit

from

being pulled

againsithe

log.

Do

not

operate your

Chainsaw

when

it

needs

repair.

Do

not

allow

the saw

to run

while

on a

cement

floor.

Do not

run

saw

when

it is

dull or

improperly

filed.

After

refueling,

move

the

engine

a. few

feet

away

from

the fue-ling

site.

Keep

Chainsaw

clean

of dust

and

inflammables,

and

check

to

see

that

spark plug

and electrical

con-

nections

are

tight.

Your

Clinton

Chainsaw

is well-built

for

maximum

safety

and

efficiency,

but

carelessness

in

operation

can

cause

accidents.

Read

the

following

sugges-

tions

carefully,

and

remember

them

as

you

work with your

saw.

l.

Do not

start

the

engine in

a closed

room.

Have

ample

ventilation

at

all times.

2.

Do not

touch

the

chain

when

the

epgine is

running

even at

a

slow

speed.

3. Keep

engine

adjusted

to an

idle

speed

which

stops

the chain

com-

pletely.

4.

Do not

move

the

chain from

one

location

to

another

without

first

stopping

the

engine.

Never

Carry

the

Chainsaw

from

Place

5.

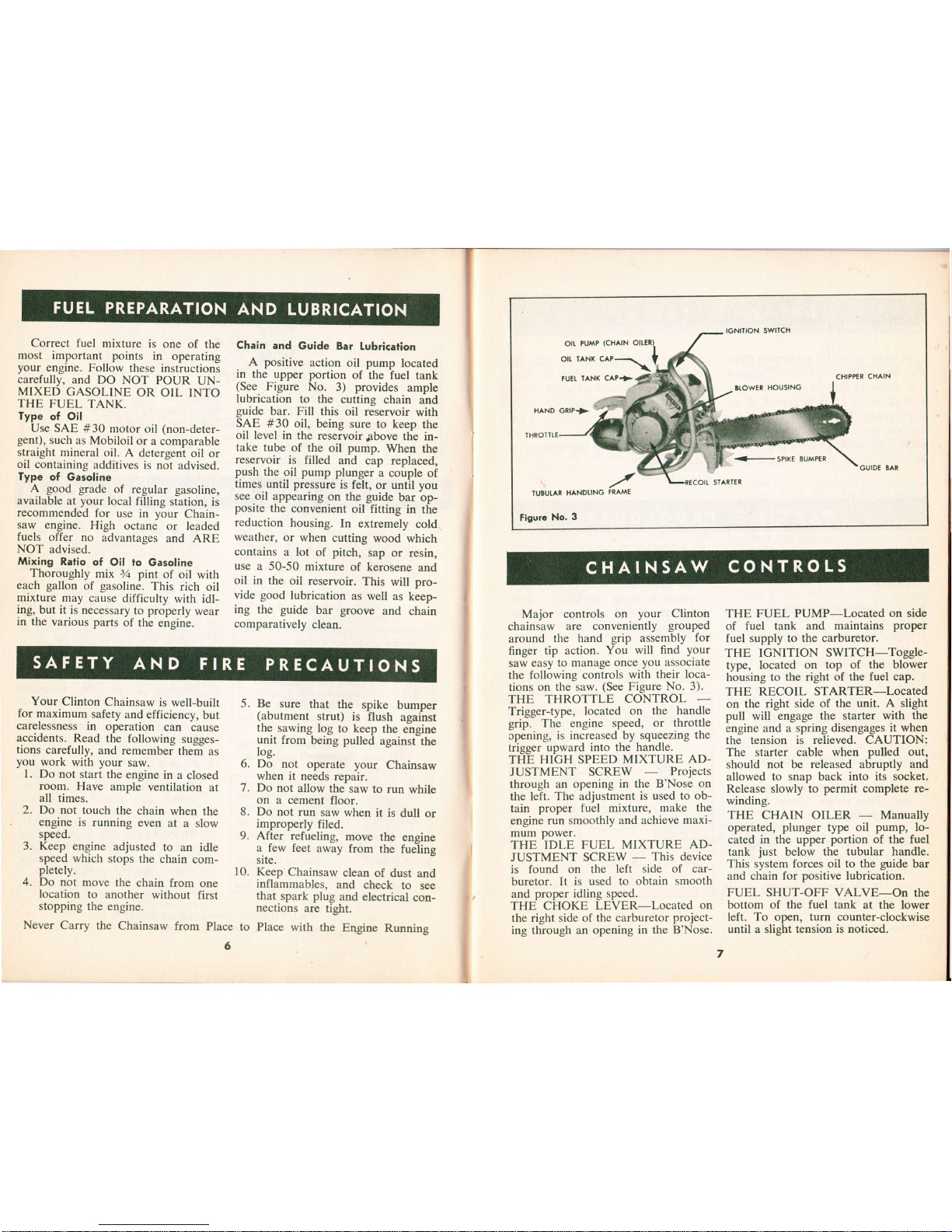

Major

controls

on

your

Clinton

chainsaw

are

conveniently

grouped

around

the

hand

grip assembly

for

finger

tip action.

You will

flnd

Your

saw

easy

to manage

once

you associate

the following controls

with

their loca-

tions on

the saw.

(See

Figure

No. 3).

THE THROTTLE

CONTROL

Trigger-type,

located on

the

handle

grip. The engine

speed,

or throttle

cpening,

is

increased by squeezing

the

trigger

upward into the handle.

THE

HIGH

SPEED

MIXTURE

AD-

JUSTMENT SCREW

Projects

through

an opening

in the B'Nose

on

the left.

The adjustment

is used to

ob-

tain

proper

fuel

mixture,

make the

engine

run

smoothly

and achieve

maxi-

mum

power.

THE IDLE

FUEL

MIXTURE AD-

JUSTMENT

SCREW

-

This device

is found

on the left

side of car-

buretor.

It is

used to obtain

smooth

and

proper

idling

speed.

THE CHOKE

LEVER-Located

on

the right side of

the carburetor

project-

ing through an

opening in

the B'Nose.

THE FUEL PUMP-Located

on side

of fuel tank

and maintains

proper

fuel supply

to the carburetor.

THE IGNITION

SWITCH-Toggle-

type,

located on

top of

the

blower

housing

to the

right of the

fuel

cap.

THE

RECOIL STARTER-Located

on the right

side of the

unit. A slight

pull will engage

the starter with

the

engine

and a spring

disengages

it when

the tension

is relieved. CAUTION:

The starter cable when

pulled

out,

should

not be released abruptly

and

allowed

to snap back into

its socket.

Release

slowly to

permit

complete re-

winding.

THE CHAIN OILER

-

Manually

operated,

plunger

type oil

pump,

lo-

cated

in

the upper

portion

of the fuel

tank

just

below

the tubular

handle.

This system forces

oil to the

guide

bar

and chain

for

positive

lubrication.

FUEL

SHUT-OFF

VALVE-On

the

bottom

of the fuel tank

at the

lower

left. To open,

turn

counter-clockwise

until a slight tension

is

noticed.

6.

7.

8.

9.

10.

IGNITION SWITCH

OII.

PUMP

(CHAIN

OII,

TANK C^P-\

FUEI

IANK

CAP+

CHIPPER

CHAIN

Er.OwtR

HOUSING

GUIDE

SAR

,/

TUEUIAR

HANDI,ING

FRAME

Figurc

No.

3

to

Place with

the

Engine

Running

FUEL

PREPARATION

AND

LUBRICATION

CHAINSAW

CONTROLS

SAFETY

AND

FIRE

PRECAUTIONS

In

order

to

obtain

maximum

effici_

ency

and service

from

your

Chainsaw,

it is

necessary

that

the

engine

be oper-

ated

during

a

break-in

period

of

ap-

proximately

five

(5)

hours.

Never

operate

the

engine

without

load

or

allow

it

to

become

overheated.

proper

breaking

in

of

key parts

will

have

1

Fill

fuel

and

oil

tanks

according

to

Fuel

Preparation

Instructions

on

Page

6.

2.

Open

fuel

tank.

Shut-off

valve.

3.

Open

high

speed

adjustment

screw

lVq

to

lVz

trtrns.

4.

Push

choke

lever

into

.,Choke',

po_

sition.

5.

Turn

ignition

switch

to

,.On.',

6.

Pull

on

recoil

starter

handle,

then

let

it

slowly

return

to

the

socket.

7 .

After

two

or

three

pulls,

engine

will

start.

Then

return

..choke,'

lever

to

"run"

position.

8.

Before

cutting

with

saw,

pump

the

chain

oiler

(See

Figure

No.

3)

a

few

times

to

lubricate

grooye

in

guide

bar.

Use

the pump

frequently

while

the

chain

is

in

operatron.

9.

Run

the

engine

for

a few

minutes

much

to

do

with

the

life

of

your

en_

gine.

Be

sure

to

check

often

for

loose

nuts

and

screws

and

make

all

neces_

sary

adjustments.

Periodic

inspection

and

service

by

your

Authorized

Clin-

ton

Service

Station

dealer

will

result

in

long

life

and good

pdrformance

of

your

Chainsaw.

POWER

RANGE ADJUSTMENTS

1. Start engine and

allow

it to run at

Vz

throttle for a few minutes until

the engine

acquires

uniform tem-

perature.

Never race the engine

when not

under load.

2.

Put the saw in cut, under load and

while cutting check to

see

if engine

backfires.

If

it does,

speed

mixture

is

too lean.

TO CORRECT: Slowly

turn high

speed

mixture needle

valve counter-

clockwise until

the engine runs

smoothly.

(Refer

to

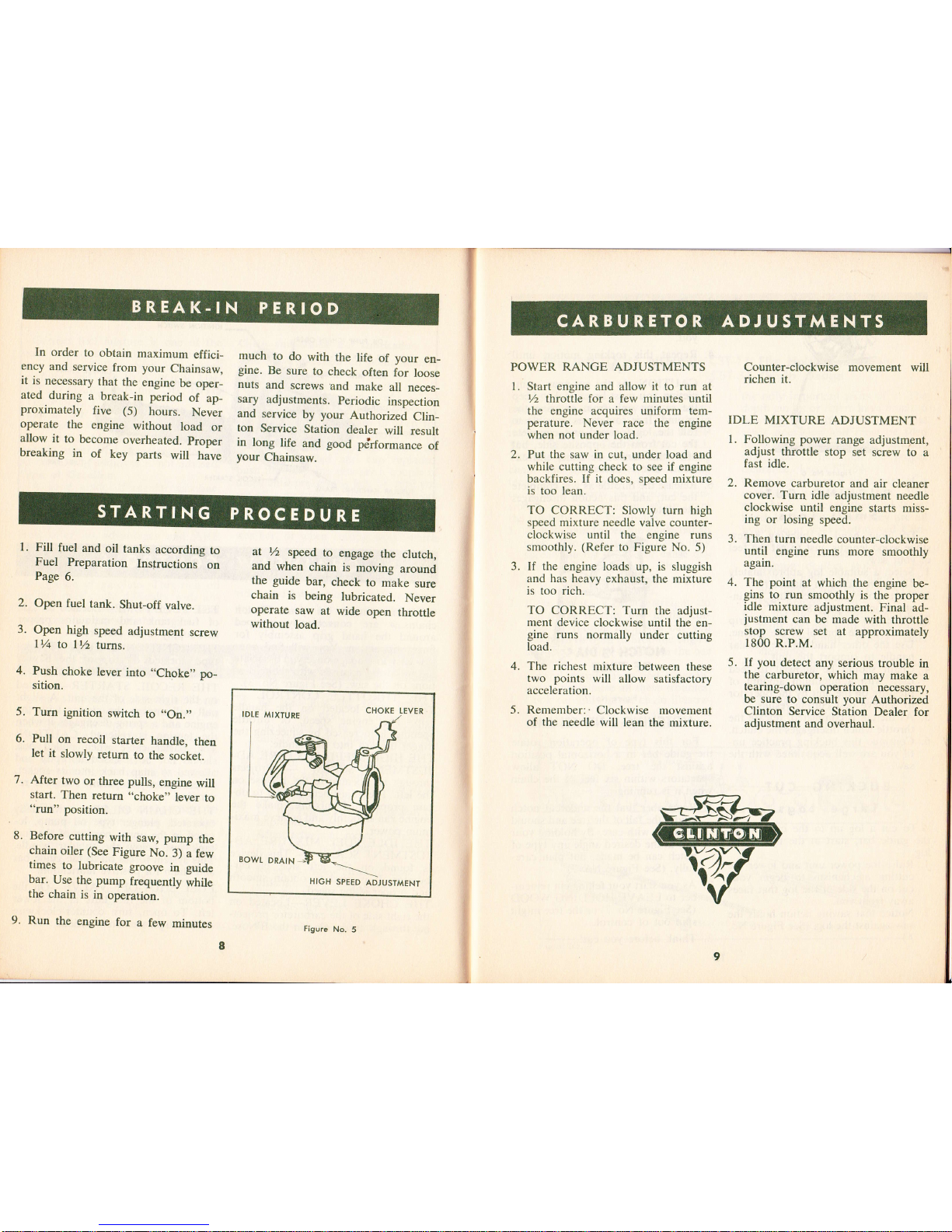

Figure No. 5)

If the engine loads up, is

sluggish

and

has

heavy exhaust, the

mixture

is

too rich.

TO CORRECT:

Turn the

adjust-

ment device

clockwise until the

en-

gine

runs normally under

cutting

load.

The richest

mixture

between these

two points

will

allow

satisfactory

acceleration.

Remember:'

Clockwise

movement

of

the

needle

will lean the mixture.

Counter-clockwise movement

will

richen it.

IDLE

MIXTURE

ADJUSTMENT

1

Following power

range

adjustment,

adjust throttle

stop

set screw to

a

fast idle.

Remove

carburetor

and

air cleaner

cover. Turn idle

adjustment

needle

clockwise

until engine

starts miss-

ing or

losing

speed.

Then

turn needle

counter-clockwise

until

engine

runs

more

smoothly

agaln.

The

point

at which

the engine

be-

gins

to run

smoothly

is the

proper

idle

mixture

adjustment.

Final ad-

justment

can be

made with

throttle

stop

screw

set

at

approximately

1800

R.P.M.

If

you

detect

any serious

trouble

in

the

carburetor,

which

may

make

a

tearing-down

operation

necessary,

be sure to

consult

your

Authorized

Clinton

Service

Station Dealer

for

adjustment

and

overhaul.

2.

at

Yz

speed

to

engage

the

clutch,

and

when

chain

is

moving

around

the guide

bar,

check

to

make

sure

chain

is

being

lubricated.

Never

operate

saw

at

wide

open

throttle

without

load.

3.

4.

J.

4.

5.

5.

CHOKE

TEVER

SPEED

ADJUST

HIGH

'MENT

Figure

No,

5

CARBURETOR ADJUSTMENTS

8

9

Loading...

Loading...