Climma CWS BASIC 121, CWS BASIC 201, CWS BASIC 161, CWS BASIC 251, CWS 121RC Installation, Operation And Maintenance Manual

...Page 1

CWS Basic 121-161-201-251

www.climma.it

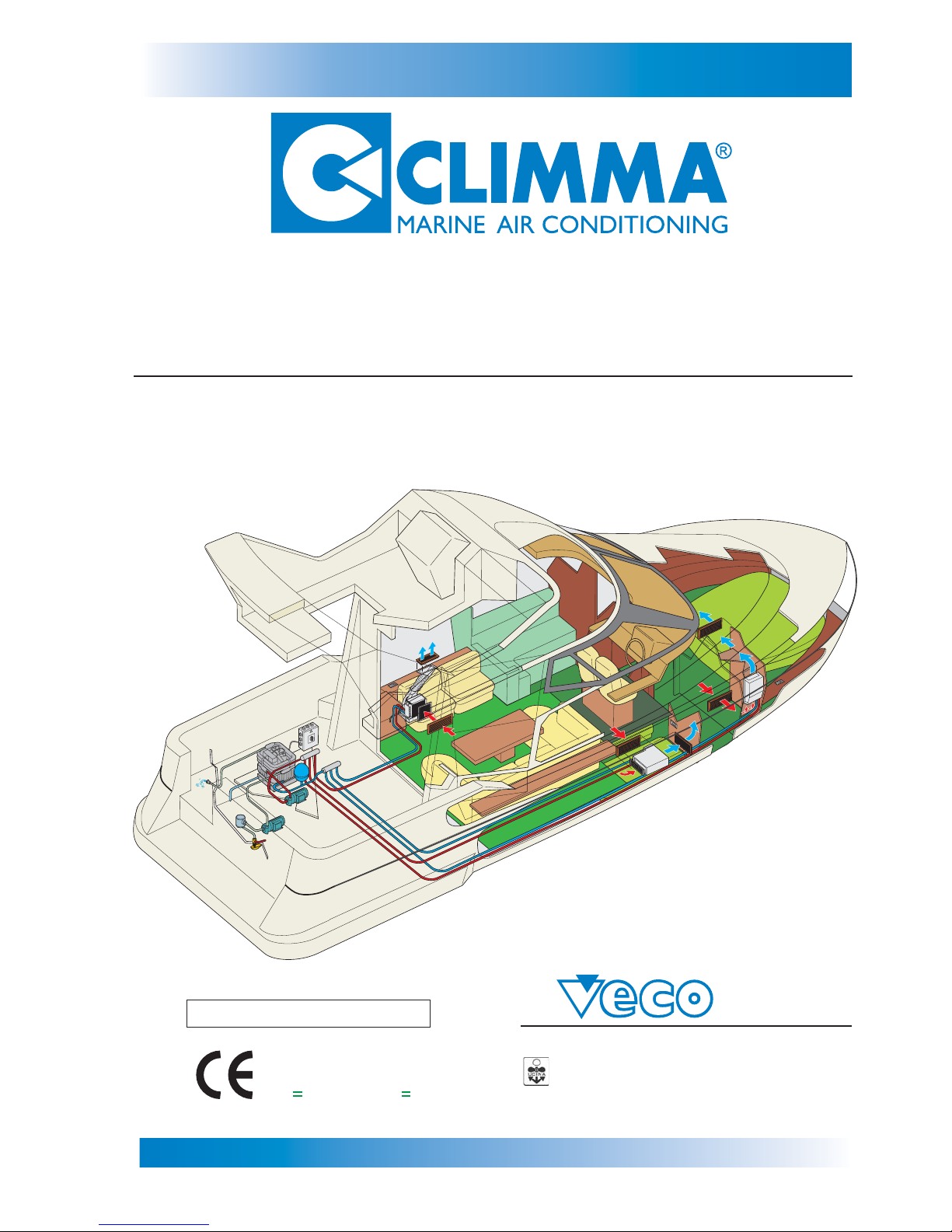

CHILLER SYSTEM

MODELS CWS BASIC

121-161-201-251

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

S.p.A.

COMPANY

WITH QUALITY SYSTEM

CERTIFIED BY DNV

ISO 9001/2000

Via Cantore, 6/8 - 20034 Giussano (MI) ITALY

Tel. +39 0362.35321 - fax +39 0362.852995

info@veco.netE-mail:

Cod. A041250 01/09/06

Page 2

Page 1

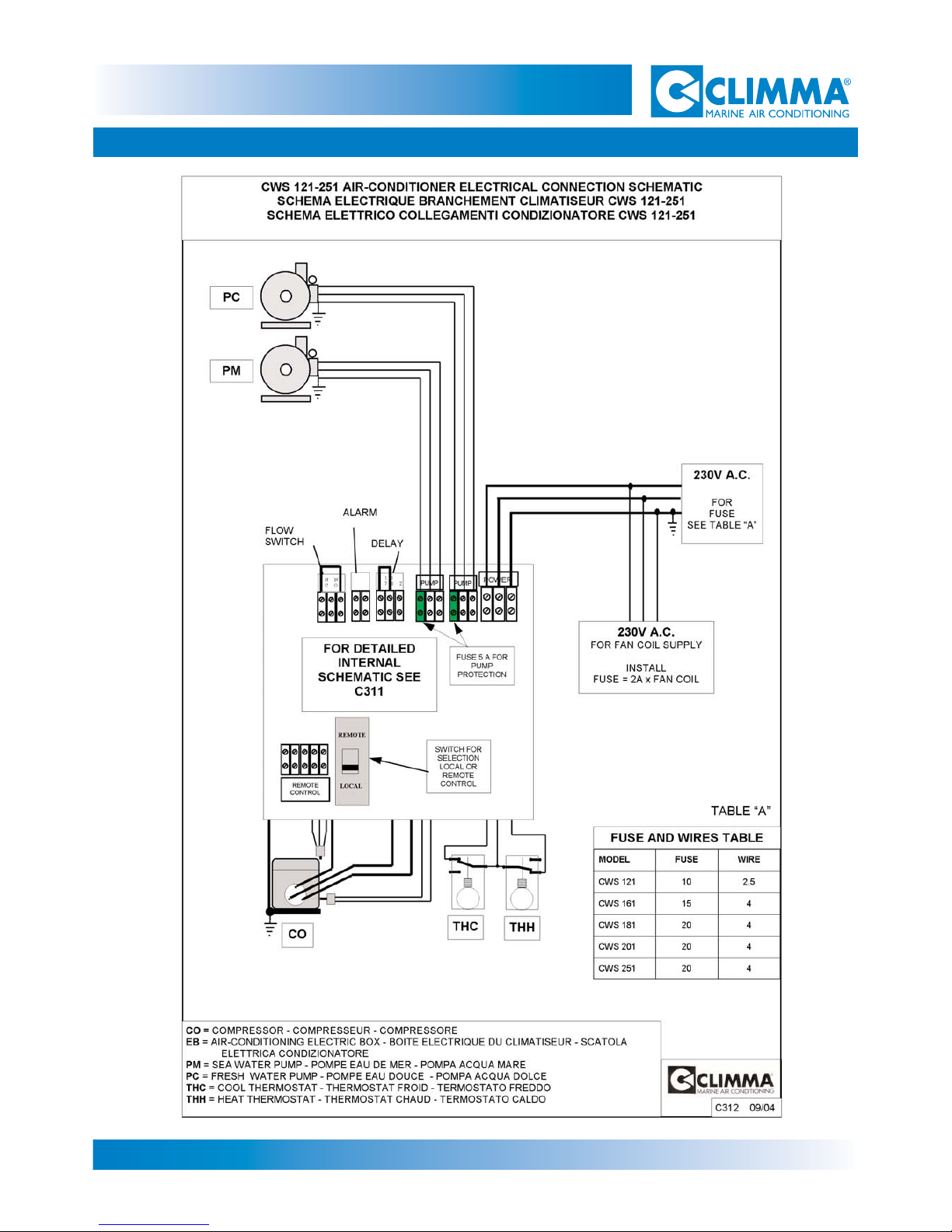

1- ELECTRICAL CONNECTIONS

CWS Basic 121-161-201-251

All the connections must be made by skilled technical engineers

and must comply with the safety rules of the country where the unit

is installed.

The unit must be connected to a good ground connection, using a

cable of correct size.

Supply must be made using a cable adequate to the maximum

operating load. Also the sea-water pump line should be done with a

cable adequate to the power.

Supply must be connected from a suitable circuit breaker. Any

maintenance or inspection to the system must be performed disconnecting first the mains supply.

1.1- Mains supply

The connections of the other system components must be made following our

schematics C312 (p.2) and C650 for the triphase version (p.3).

Both pumps connections are equipped with internal fuse (5A).

1.2- Connection of the system components

Page 3

Page 2

1- ELECTRICAL CONNECTIONS

CWS Basic 121-161-201-251

Page 4

Page 3

1- ELECTRICAL CONNECTIONS

CWS Basic 121-161-201-251

C650 02/02

CWS 251 RY AIR-CONDITIONER ELECTRICAL CONNECTION SCHEMATIC

SCHEMA ELECTRIQUE BRANCHEMENT CLIMATISEUR CWS 121 - 251 RY

SCHEMA ELETTRICO COLLEGAMENTI CONDIZIONATORE CWS 121 - 251 RY

PM

CO = COMPRESSOR - COMPRESSEUR - COMPRESSORE

EB = AIR-CONDITIO NING ELECTRIC BOX - BOITE ELECTRIQUE DU CLIMATISE UR - SCATOLA

EL ET TRICA COND I ZI ONATORE

PM = SEA WATER PUMP - POMPE EAU DE MER - POMPA ACQUA MARE

PC = FRESH WATER PUMP - POMPE EAU DOUCE - POMPA ACQUA DOLCE

THC = COOL THERMOSTAT - THERMOSTAT FROID - TERMOSTATO FREDDO

THH = HEAT THERMOSTAT - THERMOSTAT CHAUD - TERMOSTATO CALDO

230V A.C.

FOR FAN COIL SUPPLY

INSTALL

FUSE = 2A x FAN COIL

PC

CO

THC

THH

EB

FLOW

SWITCH

EXTERNAL

CONTROL

ALARM

DELAY

PUMP

PUMP

FUSE 5 A FOR

PUMP

PROTECTION

Supply

400V

A.C.

S

POWER

1 1 A

7 8 2

N N C

C O

T R N

GND S R N GND

T

POWER

La scatola elettrica contiene un dispositivo di

sicurezza per impedire al compressore di

girare nella direzione sbagliata. Quindi, dopo

av er colleg ato l’a l i mentazione, se il

compressore non dovesse avviarsi invertire

sui morsetti la fase S con la T come mostrat o

sopra.

The electric box has a motor protector inside

to avoid compressor spinning in the wrong

way. If, after supply connection, the

compressor doesn’t work, invert phase S with

ph ase T on t erminal b ase (as shown in the

scheme above

ATTENZIONE-ATTENTION

Electric Box

Cod. M66765R Y

Page 5

Page 4

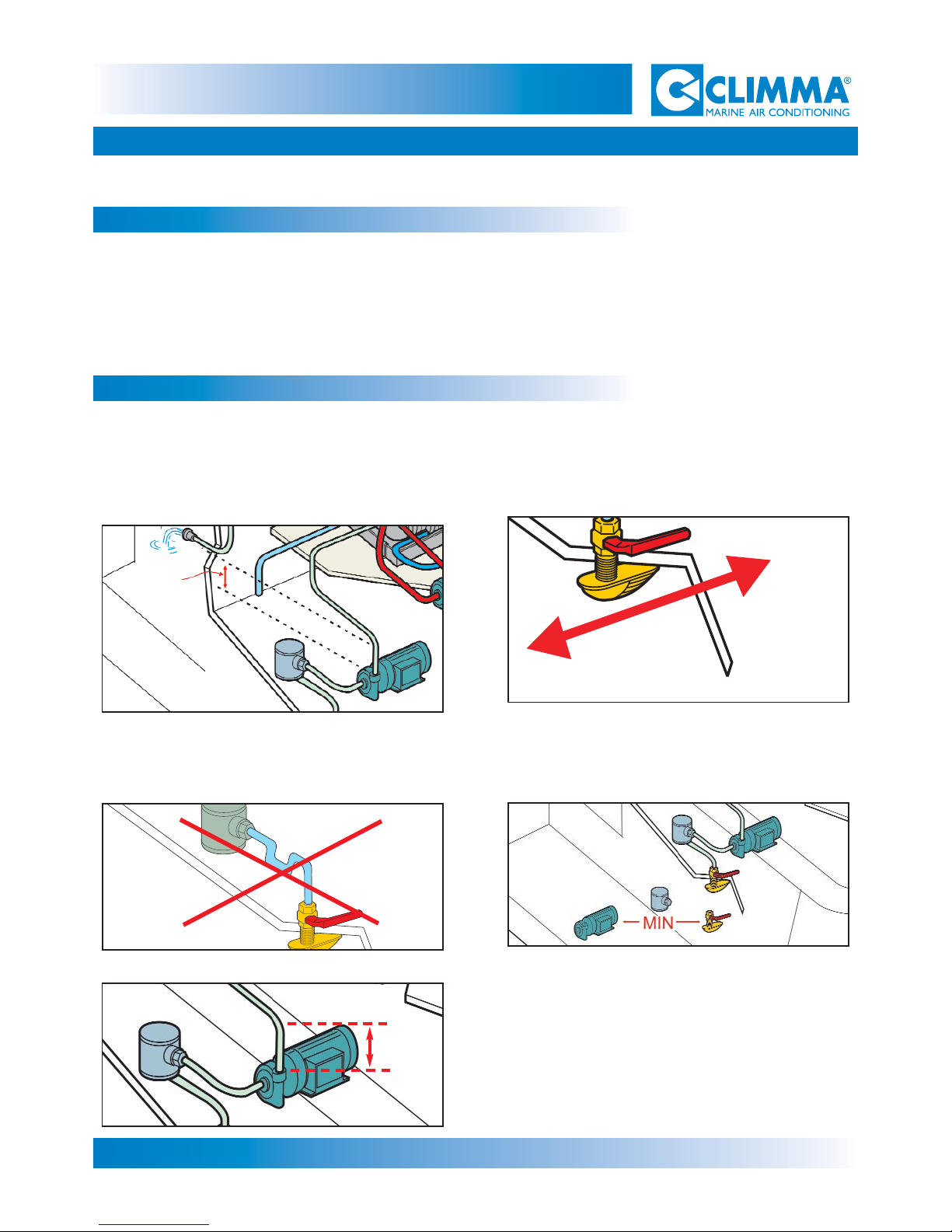

2- SEA WATER CIRCUIT

CWS Basic 121-161-201-251

2.1 - Sea-water pump

The sea-water pump is needed to circulate the given water quantity through

the refrigerant sea-water exchanger. The sea-water pump should also be

quiet, continous duty rated, of marine grade construction material.

2.2 - Location

BOW

STERN

25 cm

A - The pump should be installed with the shaft in

horizontal position and the water outlet at top. The

centrifugal pump must be installed at least 0,50 m

below the water line.

B - The water intake must be "scoop" type, oriented

forward.

C - Seacock, strainer and pump intake should be

connected without siphoning; the piping should

always rise from seacock to the pump.

D - The intake line should be as short as possible (it

is very difficult to run a good circuit with an intake

piping longer than 1 m).

E - The outlet line of the pump should rise at least

for 25 cm (10 in.) just after the pump outlet in order

to keep the pump primed at all times.

0,5 m

Page 6

Page 5

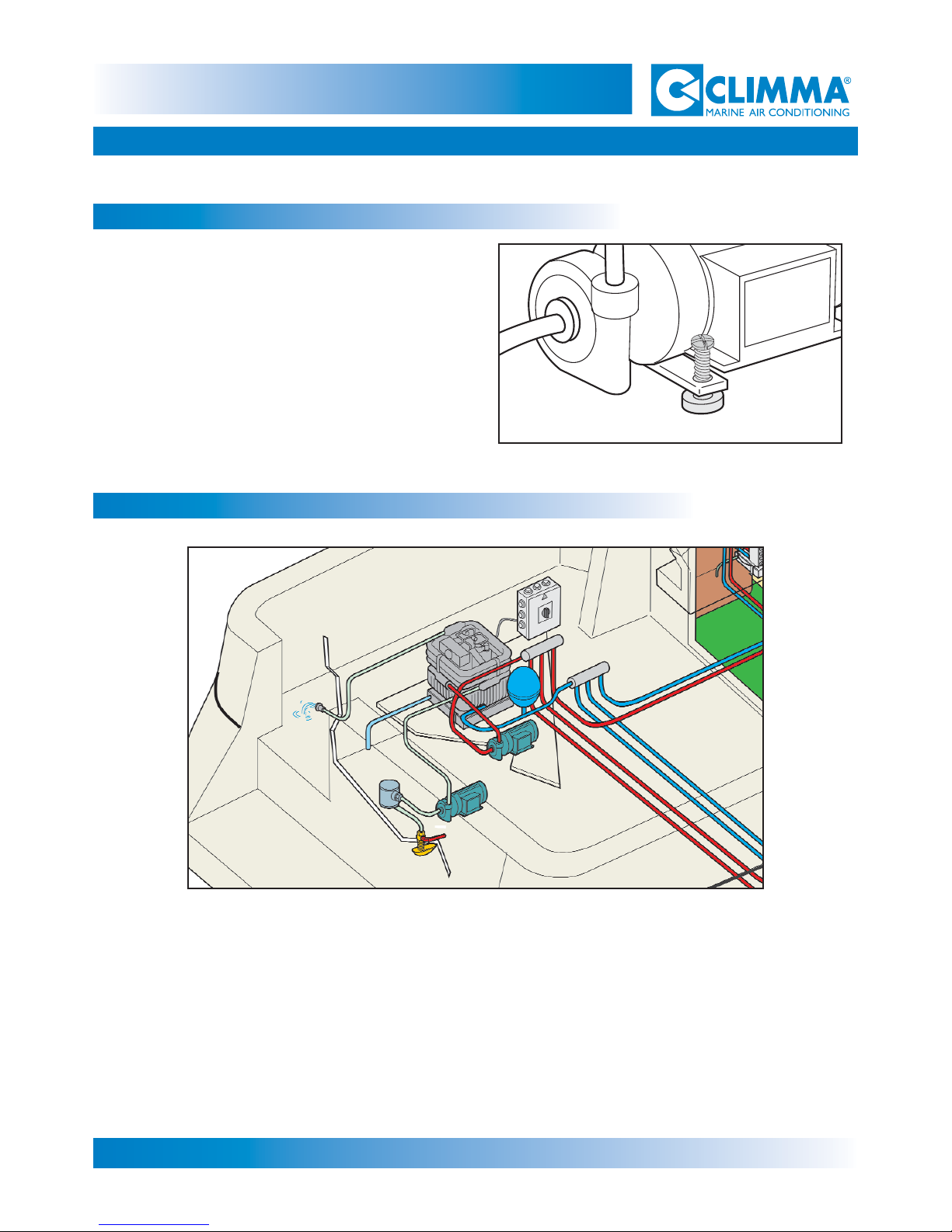

2- SEA WATER CIRCUIT

CWS Basic 121-161-201-251

The pump should be fastened with adequate

screws using the holes in its base or the special

fixing base (available for small models). For larger pumps, the original quiet and smooth running can be improved by using a silent block

mounting.

2.3 - Installation

2.4- Sea-water circuit

Some rules are given at chapter 2.2.

We can resume the following: the circuit should always rise from water intake to the unit

manifold. After that the circuit can rise again or drop to the discharge port. It is absolutely

important to prevent that the circuit rises and drops making siphons, which will prevent air

to be drained, causing an airlock during the navigation. The discharge side of the circuit

should be made so that the water discharge won't cause excessive noise both for this yacht

and its neighbours.

Page 7

Page 6

3- FRESH WATER CIRCUIT

CWS Basic 121-161-201-251

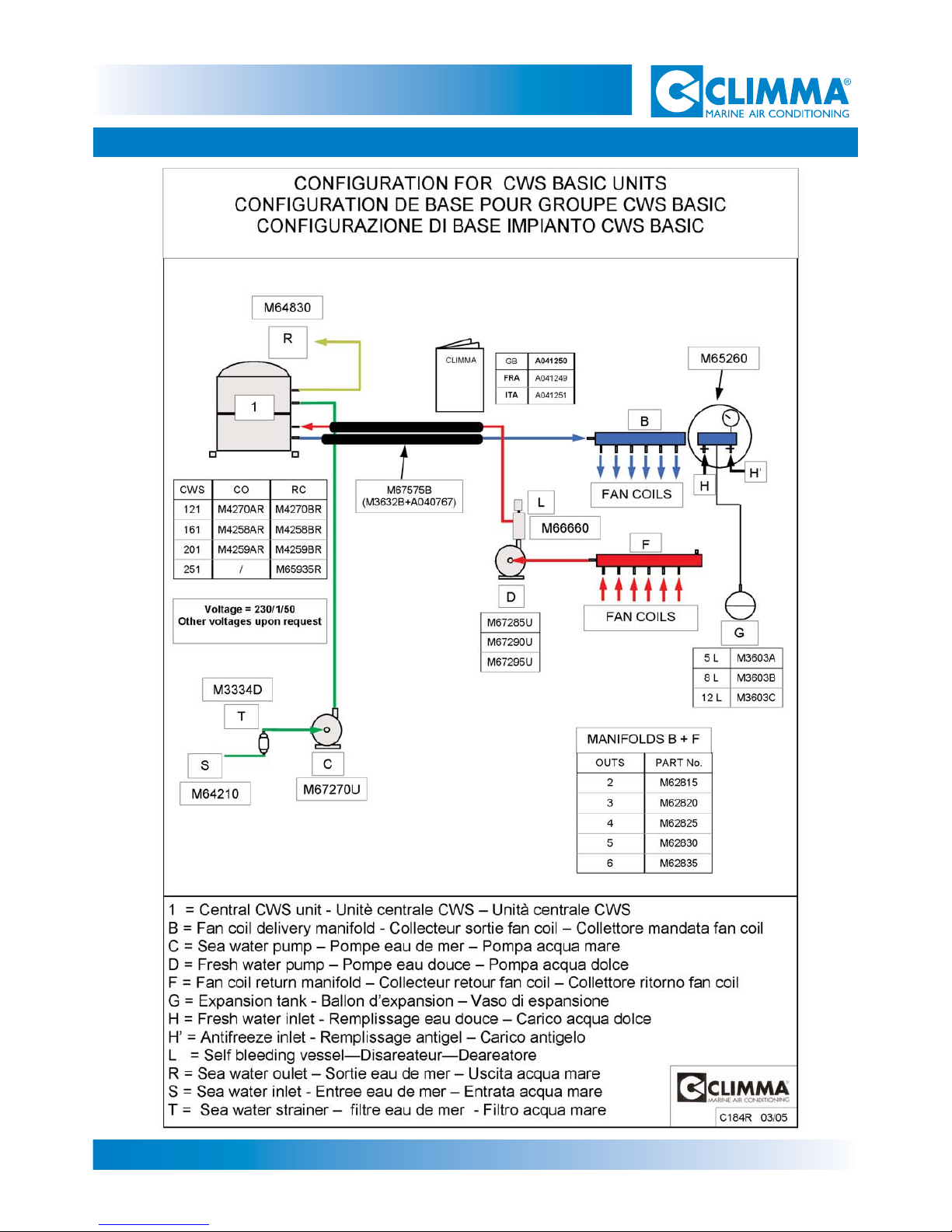

Follow the installation schematic, with particular regard to the sense and position of components.

Keep in mind the accessibility of components for the following steps of installation and also for

maintenance. Respect the flow sense marked on the unit.

Keep accessible the purging valve installed on the fresh water return. Respect the nominal diame-

ters of the manifold.

Manifold: install it in an accessible position, if possible with a certain heel (purging valve higher).

Check that each calibrating valve (if installed) of the manifold is fully open.

Expansion tank: respect the schematic. Connecting port must be upwards to drain out of it.

Fresh water pump: respect the layout schematic.

Fresh water circuit: keep in mind that the easiest and shortest is the best.

Theorethically any "high" point in the circuit must have a purging valve. Siphoning and "up-anddown" must be avoided as anyway they make the air purging difficult and trap air.

Fan coil: respect the flow sense. Each fan coil is equipped with a purging valve that must be accessible both at installation and also for maintenance.

This item must be installed on the fresh water

manifold. It must be accessible for maintenance and calibration.

The flow switch is needed as a safety device

which cuts out the compressor if the fresh

water circulation stops or is not enough.

The flow must be electrically connected to the

electrical box (two wires cables and ground

connection), as specified in the electrical

schematic.

3.1- 1Fresh water circuit connections

3.2- Flow switch (option)

Page 8

Page 7

3- FRESH WATER CIRCUIT

CWS Basic 121-161-201-251

When the circuit is under pressure with the antifreeze solution, purge the air as follows:

Bleed the entire circuit (manifold, fan coils and all the other purging points) starting from the lowest level

and keeping the circuit pressure at 1,5 Bars.

This purging must be done without running the pump.

Repeat all points, until no more air comes out from the bleeding valves, still keeping the pressure at 1,5

Bars.

Set to "Off" position each compressor switch.

Then check the sea-water intake is open and start the unit in "Cool" mode; both pumps will run.

Let the fresh water pump run for 30 seconds, then stops the system and bleed again all points, keeping

the pressure at 1,5 Bars.

Bleeding can be considered over when no more air is coming off the purging points and the fresh water

circulation pump runs even and quiet.

We strongly recommend that a special "air bleeding vessel" be installed in the fresh water circuit, just after

the pump outlet. This device will dramatically reduce the bleeding procedure and will also keep the system

free of air during its life. The "air bleeding vessel" is available in several sizes.

3.3- Pressurizing the fresh

The gauge set installed in the fresh water circuit is equipped with two charging ports, each (H-H1)

with a manual valve and an automatic check valve, which prevents the internal charge to come back

to the pressurized sanitary circuit in case of mistake. Use one of the two valves to charge and pressurize the circuit with fresh water up to 1,5 Bars, checking it with the pressure gauge. This port must

be permanently connected to the yacht sanitary water system.

Check that the circuit keeps the pressure over a certain period of time indicating that it is leak proof.

As you are sure that the circuit is leak proof, reduce the pressure to make room and add antifreeze

to the circuit.

3.4- Antifreeze solution

We suggest two methods for filling the fresh water circuit with antifreeze:

a) Calculate approximately the circuit capacity, fill it with water and add to it 20% of antifreeze, using

the second charging valve by gravity or using a pressure pump. Then connect the circuit to the sanitary water circuit of the vessel, pressurize up to 1,5 Bars and start purging the air. It is obvious that

if purging will be difficult, the percentage of antifreeze will decrease, as more water will be needed to

fill the circuit, therefore more antifreeze must be added to the circuit.

b) Empty the circuit from the water used for the leak test. Prepare the antifreeze solution in the quantity needed to fill the circuit, made with 20% of antifreeze liquid; fill the circuit, using a pressure pump.

Then proceed with purging air and topping up the pressure using the solution.

water circuit

3.5- Air bleeding

Page 9

Page 8

3- FRESH WATER CIRCUIT

CWS Basic 121-161-201-251

Page 10

Page 9

3- FRESH WATER CIRCUIT

CWS Basic 121-161-201-251

Page 11

Page 10

4- COMMISSIONING

4.1- Fresh water circuit

Important notice: The fresh water circulation must be adequate to the fan coil capacity.

Check that this capacity is > or = as to the value specified on the central unit.

The compressor cannot run without fresh water circulation. Reduced or no water circulation will cause freezing situation and might damage the evaporator coil because of ice.

The following safeties prevent the unit to be damaged by the lack of fresh water circulation.

The fresh water circuit must be filled with water and antifreeze solution

(20%). The addition of antifreeze lowers the freezing point of the water and

adds an additional safety to the circuit. Check that the fresh water circuit

pressure gauge shows 1,5 bars.

This device stops the unit if the water flow stops below the preset minimum.

As explained at chapter 3.2, a safety flow switch is installed in the fresh

water circuit outlet manifold. It is very important to make sure that this

safety device is properly wired to the control box: To do this, it is possible

to simulate a lack of fresh water flow just pushing the lever inside the switch

protecting cup. Warning: The flow switch is connected to the main electrical box and this check must be done by expert engineers only, keeping in

mind all the safety precautions.

a) Antifreeze solution:

b) Safety flow switch (option):

Page 12

Page 11

4- COMMISSIONING

CWS Basic 121-161-201-251

Give supply to the main control box.

Turn the "Mode" switch to the "Cool" or "Heat" position.

Check that both pumps have an even flow.

As the compressor runs, the fresh water temperature will begin to

cool down (if the unit is in "Cool" mode) or to heat up (if the unit is in

"Heat" mode). As the fresh water temperature is approaching the set

point ("Cool" mode = +12° C, "Heat" mode = +40° C) the thermostat

will stop the compressor.

The speed at which the water cools down depends from several factors, as the number and capacity of fan coil connected, the fan coil

speed, the room temperature, etc….; therefore this value is not a

valuable parameter.

4.2 Start up

4.3- Sea water circuit

Check that the sea-water intake is fully open

and that the flow is even.

Page 13

Page 12

4- COMMISSIONING

CWS Basic 121-161-201-251

4.4 Fan coil

Check that each fan coil is correctly fed with chilled water, measuring the inlet and outlet temperatures. The difference between the two temperatures should be between 5°

C and 10° C. If the differential is higher, it normally means that there is still air in the

circuit and the circulation in that fan coil is poor.

In case of particularly long circuit, it might be necessary to adjust the fan coil flow closing the calibrating valves of the fan coils nearer to the manifold in order to let more

water to reach the ones, which are more distant.

Check that the thermostat sensor is correctly positioned in the air intake of each fan

coil. If the temperature control is "Fan only", the thermostat stops the fan when the

ambient temperature reaches the set point.

IMPORTANT: With the "Fan only" control, the thermostat sensor must be installed on

the air intake but not on the fan coil.

If the fan coil control is "Water valve" then the thermostat closes the special water

valve connected to the fan coil while the fan keeps running. In this case the thermostat sensor must be installed on the fan coil fastened to the special thermostat bulb

holder.

Page 14

Page 13

5- OPERATION

CWS Basic 121-161-201-251

5.1 Start from the main control box

Turn the "Mode" switch installed on the main control box of the

system CWS Basic on the "Heat" or "Cool".

The system will begin to run and also the compressor.

5.3 Pumps

Pumps start when the main "Mode" switch is turned to the

"Cool" or "Heat" position.

IMPORTANT: Both pumps keep running even when the compressor is

stopped by the thermostat.

5.3 Stop from the main electrical box

Turn the "Mode" switch to the "Off" position.

Page 15

Page 14

5- OPERATION

CWS Basic 121-161-201-251

5.4 Fan coil in summer operation

(standard fan coil control panel)

The temperature in each cabin is controlled by a room thermostat, which controls

the fan motor. The panel (fan coil) "Mode" switch (see fig.1) must be set in "blue

ice star" position. Set the thermostat according to the desired temperature. From

the control panel, it is also possible to check the fan coil speed through the "speed

control" switch, as shown in fig.1.

The fan speed control can run the fan on three different speeds. The minimum

speed is in the centre of the fan control switch.

5.5 Fan coil in winter operation

(standard fan coil control panel)

The temperature in each cabin is controlled by a room thermostat, which controls

the fan motor. The panel (fan coil) "Mode" switch (see fig.1) must be set in "red sun"

position. Set the thermostat according to the desired temperature. From the control

panel, it is also possible to check the fan coil speed through the "speed control"

switch, as shown in fig.1.

The fan speed control can run the fan on three different speeds. The minimum

speed is in the centre of the fan control switch.

fig.1

Page 16

Page 15

6- MAINTENANCE

CWS Basic 121-161-201-251

Every time the unit is operated, check that:

Before turning the unit on, check that the fresh water pressure in the circuit is between 1,5 and 2 Bars (21-28 PSI) as indicated by the gauge on the unit. If the

pressure drops frequently, the circuit must be repaired and the leak(s) fixed as

continous topping up the pressure will dilute the antifreeze reducing the unit safety.

The antifreeze solution of the fan coil circuit must be checked at least every two

years or before if the circuit had leaks that caused a complete refilling. The solution to refill the circuit must be composed by 80% water and 20%. glycol.

Check frequently the efficiency of the sea-water circuit, inspecting the sea-water

strainer and evaluating or even measuring the sea-water flow from the outlet. We

suggest keeping available a spare seal for the sea-water pump and also one for

the fresh water pump.

Clean or even replace the air filters on each fan coil. Adirty air filter is dramatically

reducing the fan coil efficiency as it reduces the air flow.

At the beginning of the summer season, check that the condensate drain from

each fan coil is clean and discharges freely. Consider that in humid and hot days

the condensate can reach a flow of 1 litre per hour of each fan coil.

If the system is not operated for a while, we suggest to remove the back end of

each pump and turn (two or three turns are sufficient) the cooling forced-fit to the

driving shaft of the pumps.

IMPORTANT: Reassemble and fix adequately the protective back end

after the operation.

6.1-

Page 17

Page 16

7- TROUBLESHOOTING

CWS Basic 121-161-201-251

7-1 Central unit

Problems to the CWS central unit may be caused by:

Lack of cooling water circulation (sea water circuit). Check the sea

water circuit outlet. Long running without cooling water may damage

the system.

It's better to check also the sea water circuit without starting up the conditioning system.

Problems of main supply (low voltage). Apermanent low voltage supply

may damage the electrical components of the unit and even the compressor motor. Do not insist to run the system in low volt age conditions.

The fan coil doesn't run: make sure first that the control panel is properly set to yhe desired "Mode" function ("Cool" in summer and "Heat" in winter) and that the thermostat is turned completely to "18" for summer operations and to "24" for winter operations. Then

check the connecting plugs. If the plugs are ok, then test the voltage at the plug terminals

once the "Max" speed is selected. The voltage between the black and the blue wires must

be 230V. If the voltage is correct, then the fan motor is defective and must be replaced.

Give to the service every detail about the fan coil and, if possible, about the motor in order

to get the correct spare. Be aware that the fan coil motor must run with its specified run

capacitor, which is installed in the control box. If there is no voltage, then check the change over switch and the thermostat on the control panel.

7.2 - Fan Coil

Page 18

Page 17

7- TROUBLESHOOTING

CWS Basic 121-161-201-251

7.3 Cool mode : the fresh water

circuit doesn't cool.

Page 19

Page 18

7- TROUBLESHOOTING

CWS Basic 121-161-201-251

7.4 Heat mode : the fresh water

circuit doesn't heat up.

Page 20

Page 19

8- TECHNICAL DATAS

CWS Basic 121-161-201-251

8-1 Fan coil capacitor table

Fan coil capacitor speed table for fan coil units

capacitors codes

Fan coil code

Electrical box for

models

Capacitor

Code

Page 21

Page 22

Page 23

Page 24

Page 24

9- ELECTRICAL SCHEMATICS

CWS Basic 121-161-201-251

Page 25

Page 25

9- ELECTRICAL SCHEMATICS

CWS Basic 121-161-201-251

Page 26

Page 26

9.1- Codes of spare parts

CWS Basic 121-161-201-251

16

CWS 121-161-201-251

Page 27

Page 27

9.1- Codes of spare parts

CWS Basic 121-161-201-251

Description

Capacitor

Evaporator

Thermostat support box

"Hot cycle" thermostat

"Chilly cycle" thermostat

Thermometer

Compressor

Compressor klixon

Stopper ¼ sae

Needle valve Schrader

High pressure switch

Reversal cycle valve

Valve coil

Electrical box

Inox steel tank

Outlet rubber holder

Outlet rubber holder screw

Base fastener clamp (4 parts)

Loading...

Loading...