ClimExel M.P.I.-100M, M.P.I.-190M, M.P.I.-160M, M.P.I.-80M, M.P.I.-240T Installation Instructions Manual

...

23/96

2016/03 - Indice de révision : E - Code : 0033340

SWIMMING POOL

HEAT PUMPS

MPI - 80M .MPI - 100M .MPI - 160M . MPI - 190M / MPI - 190T

MPI - 240M / MPI - 240T . MPI - 320T . MPI - 380T

INSTALLATION INSTRUCTIONS AND RECOMMENDATIONS

(To be read carefully and kept for future reference)

You have just purchased a CLIMEXEL heat pump, thank-you for placing your trust in us. This product is

one of the best available on the market. Before installing and using the product, please read the following

information carefully. It contains important recommendations concerning the various manipulations as well

as some useful advice. Keep this document in a safe place and show it to any other users.

FR

GB

DE

NL

p.1

p.23

p.45

p.69

24/96

2016/03 - Indice de révision : E - Code : 0033340

I. Operating principal and main component ................................... Page 25

II. Recommendations concerning safety and general operation .. Page 27

III. Siting and installation ................................................................. Page 28

IV. Hydraulic connections ................................................................ Page 32

V. Wiring ............................................................................................. Page 33

V.1 – connections on the electrical panel side ....................... Page 34

V.2 – connections on the heat pump side............................... Page 34

V.3 – Slaving filtration ............................................................. Page 35

VI. Start up and operation of the heat pump ....................................... Page 35

VI.1 – The IC 121 CX regulator .............................................. Page 35

VI.2 – Keypad functions ......................................................... Page 35

VI.3 – Display ......................................................................... Page 36

VI.4 – Start up of the machine................................................ Page 37

VI.5 – Shutting down the machine.......................................... Page 37

VI.6 – Viewing and regulating the set point ............................ Page 38

VI.7 – Switching between Eco or Confort mode ...................... Page 38

VI.8 – Controlling the flow rate through the by-pass loop ....... Page 39

VI.9 – Initial heating phase ..................................................... Page 39

VI.10 – Regulation phase ....................................................... Page 39

VI.11 – Thermodynamic defrosting cycles ............................. Page 40

VII. Periodic maintenance ................................................................... Page 40

VIII. Winterizing ................................................................................... Page 41

IX. Troubleshooting .............................................................................. Page 41

X. Alarms ............................................................................................ Page 42

XI. Wiring schematics ......................................................................... Page 42

XII. Guarantees ................................................................................... Page 44

Table of contents

25/96

2016/03 - Indice de révision : E - Code : 0033340

I. Operating principal and main components

This paragraph describes how Climexel heat pumps work. An understanding of the workings of the heat pump will help

you realise the importance of the preparation work that must be carried out before installing, using or maintaining your

heat pump.

A heat transfer fluid (R 410 A) travels in a continuous loop through a copper circuit. As it moves through the circuit it

experiences the following cycle:

1) captures calories from ambient air as it flows over the fin-type “evaporator”. The fan propels

ambient air over aluminium fins covering the copper tubes through which the liquid is flowing; the fluid

is heated by the ambient air which, in turn, is cooled down.

2) the fluid enters the “compressor”, here the fluid pressure is raised significantly thus further increasing its

temperature (all models except the MPI-160 are fitted with a Scroll type compressor)

3) the fluid passes into the “condenser” or plate type heat exchanger where calories are transferred from

the heat transfer fluid to the pool water, the fluid is cooled while the pool water is heated.

4) the fluid returns to its initial temperature and pressure in the expansion chamber and the cycle starts

again

The compressor and expansion chamber delimit two half-loops:

- the half-loop situated on the condenser side is referred to as the HP or High Pressure loop

- the half-loop situated on the expansion chamber side is referred to as the LP or Low Pressure loop

With an ambient air temperature of 15°C, CLIMEXEL heat pumps transfer 4 to 5 times more energy to the pool water

than they consume (90% of this energy is consumed by the compressor): these machines have a yield (or COP Coefficient of Performance) of between 4 and 6.

Heat is transferred to

the pool water from

the heat transfer fluid

within the plate-type

heat exchanger.

Pool water

The fan draws ambient air

in from the outside and

over the evaporator where

it heats up the heat transfer

fluid

The compressor increases

the pressure of the heat

transfer fluid and thus

raising its temperature

further

POWER INVERTER SYSTEM

On the contrary to the fixed speed (50 Hz) compressor equipping conventional On/Off hat pumps, the speed of the

inverter compressor can vary between 11 and 100 Hz.

Thus, when the ambient air temperature is low, or the heating demand is high, the inverter compressor runs at high

speeds (between 50 and 100 Hz). Inversely, when the heating demand is low, notably when the pool water

The expansion chamber

decreases the pressure of

the fluid thus lowering its

temperature

26/96

2016/03 - Indice de révision : E - Code : 0033340

As the ambient air temperature increases, more calories are transferred to the heat transfer fluid at the evaporator, and

then from the heat transfer fluid to the pool water in the condenser. Inversely, as the ambient air temperature falls, less

calories will be available for transfer to the pool water.

To provide a general idea, the following reduction coefficients should be applied to the power values quoted for an

ambient air temperature of 15°C if the machine is operated at lower temperatures.

To ensure correct operation and safety, CLIMEXEL heat pumps are fitted with several safety mechanisms:

- water flow controller, controls the flow of pool water entering into the condenser: shuts down the heat pump if

the water flow drops below a certain rate or stops completely (not enough calories being transferred from the

heat transfer fluid) ;

- LP pressure gauge, on the LP loop: stops the heat pump if the gas pressure is too low and allows the heat

pump to restart automatically when the pressure returns to normal, within the limit of 3 stop/start cycles per hour,

otherwise switches to fault mode (LP alarm)

- HP pressure gauge, on the HP loop: shuts down the heat pump if the gas pressure is too high, the machine

switches to fault mode;

- CLIMEXEL POWER INVERTER heat pumps feature numerous electronic safety mechanisms.

Start up of the compressor and evaporator is controlled by a regulator that allows:

- the user to choose a temperature (the set-point) to which the pool water should be heated;

- automatic start up of the machine if the pool water temperature drops below the set-point (unless filtration is

stopped and is not slaved to the heat pump) ;

- automatic shut down of the machine once the pool water reaches the set-point

- selection of the operating mode; Comfort or Eco

- selection of the configuration; heat or chill the pool water

temperature is around the set point, the Inverter compressor runs at low speed (between 11 and 50 Hz).

Operating at low speeds, the noise level is extremely low, the COP is optimised and the service life of the compressor

is extended.

Note: the actual operating range varies depending on the heat pump model.

The power levels or "STEPs" are managed automatically by the machine, they can be viewed from the thermostat

menu. STEPs range from 0 to 7, the higher the STEP the higher the machine's power level.

The machine features a safety mechanism that allows it to switch to a higher power level if it is taking too long for pool

water to reach the set point.

Note:

In Comfort mode, the machine will run at full power until the set point is reached.

In Eco mode, the machine will regulate its power as a function of the air and water temperatures in order to optimise

power consumption. In Eco mode it will take longer for the pool water to reach the set point than in Comfort mode.

*Values indicated under the following conditions: temperature of the ambient air temperature 15°C and water at 26°C

M.P.I.-80M M.P.I.-100M M.P.I.-160M M.P.I.-190M M.P.I.-190T M.P.I.-240M M.P.I.-240T M.P.I.-320T

M.P.I.-380T

Maximum heating power*

8 kW 10 kW 16 kW 19 kW 19 kW 24 kW 24 kW 32 kW 38 kW

Quantity of gas

2.1 Kg 2.1 Kg 3.2 Kg 4.6 Kg 4.6 Kg 4.6 Kg 4.6 Kg 7.1 Kg 7.7 Kg

M.P.I.-80M M.P.I.-100M M.P.I.-160M M.P.I.-190M M.P.I.-190T M.P.I.-240M M.P.I.-240T M.P.I.-320T

M.P.I.-380T

Low speed

STEP 1:

20 Hz

COP

7.5 7.6 7.26 6.86 6.86 6.42 6.42 5.03 4.48

Sound power

(dB(A))

52 52.8 57.9 55.8 55.8 58.7 58.7 62.9 62.9

Cruising

speed

STEP 4:

50 Hz

COP

6.2 6.3 5.04 5.47 5.47 6.18 6.18 5.3 4.73

Sound power

(dB(A))

55.6 56.5 61.9 57.8 57.8 62.8 62.8 67.3 67.3

High speed

STEP 7:

100 Hz

COP

4.9 5.1 3.75 4.37 4.37 5.34 5.34 4.32 3.87

Sound power

(dB(A))

62 63 69 68.6 68.6 72 72 76 76

outside temperature (°C) 15 12 7 -7 -10 -15

Maximum power

Climexel MPI (%)

100 % 94 % 82 % 58 % 52 % 44 %

27/96

2016/03 - Indice de révision : E - Code : 0033340

Thermodynamic defrosting:

If the ambient air is very humid (rain, fog, etc.) and the air temperature is relatively cool (below 15° C), frost can rapidly

accumulate on the evaporator fins and thus hinder recovery of calories by the heat transfer fluid.

The frost must be melted before this phenomenon becomes too pronounced.

All CLIMEXEL heat pumps are equipped with an automatic thermodynamic cycle inversion defrosting system:

When the temperature sensor located on the fluid circuit at the evaporator inlet detects an abnormal drop in

temperature, the regulator causes a 4-way valve to deviate the circulation of gas in the system as described below:

It should be noted that CLIMEXEL heat pumps will decrease the speed of rotation of the compressor and the fan in

order to decrease the frequency of defrosting phases.

The roles of the evaporator and condenser are reversed: The fluid brings calories to the fin heat exchanger to melt the

ice. The fan remains stopped while the system is defrosting. When the temperature detected by the sensor increases,

defrosting is finished and the 4-way valve switches back to the normal cycle.

II. Recommendations concerning safety and general operation

While the machine is running, some parts of the heat transfer fluid circuit can become very hot, and other

parts very cold. Access to the parts of the heat pump located behind the machine’s casing is reserved to qualified

professionals.

Never insert any object through the slots in the propeller grill.

Handling:

Handle the machine with care, never leave it lying on its side.

Electricity:

All wiring should be carried out by a qualified electrician in accordance with the rules of the art and, notably,

according to the standards in effect in the country of installation.

Echangeur à ailettes air-

R407C

EVAPORATEUR

Echangeur à plaque

eau-R407C

CONDENSEUR

compresseur

Détendeur

compresseur

Détendeur

Cycle normal

Cycle inversé

Echangeur à ailettes air-

R407C

CONDENSEUR

Echangeur à plaque

eau-R407C

EVAPORATEUR

R 410 A

R 410 A

R 410 A

Fin exchanger,

air - R 410 A

EVAPORATOR

Plate heat exchanger,

water - R 410 A

CONDENSER

Plate heat exchanger,

water - R 410 A

CONDENSER

Fin heat exchanger,

air - R 410 A

CONDENSER

Normal cycle Inverted cycle

Expansion

chamber

Expansion

chamber

Compressor

Compressor

28/96

2016/03 - Indice de révision : E - Code : 0033340

Before any intervention requiring removal of the access panel or involving manipulation of the hydraulic

connections, the heat pump must be disconnected from its power source: during installation, finish hydraulic

connections before wiring the machine in, disconnect the electricity before undoing the hydraulic connections.

Physical/ chemical properties of pool water :

Never start up the heat pump in winter if the pool water temperature has been allowed to fall to 5°C or

below (do not use the heat pump as a means to prevent the formation of ice on the surface of the pool).

Pool water treatment products currently available on the market are compatible with the materials used to

manufacture the heat pumps, it being assumed that the pool water's physical and chemical properties comply with

the following recommendations:

pH between 7 and 7.4

total hardness (TH) less than 190ppm

cyanuric acid content (stabiliser) less than 80 ppm

Concentration of free chlorine: 1.0 to 1.5 ppm

Concentration of free bromine: 1.0 to 1.5 ppm

These properties must be checked at the beginning of the season before allowing water to circulate through the

heat pump, and then at regular intervals throughout the season.

Caution:

Shock treatment (super chlorination) of the pool water: should it be necessary to carry out a shock treatment

of the pool water, isolate the hydraulic circuit (isolating valves) on which the heat pump is mounted before

beginning to increase the concentration of disinfectant, and wait until the concentration of disinfectant

returns to normal levels before re-opening these valves.

Minimising heat loss:

During the initial heating phase at the beginning of the season, cover the pool with an isothermal cover to limit heat

loss through water evaporation and thermal transfer between the pool water and the overlying air.

To render this phase as short as possible, the heat pump (and hence the filtration system) should be allowed to run

24 hours a day. After the initial heating phase, the pool should be left covered with an isothermal cover while the

pool is not in use, especially when the ambient temperature is cool (night, etc.).

III. Siting and installation

CLIMEXEL heat pumps must be installed outside at a distance of at least 3.5m from the pool in order to

comply with the standard C 15-100.

We recommend that the heat pump be installed on a support on the ground next to the pool plant room. The

installation site should meet the following criteria:

- easy accessibility around the machine to facilitate maintenance and cleaning;

- the heat pump is not directly exposed to prevailing winds, this is to limit splashing of the machine with water in the

event of precipitation. If necessary, install deflectors to protect the machine against this phenomenon taking care

not to obstruct the circulation of air into or out of the heat pump (minimum distances, see page 31).

29/96

2016/03 - Indice de révision : E - Code : 0033340

* Air flow rate at full fan power.

Each fan is fitted with a single phase 50 Hz 230 V fan.

Care should therefore be taken not to impede or restrict air circulation.

Respect the minimum distances (see the diagrams below) to be left between the various sides of the machine and

surrounding obstacles (walls, partitions, hedges, etc.).

The heat pump should be solidly fastened to a rigid support structure (concrete slab, etc.), the dimensions of which

should be at least equal to the machine's foot print.

CLIMEXEL heat pumps draw ambient air in through the evaporator and expel air out through the fan grill(s).

The nominal air flow rates are as follows:

Models / Dimensions

(in mm)

A B C D E F G H

1 fan

M.P.I. - 80M 455 500 330 222 975 235 205 600

M.P.I. - 100M 455 500 330 222 975 235 205 600

M.P.I. - 160M 330 600 370 240 1145 335 266 943

2 fans

M.P.I. - 190M 330 600 370 240 1245 335 412 1350

M.P.I. - 190T 330 600 370 240 1245 335 412 1350

M.P.I. - 240M 330 600 370 240 1245 420 327 1350

M.P.I. - 240T 330 600 370 240 1245 420 327 1350

M.P.I. - 320T 330 600 370 240 1245 420 327 1335

M.P.I. - 380T 330 600 370 240 1245 420 327 1335

M.P.I.-80M M.P.I.-100M M.P.I.-160M M.P.I.-190M M.P.I.-190T M.P.I.-240M M.P.I.-240T M.P.I.-320T M.P.I.-380T

Number of fans

1 1 1 2 2 2 2 2 2

Ait flow rate m³/h *

2100 2100 3300 6000 6000 8400 8400

30/96

2016/03 - Indice de révision : E - Code : 0033340

Over time, the volume of condensates generated can be considerable if the air is humid. Water should never be

allowed to accumulate around the machine: if the condensates will not be absorbed or evacuated by the terrain,

a drain must be created.

Similarly, precipitation (rain, snow) and piles of dead leaves should not be allowed to accumulate under the

machine to the point where there reach the base of the machine: choose the site carefully and ensure that

the support provides enough elevation off the ground to prevent this risk in most situations.

To prevent water from accumulating on the evaporator and freezing during cold, wet weather, an awning may be

erected over the machine, ensure that there is a gap of at least 50 cm between the top of the machine and the

canopy.

To attenuate any vibrations, “silent-blocks” can be inserted under the feet of the machine before is it fixed in

position. (must be purchased separately).

The support should be very slightly sloped (a slope of 1 to 2% will suffice) towards the corner where the

condensate drainage hole is situated.

The condensate drain union is enclosed with the heat pump. It comprises a set of 6 plugs one of which is

perforated.

Cap the unnecessary holes on the outdoor unit (bottom) and

centralize the drainage when using a drain pipe.

MXZ-8A140VA

MXZ-8A140/160VA

MXZ-8B140/160YA

PUHZ-RP35VHA4

PUHZ-RP50VHA4

PUHZ-RP60VHA4

PUHZ-RP71VHA4

PAC-SG61DS-E

PUHZ-RP100VKA/YKA

PUHZ-RP125VKA/YKA

PUHZ-RP140VKA/YKA

PUHZ-RP200/250YKA

PUHZ-HRP71/100/125VHA2

PUHZ-P100/125/140/200/250

Descriptions

Applicable Models

Cap the unnecessary holes on th e outdoor unit (bottom) and

centralize thedrainage when using a drainpipe.

Photo

MXZ-8A140VA

MXZ-8A140/160VA

MXZ-8B140/160YA

PUHZ-RP35VHA4

PUHZ-RP50VHA4

PUHZ-RP60VHA4

PUHZ-RP71VHA4

Drain Socket

PAC-SG61DS-E

PUHZ-RP100VKA/YKA

PUHZ-RP125VKA/YKA

PUHZ-RP140VKA/YKA

PUHZ-RP200/250YKA

PUHZ-HRP71/100/125VHA2

PUHZ-P100/125/140/200/250

Descriptions

Applicable Models

Dimensions

Unit:mm

EPTrubber

PVC VP-25or vinylh ose(ID: 25mm)

Drain pipe

Material

Component

Drain socketx 1,Drain cap x5

Heat insulatorx 3(1 for liquidpipe, 1 largeand

1 smallinsulator forgas pipe), Bandx 8

No freezingallowed (Neverto be usedin cold

climates)

Operating conditions

MXZ-8A140VA

MXZ-8A140/160VA

MXZ-8B140/160YA

PUHZ-RP35VHA4

PUHZ-RP50VHA4

PUHZ-RP60VHA4

PUHZ-RP71VHA4

PAC-SG61DS-E

PUHZ-RP100VKA/YKA

PUHZ-RP125VKA/YKA

PUHZ-RP140VKA/YKA

PUHZ-RP200/250YKA

PUHZ-HRP71/100/125VHA2

PUHZ-P100/125/140/200/250

EPT rubber

PVC VP-25or vinyl hose (ID:25mm)

Drain socketx 1, Draincap x 5

Heat insulatorx 3 (1for liquid pipe, 1large and

1 smallinsulator for gaspipe), Band x 8

No freezingallowed (Never tobe used in cold

climates)

Perforated plug, ref 1

Non perforated plug, ref 2

The plugs should be

inserted in the holes in

the base of the ma

chine, see the figure

opposite.

Note that the perforated

plug (ref 1) should be

located at the low

est point to allow the

condensates to drain

properly.

31/96

2016/03 - Indice de révision : E - Code : 0033340

M.P.I 160

Minimum clearance 500 mm

Minimum clearance

350 mm

Minimum clearance

1000 mm

Minimum clearance

1500 mm

To ensure correct operation and easy access to the machine, a minimum clearance must be left

between the machine and any surrounding obstacles, see the following diagrams.

M.P.I 190

M.P.I 240

M.P.I 320

M.P.I 380

Minimum clearance 500 mm

Minimum clearance

350 mm

Minimum clearance

1000 mm

Minimum clearance

1500 mm

32/96

2016/03 - Indice de révision : E - Code : 0033340

The pipes, valves and unions constituting the by-pass loop should be made of high pressure (10 bar) PVC, diameter 50, glued. Allow the glue to dry properly before running water through the system.

In order to minimise the build-up of impurities in the filter and to minimise the risks of heat exchanger corrosion,

the by-pass tapping connections must be situated downstream from the filter and upstream of any system

injecting disinfectants or pH regulation chemicals into the pool water. The plant room throughwall flanges

should not be a source of vibration (noise), the PVC tubes should be fixed solidly in the walls or cushioned in a

material that absorbs vibrations.

Leave at least 1.5m of pipe between the by-pass return tapping point and the point at which any chemicals

are injected. Injection of any chemicals must be slaved to filtration. Make sure that the system cannot

accidentally siphon chemicals from the chemical buffer tanks while filtration is not running.

Caution:

Be careful not to allow impurities (stones, earth, etc.) into the pipes. These could form obstructions in the

titanium heat exchanger on start-up. In all cases, purge the circuit between the filter and the heat pump before

connecting the machine and starting filtration.

IV. Hydraulic connections

The heat pump features two screw type unions to allow the entry and exit of the pool water. The water inlet and

outlet lines should be glued to these unions.

These unions should be connected to a filtration by-pass loop, equipped with two isolating valves (one on the

inlet and one on the outlet) to allow isolation of the machine should it need to be removed. A third valve should

be installed on the main line between the by-pass tapping points to allow regulation of the flow rate.

33/96

2016/03 - Indice de révision : E - Code : 0033340

Water inlet

Water outlet

Climexel heat pumps are fitted with

solvent unions, Ø 50mm.

Respect the connection direction

illustrated opposite

V. Wiring

The heat pump must be wired in by a qualified professional and at a distance from the pool in accordance with the rules of the art in

the country of installation (NF C15-100 in France).

1,50 m

2,00 m

VOLUME 2

2,50 m

VOLUME 1

VOLUME 2

1,50 m

2,00 m

1,50 m

1,50 m

VOLUME 0

Volume 0: Safety extra-low voltage* (SELV) < 12 V alternating or 30 V direct + the equipment must be IPX8 rated

(dust-free, waterproof).

Volume 1: Safety extra-low voltage* (SELV) or equipment placed inside an IK07 rated cabinet that when opened cuts

the power supply to the equipment + equipment rated IPX5.

34/96

2016/03 - Indice de révision : E - Code : 0033340

Volume 2: Safety extra-low voltage* (SELV)* or dedicated 30mA differential circuit breaker on the line or separation by

an isolating transformer + equipment rated IPX2.

* transformer must be located outside volumes 0, 1, 2.

The heat pump must be wired in by a qualified professional in accordance with the rules of the art.

The power supply must comply with the following table:

V.1 - Electrical panel side:

The line supplying the heat pump must be configured and fitted with one or more devices for:

- proper earthing of the machine

- protection of people by means of a 30 mA residual current device (interrupter or circuit breaker) dedicated to the

pool electric panel or specific to the heat pump line (unless the house is already equipped with one)

- protection of the machine against “overloads” and short-circuits by means of a thermal magnetic circuit-breaker

To avoid the untimely tripping of the circuit breakers on starting up the machine, use D curve circuit breakers.

V.2 - Heat pump side

The machine is wired in by means of the white connection box beside the information plate.

• Remove the protective casing from the heat exchanger.

• Withdraw the 4 plastic screws from the lid of the connection box to release and remove the lid.

• Feed the power cable into the box, pushing them up through the cable glands located in the bottom.

• Strip the 1 cm of each wire, and connect these to the domino, taking care to respect the live, neutral and earth

phases.

• Tighten the cable gland nuts to immobilise the cable and ensure that the seal around the cable is leak tight.

• Replace the lid and screws, then replace the heat exchanger casing.

Single phase

Black wire = live

Blue wire = neutral

Yellow/green wire = earth

Three phase

Black wire = live 1

Brown wire = live 2

Grey wire = live 3

Blue wire = neutral

Yellow/green wire = earth

M.P.I.-80M M.P.I.-100M M.P.I.-160M M.P.I.-190M M.P.I.-190T M.P.I.-240M M.P.I.-240T M.P.I.-320T

M.P.I.-380T

Voltage

230 V 1ph 230 V 1ph 230 V 1ph 230 V 1ph 400 V 3ph 230 V 1ph 400 V 3ph 400 V 3ph 400 V 3ph

Power cable cross section

3 x 2.5 mm² 3 x 2.5 mm² 3 x 4 mm² 3 x 6 mm² 5 x 2.5 mm² 3 x 6 mm² 5 x 2.5 mm² 5 x 4 mm² 5 x 4 mm²

max electric current requirement

13 A 13 A 19 A 28 A 13 A 29.5 A 13 A 19 A 21 A

Electrical protection

16 A 16 A 25 A 32 A 16 A 40 A 16 A 32 A 32 A

35/96

2016/03 - Indice de révision : E - Code : 0033340

VI. Start up and operation of the heat pump

Once the previous steps have been carried out correctly and filtration is running, the heat pump may be switch on.

VI-1 The IC 121 CX regulator

The purpose of the regulator is to maintain the pool water temperature.

It's functions are as follows:

• Start/ stop the machine

• Maintain the pool water temperature as a function of the temperature difference (or T delta) between the

machine's inlet and outlet and the ambient temperature.

• Display the water temperature at the inlet and outlet, and the ambient temperature

• Display alarms/ indicate a defrosting cycle

V.3 - Slaving the heat pump to filtration:

Heat pump operation may be slaved to filtration, this will require installation of the "filtration slaving kit".

VI-2 Keypad functions

Key Function

Press and release:

Displays the chill set point (code SetC) or the heat set point (code SetH).

Press and hold down for 3 seconds:

Displays the chill or heat set point

Press and release in programming mode:

Allows access to parameter modification

Allows validation of new settings

Press and release:

Displays the sensor readings

Press and release in programming mode:

Scrolls through all parameters.

During modification, changes the value of a parameter.

36/96

2016/03 - Indice de révision : E - Code : 0033340

Key Function

Press and release:

Displays the sensor readings

Press and release in programming mode:

Scrolls through all parameters.

During modification, changes the value of a parameter.

Press and release:

Starts/ stops the machine in chill mode

Press and release:

Starts/ stops the machine in heat mode

Press and release:

Enters/exits the function menu, allows access to the following parameters:

- Eco / Confort mode

- Display and reset active alarms

- Parameter "Pout", displays the power level "Step"

- Activates / Deactivates the filtration slaving function "Ser" (option)

- Parameter "UPL" factory setting

- Parameter "ALOG" factory setting

Press and release in programming mode:

Returns to the previous programming mode level

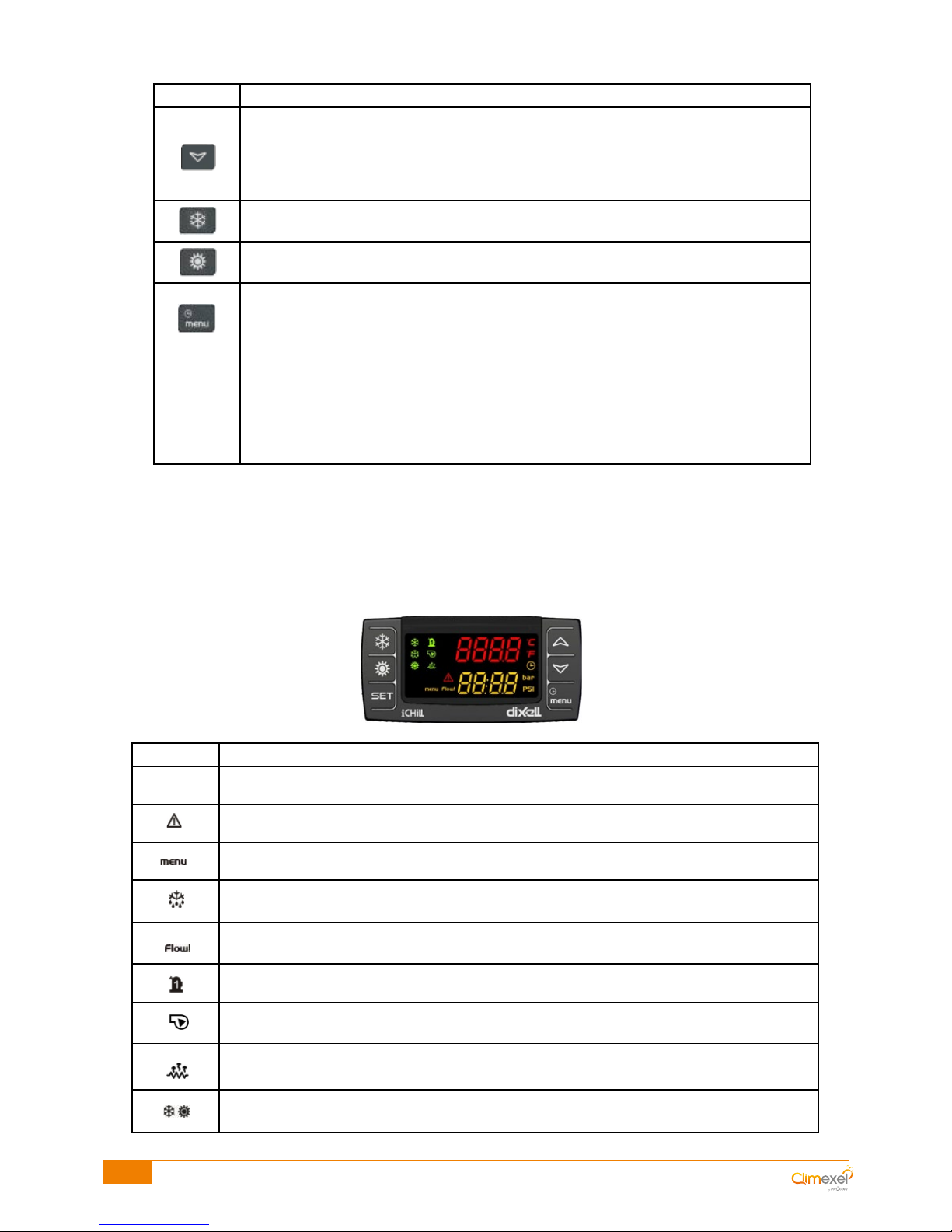

VI-3 Display

Icon Definition

°C - °F

Appears when the temperature is displayed

Appears when an alarm is detected

Appears when the Menu key is pressed

Appears when defrosting is active

Appears when the water flow rate through the exchangeur is too low or absent

Appears when the compressor is running

Appears when filtration is slaved to the heat pump (optional)

Appears when defrost is activated while the temperature is less than 5°C (optional)

Appears when the machine is in heat or chill mode

Loading...

Loading...