Page 1

V1.0-APatent # US 8,424,638

OPERATION AND INSTRUCTION MANUAL

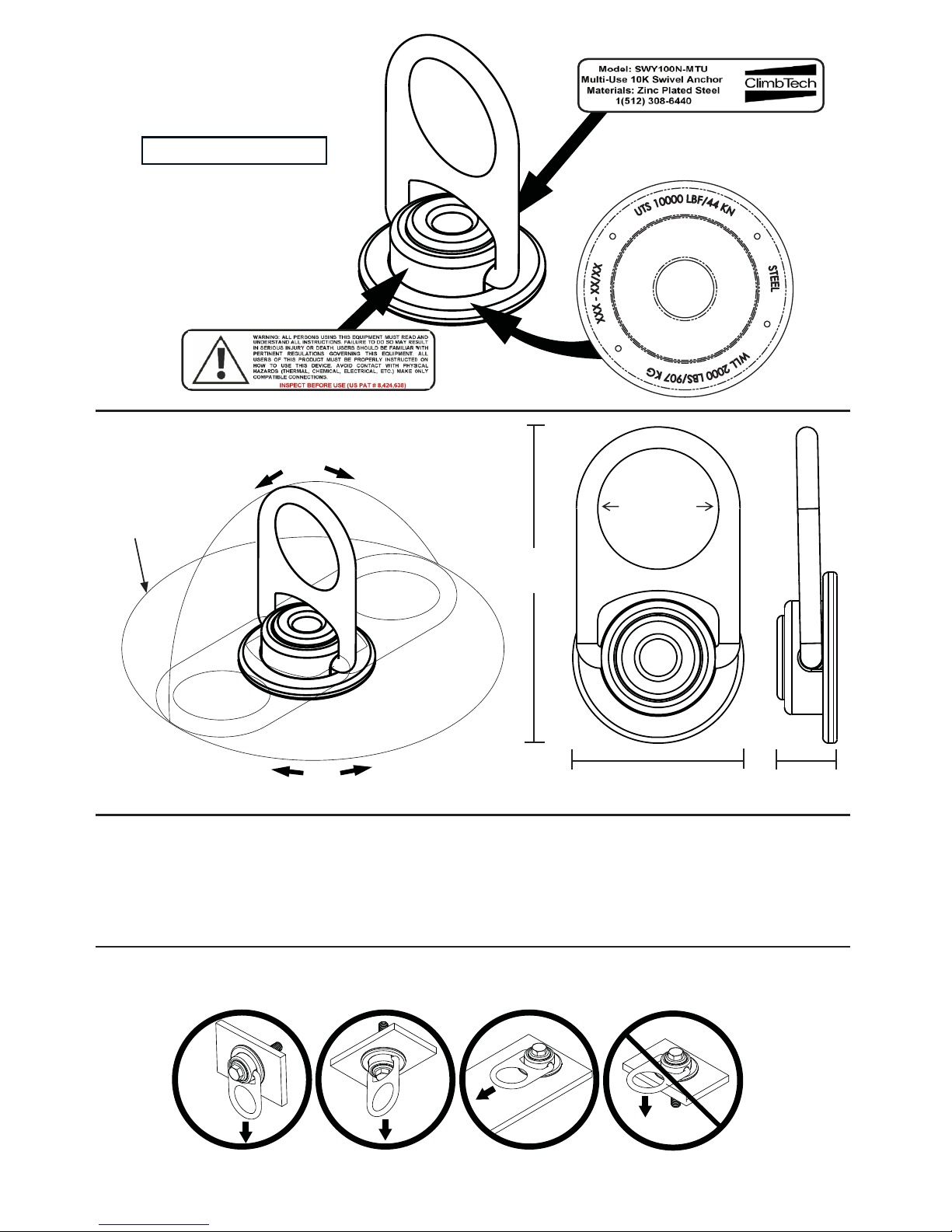

Swivel Anchor Model: SWY100N-MTU

NOT FOR FALL PROTECTION

WARNING:

ALL PERSONS USING THIS EQUIPMENT MUST

READ AND UNDERSTAND ALL INSTRUCTIONS. FAILURE TO DO

SO MAY RESULT IN SERIOUS INJURY OR DEATH. USERS SHOULD

BE FA MILIAR WITH PERTINENT REGULATIONS GOVERNING THIS

EQUIPMENT. ALL INDIVIDUALS WHO USE THIS PRODUCT MUST

BE PROPERLY INSTRUCTED ON HOW TO USE THE DEVICE. AVOID

CONTACT WITH PHYSICAL HAZARDS (THERMAL, CHEMICAL,

ELECTRICAL, ETC.). MAKE ONLY COMPATIBLE CONNECTIONS.

Page 2

User Instructions must always be available to the user and are not to be removed except by the user

of this equipment. For proper use, see supervisor, User Instructions, or contact the manufacturer.

Users and purchasers of this equipment must read and understand the User Instructions provided

for correct use and care of this product. All users of this equipment must understand the

instructions, operation, limitations and consequences of improper use of this equipment and be

properly trained prior to use.

Misuse or failure to follow warnings and instructions may result in serious personal injury or death.

PURPOSE

The SWY100N-MTU is an anchorage connector designed to function as a lift point or other nonlife

dependant applications.

Any references to “anchorage connector” in this manual include, and apply to, the SWY100N-MTU.

USE REQUIREMENTS

1. Use of this product must be approved by an Engineer or other qualied person to

be compatible with any and all structural & operational characteristics of the selected

installation location and system to be connected

to this anchor.

*Improper use may result in serious personal injury or death.

2. The anchorage connector must be inspected prior to each use for wear, damage,

and other deterioration. If defective components are found the anchorage connector

must be immediately removed from service

USE LIMITATIONS

1. The anchorage connector is designed to be used in temperatures ranging from

-40ºF to +130ºF (-40°C to +54°C).

2. Do not expose the anchorage connector to chemicals or harsh solutions which may

have a harmful eect.

3. Do not alter or modify this product in anyway.

4. Do not use/install equipment without proper training by a “competent person”

5. Do not remove the labeling from this product.

6. Additional requirements and limitations may apply depending on anchorage type and

fastening option utilized for installation. All placements must be approved by an

engineer or other qualied person.

*Improper use may result in serious personal injury or death.

LIFTING REQUIREMENTS

This product has a safe working load of 2,000-lbs. It is the end user’s responcibility to know the

weight of the object being lifted or supported. The end user must also know how to stablize the

object with the correct location(s) of anchor points as well as use mutliple anchors with an object

when necessary.

• 2,000-lbs safe working load.

• 10,000-lbf maximum breaking strength.

• Do not use in uncured concrete.

• Always inspect anchorage connector prior to use.

• Always dispose of the anchorage connector if damaged.

• Use multiple anchorage connectors to stablize an object when needed.

• Never stand underneath an object that is being lifted.

Read This Instruction Manual Carefully Before Using This Equipment.

Page 3

LOAD

LOAD

LOAD

LOAD

LABEL LOCATIONS

8”ø

(203.2mm)

180°

360°

5.5”

(139.7mm)

2.25”ø

(57.15mm)

3”

(76.2mm)

1”

(25.4mm)

Tensile Strength (UTS): 10,000-lbf (44kN)

Working Load: 2,000-lbs (907kg)

Weight: 1.2-lbs (544.3g)

Materials: Zinc Plated Steel

LOADING CONDITIONS DIAGRAM

ACCEPTABLE ACCEPTABLE IMPROPER

ACCEPTABLE

Page 4

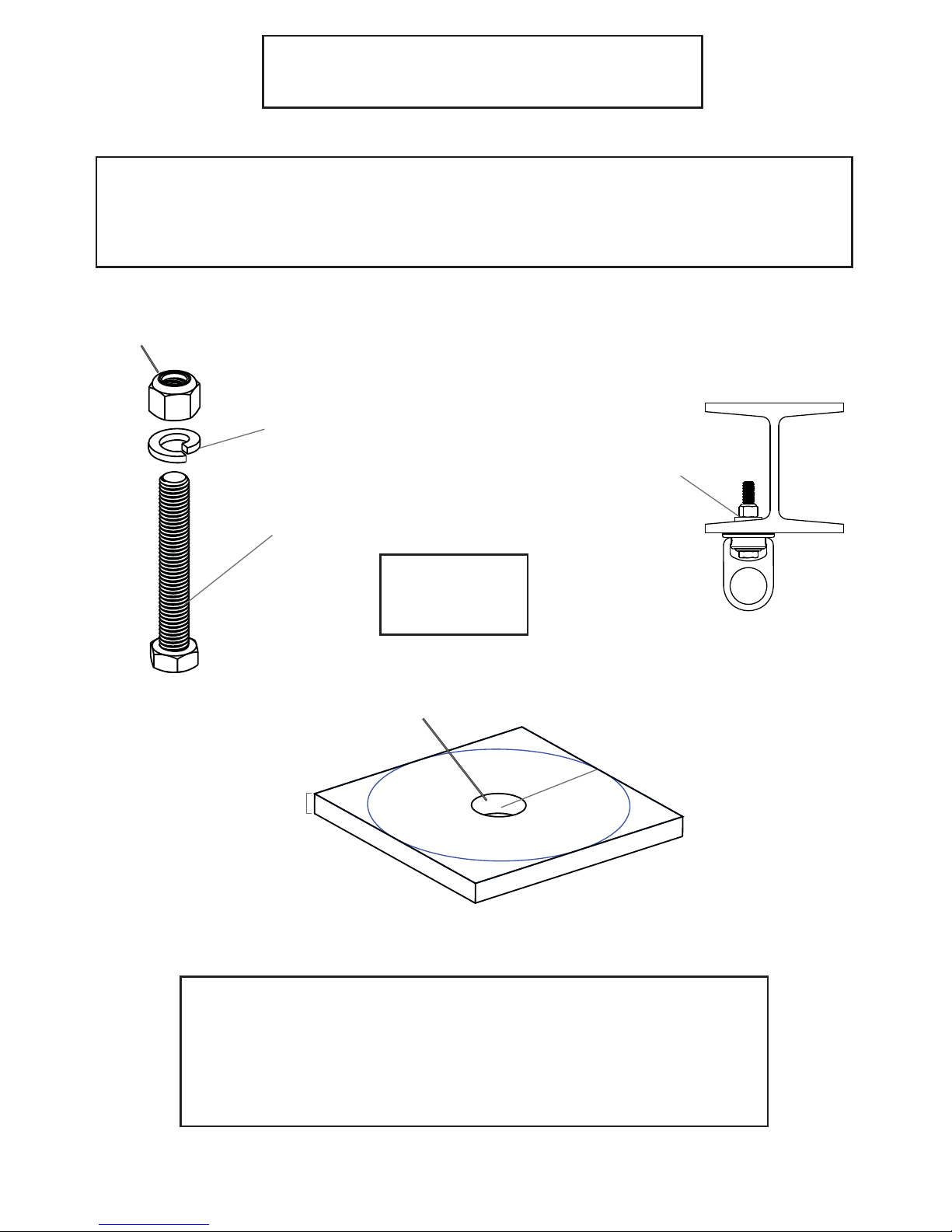

STEEL MOUNTING

Torque Range:

75 to 90 ft-lbs

(100-120Nm)

* Use tapered washer with I-beams

that have tapered anges.

.75”

(6mm)

min

drill 5/8” (16mm)Ø

3”(76mm)

min from any edge

Lock Nut

5/8” Lock

Washer

5/8”-11x4”

Hex Bolt *

5/8”-11

* For steel applications a grade 5, grade 8 (or equivalent) bolt no

shorter than 4” (100mm) with a locking nut and washer must be

used. Swivel anchor must be ush with steel surface. A 16mm

bolt of equal strength may be used in place of a 5/8”-11

for metric applications.

1. Use a proper drill and bit for steel.

2. Drill a 5/8” (16mm) hole no less than .75” (6mm) deep 3” (76mm) away from any edge.

3. Hole must be straight and perpendicular to surface.

4. Hole must be free of debris.

Page 5

CONCRETE MOUNTING

1. Use a proper drill and bit for concrete (SDS drill bit).

2. Drill a .75” (19mm) hole no less than 5” (114mm) deep 9” (229mm) away from any edge.

3. Hole must be straight & perpendicular to surface.

4. Hole must be free of debris

5. Concrete strength must be at least 3000psi (20.7MPa) and no less than 7” (178mm)

thick.

9”

(

22

9m

m

)

drill

3/4” (19mm)

Ø

m

i

n

f

ro

m

a

ny

e

d

g

e

7”

(178mm)

min

Embedment Depth

4.5” min (114mm)

Torque:

110 ft-lbs (149Nm)

Page 6

BACK PLATE MOUNTING

WELD ON MOUNTING

* Welding procedure must be approved by an engineer or other

qualied person to be compatible with any and all structural &

operational characteristics of the selected installation location.

Torque Range:

to be determined

by an engineer or

qualied person.

Back Plate to be used with 5/8” (16mm)

bolts or all thread. Drill hole perpendicular

into surface so bolt can pass freely through

the substrate. Nut must be fully threaded

on the bolt to insure maximum strength

ratings and integrity of anchor.

* Bolt or All-thread and nut not included with Back Plate.

Torque Range:

75 to 90 ft-lbs

(100-120Nm)

Grade - 5 or 8 bolt

5/8”-11 x 1-3/4”

Weld Puck

(AISI 1018)

3/8” min

(9.5mm)

* Weld

Internal Tooth Lock Washer

Page 7

STRAIGHT LOOP INSERT

See Straight Loop Insert Manual for anchorage casting instructions.

Internal Tooth

Lock Washer

WARNING: Do not install if insert was knocked over during installation.

Mega Swivel must mount ush to surface when fastened with the

proper torque.

Torque Range:

70 to 80 ft-lbs

Orange

Housing

Plastic Bolt to

be removed

5/8”-11x3.25”

Hex Cap Bolt *

Note: Ensure internal threads are

thoroughly coated with NLGI2

multi-purpose lithium grease

(meeting Sinopec specification

Q/SH303 242-2007 or equivalent).

1. Strip decking to expose the Straight Loop Insert.

2. Ensure that anchorage was properly installed. Orange indicator should be ush with

concrete surface, and at least 9” from any edge or corner. Concrete should be at least

6” thick and cured to a minimum of 3000 psi.

3. Remove plastic bolt and o-ring using 1/2” allen wrench.

4. Save plastic bolt and o-ring to re-insert into Straight Loop Insert when not in use.

5. Insert bolt and washer through Mega Swivel and into the threaded

hole of the Straight Loop Insert.

6. To fasten Mega Swivel, tighten bolt* to 70-80 ft-lbs using torque wrench.

Page 8

+

CONCRETE METALACCESSORIES

KIT CONTENTS

PART NUMBER

+

SWY1SBA-400-CTS

(Steel Mounting Hardware Kit)

SWY100S-MTU-CTS

(Swivel with Steel Mounting kit)

SWY1CSA-55P-CTS

(Concrete Hardware Kit)

SWY100C-MTU-CTS

(Swivel with Concrete Mounting Kit)

SWP100N-KIT-CTS

(Weld-on Mounting Kit)

SWX100N-QPQ-CTS

(Backing Plate Only)

+

SWY100P-MTU-CTS

(Swivel with Straight Loop Insert

Mounting kit)

SWY1PBA-325-CTS

(Straight Loop Insert Mounting Kit)

+

SL4625C-ZNO-CTS

(Straight Loop Insert)

Page 9

Part Number Comments Inspector Name

Date

MODEL NUMBER:

DATE OF MANUFACTURE:

Inspection:

Ocial periodic inspection must be made at least semiannually. The inspection must be performed by a

qualied person other than the intended user. If severe weather or conditions exist then inspections must be

carried out more frequently. All inspection results must be logged in the space provided above.

1. Inspect swivel to make sure it is ush with mounting surface.

2. Make sure all labeling is axed to the unit.

3. Make sure the unit can rotate 360° and D-ring can ip from side to side.

4. When reusing a previously drilled hole, inspect for for debris or wallowing.

5. Record inspection results in the space provide above.

*If any damage that could aect the strength or operation of the device, or unsafe conditions are found, proper disposal is required. The anchorage connector must be rendered

unusable and then properly discarded.

MAINTENANCE, CLEANING AND STORAGE

Cleaning periodically will prolong the life and proper functioning of the product. The frequency

of cleaning should be determined by inspection and by severity of the environment. Clean with

compressed air and/or a sti brush using plain water or a mild soap and water solution. Do not use

any corrosive chemicals that could damage the product. Wipe all surfaces with a clean, dry cloth

and hang to dry, or use compressed air. When not in use, store anchorage connectors in a cool, dry,

clean environment, out of direct sunlight and free of corrosive or other degrading elements.

INSPECTION AND MAINTENANCE LOG

Page 10

NOTES

Page 11

NOTES

Page 12

ClimbTech, LLC.

7303 Burleson Rd. Suite 901 Austin, TX 78744

1(512) 308-6440 / www.climbtech.com

Product Warranty, Limited Remedy and Limitation of Liability

WARRANTY: THE FOLLOWING IS MADE IN LIEU OF ALL WARRANTIES OR CONDITIONS, EXPRESS OR

IMPLIED, INCLUDING THE IMPLIED WARRANTIES OR CONDITIONS OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. Equipment oered by ClimbTech is warranted against factory defects in

workmanship and materials for a period of one year from date of purchase or rst use by the original owner.

LIMITED REMEDY: Upon notice in writing, ClimbTech will repair or replace all defective items at ClimbTech’s

sole discretion. ClimbTech reserves the right to require that the defective item be returned to its plant for

inspection before determining the appropriate course action. Warranty does not cover equipment damage

resulting from wear, abuse, damage in transit, failure to maintain the product or other damage beyond the

control of ClimbTech. ClimbTech shall be the sole judge of product condition and warranty options. This

warranty applies only to original purchaser and is the only warranty applicable to this product. Please contact

ClimbTech technical service department for assistance.

LIMITATION OF LIABILITY: IN NO EVENT WILL CLIMBTECH BE LIABLE FOR ANY INDIRECT, INCIDENTAL,

SPECIAL OR CONSEQUENTIAL DAMAGES INCLUDING, BUT NOT LIMITED TO LOSS OF PROFITS, IN ANY

WAY RELATED TO THE PRODUCTS REGARDLESS OF THE LEGAL THEORY ASSERTED.

For more information:

Loading...

Loading...