Page 1

Part 5442225 issue E

General Information &

Installation Instructions

Read general information instructions first followed by

the relevant installation instructions.

3 & 4 STAR DUCTED GAS CENTRAL HEATER

ABN 13 001 418 042

26 Nylex Avenue, Salisbury, South Australia 5108 AUSTRALIA

Telephone No.: 61 8 8307 5100 Fax No.: 61 8 8283 0401

Page 2

2

Part 5442225 issue E

I

General Information

Name of appliance: Bonaire & Pyrox 3 & 4 Star Gas Central Heater

Models: MB314iNG, MB320iNG, MB330i NG, MB330i NG X/A, MB314e

NG, MB320e NG, MB330e NG,

MB414i NG, MB420i NG, MB420i NG X/A, MB430i NG, MB430i

NG X/A, MB414e NG, MB420e NG, MB430e NG, MB430e NG X/A.

Gas Consumption: 14i unit – 60MJ/h

20i unit – 80MJ/h

30i unit – 120MJ/h

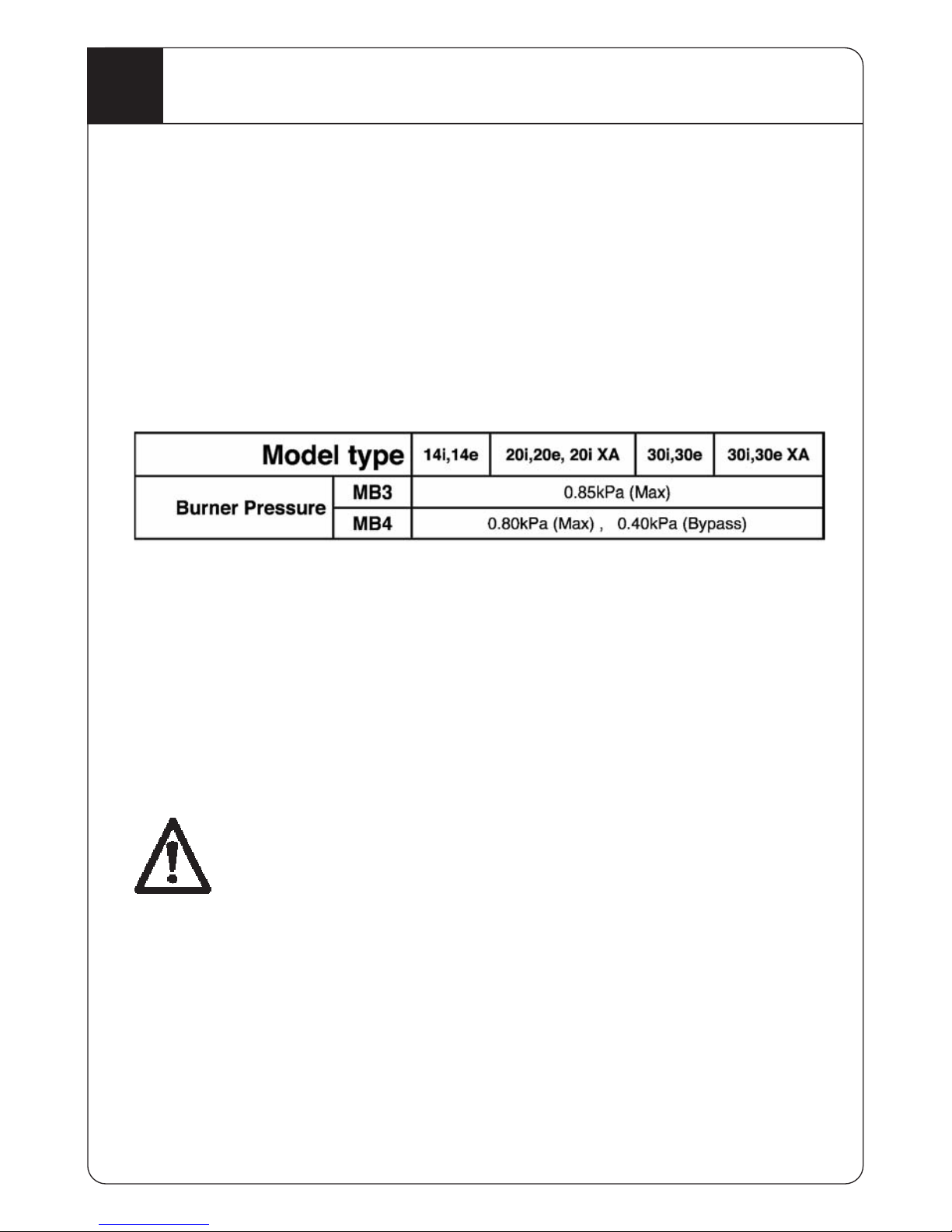

Burner Pressures:

Gas Connection: Connection on gas valve is via ¾” BSP (female) flare nut

onto which the inlet pipe and ¾” manual shut-off valve

(Refer to AS/NZS 5601) Use only gas copper pipe which

complies with AS 1432 Type B.

When connecting the gas supply inlet pipe to the gas valve, hold the

connection nipple on the valve with a spanner while tightening the inlet pipe

compression nut. This ensures the nipple is not over tightened. Cracked

gas valves or regulator castings due to over tightening during

installation or service are not the manufacturerʼs responsibility.

Statutory Requirement: This product must be installed only by

an authorised person and in accordance with the current editions

AS/NZS 5601 & AS/NZS 3000.

DO NOT OPERATE THIS APPLIANCE BEFORE READING THIS

GENERAL INFORMATION & INSTALLATION BOOKLET.

Checking Supply & Burner Pressures:

Refer to data plate on the product for burner pressures.

NOTE: All wiring coming out of the unit (mains power lead, thermostat

wiring etc…) must be fully extended and securely anchored using the cable

tie provided.

Page 3

3

Part 5442225 issue E

General Information (cont)

I

Items to be supplied by the Installer:

- Suitable base material for heater.

- Platform/Walkway for roof installation (heat resistant material not required).

- Electric lighting above the central heater and switch to be placed next to

the access opening.

- AGA approved manual shut-off valve (3/4” Natural Gas Heater).

- AGA approved metal flue pipe and required elbows where a flue pipe with

bends is present. AGA approved flue cowl for the flue pipe.

- At the completion of the installation compliance certificates must be

completed for gas & electrical work.

Locations:

1) Do not install the heater in a location where combustible vapours from

flammable or combustible liquids may be present as these can be drawn

into the heater and ignited.

2) Do not install the heater in any location where noise from its operation

may disturb occupants or neighbours. Before installing this product

consider placement of this unit away from areas of the home where

occupants will sleep or relax, such as bedrooms, lounge and dining

rooms. Check local council regulations to ensure compliance.

3) Do not install the heater downstream of an evaporative air conditioner, air

washer or refrigeration coil.

DESCRIPTION OF OPERATION OF ELECTRONIC CONTROL MODULE.

The design of the control module conforms to the Australia Gas Association

AS4622 and AS4625 Standards and is classified as a Class 2Ca device. It

receives instructions via a wired or RF Controller/thermostat.

Electrical rating:

240V, 50 Hz, 10 VA input.

Start up sequence for Central Heater:

1) Turn gas supply on.

2) Turn on power supply to unit.

3) A 2-second self-diagnosis is performed and the fans will run for a few

seconds. If a successful diagnosis is completed the unit will then go to

stand-by mode.

NOTE: Where Navigator RF thermostat is used this must be configured (paired)

with the transceiver before the unit can be operated refer to section 7.

4) To start unit set the thermostat temperature above the room temperature.

5) Combustion air fan will commence operation.

Page 4

4

Part 5442225 issue E

General Information (cont)

I

6) When combustion fan reaches required pressure level, the pressure

switch closes.

7) A further 20 seconds elapses as purge time.

8) Igniter function commences.

9) Gas valve is energised allowing 4 seconds for the gas to ignite.

10) If flame is detected by a sensor. The gas valve remains energised.

11) Room air fan will commence 20 seconds after the gas valve is

energised.

12) At the end of the heating cycle, the room air fan will have a run down

period of 80-180 seconds.

13) Should the flame not ignite after the 6th attempt, the unit will go to

lockout. Reset unit to restart.

14) To reset the unit, switch the mains power OFF then wait 2 seconds

before switching the power back ON or with the navigator control a

error code is displayed when a lockout has occurred. When the word

“enter” appears in the display press the enter key to reset the unit.

CHECKING THE SYSTEM PERFORMANCE

Having set the gas pressure check the discharge temperature of the air in

the discharge duct to confirm the correct operation of the central heater.

For best performance, the discharge temperature should be 50C – 60C

when measured 300mm from the appliance inside the discharge air duct.

Checking the correct operation of the heater:

1) Using the thermostat, switch the heater OFF. Wait for the room air fan

to cease operation (approximately 80 -180 seconds), then switch ON

again to recheck the starting sequence.

2) Using the thermostat, switch the heater OFF unless the customer

requires that it be left running.

3) Before leaving, make sure that the customer understands how to

operate the heating system.

4 Star (MB4XXX) product will not operate unless the

thermistor has been connected and the sensor installed

correctly in the air discharge duct.

Page 5

5

Part 5442225 issue E

General Information (cont)

I

Special Conditions:

Blocked fresh air inlet or flue outlet:

The unit will go to lockout. ʻWhen the restriction is removed the unit can then

be reset.

NOTE: If the fresh air inlet, the flue outlet is blocked or combustion fan is not

operating correctly the red LED on the controller may not light-up. If this

occurs, the unit will not commence the ignition sequence and will then lockout.

The green LED will then flash the appropriate fault code.

Electric power loss:

3 star units – The unit will restart automatically if the manual

controller/thermostat is ON, once power is resumed.

4 star units – if a manual controller/thermostat is left switched ON, the unit

will automatically lock-out when power is resumed. The reset procedure must

then be followed to restart the unit. Once power is resumed.

Gas interruption:

A gas interruption will cause the unit to lockout. The Controller/thermostat

must be reset after gas supply is re-established.

Controller diagnostic LED flash codes:

The controller will flash a coded message if an operation fault occurs.

For 3 star product refer to the table listed on the appliance data plate for

further details. For 4 star product refer to page 11-13 of this book or the

service manual.

Normal Operation:

3 star units – Green LED will flash a single short flash (approximately 0.2

seconds/pulse) when in the idle state and flash one short pulse when calling

for heat. Red LED will light-up when combustion fan is operating correctly.

4 star units – Green LED will flash four short pulses (approximately 0.2

seconds/pulse) when in the idle state and flash one short pulse when calling

for heat. Red LED will light-up when combustion fan is operating correctly.

Trouble Shooting:

• Check there is power and gas supplied to the heater.

• Check thermostat set temperature is above room temperature.

• Confirm thermistor is connected correctly installed in the air discharge

duct. (4 star models only)

• Check that the power LED is lit on the controller. If it isnʼt check power is

available at the GPO, check the circuit breaker and check the fuses on

electrical panel within the unit.

• If the heater will still not operate, the safety shut down device within the

heater may have locked the control. Reset the control.

• If the heater still fails to operate correctly, contact service.

• For Service Australia Wide see the contact details on the rear cover.

Page 6

6

Part 5442225 issue E

1

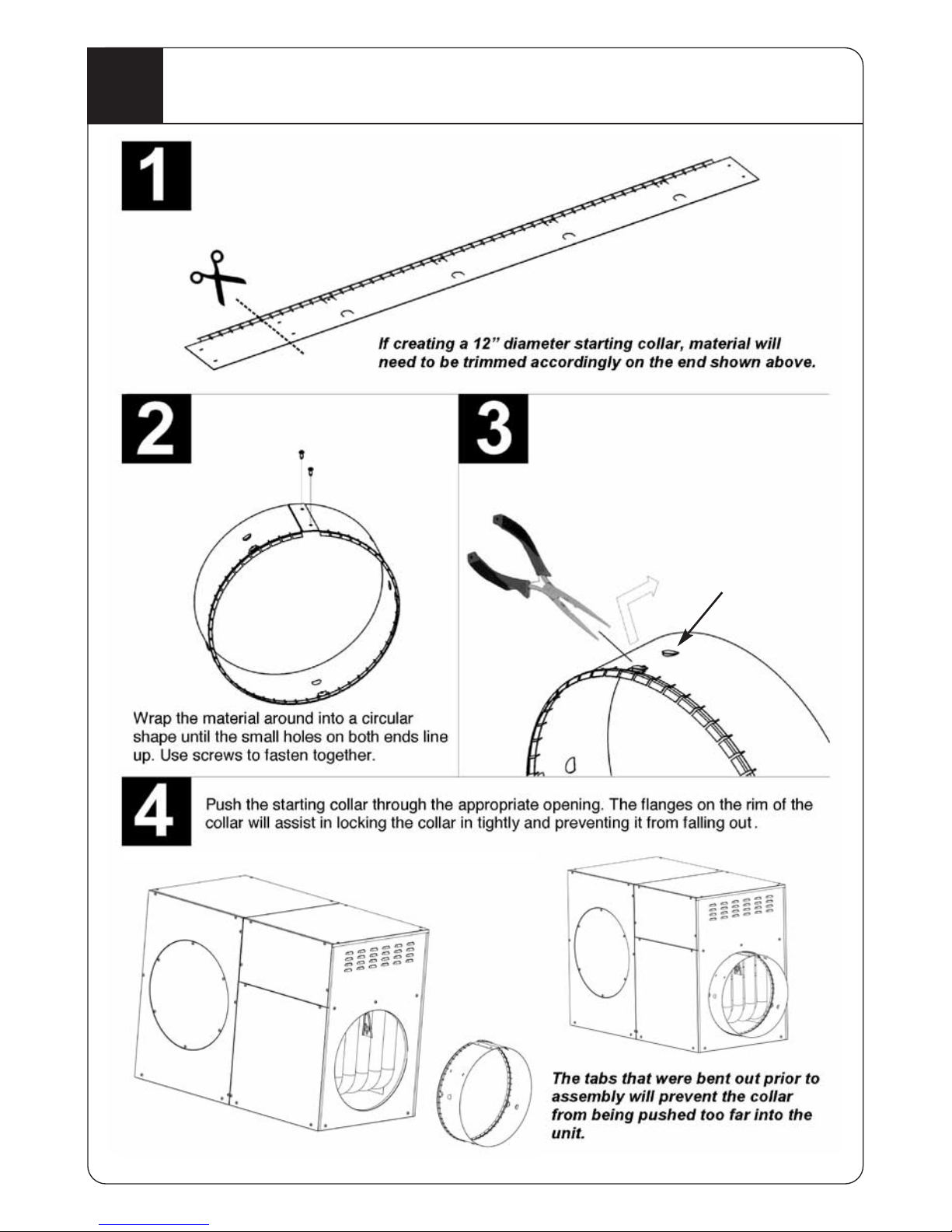

Starting Collars

Starting collars are manufactured from pre-painted or

galvanised steel and supplied as a flat part

Use pliers to bend the four stop tabs

out. Be sure to bend them out to at

least a 90 angle.

Four ducting

retention hooks

are provided to

assist with fixing

duct to collar.

Page 7

7

Part 5442225 issue E

2

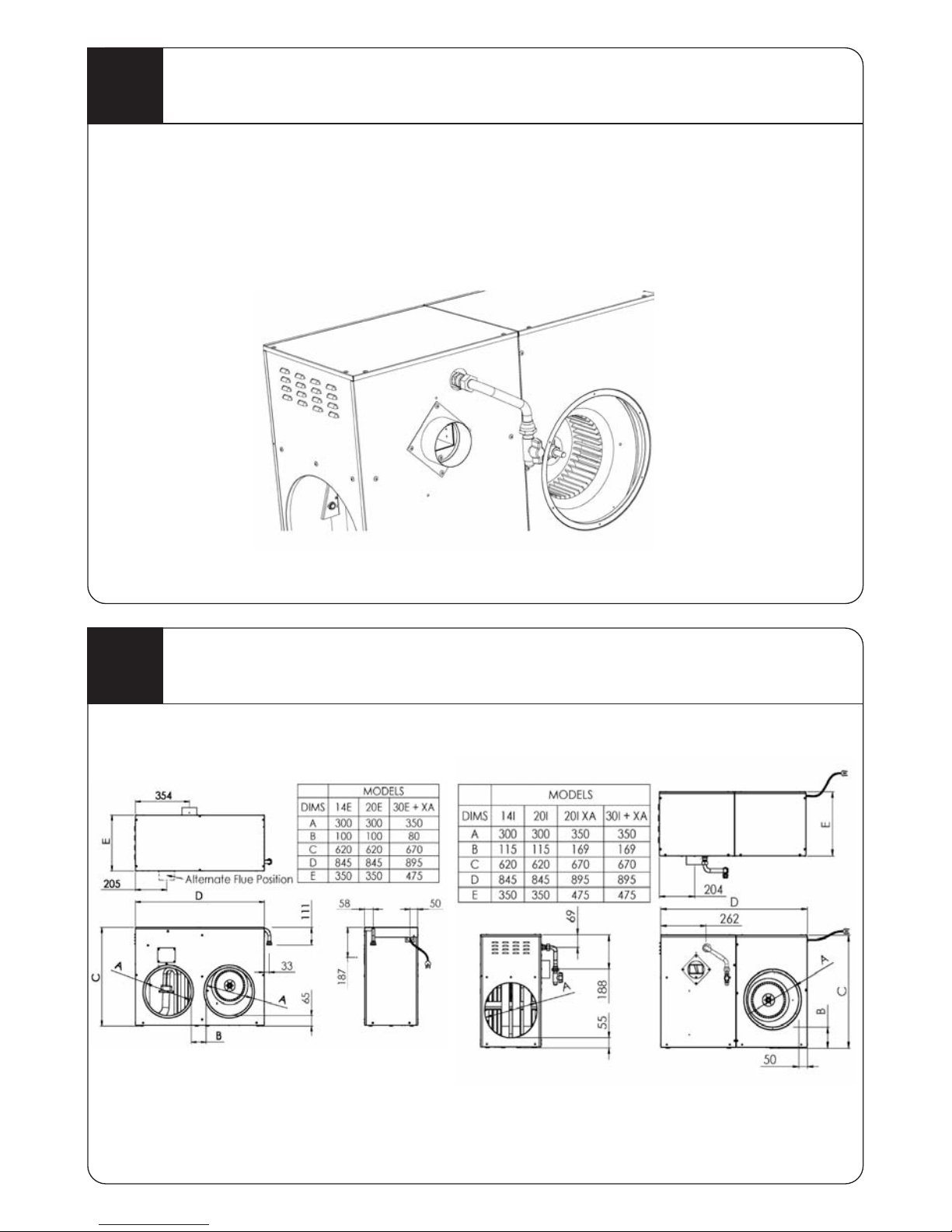

Gas supply and manual shut-off valve

3

Product Dimensions

All gas piping must comply with AS/NZS 5601. Piping must be correctly sized to

suit product supply requirements and ensure a minimum supply pressure of

1.13kpa (natural gas). The maximum gas consumption for this product can be

found on the product label affixed to the unit. An AGA approved manual shut-off

valve must be installed in the gas supply line for this unit. The valve should be

installed in a suitable location adjacent to the unit which will ensure easy access

for service.

Once an A.G.A approved manual shut-off valve is fitted it may be positioned

horizontally or vertically subject to location of heater and ease of access.

External products Internal products

Page 8

8

Part 5442225 issue E

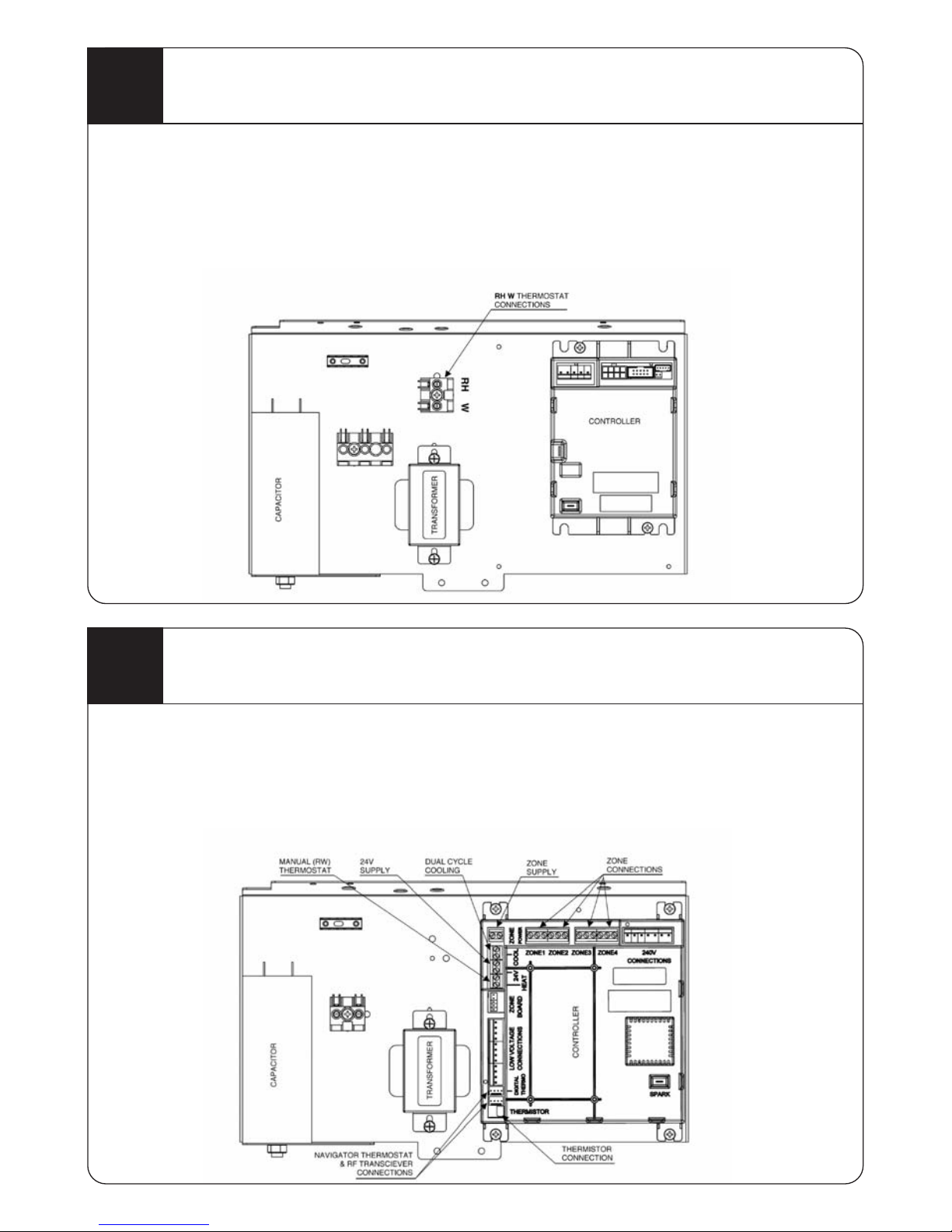

5

4 Star Thermostat Connection

4

3 Star Thermostat Connection

For manual thermostat installation and wiring connection information, refer to

instruction sheet supplied with the thermostat.

For navigator thermostat control installation refer to the navigator user manual.

Where a 2 wire manual thermostat is used the connecting wiring used must have a

minimum cross sectional area of 0.75mm or greater.

For manual thermostat installation and wiring connection information refer to

instruction sheet supplied with thermostat.

For navigator thermostat control installation refer to the navigator user manual.

Where a 2 wire manual thermostat is used connecting wiring used must have a

minimum cross sectional area of 0.75mm or greater.

Page 9

9

Part 5442225 issue E

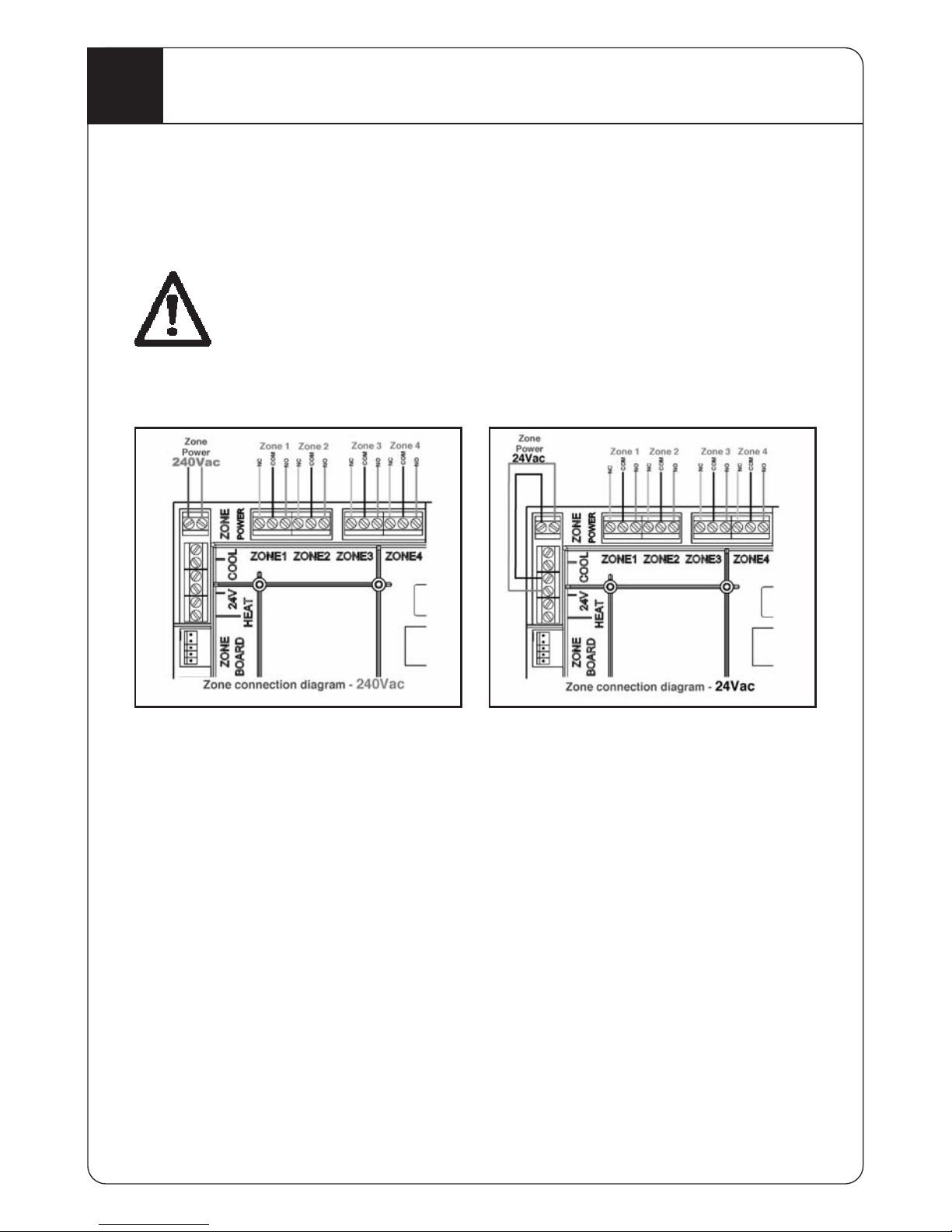

6

4 Star Zone Connection and Dual Cycle cooling

The control module in every 4 star heater has integrated zone outputs.

This control has four relay switched outputs for connection of zone dampers.

The control will manage zone outputs in accordance with commands sent by the

Navigator thermostat. Zone control can be expanded from four to eight if required

by purchasing an expansion card and a connection cable.

The installer is responsible for all electrical cabling and sizing and

compliance with AS/NZS 3000 (latest edition).

Zone Power Supply:

Zone power can be taken from the 24VAC supply on the control by connecting as

shown below or from an external supply.

Zone Output Connections:

Depending on the desired configuration each zone output has a common (COM)

connection and a normally open (NO) or normally closed (NC) as shown. Connect

either to NC or NO as required.

Enabling Zone Control:

To activate zone control and zone expansion board installation parameters must

be enabled. Refer to the Navigator digital thermostat user manual for instructions.

For each zone required, the control parameter number must be set for the total

number of zones required (e.g. for “4” zones set parameter to “4”).

NOTE: For zone expansion board installation, refer to instructions supplied with

expansion board kit.

Dual Cycle Cooling:

The control has available a 24 volt only connection for installations where a

refrigerated cooling coil is installed. To activate this function a installation

parameter must be enabled using the Navigator thermostat (refer to Navigator

thermostat user manual).

NOTE: For cooler connection details, refer to installation instructions supplied with

the cooler.

Page 10

10

Part 5442225 issue E

7

Installation of Navigator Controller

BEFORE STARTING

Before attempting to use the setup instructions for the controls system, make sure the

transceiver (remote control units only) or the wired low voltage cable is connected,

batteries have been correctly installed in the Navigator Controller (remote control units)

and the 240 volt power has been turned on to the product.

NOTE: Do not run the low voltage loom in long parallel runs with 240V mains

cables. Keep the low voltage loom 200mm away from any long runs of mains

wiring. Cross over mains wiring at right angles. Do not use existing access holes

in wall cavities where 240V mains wiring exist. Drill a new access hole 200mm

from the existing hole.

INSTALLATION

Where the control is using the thermostat for operation, it

must be installed approximately 1.5 metres above the floor

level on a room wall which is most commonly used for best

average sensing.

Secure the Navigator Controller cradle to the wall using the

screws and plugs provided.

• For hard wired versions drill an access hole through the

cradle to bring the cable into the control. Once

connected snap the control into the cradle.

• For the remote Navigator Controller (wireless) install

batteries and slide the Navigator Control into the cradle.

The Navigator Controller should remain in the cradle

during normal operating conditions for optimum

temperature thermostat control.

Do not locate Navigator Controller near concealed hot or

cold water pipes, warm air ducts, radiators, sunlight,

televisions or draughts from hallways, stairways and

fireplaces or external walls. These can all affect the

temperature.

Remote Control Units ONLY

Ensure the transceiver has been installed at least 500 mm clear of all metal masses. The

transmissions between the remote Navigator Controller (wireless) and the unit control

box are radio signals which are subject to interference. The primary causes for signal

interference are:

• Metal Construction buildings or metal masses near the antenna.

• Incorrect location of the antenna

• Cordless RF door bells

• Other Faulty appliances

• Navigator Controller too close to computers

• Powerful radio scanners

Page 11

11

Part 5442225 issue E

8

Installation of Navigator Controller

(cont)

INSTALLATION OF TRANSCEIVER

The transceiver cable connects to the control box as

shown.

Fully extend the transceiver cable (4 meters) and attach

the transceiver housing to a solid surface such as a rafter

or vertical column using the two screws provided. Avoid

direct contact with metal surfaces. Connect the

transceiver plug to one of the two thermostat connections

on the control box.

When the installation is complete and the power to the

heater is turned on, a green LED in the transceiver case

should be visible confirming it is connected correctly and

is ready for pairing with a Navigator controller.

To ensure trouble free operation, the transceiver

housing & connecting cable should not be installed

within 200mm of any power cables or other radio

transmitting devices. The transceiver housing should

be placed 1m away from any metal object.

Do not screw the transceiver to the back of the

control box; it must be run into roof space.

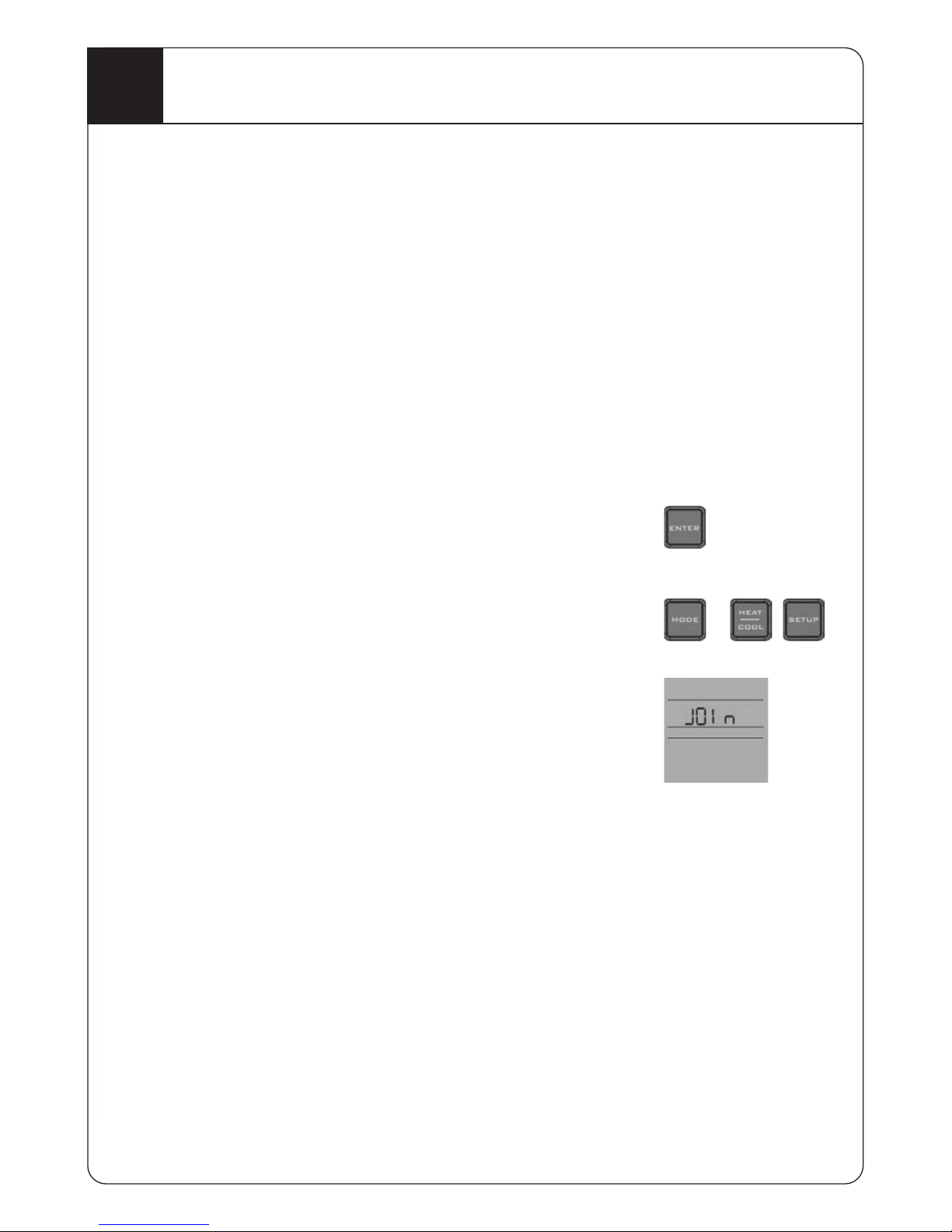

PAIRING THE NAVIGATOR CONTROLLER (Remote Only)

The BONAIRE Navigator Controller and transceiver does

not have any pairing information when they are delivered

from the factory.

On the first power up, the transceiver will request to PAir

with Navigator Controller for period of a 30 min window

and its green light will be illuminated. If it does not PAir

within that time, it will PAir on the next power up. Put the

Navigator Control in pairing mode -

1. Press & hold the ENTER button for 3 seconds.

2. Press the Heat/Cool, Mode & Setup buttons in

sequence. The display will flash “PAir”.

3. After a few seconds the Navigator Controller displays

the “ro XX” (“XX” is the unique serial number. For

example “ro 22”). It will also display the strength of the

signal.

4. Press the ENTER button to pair the transceiver and the

Navigator Controller.

NOTE: Wait until the backlight turns off and press

any key after 2 minutes.

5. Press the ON/OFF button to go to the main display.

RF Transceiver & cable

assembly

Page 12

12

Part 5442225 issue E

9

Multiple Navigator Controller 9 Operation

OPERATION OF MULTIPLE NAVIGATOR CONTROLLERS

The Navigator control system is capable of supporting up

to 4 controllers. By default, the system will allow one

controller to control the appliance or multiple appliances.

Certain parameter set ups must be made to configure

multiple controllers.

The options available are

• 2 wired Navigators only

• 1 wired Navigator and up to 3 Remote Navigators.

MULTIPLE WIRELESS REMOTE CONTROLLERS

In a multiple Navigator controller system, the other

controller may be joined to a master by putting the slave

controller into a PAir mode. It will then send out a PAir

request to the master controller. The master controller is

then put in a JOin state and can then join the request to

set up a Navigator system.

JOINING NAVIGATOR CONTROLLERS (JO

IN

)

Controllers requesting to JOIn another controller in the

Navigator system, can be put in the join mode as follows.

1. To enter the JOIn state, press and hold the ENTER

button for 3 seconds & release.

2. Press and release the, MODE, HEAT/COOL and

SETUP buttons in sequence.

3. The master wireless Remote controller should display

JOin state to receive a command from the other

handset to JOIn the Navigator system.

4. The slave controller should be placed into a Pair state

to join with the master controller. The slave controller

should display Pair.

Page 13

13

Part 5442225 issue E

10

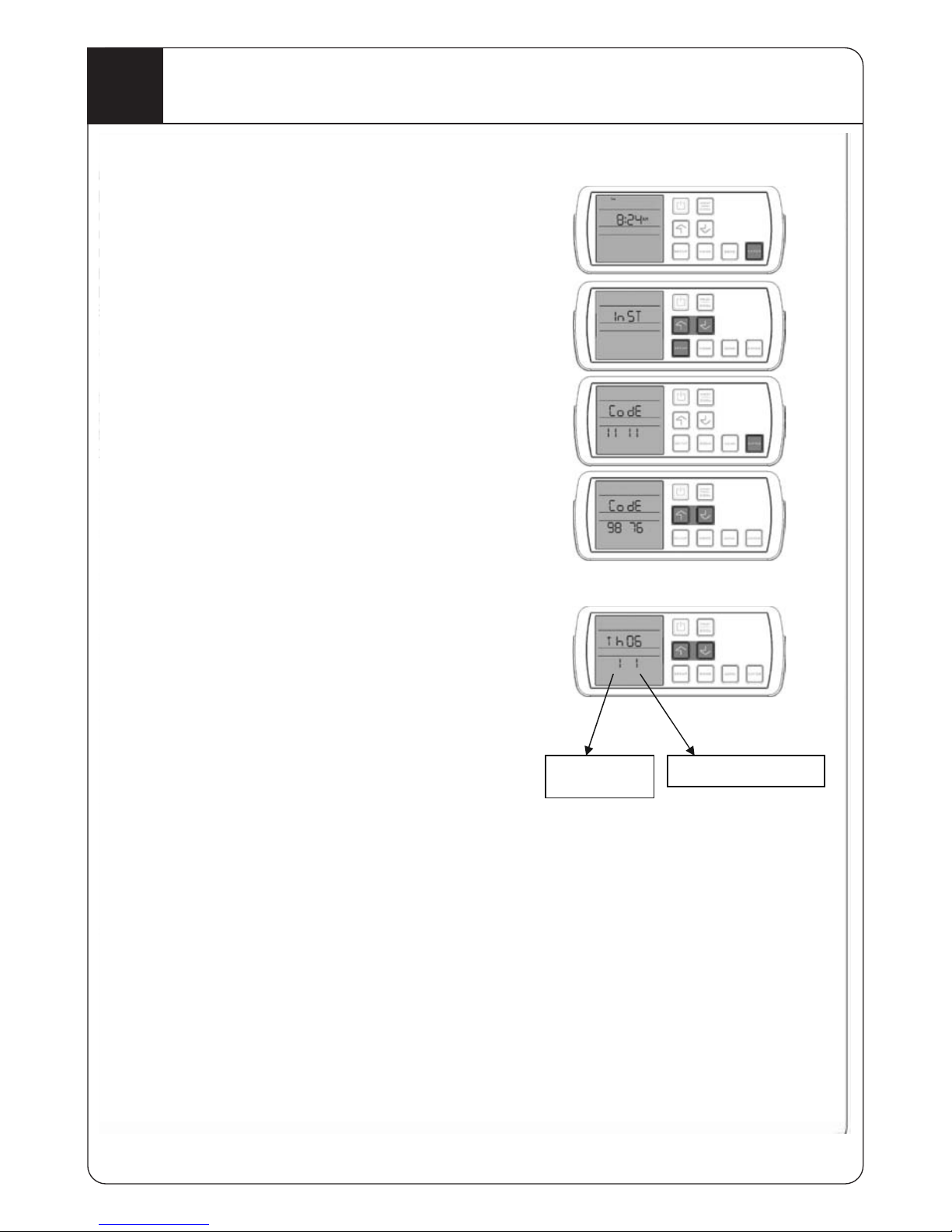

Accessing Navigator Controller Installer Setups

NOTE: The Navigator Controller must be in the OFF

status to change the parameters.

1. Press and hold the ENTER button for 3 seconds.

2. Press & release the Ï then Ð then SETUP

buttons to enter the installer set up mode.

3. The word “InST”, ”nSTA”, ”STAL”, ”TALL”,

”ALLE”, ”LLEr” (Installer) scrolls across the upper

part of the display. Press the ENTER button.

4. When the CodE “11 11” appears, input the code

“98 76” using the Ï and Ð buttons to select each

digit, and press the ENTER button to move to the

next digit

NOTE: The Navigator Controller will display

the abbreviated name of the

appliance such as “EC XX” for

Evaporative Cooler, “HE XX” for

Central Heater or “th XX” for the

Navigator controller settings (“XX” is

the unique serial number). For

example “th 06”.

5. Use the Ï and Ð buttons to scroll to the “th XX”

and then press the ENTER button to access

Navigator Installer setup.

The display will now show digits “1 1”. The lower left

digit is the parameter number and the lower right digit

is the parameter option value. Parameter numbers

and option values can be found in the Navigator

Controller Installer Parameters Table.

6. To select the parameter number use the Ï and Ð

buttons to find the desired parameter and press

ENTER.

7. Adjust the option value (See Navigator Parameter

Table) to the required value and press ENTER.

This will set the option value and return you to the

parameter number selection menu.

8.

When finished Press the ON/OFF button to exit.

Parameter

Options value

Page 14

14

Part 5442225 issue E

11

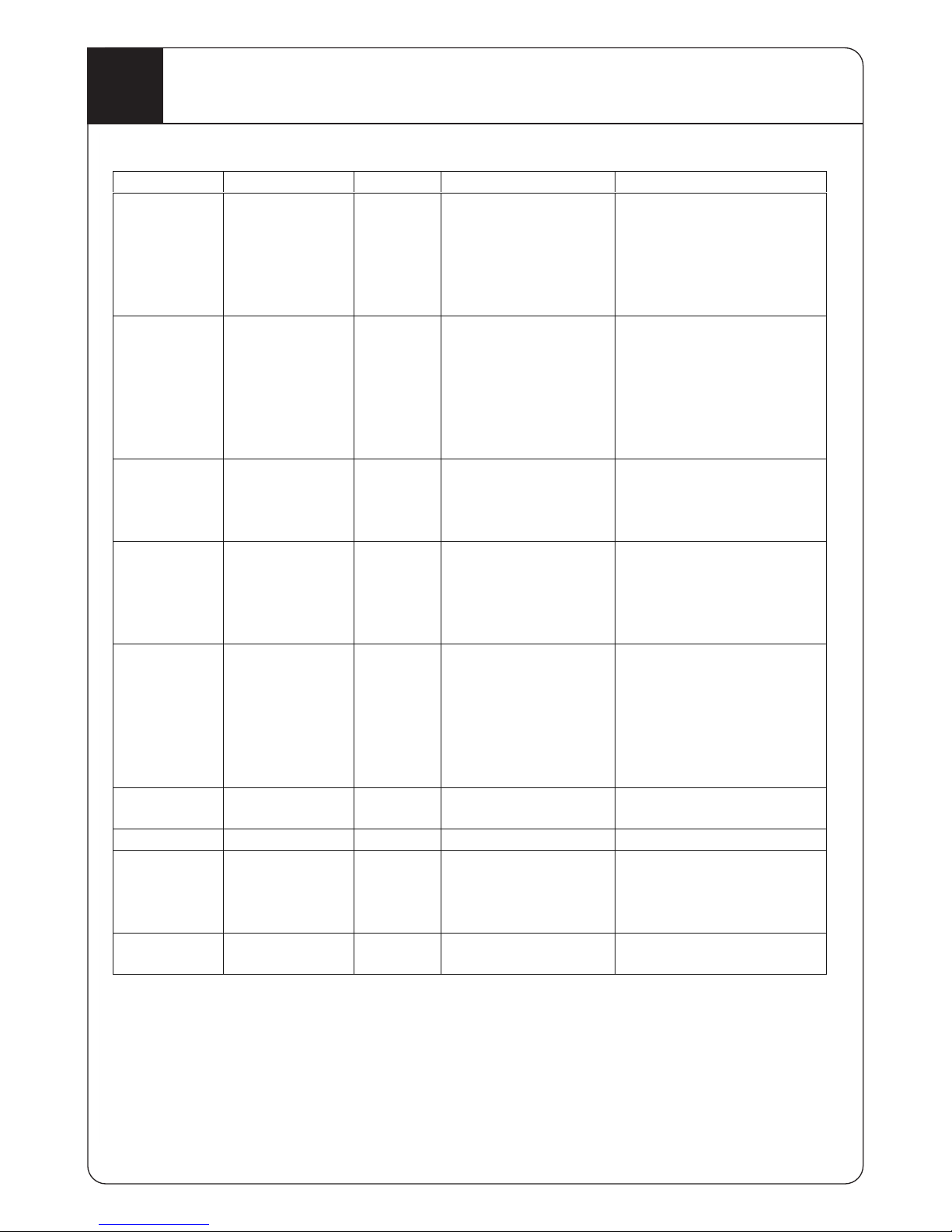

Navigator Controller Parameters Table

th parameter Table (“th XX”)

Parameter Description Default Definition Options Values

1

Un switched

Zone Option

1

Tells system if

there is a common

zone present

1= common zone

present.

0= no common zone

(Note that a cooler is

usually installed into the

common zone)

2

Switched

Zones

15

To display all

available switched

zones

15= Zone 1, 2,3 & 4

6 = Zone 2&3

127 = 8

Using ZONE and ÐÏ

buttons whilst in this

parameter will set the

number

3

Temperature

Display zone

0

Selects which zone

the Navigator will

display the

temperature of

0 –Common zone

1-8 Zones 1-8

4

Temperature

Measurement

-Un switched

Zone option

1

Determines if the

navigator is

measuring the

temperature in the

common zone

1Measuring common

zone.

0= Not measuring

common zone

5

Temperature

Measurement

- Switched

Zones

15

Determines which

of the switched

zones the

Navigator is

measuring,

15= Zone 1, 2,3 & 4

6 = Zone 2&3

127 = 8

Using ZONE and ÐÏ

buttons whilst in this

parameter will set the

number

6

Not used

0

7 Not used

8

RF Network

(RF handset

only)

0

The current RF

network number

0 = not assigned

Any other = actual

network

0

Not used

0

Page 15

15

Part 5442225 issue E

12

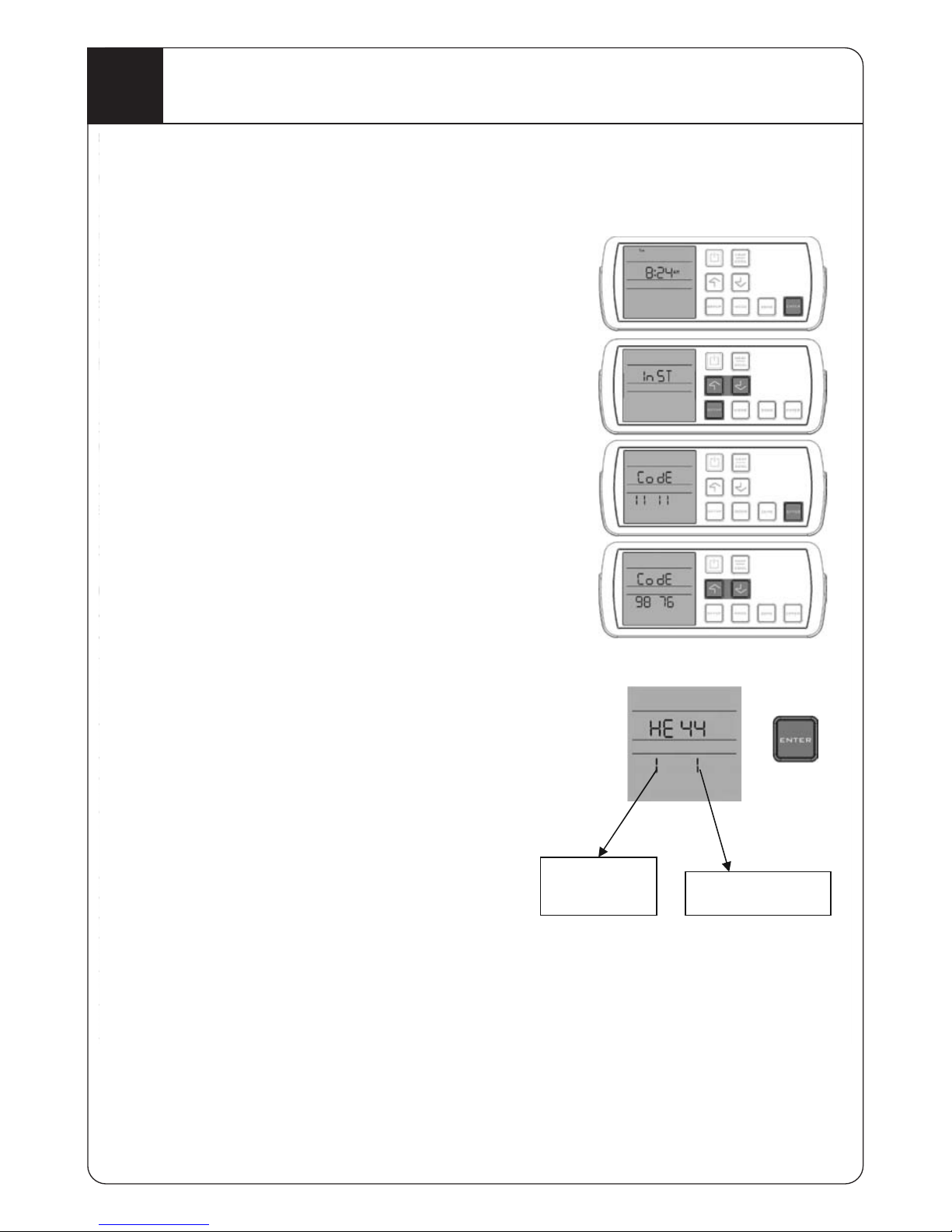

Accessing Ducted Gas Central Heater (DGCH) Installer Setup

NOTE: The Navigator Controller must be in the

OFF status to change the parameters.

(Except Fan Speed)

1. Press and hold the ENTER button for 3 seconds.

2. Press & release the Ï then Ð then SETUP

buttons to enter the installer set up mode.

3. The word “InST”, ”nSTA”, ”STAL”, ”TALL”, ”ALLE”,

”LLEr”(Installer) will scroll across the upper part of

the display. Press the ENTER button now to

access.

4. When the CodE “11 11” appears, input the code

“98 76” using the Ï or Ð buttons to change each

digit, and press the ENTER button to move on to

the next digit.

NOTE: The Navigator Controller will display

the appliance controller ID “HE XX” for

a central heater (“XX” is the unique ID

number).For example “HE 44”.

5. Press the ENTER button when “HE XX” appears.

The display will now show digits “1 1”. The lower

left digit is the parameter number and the lower

right digit is the parameter option value.

Parameter numbers and option values can be

found in the Ducted Gas Central Heater Installer

Parameters Table.

6. To select the parameter number use the Ï or Ð

buttons to find the desired parameter and press

ENTER.

7. Adjust the option value (See DGCH parameter

table) to the required value and press ENTER.

This will set the option value and return you to the

parameter number selection menu.

8. When finished press the ON/OFF button to exit.

Parameter

Number

Options Value

Page 16

16

Part 5442225 issue E

13

Ducted Gas Central Heater (DGCH) Installer Parameter Table

HE Parameter Table (“HE XX”)

Parameter Description Default Definition Options Values

1

Un switched Zone

Option

1

To allow for a

common zone

and all zones to

be switched off if

necessary

1= Allows all zones

to be switched off.

0= Does not allow all

zones to be

switched off

2

Switched Zones

15

To display all

available

switched zones

0=No switched

zones.

15= Zone 1, 2,3 & 4

6 = Zone 2&3

127 = 8

Using ZONE and

ÐÏ buttons whilst in

this parameter will

set the number

3

Cool Enable

0

Enables the

control board to

drive refrigerated

cooling

0=Off – Not driving

Refrig cooling (Dual

Cycle)

1=On – Allowing

Refrig cooling to

operate.

4

Room fan speed

minimum

12

Low modulated

fan speed

Range 3 - 25

5

Room fan speed

maximum

30

Maximum fan

speed

Range 10 - 31

6

Zone 1 Weight

8

Air flow capacity

required for zone

Range 1 - 16

7

Zone 2 Weight

8

Air flow capacity

required for zone

Range 1 - 16

8

Zone 3 weight

8

Air flow capacity

required for zone

Range 1 - 16

9

Zone 4 Weight

8

Air flow capacity

required for zone

Range 1 - 16

10

Zone 5 Weight

8

Air flow capacity

required for zone

Range 1 - 16

11

Zone 6 Weight

8

Air flow capacity

required for zone

Range 1 - 16

12

Zone 7 Weight

8

Air flow capacity

required for zone

Range 1 - 16

13

Zone 8 Weight

8

Air flow capacity

required for zone

Range 1 - 16

14

Zone Common

Weight

16

Air flow capacity

required for zone

Range 1 - 16

15 Not used

0 Not used 0

Page 17

17

Part 5442225 issue E

14

Zones Setup

Unswitched Zones- (Common Zone)

The system is capable of operating a common (or unswitched) zone allowing all

other zones to be turned off.

In the unswitched zone parameter, set the parameters required according to HE

parameter table.

1 – Allows all other zones to be switched off

0 – Will not allow all zones to be turned off and one must always be on.

Switched Zones

The system is capable of controlling up to 8 switchable zones. The number of zones

shown in the display is set from parameter 2 in the Ducted Gas Central Heater

Installer Parameter table. The Navigator Controller needs to have parameter 2

changed to 127, this will display all zones on the controller.

DGCH INSTALLER SETUP PARAMETERS (Example)

Single heater- No zone dampers, common zone only

Parameter Id Value Meaning

Unswitched Zones 1 1 common zone enabled

Switched Zones 2 0 no switched zones

Single Heater - 2 zone dampers

Parameter Id Value Meaning

Switched Zones 2 3 Zones 1 & 2 installed

Single Heater - 4 zone dampers

Do nothing

. Default controller parameters are set for 4 zones and no common zone.

ADDING ZONES

1. Enter the Installer Navigator Controller set up parameters.

2. Proceed to parameter 2 and press ENTER.

3. Set the value to 127 and press ENTER.

4. Exit this setup by pressing ON/OFF.

5. Enter the Ducted Gas Central Heater Installer parameter setup.

6. Press the ZONE button to toggle on or off the zones you require (indicated by the

S under the zone number).

7. Press the Ï or Ð buttons to move to the next zone.

8. Press the ENTER button to select.

MULTIPLE CONTROLLERS – SHARED ZONES

Single DGCH with individual zones and multiple Navigator controllers

For multiple Navigator controllers, the best results require one Navigator measuring

the temperature in zones 1 & 2, the other measuring zones 3 & 4. None should

measure the common zone. This assumes that the Navigators are physically

installed in Zones 1 and 3 respectively

Page 18

18

Part 5442225 issue E

14

Zones Setup

(cont)

Navigator 1 Thermostat Installer Parameters

Parameter Id Value Meaning

Temperature Display Zone 3 1 Displaying temperature in zone 1

Temperature Measurement –

Common Zone

4 0 No measurement from common zone

Temperature Measurement –

Switched Zones

5 3 Measuring zones 1 & 2

Navigator 2 Thermostat Installer Parameters

Parameter Id Value Meaning

Temperature Display Zone 3 3 Displaying temperature in zone 3

Temperature Measurement –

Common Zone

4 0 No measurement from common zone

Temperature Measurement –

Switched Zones

5 12 Measuring zones 3 & 4

NOTE: There is no difference in setup between a wall mounted wired and wireless

remote Navigator installation.

LTIPLE CONTROLLERS – INDIVIDUAL ZONES (Example)

This feature allows each controller on the navigator system to be assigned to a zone

or a group of zones that is not assigned to any other controller on the system. In this

configuration, there is no interaction between controllers. Each has complete

independent control over its zones and the program set on that control is unique to

that controller and zone. In this mode, you will NOT assign any controller to the

common or unswitched zone.

To enable this feature, Multiple Controllers in individual zones, the system

configuration parameter must be set to 3 (Individual) on all controllers. Best results

will be achieved when one Navigator controller is assigned to zones 1 & 2, the other

to zones 3 & 4. The common zone must be disabled. This assumes that the

Navigators are physically installed in Zones 1 and 3 respectively.

Navigator 1 Controller Installer Parameters

Parameter Id Value Meaning

Unswitched Zone 1 0 Common zone disabled

Switched Zones 2 3 Controlling Zones 1 & 2

Temperature Display Zone 3 1 Displaying temperature in zone 1

Temperature Measurement –

Common Zone

4 0 No measurement from common zone

Temperature Measurement –

Switched Zones

5 3 Measuring zones 1 & 2

Navigator 2 Controller Installer Parameters

Parameter Id Value Meaning

Unswitched Zone 1 0 Common zone disabled

Switched Zones 2 12 Controlling Zones 3 & 4

Temperature Display Zone 3 3 Displaying temperature in zone 3

Temperature Measurement –

Common Zone

4 0 No measurement from common zone

Temperature Measurement –

Switched Zones

5 12 Measuring zones 3 & 4

MULTIPLE CONTROLLERS – INDIVIDUAL ZONES (Example)

Page 19

19

Part 5442225 issue E

14

Zones Setup

(cont)

NOTE: There is no difference in setup between a wall mounted wired and wireless

remote Navigator installation.

MULTIPLE NAVIGATOR CONTROLLERS – UPSTAIRS DOWNSTAIRS CONFIGURATION

This feature allows two Navigator Controllers to be used to control an installation with

a common zone downstairs and one or more damper controlled zones upstairs. Both

Navigators have equal control over the system and the last change made on one

Navigator will be copied to the other Navigator to keep the system in synchronisation.

(Note that with remote thermostats, the change may take some minutes to appear on

the second Navigator while they are in the “sleep” state. The heater will respond

immediately to any change).

To enable this feature for a two damper installation,

1. Pair the common zone (downstairs) Navigator Controller.(Remote only)

2. Join the upstairs zone Navigator Controller to the common zone

controller.(Remote only)

3. Set the parameters as per the following table,

Navigator 1 Controller Installer Parameters

Parameter Id Value Meaning

Unswitched(common) Zone 1 1 Common zone present

Switched Zones 2 3 Zones 1 & 2 available

Temperature Display Zone 3 0 Displaying temperature in common

zone

Temperature Measurement –

Common Zone

4 1 Measurement from common zone

Temperature Measurement –

Switched Zones

5 0 Not Measuring other zones

Navigator 2 Controller Installer Parameters

Parameter Id Value Meaning

Unswitched (common) Zone 1 1 Common zone present

Switched Zones 2 3 Zones 1 & 2 available

Temperature Display Zone 3 1 Displaying temperature in zone 1

Temperature Measurement –

Common Zone

4 0 No measurement from common zone

Temperature Measurement –

Switched Zones

5 3 Measuring zones 1 & 2

Heater Installer Parameters

Parameter Id Value Meaning

Unswitched (common) Zone 1 1 Common zone present

Switched Zones 2 3 Zones 1 & 2 available

Page 20

20

Part 5442225 issue E

14

Zones Setup

(cont)

ZONE WEIGHTING

The Navigator controller supports 8 switched zones and 1 common zone. Each zone

(switched and common) will have a “weighting” (air flow balance) associated with the

zone to define the fan speed for that zone.

The “weightings” are stored in the DGCH installer set up parameters and may be

altered to suit the load of each zone or the balance of the air for that zone. The table

below outlines the defaults and setting options. The zone weighting only applies to

heating and fan, Dual Cycle refrigerated cooling will default to maximum air flow and

zones should be set accordingly.

To understand zone weighting, is to simply understand that a total zoned duct system

irrespective of how many zones must equal the number 32.

Each switched zoned area must have a number between 4 & 16. The table below

shows the default numbers for zones.

If the common zone facility is turned on in the Navigator controller to allow all

available zones to be switched off, the common zone will have a number 16.

If the common zone facility is not turned on and there are 4 switchable zones, each

zone will have the number of 8.

Parameter Description Default Range

6 Weight Zone 1 8 1-16

7 Weight Zone 2 8 1-16

8 Weight Zone 3 8 1-16

9 Weight Zone 4 8 1-16

10 Weight Zone 5 8 1-16

11 Weight Zone 6 8 1-16

12 Weight Zone 7 8 1-16

13 Weight Zone 8 8 1-16

14 Weight Zone Common 16 1-16

To Decrease the air flow of the zoned area adjust the number value down.

To Increase the air flow to a zoned area, adjust the number value up

Example below of a typical 3 switched zone system that has a common zone

enabled.

Therefore If…

Living area (The common area) 16

Bedroom 4

Meals Kitchen 8

Study 4

Total of the zoned system 32

If it is found that the bedrooms do not have enough air and Meals Kitchens has too

much air the following changes would be made to the zone weight numbers.

Living area (The common area) 16

Bedrooms 5

Meals Kitchen 7

Study 4

Total of the zoned system 32

Page 21

21

Part 5442225 issue E

15

Wiring Diagram 3 Star

16

Wiring Diagram 4 Star

24/240Vac

Fault Code LED

Page 22

17

Fault Codes 4 Star

22

Part 5442225 issue E

LEDʼs and Status flash codes

The Red LED indicates the combustion fan is operating correctly and the pressure

switches have activated which then allows the ignition sequence to commence.

The Green LED will display the status of the heater controller. The LED flashes will be

of different duration times & patterns to indicate controller status.

LED patterns are divided into groups to aid the troubleshooting. Presence of LONG

pulse always indicates that the unit is in a lockout. The number of long pulses in an

LED pattern indicates the category of the lockout and the number of the following

short pulses in an LED pattern points to

the actual cause of a lockout.

Short pulses only indicate normal operation and non-lockout events or status.

1 LONG pulse followed by short pulses:

Lockouts caused by external switches and sensors (i.e.; thermistor, over temperature

switch, pressure switch or flame sensor).

2 LONG pulses followed by short pulses:

Lockouts caused by the controller hardware or by ignition, main valve, or modulation

valve.

3 LONG pulses followed by short pulses:

Lockouts caused by safe start faults or ground connection faults.

NOTE: 3 star status flash codes can be found on the product label.

Page 23

23

Part 5442225 issue E

18

Fault Codes 4 Star (cont)

Page 24

24

Part 5442225 issue E

19

Fault Codes 4 Star (cont)

20

Service Access

IMPORTANT: For service the nearest obstruction above the top of the unit must be 30mm or greater

for internal units and 300mm or greater for external units.

Page 25

25

Part 5442225 issue E

21

Commissioning Check List

GENERAL

All equipment ordered by the customer is installed.

The unit is level and secure.

The mains and control wiring are complete, the circuit breaker and GPO are

turned ON.

All Controller functions for the appliance operate.

All electrical or gas connections are to manufacturer’s specifications and the

relevant electrical or gas standards and codes.

DUCTED EVAPORATIVE AIR CONDITIONER UNIT

The water supply line has been flushed to clear swarf and debris and is free of

leaks.

The tank is free of foreign matter and debris and the water isolating tap is

turned ON.

Water drainpipe work is completed and sealed.

The water basin fills with water and the float valve closes correctly when the

water level is 65-70mm below the overflow level.

The water pump operates correctly when turned ON at the controller.

The Dialflo water bleed rate is adjusted to suit local water conditions – if

required.

The tank drains correctly when unit turns off.

The fan deck is correctly located and the fan blade spins freely.

The fan operates through the entire speed range.

The minimum & maximum fan speeds is correctly set.

Water distribution is even with the filter pads fitted and the air conditioner

operating pump and fan.

DUCTED CENTRAL HEATING UNIT

Electrical polarity of the power outlet is correct.

Heater is installed away from sources of dust and fumes (i.e. pool

chlorine/petrol etc).

Checked for gas leaks, none present.

Flue outlet pipe complies with limits given / code and is sealed waterproof.

Page 26

26

Part 5442225 issue E

21

Commissioning Check List

(cont)

Combustion air meets requirements (internal, under floor).

Fan speed settings are correct.

Burner pressure is correct.

Mounting pad/platform complies with requirements / codes.

Internal unit access platforms & service light fitted and complies with codes.

DUAL CYCLE REFRIGERATED AIR CONDITIONING UNIT

Unit Foundation correct and Condenser unit is level

Leak test performed

System vacuumed down

Condenser service valves opened.

System is charged with additional charge as required

All clearances around the condenser set to manufacturer’s specifications.

DUCTWORK

All ductwork is completed to plan, correctly supported and airtight, with no bend

less than 1.5 x the ductwork diameter.

Air distribution checked, dampers are adjusted and all outlets correctly adjusted

and wiped clean.

All roof penetrations are fully sealed and watertight.

Service access cover replaced.

SITE

All rubbish has been removed from inside and on the roof.

CUSTOMER HAND OVER

The following has been explained to the customer –

The operation of the Controller.

The need to open windows and doors for the correct operation of Ducted

Evaporative Air Conditioning

The operation of the bleed or dumping system and it’s importance to operate all

the time while ducted Evaporative cooling is in use.

Maintenance requirements

Page 27

27

Part 5442225 issue E

I

NOTES

Page 28

Part 5442225 issue E

Installation Instructions

Roof Installation

Read general information instructions first followed by

the relevant installation instructions.

Installation must comply with the current editions of

AS/NZS 5601 and AS/NZS 3000.

Page 29

29

1

Location of heater

Part 5442225 issue E

Roof Installation

2

Roof Space

Roof Installation

Consideration should be given to the placement of heater away from

sleeping and living areas of the home. Areas above the laundry, garage or

bathrooms may provide the lowest noise impact to the home environment.

Installation in a roof space must comply with the current editions of AS/NZS 5601.

Walkways and platforms must be installed and capable of supporting the

combined weight of the heater and persons accessing the heater, isolating gas

valve or power switch.

DO NOT install the heater in a location where cooking, grease of other flammable

vapours may be drawn into the heater and ignited.

The heater platform should be installed in a location where noise will not easily

be transmitted into sleeping or resting areas of the home.

Page 30

30

Part 5442225 issue E

3

Lighting & Power

Roof Installation

Roof space must have adequate lighting so as to provide enough illumination on

the walkway as well as the serviceable areas of the heater. This unit requires a

10AMP GPO power supply within 600mm of the unit.

Page 31

31

Part 5442225 issue E

4

Splitting the unit (OPTIONAL)

Roof Installation

In the event that the assembled unit

will not fit through a designated roof

access point for installation all internal

products can be split into two parts.

Each half of the unit can then be

passed through the roof access point.

Reassemble the two halves after they

are placed in a suitable location.

Lift off top panel.

Remove two screws “X” at the top above electrics

panel and disconnect ignition wire “Z”.

Disconnect harness connectors.

Lift the fan box off the hooks and the two halves can now be separated. Reassemble in

reverse order. Ensure the fan box is correctly engaged on both hooks before screwing the

two halves back together.

X

XX

Z

Page 32

32

Part 5442225 issue E

5

Flue Installation

Roof Installation

All flue materials not supplied with this product and used in its installation must be

AGA approved.

This heater must be flued using Ø100mm (minimum) metal flue pipe.

Any flue pipe sections which are not accessible for inspection shall be twin walled

or stainless steel.

Total flue length shall not exceed 6 metres and have no more than two 90 bends.

All flue pipe connections and joins must be sealed with approved materials to

comply with AS5601.

All flue configurations must comply with AS/NZS 5601 and local building codes.

6

Duct Configurations Suitable duct configurations to suit installation needs

Roof Installation

Page 33

33

Part 5442225 issue E

7

Ducts & Fittings

Roof Installation

Do not squash ductwork to fit through

an opening, as airflow will be

restricted. Find a better location.

If more than 6m of flexible ductwork is

required in one length, the next

available size flexible duct must be

used.

Return Air Grille

Locate the return air grille in a central heated area. Where a zoned installation is

planned ensure the return air grille is located in a common zone which cannot be

isolated.

Supply Air Duct to have 2-3m straight section before any bends or Y junctions.

4 star units install the thermistor into the discharge air duct

between two and three metres from the outlet of the unit.

Ductwork should be sized to suit the heater and installation to

prevent excessive back pressure.

Page 34

34

Installation Instructions

Under Floor Installation

Read general information instructions first followed by

the relevant installation instructions.

Part 5442225 issue E

Installation must comply with the current editions of

AS/NZS 5601 and AS/NZS 3000.

Page 35

35

Part 5442225 issue E

1

Water / Drainage Provisions

2

Spacing and Clearances

Under Floor Installation

Under Floor Installation

Page 36

36

3

Spacing and Clearances

4

Obstructions

Part 5442225 issue E

Under Floor Installation

Under Floor Installation

Page 37

37

Part 5442225 issue E

5

Lighting

6

Power Outlet

Under Floor Installation

Under Floor Installation

Page 38

38

Part 5442225 issue E

8

Wall Cover Plate

Under Floor Installation

7

Flue Installation

Under Floor Installation

All flue materials not supplied with this product and used in its installation must be

AGA approved.

This heater must be flued using Ø100mm (minimum) metal flue pipe.

Any flue pipe sections which are not accessible for inspection shall be twin walled

or stainless steel.

Total flue length shall not exceed 6 metres and have no more than two 90 bends.

All flue pipe connections and joins must be sealed with approved materials to

comply with AS/NZS 5601.

All flue configurations must comply withAS/NZS 5601 and local building codes.

Page 39

39

Part 5442225 issue E

9

Duct Configurations Suitable duct configurations to suit installation needs

Under Floor Installation

4 Star units install the thermistor into the discharge air duct

between two & three metres from the oulet of the unit.

Page 40

40

10

Duct & Fittings

Part 5442225 issue E

Under Floor Installation

Do not squash ductwork to fit through

an opening, as airflow will be

restricted. Find a better location.

If more than 6m of flexible ductwork is

required in one length, the next

available size flexible duct must be

used.

Return Air Grille

Locate the return air grille in a central heated area. Where a zoned installation is

planned ensure the return air grille is located in a common zone which cannot be

isolated.

Supply Air Duct to have 2-3m straight section before any bends or Y junctions.

4 star units install the thermistor into the discharge air duct

between two and three metres from the outlet of the unit.

Ductwork should be sized to suit the heater and installation to

prevent excessive back pressure.

Page 41

Installation Instructions

External Installation

Read general information instructions first followed by

the relevant installation instructions.

41

Part 5442225 issue E

Installation must comply with the current editions of

AS/NZS 5601 and AS/NZS 3000.

Page 42

42

Part 5442225 issue E

2

Clearances and Distances

External Installation

1

Unit Location

External Installation

Page 43

43

Part 5442225 issue E

3

Ground Surface Provisions

External Installation

4

External Installation

Wall Opening Clearances and Distances

Spirit level

Concrete or brick base

Page 44

44

Part 5442225 issue E

5

Wall Preparations

External Installation

6

External Installation

Wall Preparation Distancing

Page 45

45

Part 5442225 issue E

7

GPO and Distance

External Installation

8

Ducts and Fittings

External Installation

4 Star units install the thermistor into the discharge air duct between two &

three metres from the oulet of the unit. Air inlet and outlet on external units

can be changed to opposite side to suit installation needs.

If the inlet/outlet configuration is changed it may be necessary to also swap the

outlet position for the combustion fan. See instruction in section 9.

NOTE: 4 Star units also have an internal cover on the

heat exchanger side which must also be removed &

fitted to other side if the covers are being

GPO and all electrical wiring must comply with AS/NZS 3000.

Ensure service cord is properly secured and protected from mechanical damage.

Page 46

46

Part 5442225 issue E

10

Combustion Fan Repositioning

External Installation

9

Flue Spigot Assembly

External Installation

If an alternative flue cowl is used this must be AGA approved.

NOTE: THE FLUE COWL MUST BE SECURELY ATTACHED

TO THE UNIT WITH THE SCREWS PROVIDED.

Page 47

I

NOTES

47

Part 5442225 issue E

Page 48

Part 5442225 issue E

Manufactured by

Climate Technologies

ABN 13 001 418 042

26 Nylex Avenue

Salisbury, SA 5108

Australia

www.climatetechnologies.com.au

“Excelling today for a better tomorrow”

FOR SERVICE:

Tas, Vic: (03) 8795 2456

ACT, NSW, NT, Qld, SA: 1300 665 087

Mobile Callers all states: (03) 8795 2460

Victoria: vicservice@climtech.com.au

South Australia: saservice@climtech.com.au

New South Wales & Queensland: nswservice@climtech.com.au

Western Australia: waservice@climtech.com.au

Loading...

Loading...