ClimateMaster TSL Series, Tranquility Vertical Stack Series, TSL09, TSL12, TSL18 Installation Operation & Maintenance

...

Tranquility®Vertical Stack

(TSL)

Series

Commercial

Vertical Stack

Water-Source Heat Pumps

Installation, Operation

& Maintenance

97B0127N01

Rev.: April 24, 2019

Table of Contents

General Information 3

TSL Model Nomenclature - Cabinet 4

TSL Hybrid Nomenclature - Cabinet 5

Heat Pump Cabinet Slot Dimensions and Riser

Arrangements 6

E Cabinet Slot Dimensions and Riser Arrangements 7

TSL Model Nomenclature - Chassis 8

Accessory Nomenclature 9

Pre-Installation Information 11

Riser Installation 12-15

Cabinet Installation 16-22

Water-Loop Heat Pump Applications 23

Ground-Loop Heat Pump Applications 24

Ground-Water Heat Pump Applications 25

Water Quality Standards 26

Electrical Wiring - Line Voltage 27

Electrical Wiring - Low Voltage 28

Blower Performance Data 29-36

Thermostat Installation 37

Chassis Pre-Installation 38

Hose Kit & Chassis Installation 39-41

Start-Up Preparation 42

CXM Control 43

DXM2 Control 44

Safety Features - CXM/DXM2 Controls 46

Unit Commissioning and Operating Conditions 48

Unit and System Checkout 49

Unit Start-Up Procedures 50

Unit Operating Pressures and Temperatures 51-53

Coax Water Pressure Drop 54

Hybrid Unit CorrectionTables 54

Start-Up Log Sheet 55

Preventive Maintenance 56

Functional Troubleshooting 57

Performance Troubleshooting 58

Harness Part Numbers 59-65

Troubleshooting Form 66

Warranty 67

Revision History 68

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

This Page Intentionally Left Blank

2

ClimateMaster Water-Source Heat Pumps

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Safety

Warnings, cautions, and notices appear throughout this

manual. Read these items carefully before attempting any

installation, service, or troubleshooting of the equipment.

Vertical Stack

Rev.: 04/24/2019

General Information - Inspection

CAUTION: Indicates a potentially hazardous situation or

an unsafe practice, which if not avoided could result in

minor or moderate injury or product or property damage.

DANGER: Indicates an immediate hazardous situation,

which if not avoided will result in death or serious injury.

DANGER labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation,

which if not avoided could result in death or serious injury .

WARNING!

WARNING! Verify refrigerant type before proceeding.

Units are shipped with R-407c and HFC-410A (EarthPure®)

refrigerants. The unit label will indicate which refrigerant is

provided. The EarthPure® Application and Service Manual

should be read and understood before attempting to service

refrigerant circuits with R-407c or HFC-410A.

WARNING!

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal profi ciency requirements.

WARNING!

WARNING! The installation of water-source heat pumps and

all associated components, parts, and accessories which

make up the installation shall be in accordance with the

regulations of ALL authorities having jurisdiction and MUST

conform to all applicable codes. It is the responsibility of

the installing contractor to determine and comply with ALL

applicable codes and regulations.

Dimensions ar e inch es ( m m ).

NOTICE: Notifi cation of installation, operation, or

maintenance information, which is important, but which is

not hazard-related.

WARNING!

WARNING! All refrigerant discharged from this unit must

be recovered WITHOUT EXCEPTION. Technicians must

follow industry accepted guidelines and all local, state, and

federal statutes for the recovery and disposal of refrigerants.

If a compressor is removed from this unit, refrigerant circuit

oil will remain in the compressor. To avoid leakage of

compressor oil, refrigerant lines of the compressor must be

sealed after it is removed.

CAUTION!

CAUTION! To avoid equipment damage, DO NOT use

these units as a source of heating or cooling during the

construction process. The mechanical components and fi lters

will quickly become clogged with construction dirt and debris,

which may cause system damage.

WARNING!

WARNING! Polyolester Oil, commonly known as POE oil, is

a synthetic oil used in many refrigeration systems including

those with HFC-410A refrigerant. POE oil, if it ever comes

in contact with PVC or CPVC piping, may cause failure of

the PVC/CPVC. PVC/CPVC piping should never be used

as supply or return water piping with water source heat

pump products containing HFC-410A as system failures and

property damage may result.

Inspection -

check the shipment against the bill of lading. See fi gure 1

for components. Make sure all units have been received.

Inspect the packaging of each unit, and inspect each unit

for damage. Ensure that the carrier makes proper notation

of any shortages or damage on all copies of the freight

bill and completes a common carrier inspection report.

Concealed damage not discovered during unloading

must be reported to the carrier within 15 days of receipt of

shipment. If not fi led within 15 days, the freight company

can deny the claim without recourse. Note: It is the

responsibility of the purchaser to fi le all necessary claims

with the carrier. Notify your equipment supplier of all

damage within fi fteen (15) days of shipment.

Upon receipt of the equipment, carefully

climatemaster.com

3

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

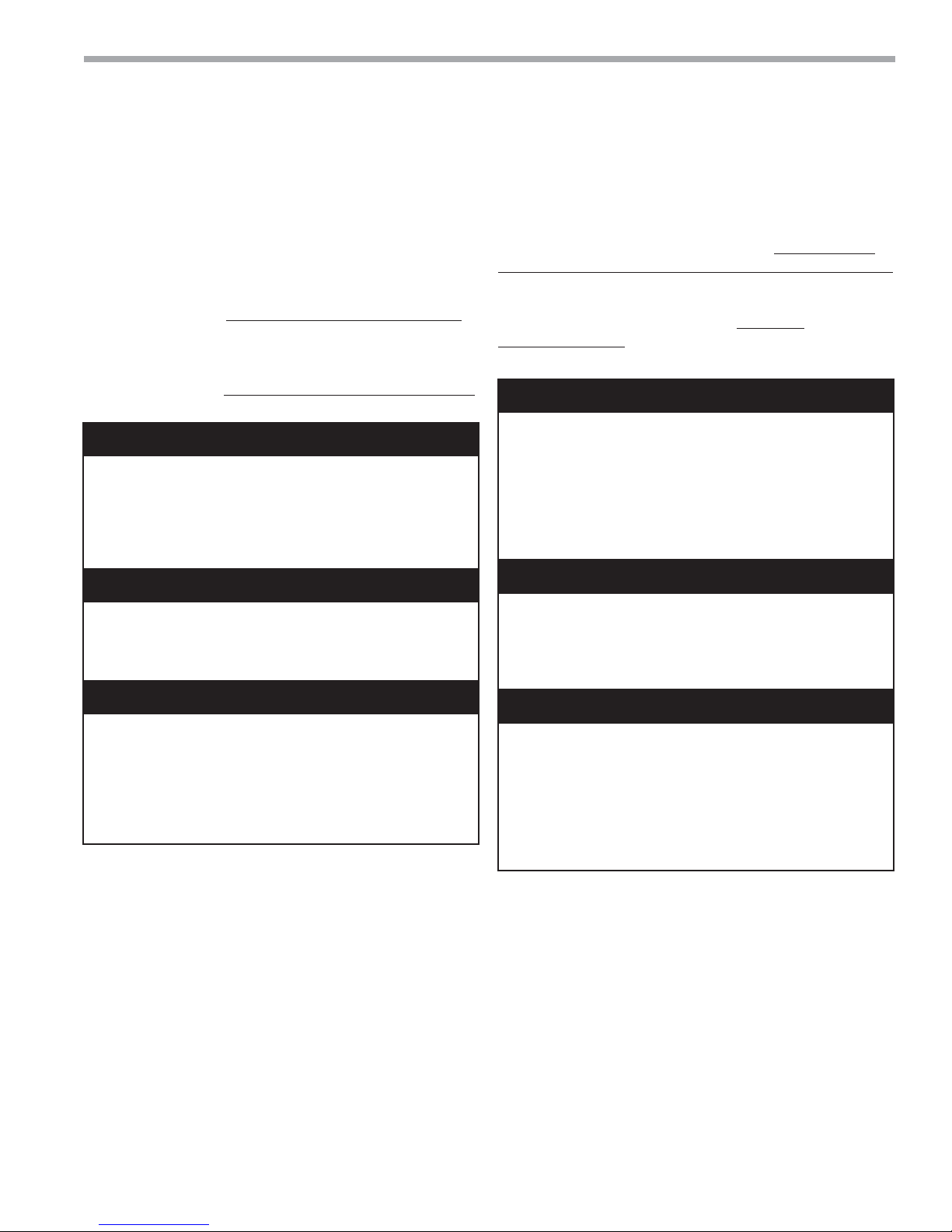

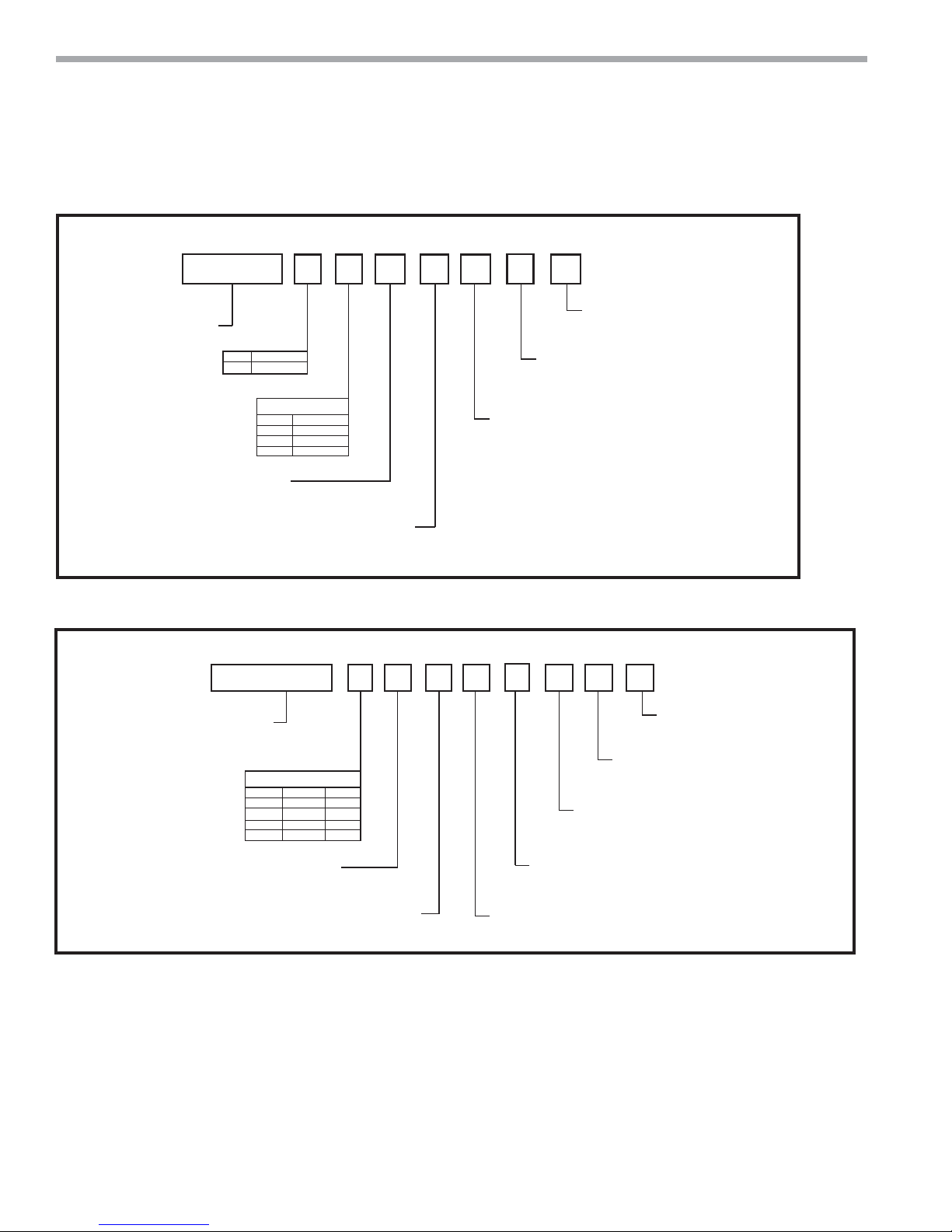

TSL Model Nomenclature - Cabinet

Heat Pump Cabinet

CABINET SIZE

1 = 09

2 = 12

3 = 15

4 = 18

5 = 24

6 = 30

7 = 36

OPTION

S.S. DRAIN PAN

–

A

B

X

C

X

–

0

–

1

X

2

3

X

4

–

HARNESS CONTROLS

PSC

STANDARD

YES

NO

YES

NO

YES

NO

YES

NO NO

ECM CONSTANT

VOLUME

OPTION

A

B

C

D

L

M

N

R

T

U

V

1

2

3

4

1 2835

D1

4

NG 0E 0 0 0 0 D

0

6

0

VOLTAGE

Volt/Hertz/PhazeOPTION

208/230/60/1

G

265/60/1

E

OPTIONS

PREMIUM SEAL

(DXM2 ONLY)

NO

YES

NO

YES

NO

YES

NO

YES

1Ý and 2Ý FILTER

X

–

X

–

X

–

X

–

ECM CONSTANT

TORQUE

A

B

C

D

E

0

1Ý

1Ý

1Ý

1Ý

2Ý

2Ý

2Ý

2Ý

S=SURFACE

M = MPC

R =REMOTE

A = ADA

A

W

R

R

A

W

R

A

W

R

L = LON

NO

M

L

NO

M

NO

M

L

NO

BREAKERDISCONNECT SWITCHOPTION

NO

YES

YES

NO

NO NO

W = WALL SENSOR

NO

YES

POWER TERMINATION

YES

NO

YES

NO NO YES

NO

ISP

NO

YES

YES

7

9

1

0

RISER STYLE

0 = SLAVE / NONE

1 = STANDARD

2 = MASTER

RISER: LOCATION

0 = None

1 = Shipped Separately

6 = Chassis ships in Cabinet (Risers Not Attached)

CABINET HEIGHT 65”

OPTION

ENO

F

L

M

ISO PAD

YES

NO

YES

10 11 12 13 14 15

STANDARD

0 = STANDARD

A, B, C etc.... = SPECIAL 1, 2, 3 etc....

T-STAT WHIP

0 = No Whip

1 = 15’ whip

2 = 25’ whip

3 = 35’ whip

A = Knock Out + Cover + No Whip

B = Knock Out + Cover + 15’ Whip

C = Knock Out + Cover + 25’ Whip

D = Knock Out + Cover + 35’ Whip

Discharge Openings

N/A

0 = Not Used

Discharge Air

E = Top Opening

Riser Ball Valve Options

0 = None

4 = Ball Valve, Union

5 = Ball Valve, Sweat

For Unit Size 65”

09 thru 12

15 thru 18

24 thru 36

REVISION LEVEL

D = CURRENT REVISION

TOPUNIT SIZE

11.5” x 6”

11.5” x 6”

12” x 16”

4

ClimateMaster Water-Source Heat Pumps

Hybrid Cabinet

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

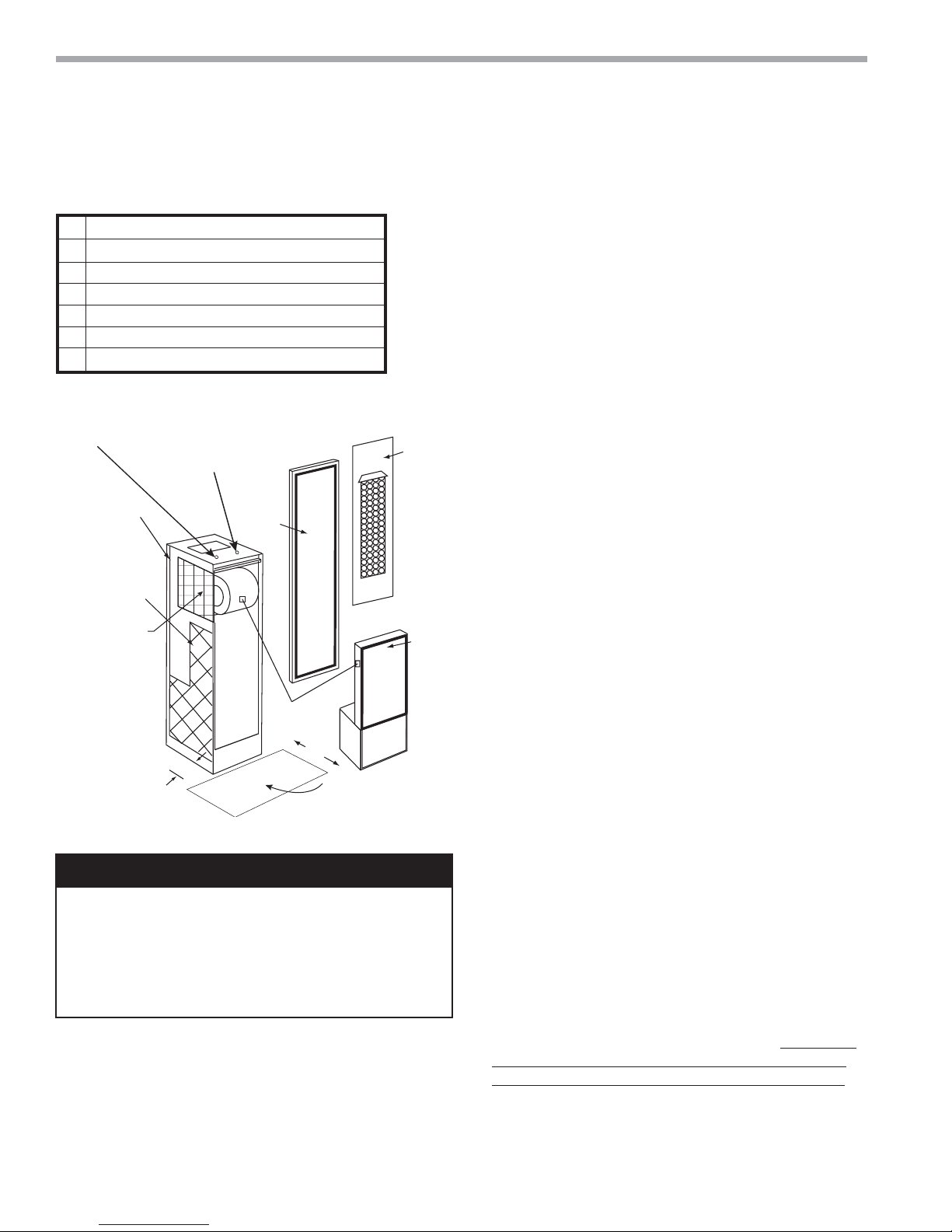

TSL Hybrid Series Nomenclature

1

SERIES

E = 65” 80” and 88”

HYBRID CABINETS

UNIT SIZE

OPTION

B

D

R

S

1

2

4

5

E

1 = 09

2 = 12

3 = 15

4 = 18

5 = 24

6 = 30

7 = 36

S.S. DRAIN PANOPTION

NO

A

YES

B

YES

C

NO

0

NO

1

2

YES

3

YES YES

4

NO NO

HARNESS CONTROLS

ECM

CONSTANT

VOLUME

YES

NO

2835

1

VOLTAGE

Volt/Hertz/PhazeOPTION

208/230/60/1

G

265/60/1

E

OPTIONS

PREMIUM SEAL

YES

NO

YES

NO

YES

NO

A = ADA

ECM

R =REMOTE

CONSTANT

S=SURFACE

TORQUE

W=WALL SENSOR

NO

YES

POWER TERMINATION

A

B

C

D

E

0

FILTER SIZE

1”

1”

1”

1”

2”

2”

2”

2”

A

W

R

S

A

W

R

S

YES

NO

YES

NO

NO OPTIONS

A

B

C

D

E

F

4

NG NA 0 0 0 0 A

0

MPC

NO

YES

NO

YES

NO

BREAKERDISCONNECT SWITCHOPTION

ISP / BREAKER

NO

NO

YES

YES

NO

CABINET HEIGHT

88”

YES

NO

NO

YES

YES

NO

NO

NO

NO

NO

NO NO

RISER STYLE OPTIONS

OPTION

0 = SLAVE/NONE

1 = STANDARD

2 = MASTER

1, 2, 3 , 4, 5, 6

6

0

65”80”OPTION

NO

NO

NO

NO

YES

YES

DIGIT 9

0, 8

ISO PAD

NO

YES

NO

YES

7

1

10 1 1 12 13 14 15

9

1

REVISION LEVEL

TYPE

0 = STANDARD

A - Z = SPECIAL EXCEPT “W”

A = CURRENT REVISION

MISCELLANEOUS CABINET OPTIONS

A = Factory Configure Supply Air Openings + Dust Protection + No Whip

B = Factory Configure Supply Air Openings + Dust Protection + 15’ Whip

C = Factory Configure Supply Air Openings + Dust Protection + 25’ Whip

D = Factory Configure Supply Air Openings + Dust Protection + 35’ Whip

0 = Field to Configure Supply Air Openings + No Whip

1 = Field to Configure Supply Air Openings + 15’ Whip

2 = Field to Configure Supply Air Openings + 25’ Whip

3 = Field to Configure Supply Air Openings + 35’ Whip

4 = Factory Configure Supply Air Openings + No Whip

5 = Factory Configure Supply Air Openings + 15’ Whip

6 = Factory Configure Supply Air Openings + 25’ Whip

7 = Factory Configure Supply Air Openings + 35’ Whip

SIDE DISCHARGE OPTIONS

DISCHARGE

OPTION

0

NONE

A

RIGHT SMALL

B

RIGHT LARGE

LEFT SMALL

C

D

LEFT LARGE

RIGHT SMALL & LEFT SMALL

E

F

RIGHT LARGE & LEFT LARGE

RIGHT SMALL & LEFT LARGE

G

RIGHT LARGE & LEFT SMALL

H

BACK/FRONT/TOP DISCHARGE OPTIONS

UNIT SIZE

OPTION

DISCHARGE

NONE

0

A

BACK SMALL

BACK LARGE

B

FRONT SMALL

C

FRONT LARGE

D

TOP

E

BACK SMALL & TOP

F

BACK LARGE & TOP

G

FRONT SMALL & TOP

H

J

FRONT LARGE & TOP

BACK SMALL & FRONT SMALL

K

BACK LARGE & FRONT LARGE

L

BACK SMALL & FRONT LARGE

M

N

BACK LARGE & FRONT SMALL

P

BACK SMALL & FRONT SMALL W/TOP

BACK LARGE & FRONT LARGE W/TOP

Q

R

BACK SMALL & FRONT LARGE W/TOP

BACK LARGE & FRONT SMALL W/TOP

S

UNIT SIZE

09-18 TOP

15-16 TOP

N/A

12 X 12 14 X 14 16 X 16

N/A

12 X 12 14 X 14 16 X 16

UNIT SIZE

24-36 TOP

C-SERIES

80”

TSM

YES

NO

YES

NO

YES

NO

NO

YES

YES

NO

NO

YES

C-SERIES

88”

TSM

YES

RISER: RISER BALL VALVE OPTIONS

4 = Ball Valve, Union

RISER LOCATION/PACKAGING OPTIONS

OPTION

0 = NONE

1 = SHIPPED SEPERATEL Y

2 = LEFT BACK

3 = RIGHT BACK

4 = LEFT SIDE

5 = RIGHT SIDE

6 = CHASSIS SHIPPED IN CABINET

5 = Ball Valves, Sweat N = None

VERTICAL

PKG

YES

NO

YES

HORIZONTAL

PKG

NO

YES

NO

VALVE ASM QTY 2

SHIPPED IN CABINET

YES

NO

VALVE ASM QTY 2

SHIPPED W/RISERS

NO

YES

climatemaster.com

5

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

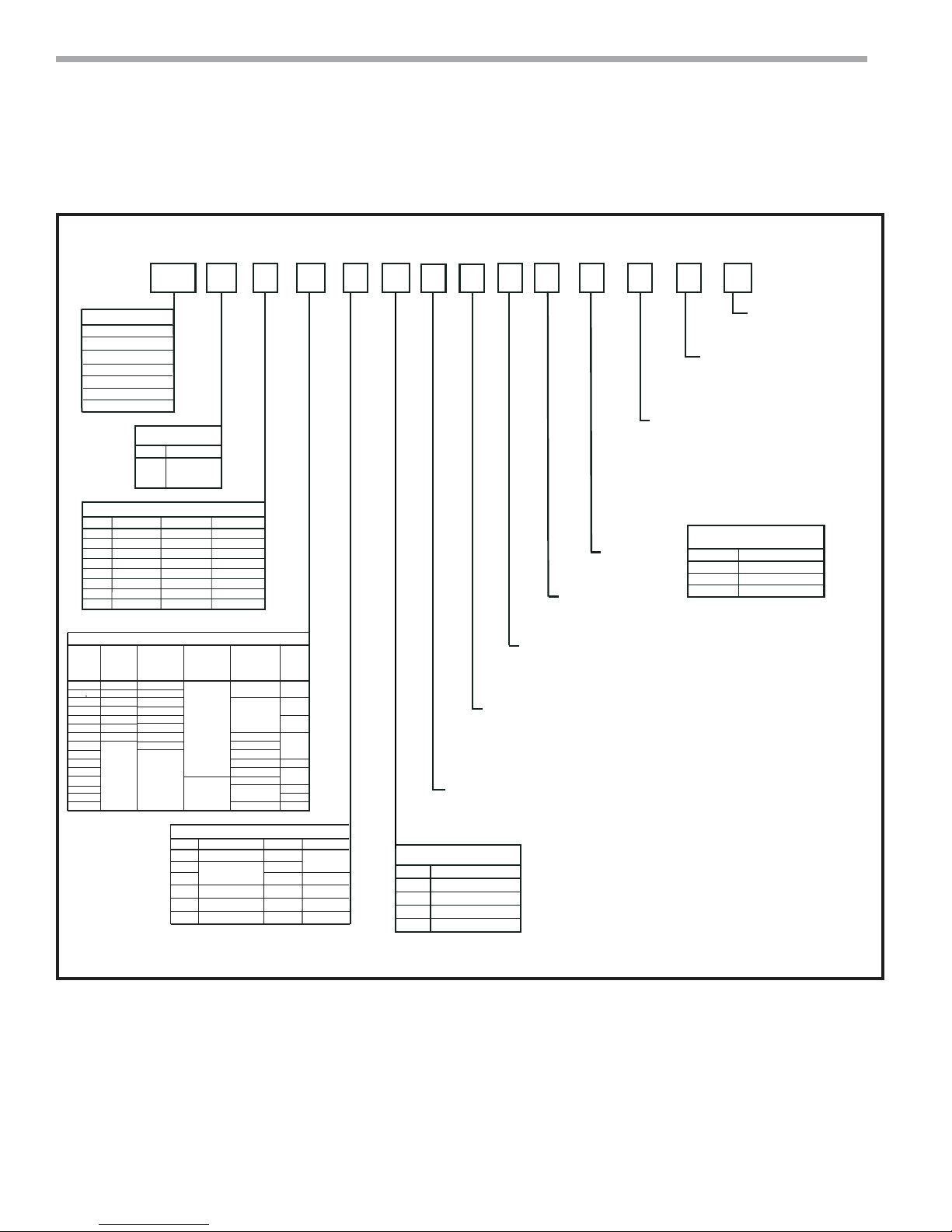

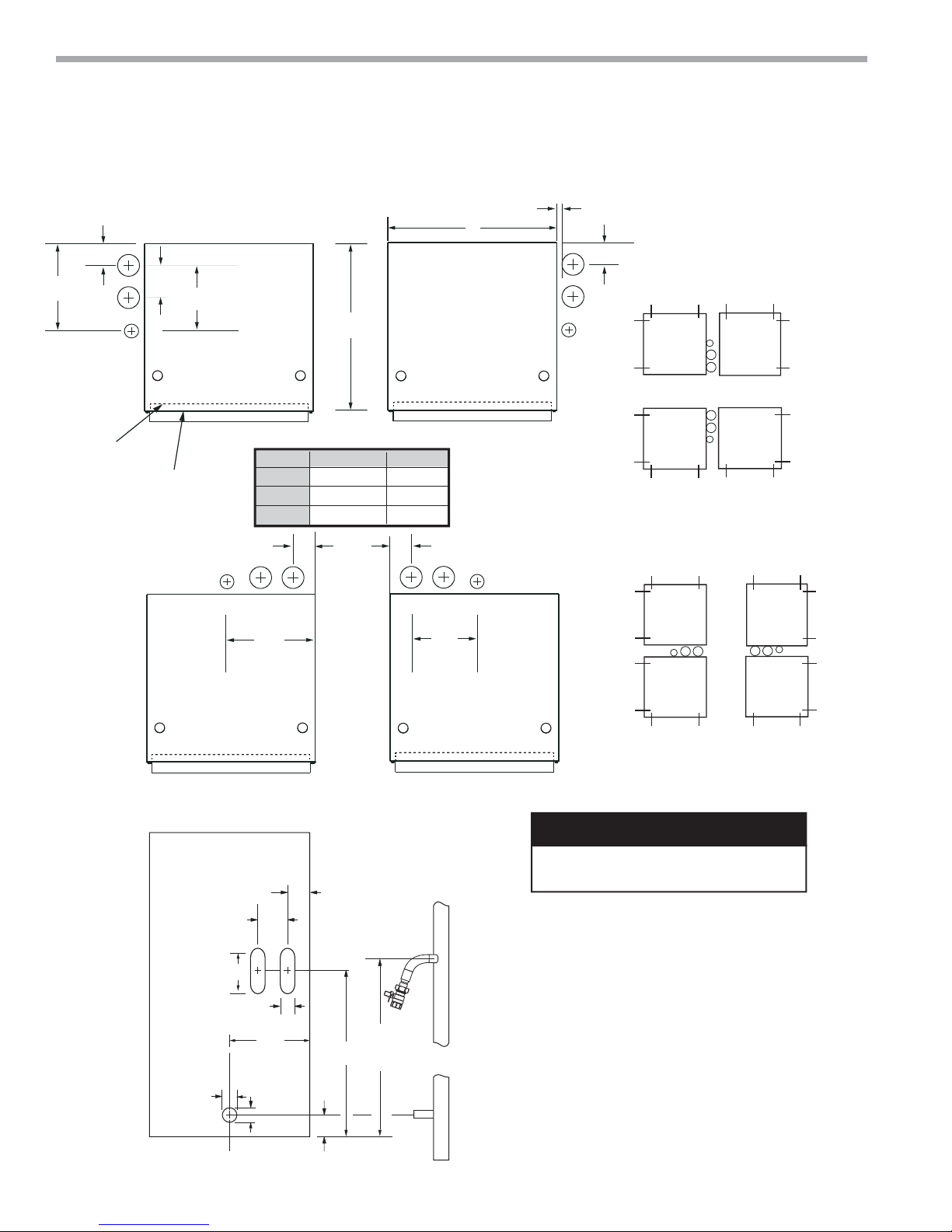

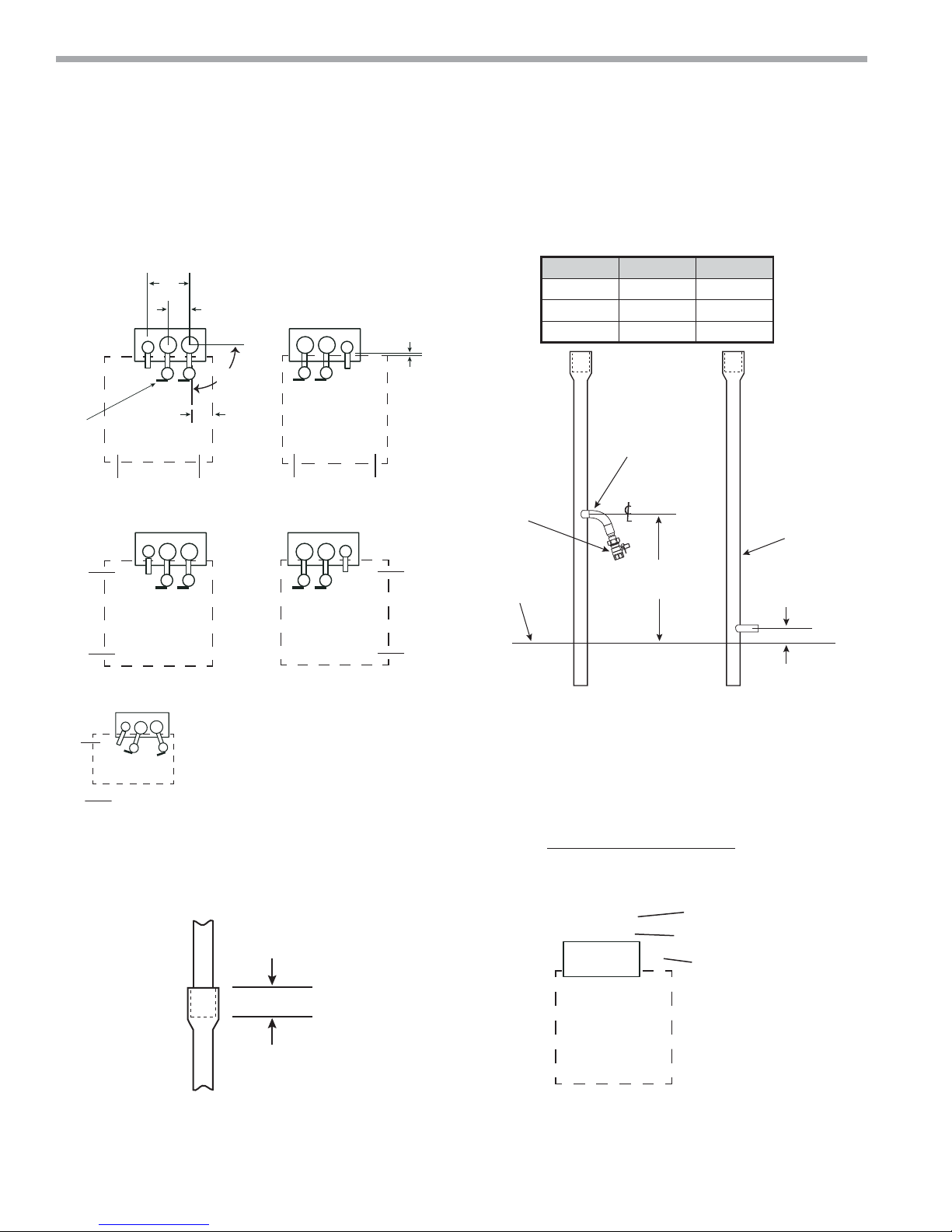

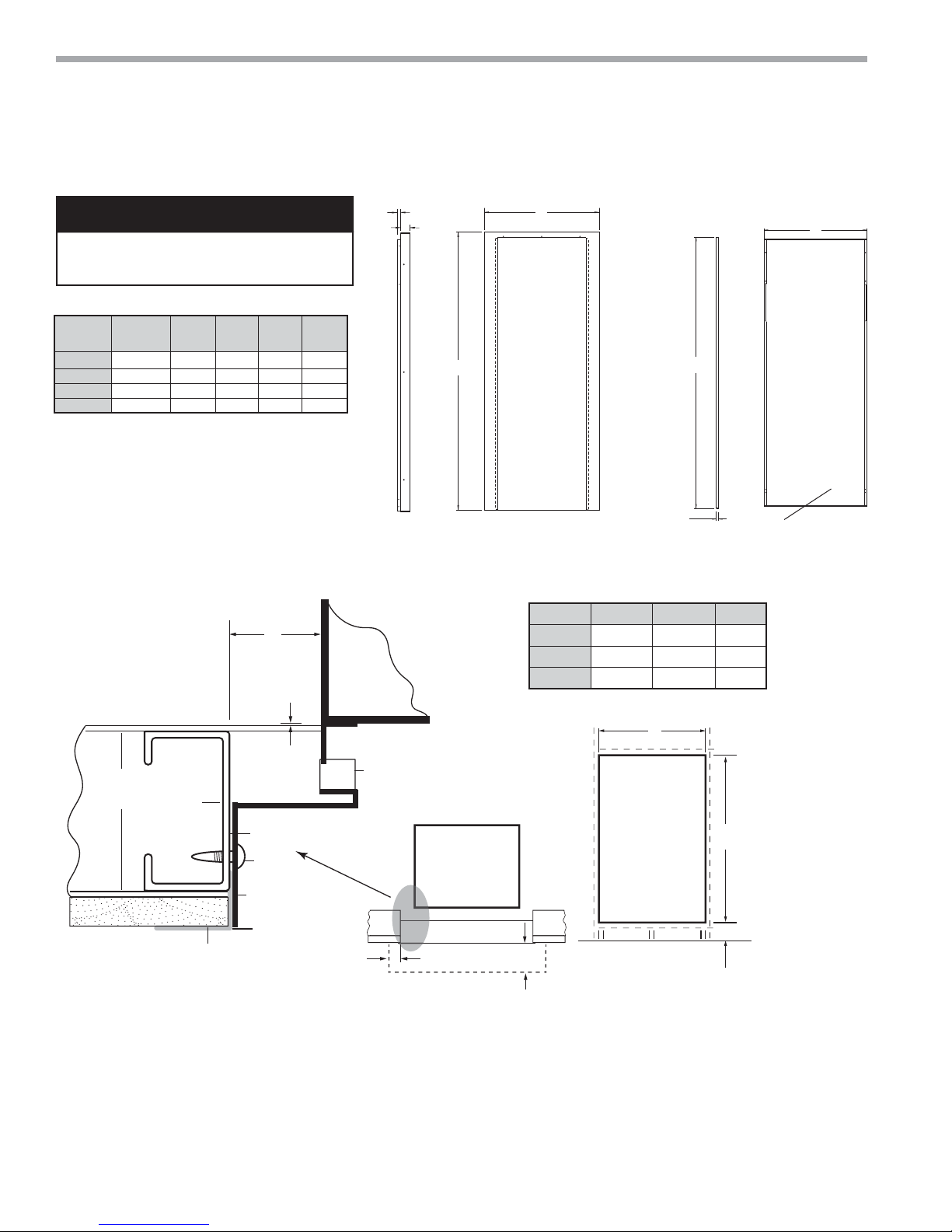

Heat Pump Cabinet Slot Dimensions and Riser Arrangements

Cabinet Shown Up to Riser

2.75”

12.00”

(305)

(70)

INNER

PANEL

S

5.00”

(127)

9.25”

(235)

R

D

FRONT OF

CABINET

STYLE 4

Risers Left

Side

RA

SIDE

2.88”

(73)

12.12”

Model

09-12

15-18

24-36

(308)

TOP VIEWS

B

A

17.00 [432]

19.25 [489]

24.25 [616] 24 [610]

SRD

STYLE 5

Risers Right

B

17 [432]

19 [483]

2.88”

(73)

SRD

9.25”

(235)

A

Side

RA

SIDE

1/4” to 1”

(6 to 25)

2.75”

S

R

D

(70)

STYLE

3 RA

STYLE

2 RA

STYLE

4 RA

STYLE

5 RA

STYLE

5 RA

STYLE

2 RA

STYLE

3 RA

STYLE

4 RA

Note 8

STYLE

2 RA

STYLE

5 RA

STYLE

3 RA

STYLE

4 RA

STYLE 3

Risers Back

Right

RA

SIDE

FRONT VIEW

STYLE 3

2.88”

(73)

12.00”

[305]

2.50”

(64)

2.25”

(57)

5.00”

(127)

12.12”

(308)

3.00”

(76)

35.75”

[908]

3.125” (all sizes)

(79)

39.75”

[1100]

± .50” (13)

Note 7

STYLE

STYLE 2

Risers Back

Left

4 RA

STYLE

3 RA

STYLE

2 RA

Note 8

RA

SIDE

NOTICE!

NOTICE! Not all styles will stack above

or adjacent to each other. (See Note 8).

Notes:

1. Dimensions are inches [mm].

2. Style refers to cabinet to riser confi guration.

3. Return air side is the front of the cabinet.

4. Supply riser is closest to corner.

5. Drain is not centered on all cabinets

6. Slots allow for riser stack expansion and

contraction.

7. Riser stub out is 39.75" (1100) from bottom cabinet and

is not centered in slot.

8. From fl oor to fl oor on one riser stack you can only

have; all same style, styles 2 and 5; or styles 3 and 4.

For master/slave units you can only have styles 3 or 4

adjacent to 2 or 5.

STYLE

5 RA

6

ClimateMaster Water-Source Heat Pumps

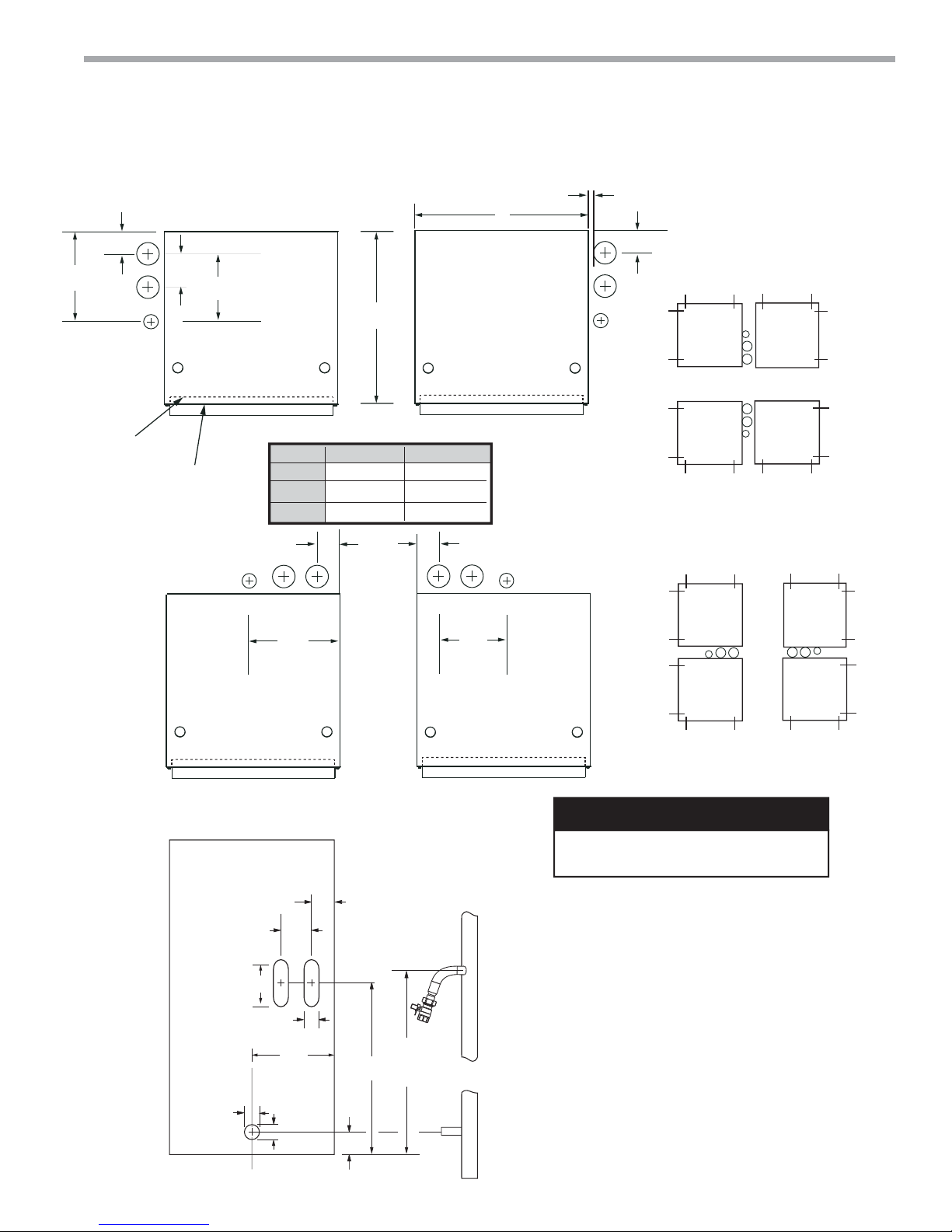

Cabinet Shown Up to Riser

2.75”

12.00”

(305)

(70)

S

5.00”

(127)

R

9.25”

(235)

D

STYLE 4

Risers Left

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

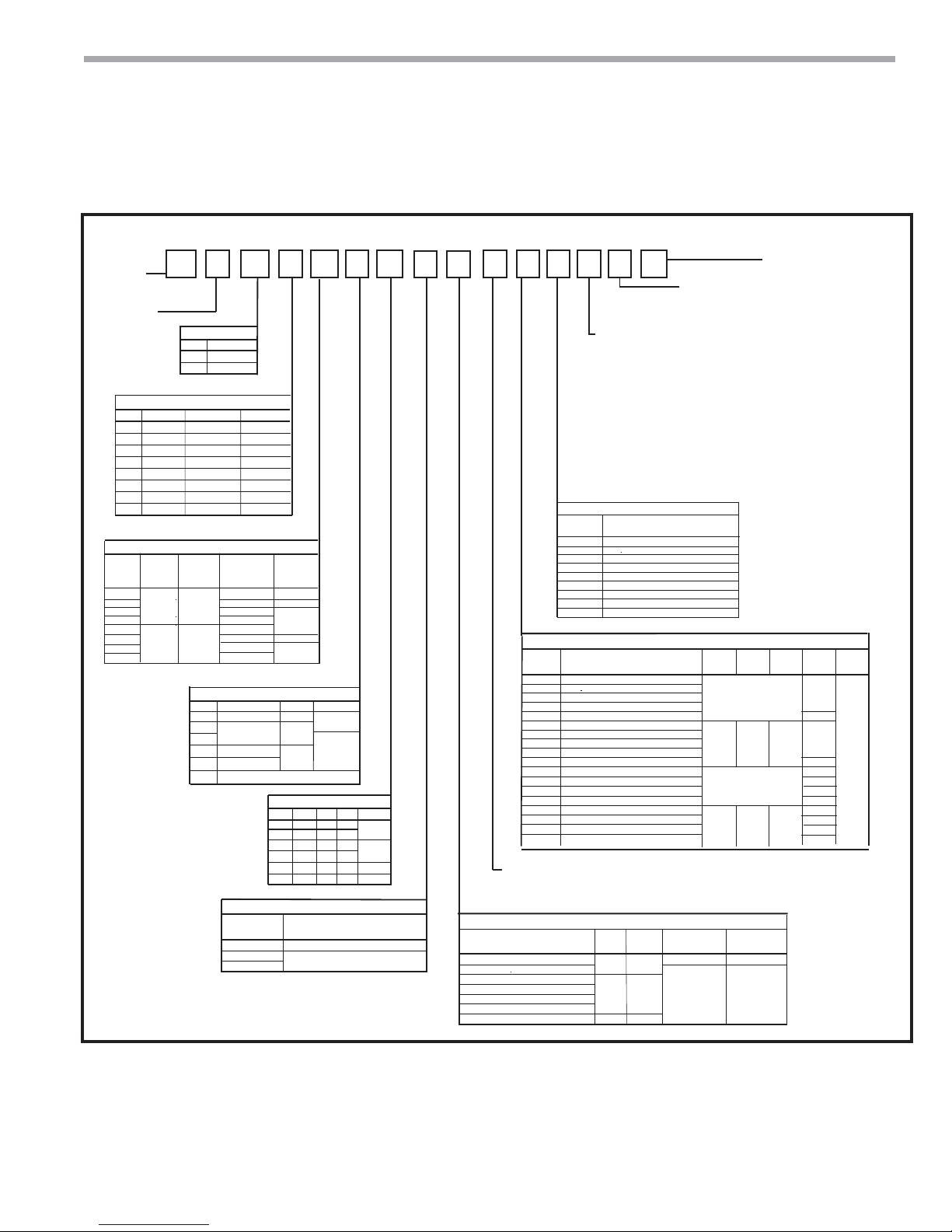

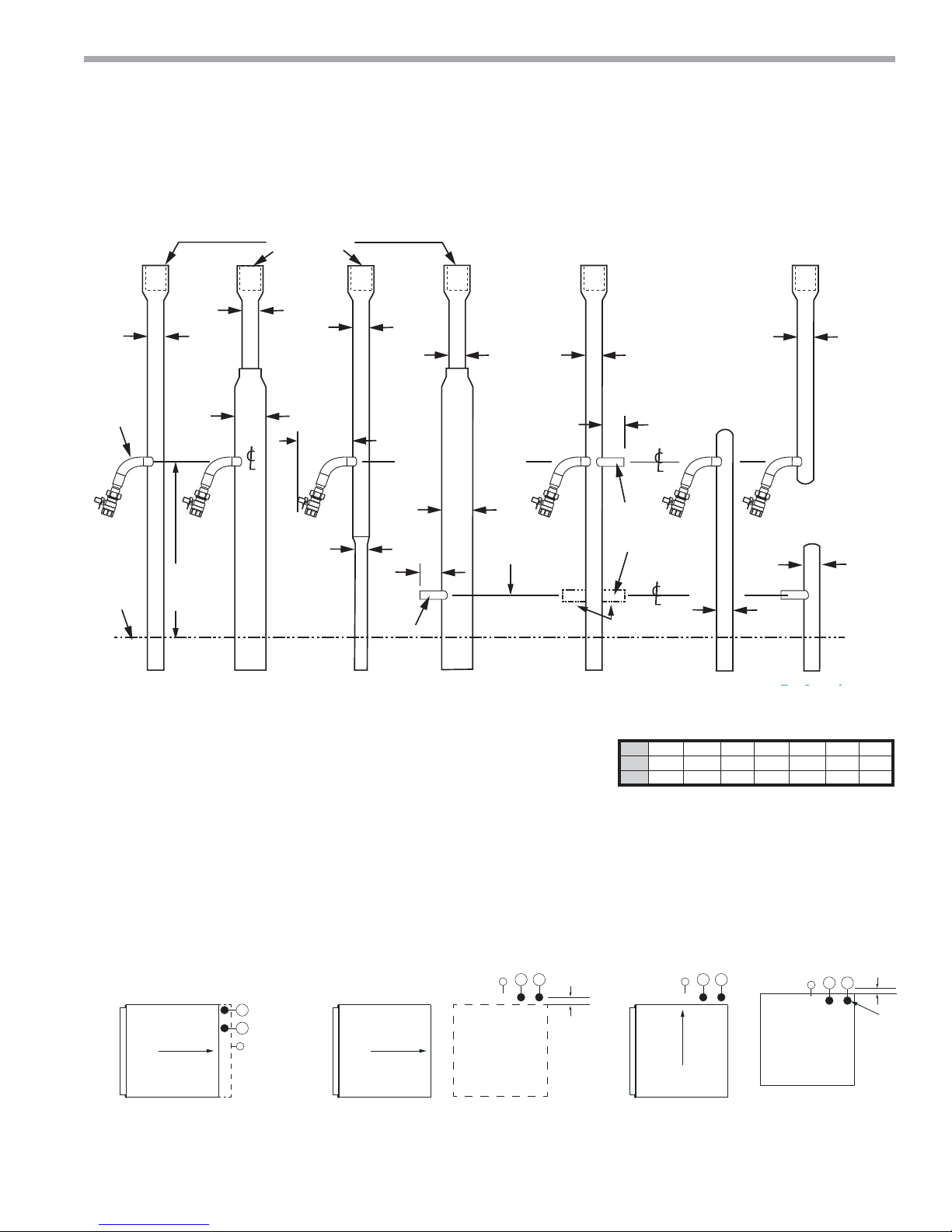

E Cabinet Slot Dimensions and Riser Arrangements

1/4” to 1”

(6 to 25)

2.75”

S

R

D

(70)

STYLE

3 RA

STYLE

4 RA

STYLE

5 RA

STYLE

2 RA

Side

TOP VIEWS

B

A

STYLE 5

Risers Right

Side

INNER

PANEL

FRONT OF

CABINET

FRONT VIEW

RA

SIDE

2.88”

(73)

STYLE 3

Risers Back

Right

RA

SIDE

STYLE 3

Model

09-12

15-18

24-36

12.12”

(308)

17.00 [432]

19.25 [489]

24.25 [616]

SRD

RA

A

B

SIDE

20.00 [508]

22.00 [559]

27.00 [686]

2.88”

(73)

SRD

9.25”

(235)

STYLE 2

Risers Back

Left

STYLE

2 RA

STYLE

5 RA

STYLE

4 RA

STYLE

5 RA

STYLE

2 RA

STYLE

3 RA

STYLE

Note 8

STYLE

3 RA

4 RA

STYLE

3 RA

STYLE

4 RA

STYLE

5 RA

STYLE

2 RA

Note 8

RA

SIDE

NOTICE!

NOTICE! Not all styles will stack above

or adjacent to each other. (See Note 8).

2.88”

(73)

5.00”

(127)

12.00”

[305]

2.50”

(64)

12.12”

(308)

2.25”

(57)

3.00”

(76)

35.75”

[908]

3.125” (all sizes)

(79)

39.75”

[1100]

± .50” (13)

Note 7

climatemaster.com

Notes:

1. Dimensions are inches [mm].

2. Style refers to cabinet to riser confi guration.

3. Return air side is the front of the cabinet.

4. Supply riser is closest to corner.

5. Drain is not centered on all cabinets.

6. Slots allow for riser stack expansion and

contraction.

7. Riser stub out is 39.75" (1100) from bottom cabinet and

is not centered in slot.

8. From fl oor to fl oor on one riser stack you can only

have; all same style, styles 2 and 5; or styles 3 and 4.

For master/slave units you can only have styles 3 or 4

adjacent to 2 or 5.

7

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

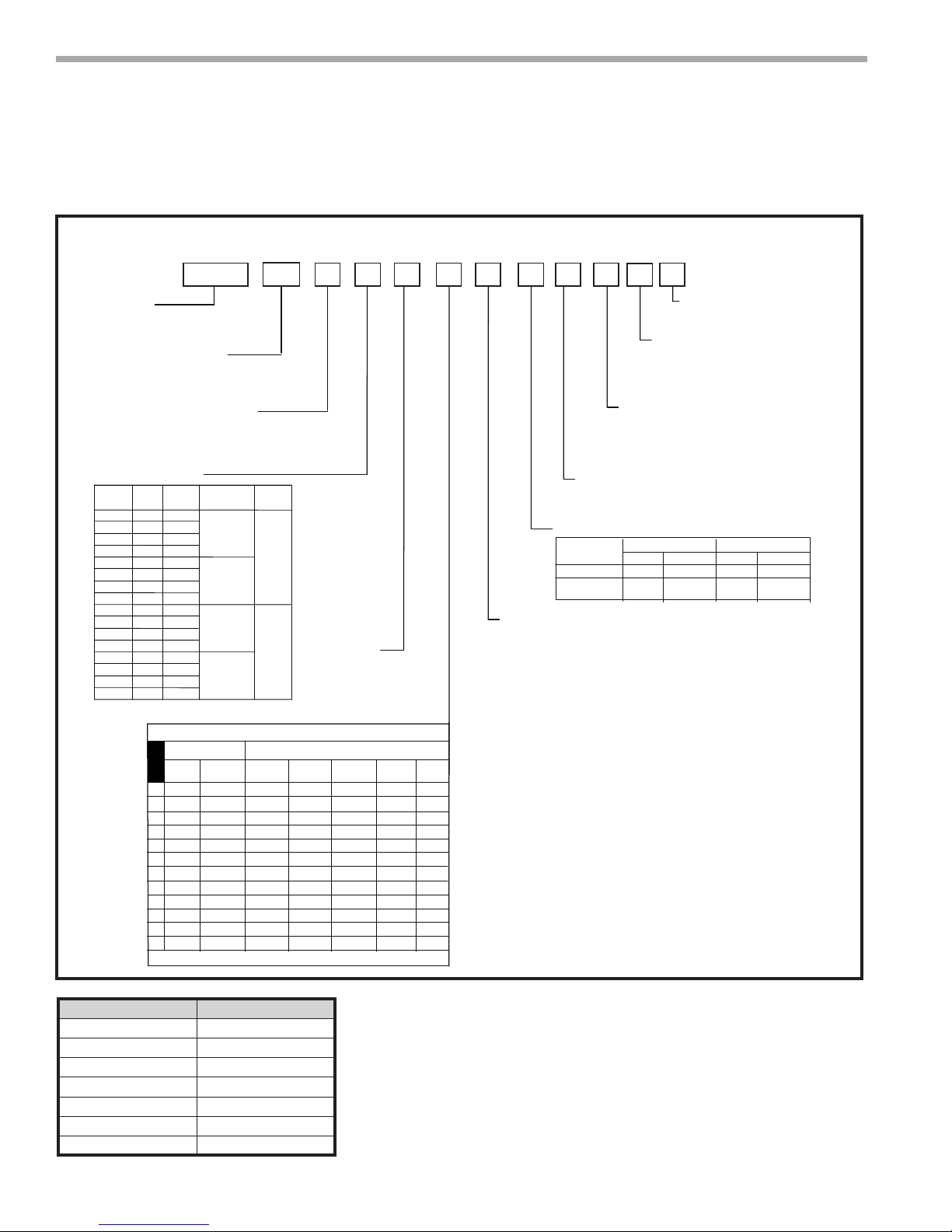

TSL Model Nomenclature - Chassis

Chassis

T S L

Series

TSL = TRANQUILITY®

HIGH RISE CHASSIS

Unit Size

09

12

15

18

24

30

36

Chassis Options

S.S.

OPTION

Drain

Ultraquiet

Pan

A

B

C

S

D

E

F

G

H

K

L

M

N

P

Q

R

NO

YES

YES

NO

YES

YES

NONO

NO

YES

YES

NO

YES

YES

NONO

NO

YES

YES

NO

YES

YES

NONO

NO

YES

YES

NO

YES

YES

NONO

AUTO-FLOW REGULAT OR (US GPM) CODE

5/8 SWEAT

UNIT

09

1.5 - - - - - -

C

D

2.0

2.5

E

3.0

F

-

G

-

H

-

J

K

--

L

----

M

----

N

-----

P

S = STANDARD - NO FLOW REGULATOR

1 2 3

Voltage

E = 265/60/1

G = 208/230/60/1

For

Communicating

T-Stat

NO

YES

NO

YES

UNIT

12

2.0

2.5

3.0

3.5

UNIT

-

-

4 5 6 7 9 10 11 12 13

09 G

RIB

RELAY

8

S S S C S

A

Shipping

6 = Chassis Will Ship In Cabinet

S = Standard

Heat Exchanger Options

NO

Position 11

Standard Tubing

Insulated Tubing

(Extended Range)

Water Valve & Pump Option

S = No Water Options

YES

Controls

A = CXM

B = DXM2

7/8 SWEAT

UNIT

18

15

-----

2.5 - - - -

3.0 - - -

3.0

3.5

3.5

4.0

4.0

-

5.0-5.0

-

-

-

-

UNIT30UNIT

UNIT

24

---

4.0

6.0

7.0

-

-

36

--

-

5.0

6.0

6.0

7.0

7.0

8.0

8.0

-

9.0

10.0

-

M = 2-Way Water Valve (Normally Closed)

N = 2-Way Water Valve (Normally Open)

P = Secondary Circulating Pump

T = Modulating Water Valve

H = Hybrid with Standard Water Valve (Normally Closed)

J = Hybrid with Standard Water Valve (Normally Open)

L = Hybrid with 3-Way Water Valve

K = Hybrid with Secondary Water Pump and 3-Way Water Valve

15

14

A

S

C

Revision Level

C = Current Revision Level

Standard

S = Standard

A = Special #1

B = Special #2

Etc.....

Blower Motor

A = PSC High Static

C = ECM Constant Torque

D = ECM Constant Volume

Tin Plated Air Coil Non-Coated Air Coil

Copper

Cupro-nickel Cupro-nickelCopper

C

DE

NL

(Risers Not Attached)

M

FG

Chassis Cabinet

09 D1/E1

12 D2/E2

15 D3/E3

18 D4/E4

24 D5/E5

30 D6/E6

36 D7/E7

8

ClimateMaster Water-Source Heat Pumps

Hose Kit

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

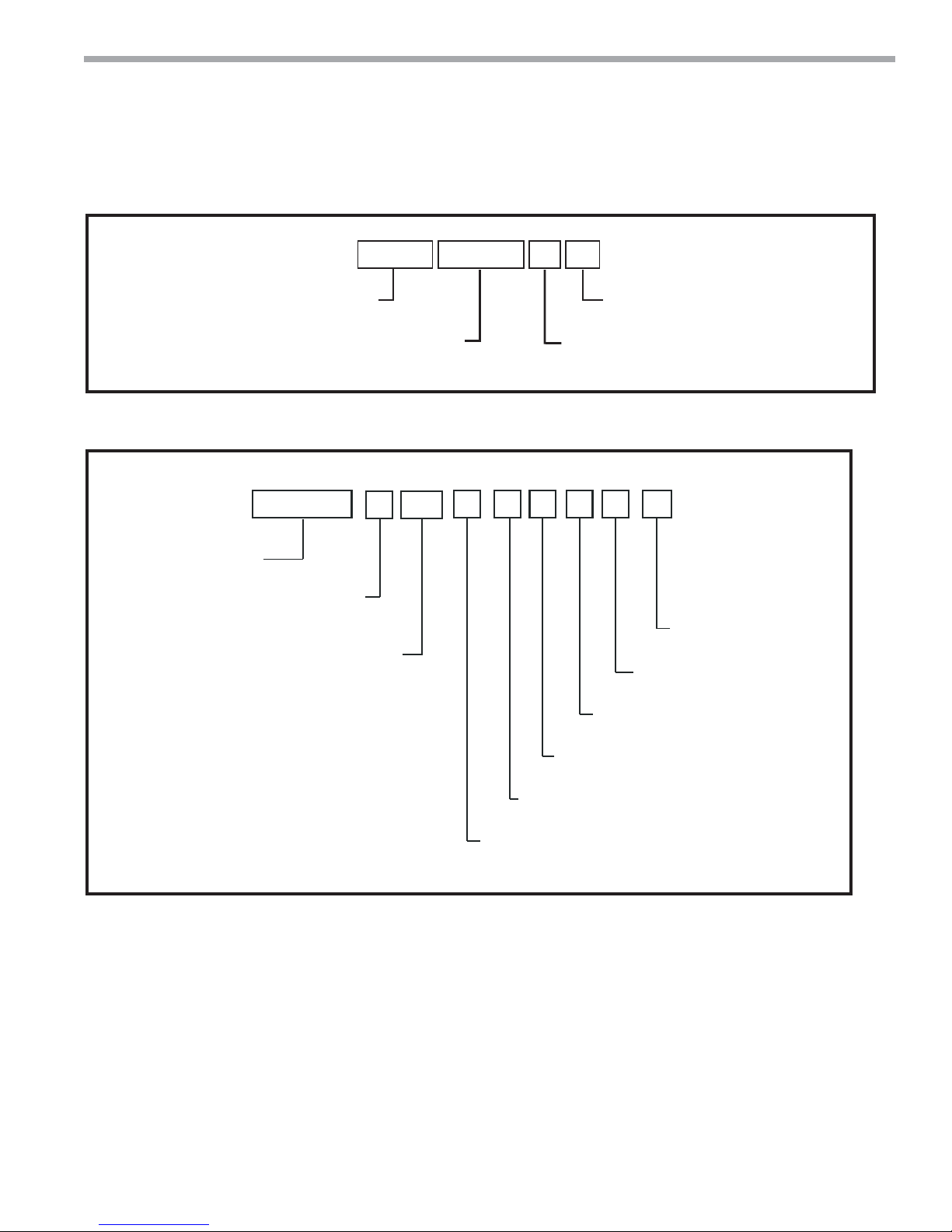

Accessory Nomenclature

1 2 3 4 5 6 8

7

0 5 0A H H B3

AHH = Accessory Hose Kit

AHU = Accessory Hose Kit

Note: If cabinet digit 10 is 4

use AHH; 5 use AHU

Group

Cabinet Stands (Ship loose in bulk)

1 2 3 4

ACST

Accessory

Cabinet Stand

TSM/TSL

CABINET SIZE

0 = 17” x 17”

1 = 19” x 19”

2 = 24” x 24”

3 = 17” x 20”

4 = 19” x 22”

5 = 24” x 27”

050 = 1/2” Nominal

075 = 3/4” Nominal

5

0

HEIGHT

01 = 1”

02 = 2”

03 = 3”

04 = 4”

05 = 5”

06 = 6”

07 = 7”

08 = 8”

09 = 9”

10 = 10”

11 = 11”

12 = 12”

13 = 13”

Hose Size

100 = 1” Nominal

7

6

01

8

0

10

9

0

0

FUTURE USE

0 = STANDARD

Revision Level

B = Current Revision

Length

3 = Length in Feet

011012B

FUTURE USE

0 = STANDARD

FUTURE USE

0 = STANDARD

13

REVISION

B = CURRENT REVISION

FUTURE USE

0 = STANDARD

ISO PAD

0 = STANDARD (NO ISO PAD)

1 = ISO PAD

climatemaster.com

9

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

Accessory Nomenclature

Return Air Panel “G”

A V H S 1 S F S S

ACCESSORY VHS

RETURN AIR PANEL

Return Air Panel “L”

1 2 3 4

TYPE

“G”

5

G

DESCRIPTION

Removable

UNIT WIDTH

WIDTH

OPTION

17”

1

19”

2

24”

3

789

6

STYLE

A = DOOR w/ADA TSTAT MOUNTING

C = DOOR w/ADA TSTAT MOUNTING & LOCK

L = DOOR w/KEY LOCKS (18 GA. SHEET METAL)

S = STANDARD (20 GA. SHEET METAL)

COLOR

S = STANDARD (POLAR ICE)

W = BRIGHT WHITE

INSULATION TYPE

F = FIBERGLASS

1 2 3 4 5

789

6

A V H R L 1 S F S 0

10

11

N

STANDARD

S = STANDARD

REVISION LEVEL

N = CURRENT REVISION TSM (”G” PANEL)

10

F

11

13

A12S

ACCESSORY VS

RETURN AIR PANEL

AVHRL = L-PANEL

UNIT WIDTH

OPTION WIDTH

1

2

3

4

TSM/TSL

17”

09 - 12,

19”

15, 18

24

24”

24”

30 - 36

COLOR

S = STANDARD (POLAR ICE)

W = BRIGHT WHITE

INSULATION TYPE

F = FIBERGLASS

COMPONENT

F = FRAME

P = PANEL

STYLE

S = STANDARD

STANDARD

S = STANDARD

REVISION LEVEL

A = CURRENT REVISION

RESERVED FOR FUTURE USE

0 = STANDARD

10

ClimateMaster Water-Source Heat Pumps

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

Pre-Installation Information

Storage -

packaging in a clean, dry area. Store chassis in an upright

position at all times. Stack units at a maximum of 2 units high.

Store cabinets how they were shipped - vertical, keeping

them on their pallets for protection. Do not stack

multipacks. Store risers in secure area. ClimateMaster will

not replace missing risers.

Unit Protection -

the original packaging or an equivalent protective

covering. Cap the open ends of pipes stored on the

job site. In areas where painting, plastering, and/or

spraying has not been completed, all due precautions

must be taken to avoid physical damage to the units and

contamination by foreign material. All openings in cabinet

must be covered during all stages of construction. Physical

damage and contamination may prevent proper start-up

and may result in costly equipment clean-up.

Examine all pipes, fi ttings, and valves before installing

any of the system components. Remove any dirt or debris

found in or on these components.

Prior to fl ushing risers with water, be sure that the

temperature in building will always be above freezing.

Pre-Installation -

Maintenance instructions are provided with each unit. The

installation site chosen should include adequate service

clearance around the unit. Before unit installation and

start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check the system

before operation.

Your installation may require additional, different

sequence, or modifi cation to steps in this IOM.

Equipment should be stored in its original

Cover units on the job site with either

Installation, Operation, and

7. A base vibration dampening pad is recommended to

help eliminate transfer of vibration to the structure.

If isolation pad was not ordered, obtain of 0.070” to

0.125” (1.5 to 3) thick pad and apply to the bottom

of the cabinet.

8. For chassis shipped inside cabinet remove and discard

4 shipping bolts.

9. Remove inner panel (8 screws) and save for

reinstallation after chassis is installed.

10. For standard cabinets remove and discard condensate

pan shipping wire ties.

Prepare chassis for installation as follows:

1. Verify refrigerant tubing is free of kinks or dents and

that it does not touch other tubes or unit parts as it

passes over or through. Adjust if needed and separate

with closed cell insulation.

2. Inspect all electrical connections. Connections must

be clean and tight at the terminals.

3. If chassis is not installed in cabinet, store in

original carton in a clean and dry location.

WARNING!

WARNING! To avoid damage from clogged coil surfaces,

clogged motor ventilation openings, seized fan blades and

potential unit failure, DO NOT OPERATE UNIT without

complete enclosure, supply grille, return air panel and fi lter in

place.

CAUTION!

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature or

humidity extremes (e.g., attics, garages, rooftops, etc.).

Corrosive conditions and high temperature or humidity can

signifi cantly reduce performance, reliability, and service life.

Always move and store units in an upright position. Tilting

units on their sides may cause equipment damage.

Prepare cabinet for installation as follows:

1. Compare the electrical data on the unit nameplate

with ordering and shipping information to verify that

the correct unit has been shipped.

2. Each cabinet has a tag to indicate the location to be

installed.

3. Keep the cabinet openings and exposed sheet

metal covered until installation is complete and all

plastering, painting, etc. is fi nished and cleaned.

4. Inspect all electrical connections. Connections must

be clean and tight at the terminals.

5. Remove correct riser knockouts, slit insulation vertical

down center (do not remove).

6. Repair any torn insulation with foil tape.

CAUTION! CUT HAZARD - Failure to follow this caution may

result in personal injury. Sheet metal parts may have sharp

edges or burrs. Use care and wear appropriate protective

clothing, safety glasses and gloves when handling parts and

servicing heat pumps.

climatemaster.com

CAUTION!

11

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

5

3

Low Voltage Exit

For Remote Thermostat

(Optional Whip Exit)

2

High Voltage Entry

4

Do not

drive screws

into this area

both sides

Service Area

Note

24”

(610)

2”

(50)

and this area

far side

TSL Vertical Stack

Rev.: 04/24/2019

Riser Installation

Figure 1: Vertical Stack Unit Components

1 Supply, Return, and Condensate Risers (not shown)

2 Cabinet

3 Cabinet Inner Panel and Filter

4 Chassis

5 Return Air Panel

6 Thermostat (Not shown)

7 Hoses (Not shown)

Note:

Matching

labels for

visual aid,

chassis, and

cabinet same

size and

voltage.

WARNING! To prevent electrical shorts and drain pan leaks,

assure that screws do not penetrate unit components when

driving screws near the unit control box or drain pan. Do not

allow screws or nails to penetrate chassis, risers, electrical

junction boxes, raceways or to interfere with chassis removal.

To avoid motor or compressor damage, keep drywall dust out

of the unit.

12

WARNING!

Core Drilling For Vertical Riser Stack

Core drilling slab slot/holes will determine cabinet place-

Install

Now

}

Install

Later

}

ClimateMaster Water-Source Heat Pumps

ment and surrounding walls. Slot/holes size, location on fl oor

and plumb alignment in two planes from top to bottom are

all very important, check plans. Size of slot/hole will depend

on slab thickness, ceiling height, riser length. See TSL submittal.

Risers -

in crates. Crates will have layers of risers by fl oors, each

cabinets 3 risers (S,R,D) will be next to each other. Lowest

fl oor will be on top layer. Risers will have tag with fl oor,

riser number (if fi lled out on EZ Order). Entire riser stacks

can be assembled, pressure tested, fl ushed, and fi lled

before setting cabinets. Use caution if fi lled risers are in

unconditioned space, prevent freezing. Do not construct

walls until cabinets are set.

Description - Supply and return risers can be straight,

transition up, transition down, bottom capped, or top

capped. Drain risers can be straight, transition up, or top

capped. All drain risers and extended range (operation

below 60 ºF entering water temperature) supply and return

risers need insulation. Repair or replace any damaged or

missing insulation.

Type M has red identifi cation marking (stripe running down

the tube) and Type L (thicker wall) has blue identifi cation

marking.

If tube is insulated pull back carefully to check color.

Shutoff and hose size for cabinet/chassis- ½” for D1 (09) and

D2 (12); ¾” for D3 (15) and D4 (18); 1” for D5 (24), D6 (30),

and D7 (36).

Supply riser is always closest to back corner of cabinet,

return riser next, and drain riser in approx. middle of the

cabinet. Risers are 9.25” (235) apart on centerline. See

Figure 5.

1. Check riser diameter, type, valve size, and position

2. Suggest each cabinet location be marked with all

3. Starting on lowest fl oor center risers in slot. Set height

4. If riser extensions are used insert them on lower fl oor

Risers are ordered loose and will be shipped

Note: Type L may be substituted for type M.

(S,R,D or D,S,R) of risers per cabinet confi guration (see

fl oor plans).

information (see fi gure 5 ).

of supply and return runouts to 39.75” (1100) and

drain runout to 3.12” (79) from bottom of cabinet.

Temporally secure risers (not by runout or valve) so they

do not move.

top of riser , mark like step 5.

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

5. Next fl oor up mark riser at bottom at 1” (25) and 2.50”

(63), drop through slot and position runouts same as

step 2. Temporally support.

6. On lower fl oor check that above riser is inserted

between 1” (25) and 2.50” (63) (between 2 marks you

made). Cut riser if needed or use extension.

CAUTION!

CAUTION! To ensure correct riser positioning and to

compensate for variations in fl oor-to-fl oor dimensions, do not

allow the unit to unit riser joint to bottom out.

7. Insert expansion devices if required by plans.

8. Continue until complete riser stack is assembled.

9. Check all risers are correct diameter , type, valve size;

correctly positioned; centered in slot; plumb from top to

bottom; depth into swedge correct; runouts at correct

height, and shutoff valve handles are parallel with the

side of cabinet. (see Figure 2)

10. Braze all joints with high temperature alloy like Phoscopper or Silfos. (DO NOT use soft solder 50-50, 60-40

or 85-15; low temperature alloys are not acceptable for

this application).

11. Must securely anchor riser stacks to building structure

at least on one fl oor. Typically at middle fl oor and

additional fl oors as needed. Example: 40 fl oors, anchor

at 10, 20, and 30. Use expansion devices between

anchors.

12. Remove temporary supports.

13. Check that risers did not drop. If stack dropped, jack up

and add additional anchor support.

14. V erify all shutof f valves are closed. DO NOT OPEN

VALVES until system has been cleaned and fl ushed.

15. Pressure check risers–locate and r epair any leaks–r etest

during installation.

NOTICE

location, brazed incorrect, modifi ed incorrect (including

cutting off or extending), runoff at incorrect height,

Supply and Return Stack

1. Install a drain valve, shut-off/balancing valves, fl ow

2. Install strainers at the inlet of each circulating pump.

3. Insulate loop water piping which runs through

4. Cabinet slots and riser stack assemblies are designed

5. Installer must remove riser knockouts (2). Replace and

Condensate Stack - All TSL cabinets - installer must

remove drain knockout and connect drain pan to riser

Installer must clip and remove 2 drain pan shipping ties,

lift drain pan, cut drain hose to length, connect to drain

pan and riser, and clamp both ends. For slave cabinets

- suggest extending drain stub into cabinet so clamp is

accessable.

If local codes allow-PVC drain risers may be used. All

couplings and reducers are to be fi eld supplied.

: Any risers misplaced, assembled in wrong

indicators and drain tees at the base of each supply and

return riser stack to enable system fl ushing at start-up,

balancing and during servicing.

nonconditioned areas or outside the building. For

boiler tower applications loop temperature is normally

between 60°F and 90°F, piping does not sweat or suffer

heat loss under ambient conditions. For geothermal

applications insulate all loop water piping.

to accommodate a maximum of 1-½”(38) expansion

and 1-½”(38) contraction. If the calculated riser stack

expansion or contraction exceeds 1-½”(38), expansion

devices must be provided.

seal any KO’s removed by mistake.

.

Secure Riser Stack to building structure so stack does not

drop over time. Cabinet slots allow for 1.50” (38mm) maximum expansion and 1.50” (38mm) maximum contraction,

use expansion devices if you exceed these values.

To facilitate cleaning and fl ushing, install the hose kit at

the end farthest from the pump and connect the ends

of the hoses with the riser fl ush adapter (Kit - AFL5751).

Then open both valves before pumping fresh water

through the system, close the valves when the system

is clean. Remove the fl ush adapter before installing the

chassis.

Note: Refer to System Flushing Section of this manual

for more information.

Install air vents in piping loop at highest accessible point

as required to bleed the system of air accumulated

Misalignment found anytime including when cabinets are

set, not using expansion devices if specifi ed, or stack was

not supported correctly is the sole responsibility of the

installing contractor.

climatemaster.com

13

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

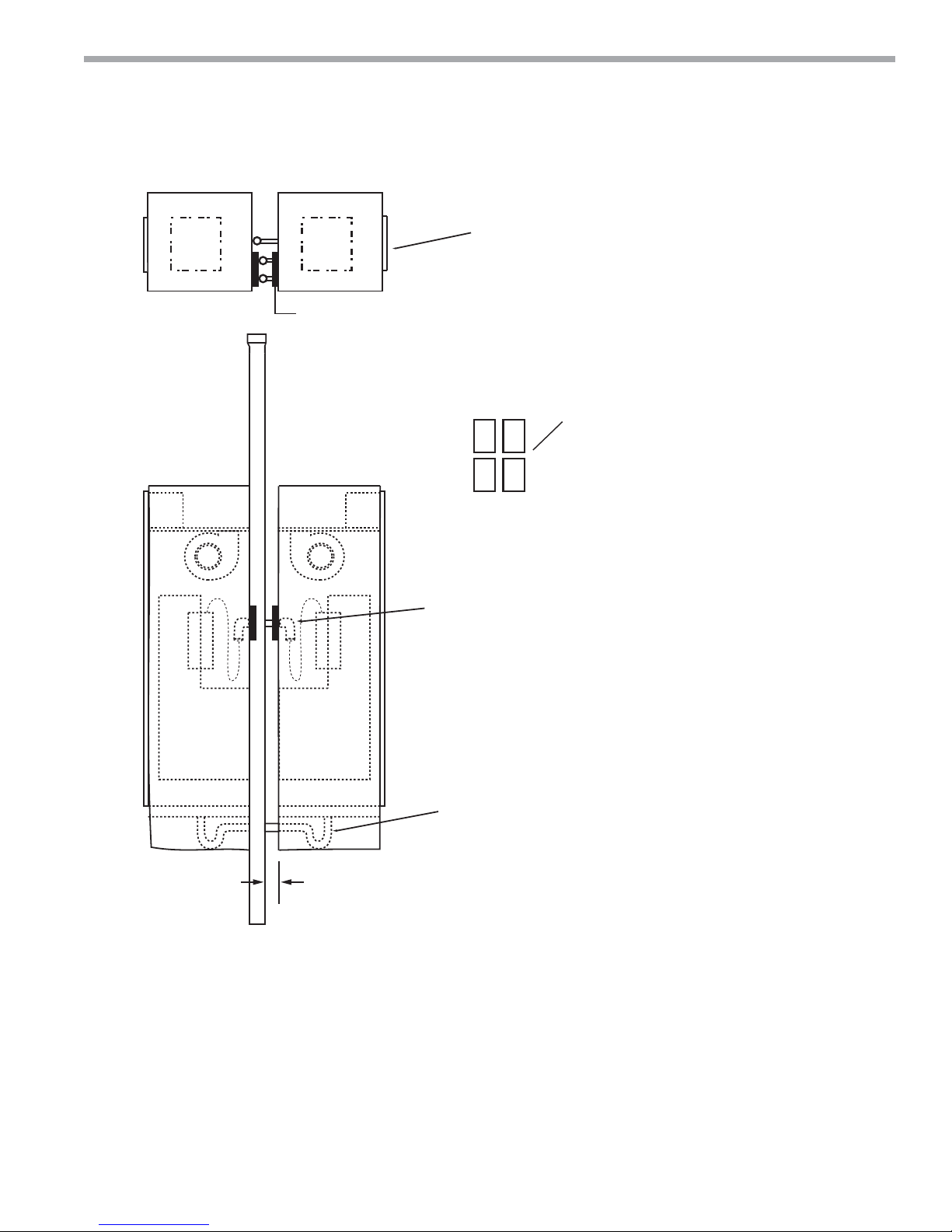

Figure 2: Riser Placement Figure 3: Riser Setting Detail

Shuto

Handle

RA

Side

DR S

Style 3

Only

RA Side

DR S

Style 4

Only

DR S

9.25

(235)

5.00

90°

±3°

2.75

(70)

Note: Cabinet Model Digit 9 Indicates Style

SRD

Style 2

Only

RA Side

SSRSR D

Style 5

Only

1/4” to 1” GAP

(6 to 25mm)

RA

Side

Cabinet Size Valve FPT

D1, D2 09, 12 1/2“ (13)

D3, D4 15, 18 3/4” (19)

D5, D6, D7 24, 30, 36 1” (25)

Runout

Shuto

Valve

Bottom of

Cabinet

Supply and Return Drain

39.75 (1100)

± .50 (13)

Always

Insulated

3.12 (79)

± .12 (3)

Not Acceptable

Figure 4: Riser or Extension Insertion

1.00 Min (25)

2.50 Max (63)

14

Figure 5: Suggested Floor Markings

(Change data for your unit)

(

/

¹

¹

(S) (R) (D)

Model (

Size (12)

Style (5)

Tag (_)

Riser Number (_)

ClimateMaster Water-Source Heat Pumps

)(

Slot

Riser DIA

/

)(

/

)

¹

¹

¹

¹

Top/Bottom

DIA Placement

/

¹

²

Valve Size

D2)

(

(

RA

Side

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Figure 6: Riser Identifi cation

Propress Riser

is straight (no swage)

Standard Riser

Swaged 3” Deep

For A Dia. Riser

From Above

A Dia.

Shutoff

Valve

Assembly

Runout

Into

Cabinet

Bottom of

Cabinet

Runout

Into

Cabinet

39.75

(1100)

± .50ß (13)

(Note 10)

A Dia.

B Dia.

Runout

Into

Cabinet

6.00

(152)

MAX

A Dia.

C Dia.

3.00

(76)

Drain Runout

Into Cabinet

A Dia. A Dia.

B Dia.

3.12 (79)

± .50ß (13)

(Note 10)

Runout

Into

Cabinet

Runout

for Slave

Cabinet

(Note 8)

Drain Only

3.00

(76)

Runout

Into

Cabinet

Vertical Stack

Rev.: 04/24/2019

A

Bottom Capped

Supply and Return

A

A

Notes:

1. Y ou must know water fl ow direction to determine if cabinet requires

transition up or down.

2. T ransitions can only change by one diameter (1" to 1¼", 1¼" to 1½", etc.)

3. Riser transition couplings and runouts are factory brazed.

4. All risers are factory pressure tested.

5. Standard riser diameters are 1", 1¼", 1½", 2", 2½" and 3"nominal water tubing.

6. Copper Type M and L available.

7. Drain riser insulated standard. Supply and return insulated optional.

8. Master riser - contractor provides tubing from runout to slave cabinet if needed

and brazes shutoff for slave.

9. Shutoff and hose size 1/2” for C1(09), C2(12); 3/4” for C3(15), C4(18); or 1” for

C5(24), C6(30), C7(36).

10. Position runout perpendicular to side of cabinet.

When cabinets are pushed up to risers allow suent clearance.

Shutos should be inside cabinet.

Push Push

Step 1

Risers Opposite

Return Air Opening

Risers Adjacent to

Return Air Opening

A 1.00 1.25 1.50 2.00 2.50 3.00 4.00

B 1.25 1.50 2.00 2.50 3.00 - -

C - 1.00 1.25 1.50 2.00 2.50 -

Note - All ClimateMaster units with

optional motorized valve have water

high pressure switches. Do not design

riser stack where switch will not reset.

(Trip - 300 PSI; Reset - 250 PSI)

Approx.

6”

(152)

Push

Step 2Step 1

Final

Cabinet Postion

1/4” to 1”

(6 to 25)

Shutos

Inside

climatemaster.com

15

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

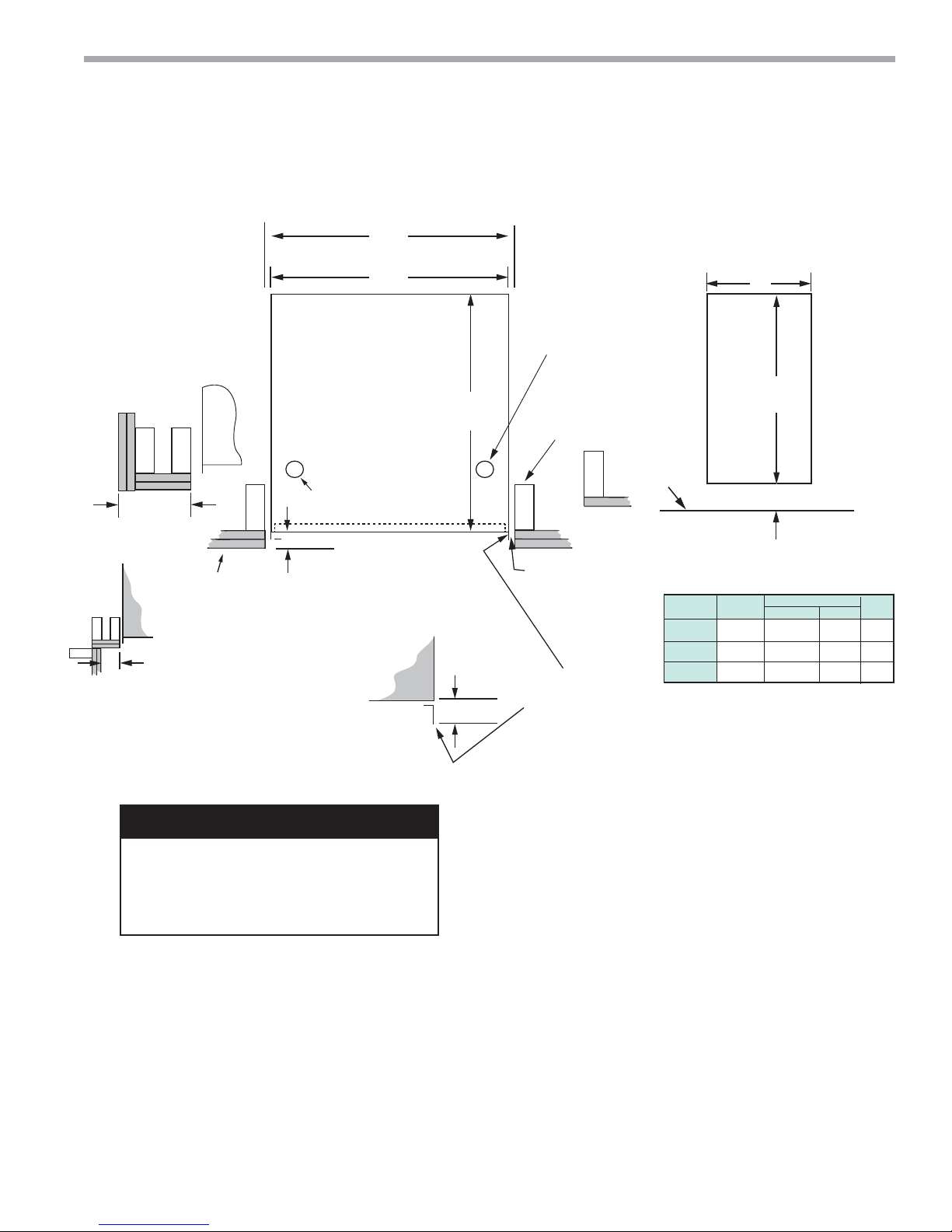

Cabinet Installation

Cabinet Installation

1. Check plans that cabinet is correct for location,

cabinet will have tag and data plate with information,

including unit size, diameters of risers, and electrical

data.

2. Remove riser KO’s (3) for your cabinet confi guration

(see fi gure 2).

3. Cover supply and return openings with 4 pads. Slit

with knife (see fi gure 7).

4. Slide cabinet up to riser allow 1/4” to 1” (6 to 25mm)

clearance.

5. Attach the cabinet assembly to the fl oor on at least two

sides using sheet metal angles. Additional anchorage

may be provided by installing brackets at the top of the

cabinet.

a. Anchor built-in risers to the building structure

with at least one contact point. To accommodate

vertical expansion and contraction DO NOT fasten

risers rigidly within the unit.

b. Verify that unit shut-off valves are closed. DO NOT

OPEN VALVES until the system has been cleaned

and fl ushed.

6.

For cabinets with chassis inside - remove 4 shipping

screws, discard.

7. Remove inner panel (8 screws), save both.

8.

Remove condensate pan shipping wire ties.

9. P-Trap Hose must be connected, lift drain pan, and

clamp to riser stub and pan. If condensate hose must

be rotated, loosen clamp on pan, rotate, and reclamp.

Check condensate drain - clean pan if needed. Slowly

pour 1 to 2 quarts (1 to 2 liters) of water into pan.

Water should drain freely. Check for water in cabinet

and on fl oor. Repair if needed, Retest.

10.

Sheet metal ductwork should not be attached to

the cabinet. A canvas-type fl exible connection is

recommended between the cabinet and the ductwork.

11. Optional Electric Heater – Single point power to unit.

Note: Steps 6-10 do after drywall installation.

Figure 7

Slit

Through

Cover S/R Openings

with 4 Pads

NOTICE! ClimateMaster is not responsible for drywall repair

if 2 x 4 box was not in correct orientation.

Optional Frame for G Return Air Panel -

cabinet) Position studs in front of cabinet and install frame

in opening. Seal the gap between the cabinet and the

frame. If fresh air motorized damper assembly is used,

fi eld fabricate and install duct from outside to frame

opening. Assembly is installed later. See instructions with

assembly. NOTICE! Allow for drywall thickness under

frame front fl ange. Must use damper motor assembly if

fresh air is needed.

Optional Field Supplied Return Air Duct Installation

-

When return air is required to enter the unit through

openings in a stud wall, supply and fi eld install an optional

duct. Seal duct against the return air opening with foam.

Ensure that all air entering the unit passes through the

fi lter and refrigerant-to-air coil. Note: Chassis must be

removable for service.

Drywall Installation

For best sound attenuation, it is recommended not to

attach drywall to cabinet. Install studs and drywall using

conventional construction methods. Secure drywall to

studs with low profi le, pan-head sheet metal screws.

Drywall can be attached directly to cabinet (except in

places indicated in Fig 1), front of cabinet requires double

thickness. Must not be fastened to drain pan edges or

control box enclosure. Do not attach studs to cabinet. Do

not install drywall using adhesive alone.

See typical construction fi gures to determine stud layouts

and dimension from cabinet to fi nished wall.

Vacuum all drywall dust and construction debris from

cabinet insulation, drain pans and blower discharge

plenum after cutting out supply. Insulation should be

placed between the drywall and the cabinet for sound

attenuation.

When drywall installation is complete, cover all cabinet

openings and exposed sheet metal. (Cardboard from unit

shipping cartons can be used). Do not allow paint or wall

texture over-spray to contact insulation, sheet metal, coil,

fan or other unit components. Warranties are void if paint

or other foreign debris is allowed to contaminate internal

unit components.

NOTICE!

(See recessed

Cabinet Side

16

ClimateMaster Water-Source Heat Pumps

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

Master/Slave Cabinet Installation

RA

R

R

RS

S

(Note 4)

S

RA

Field connect

hoses in both cabinets-

supply to supply and return to return.

(Cabinet supply is closest to corner,

chassis supply is on left facing air coil)

Slave Cabinet

Riser Pads (4)

Note 4

Field braze valve package

slave side (shut off with tubing).

(Note 5) Shuttoff handle to be

inside cabinet.

2” (50) Minimum

extend copper stubs

for S/R/C if over 3” (75)

Master Slave

Field install P-Trap and clamp

both ends. Suggest hard drain

connection be extended into

cabinet so clamp is always

accessable.

Notes:

1. Contractor must meet all fi re code requirements.

2. Size riser diameter for both units GPM.

3. Master/Slave means both units share common riser.

4. Install pads on back of slave cabinet to cover slots used for S/R risers.

climatemaster.com

17

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

TSL Vertical Stack

Rev.: 04/24/2019

Typical Cabinet with L Return Flush Mounted Air Panel Installation

NOTICE!

Frame is attached to studs. Panel is

removable for chassis access.

24

AVHRL

Digit 6

1 22.1 2.0 19.5 55.8

2 24.1 2.0 21.5 55.8

3 29.6 2.0 26.5 55.9

4 29.6 2.0 26.5 55.9

DEFG

C

Unit

09,12

15,18

30,36

Frame Installation

Cabinet

.75

D

E

58.50

Fixed

Frame

G

.50

30 and 36 will have

stamped louvers.

F

Removable

Inner Panel

Unit A B C

09,12

15,18

24,30,36

22.3 58.6 2.5

24.3 58.6 2.5

29.7 58.6 2.7

1/8

Continuous

Bottom

Track

Steel

Stud

3

1/2

Drywall

web

Corner Bead

Shim

Screw

Frame

Caulk Gap

Note 5

(if needed)

Foam

Top View

Cabinet

Return Air Panel

4” TYP 8”

Note 7

1. Dimensions are in inches .

2. Frame and panel painted bright white.

3. Panel is removavable for fi lter replacement or chassis removal.

4. Frame ships with cabinet—must be installed while framing.

5. Set bottom track 1/8" in front of cabinet.

6. Drywall mud is added to the corner bead to produce a smooth fi nished surface.

7. Unobstructed area for required air fl ow.

A

(RO)

Front View

Cabinet

B

(RO = Rough Opening)

6”

From bottom of cabinet

18

ClimateMaster Water-Source Heat Pumps

Figure 8

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

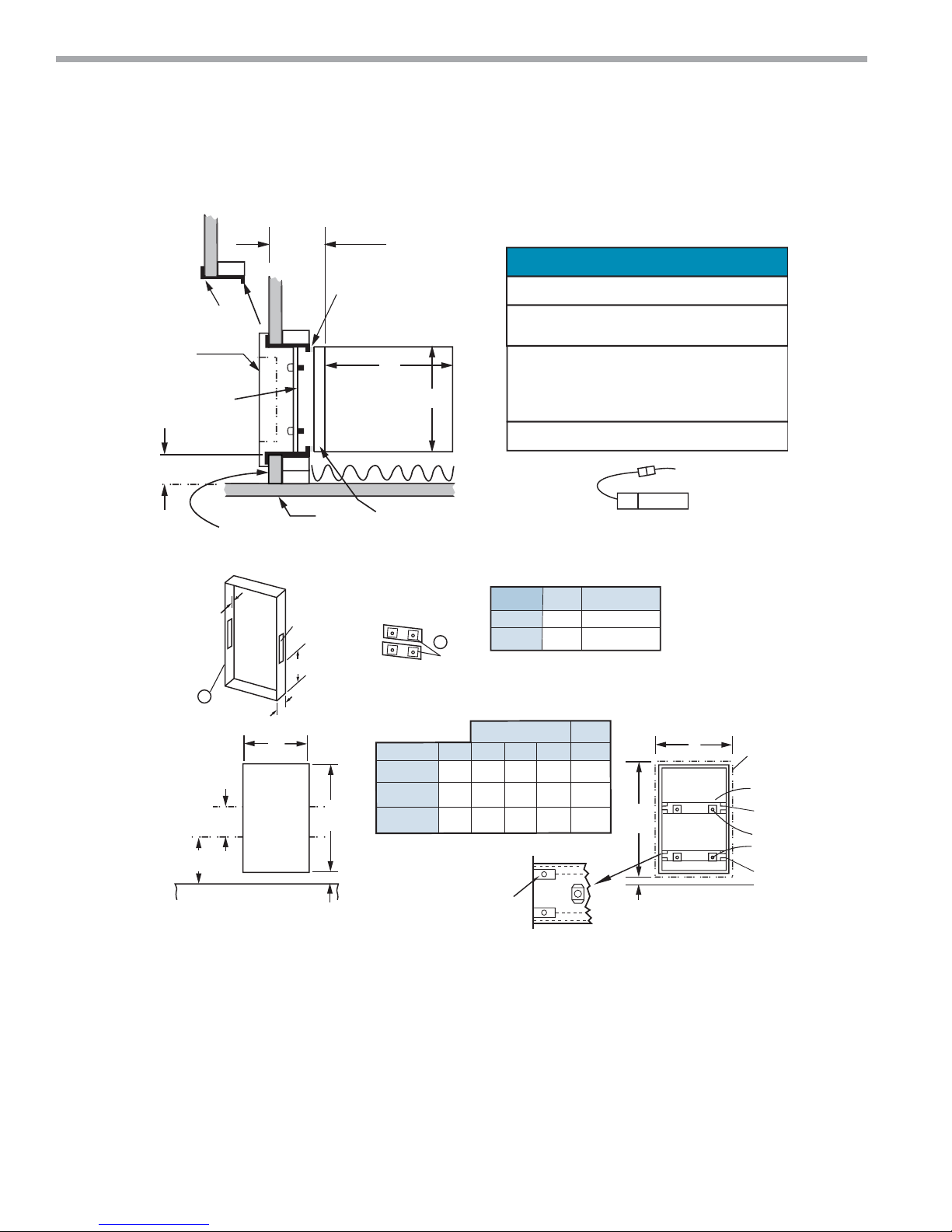

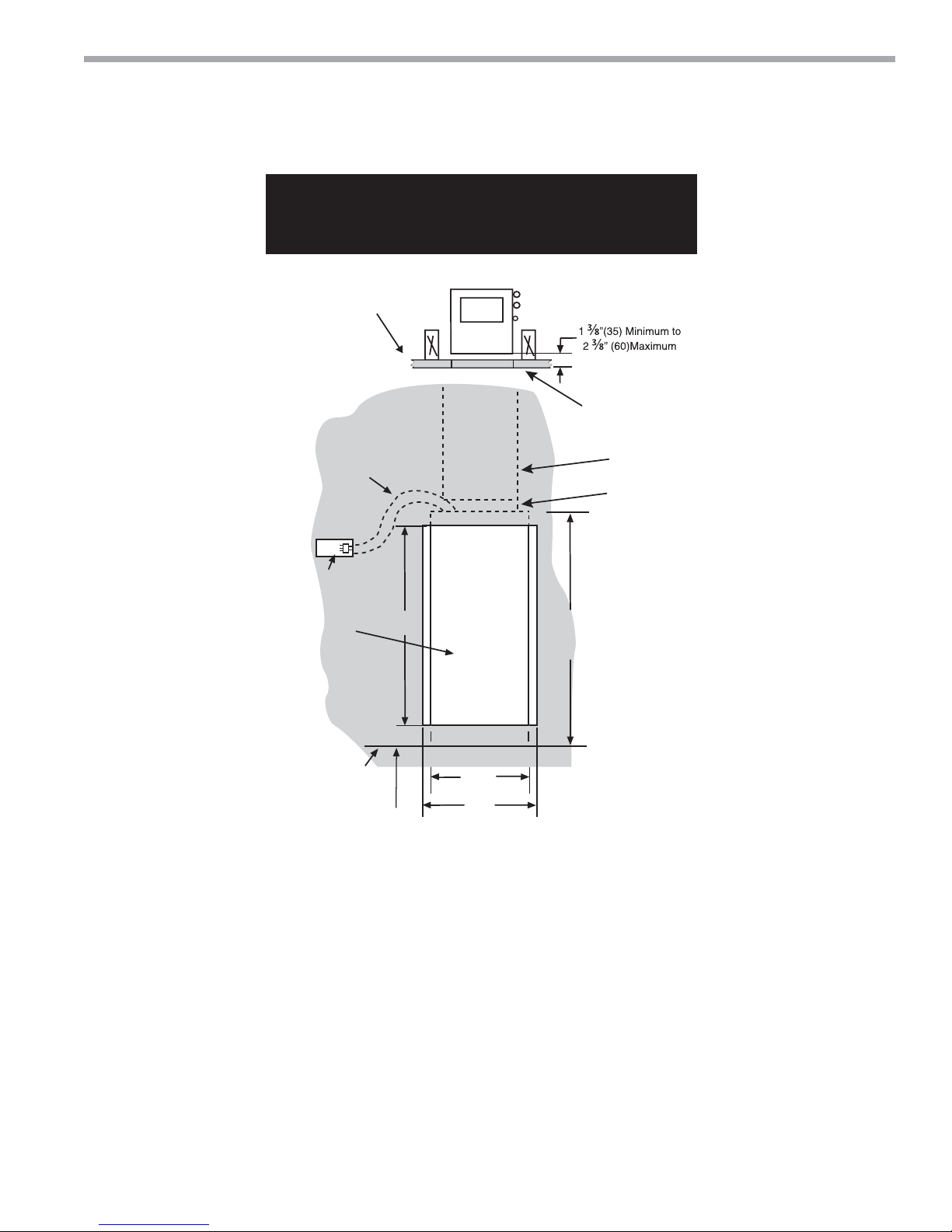

Typical Cabinet with G Return Air Panel Installation

C

R.O.

A

C

X X

Note 4

OUTSIDE

CORNER

X

X

X

Note

4

INSIDE

CORNER

X

5/8” (16) drywall 1

or 2 layers. Position

studs accordingly.

TSL CABINET

REMOTE

MOUNTED

THERMOSTAT

TOP VIEW

Low Voltage Conduit

1-3/8” (35) min - Note 7

to 2 3/8” (60) max from cabinet

to front of finished wall

1.25 (32)

High Voltage

FRONT

VIEW

57 1/2

B

2 x 4

nominal

studs

X

seal gap

(4) sides

Cabinet Flange

(4) sides

1 Layer

X

Floor

Model

09-12

15-18

24-36

(1460)

5 7/8

(149)

Note 6

Drywall Opening

A

17

[432]17[432]20[508]

19.25

[489]

24.25

[610]

B

Heat Pump Hybrid

19

[483]

24

[610]

22

[559]

27

[686]

C

17.25

[438]

19.5

[495]

24.5

[622]

NOTICE!

Seal between studs and cabinet fl anges

with weather tight foam material to

prevent wall cavity air from infi ltrating unit

or room.

1. All dimensions are in inches (mm).

2. Cabinet confi guration will determine slab core

3. Recommend stud walls surrounding cabinet.

4. Return air panel (not shown) overlaps rough

5. Installer supplied top duct should connect with

6. If cabinet stand or ISO pad is used add to

7. For 2"(50) fi lter set cabinet 2"(50) minimum

climatemaster.com

drilling location and walls surrounding cabinet.

Drywall and studs should not be attached or

contacting cabinet for best sound attenuation.

Where possible fi ll gaps with sound absorbing

material. Use iso pad under cabinet. Secure

cabinet to fl oor in two places at back.

opening, allow minimum of 3 1/2" (89) dry wall

to corner. Do not caulk G panel to wall.

fl ex boot.

dimension.

from front of drywall.

19

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

e

l

a

P

r

m

-

t

(

TSL Vertical Stack

Rev.: 04/24/2019

Typical Cabinet with G Panel Installation - Flush Air Frame

6.00

(152)

Note 8, 9

X

Seal Gap (4) Sides

B

CABINET

TOP VIEW

ѥ NOTICE! ѥ

Recessed cabinet requires frame kit.

Outside air requires motorized damper

or pre-treated air Above 45°F (7°C).

between the frame and cabinet with

Seal

weather seal material to avoid air being pulled

A

in from the wall cavity.Attach frame to studs

not cabinet.

Do not distort frame shim sides if required.

Frame

Outside

Drywall

G Style

Return Air Panel

Frame

Crossbars

(Note 4)

X

3-1/2

(89)

It is recommended to leave 2” (51) minimum clearance

on both sides for removing panel

1

“G” Frame

12-1/4

(311)

28-5/8

(727)

Floor

* Dimension if cabinet is on floor.

Add if cabinet is on stand/pad.

Notes

1. Cabinet conƂguration will determine slab coredrilling location and walls surrounding cabinet.

.38

(10)

R.O.

FRONT VIEW

XX

DRYWALL

5/8"

(16)

9.00 x 2.00 KO (228 x 51)

Outside air opening,

left or right side

to suit installation.

24.12

(612)

(120)

4.75

C

57-1/2

(1460) R.O.

5-7/8*

(149)

Cabinet

Flange

1.25 (32)

Kit Size

48A0100N

48A0100N51

48A0100N52

2

Cross bars

09-12

15-18

24-36

Kit Part

Frame Kit

17.00

(432)

19.25

(489)

24.25

(616)

Note 5

2

BA

17.00

(432)

19

(483)

24

(610)

Optional Damper Motor

(Order seperately) 48A0100N04 may be

installed on left or right side. Note 7

short wire harness to be installed in electric box,

remove ko in box cover, snap in molex.

Description

Qty

1

2

Frame1

Cross Bar

Panel

C

(400)

(498)

(620)

D

18.50

(470)

21.50

(546)

25.50

(648)

59

(1599)

4.50

* (114)

16-5/8

19-5/8

24-3/8

D

Front View

Frame Installed

G Panel

Perimet

Crossb

Third Pai

Tabs fro

4 Pane

Mounting

Nuts (1/4

Lowest

of Tabs

2. Recommend stud walls surrounding cabinet. Drywall and studs should not be attached or contacting cabinet for best

sound attenuation. Where possible Ƃll gaps with sound absorbing material. Use iso pad under cabinet. Secure cabinet

ƃoor in two places atback.

3. Return air panel overlaps rough opening, allow minimum of 3 1/2" (89) dry wall to corner. Do not caulk panel to wall.

4. G Panel attaches to frame cross bars. Cabinet must be recessed behind wall.

5. Bend out 4 tabs per side on frame. Position cross bars behind ears, attach with 8 screws.

6. For Ƃlter access, pivot inner panel, open Ƃlter access snap. For chassis removal, remove G Panel, remove 2 cross bars,

remove Ƃlter panel, slideout chassis.

7. When untreated outside air is required, 48A0100N04 motorized damper must be used, mixed air temperature

must be no lower than 45°F (7°C), no higher than 95 DB/75 WB, and not exceed 20% of total CFM. Contractor

must supply air duct, cut hole in stud, remove K.O., assemble and wire damper assembly.

Note: Use extreme weather temperatures.

8. For 2" wlter set cabinet 6.25"

158) from front of drywall.

20

ClimateMaster Water-Source Heat Pumps

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Vertical Stack

Rev.: 04/24/2019

NOTICE - Drywall openings shown below are for specifi c

cabinets as indicated. Cut openings for your cabinet

and thermostat.

One or two layers

of drywall. Set

studs accordingly.

Finished Wall

(Notes 1 and 3)

Note 2

Opening for

“G” Panel

15' Whip

Slab

5⁄”

(622)

57½”

(1461)

24.25”

(616)

24

½”

(622)

Cabinet

Figure 10

Supply Air

Ductwork

(Customer Supplied)

Canvas Type

Flex Boot

(Customer

Supplied)

65”

(1650)

Cabinet

for D5G0RAE115E010C and G Return Air Panel

Notes:

1. Optional factory-installed whips (Model Digit 13) end with 9 pin molex connector.

2. Field-supplied 2x4 Box must be a type that the side can be removed so molex can be put inside. Position box

horizontal or vertical for thermostat.

3. Optional 15, 25, or 35 foot whips (thermostat cable Class 2) available. Whips in BX armor available as special.

4. 1” to 12”(25 to 305) stands available, stands are bulk shipped and must be fi eld installed.

5. When stands are used, make sure riser length and position is calculated correctly. Stand pads raises everything up.

6. For 2” fi lter, set cabinet 2” (50) minimum from front of drywall.

Drywall Openings

climatemaster.com

21

Loading...

Loading...