ClimateMaster CCE07 Series, CCE12 Series, CCE15 Series, CCE19 Series, TRC09 Series Installation, Operation & Maintenance Instructions Manual

...

Console (CCE) Series

Tranquility Console

(TRC) Series

Commercial Console

Water-Source Heat Pumps

50Hz & 60Hz

Installation, Operation &

Maintenance Instructions

97B0035N01

Revision: 5 Nov., 2009B

Table of Contents

Model Nomenclature 3-4

General Information 5

Storage 6

Pre-Installation 6

Physical Data 7-9

Installation 10

Condensate Piping 11

Piping Connection 12-14

Piping Installation 15

Water-Loop Heat Pump Applications 16

Ground-Loop Heat Pump Applications 17

Ground-Water Heat Pump Applications 18

Water Quality Standards 20

Electrical Wiring - Line Voltage 21-23

Electrical Wiring - Low Voltage 24

Thermostat Wiring 25

Electrical Wiring Diagram Matrix 26

Electrical Wiring Schematics 27-31

CXM/DXM Controls 32-34

CXM/DXM Safety Control Reset 35-36

Unit Commissioning

and Operating Conditions 37

Piping System Cleaning and Flushing 38

Unit and System Checkout Procedure 39

Unit Start-Up 40

Unit Operating Conditions 41

Preventive Maintenance 43

Functional & Performance Troubleshooting 44-45

Refrigerant Circuit Diagram 46

Warranties 47-48

Revision History 50

Model Type

CCE = Console

THE SMART SOLUTION FOR ENERGY EFFICIENCY

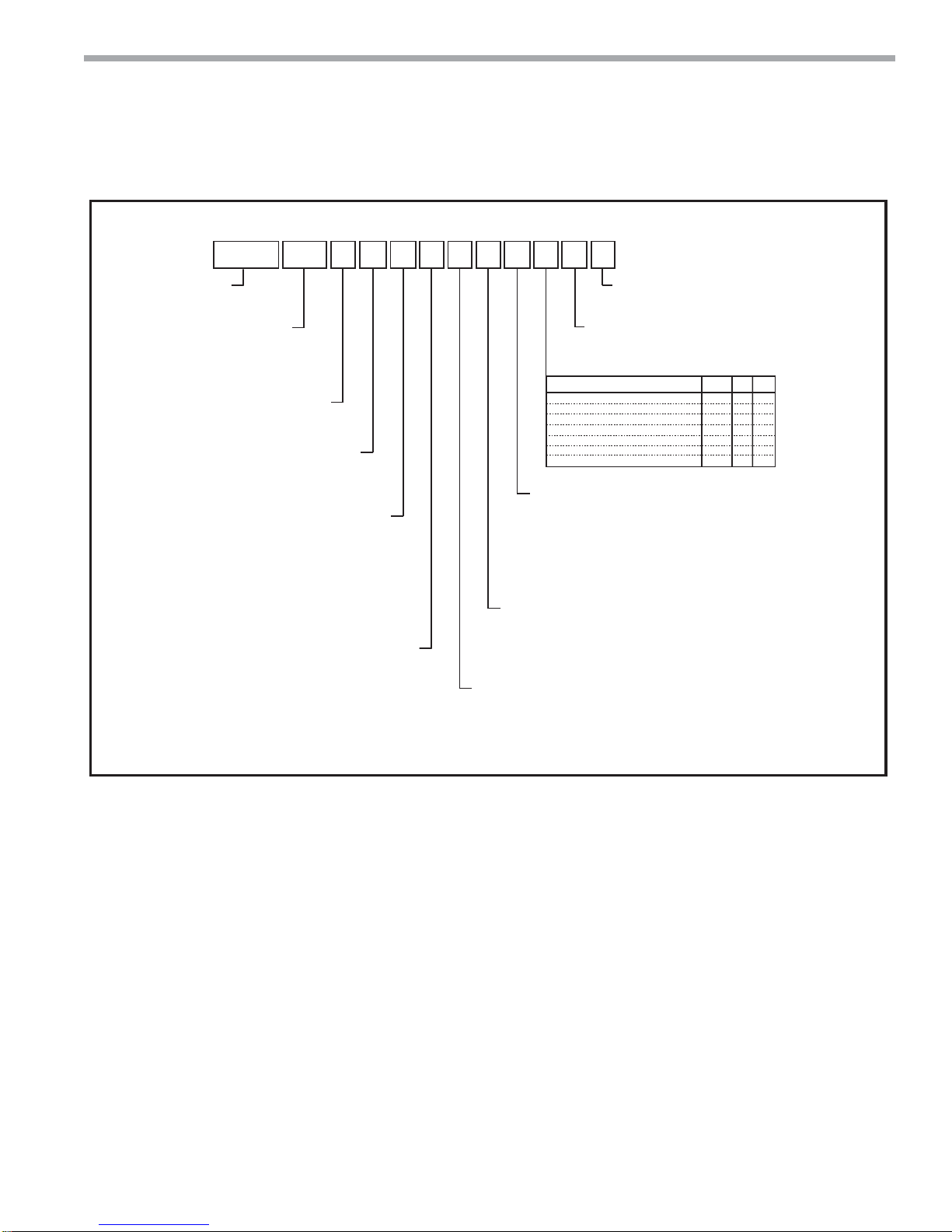

Model Nomenclature: Console (CCE) Series

94 5 6

1 2 3

8 101112131415

7

C C E AB0 7 CG S S C S R S

Standard

S = Standard

Consoles

Rev.: 5 Nov., 2009B

Unit Size

07

09

12

15

19

Revision Level

C = Current

Voltage

A = 115/60/1

E = 265/60/1

G = 208-230/60/1

A = MCO Unit Mounted Tstat w/CXM

B = MCO Unit Mounted Tstat w/DXM

C = ACO Unit Mounted Tstat w/CXM

D = ACO Unit Mounted Tstat w/DXM

R = Remote Mounted Tstat w/CXM

S = Remote Mounted Tstat w/DXM

L = Remote Mounted w/CXM & LON

M = Remote Mounted w/DXM & LON

N = Remote Mounted w/CXM & MPC

P = Remote Mounted w/DXM & MPC

A = Field Connected (Hard Wire)

D = Disconnect Switch & 15Amp Fuse

F = Disconnect Switch (Non Fused)

H = 20Amp Plug, Cord, Receptacle,

Disconnect Switch & 15Amp Fuse

K = 20Amp Plug, Cord, Receptacle &

Disconnect Switch (Non Fused)

Controls

Power Termination

B = 20Amp Plug & Cord

Piping Connections

R = Right Piping

L = Left Piping

Water Circuit Options

None S F M

Motorized Water Valve A G N

Autoflow (2.25 Gpm/Ton) B H P

Autoflow (3.0 Gpm/Ton) C J Q

Motorized Water Valve & Afr (2.25) D K R

Motorized Water Valve & Afr (3.0) E L T

Secondary Circulation Pump U V W

Heat Exchanger Options

A = Copper Water Coil w/E-Coated Air Coil

C = Copper Water Coil

J = Cupro-Nickel Water Coil w/E-Coated Air Coil

N = Cupro-Nickel Water Coil

V = Copper Water Coil w/E-Coated Air Coil & Extended Range Insulation

E = Copper Water Coil w/Extended Range Insulation

M = Cupro-nickel Water Coil w/E-Coated Air Coil & Extended Range Insulation

F = Cupro-nickel Water Coil w/Extended Range Insulation

Subbase

S = 3” Subbase

D = 3” Subbase w/Motorized Damper

G = 5” Subbase

H = 5” Subbase w/Motorized Damper

N = None

Cabinet Construction

With UltraQuiet

M = Bottom Return

D = Bottom Return w/Locking Control Door

B = Front Return

E = Front Return w/Locking Control Door

C = No Cabinet BR Chassis Only

J = No Cabinet FR Chassis Only

Sweat FPT MPT

Without UltraQuiet

S = Bottom Return

L = Bottom Return w/Locking Control Door

F = Front Return

G = Front Return w/Locking Control Door

N = No Cabinet BR Chassis Only

H = No Cabinet FR Chassis Only

Rev.: 8 Aug, 2008B

climatemaster.com

3

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Consoles

Rev.: 5 Nov., 2009B

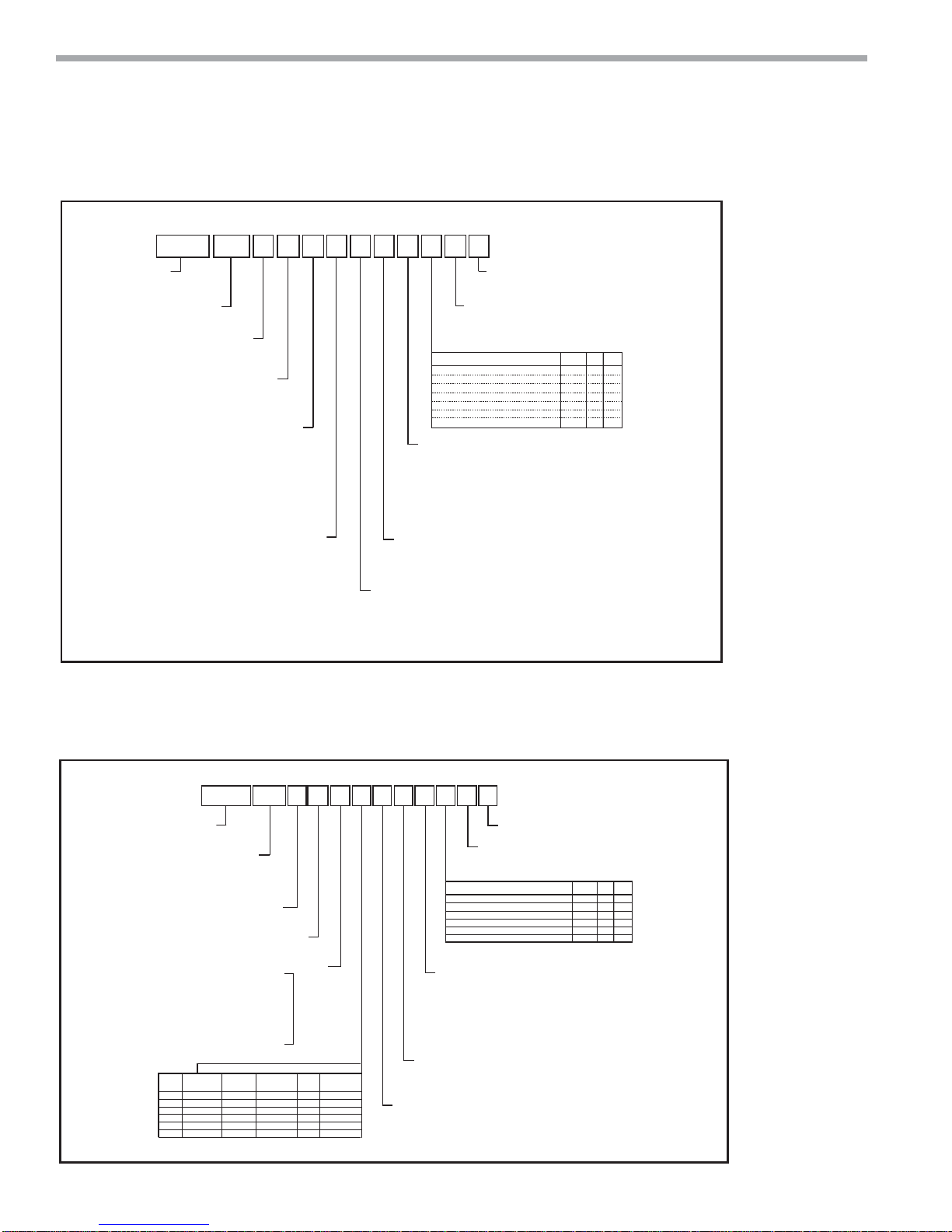

Model Nomenclature: Tranquility Console (TRC) Series (60Hz)

94 5 6

1 2 3

8 101112 131415

7

T R C AA0 9 CG S S C S R S

Model Type

TRC = Console

Unit Size

09, 12, 15, 18

Revision Level

B = Size 09 (115V) & Size 18 (265V)

A = Current Revision

A = MCO Unit Mounted Tstat w/CXM

B = MCO Unit Mounted Tstat w/DXM

C = ACO Unit Mounted Tstat w/CXM

D = ACO Unit Mounted Tstat w/DXM

R = Remote Mounted Tstat w/CXM

S = Remote Mounted Tstat w/DXM

L = Remote Mounted w/CXM & LON

M = Remote Mounted w/DXM & LON

N = Remote Mounted w/CXM & MPC

P = Remote Mounted w/DXM & MPC

D = Disconnect Switch & 15Amp Fuse

K = 20Amp Plug, Cord, Receptacle &

Disconnect Switch (Non Fused)

Voltage

G = 208-230/60/1

A = 115/60/1

E = 265/60/1

Controls

Power Termination

A = Field Connected (Hard Wire)

B = 20Amp Plug & Cord

F = Disconnect Switch (Non Fused)

H = 20Amp Plug, Cord, Receptacle,

Disconnect Switch & 15Amp Fuse

Water Circuit Options

None S F M

Motorized Water Valve A G N

Autoflow (2.25 Gpm/Ton) B H P

Autoflow (3.0 Gpm/Ton) C J Q

Motorized Water Valve & Afr (2.25) D K R

Motorized Water Valve & Afr (3.0) E L T

Secondary Circulation Pump U V W

Heat Exchanger Options

A = Copper Water Coil w/E-Coated Air Coil

C = Copper Water Coil

J = Cupro-Nickel Water Coil w/E-Coated Air Coil

N = Cupro-Nickel Water Coil

V = Copper Water Coil w/E-Coated Air Coil & Extended Range Insulation

E = Copper Water Coil w/Extended Range Insulation

M = Cupro-nickel Water Coil w/E-Coated Air Coil & Extended Range Insulation

F = Cupro-nickel Water Coil w/Extended Range Insulation

Subbase

S = 5” Subbase

H = 5” Subbase w/Motorized Damper

N = None

Cabinet Construction

With UltraQuiet Without UltraQuiet

M = Bottom Return

D = Bottom Return w/Locking Control Door

B = Front Return

E = Front Return w/Locking Control Door

C = No Cabinet BR Chassis Only

J = No Cabinet FR Chassis Only

Standard

S = Standard

Piping Connections

R = Right Piping

L = Left Piping

V = Left Piping w/SS Drain Pan

W = Right Piping w/SS Drain Pan

Sweat FPT MPT

S = Bottom Return

L = Bottom Return w/Locking Control Door

F = Front Return

G = Front Return w/Locking Control Door

N = No Cabinet BR Chassis Only

H = No Cabinet FR Chassis Only

Rev.: 29 July, 2009B

Model Nomenclature: Tranquility Console (TRC) Series (50Hz)

94 5 6

8 101112131415

7

CE Mark

15 Amp

RECEPTACLE

FUSE

-

-

-

-

-

X

-

X

X

X

-

CABINET

S = Bottom Return (Standard)

L = Bottom Return w/Locking Control Door (Standard)

F = Front Return (Standard)

G = Front Return w/Locking Control Door (Standard)

N = No Cabinet Chassis Only (Standard)

S = STANDARD

PIPING CONNECTIONS

R = Right Piping

L = Left Piping

WATER CIRCUIT OPTIONS

None

Motorized Water Valve

AutoFlow (2.25 gpm/ton)

AutoFlow (3.0 gpm/ton)

Motorized Water Valve & AFR (2.25)

Motorized Water Valve & AFR (3.0)

HEAT EXCHANGER OPTIONS

A = Copper Water Coil w/E-Coated Air Coil

C = Copper Water Coil w/Non-Coated Air Coil

J = Cupro-Nickel Water Coil w/E-Coated Air Coil

N = Cupro-Nickel Water Coil w/Non-Coated Air Coil

V = Copper Water Coil w/E-Coated Air Coil & Extended Range Insulation

E = Copper Water Coil w/Non-Coated Air Coil & Extended Range Insulation

M = Cupro-Nickel Water Coil w/E-Coated Air Coil & Extended Range Insulation

F = Cupro-Nickel Water Coil w/Non-Coated Air Coil & Extended Range Insulation

SUBBASE

S = 5” Subbase (Black)

H = 5” Subbase w/Motorized Damper

N = None

Sweat FPT MPT

S F M

A G N

B H P

C J Q

D K R

E L T

SERIES

TRC = Tranquility Console

E = MCO Unit Mounted Tstat w/CXM

F = ACO Unit Mounted Tstat w/CXM

J = MCO Unit Mounted Tstat w/DXM

K = ACO Unit Mounted Tstat w/DXM

Q = Remote Mounted Tstat w/CXM

G = Remote Mounted Tstat w/DXM

H = Remote Mounted LON w/CXM

V = Remote Mounted LON w/DXM

T = Remote Mounted MPC w/CXM

U = Remote Mounted MPC w/DXM

FIELD

OPTION

CONNECTED

(HARD WIRE)

A

B

D

F

H

K

1 2 3

TRC FB12 EV S S E S R S

UNIT SIZE

09

12

15

18

REVISION LEVEL

B = Current Revision

VOLT AGE

V = 220-240/50/1

CONTROLS

POWER TERMINATION & OPTIONS

20 Amp

DISCONNECT

PLUG &

SWITCH

CORD

X

-

-

-

-

-

-

-

-

X

X

X

X

X

X

X

Rev.: 21 Nov, 2007J

4

ClimateMaster Water-Source Heating and Cooling Systems

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Consoles

Rev.: 5 Nov., 2009B

General Information

Safety

Warnings, cautions and notices appear throughout this manual.

Read these items carefully before attempting any installation,

service or troubleshooting of the equipment.

DANGER: Indicates an immediate hazardous situation, which

if not avoided will result in death or serious injury. DANGER

labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation, which if

not avoided could result in death or serious injury.

WARNING!

WARNING! Verify refrigerant type before proceeding. Units

are shipped with R-22, R-407c and R-410A (EarthPure®)

refrigerants. The unit label will indicate which refrigerant is

provided. The EarthPure® Application and Service Manual

should be read and understood before attempting to service

refrigerant circuits with R-407c or R-410A.

WARNING!

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal profi ciency requirements.

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice, which if not avoided could result in minor or

moderate injury or product or property damage.

NOTICE: Notifi cation of installation, operation or maintenance

information, which is important, but which is not hazardrelated.

WARNING!

WARNING! All refrigerant discharged from this unit must be

recovered WITHOUT EXCEPTION. Technicians must follow

industry accepted guidelines and all local, state, and federal

statutes for the recovery and disposal of refrigerants. If a

compressor is removed from this unit, refrigerant circuit oil will

remain in the compressor. To avoid leakage of compressor oil,

refrigerant lines of the compressor must be sealed after it is

removed.

CAUTION!

CAUTION!

these units as a source of heating or cooling during the

construction process. The mechanical components and

fi lters will quickly become clogged with construction dirt

and debris, which may cause system damage.

To avoid equipment damage, DO NOT use

climatemaster.com

5

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Consoles

Rev.: 5 Nov., 2009B

General Information

Inspection

Upon receipt of the equipment, carefully check the

shipment against the bill of lading. Make sure all units

have been received. Inspect the packaging of each unit,

and inspect each unit for damage. Insure that the carrier

makes proper notation of any shortages or damage on all

copies of the freight bill and completes a common carrier

inspection report. Concealed damage not discovered

during unloading must be reported to the carrier within

15 days of receipt of shipment. If not fi led within 15 days,

the freight company can deny the claim without recourse.

Note: It is the responsibility of the purchaser to fi le all

necessary claims with the carrier. Notify your equipment

supplier of all damage within fi fteen (15) days of shipment.

Storage

Equipment should be stored in its original packaging in

a clean, dry area. Store units in an upright position at all

times. Stack units a maximum of 3 units high.

Unit Protection

Cover units on the job site with either the original

packaging or an equivalent protective covering. Cap

the open ends of pipes stored on the job site. In areas

where painting, plastering, and/or spraying has not been

completed, all due precautions must be taken to avoid

physical damage to the units and contamination by foreign

material. Physical damage and contamination may prevent

proper start-up and may result in costly equipment cleanup.

Examine all pipes, fi ttings, and valves before installing

any of the system components. Remove any dirt or

debris found in or on these components.

3. Verify refrigerant tubing is free of kinks or dents and

that it does not touch other unit components.

4. Inspect all electrical connections. Connections must

be clean and tight at the terminals.

5. Remove any blower support packaging.

6. Loosen compressor bolts on units equipped with

compressor spring vibration isolation until the

compressor rides freely on the springs. Remove

shipping restraints.

7. REMOVE COMPRESSOR SUPPORT PLATE 1/4”

SHIPPING BOLTS (2 on each side) TO MAXIMIZE

VIBRATION AND SOUND ATTENUATION.

CAUTION!

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature or

humidity extremes (e.g., attics, garages, rooftops, etc.).

Corrosive conditions and high temperature or humidity can

signifi cantly reduce performance, reliability, and service life.

Always move and store units in an upright position. Tilting

units on their sides may cause equipment damage.

CAUTION!

CAUTION! CUT HAZARD - Failure to follow this caution

may result in personal injury. Sheet metal parts may have

sharp edges or burrs. Use care and wear appropriate

protective clothing, safety glasses and gloves when

handling parts and servicing heat pumps.

NOTICE! Failure to remove shipping brackets from springmounted compressors will cause excessive noise, and could

cause component failure due to added vibration.

Pre-Installation

Installation, Operation, and Maintenance instructions

are provided with each unit. Horizontal equipment is

designed for installation above false ceiling or in a ceiling

plenum. Other unit confi gurations are typically installed

in a mechanical room. The installation site chosen

should include adequate service clearance around the

unit. Before unit start-up, read all manuals and become

familiar with the unit and its operation. Thoroughly check

the system before operation.

Prepare units for installation as follows:

1. Compare the electrical data on the unit nameplate

with ordering and shipping information to verify that

the correct unit has been shipped.

2. Keep the cabinet covered with the original packaging

until installation is complete and all plastering,

painting, etc. is fi nished.

6

ClimateMaster Water-Source Heating and Cooling Systems

THE SMART SOLUTION FOR ENERGY EFFICIENCY

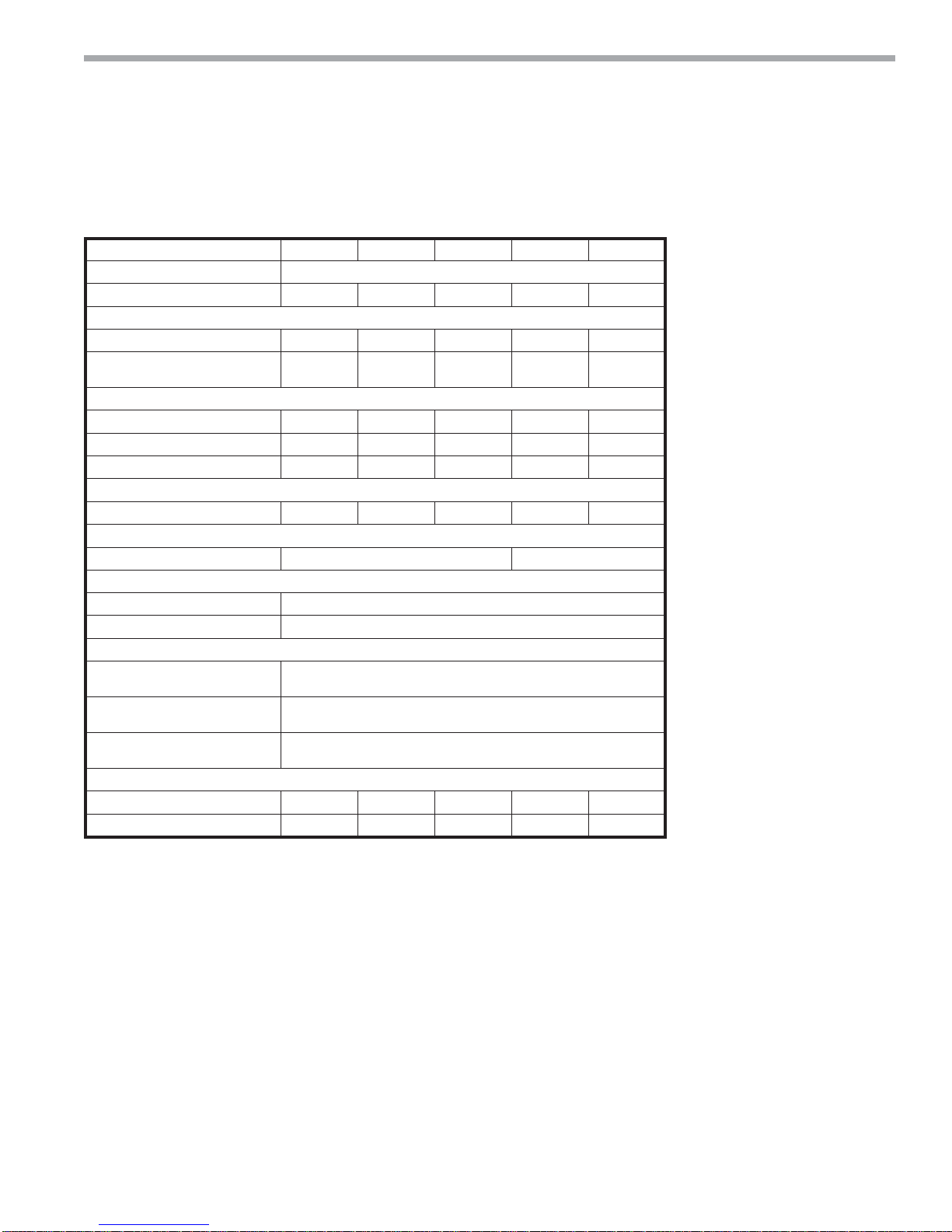

Console (CCE) Series

Model 07 09 12 15 19

Compressor (1 Each) Rotary

Factory Charge R22 (oz) [kg] 16 [0.454] 16 [0.454] 21 [0.595] 27 [0.765] 24 [0.680]

PSC Fan Motor & Blower (3 Speeds)

Fan Motor (hp) [W] 1/20 [27] 1/15 [50] 1/15 [50] 1/6 [124] 1/6 [124]

Blower Wheel Size (dia x w) (in) [mm]

Water Connection Size

O.D. Sweat (in) [mm] 5/8 [15.9] 5/8 [15.9] 5/8 [15.9] 5/8 [15.9] 5/8 [15.9]

Optional IPT Fittings (in) 1/2 1/2 1/2 1/2 1/2

Optional EPT Fittings (in) 1/2 1/2 1/2 1/2 1/2

Condensate Connection Size

I.D. Vinyl Hose (In) [mm] 5/8 [15.9] 5/8 [15.9] 5/8 [15.9] 5/8 [15.9] 5/8 [15.9]

Air Coil Size

Dimensions (h x w) - (in) [mm] 8 x 26 [20.3 x 66.0] 10 x 26 [25.4 x 66.0]

Filter Size

Bottom Return (in) [cm] 1 - 8 x 29-1/2 x 3/8 [20.3 x 74.9 x 0.95]

Front Return (In) [cm] 1 - 7 x 29-1/2 x 1/8 [17.8 x 74.9 x 0.32]

Cabinet Size

Bottom Return (Std. 3" Base)

(W x H x D) - (In) [cm]

Bottom Return (Std. 5" Base)

(W x H x D) - (In) [cm]

Bottom Return (No Subbase)

(W x H x D) - (In) [cm]

Unit Weight

Weight - Operating, (lbs) [kg] 173 [78.5] 177 [80.3] 187 [84.5] 193 [87.5] 198 [89.8]

Weight - Packaged, (lbs) [kg] 181 [82.1] 185 [83.9] 195 [88.5] 201 [91.2] 206 [93.4]

5-1/4 x 6-1/4

[133 x 159]

5-1/4 x 6-1/4

[133 x 159]

48 x 24 x 12 [121.9 x 61.0 x 30.5]

48 x 26 x 12 [121.9 x 66.0 x 30.5]

48 x 21 x 12 [121.9 x 53.3 x 30.5]

5-1/4 x 6-1/4

[133 x 159]

5-1/4 x 6-1/4

[133 x 159]

5-1/4 x 6-1/4

[133 x 159]

Consoles

Rev.: 5 Nov., 2009B

Unit Physical Data

climatemaster.com

7

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Consoles

Rev.: 5 Nov., 2009B

Unit Physical Data

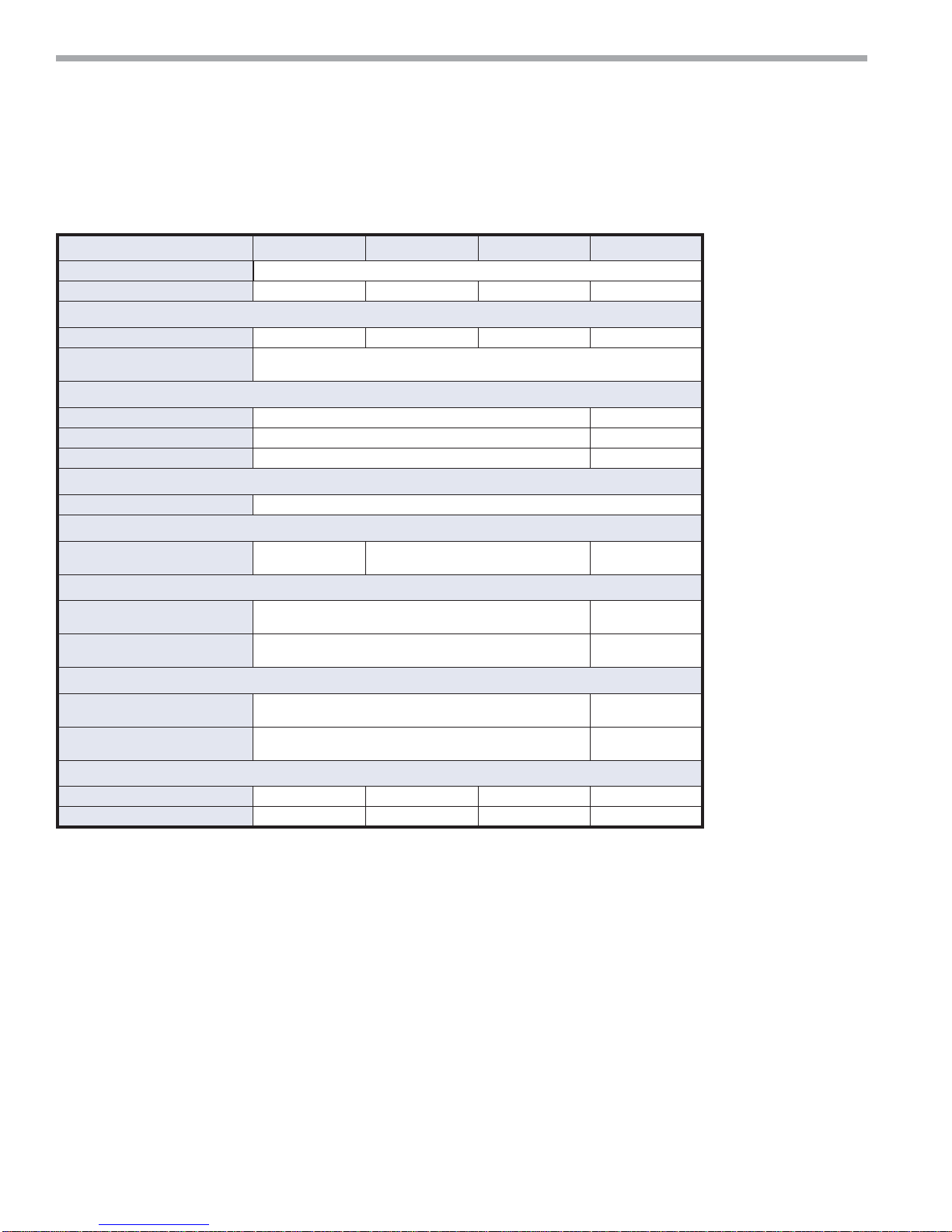

Tranquility Console (TRC) Series (60Hz)

Model 09 12 15 18

Compressor (1 Each)

Factory Charge R410A (oz) [kg] 28 [0.794] 29 [0.822] 33 [0.907] 39 [1.105]

PSC Fan Motor & Blower (3 Speeds)

Fan Motor (hp) [W] 1/20 [37] 1/12 [62] 1/8 [93] 1/8 [93]

Blower Wheel Size (dia x w) -

(in) [mm] - Qty 2

Water Connection Size

O.D. Sweat (in) [mm] 1/2 [12.7] 3/4 [19.1]

Optional IPT Fittings (in) 1/2 3/4

Optional EPT Fittings (in) 1/2 3/4

Condensate Connection Size

I.D. Vinyl Hose (In) [mm] 5/8 [15.9]

Air Coil Size

Dimensions (h x w) - (in) [mm]

8 x 26

[203 x 660]

Filter Size

Bottom Return (in) [mm] 1 - 10 x 30 x 1 [254 x 762 x 25]

Front Return (In) [mm] 1 - 7 x 29.5 x 1/8 [178 x 749 x 3.2]

Cabinet Size

Bottom Return (Std. 5" Base)

(W x H x D) - (In) [mm]

Front Return (No Subbase)

(W x H x D) - (In) [mm]

48 x 26 x 12 [1219 x 660 x 305]

48 x 21 x 12 [1219 x 533 x 305]

Cabinet Size

Weight - Operating, (lbs) [kg] 175 [79] 180 [82] 190 [86.2] 220 [99.8]

Weight - Packaged, (lbs) [kg] 185 [83.9] 190 [86] 200 [90.8] 232 [105.2]

5.25 x 6.25 [133 x 159]

10 x 26 [254 x 660]

10 x 32

[254 x 812]

1 - 10 x 36 x 1

[254 x 914 x 25]

1 - 7 x 35.5 x 1/8

[178 x 902 x 3.2]

54 x 26 x 12

[1372 x 660 x 305]

54 x 21 x 12

[1372 x 533 x 305]

* Data not available at time of publication.

All units have rubber grommet compressor mountings and TXV expansion devices.

8

ClimateMaster Water-Source Heating and Cooling Systems

THE SMART SOLUTION FOR ENERGY EFFICIENCY

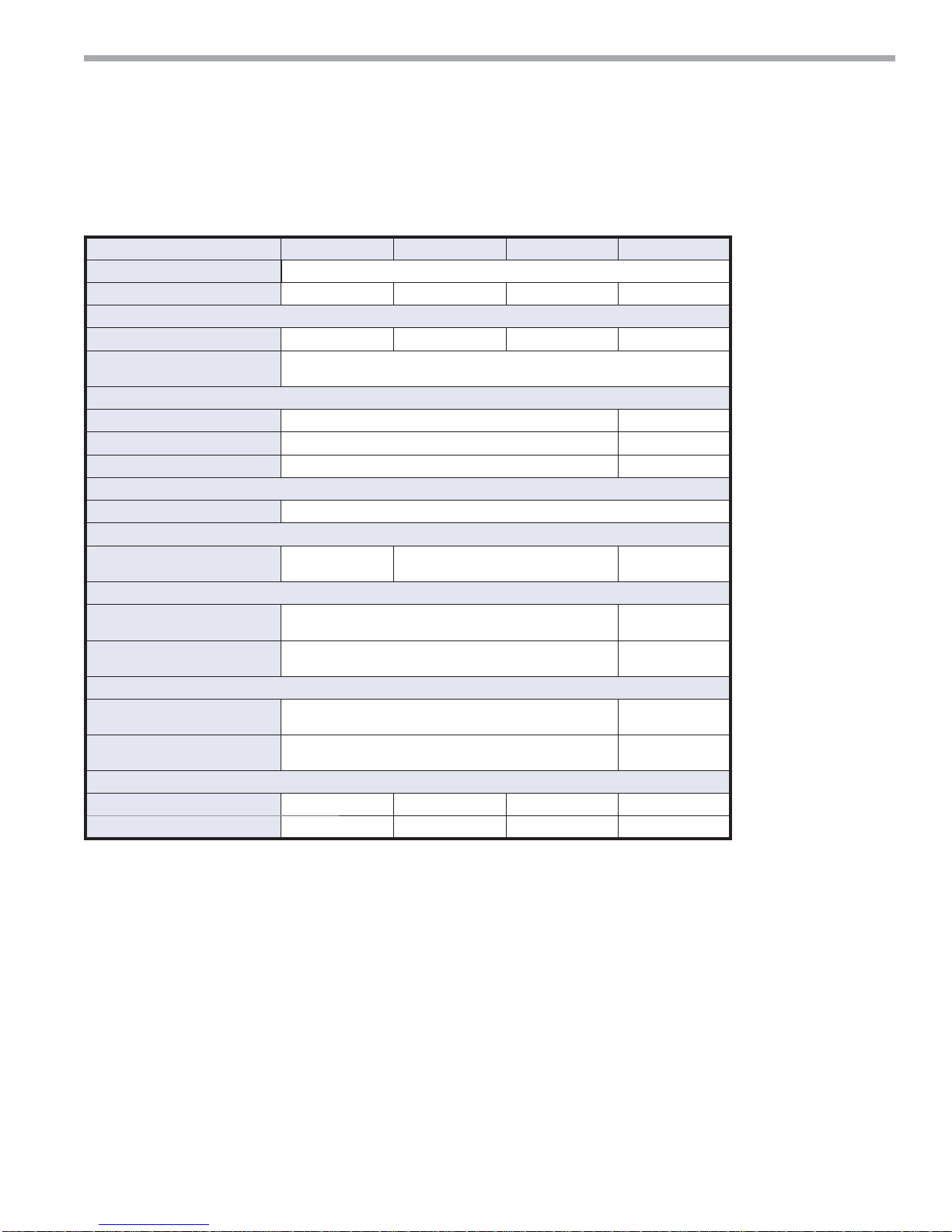

Tranquility Console (TRC) Series (50Hz)

Model 09 12 15 18

Compressor (1 Each) Rotary

Factory Charge R410A (oz) [kg] 26 [0.737] 29 [0.822] 33 [0.936] 30 [0.850]

PSC Fan Motor & Blower (3 Speeds)

Fan Motor (hp) [W] 1/20 [37] 1/12 [62] 1/8 [93] 1/8 [93]

Blower Wheel Size (dia x w) (in) [mm] - Qty 2

Water Connection Size

O.D. Sweat (in) [mm] 1/2 [12.7] 3/4 [19.1]

Optional IPT Fittings (in) 1/2 3/4

Optional EPT Fittings (in) 1/2 3/4

Condensate Connection Size

I.D. Vinyl Hose (In) [mm] 5/8 [15.9]

Air Coil Size

Dimensions (h x w) - (in) [mm]

8 x 26

[203 x 660]

Filter Size

Bottom Return (in) [mm] 1 - 10 x 30 x 1 [254 x 762 x 25]

Front Return (In) [mm] 1 - 7 x 29.5 x 1/8 [178 x 749 x 3.2]

Cabinet Size

Bottom Return (Std. 5" [127] Base)

(W x H x D) - (In) [mm]

Front Return (No Subbase)

(W x H x D) - (In) [mm]

48 x 26 x 12 [1219 x 660 x 305]

48 x 21 x 12 [1219 x 533 x 305]

Cabinet Size

Weight - Operating, (lbs) [kg] 175 [79] 180 [82] 190 [86.2] 220 [99.8]

Weight - Packaged, (lbs) [kg] 185 [83.9] 190 [86] 200 [90.8] 232 [105.2]

5.25 x 6.25 [133 x 159]

10 x 26 [254 x 660]

10 x 32

[254 x 813]

1 - 10 x 36 x 1

[25.4 x 91.4 x 2.5]

1 -7 x 35.5 x 1/8

[178 x 902 x 3.2]

54 x 26 x 12

[1372 x 660 x 305]

54 x 21 x 12

[1372 x 533 x 305]

Consoles

Rev.: 5 Nov., 2009B

Unit Physical Data

All units have rubber grommet compressor mountings and TXV expansion devices.

climatemaster.com

9

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Consoles

Rev.: 5 Nov., 2009B

Installation

The installation of Console Water-Source Heat Pumps

and all associated components, parts and accessories

that make up the installation shall be in accordance with

the regulations of ALL Authorities having jurisdiction

and MUST conform to all applicable Codes. It is the

responsibility of the Installing Contractor to determine

and comply with ALL applicable Codes and Regulations.

NOTE: An Installation Checklist is provided in this

manual. Complete this checklist after all installation

procedures are completed. A periodic maintenance

checklist provided in the Maintenance section outlines

recommended maintenance schedules. A Start-Up

Inspection Log is also included at the end of this manual

to encourage thorough unit checkout at initial start-up.

These checklists are not a substitute for the detailed

information found in the Installation section of this

manual

1. Console units are typically installed along an outside

2. Unpack the Console Unit from the shipping carton.

3. Remove compressor isolation plate shipping screws

4. Using a carpenter's square and a level, ensure the

.

wall of the room. Provide adequate space in front

of the unit for service and maintenance. Locate

the Console Unit so that it provides adequate air

circulation throughout the room.

Remove the front cabinet by lifting up and away from

the backplate. Protect the cabinet from damage

during installation by returning it to its original

packaging until required.

(4) as shown in Figure 1a. (All CCE and TRC09-12)

unit is level. Shim the unit if necessary to assure

proper installation.

CAUTION!

Poor or inadequate installation may result in noisy unit

operation or unattractive installation.

Figure 1a: Compressor Shipping Screws (All

CCE and TRC 09-12)

4 Shipping

Screws

5. Select the proper fasteners to connect the backplate

securely to the wall.

6. Fasten the backplate onto the wall through the screw

holes located in the back fl ange. Secure the subbase

in place.

7. Make all necessary electrical connections as

described in the Electrical Wiring section of this

manual. Consult the wiring diagram to ensure proper

hook-up.

8. Connect the fi nal piping as described in the Supply

and Return Piping and Condensate Piping section

of the manual. Install shut-off valves, piping and/or

hoses and other accessories as specifi ed.

9. Before making the fi nal water connections, fl ush

the system as described in the Start Up section

of this manual. After fl ushing the system, connect

piping and hoses to the proper supply, return and

condensate connections of the unit.

NOTE: When necessary, use adapters to connect hoses.

10. Install any other system components as required

following manufacturer's instructions.

11. After Start-up, reinstall the front cabinet by

carefully lowering the front cabinet over the chassis

onto the backplate.

Supply and Return Hoses

Optional pressure-rated hose assemblies are available

for use with ClimateMaster Console Units. Use the

following guidelines when installing supply and return

hose assemblies.

1. Install supply and return hoses fi tted with swivel-joint

fi ttings at one end to prevent the hose from twisting.

2. Use adapters to secure the hose assembly to the unit

and the riser.

3. Do not allow the hose to twist during installation.

Twisting may damage the hose wall or the interior

rubber compound.

4. Use pipe joint compound sparingly on the pipe

threads of the fi tting adapters.

5. Prevent sealant from reaching the fl ared surfaces of

the joint.

6. Do not use pipe joint compound when tefl on thread

tape is pre-applied to hose assemblies or when

fl ared-end connections are used.

7. Maximum torque which may be applied to brass

fi ttings is 30 ft-lbs [41 N-m]. When a torque wrench

is not used, tighten brass fi ttings fi nger-tight plus one

quarter turn.

8. Tighten steel fi ttings as necessary.

9. Shut-off/balancing valves, fl ow indicators, and drain

tees in the supply runout and return at each fl oor to

aid in loop balancing and servicing.

10

ClimateMaster Water-Source Heating and Cooling Systems

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Consoles

Rev.: 5 Nov., 2009B

Installation

CAUTION!

Loop Fluids should be of good quality with no more than 0.50

ppm of chlorides w/copper heat exchangers (125 ppm w/

Cupro-nickel) to prevent corrosion and should also be fi ltered

to a maximum 800 micron [0.8mm particle size to prevent

erosion of the heat exchangers.

Condensate Piping

Unit is supplied with condensate drain hose, 5/8

inch [16mm] I.D. fl exible plastic nonpressure-rated,

protruding from piping side of unit. Connect this hose

to building drain. Avoid making kinks in hose to ensure

an unobstructed fl ow of condensate from the unit to the

drain. DO NOT twist, pull hose out, or push excess

hose into unit. If hose will not connect to your building

drain several options include, relocate end of building

drain, add to or cut hose, use hard plastic or copper

elbow fi ttings for tight radii (put inside hose). Keep hose

positioned within or over subbase area so hose does not

interfere with front cabinet. Cabinet should not push or

reroute hose. Clamp all joints watertight. Check for leaks.

Internally the drain hose is clamped to drain pan and

pitched correctly. Horizontal runs of condensate hose

should be pitched downward 1/4 inch minimum for every

foot [10mm per 46cm] of hose. Avoid low points because

dirt collects in these areas and may cause blockage. If

blocked the condensate level in drain pan increases.

When the level gets too high, the Console unit has sensor

switch that will shut unit off. Overfl ow may still occur.

If the building drain connection is parallel with fl oor,

the height can be up to 1-1/2 inches [38mm] above

the subbase for proper pitch and correct drainage. Up

to 5 inches [127mm] above the subbase is allowable,

but drainage will be slower. When the drain connection

is 2-1/2 to 5 inches [64 to 127mm] above, the hose

inside the unit will act as a trap. Heights of more than 5

inches [127mm] above the subbase are NOT allowable

(condensate overfl ow may occur). If the unit has a

disconnect option, drain locations are limited. See unit

confi guration pages for details.

Field installation of a trap or vent is not required unless

specifi ed by local codes. Console units are designed

in a blow-through confi guration. The condensate drain

pan is located on the outlet side of the blower so that

the pressure in the drain pan is higher than atmospheric

pressures.

When drain connection is completed check for proper

drainage and leaks. Correct if necessary.

If trap is used, check and clean often. See Preventive

Maintenance Instructions.

climatemaster.com

11

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

Consoles

Rev.: 5 Nov., 2009B

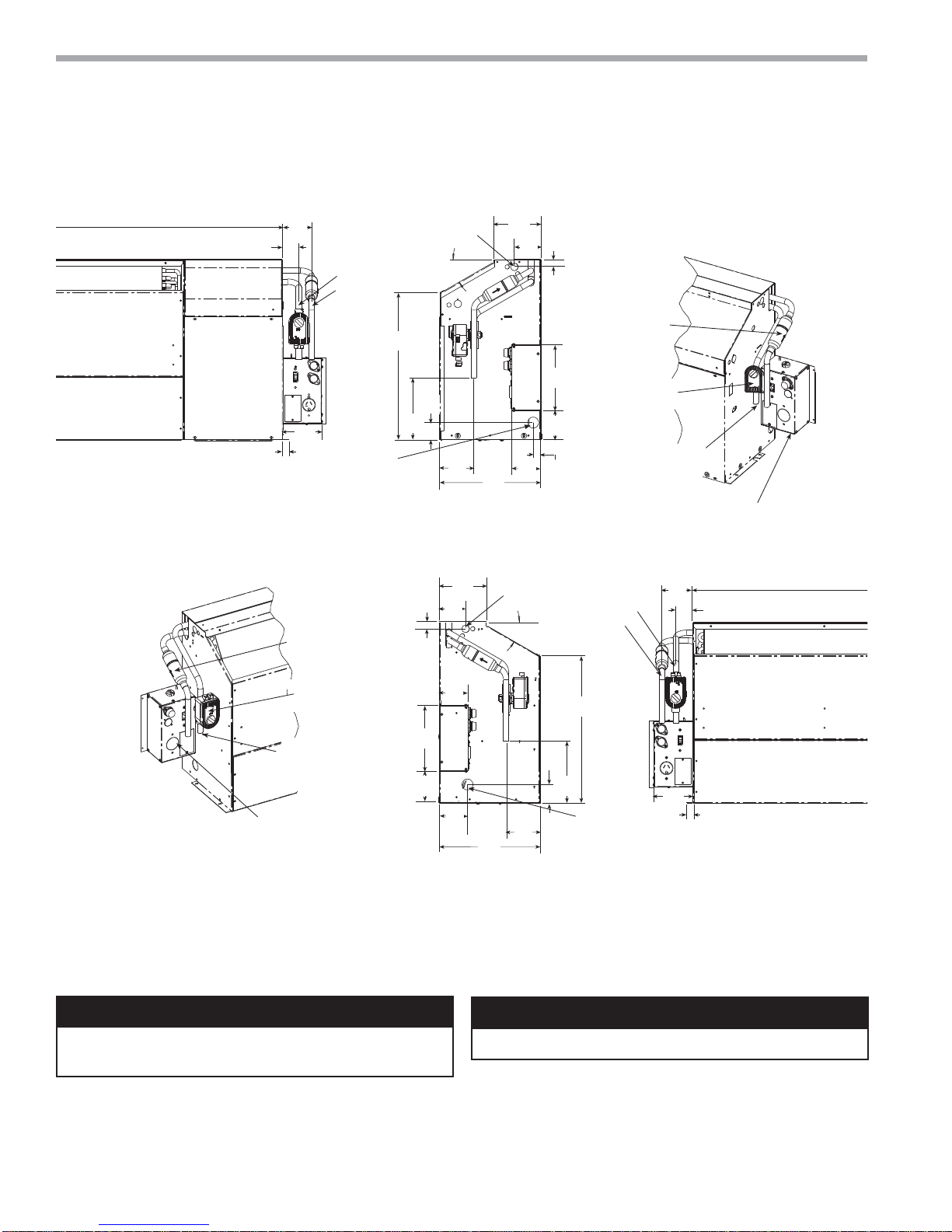

Piping Connections - CCE

Figure 1b: Water Connection Details

3.28

(83)

1.84

(47)

4.46

(113)

0.75

(19)

Water Out

Water In

Condensate

5/8" (15.9 mm)

ID Vinyl Hose

Control Box

Compressor

Access

Panel

Right Hand Configuration

Optional

Autoflow

Valve

Power Supply

30°

*16.66

(423)

*1.94

(49)

*7.06

(179)

3.88

(99)

5.36

(136)

3.01

(76)

0.87

(22)

5.36

(136)

3.01

(76)

3.43

(87)

11. 54

(293)

Power Supply

30°

0.87

(22)

7.5

(191)

3.56

(90)

0.99

(25)

Optional

Motorized

Water Valve

Water Connections

5/8" (15.9 mm)

OD Copper,

1/2" IPT or

1/2" EPT

Water Out

Water In

Optional

Autoflow

Valve

3.50

(89)

1.93

Optional

Disconnect Box

(mounted to cabinet

not chassis)

(49)

Optional

Motorized

Water Valve

7.5

Water Connections

5/8" (15.9 mm)

OD Copper,

1/2" IPT or

1/2" EPT

Optional

Disconnect Box

(mounted to cabinet

not chassis)

(191)

3.56

(90)

Left Hand Configuration

Notes:

All Dimensions are in inches (mm)

* For installed dimension, add to dimension shown 2.9" [74mm] with 3" subbase and 4.9" [124mm] for 5" subbase.

Optional autoflow valve, motorized water valve and disconnect box are shown.

Water connection in same location regardless of connection type.

CAUTION!

CAUTION! Corrosive system water requires corrosion re-

sistant fi ttings and hoses, and may require water treatment.

3.42

(87)

3.22

(82)

11. 54

(293)

3.88

(99)

*1.94

(49)

*7.06

(179)

*16.66

(423)

Condensate

5/8" (15.9 mm)

ID Vinyl Hose

4.49

(114)

Blower Deck

Blower Access Panel

0.75

(19)

CAUTION!

CAUTION! Piping must comply with all applicable codes.

12

ClimateMaster Water-Source Heating and Cooling Systems

Control Box

o

r

r

i

o

v

C

5

p

T

P

y

a

1.62 (41)

2.00

(51)

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Consoles

Rev.: 5 Nov., 2009B

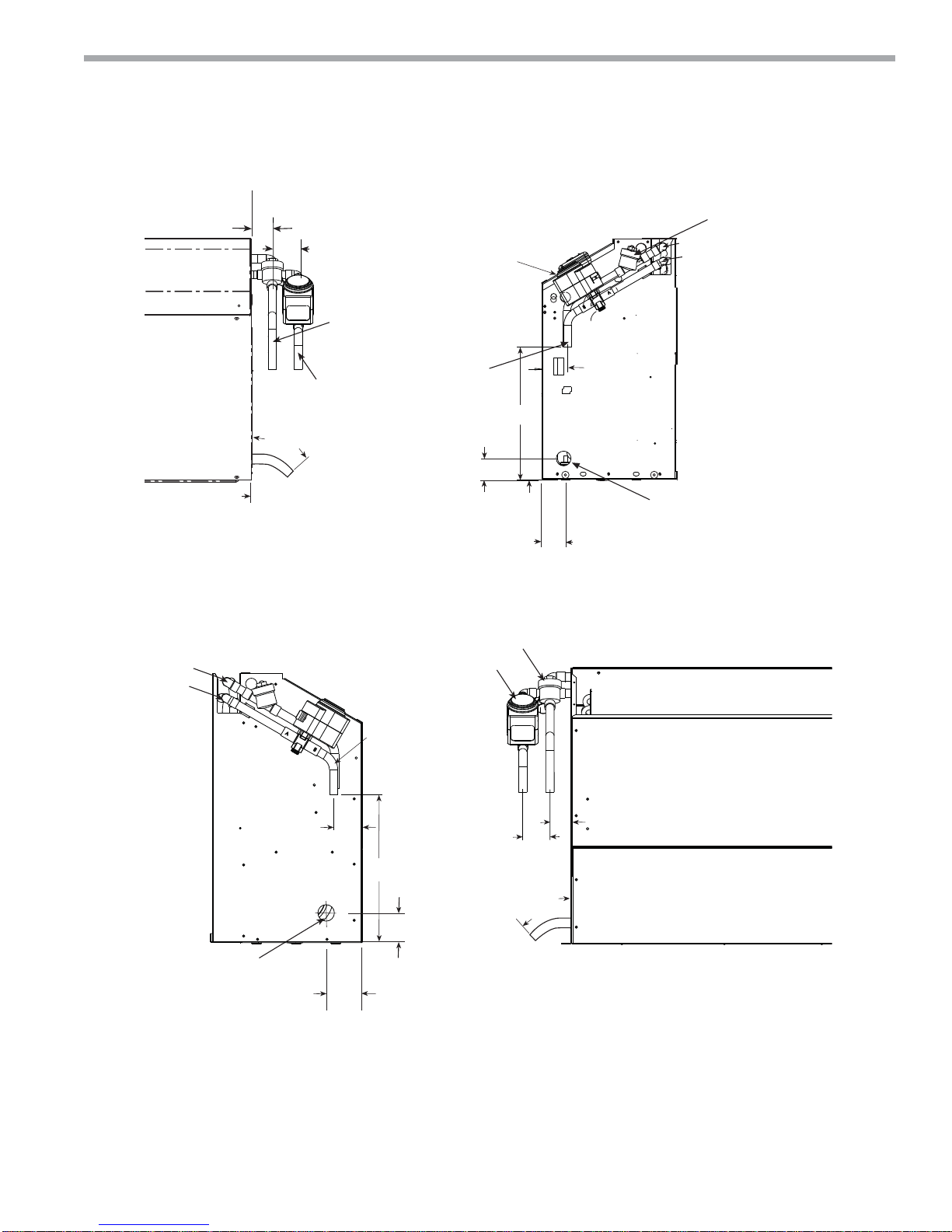

Piping Connections -

TRC Size 06-15

Optional Flow

Optional

Motorized

Water Valve

Regulator

Out

In

al

w

e

Compressor

Access

Panel

Out

In

Water Out

Water In

Water Connections

5/8” (15.9) OD

Copper, 1/2” IPT, or

1/2” EPT

2.25

(57)

*11.25 (286)

8.00 Min

(203)

1.75 (44)

Condensate

1.84

(77)

5/8" (15.9) ID

Vinyl Hose

Right Hand Configuration

Water Out

Water In

Water Connections

5/8” (15.9) OD

Copper, 1/2” IPT,

or 1/2” EPT

Opt

Aut

Val

Opti

Moto

Wate

Water

5/8" (1

OD Co

1/2" IP

1/2" E

nal

ized

lve

2.25

(57)

nnections

AA)

r,

r

Condensate

5/8" (15.9) ID

Vinyl Hose

Left Hand Configuration

Notes:

* Dimension reduced b

2.72

(96)

*11.25 (286)

2.25

(57)

fitting if selected

climatemaster.com

2.00

(51)

8.00 Min

(203)

1.50 (38)

Rev.: 10/06/08B

13

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

n

T

O

R

Consoles

Rev.: 5 Nov., 2009B

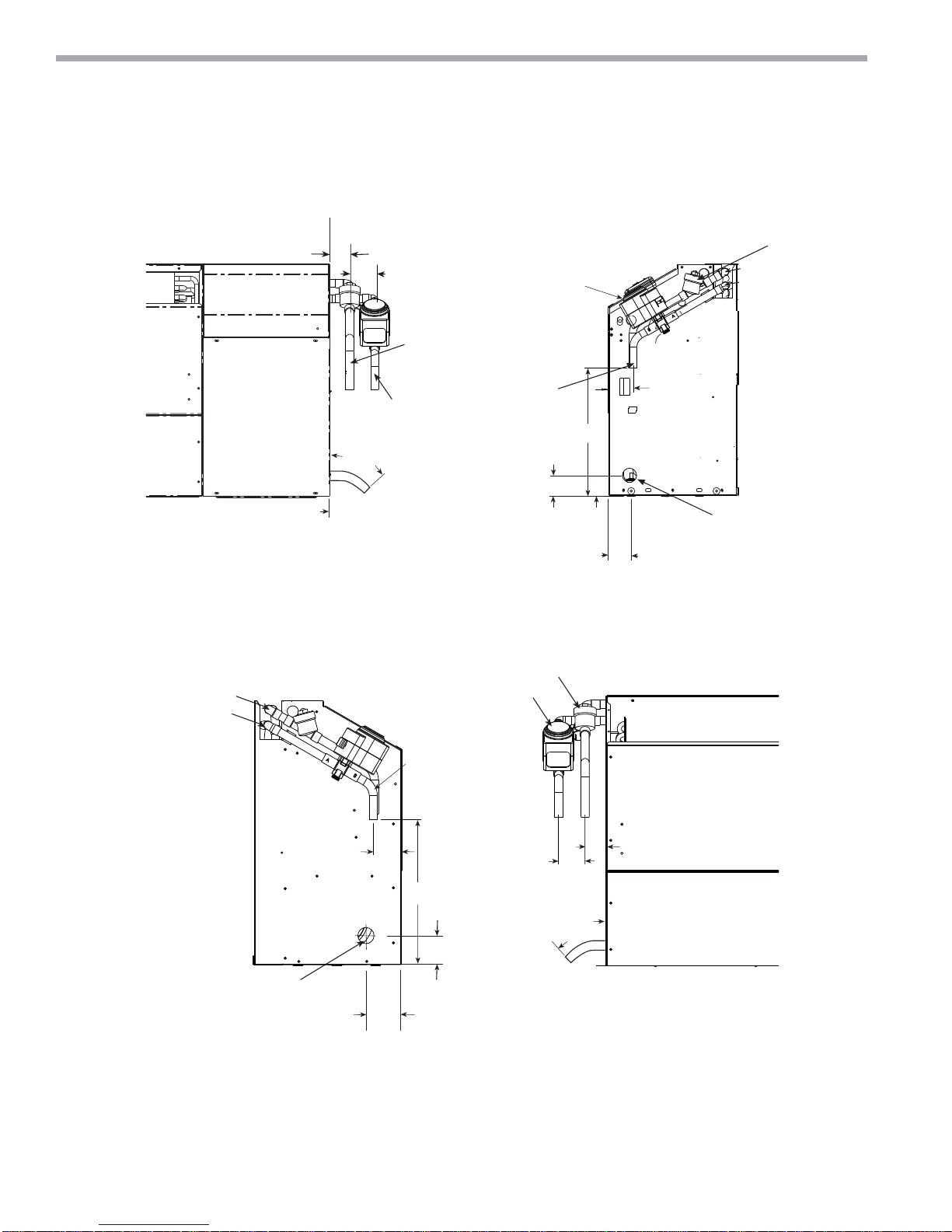

Piping Connections TRC Size 18

nal

low

lve

Control Box

Out

In

Compressor

Access

Panel

1.62 (41)

2.00

(51)

Optional

Motorized

Water Valve

Out

In

Water Out

2.25

(57)

Water In

Water Connections

5/8” (15.9) OD

Copper, 1/2” IPT, or

1/2” EPT

*11.25 (286)

8.00 Min

(203)

1.75 (44)

Condensate

1.84

(77)

5/8" (15.9) ID

Vinyl Hose

Right Hand Configuratio

Water Out

Water In

Water Connections

5/8” (15.9) OD

Copper, 1/2” IPT,

or 1/2” EPT

tional

rized

Valve

onnections

.9AA)

per,

or

Condensate

5/8" (15.9) ID

Vinyl Hose

14

ClimateMaster Water-Source Heating and Cooling Systems

2.25

(57)

2.00

(51)

1.50 (38)

*11.25 (286)

8.00 Min

(203)

2.72

(96)

2.25

(57)

Left Hand Configuration

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Consoles

Rev.: 5 Nov., 2009B

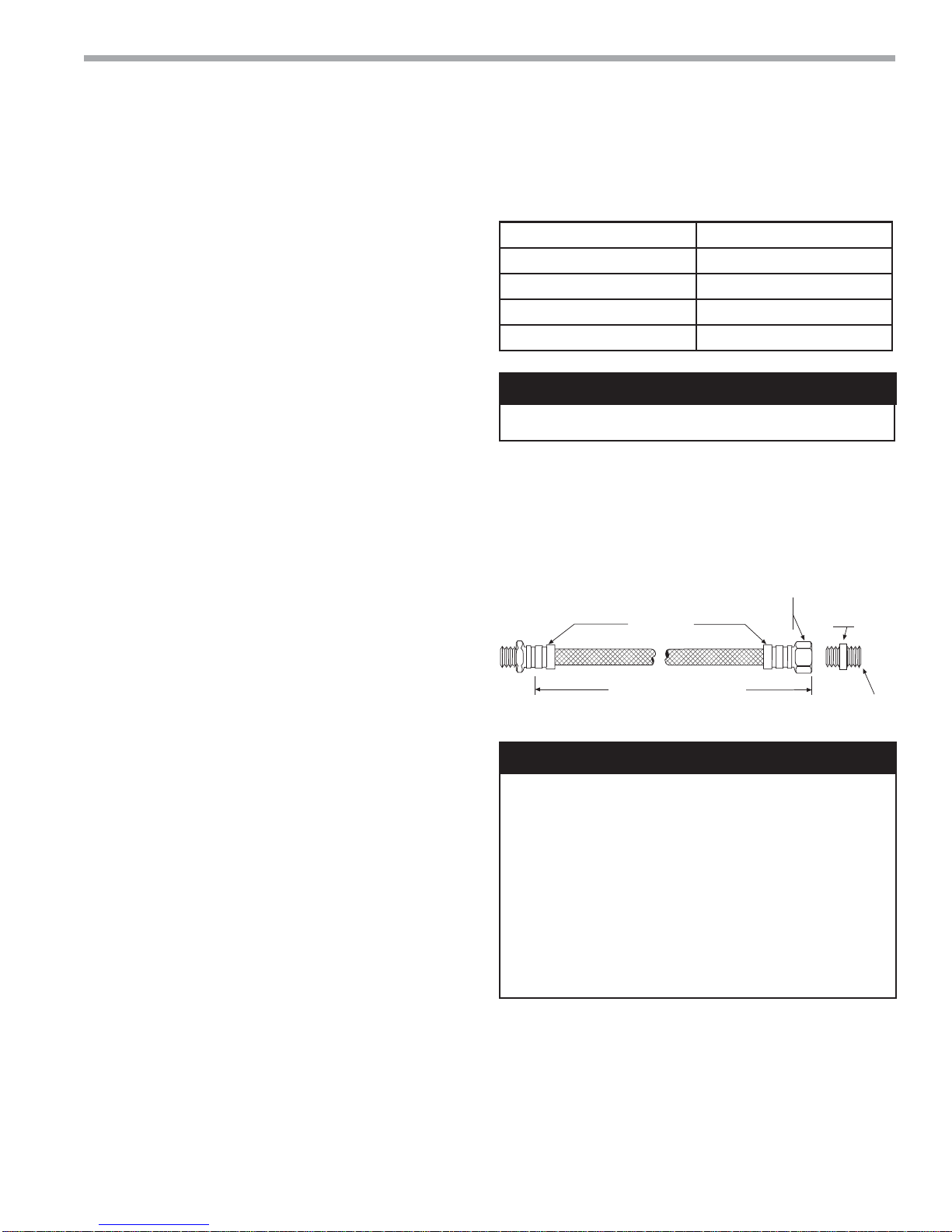

Piping Connections

Installation of Supply and Return Piping

Follow these piping guidelines.

1. Install a drain valve at the base of each supply and

return riser to facilitate system fl ushing.

2. Install shut-off / balancing valves and unions at each

unit to permit unit removal for servicing.

3. Place strainers at the inlet of each system

circulating pump.

4. Select the proper hose length to allow slack between

connection points. Hoses may vary in length by +2%

to -4% under pressure.

5. Refer to Table 1. Do not exceed the minimum bend

radius for the hose selected. Exceeding the minimum

bend radius may cause the hose to collapse, which

reduces water fl ow rate. Install an angle adapter to

avoid sharp bends in the hose when the radius falls

below the required minimum.

Insulation is not required on loop water piping except

where the piping runs through unheated areas, outside

the building or when the loop water temperature is

below the minimum expected dew point of the pipe

ambient conditions. Insulation is required if loop water

temperature drops below the dew point (insulation is

required for ground loop applications in most climates).

Pipe joint compound is not necessary when Tefl on®

thread tape is pre-applied to hose assemblies or when

fl ared-end connections are used. If pipe joint compound

is preferred, use compound only in small amounts on

the external pipe threads of the fi tting adapters. Prevent

sealant from reaching the fl ared surfaces of the joint.

Note: When anti-freeze is used in the loop, insure

that it is compatible with the Tefl on tape or pipe joint

compound that is applied.

Maximum allowable torque for brass fi ttings is 30 ft-lbs

[41 N-m]. If a torque wrench is not available, tighten

fi nger-tight plus one quarter turn. Tighten steel fi ttings

as necessary.

Optional pressure-rated hose assemblies designed

specifi cally for use with ClimateMaster units are available.

Similar hoses can be obtained from alternate suppliers.

Supply and return hoses are fi tted with swivel-joint

fi ttings at one end to prevent kinking during installation.

Table 1: Metal Hose Minimum Bend Radii

Hose Diameter Minimum Bend Radii

1/2" [12.7mm] 2-1/2" [6.4cm]

3/4" [19.1mm] 4" [10.2cm]

1" [25.4mm] 5-1/2" [14cm]

1-1/4" [31.8mm] 6-3/4" [17.1cm]

CAUTION!

CAUTION! Do not bend or kink supply lines or hoses.

NOTICE! Do not allow hoses to rest against structural

building components. Compressor vibration may be

transmitted through the hoses to the structure, causing

unnecessary noise complaints.

Figure 2: Supply/Return Hose Kit

Rib Crimped

Length

(2 ft [0.6m] Length Standard)

Swivel

Brass

Fitting

Brass

Fitting

CAUTION!

CAUTION! Many units are installed with a factory or fi eld

supplied manual or electric shut-off valve. DAMAGE WILL

OCCUR if shut-off valve is closed during unit operation. A

high pressure switch must be installed on the heat pump side

of any fi eld provided shut-off valves and connected to the

heat pump controls in series with the built-in refrigerant circuit

high pressure switch to disable compressor operation if water

pressure exceeds pressure switch setting. The fi eld installed

high pressure switch shall have a cut-out pressure of 300

psig and a cut-in pressure of 250 psig. This pressure switch

can be ordered from ClimateMaster with a 1/4” internal fl are

connection as part number 39B0005N02.

EPT

Refer to Figure 2 for an illustration of a typical supply/

return hose kit. Adapters secure hose assemblies to

the unit and risers. Install hose assemblies properly and

check regularly to avoid system failure and reduced

service life.

climatemaster.com

15

Loading...

Loading...