ClimateMaster TMW036, TMW120, TMW060, TMW340, TMW170 Installation Operation & Maintenance

Table of Contents

Model Nomenclature 3

Storage 5

Pre-Installation 5

Physical Data 6

Dimensional Data 7

Unit Installation 9

Piping Installation 9

Load Plumbing Installation 10

Water Loop Applications 11

Open Loop - Ground Water Systems 12

Water Quality Standards 12

Ground Loop Applications 14

Electrical - Line Voltage 15

Electrical - Low Voltage Wiring 16

Electrical - Accessories 17

Water Valve Wiring 17

TMW Series Wiring Diagram Matrix 18

Electrical Wiring Schematics 19

CXM/DXM Controls 25

CXM/DXM Safety Control Reset 28

Unit Commissioning and Operating Conditions 29

Piping System Cleaning & Flushing 30

Unit and System Checkout Procedure 31

Start Up Procedure 32

Preventive Maintenance 33

Warranties 34

Refrigeration Troubleshooting Form 35

Revision History 36

Tranquility® Modular

Water-to-Water

(TMW) Series

Water-Source Heat Pumps

50Hz-HFC-410A

Installation, Operation &

Maintenance

97B0059N05

Rev.: 02 January, 2013

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

2

ClimateMaster Water-Source Heat Pumps

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

This Page Intentionally Left Blank

THE SMART SOLUTION FOR ENERGY EFFICIENCY

3

climatemaster.com

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

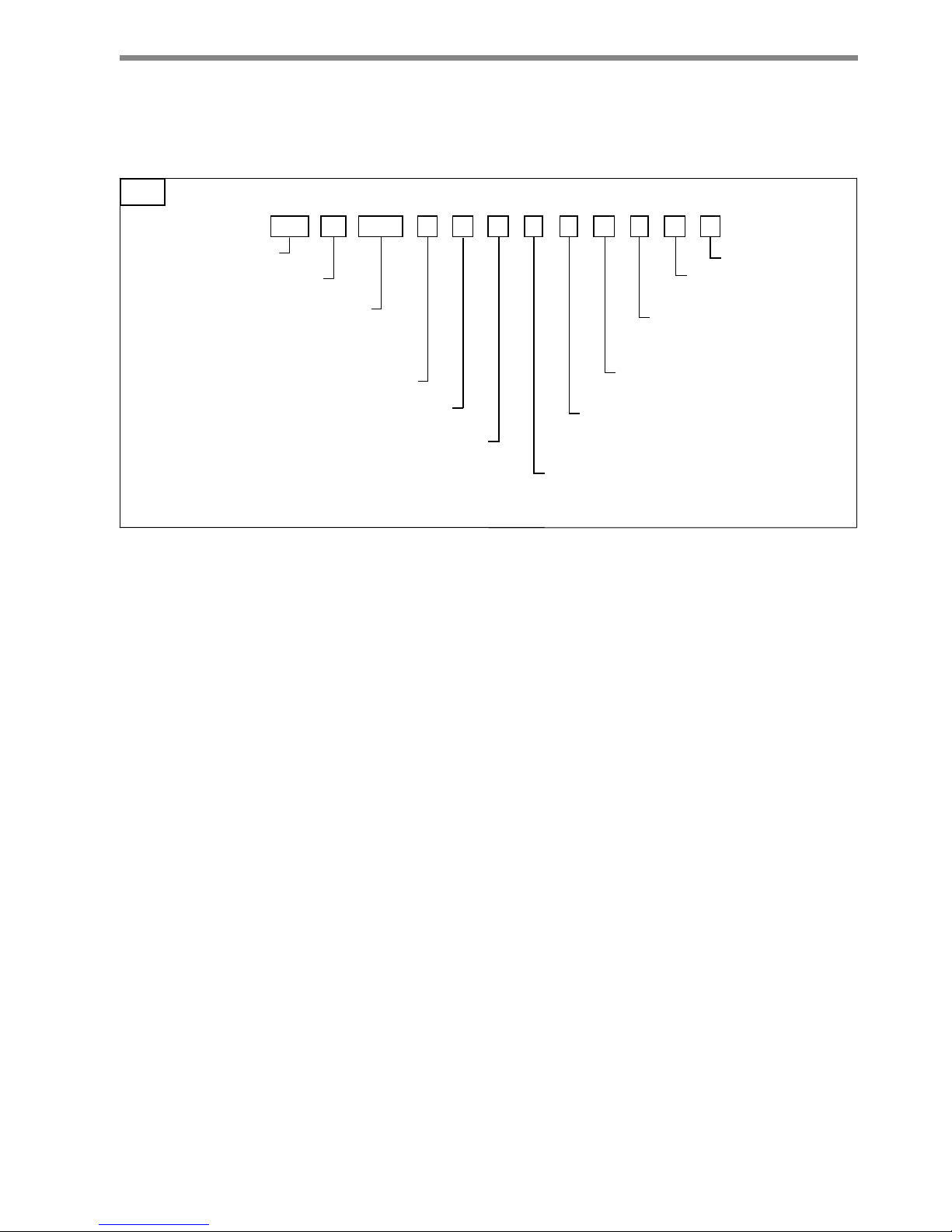

Model Nomenclature

TM W A FU 1 0 C 0 C S

1 2 3 4 5 6 7

8

9101112131415

TM = TRANQUILITY® MEDIUM TEMPERATURE

MODEL TYPE

W = WATER TO W A TER HEA T PUMP

CONFIGURATION

UNIT SIZE

036

060

120

170

340

REVISION LEVEL

A = CURRENT

VOL TAGE

CONTROLS

1 = COMMERCIAL EXTENDED RANGE

CABINET INSULATION

2 = COMMERCIAL EXTENDED RANGE w/ULTRA QUIET

HOT WA TER GENERA T OR OPTIONS

C = Copper

SOURCE WA TER COIL OPTIONS

N = Cupro-nickel

C = Copper

LOAD WA TER COIL OPTIONS

N = Cupro-nickel

S = STANDARD

Z17

0 = N O NE (036-340)

2 =HOT WATER GENERATOR COIL (036-120 ONLY)

RESERVED - FUTURE OPTIONS

0 = NONE

V = 220-240/50/1

}

F = CXM

G = DXM

H = CXM w/LON

J = DXM w/LON

T = CXM w/MPC

U = DXM w/MPC

CE

MARKED

FOR EUROPE

340

U = 380-420/50/3

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

4

ClimateMaster Water-Source Heat Pumps

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

General Information

WARNING!

WARNING!

CAUTION!

CAUTION! To avoid equipment damage, DO NOT use

these units as a source of heating or cooling during the

construction process. The mechanical components and

fi lters will quickly become clogged with construction dirt

and debris, which may cause system damage.

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal profi ciency requirements.

Safety

Warnings, cautions, and notices appear throughout this

manual. Read these items carefully before attempting

any installation, service, or troubleshooting of the

equipment.

DANGER: Indicates an immediate hazardous situation,

which if not avoided will result in death or serious

injury. DANGER labels on unit access panels must be

observed.

WARNING: Indicates a potentially hazardous situation,

which if not avoided could result in death or serious

injury.

CAUTION: Indicates a potentially hazardous situation

or an unsafe practice, which if not avoided could result

in minor or moderate injury or product or property

damage.

NOTICE: Notifi cation of installation, operation, or

maintenance information, which is important, but which

is not hazard-related.

WARNING! All refrigerant discharged from this unit must

be recovered WITHOUT EXCEPTION. Technicians must

follow industry accepted guidelines and all local, state,

and federal statutes for the recovery and disposal of

refrigerants. If a compressor is removed from this unit,

refrigerant circuit oil will remain in the compressor. To

avoid leakage of compressor oil, refrigerant lines of the

compressor must be sealed after it is removed.

THE SMART SOLUTION FOR ENERGY EFFICIENCY

5

climatemaster.com

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

Inspection

Upon receipt of the equipment, carefully check the

shipment against the bill of lading. Make sure all units

have been received. Inspect the carton or crating of

each unit, and inspect each unit for damage. Assure

the carrier makes proper notation of any shortages or

damage on all copies of the freight bill and completes a

common carrier inspection report. Concealed damage

not discovered during unloading must be reported to

the carrier within 15 days of receipt of shipment. If not

fi led within 15 days, the freight company can deny the

claim without recourse. Note: It is the responsibility of

the purchaser to fi le all necessary claims with the carrier.

Notify the ClimateMaster Traffi c Department of all

damage within fi fteen (15) days of shipment.

Storage

Equipment should be stored in its original packaging in

a clean, dry area. Store units in an upright position at all

times. Do not stack TMW170 or 340. The stack limit for

TMW036, 060 and 120 is three.

Unit Protection

Cover units on the job site with either shipping

packaging, vinyl fi lm, or an equivalent protective

covering. Cap the open ends of pipes stored on the

job site. In areas where painting, plastering, and/or

spraying has not been completed, all due precautions

must be taken to avoid physical damage to the units and

contamination by foreign material. Physical damage and

contamination may prevent proper start-up and may

result in costly equipment clean-up.

Examine all pipes, fi ttings, and valves before installing

any of the system components. Remove any dirt or trash

found in or on these components.

Pre-Installation

Installation, Operation, and Maintenance instructions

are provided with each unit.. The installation site chosen

should include adequate service clearance around the

unit. Before unit start-up, read all manuals and become

familiar with the unit and its operation. Thoroughly check

the system before operation.

Prepare units for installation as follows:

1. Compare the electrical data on the unit nameplate

with ordering and shipping information to verify that

the correct unit has been shipped.

2. Keep the cabinet covered with the shipping

packaging until installation is complete and all

plastering, painting, etc. is fi nished.

3. Verify r efrigerant tubing is fr ee of kinks or dents and

that it does not touch other unit components.

4. Inspect all electrical connections. Connections must

be clean and tight at the terminals.

CAUTION!

CAUTION!

CAUTION!

CAUTION! CUT HAZARD - Failure to follow this caution

may result in personal injury. Sheet metal parts may have

sharp edges or burrs. Use care and wear appropriate

protective clothing, safety glasses and gloves when

handling parts and servicing heat pumps.

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature or

humidity extremes (e.g., attics, garages, rooftops, etc.).

Corrosive conditions and high temperature or humidity can

signifi cantly reduce performance, reliability, and service life.

Always move and store units in an upright position. Tilting

units on their sides may cause equipment damage.

CAUTION! All three phase scroll compressors must have

direction of rotation verifi ed at start-up. Verifi cation is

achieved by checking compressor Amp draw. Amp draw

will be substantially lower compared to nameplate values.

Additionally, reverse rotation results in an elevated sound

level compared to correct rotation. Reverse rotation will

result in compressor internal overload trip within several

minutes. Verify compressor type before proceeding.

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

6

ClimateMaster Water-Source Heat Pumps

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

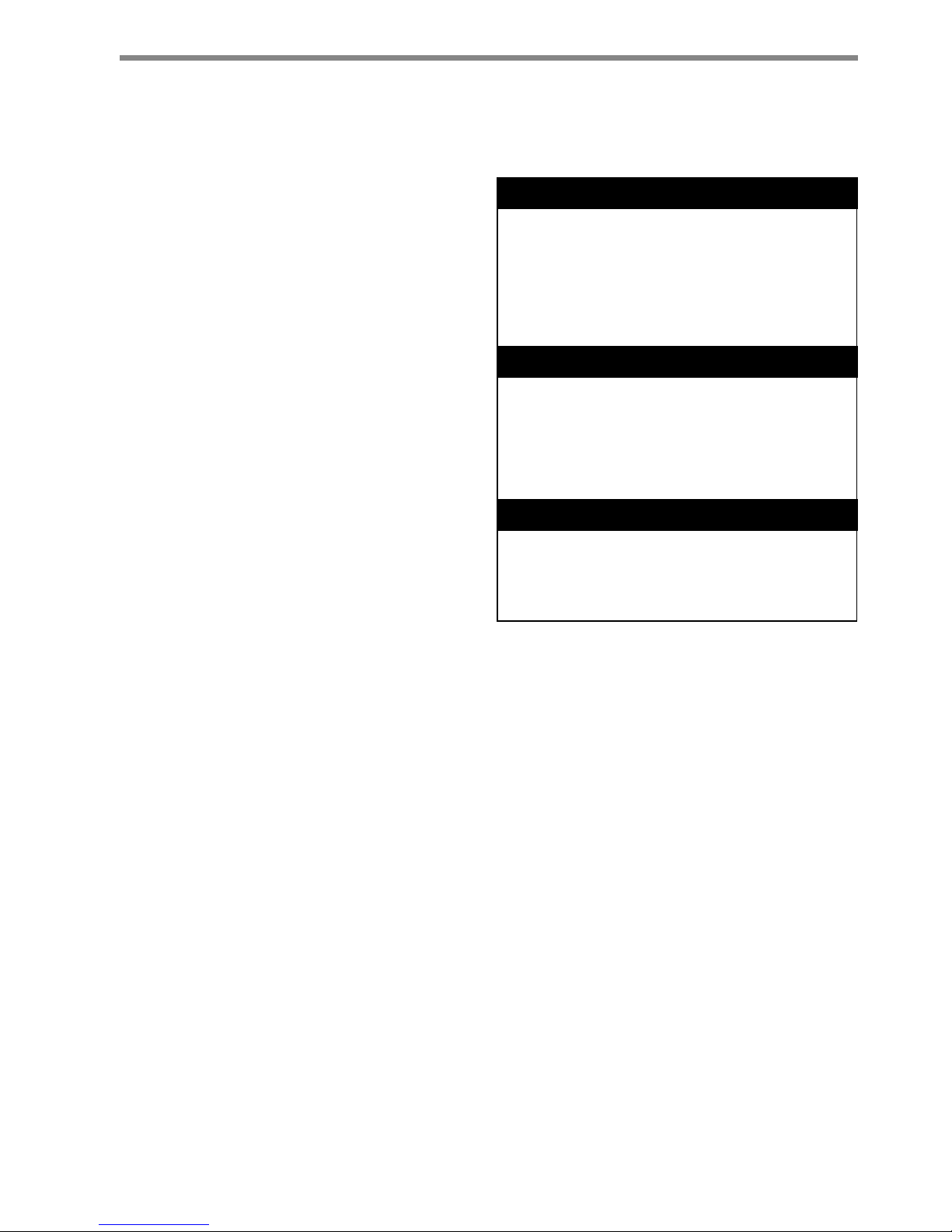

Unit Physical Data

Model 036 060 120 170 340

Compressor (qty) Scroll (1) Scroll (2) Scroll (1) Scroll (2)

Factory Charge HFC-410A kg per circuit 2.04 2.83 6.8

Water Connection Size

Source/Load (in) 3/4 1 1-1/2 2

Hot Water Generator FPT (in)

½

N/A

Weight - Operating kg 158 163 329 329 604

Weight - Packaged kg 169 175 349 347 608

Water Volume (Source)

Liters 3.64 5.04 10.02 13.27 25.44

Dual isolated compressor mounting

Balanced port expansion valve (TXV)

Insulated Source and Load Water Coils standard

Insulated Refrigerant Circuit standard

Compressor on (green) and fault (red) light

FPT - Female Pipe Thread

Unit Maximum Water Working Pressure

Options Max Working Pressure [kPa]

Base Unit 2,068

THE SMART SOLUTION FOR ENERGY EFFICIENCY

7

climatemaster.com

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

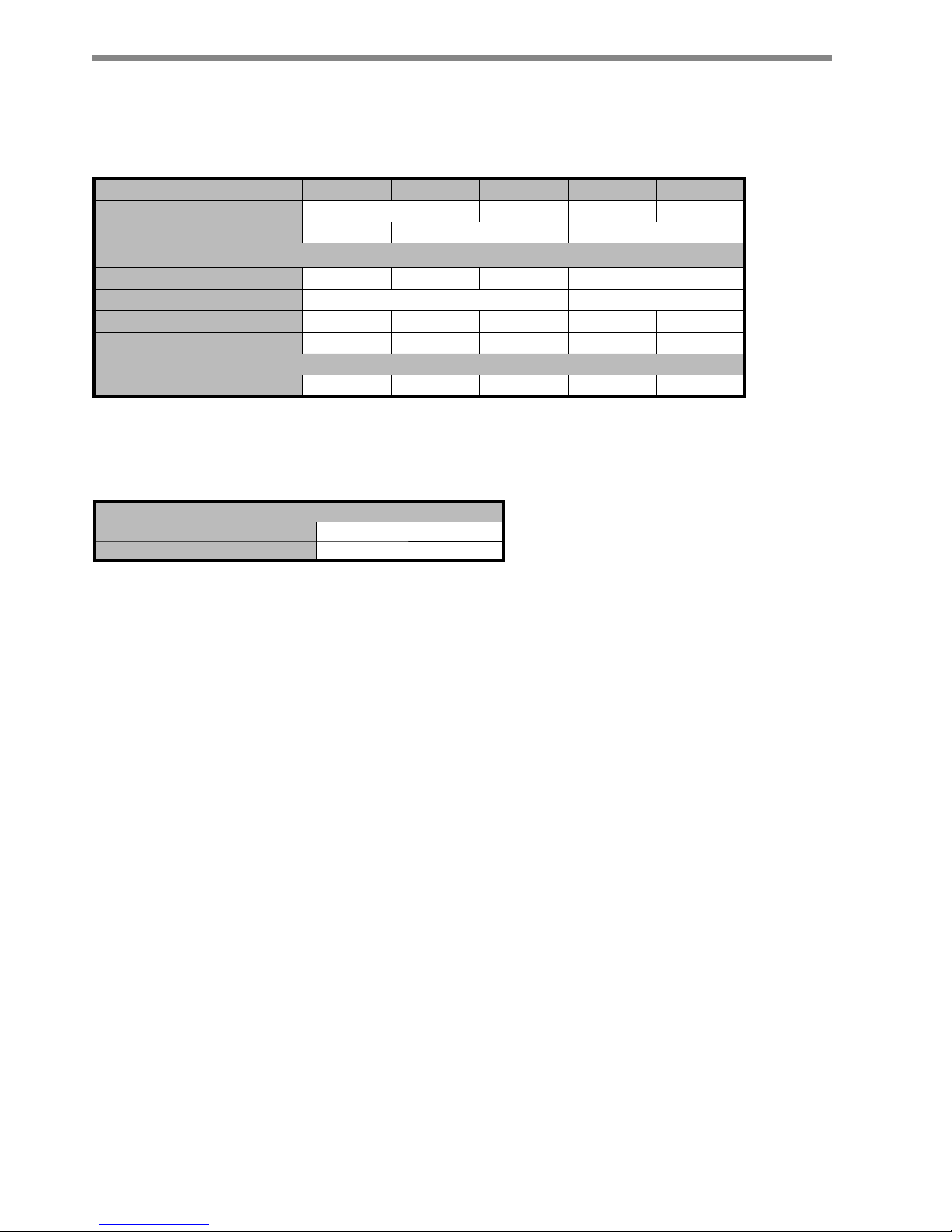

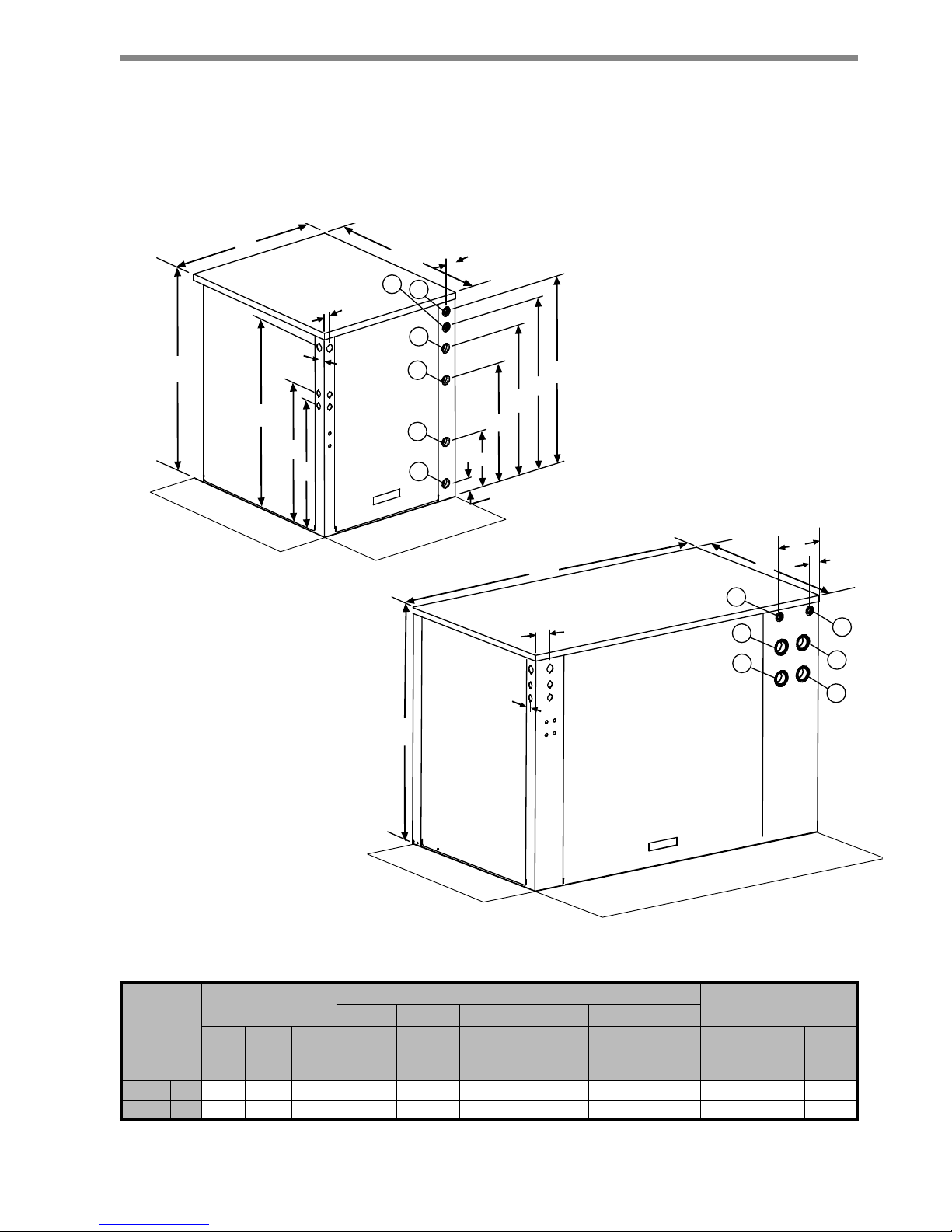

TMW036 - 120 - Unit Dimensional Data

%

&

$

0

/

.

FP

-

+

*

)

(

'

5HTXLUHG

6HUYLFH$FFHVV

2SWLRQDO

6HUYLFH$FFHVV

FP

FP

5HTXLUHG

6HUYLFH$FFHVV

2SWLRQDO

6HUYLFH$FFHVV

%

&

$

FP

FP

FP

FP

Notes:

1. Front & side access is preferred for service

access. However, all components may be

serviced from the front access panel if side

access is not available.

2. While clear access to all removable panels

is not required, installer should take care

to comply with all building codes and allow

adequate clearance for future fi eld services.

Water to

Water

Overall Cabinet

Water Connections

Electric Access Plugs

123 456

A

DepthBWidthCHeight

D

Source

(Outdoor)

Water In

E

Source

(Outdoor)

Water Out

F

Load

(Indoor)

Water In

G

Load

(Indoor)

Water Out

H

HWG

Water In

J

HWG

Water

Out

K

Low

Voltage

L

External

Pump

M

Power

Supply

036-060 cm. 77.8 64.5 83.8 6.9 23.9 49.3 62.2 70.9 77.2 53.1 58.2 78.5

120 cm. 77.8 134.4 94 64.0 64.0 76.5 76.5 88.6 88.6 75.9 81.0 87.4

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

8

ClimateMaster Water-Source Heat Pumps

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

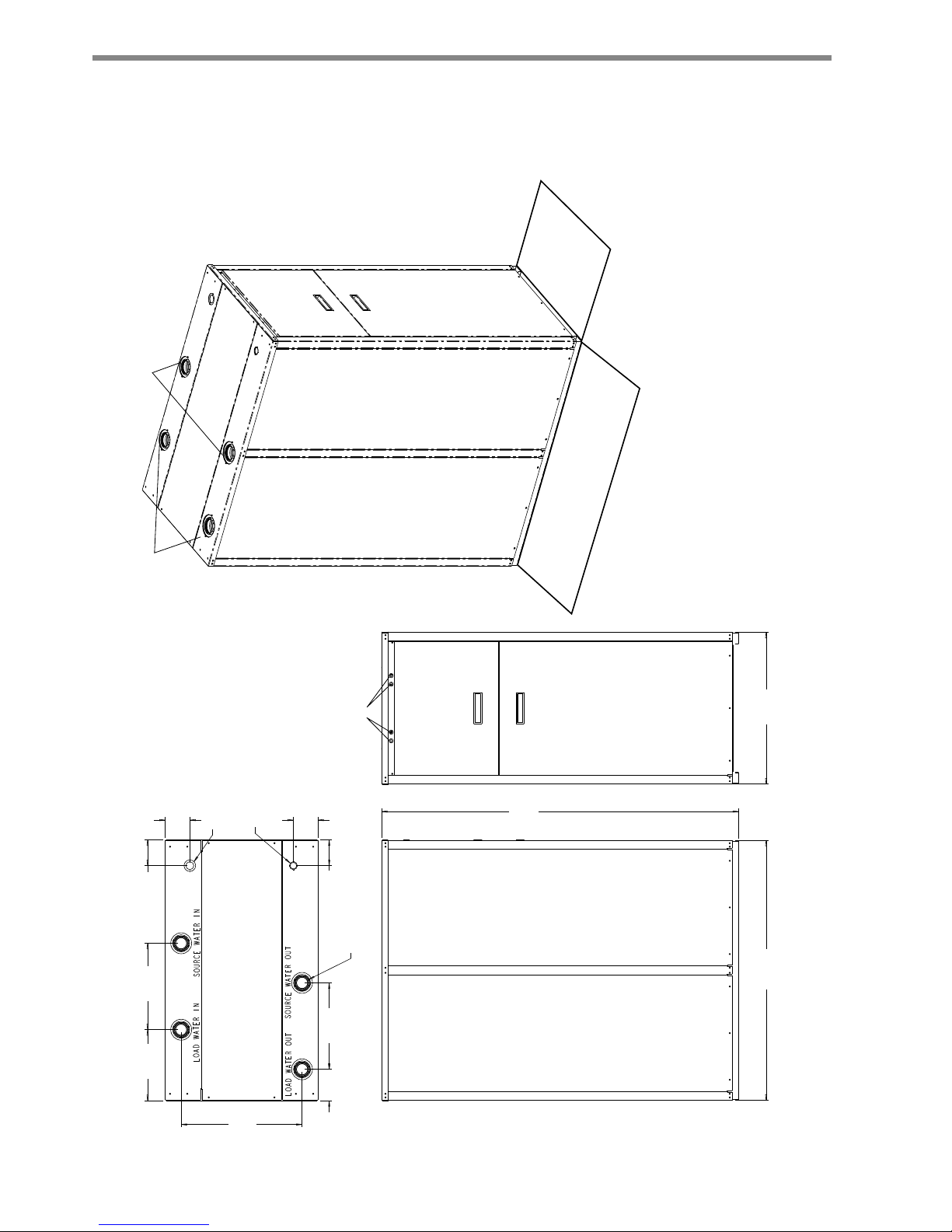

TMW170 & 340 - Unit Dimensional Data

3RZHU6XSSO\:LULQJ

[PP'RXEOH.QRFNRXW

&RQWURO:LULQJ

[PP'RXEOH.QRFNRXW

µ)37:DWHU&RQQHFWLRQV

)DXOW5XQ/LJKWV

/HIW

6LGH

9LHZ

)URQW

9LHZ

7RS

9LHZ

/RDG

6RXUFH

6LGH

5HIULJ

&LUFXLW

$FFHVV

3DQHO

)URQW

&RPSUHVVRU

$FFHVV

3DQHO

(OHFWULFDO

$FFHVV

3DQHO

+HDGHU

$FFHVV

3DQHO

7RS

1RWHV'LPHQVLRQVVKRZQLQFHQWLPHWHUVXQOHVVQRWHGRWKHUZLVH

)RUPXOWLSOHXQLWVSODFHGVLGHE\VLGHDOORZ

FPPLQLPXPIURQWDFFHVV

)37)HPDOH3LSH7KUHDG

0LQLPXP FP

5HTXLUHG6HUYLFH

$FFHVV

2SWLRQDO6LQJOH8QLW

FP $GGLWLRQDO

6HUYLFH$FFHVV

THE SMART SOLUTION FOR ENERGY EFFICIENCY

9

climatemaster.com

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

Unit Installation

Installation of Supply and Return Piping

Follow these piping guidelines.

1. Install a drain valve at the base of each supply and

return riser to facilitate system fl ushing.

2. Install shut-off / balancing valves and unions at

each unit to permit unit removal for servicing.

3. Place strainers at the inlet of each system

circulating pump.

4. Select the proper hose length to allow slack

between connection points. Hoses may vary in

length by +2% to -4% under pressure.

5. Exceeding the minimum bend radius may cause

the hose to collapse which reduces water fl ow rate.

Install an angle adapter to avoid sharp bends in

the hose when the radius falls below the required

minimum and causes a slight kink.

PIPING INSTALLATION

Insulation is not required on loop water piping

except where the piping runs through unheated

areas or outside the building or when the loop water

temperature is below the minimum expected dew

point of the pipe ambient temperature. Insulation is

required if loop water temperature drops below the

dew point.

Pipe joint compound is not necessary when Tefl on

threaded tape is pre-applied to hose assemblies or

when fl ared-end connections are used. If pipe joint

compound is preferred, use compound only in small

amounts on the pipe threads of the fi tting adapters.

Prevent sealant from reaching the fl ared surfaces of

the joint.

Note: When antifreeze is used in the loop, assure

that it is compatible with Tefl on tape or pipe joint

compound employed.

Maximum allowable torque for brass fi ttings is

41 N-m. If a torque wrench is not available, tighten

fi nger-tight plus one quarter turn. Tighten steel

fi ttings as necessary.

TMW Unit Location

These units are not designed for outdoor installation.

Locate the unit in an INDOOR area that allows

enough space for service personnel to perform typical

maintenance or repairs.

The installation of water source heat pump

units and all associated components, parts and

accessories which make up the installation shall

be in accordance with the regulations of ALL

authorities having jurisdiction and MUST conform

to all applicable codes. It is the responsibility of the

Installing Contractor to determine and comply with

ALL applicable codes and regulations.

Locate the unit in an indoor area that allows easy

removal of access panels, and has enough space for

service personnel to perform maintenance or repair.

Provide suffi cient room to make water and electrical

connections.. Any access panel screws that would be

diffi cult to remove after the unit is installed should be

removed prior to setting the unit. These units are not

approved for outdoor installation and, therefore, must

be installed inside the structure being conditioned. Do

not locate in areas where ambient conditions are not

maintained within 4-38°C.

WARNING!

WARNING! Piping must comply with all applicable codes.

WARNING!

WARNING! Do not bend or kink supply lines or hoses.

CLIMATEMASTER WATER-SOURCE HEAT PUMPS

10

ClimateMaster Water-Source Heat Pumps

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

Piping Installation

TMW Unit Load Plumbing

The applications are too varied to describe in this

document. However, some basic guidelines will be

presented. Much of the discussions on water loop

applications would be valid for the load plumbing

discussion as well. All plumbing should conform to local

codes with the following considerations:

Wide temperature variation applications such as

heating/cooling coils:

- Employ piping materials that are rated for the

maximum temperature and pressure combination.

This excludes PVC for most heating applications.

- Insure that load water fl ow in high temperature

heating applications is at least 3.2 l/m per kW

to improve performance and reduce nuisance high

pressure faults.

- DO NOT employ plastic to metal threaded joints

- Utilize a pressure tank and air separator vent system

to equalize pressure and remove air..

Swimming Pool Hot Tub Applications:

- Load side heat exchanger should be isolated with

secondary heat exchanger constructed of anticorrosion material in all chlorine/bromine fl uid

applications.

Potable Water Applications:

- Load side heat exchanger should be isolated with

secondary heat exchanger for use in potable water

systems.

- Insure load water fl ow in high temperature heating

applications is at least 3.2 l/m per kW to improve

performance and reduce nuissance to high pressure

faults.

LOAD PLUMBING INSTALLATION

Optional pressure-rated hose assemblies designed

specifi cally for use with ClimateMaster units are available.

Similar hoses can be obtained from alternate suppliers.

Supply and return hoses are fi tted with swivel-joint fi ttings

at one end to prevent kinking during installation.

CAUTION!

CAUTION! Corrosive system water requires corrosion

resistant fi ttings and hoses and possibly water treatment.

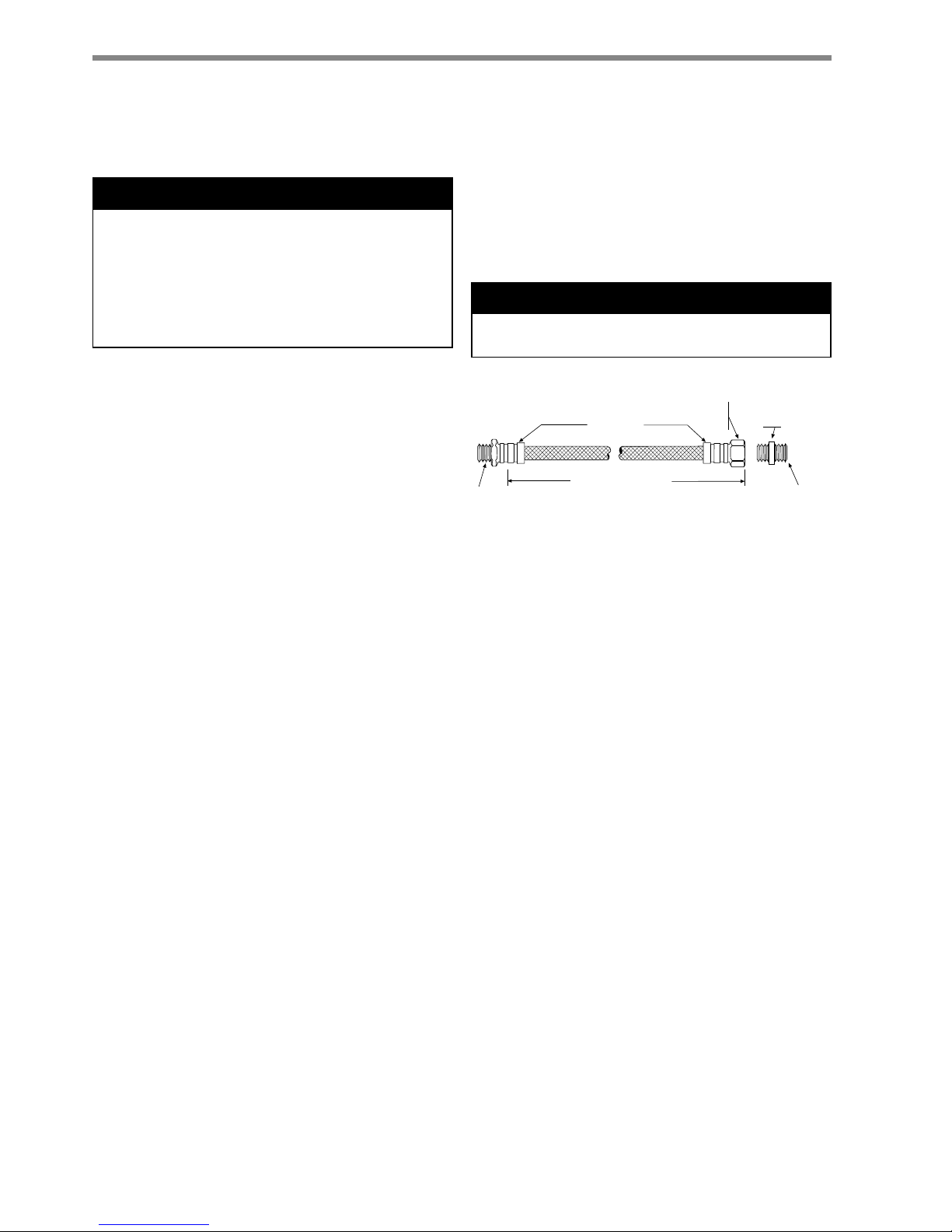

Figure 1: Supply/Return Hose Kit

Rib Crimped

Length

(0.6m Length Standard)

Swivel

Brass

Fitting

Brass

Fitting

MPT

MPT

Note: The manufacturer strongly recommends all

piping connections, both internal and external to

the unit, be pressure tested by an appropriate

method prior to any fi nishing of the interior space

or before access to all connections is limited. Test

pressure may not exceed the maximum allowable

pressure for the unit and all components within

the water system. The manufacturer will not be

responsible or liable for damages from water leaks

due to inadequate or lack of a pressurized leak test,

or damages caused by exceeding the maximum

pressure rating during installation.

Refer to Figure 1 for an illustration of a Supply/Return

Hose Kit. Male adapters secure hose assemblies to the

unit and risers. Install hose assemblies properly and

check them regularly to avoid system failure and reduced

service life.

WARNING! Polyolester Oil, commonly known as POE

oil, is a synthetic oil used in many refrigeration systems

including those with HFC-410A refrigerant. POE oil, if it

ever comes in contact with PVC or CPVC piping, may

cause failure of the PVC/CPVC. PVC/CPVC piping should

never be used as supply or return water piping with water

source heat pump products containing HFC-410A as

system failures and property damage may result.

WARNING!

THE SMART SOLUTION FOR ENERGY EFFICIENCY

11

climatemaster.com

Tranquility® Modular Water-to-Water (TMW )Series

Rev.: 02 January, 2013

Water-Loop Heat Pump Applications

Commercial systems typically include a number of

units plumbed to a common piping system. Any unit

plumbing maintenance work can introduce air into the

piping system, therefore air elimination equipment is

a major portion of the mechanical room plumbing. In

piping systems expected to utilize water temperatures

below 10°C, 13mm closed cell insulation is required on

all piping surfaces to eliminate condensation. Metal to

plastic threaded joints should never be employed due

to their tendency to leak over time. Tefl on tape thread

sealant is recommended for FPT water connections

(commercial class) to minimize internal fouling of the heat

exchanger. Do not overtighten connections and route

piping so as not to interfere with service or maintenance

access. Hose kits are available from ClimateMaster in

Figure 2 for connection between the TMW unit and the

piping system.

The hose kits include shut off valves, P/T

plugs for performance measurement, high pressure

stainless steel braid hose, "Y" type strainer 20 mesh

(841 micron) [0.84mm]) with blowdown valve, and "J"

type swivel connection. Balancing valves to facilitate

the balancing of the system, may also be included in

the hose kit. The piping system should be fl ushed to

remove dirt, piping chips, and other foreign material

prior to operation. See Piping System Cleaning and

Flushing Procedures later in this document. The fl ow

rate is usually set between 2.4 l/m and 3.2 l/m per kW

of cooling capacity. ClimateMaster recommends 2.7

l/m per kW for most applications of water loop heat

pumps. To insure proper maintenance and servicing,

P/T ports are imperative for temperature and fl ow

verifi cation, as well as performance checks.

Cooling Tower/Boiler Systems typically utilize a

common loop maintained between 16-32°C. The use

of a closed circuit evaporative cooling tower with a

secondary heat exchanger between the tower and the

water loop is recommended. If an open type cooling

tower is used continuously, chemical treatment and

fi ltering will be necessary.

Low Water Temperature Cutout Setting

CXM or DXM Control:

When an antifreeze is selected,

the FP1 jumper (JW3) should be clipped to select the

low temperature 12°C setpoint to avoid nuisance faults.

See Figure 4: Low Water Temperature Cutout - FP1.

Figure 2: Typical Water Loop Application

Load Connections

(Hot Water/Chilled Water)

Source Connections

Power Disconnect

Loading...

Loading...