ClimateMaster TAH Series, TAH 026-A, TAH 038-B, TAH 026-B, TAH 049-B Installation, Operation & Maintenance Instructions Manual

...

Tranquility Air Handler (TAH)

Tran

l

e

Air Handler for

Tranquility Split Series

Installation, Operation &

Insta

Maintenance Instructions

aint

97B0101N01

Rev: 5/2/12

Table of Contents

Model Nomenclature 3

General Information 4

Pre-Installation 4

Safety 5

Physical Data 6

Dimensional Data 7

Installation 8-13

Electrical - Thermostat Wiring 14

ECM Blower Control 15-16

Electrical - Power Wiring 17

Electrical Table 17

Wire Diagram 18

Blower Data 19

Electric Heat Installation 20

Electric Heat Wiring 21-22

Electric Heat Staging Options 23

Unit & System Checkout 24

Maintenance 24

Warranty 25

Revision History 26

Tranquility Air Handler (TAH)

Rev.: May 2, 2012

This page was intentionally left blank.

2

Geothermal Heat Pump Systems

Tranquility Air Handler (TAH)

Rev.: May 2, 2012

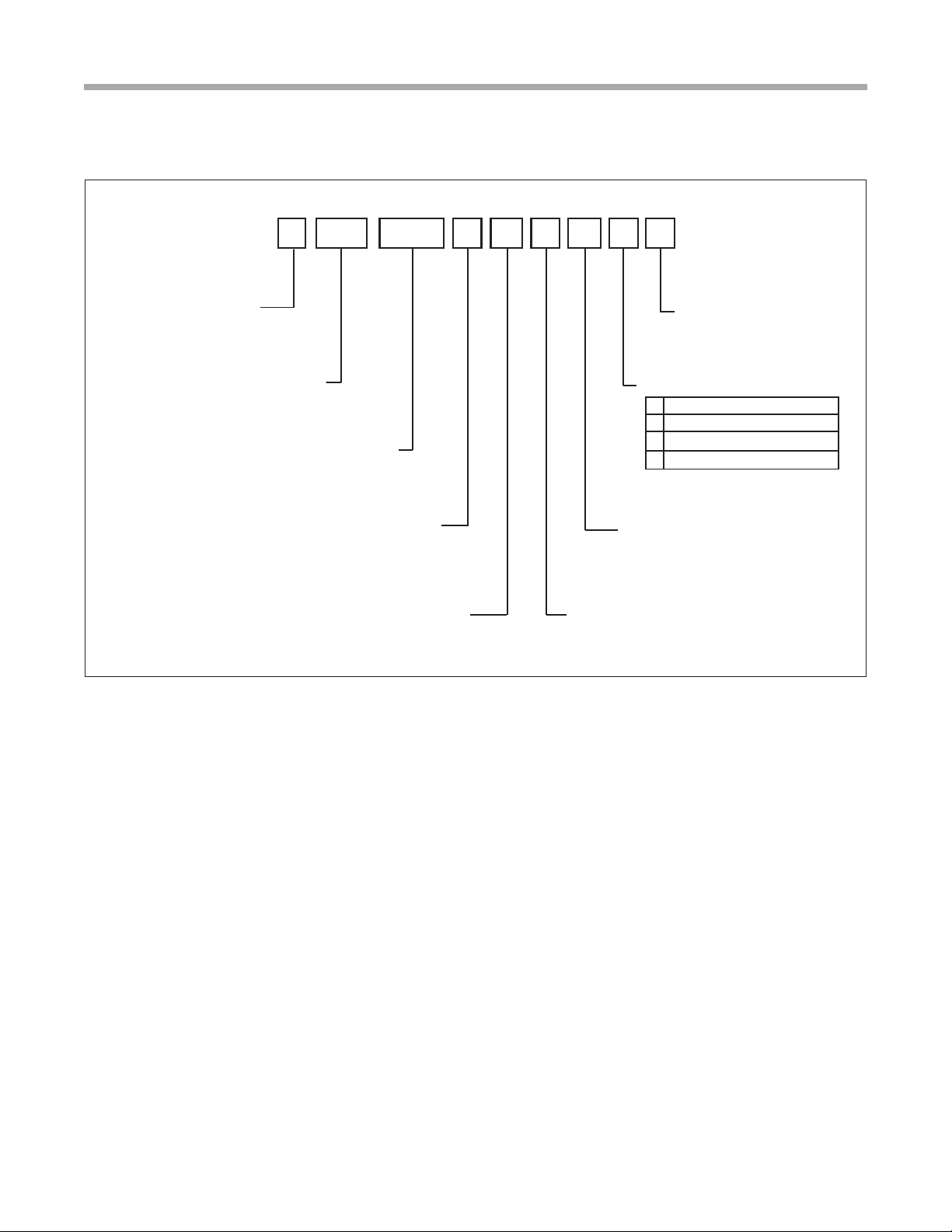

Model Nomenclature

MODEL TYPE

T = TRANQUILITY R410A

CONFIGURATION

AH = AIR HANDLER

NOMINAL CAP ACITY

026

038

049

064

2 31 4 5 6

A HT 0 2 6

REVISION

A = CURRENT REVISION

VOLTAGE

G = 208-230/60/1

( NOTE; FIELD CONVERTIBLE TO 1 15v )

7

A

8

G

9

S

10

11

M

A

CABINET OPTIONS

M = MULTI-POSITION

CONTROLS

S = STANDARD

12

S

FUTURE USE

S = STANDARD

CABINET SIZE

(WIDTH, INCHES)

SIZE 026 ONLY ; 18.5 WIDTH

A

SIZES 026, 038, 049 ONLY ; 22.5 WIDTH

B

SIZES 038, 049, 064 ; 25.5 WIDTH

C

3

Tranquility Air Handler (TAH)

Rev.: May 2, 2012

General Information

Air Handler Description

ClimateMaster Tranquility Air Handlers are designed for

use with ClimateMaster indoor/outdoor split units and are

available for vertical upfl ow or downfl ow, and horizontal left

or horizontal right airfl ow.

• Air coils are constructed of aluminum fi ns bonded to

internally grooved copper tubing.

• Air coils are tested at the factory with an extensive

refrigerant leak check.

• Air coils have sweat refrigerant connections.

• Ideally suited for new installations or add on air

conditioning.

• Feature two sets of 3/4” [14.1 mm] F.P.T. Condensate

drain connections for ease of connection.

• Air Handlers are A.H.R.I. certifi ed for system application

with ClimateMaster indoor and outdoor split units.

• Condensate drain pan is constructed of high grade, heat

resistant, corrosion free thermal-set material.

• Bi-Directional airfl ow eliminates the need to switch any

internal components from horizontal left to right.

• Unique drain pan design maximizes application fl exibility

and condensate removal.

Inspection

Upon receipt of the equipment, carefully check the shipment

against the bill of lading. Make sure all units have been

received. Inspect the packaging of each unit, and inspect each

unit for damage. Insure that the carrier makes proper notation

of any shortages or damage on all copies of the freight bill and

completes a common carrier inspection report. Concealed

damage not discovered during unloading must be reported

to the carrier within 15 days of receipt of shipment. If not fi led

within 15 days, the freight company can deny the claim without

recourse. Note: It is the responsibility of the purchaser to fi le

all necessary claims with the carrier. Notify your equipment

supplier of all damage within fi fteen (15) days of shipment.

Storage

Equipment should be stored in its original packaging in a

clean, dry area. Store units in an upright position at all times.

Stack units a maximum of 3 units high.

Unit Protection

Cover units on the job site with either the original packaging

or an equivalent protective covering. Cap the open ends of

pipes stored on the job site. In areas where painting, plastering,

and/or spraying has not been completed, all due precautions

must be taken to avoid physical damage to the units and

contamination by foreign material. Physical damage and

contamination may prevent proper start-up and may result in

costly equipment clean-up.

are provided with each unit. Horizontal equipment is

designed for installation above false ceiling or in a ceiling

plenum. Other unit confi gurations are typically installed

in a mechanical room. The installation site chosen should

include adequate service clearance around the unit. Before

unit start-up, read all manuals and become familiar with the

unit and its operation. Thoroughly check the system before

operation.

Prepare units for installation as follows:

1. Compare the electrical data on the unit nameplate with

ordering and shipping information to verify that the

correct unit has been shipped.

2. Keep the cabinet covered with the original packaging

until installation is complete and all plastering, painting,

etc. is fi nished.

3. Verify refrigerant tubing is free of kinks or dents and that

it does not touch other unit components.

4. Inspect all electrical connections. Connections must be

clean and tight at the terminals.

WARNING!

WARNING! These instructions are intended as an aid to

qualifi ed licensed service personnel for proper installation,

adjustment and operation of this unit. Read these

instructions thoroughly before attempting installation

or operation. Failure to follow these instructions may

result in improper installation, adjustment, service or

maintenance possibly resulting in property damage,

personal injury or death.

CAUTION!

CAUTION! DO NOT store or install units in corrosive

environments or in locations subject to temperature

or humidity extremes. Corrosive conditions and high

temperature or humidity can signifi cantly reduce

performance, reliability, and service life.

CAUTION!

CAUTION! CUT HAZARD - Failure to follow this caution

may result in personal injury. Sheet metal parts may have

sharp edges or burrs. Use care and wear appropriate

protective clothing, safety glasses and gloves when

handling parts and servicing.

Examine all pipes, fi ttings, and valves before installing any of

the system components. Remove any dirt or debris found in

or on these components.

Pre-Installation

Installation, Operation, and Maintenance instructions

4

Geothermal Heat Pump Systems

Tranquility Air Handler (TAH)

Rev.: May 2, 2012

Safety

The installation of water source heat pump units and all

associated components, parts and accessories which make

up the installation shall be in accordance with the regulations

of ALL authorities having jurisdiction and MUST conform to

all applicable codes. It is the responsibility of the installing

contractor to determine and comply with ALL applicable

codes and regulations.

Replacement Parts

Any replacement part must be the same as or an approved

alternate to the original part supplied. The manufacturer will

not be responsible for replacement parts not designed to

physically fi t or operate within the design parameters the

original parts were selected for. When ordering replacement

parts, it is necessary to order by part number and include

the complete model number and serial number from the coil

rating plate. (See parts list for unit component part numbers.

Parts are available through the local distributor.)

Safety

Warnings, cautions and notices appear throughout this

manual. Read these items carefully before attempting any

installation, service, or troubleshooting of the equipment.

DANGER: Indicates an immediate hazardous situation, which

if not avoided will result in death or serious injury. DANGER

labels on unit access panels must be observed.

CAUTION!

CAUTION! It is recommended that an auxiliary

secondary drain pan be installed under units containing

evaporator coils that are located in any area of a structure

where damage to the building or building contents may

occur as a result of an overfl ow of the coil drain pan or a

stoppage in the primary condensate drain piping.

WARNING!

WARNING! All refrigerant discharged from this unit must

be recovered WITHOUT EXCEPTION. Technicians must

follow industry accepted guidelines and all local, state, and

federal statutes for the recovery and disposal of refrigerants.

To avoid leakage of compressor oil, refrigerant lines of the

compressor must be sealed after it is removed.

CAUTION!

CAUTION! To avoid equipment damage, DO NOT use

these units as a source of heating or cooling during the

construction process. The mechanical components and

fi lters will quickly become clogged with construction dirt

and debris, which may cause system damage.

WARNING: Indicates a poten tiall y hazardous situa tion , which

if not avoided could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation or an

unsafe practice, which if not avoided could result in minor or

moderate injury or product or property damage.

NOTICE: Notifi cation of installation, operation or maintenance

information, which is important, but which is not hazardrelated.

WARNING!

WARNING! The EarthPure® Application and Service

Manual should be read and understood before

attempting to service refrigerant circuits with HFC-410A.

WARNING!

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal profi ciency requirements.

5

Tranquility Air Handler (TAH)

Rev.: May 2, 2012

Unit Physical Data

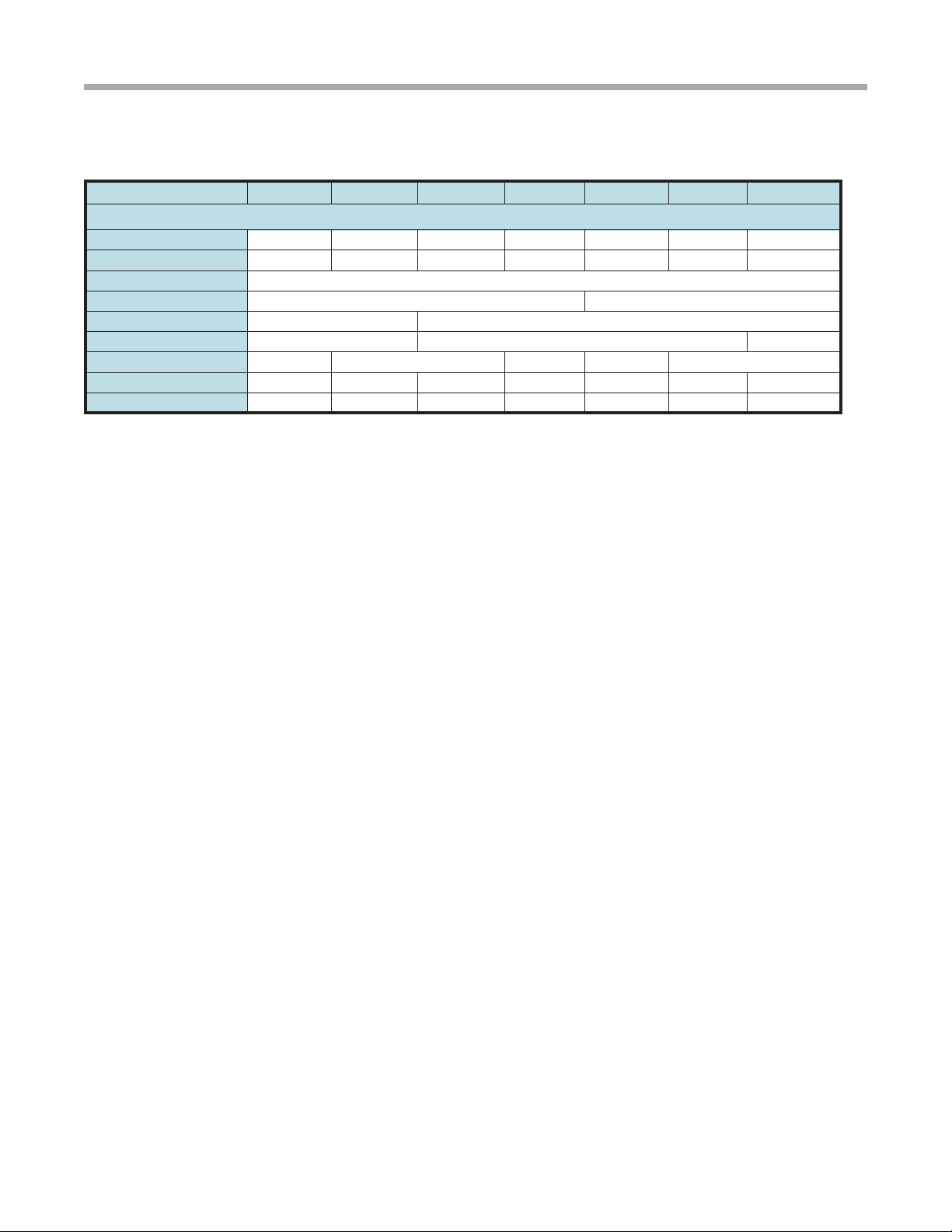

Model 026-A 026-B 038-B 038-C 049-B 049-C 064-C

Emerson ECM Fan Motor & Blower

Liquid I.D. 3/8 3/8 3/8 3/8 3/8 3/8 3/8

Suction I.D. 3/4 3/4 7/8 7/8 7/8 7/8 7/8

Fan Motor Type/Speeds ECM Variable

Fan Motor (hp) 1/2 1

Blower Wheel Size (Dia x W) 9 x 7 12 x 10

Air Coil Dimensions (H x W) 3 - 2 Row 14 x 17 3 - 2 Row 24 x 17 3 - 3 Row 24x17

Filter Standard - 1” Throwaway 16 x 20 20 x 20 20 x 24 20 x 20 20 x 24

Weight - Operating (lbs.) 80 163 173 181 180 188 198

Weight - Packaged (lbs.) 96 179 198 206 218 226 236

6

Geothermal Heat Pump Systems

Tranquility Air Handler (TAH)

Rev.: May 2, 2012

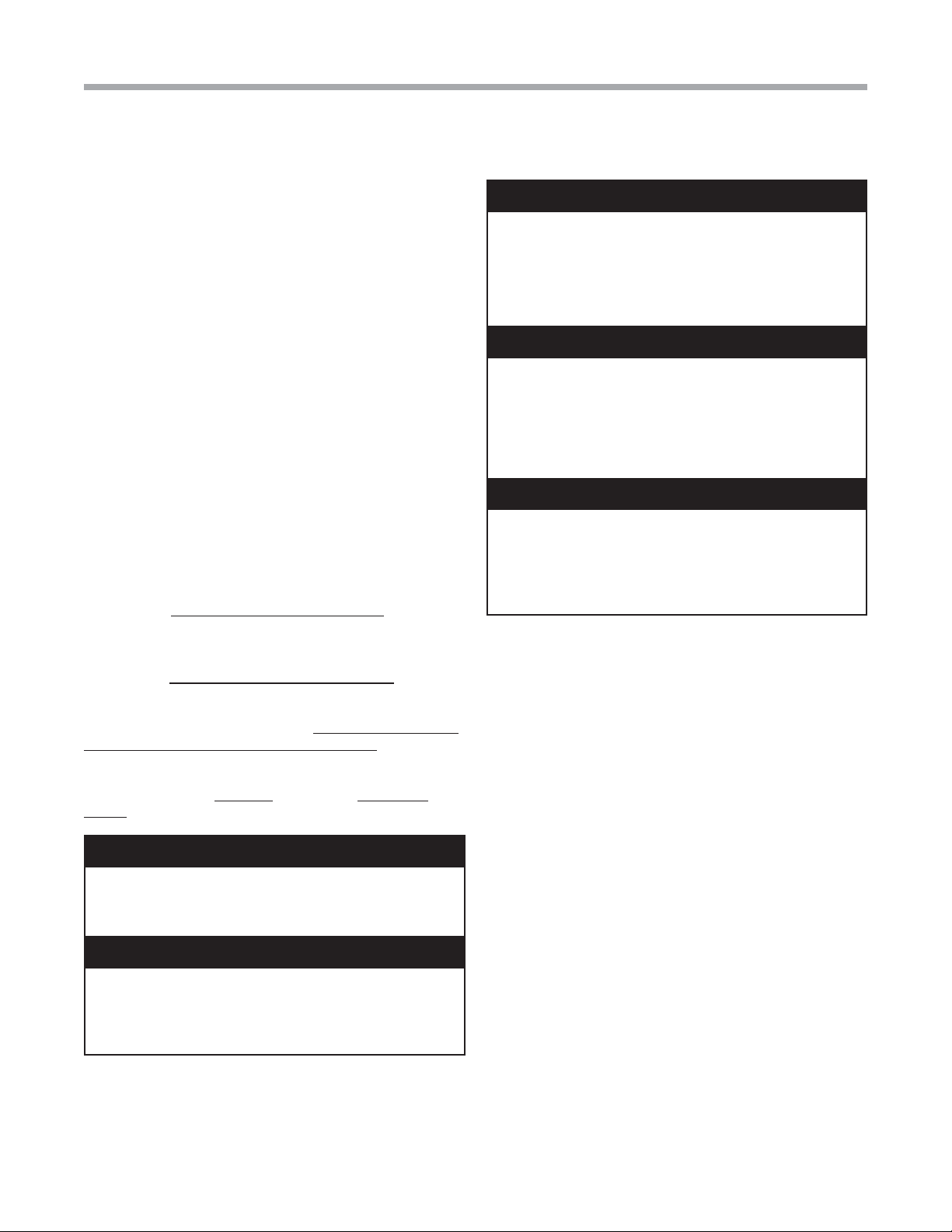

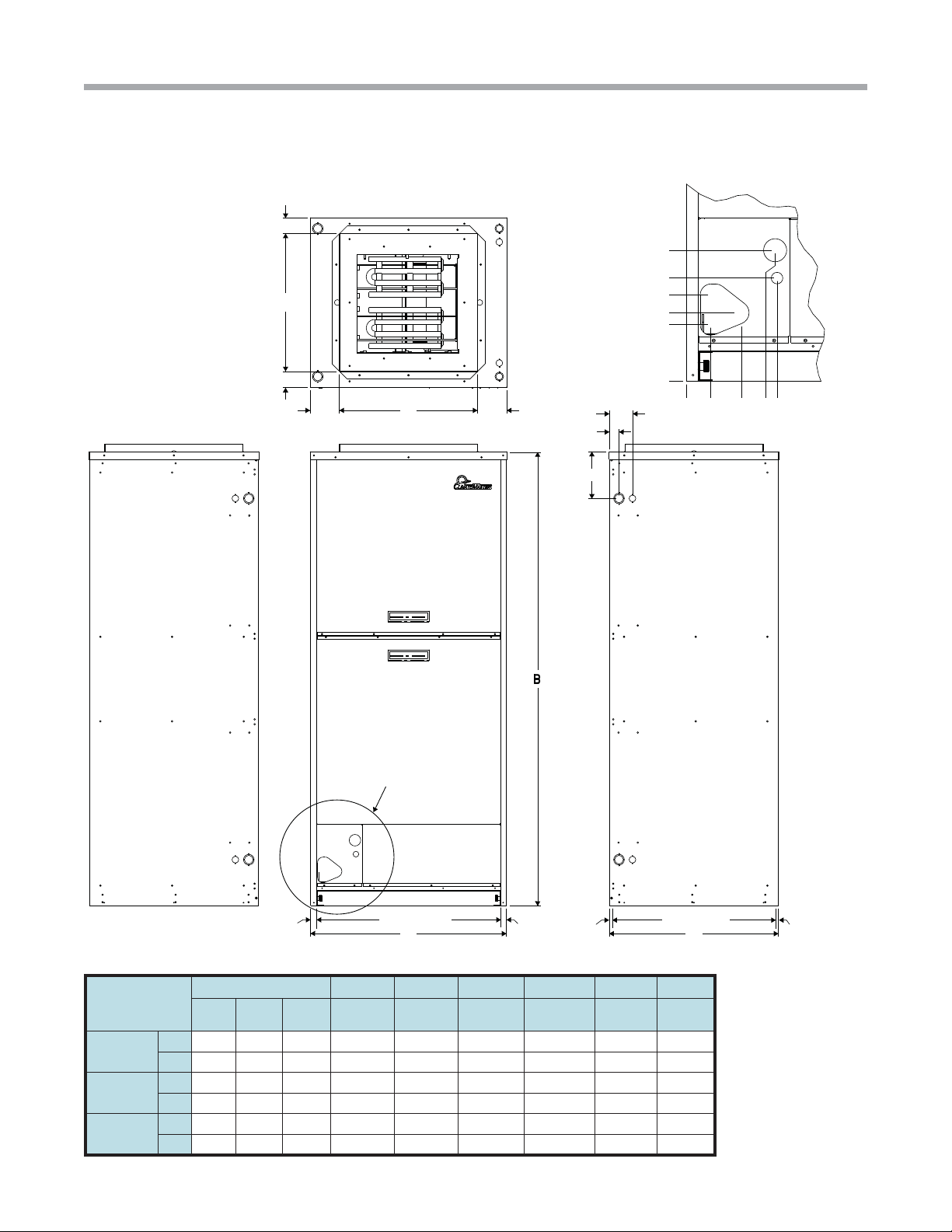

Unit Dimensional Data

J

8.5

6.7

E

5.6

4.5

3.7

H

G

See Detail A

FD

3.

1.3

6.1

0.0

0.0

1.6

3.6

5.8

Detail A

Scale 5/32

5.9

Cabinet

Size

A - Cabinet

B - Cabinet

C - Cabinet

R.A. Opening

A

0.6250.625

R.A. Opening

Overall Cabinet 1 2 3 4 5 6

A

WidthBHeightCDepth

in. 18.5 44.0 22.0 14.0 14.0 2.3 2.3 4.1 4.1

cm. 47.0 111.8 55.9 35.6 35.5 5.8 5.8 10.3 10.3

in. 22.0 55.0 22.0 18.0 18.0 2.1 2.1 2.1 2.1

cm. 55.9 139.7 55.9 45.7 45.7 5.2 5.2 5.2 5.2

in. 25.5 59.0 22.0 18.0 18.0 3.8 3.8 2.1 2.1

cm. 64.8 149.9 55.9 45.7 45.7 9.9 9.9 5.2 5.2

D E F G H J

C

0.8750.75

7

Loading...

Loading...