MPC MULTIPROTOCOL DDC CONTROLS

Application, Operation & Maintenance

97B0031N01

Revised: November 19, 2018

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Table of Contents

MPC Controller Overview .................................................................................................. 3-10

BACview6 Service Tool and Addressing ......................................................................... 11-13

Equipment Touch Tool Overview ..........................................................................................14

MPC LED Codes .....................................................................................................................17

MPC Sequence of Operation .......................................................................................... 18-23

Multi-Generation Water-to-Air Point Matrix ................................................................... 24-34

MPC Feature Conguration ............................................................................................. 35-37

Generation 4 Water-to-Water Points Matrix ................................................................... 38-41

MPC Wall Sensors ............................................................................................................ 42-47

Android App Installation ........................................................................................................48

Equipment Touch Manual- Screen Descriptions ............................................................ 50-68

Frequently Asked Questions (FAQs) .....................................................................................49

Revision History ......................................................................................................................72

2

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC Controller Overview

MPC MultiProtoCol DDC Controls

November 19, 2018

The Multi-Protocol (MPC) Heat Pump controller is a dual

purpose controller. It contains the logic to perform as an

advanced customizable thermostat when combined with

a wall sensor and is designed to allow the integration of

water source heat pump equipment into DDC systems.

The MPC Controller has the ability to communicate

through a choice of four widely used protocols:

1. BACnet MS/TP

2. Johnson Controls N2

3. Modbus

4. LonWorks.

The protocol of choice for the particular system is

selected by simply conguring DIP switches on the MPC

Controller with the exception of LonWorks. The LonWorks

option requires an additional Lon option card (LOC).

This exibility allows one controller, the MPC, to be used

in a multitude of buildings which use any of these four

common protocols.

The MPC serves as a node of information processing

between the heat pump and the DDC network. The MPC

commands the heat pump to heat and cool based upon

sensor inputs. The MPC monitors the operation of the heat

pump and communicates the operating parameters to the

DDC network. The MPC will always work in conjunction

with a CXM, DXM or DXM2 controller, which also resides

in the heat pump control box. The MPC has factory preloaded application software which allows optimal control

of the heat pump equipment. The MPC can run in standalone operation as well as with the DDC network. The heat

pump arrives at the jobsite with the factory installed MPC

Controller. The heat pump is ready to run stand-alone and

then can be connected to the DDC network at any time.

Features

System Controls: In conjunction with the wall sensors, the

MPC offers features such as:

• Room temperature sensing.

• Local setpoint adjustment.

• Local override into Occupied Mode.

• LED for alarm status.

• LED for fault status type.

• Heat pump reset at the wall sensor.

• Digital room temperature display.

• Information from the wall sensors can then be reported

to the DDC network system.

• Various sensors such as occupancy sensors, supports

various sensors for occupancy determination. Also

avalable in combination with humidity and/or

sensors.

Co

2

• Supports water to air application or water to water

applications.

• The MPC can be programed with a 7-day schedule.

• One binary Aux output can be programmed to

control various functions.

Communications: The Multi-Protocol communications

provides DDC system flexibility.

• Supports native BACnet MS/TP communications (the

ASHRAE standard protocol for interoperability).

• Supports Johnson Controls N2 communications (for

integration into Johnson Controls Metasys

(DDC systems).

• Supports Modbus communications for integration into

Modbus DDC networks.

• Supports LonWorks communications. Requires LOC

daughter card (PN-17B0012N08).

• Four baud rate levels offer flexible communications

speeds of 9600, 19.2k, 38.4k, or 76.8k baud.

• High speed 16-bit Hitachi Processor with 1024 kBytes

RAM and 4096 kBytes Flash Memory which allows,

if needed, MPC programs to be upgraded and easily

downloaded in the field.

• Removable field wiring connectors for ease of

field service.

• Engineered for quality and reliability.

• Enables building operators to easily upgrade

firmware in the future.

• Program archival feature.

• Supports up to five AWS13,14,15 (Rnet) sensors.

• Supports equipment touch maintenence and

configuration tool.

Added Features on Gen 7

• Ability to operate in heating or cooling only mode.

• Ability to operate in full time electric or external

heat mode.

• Ability to archive the current control program.

• Input for pressure switch for dirty filter notice

applications.

• Can operate without ASW sensor if so equiped with

an Equipment Touch unit (temperature and

humidity only).

• Can alternate compressor (lead LAG) based on manual

control, timed control or compressor accumulated time

High time compessor becomes secondary or LAG at

beginning of next heat/cool cycle.

• Supports Android based tablet in place of Equipment

Touch (does not support temp/humidity control).

• Selectivly supports zone averaging using up to 5 ASW

wall sensors.

• 17B0012N10 uses new maintenance tool/user interface

(Equipment Touch).

3

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Entering

Air

DDC Communications Network

Ent

MPC MultiProtoCol DDC Controls

November 19, 2018

MPC Controller Overview

Figure 1: Typical System

Water to Air Heat Pump

Heat Pump

Regerant/Water

Heat Exchanger

LWT

Sensor

CXM

MPC

Controller

LAT

Sensor

Leaving

Air

Figure 2: Typical System

Water to Water Heat Pump

DDC Communications Network

CXM

Source

MPC

LWTS

Sensor

Controller

Switch

Load

Digital Wall Sensor

EWTL

Sensor

LWTL

Sensor

Ent

4

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

MPC General Specications

Power: 24VAC ± 10%, 50 or 60Hz, 15VA max. power consumption.

Size: 5-1/16” [129mm] width x 5-11/16” [144mm] height x 1-1/2” [38mm] (minimum panel depth).

Housing: Rugged GE C2905HG Cycoloy plastic housing (complies with UL 94 V-O).

Environmental: 0-130°F (-17.8 to 54.4 °C), 10% to 95% non-condensing.

Protection: Surge & transient protection circuitry for the power and I/O. Optical isolation for

communications port.

Processor/Memory: High speed 16-bit Hitachi Processor with 1024kB RAM and 4096kB Flash Memory.

LED Indicators: Individual LEDs for digital outputs, power, run, error, transmit, and receive.

Compliance: UL916; FCC Part 15, Subpart B, Class A; ICES, Class A; EN55022, Class A;

IEC61000-6-1; RoHS complaint, WEEE Complaint; BTL listed

I/O Point Count: 5 digital outputs (on-board relays rated for 1A resistive at 24VAC).

6 universal inputs (IN-1 and IN-2 are jumper selectable for dry contact or 0-5VDC).

1 analog wall sensor port for non-communicating (Lstat) wall sensors.

1 digital wall sensor port for communicating (Rnet) wall sensors.

Communications: EIA-485 communications port using twisted pair. A two position DIP switch allows for manual

selection of desired protocol. Available protocols are BACnet MS/TP, Johnson Controls N2,

Modbus and LonWorks (requires Loc daughter card. Another 2 position DIP switch allows

for manual selection of desired baud rate. Available baud rates are 9600, 19.2k, 38.4k,

and 76.8k.

Addressing: 2 rotary switches are provided for setting the individual controller’s primary network address

(for more information on network addressing, see Addressing & Power Up).

Wall Sensor: The wall sensors provide room temperature sensing with digital display, local setpoint adjust,

local override, LED for alarm status and fault type indication, and heat pump reset. The wall

sensors require a 4 wire connection for communication or 5 wire connection for non-

communicating.

Mounting Hole Two mounting holes center line as below with 5-9/16” [141mm] height spacing.

Dimensions: Factory mounted.

5

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Figure 3:

Communications

LonWorks Daughter

Card Connection

Module Hardware

Addressing

(Communicating

ASW13 - 15 (Rnet)

Inputs

Sensor)

1-4

Local

Access Port

Room Sensor

Type Selection

Gain

Jumper

24Vac

Connector

IN-1*

IN-2**

Protocol &

Baud Rate

Outputs

(Non-Communicating)

ASW 6 - 8 (LStat) Sensor

Connector

Physical Dimension: 5.88" (149.4mm) x 5.66" (143.8mm)

6

Output

LED’s

Communications Type Selection

BACnet

Over ARC156

Communications Selection

‘PRO’ Space Sensor

Connection

(w/display)

RS-485 Communications Options

PROTOCOLS

BACnet

MS/TP

N2

Modbus

Thermistor/dry contact

0-5Vdc

Thermistor/dry contact

0-5Vdc

Power

Run

Error

IN-1

IN-2

24 Vac

Gnd

Hot

Rx

Tx

Batt

TensOnes

G

G

R

G

G

RS-485

Options

DIP

Protocols

Baud Rate

IN-1

IN-2

Communications Select

Factory 2

Factory 1

Room Sensor

Basic or Plus/Loginet

Therm Input Gain

Jumper 1x/ No Jumper 3x

8

9

0

1

2

7

6

5

4

3

8

9

0

1

2

7

6

5

4

3

8

9

0

1

2

7

6

5

4

3

8

9

0

1

2

7

6

5

4

3

Dry

0-5Vdc

Dry

0-5Vdc

RS 485

BACnet

over ARC156

RS-485

Off

Off

On

SW3 SW4

Off

On

Off

Figure 3:

Factory Use Only - 1

Default = no jumper

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Selects 1x (jumpered) or 3x (no jumper)

gain for “Therm” Input.

W3 Selects “LSTAT (ASW 6 - 8) Sensor

Connection” or “RNET” (ASW 13 - 15) port as

the active port for room sensor.

Default = RNET

Default = 3x (no jumper)

Selects “Thermistor/Dry

contact or “0 to 5Vdc” input

for ALI/AL2

Default = “Thermistor/Dry

Contact”

Address

Wheels

02 Default

Factory Use Only - 2

Default = jumpered

Selects “Thermistor/Dry

contact or “0 to 5Vdc” input

for EHZ/GND

Default = “Thermistor/Dry

Contact”

Selects “RS-485 MS/TP” or “ARC156”

Default = “RS-485 MS/TP”

7

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

MPC Controller Overview

Communications Selection

When the Communications Selection jumper is in the

“BACnet over ARC156” position, DIP switch selectors

SW1, SW2, SW3, and SW4 are all disabled. When the

communications selection jumper is in the “BACnet over

ARC156” position, BACnet protocol is selected and the

baud rate is also selected to be 156 kbps.

When the communications port is congured for RS-

485 communications, use standard dedicated 22AWG18AWG twisted pair wire.

When the communications port is congured for the

ARC156, use a ARC156 cable available from

Automated Logic.

For complete details on wiring, termination, for BACnet

MS/TP, refer to ANSI/ASHRAE 135-1995, clause 9.2.2.

Refer to the Application Note for the BACnet devices

that you will be interfacing with for specic wiring.

Communications Wiring Instructions

1. Be sure the module’s power is off before

wiring it to the ARC156 or RS-485

communications bus.

2. Check the network communication wiring

for shorts and grounds.

3. Connect the ARC156 or RS-485 wires and

shield to the module’s screw terminals as

shown in Figure 9. Be sure to follow the

same polarity as the rest of the ARC156 or

RS-485 communications network.

4. Power up the module.

5. Proper communications for all protocols

and baud rates can be veried by making

sure the transmit (Tx) and receive (Rx) LEDs

are active.

Protocol Congure

The communications port on the MPC has MultiProtoCol

capability which means the MPC can be congured

to communicate via BACnet, Johnson Controls N2, or

ModBus communication protocols. This conguration is

done via the “Communications Selection” jumper and

the 4-position DIP switch package (SW1, SW2, SW3,

SW4) located on the MPC. The communications port’s

baud rate is also set with this same 4-position DIP switch

package. See Figure 5 below.

Note: If using ARC156 wiring, then only BACnet

protocol can be used. When using RS-485 wiring, any

of the 3 protocols (BACnet, N2, ModBus) can be used.

Figure 5: Wiring the ARC156

Figure 6: Communications Selections

8

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC Controller Overview

BACnet Setup – The MPC can be set up to communicate

via “BACnet over ARC156” or “BACnet MS/TP”. Refer to

Table 1 for setup.

N2 Setup – N2 must be congured for RS-485

communications with a baud rate of 9600, using 8 data

bits, no parity, and 1 stop bit. The MPC is always an N2

slave. Refer to Table 1 for setup.

ModBus Setup – ModBus must be congured for RS-485

communications. Baud rate can be selected from 38.4

kbps, 19.2 kbps, or 9.6 kbps. Refer to Table1 for setup.

Table 1: Communications Set Up

MPC MultiProtoCol DDC Controls

November 19, 2018

9

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Additional Information

Room Sensors

The MPC is design to work with specic sensors. Two

types of sensors may be used:

1. Lstat

2. RNet

The RNet connection is at the upper left of the MPC and

the LSat is at the lower left. Both are four to ve wire

sensors. The MPC comes factory set for the Lstat sensor

at the room sensor jumper. To utilize the RNet sensors

the jumper must be changed to RNet.

The use of the RNet sensor allows for an extra input

into the MPC. The sensors are available with additional

internal sensors possibilities including Humidity, CO2 or

VOC. When using a unit equipped with Climadry Reheat,

a combination temperature and humidity sensor is

required. Refer to ASW section.

It is also possible to use the equipment touch as a wall

sensor if only temperature or temperature and humidity

are required. See the Equipment Touch IOM for specic

instructions on enabling the Equipment Touch internal

sensors. The ASW 6, 7, 8 ase LSTAT sensors. The ASW 13,

14, 15 are RNET sensors.

The LSTAT sensors are the ASW06, 07 and 08. The RNET

sensors are the ASW13, 14 or 15. Additional sensors

included can be humididity and CO2 . This is designated

by the H and/or C sufx.

Retrotting MPC to Existing Units

The MPC can be added to any ClimateMaster unit with

the CXM, DXM, DXM2 thermostat boards. A retrot

kit has been assembled with the board, the wiring and

additional sensors are required.

LAT

The leaving air temperature is reported to the BNS. LAT

control is not supported.

iGate Communication

On units equiped with a DMX2 board, the iGate functions

are not available when the MPC is installed. The Service

Tool can be connected directly to the DXM2 – to access

the board functions. The MPC does not access these

functions.

Additional Inputs

The AL1/AL2 and EHZ/GND inputs are available with

either type of sensor. Two additional inputs are available

when the Rnet sensor is used. These are Temp/GND and

SW/GND.

AL1/AL2 and EH2 input terminals can accept 0-5VDC,

Thermistor, or dry contact signals. Terminals LAT/LWTL

and LWT/LWTS accept thermistor or dry contact signals.

LAT/LWTL and LWT/LWTS come with leaving air and

leaving water temperature thermistors installed but can

be repurposed. The Lsat terminals can be used for a

additional thermistor input (Gnd/Temp) and SW can be

used as a dry input contact.

The MPC allows custom factory programing of the

various inputs to accomplish various sequence of

operations as the building may require.

Certain options can be added to the MPC programing

after installation of controls system upgrades/changes

are being considered. Consult factory for applicability.

The MPC can be programmed with a 7 day program: the

routine is built into the software.

10

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

BACview6 Service Tool and Addressing

For existing installations only! For new installations use

Equipment Touch Service Tool (BACview6 or Equipment Touch is required

to set up unit)

The BACview6 Service Tool provides local access to control and operational properties of

equipment. The BACview6 simply plugs into an Rnet connection (local access port) and

allows you to display and modify Climate Master-dened properties without any computer

software. The BACview6 features a numeric keypad, directional keys, and four function keys.

A large 4-line by 40-character backlit LCD display is provided for easy reading even in poor

lighting conditions. The device also includes an alarm indicator light and audible warning.

ClimateMaster recommends this service tool for sites over 25 units or units with the standalone application.

Part#1: ABACVIEW6

Part#2: ABACVIEW6A (cable)

November 19, 2018

Figure 6:

HOW TO WIRE ABACVIEW to ABACVIEW6A

When prompt for password.

ClimateMaster Password: 1111

Red

Blue

White

Black&Green

12v

RnetRnet+

GND

11

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

BACview6 Service Tool and Addressing

Addressing & Power Up

Before setting or changing the module's hardware

address, make sure the MPC Controller power is off. The

MPC only reads the address when the module is turned

on. The MPC has two rotary switches for assigning the

module’s hardware address. One switch corresponds to

the “tens” digit and the second switch corresponds to

the “ones” digit, allowing for hardware- based addressing of up to address 99. For example, if the module’s

address is three, set the tens switch to zero and the

ones switch to three. The station ID for each MS/TP

node must be unique on a MS/TP segment. The MPC’s

rotary address switches are used to set this unique ID.

Figure 8: Setting Module Address

After setting the address, turn power on to the MPC.

The Run, Error, and Power LEDs should turn on. The Run

LED should begin to blink and the Error LED should

turn off.

Note: Set address for heat pump #1 (HP-1) at 02 per

typical BMS naming conventions. All other heat pump

addresses should be assigned as HP# + 1.

Changing the device instance when using a network

of more than 99 MPC units

Note – This applies to Gen4 MPC’s only. When using

Gen3 MPC’s, to allow for more than 99 unique addresses,

a special request should be made through the Product

Management and Applications team.

The Gen 4, 5 and 6 MPC allows the device instance

to be changed using the BACview6 service tool. This

feature allows an installation with more than 99 MPCbased units to be set and managed on-site rather than

factory preset.

In order to change the device instance, the MPC must

be powered up. Connect the BACview6 service tool to

the MPC using the local access port. When the main

screen appears, scroll down to “Manual Control” using

the down arrow and press “Enter”;

At the “Manual Control” screen, press “Enter” with

“Unit Conguration” highlighted and again with “BAC-

net” highlighted. The following screen should appear:

Figure 9:

1

12

THE SMART SOLUTION FOR ENERGY EFFICIENCY

BACview6 Service Tool and Addressing

Addressing & Power Up

MPC MultiProtoCol DDC Controls

November 19, 2018

Figure 10:

2

The device instance is typically six digits long. The last

two digits correspond to the addressing roatary dials so

these should not be changed using the BACview6.

To change the device instance, use the down arrow to

highlight the numbers beside “Base BACnet Device ID”

and press “Enter”. Leave the leading zeros (ex: "0001",

"0002" You will be prompted for an Admin Password, the

password is 1111. A cursor underlining the nal digit of

the “Base BACnet Device ID” will appear.

Figure 11:

3

Figure 12:

4

13

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Equipment Touch Service Tool Overview

Figure 12:

Touch to Display:

Home Screen

Previous Screen

Alarm Screen

Wire the Equipment Touch to the controller's RNet port. The RNet can have one

Equipment Touch device and up to ve RNet (ASW13) sensors.

Note: The Equipment Touch RNet does not support RS Sensors.

When prompted for password: ClimateMaster Password = 1111

14

Touch a Button to

Display that Screen

THE SMART SOLUTION FOR ENERGY EFFICIENCY

Power

Rnet + (white)

Panel

MPC MultiProtoCol DDC Controls

Equipment Touch Service Tool Overview

The Equipment Touch (Figure 12) is a touchscreen device with a 4.3 Inch color LCD Screen

that is connected to an MPC GEN 7 Controller Unit. It will allow access to most all internal

control/ status points, alarms that would normally require access to the system server

(WebCNTL) to access. It is a replacement for the BACVIEW 6 service tool previously used for

this purpose, but has increased functionality. Equipment Touch does not currently support

water to water applications. The Equipment Touch (or EQT) can also function as a wall sensor

providing Temperature and Humidity data to the Controller when congured correctly. The

EQT connects to the MPC Controller’s RNet port in the same manner as the RNET Wall

sensors and can reside with up to 5 RNet Sensors. Each MPC GEN 7 controller can support

up to 5 RNet Sensors and one EQT (Figure 13 and 14).

Figure 13: Basic Equipment Touch connection program

November 19, 2018

Display

Red

Green

White

Black

Supply

24

VAC

Panel

Controller

24 ac

GND

Rnet

Rnet Wiring

Rnet - (black)

Figure 14: Equipment Touch wiring diagrams

• Wire the Equpment Touch in a daisy-chain conguration with up to 5 RNet zone

sensors as shown below.

Equipment

Touch

Green

Red

Black

White

Rnet

Sensor

Green

Red

Black

White

Green

Red

Black

White

Rnet

Sensor

Green

Red

Black

White

Rnet

24V Sensor

GND

Controller

Rnet

210 mA

12 VDC

S1

S2

S1DCBA

S2

External

Thermistor

Power Wiring

24 V + (red)

GND + (green)

Note- You do not need to set an address for the Equipment Touch.

Green

Red

Power

Supply

24

VAC

15

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Equipment Touch Mounting Details

Wiring and Mounting the Equipment Touch

1. Remove the backplate from the Equipment Touch:

a. Hold the Equipment Touch as shown in the

image below.

Figure 15:

b. While rmly pressing the two tabs on top of

the Equipment Touch, pull on the back plate with your index nger untill the back-

plate releases from the Equipment Touch.

2. Pull the communication cable, power cable and

external thermistor wiring (if applicable) through the

large hole in the center of the backplate.

3. Partially cut, then bend and pull off the outer

jacket of the RNet cable(s). Do not nick the individual

wire insulation.

4. If wiring 1 cable to the Equipment Touch, cut the

shield wire off at the outer jacket, then wrap the

cable with tape at the outer jacket to cover the end

of the shield wire. If wiring 2 cables in a daisy-chain

conguration, twist together the shield wires, then

wrap the cable with tape.

5. Strip about 0.25 inch (0.6) insulation from the end

of each wire.

6. Connect wiring to the Equipment Touch as

shown below:

7. Attatch the backplate to the wall or panel.

If mounting in or on a panel:

a. Drill two 3/16 inch (4.8mm) pilot holes in

the panel.

b. Attatch a backplate using pan head 6-32 x 3/8"

to 1/2" long machine screws. Do not over tighten

screws to prevent damage to plastic housing.

Recommendation: Use Loctite 220 on screw

threads if the Equipment Touch will be subject

to vibration.

8. Attatch the Equipment Touch to the backplate:

a. Place the bottom of the equipment touch onto

the backplate by aligning the 2 slots on the

Equipment Touch with the tabs on the backplate.

b. Push the Equipment Touch onto the backplate

until the tabs at the top of the Equipment Touch

snap onto the backplate.

9. Turn off the controller's Power.

10. Connect the other end of the RNet wiring to the

controller's RNet port or to a zone sensor.

Notes- Insert the shield wire with the ground wire

into the controller's GND terminal. Use the same

polarity throughout the RNet.

11. Connect power wiring to a 24 Vac power supply.

12. Tur n on the controller's power.

� CAUTION! �

Allow no more than 0.6 inch (1.5mm) bare

communication wire to protrude. If bare

communiaction wire contacts the cables foil

shield, shield wire or a metal surface other than the

terminal block, the device may not communicate

correctly.

Figure 16:

16

MPC LED Codes

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

The MPC Controller has the following LEDs:

Power - indicates when power is on.

Run - blinks when the processor is running.

Error - lights when an error is detected.

Receive (Rx) - lights when the Comm Port receives data.

Transmit (Tx) - lights when the Comm Port transmits data.

Digital Output - lights when the associated digital output

turns on.

LED Power-Up Sequence

During power-up, the module goes through an

initialization and self test sequence.

Proper module power-up can be veried by observing

the LEDs as follows:

1. The Run and Error LEDs turn on and begin blinking.

2. The Error LED then turns off.

3. The Run LED continues blinking.

Note: The Error LED ashes three times in sync with

the Run LED when the module is being formatted.

The Run LED should never stop ashing. If it stops

ashing for 1.5 seconds, the watchdog timer will reset

the module.

Overcurrent Protection

The MPC Controller is protected by internal solid state

polyswitches (polymeric PTC, resettable overcurrent

protection device, also called PPTC) on the incoming

power. The overcurrent protection circuitry is a positive

temperature coefcient (PTC) thermistor that increases

in resistance as it warms up and stays in that mode until

the power is removed. Once the power is removed, the

polyswitch resistance lowers to operational level as the

device cools down. After power has been re-applied, the

unit will operate properly if the fault condition has been

removed.

It is not necessary to remove power on the

communication line in order to reset the solid state

overcurrent circuit. Once the power level is low enough,

the overcurrent circuit cools down to operating

temperature. A blown polyswitch can indicate incorrect

wiring if the polyswitch is blown during installation.

Generally, a blown polyswitch indicates a power surge

was received by the board.

Digital Output LEDs

There are 5 digital outputs on the MPC. One output

(AUX) can be custom congured to control an external

device (1amp at 24VAC.). G, O, Y2, and Y1 are required to

operate the heat pump and are connected to the CXM,

DXM or DXM2 board.

Table 2: MPC Flash Codes

Run

LED

2 ashes

per second

2 ashes

per second

2 ashes

per second

2 ashes

per second

2 ashes

per second

2 ashes

per second

5 ashes

per second

5 ashes

per second

7 ashes

per second

14 ashes

per second

Error

LED

OFF Normal

2 ashes,

alternating

with Run

LED

3 ashes

then OFF

4 ashes

then

pause

6 ashes

then OFF

ON

ON

OFF

7 ashes

per

second,

alternating

with Run

LED

7 ashes

per

second,

alternating

with Run

LED

Condition Action

Expected behavior of a

congured controller

Controller will count

down the ve minutes,

Five minute autorestart delay after

system error

Module has just

been formatted

Two or more

devices on this

network have the

same ARC156

network address

Module’s response

to a LonTalk

‘wink’ command

received from a

LonWorks Network

Management Tool

Exec halted after

frequent system

errors or GFB’s

halted

Exec start-up

aborted, Boot is

running

Firmware transfer

in progress, Boot is

running

Ten second

recovery period

after brownout

Brownout

then attempt to restart

normally if the condition

that caused the fault

returns to normal.

Disconnect all wiring and

see if the controller will

restart normally.

This condition should not

occur with a congured

controller. Memory archive

ensures the controller

will always have a

conguration.

Disconnect the comm

connector then assign a

unique network address.

If this condition occures

you have two options:

• Manual restore of

memory from archive

• Download memory

Normal behavior during a

memory download

Precedes the brownout

condition

Check power supplied to

the controller

N/A

N/A

17

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

MPC Sequence of Operation

Fan Operation – Digital output point G (DO4) is the fan

output and is connected to the "G" terminal on the

CXM, DXM or DXM2 control. If fan Mode is set to "Auto"

ECM, then the fan is energized only during a call for

heating or cooling. "Auto" mode is the default mode of

operation At 30% PID, the fan(G) energizes in Auto

mode.

Heating/Cooling Changeover – The Digital output

"O" (DO3) is the RV output and is connected to the

"O" terminal on the CXM, DXM or DXM2 board. "O" is

energized during call for cooling. The RV (O) energizes

at 40% PID in cooling only.

Compressor Operation – The Digital outputs Y1 (DO1)

and Y2 (DO2) are the outputs for compressors stage

1 and 2. Y1 is connected to Y terminal on the CXM/

DXM/DXM2 and if the heat pump is dual stage, Y2 is

connected to a second CXM Y input or Y2 on the

DXM/DXM2.

Y1 and Y2 are off when the zone temperature is between

the heating and cooling set points. As the zone

temperature rises above cooling set point or below

heating setpoint, Y1 is energized at 50% PID and Y2 is

energized at 75%.

Troubleshooting Tips – If the BMS is having trouble

communicating with the MPC, check the following items

before contacting technical support.

• Make sure the MPC wiring is correct. Make sure

all color codes match and that no wire strands are

shorting over to other terminals.

• Make sure the MPC and other network controllers

have power and are turned on. Make sure all

equipment have power and LEDs lit with no solid

error light. Some devices, especially communication

devices, receive power from a source other than

a power cable or adapter. Some panels can be

reinitialized by resetting the panel.

• Verify operation of all LEDs: RX, TX, Power, Run,

DOs and error.

• Make sure that all jumpers are set to default and that

there is nothing jumped on the format pin.

There is also a load sharing mode which permits

swapping the primary status of Y1 with Y2 depending

on compressor run time. The low time compressor

becomes primary and the high time compressor assumes

secondary status.

Note: All 5 digital outputs have associated LEDs to

indicate operating status. If the digital output is on,

then the associated LED will be on.

Occupied/Unoccupied Changeover – When the

MPC is in the stand-alone mode of operation, the

MPC defaults to the occupied mode of operation.

Occupancy changeover may be provided through the

communications network.

18

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC Sequence of Operation

MPC MultiProtoCol DDC Controls

November 19, 2018

Water -to-Water Start Up Check

1. Unit powered up and running.

2. LED check: Rx, Tx, Power, Run and no solid

red error led.

3. Program initializing schedule status for Occupied

Mode (default) or Unoccupied Mode to determine

set point range. Occupied set points will be

defaulted to 60 cooling and 105 heating. If a

schedule is implemented, the unoccupied set points

will default to 80 cooling and 85 heating.

4. The Program will determine if the unit is either a

Master or Slave.

5. The Program will control the water temperature

based on the Entering Water Temperature (EWT)

load sensor. This can be changed to control based

off of the LWT via BAS or BACview6 service tool.

6. The Program will check for which water temperature

set point to use based on Heating Mode or Cooling

Mode determined by the state of the RV.

7. In a water to water application, the mode has to be

manually changed via Bacnet or with BACVIEW6

service tool. If it is in heating, it will permanently stay

in heating mode until it is changed to specically

cooling mode.

8. Like water to air, Y1 will come on a 50% and Y2 at

75% and not off until the EWT/LWT conditions have

been satised.

9. 5-minute delay is built in between compressor cycles.

10. While the unit is on, the program will continue to

monitor the CXM/DXM/DXM2 board for faults. If

an event of a fault occurs and the unit is in lockout

mode, then the relay will close (IN1/AL1/AL2/GND)

and the fault code is transmitted via EH2 output to

the EHZ input on the MPC. This is available through

BAS network points. A history counter will also keep

track of past and present faults which can also be

seen via BAS or BACview6.

11. The MPC can also function in metric mode

(Celsius mode).

Water-to-Air Startup CheckEquipment Touch Method

1. Unit is Powered up?

YES: Go to step 2

NO: Apply power to MPC.

2. Check Led status.

a. Green (TxD) LED should be blinking rapidly.

b: Green power LED should be on solid .

c: Green RUN LED should be blinking at 1-2

blinks per second.

d: RED error LED should be off.

YES: Go to step 3.

Power down MPC and wire up the Equipment Touch

Service Tool and RNet Sensor(s). Once these are

installed, power MPC back up.The Equipment Touch

should power up and display the “Main” (Home)

Figure 16: Menus screen

3. Navigate to the “Sensor Setup and Status” screen

by pressing <MPC Setup/Status> then <Sensor

Setup/Status> buttons. Press the <ZS Sens Active>

button. This should display the correct address and

number of ZS Sensors that are attached to the MPC.

Press the <Back> and go to the “ZS Sensor Setup”

screen where you will need to enable the alarms for

each sensor installed and detected in the previous

step.

4. From the EQT menu press <Temp Setup and

Status> then press <Temp Units>. “Current Mode”

should be set to <Fahrenheit>. If this is ok, you are

nished here and can move on to Step 5. Otherwise

uncheck the “Metric Mode” (BV:39) point to set the

MPC to Fahrenheit mode. Make sure the “Current

Mode” changes to “FAHRENHEIT” before pressing

<BACK> and exiting this screen.

19

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

MPC Sequence of Operation

From the <Temp Setup and Status> screen press

<Temp Setpoints>.

• The default settings for the Fahrenheit and Celsius

operation modes are listed here in this screen. If

your setpoints differ from the default values listed

here, please enter them in the appropriate box.

Table 3:

Description Fahrenheit° Celsius°

Master Zone Temp 73.0 22.7

Unoccupied Dead Band 17 9.44

Occupied Dead Band 2 1.11

Unoccupied Heat Setpoint 82 27.7

Occupied Cool Setpoint 74 23.3

Slave Heat Setpoint 72 22.2

Slave Cool Setpoint 74 23.3

• Press the <Manual SP> button to go to the

“MANUAL SP” Screen in which you can edit

the Manual Setpoint Adjust Range. It is defaulted

to +/- 5° Fahrenheit or 2.8 ° Celsius. This will

allow you to have a 10 F° / 4.6 C° adjustment

range of the setpoint from the sensor. If you wish

a looser or tighter range, please enter it now.

Note: if it is set to zero, no adjustment can

be made from the Wall Sensor.

5. The MPC will default to RNet Sensors. If you have

LSTAT Sensor types you will need to set jumper W3

to LSTAT.

6. From the “MPC Setup/Status” screen press

<Compressor Setup>. Please check the compressor

setting to ensure all are set to the default factory

settings. Load Balance Select controls the stage

assignment of compressors. The default setting

assigns compressor 1 as primary and compressor 2

as secondary. Note: For single compressor systems

C1 should always be primary.

Table 4:

Description Point Default

Load Balance Select AV:59 2

Compressor Shut Down BV:53 Unchecked

C1 Manual BV:30 Unchecked

C2 Manual BV:31 Unchecked

C1 Runtime Reset BV:2 Unchecked

C2 Runtime Reset BV:5 Unchecked

C1 Cycle Reset BV:21 Unchecked

C2 Cycle Reset BV:22 Unchecked

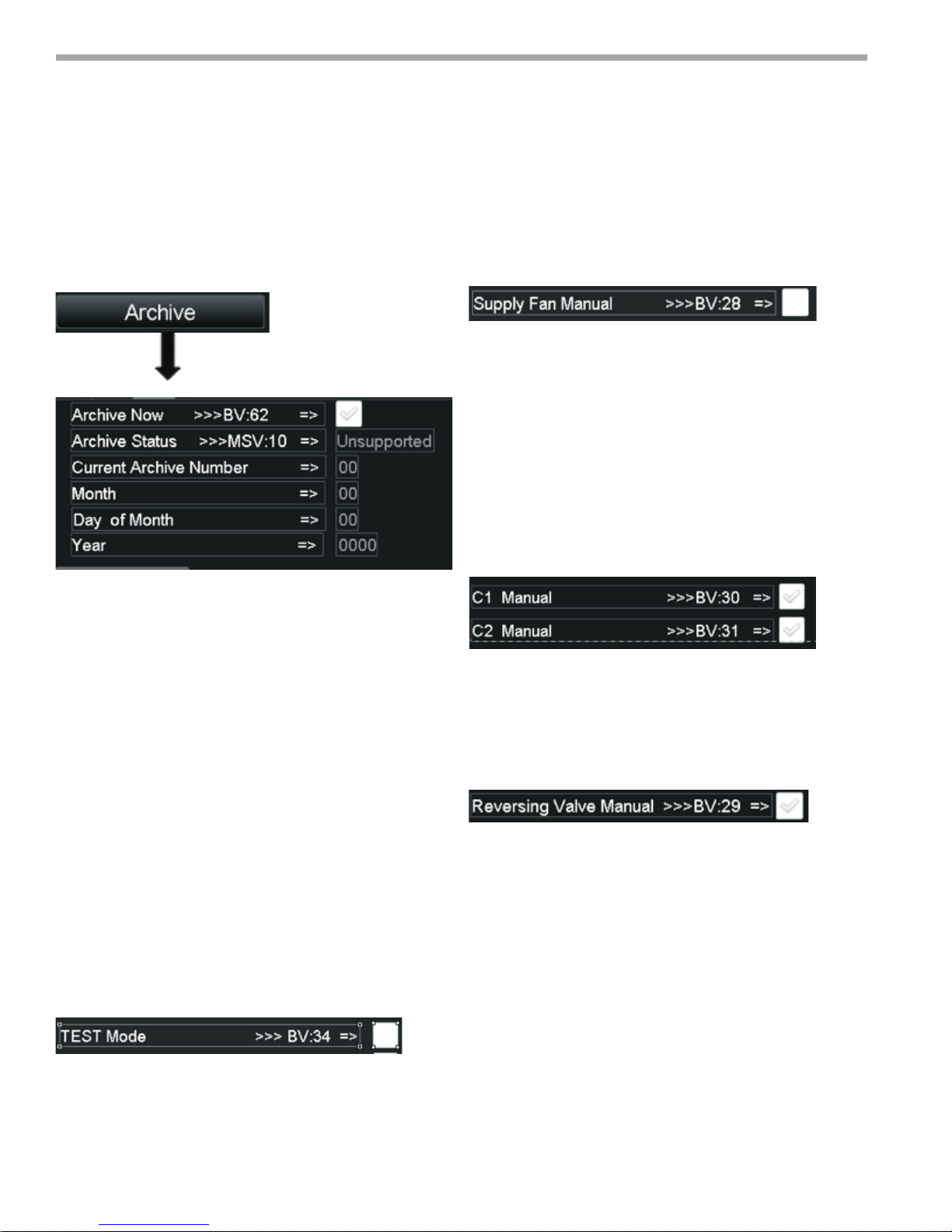

7. From the “MPC Setup/Status” screen press <Heat/

Cool Control>. Ensure that the following points

are set to the default values. The default values

enable both the heating and cooling modes and

ensures the reversing value is not in manual mode.

If you need “Heat Only” or “Cool Only” modes,

uncheck the appropriate enable for the mode you

wish to disable. 99% of all applications will have both

enabled.

Table 5:

Description Point Default

Heat Mode Enabled BV:61 Checked

Cool Mode Enabled BV:54 Checked

Reversing Valve Manual BV:30 Unchecked

8. From the <MPC Setup/Status> screen press <Fan/

Filter Control>.Check the following point for the

correct default value. The Supply FAN is congured

to cycle anytime the compressor is “ON”.

Table 6:

Description Point Default

Emergency Shutdown BV:8 Unchecked

Supply Fan Manual BV:28 Unchecked

Supply Fan Congure AV:33 1

Dirty Filter Reset BV:7 Unchecked

Dirty Filter Interval AV:30 1500

Dirty Filter Mode BV:60 Time

Dirty Filter Sens BV:59 Unchecked

Fan Speed Enable BV:51 Unchecked

Fan Speed Trigger Type AV:56 75%

9. From the “MPC Setup/Status” screen press <Heat/

Cool Control>. Check Occupancy BV:12 and make

sure it is set to “Occupancy”.

From the “MPC Setup/Status” screen press

<AUX Outputs>. Check the “AUX CFG” setting

for the default value of 1. This is Emergency Electric

Heat. If other functions are needed please consult

the Control Points Matrix for other functional

settings associated with this point.

20

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC Sequence of Operation

MPC MultiProtoCol DDC Controls

November 19, 2018

From the “MPC Setup/Status” screen press

<Maintenance>. From this screen, you can adjust

the temperature setpoint and watch the function of

the MPC. You can remove the Y1, Y2 output wires to

keep unit from going into Heat or Cool mode for this

operation.

1. You should see both the Occupied ICON

and the ”AUX Mode = Emergency ELEC

Heat”. If there is no RNET Sensor installed

with a humidity sensor present, the “RH”

Icon will be equal to 0.0.

2. Read the Zone Temperature and adjust the

Zone Heating Setpoint at least 2 ° above

the ambient zone temperature. (You

can use the RNet Sensor or the Equipment

Touch for this operation). You should be able

to observe the “Heat PID” Icon start

increasing as the MPC is set to go into a

heating cycle.

a. When the PID value increases above

30% the FAN ICON for the Supply

Fan will appear.

b. When the PID rises above 40% the RV

ICON will appear indicating the

Reversing Valve is on.

c. When the PID gets to 50% the

Compressor C1 will turn on after a 2

minute delay. You should see the C1

ICON after the delay.

d. If the Heating unit is wired to the unit

and thus not heating, the PID will

continue until it reaches 75% and then

you should see Compressor 2 or C2

ICON appear. If the PID is allowed to

rise it will trigger the Emergency

Electric Heat (AUX) output when it

goes above 90%. This assumes

heat demand has not been satised.

e. Decrease the Heating Setpoint 2°

below the Zone Temperature

and the Heating PID will begin to

move downward.

f. Once it falls below 90%, the ”AUX”

output will turn off and below 75%,

C2 will turn off.

g. When it falls below 50%, the

compressor output C1 will turn of

and once it falls below 40% the Supply

Fan will turn off.

3. Read the Zone Temperature and adjust the

Zone setpoint at least 2° below the

ambient Zone Temperature. You should be

able to observe the Cool PID start increasing

as the MPC is set to go into a Cooling cycle.

a. When the PID rises above 40% the

FAN ICON will appear indicating the

Fan has cycled on.

b. When the PID gets to 51% the

Compressor C1 will turn on after a 2

minute delay. You should see the C1

Icon after the delay.

c. When the Compressor C1 is “ON”

decrease the Zone Cooling Setpoint

2° above the Zone

Temperature and the Cooling PID will

begin to move downward.

d. Once it falls below 90%, C2 will

turn off.

e. When it falls below 50%, C1 will turn

of and once it falls below 40% the

Supply Fan will turn on.

21

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

MPC Sequence of Operation

Table 7:

Water-to-Air Startup CheckBACview6 Method

1. Unit is Powered up?

YES: Go to step 2

NO: Apply power to MPC.

2. Check Led status.

a. Green (TxD) LED should be blinking rapidly.

b: Green Power LED should be “ON” Solid

(not Blinking).

c: Green RUN LED should be blinking at 1-2

blinks per second.

d: RED error LED should be "OFF".

YES: Go to step 3.

3. Power down the MPC and wire up the BACview6

Service Tool and ZS Sensor(s). Once these are

installed, power MPC back up. The BACview6 should

power up and display the “Main” (Home)

Figure17: Main menu screen

4. Navigate to the “Sensor Setup and Status” screen

by highlighting [Manual Control] and clicking

<Enter>, then highlighting [Unit Control], and

clicking <Enter> cursor down the list and make sure

the following are set correctly.

Description Point Default

Test Mode OFF

Reversing Valve Output OFF

Supply Fan Output OFF

Compressor 1 Output OFF

Compressor 2 Output OFF

Auxillary Output OFF

Supply Fan Mode AUTO

Dirty Filter Interval 1500

Emergency Shutdown OFF

Heating Mode ON

Cooling Mode ON

Dirty Filter Mode Time

Load Balance Select 2

EXT OCC/ Dirty FILT Sens OCC

Archive Enable OFF

RNET Sens1 Enable ON

RNET Sens2 Enable OFF

RNET Sens 3 Enable OFF

RNET Sens4 Enable OFF

RNET Sens5 Enable OFF

5. Navigate to “AUX Output Conguration” by

highlighting [Manual Control] and clicking <Enter>,

then highlighting [Unit Conguration], and clicking

<Enter> cursor down the list and make sure “AUX

OUTPUT” Conguration is set to 1 and Supply Fan

Conguration is set to 1.

6. Navigate to Zone Temperature Control settings by

highlighting [Manual Control] and clicking <Enter>,

then highlighting [Zone Temperature Control], and

clicking <Enter> cursor down the list and make sure

“Occupied Mode” is set to Occupied and “Metric

Mode” is OFF.

22

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC Sequence of Operation

MPC MultiProtoCol DDC Controls

November 19, 2018

7. Adjust the temperature setpoint from the

RNet Wall Sensor.

1. Read the Zone Temperature and adjust the

“Zone Heating Setpoint” at least 2°

above the ambient Zone Temperature. (You

can use the RNet Sensor). You should be able

to observe the Heat PID start increasing via

WEBCNTL (if it is being used). The MPC

should now be set to go into a Heating cycle.

a. When the PID value increases above

30% the SF (Supply Fan) LED for

the Supply Fan will illuminate on the

MPC unit.

b. When the PID rises above 40% the RV

(Reversing Valve) LED will illuminate

indicating the Reversing Valve has

cycled on.

c. If the Heating unit is wired to the unit

and thus not heating, the PID will

continue until goes above 90% and

then you should see Compressor 2

or C2 LED light up.

d. Decrease the Heating Setpoint 2°

below the Zone Temperature

and the Heating PID will begin to

move downward. (Check with

WEBCntl or BMS).

e. Once it falls below 90%, C2 will

turn off.

f. When it falls below 50%, C1 will turn

off and once it falls below 30% the

Supply Fan LED will turn off.

2. Read the Zone Temperature and adjust the

Zone Heating Setpoint at least 2°

above the ambient Zone Temperature. (You

can use the RNet Sensor or WEBCNTL for

this operation). You should be able to

observe the Cooling PID start increasing via

WEBCNTL as the MPC is set to go into

a Cooling cycle.

a. When the PID rises above 30% the SF

(Supply Fan) will illuminate indicating

the Fan has cycled on.

b. When the PID gets above 50%, the

Compressor C1 LED will illuminate

after a 2 Minute delay.

c. Decrease the Cooling Setpoint 2

degrees below the Zone Temperature

and the Cooling PID will begin to

move downward.

d. Once it falls below 50%, C1 will turn

off. Then nally when the PID goes

below 30% the SF will shut off.

23

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

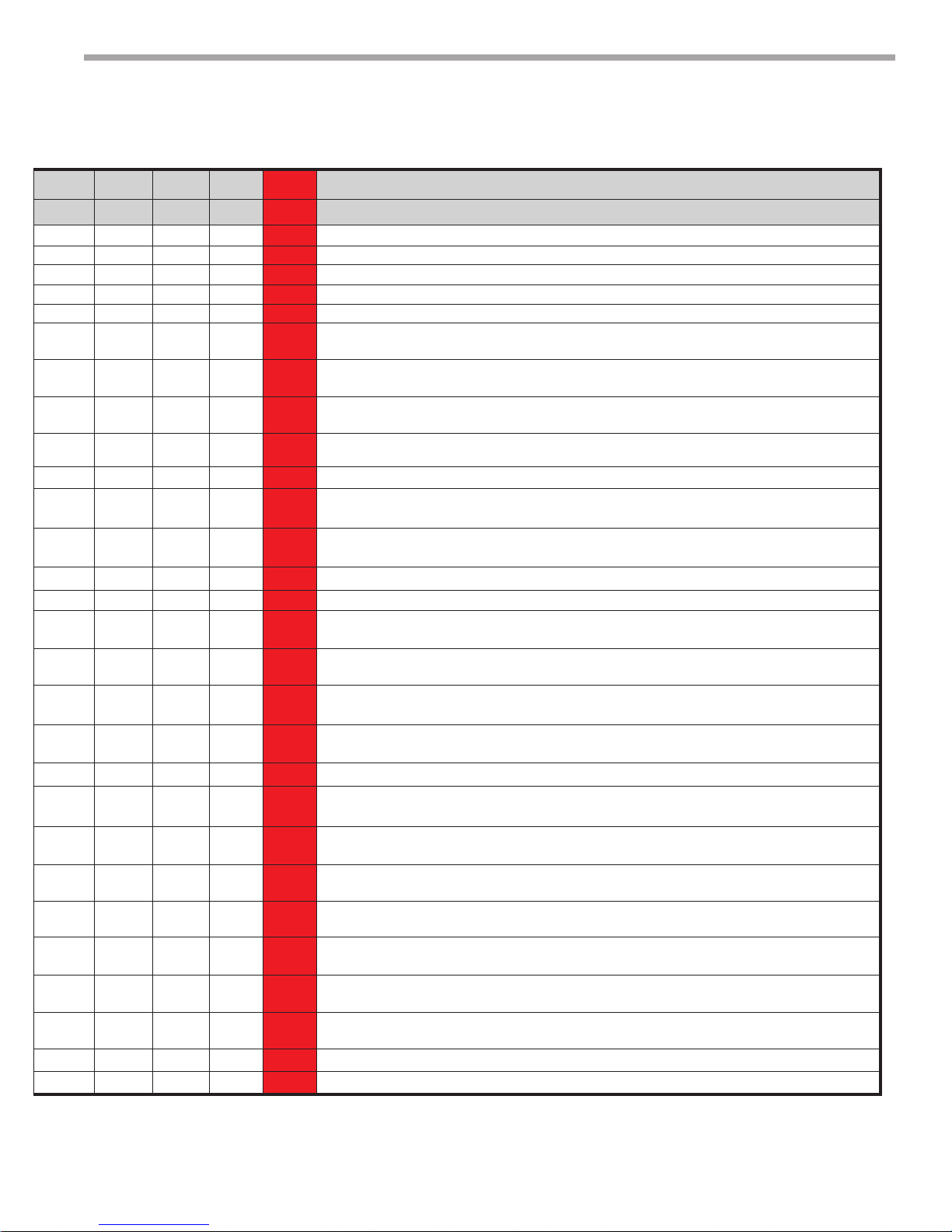

Multi Generation Water-to-Air Points Matrix

Point Name Type Number

(Read Left to Right Across Spread)

Type Register Type ID NV Name Default Gen 3 Gen 4 Gen 5 Gen 6 Gen 7 Description

Read/Write

BACNet ModBus N2 LON

Archive Status MSV 10 R NA NA NA NA NA NA X Reports the status of the archival process.

Zone Temp AI 1 R Float 30001 Analog In 1 Special* NA X X X X Raw Space Temperature from the Wall Sensor, RENet and RS sensors.

Actual CL Setpoint AV 1 R Float 30007 Data Float 1 nvoActCLSP 74° F X X X X X Actual cooling setpoint based upon occupancy status, setpoint adjustment and metric conversion.

Actual HT Setpoint AV 2 R Float 30009 Data Float 2 nvoActHTSP 72° F X X X X X Actual heating setpoint based upon occupancy status, setpoint adjustment and metric conversion.

Occupied CL SP/ Fahrenheit AV 3 R/W Float 40001 Data Float 3 NA 74° F X X X X Network setpoint for the cooling setpoint (Fahrenheit) in occupied mode.

Master ZT/ Fahrenheit AV 4 R/W Float 40003 Data Float 4 nviMasterZT 73° F X X X X X

Occupied Deadband/

Fahrenheit

Pulse Signal Value AV 6 R Float 30011 Data Int 1 nviPSV 1 X X X X X

Unoccupied CL SP/

Fahrenheit

Override Time Remaining AV 8 R NA NA NA NA NA NA X X Obsolete point found only in Gen 3 and Gen 4

Slave HT SP/ Fahrenheit AV 9 R/W Float 40011 Data Float 8 nviSlaveHTSP 72° F X X X X X

Slave CL SP/ Fahrenheit AV 10 R/W Float 40009 Data Float 7 nviSlaveCLSP 74° F X X X X X

HP Fault Counter AV 11 R Float 30014 Data Int 2 Special* 0 X X X X X Indicates the number of High Pressure faults since startup or the last reset via Fault Reset (BV:24).

LP Fault Counter AV 12 R Float 30015 Data Int 3 Special* 0 X X X X X Indicates the number of Low Pressure faults since startup or the last reset via Fault Reset (BV:24).

AV 5 R/W Float 40005 Data Float 5 nviOccDB 2° F X X X X X

AV 7 R/W Float 40007 Data Float 6 NviUnOccDB 82° F X X X X X Network setpoint for the Fahrenheit Cooling Setpoint in Unoccupied mode.

LT1 Fault Counter AV 13 R Float 30016 Data Int 4 Special* 0 X X X X X

LT2 Fault Counter AV 14 R Float 30017 Data Int 5 Special* 0 X X X X X

CO Fault Counter AV 15 R Float 30018 Data Int 6 Special* 0 X X X X X

Over/Under Voltage

Fault Counter

UPS Fault Counter AV 17 R Float 30020 Data Int 8 Special* 0 X X X X X Indicates the number of UPS faults since startup or the last reset via Fault Reset (BV:24).

Swapped LT1/LT2

Fault Counter

C1 Cycle Counter AV 19 R Float 30022 Data Int 10 Special* 0 X X X X X

C2 Cycle Counter AV 20 R Float 30023 Data Int 11 Special* 0 X X X X X

Occupied HT Setpoint AV 21 R/W Float 40051 Data Float 34 nviOccHTSP 72° F X X X

Occupied HT Setpoint

Celsius

Unoccupied HT Setpoint AV 23 R/W Float 40055 Data Float 36 nviUnOccHTSP 65° F X X X

Unoccupied HT Setpoint

Celsius

HT PID AV 28 R Float 30024 Data Float 17 nvoHtPID 0 X X X X X Heating PID based on the setpoint and actual space temperature in Percent (%).

CL PID AV 29 R Float 30026 Data Float 18 nvoClPID 0 X X X X X Cooling PID based on the setpoint and actual space temperature in Percent (%).

AV 16 R Float 30019 Data Int 7 Special* 0 X X X X X

AV 18 R Float 30021 Data Int 9 Special* 0 X X X X X

AV 22 R/W Float 40053 Data Float 35 Special* 22.2° C

AV 24 R/W Float 40057 Data Float 37 Special* 18.3° C X X X

24

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Fahrenheit network setpoint for multiple MPC's sharing the same space temperature sensor.

Only for slave units when (BV:16) is"ON".

Creates the Fahrenheit Heating Setpoint using Occupied Cooling Setpoint minus current value

when using Deadband Mode. Minimum value is 2° F. DB Mode: (BV:48) must be "ON".

Indicates the last fault code in memory on the CXM/DXM/DXM2 board. Refer to CXM/DXM/DXM2

manual for fault code descriptions.

X X X

Network Input for the actual Fahrenheit Heating Setpoint when used as a slave unit. This input is

only used for slave units when the M/S Switch (BV:16) is "ON".

Network Input for the actual Fahrenheit Cooling Setpoint when used as a slave unit. This input is

only used for slave units when the M/S Switch ( BV:16) is "ON".

Indicates the number of Liquid Temperature 1 faults since startup or the last reset via Fault

Reset (BV:24).

Indicates the number of Liquid Temperature 2 faults since startup or the last reset via Fault

Reset (BV:24).

Indicates the number of Condensate Overow faults since startup or the last reset via Fault

Reset (BV:24).

Indicates the number of Over/Under Voltage faults since startup or the last reset via Fault

Reset (BV:24).

Indicates the number of swapped LT1/LT2 faults since startup or the last reset via Fault

Reset (BV:24).

Indicates the number of times Compressor 1 has cycled ON/OFF more than 6 times in one hour

since startup or the last reset via Fault Reset (BV:24).

Indicates the number of times Compressor 2 has cycled ON/OFF more than 6 times in one hour

since startup or the last reset via Fault Reset (BV:24).

Network input for the Fahrenheit Occupied Heating Setpoint when not using Deadband Mode.

DB Mode ( BV:48) must be "OFF".

Network input for the Celsius Occupied Heating Setpointwhen not using Deadband Mode.

DB Mode (BV:48) must be "OFF".

Network input for the Fahrenheit Unoccupied Heating Setpoint when not using deadband mode.

DB Mode (BV:48) must be "OFF".

Network input for the Celsius Unoccupied Heating Setpoint when not using Deadband Mode.

DB Mode (BV:48) must be "OFF".

25

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Multi Generation Water-to-Air Points Matrix - cont'd

Point Name Type Number

Type Register Type ID NV Name Default Gen 3 Gen 4 Gen 5 Gen 6 Gen 7 Description

(Read Left to Right Across Spread)

Read/Write

BACNet ModBus N2 LON

Dirty Filter Interval AV 30 R/W Float 40027 Data Float 19 nviDFI 1500 Hrs X X X X Time Interval for the time based Dirty Filter Replacement Alarm.

AUX CFG AV 31 R/W Float 29 Data Float 20 nviAuxCfg 1 X X X X

TSTAT Mode AV 32 R/W 1 X X Determines method of Temp Control in GEN 3 Hardware.

SF CFG AV 33 R/W Float 33 Data Float 22 nviSfCfg 1 X X X X X Sets Conguration parameters for the Supply Fan.

Zone Temp Status AV 34 R Float 30028 Data Float 23 nvoZTStatus NA X X X X Network Output for Space (Room Temp)Temerature. Celsius /Fahrenheit.

LVG Temp Status AV 35 R Float 30030 Data Float 24 nvoLAT NA X X X X Leaving Air Temperature for WSHP. Celsius/ Fahrenheit.

LVG Air Water Temp Status AV 36 R Float 30032 Data Float 25 nvoLWT NA X X X X Leaving Water Temperature for WSHP. Celsius/ Fahrenheit.

Manual SP Adjust AV 37 R/W Float 40035 Data Float 26 nviManSPAdj 5° F X X X X

Master ZT Celsius AV 38 R/W Float 40037 Data Float 27 Special* 22.7° C X X X X

Unoccupied CL SP Celsius AV 39 R/W Float 40039 Data Float 28 Special* 27.7° C X X X X Network Input for the Celsius cooling setpoint in the unoccupied mode.

Occupied DeadBand Celcius AV 40 R/W Float 40041 Data Float 29 Special* 1.1° C X X X X

Slave CL Setpoint Celsius AV 41 R/W Float 40043 Data Float 30 Special* 23.3° C X X X X

Slave HT Setpoint Celsius AV 42 R/W Float 40045 Data Float 31 Special* 22.2° C X X X X

Occupied CL SP Celsius AV 43 R/W Float 40047 Data Float 32 Special* 23.3° C X X X X Network Input for the Celsius cooling setpoint in the occupied mode.

Manual Setpoint Adj Celsius AV 44 R/W Float 40049 Data Float 33 Special* 2.7° C X X X X

Unoccupied Dead Band AV 45 R/W Float 40015 Data Float 10 Special* 17.0° f X X X X

RV Status BV 13 R DI 10006 BI 6 nvoRVStatus NA X X X X X Indicates the Reversing Valve Status (ON/ OFF).

Work Schedule BV 14 R/W NA NA NA NA NA NA X X X X X

UPS Signal BV 15 R DI 10007 BI 7 Special* NA X X X X X Indicates if the UPS Mode is ON/OFF. Refer to CXM DXM DXM2 AOM for UPS Denition.

M/S Switch BV 16 R/W DO 8 BI 8 nviMS OFF X X X X X

C1 Rumtime Alarm BV 17 R DI 10008 BI 8 Special* NA X X X X X Indicates the number of operational hours for C1 has exceeded 5000. Reset via C1 Reset(BV:2).

C2 Runtime Alarm BV 18 R DI 10009 BI 9 Special* NA X X X X X Indicates the number of operational hours for C2 has exceeded 5000. Reset via C2 Reset(BV:5).

Dirty Filter Alarm BV 19 R DI 10010 BI 10 nvoDFAlarm NA X X X X X

Valid SensorAlarm BV 20 R DI 10011 BI 11 nvoVSAlarm NA X X X X X Indicates there is no valid Room Sensor connected to the MPC Unit.

C1 Cycle Reset BV 21 R/W DO 9 BO 9 Special* OFF X X X X X Network Input to reset the C1 Cycle Counter (AV:20) back to Zero.

C2 Cycle Reset BV 22 R/W DO 10 BO 10 Special* OFF X X X X X Network Input to reset the C2 Cycle Counter (AV:20) back to Zero.

Lockout Alarm BV 23 R DI 10012 BI 12 nvoLOAlarm NA X X X X X Indicates the CXM/DXM/DXM2 is in Lockout Mode.

Fault Coutner Reset BV 24 R/W DO 11 BO 11 Special* OFF X X X X X Network Input used to reset the historical counters for each error code back to Zero.

26

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Sets Conguration parameters for the AUX output Relay (W). See AUX CFG SETTINGS

section below.

Network Input for User Dened Fahrenheit Setpoint Adjustment. Should not be used with LSTAT

Sensors If = 0 cannot adjust SP at ASW.

Celsius Network input for Multiple WSHP sharing the same Space Sensor This is only for Slave

units where the M/S Switvh is (BV:16) ON.

Creates the Celsius Heating Setpoint using Occupied Cooling Setpoint minus current value when

using the Dead Band mode. Minimum Value is 1.11° C with a default of 1.11°C. DB Mode

(BV:48) must be "ON".

Network input for the actual Celsius cooling Setpoint when used as a slave unit. This input is only

used for slave units where the M/S Switch (BV:16) is "ON".

Network input for the actual Celsius Heating Setpoint when used as a slave unit. This input is only

used for slave units where the M/S Switch (BV:16) is "ON".

Network Input for user dened Celsius Setpoint Adjustment. Should not be used with

RS Pro Sensors.

Creates the Fahrenheit heating setpoint using Unoccupied Cooling Setpoit minus current value

when using deadband mode. Minimum value is 2° F with a default of 17° F. DB Mode (BV:48)

value must be "ON").

Reads Schedule from BMS and informs controls whether they are in Occupied or

Unoccupied Mode.

Master/Slave network input to enable the use of Master ZT. Master unit is dened as one WSHP

per sensor and the defaul value is "OFF". Slave is dened as a unit that does not have it's own wall

sensor and that shares a wall sensor with Master unit and the value is "ON".

Indicates the number of Supply Fan operational Hours has exceeded the Dirty Filter Interval setting.

Reset via Dirty Filter Reset (BV:7)

27

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Multi Generation Water-to-Air Points Matrix - cont'd

Point Name Type Number

Type Register Type ID NV Name Default Gen 3 Gen 4 Gen 5 Gen 6 Gen 7 Description

(Read Left to Right Across Spread)

Read/Write

BACNet ModBus N2 LON

C1 Cycle Alarm BV 25 R DI 10013 BI 13 Special* NA X X X X X Indicated the Compressor C1 has cycled ON/OFF more than 5 time during 1 hour.

C2 Cycle Alarm BV 26 R DI 10014 BI 14 Special* NA X X X X X Indicated the Compressor C2 has cycled ON/OFF more than 5 time during 1 hour.

AUX Status BV 27 R DI 10015 BI 15 nvpAuxStatus NA X X X X X Indicates the AUX output (W) is OFF/ON.

SF Manual BV 28 R/W DO 12 BO 12 nviSFMan OFF X X X X X Manual Switch to turn Supply FAN (OFF/ ON). Only Works while in Test Mode.

RV Manual BV 29 R/W DO 13 BO 13 nviRVMan OFF X X X X X Manual Switch to turn Reversing Valve (OFF/ ON). Only Works while in Test Mode.

C1 Manual BV 30 R/W DO 14 BO 14 nviC1Man OFF X X X X X Manual Switch to turn Compressor C1 off or ON. Only Works while in Test Mode.

C2 Manual BV 31 R/W DO 15 BO 15 nviC2Man OFF X X X X X Manual Switch to turn Compressor C2 off or ON. Only Works while in Test Mode.

TSTAT Reset BV 33 R/W ADF 28 Coil 29 nviTstatMode OFF X Obsolete Point found only in Gen 5.

AUX Manual BV 32 R/W DO 16 BO 16 nviAuxMan OFF X X X X X Manual switch to turn AUX Ouput (W) "OFF" or "ON". Only works while in Test Mode.

Test Mode BV 34 R/W DO 18 BO 18 nviTestMode OFF X X X X

Test Mode BV 37 R/W X Manual switch to turn AUX Ouput (W) either "OFF" or "ON".

Test Mode Alarm BV 38 R DI 10025 BI 21 Special* NA X X X X Indicates the unit is still in Test Mode after the test mode timer has expired.

Metric BV 33 R/W DO 21 BO 28 Special* OFF X X X X Network input used to dene inputs and outputs. Celsius- ON / Fahrenheit -Off.

AUX Toggle BV 40 R/W DO 17 BO 17 nviAuxToggle OFF X X X X

Unoccupied Deadband

Celsius

Relative Humidity Setpoint AV 47 R/W Float 59 Data Float 38 nviRHSP 60% X X X

Relative Humidity Deadband AV 48 R/W Float 61 Data Float 39 nviRHDB 5% X X X

Relative Humidity Status AV 49 R Float 34 Data Float 40 nvoRHStatus NA X X X Network Output for Space Relative Humidity when using appropriate sensor.

Aux 5 Temp AV 50 R Float 36 Data Float 41 nvoAux5Temp NA X X X

Aux 6 Temp AV 51 R Float 38 Data Float 42 nvoAux6Temp NA X X X

CO2 Status AV 52 R Float 40 Data Float 43 nvoCO2Status NA X X X Network Output for Space CO2 level when using the appropriate sensor.

VOC Status AV 53 R Float 42 Data Float 44 Special* NA X X X Network Output for Space VOC level when using the appropriate sensor.

CO2 Trip point AV 54 R/W Float 63 Data Float 45 nviCO2Trip 800 PPM X X X

VCO Trippoint AV 55 R/W Float 65 Data Float 46 Special* 800 PPM X X X

FAN Speed Trigger AV 56 R/W Integer 67 Data Int 12 nviFanSpdTrig 75% X X

Airow Fault Counter AV 57 R Integer 44 Data Int 13 Special* 0 X X

Pump Fault Counter AV 58 R Integer 45 Data Int 14 Special* 0 X X

AV 46 R/W Float 40017 Data Float 11 Special* 9.44° C X X X X

Application Type AV 99 R Float 13 Data Float 9 NA NA X X X Factory Use Only.

28

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Network input used to bypass normal operations in order to operate the unit manually,

maximum ON time for Test Mode is 60 Minutes.

Network input used to toggle the auxillary output (W) "ON" and "OFF" Used when AUX

CFG (AV:31) is set to a value of 11.

Creates the Celsius Heating Setpoint using Unoccupied Cooling Setpoint minus current value

when using the Deadband Mode. Minimum value is 1.1° C with default of 9.44° C . DB Mode

(BV:48) must be "ON".

Network input for the Dehumidication Setpoint above which the Auxillary output(W) is activated

when AUX CFG (AV:31) is set to 12 for Humidity Control.

Creates Dehumidifcation turn off point using Relative Humidity SP minus the RH current value

when AUX CFG ( AV:31) is set to 12 for Humidity Control.

Network Output for Auxillary Temperature 5 when RNET Mode (BV:44) is "ON" and AUX 5 CFG

(BV:47) is set to "ON" for temperature sensor.

Network Output for Auxillary Temperature 6 when RNET Mode (BV:44) is "ON" and AUX 6 CFG

(BV:46) is set to "ON" for temperature sensor.

Network Input for CO2 trip point above which the Auxillary Output is activated when AUX CFG

(AV:31) is set to13 for CO2 Control.

Network Input for VOC trip point above which the Auxillary Output is activated when AUX CFG

(AV:31) is set to 14 for VOC Control.

Network input for Heating or Cooling PID above which the AUX Output (W) turns "ON" when AUX

CFG is set to 5 for Fan Speed Control. Requires eld wired relay for PSC Motors Only.

Indicates the number of airow faults that have occured since unit startup or resetting the fault

counter via Fault Count Reset (BV:24).

Indicates the number of pump faults that have occured since unit startup or resetting the fault

counter via Fault Count Reset (BV:24).

29

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Multi Generation Water-to-Air Points Matrix - cont'd

Point Name Type Number

Type Register Type ID NV Name Default Gen 3 Gen 4 Gen 5 Gen 6 Gen 7 Description

(Read Left to Right Across Spread)

Read/Write

BACNet ModBus N2 LON

Alarm State BV 1 R DI 10001 BI 1 nvoAlarmState NA X X X X X "ON" indicates a lockout condition exists, "OFF" indicates normal operation.

C1 Reset BV 2 R/W DO 1 BO 1 Special* OFF X X X X X Network Input used to reset the C1 Runtime Alarm (BV:17) once the event is triggered

C1 Status BV 3 R DI 10002 BI 2 nvoC1Status NA X X X X X Indicates if Compressor 1 is "ON" or "OFF".

System Reset BV 4 R/W DO 2 BO 2 nviSystemReset OFF X X X X X

C2 Reset BV 5 R/W DO 3 BO 3 Special* OFF X X X X X Network Input used to reset the C2 Runtime Alarm (BV:17) once the event is triggered

C2 Status BV 6 R DI 10003 BI 3 nvoC2Status NA X X X X X Indicates if Compressor 2 is "ON" or "OFF".

Dirty Filter Reset BV 7 R/W DO 4 BO 4 nviDFReset OFF X X X X X Network Input used to reset the Dirty Filter Alarm (BV:19).

Emergency Shutdown BV 8 R/W DO 5 BO 5 nviESD OFF X X X X X Network Input for Emergency ShutDown. When Engaged, Y1,Y2,G & W output relays turn "OFF".

Supply Fan Operational

Mode

SF Status BV 10 R DI 10004 BI 4 nvoSFStatus NA X X X X X Indicates if the Supply Fan is "ON" or "OFF".

Occupied Status BV 11 R

Occupied Mode BV 12 R/W DO 7 BO 7 N/A ON X X X X X

Air Duct Mode BV 41 R/W DO 26 BO 30 nviDuctMode OFF X X X

AUX 5 BV 42 R DI 10026 BI 22 nvoAux5 NA X X X

BV 9 NA NA NA NA NA NA X X Sets Supply Fan Mode Auto-OFF, ON ON GEN2 , GEN3 and GEN 4 only

DI

10005

BI 5

nvoOccStatus NA X X X X X Indicates whether the WSHP is in Occupied "ON" or Unoccupied "OFF" Mode.

AUX 6 BV 43 R DI 10027 BI 23 nvoAux6 NA X X X

RNet Mode BV 44 R/W DO 27 BO 31 nviRnetMode ON X X X

Humidity Occupancy BV 45 R/W DO 28 BO 32 nviRHOcc OFF X X X Network Input used to enable/ disable humidity control when AUX CFG (AV:31) set to 12 .

Aux 5 Cong BV 46 R/W DO 29 BO 33 nviAux5Cfg ON X X X

Aux 6 Cong BV 47 R/W DO 30 BO 34 nviAux6Cfg ON X X X

DB Mode BV 48 R/W DO 31 BO 35 nviDBMode OFF X X X

CO2 Alarm BV 49 R DI 10028 BI 24 nvoCO2Alarm NA X X X

VOC Alarm BV 50 R DI 10029 BI 25 Special* NA X X X

Fan Speed Enable BV 51 R/W DO 32 BO 36 Special* X X

Compressor Shutdown BV 52 R/W DO 33 BO 37 Special* OFF X X

Fault MSV 1 R NA NA NA NA NA X X X Multistate BACnet value for text description of current alarm state.

AUX Cong Status MSV 2 R NA NA NA NA NA X X X Multistate BACnet value for text description of current Auxillary Output Conguration..

Zone Mode Status MSV 3 R NA NA NA NA NA X X X Multistate BACnet value for text description of current operating mode.

Heating Mode BV 61 R/W DI 78 BI 74 Special* ON X

30

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Network Input used to reset the unit from lockout mode. User must turn it "ON" then turn it "OFF",

not a momnetary switch.

Network Input to put WSHP in unoccupied Mode "OFF" or Occupied Mode "ON". Can be used

instead of Work Schedule.

Network Input used to activate Air Duct Mode. The Air Duct Mode uses Aux 5 Temp for the

controlling zone temperature.

Indicates the status of Aux Input 5 when RNet (BV:44) is "ON". And AUX5 CFG ( BV:46) is set to

"OFF" for Binary Input.

Indicates the status of Aux Input 6 when RNET (BV:44) is "ON". And AUX6 CFG ( BV:47) is set to

"OFF" for Binary Input.

Network Input used to select between LSTAT (ASW06-08) wall sensors and communicating was

sensors(ASW13-15). RNet should be "OFF" when using LSTAT Sensors and "ON" for all other

congurations. The MPC board jumper W3 must be set to LSTAT for LSTAT sensors or RNet for

RNet sensors.

Network input used to select the conguration of Auxillary Input 5. Setting RNet (BV:44 ) "ON"

sets input for Thermistor mode,"OFF" sets input for Dry Contact mode.

Network input used to select the conguration of Auxillary Input 6 .Setting RNet (BV:44 ) "ON"

sets input for Thermistor mode,"OFF" sets input for Dry Contact mode.

Network input to select between using separate cooling and heating setpoints. Set to "OFF for

Cooling or Heating Setpoint or "ON" for the cooling setpoint and deadband to determne the heating

setpoint. Used when replacing GEN 4 or Lower with GEN 6 or higher.

Indicates the CO2 status (AV:52) is above the CO2 trippoint (AV:54) when using an appropriate

wall sensor.

Indicates the CO2 status (AV:53) is above the VOC trippoint (AV:55) when using an appropriate

wall sensor.

Network input to activate the auxillary output for High Speed Fan when AUX CFG (AV:31) is set

to 5 for Fan Speed Control: Required Field wired Relay for PSC Motors only.

Network input used to shutdown all compressor functions, C1 and C2. Compressors Enabled =

"ON", Compressors disableld = "OFF"

This is used to disable heating demand when it is desired to run Cooling Mode only. "ON"= Heating

Enabled, "OFF"= Heating Disabled. Special feature in GEN6, Standard Feature in GEN7.

31

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Multi Generation Water-to-Air Points Matrix - cont'd

Point Name Type Number

Type Register Type ID NV Name Default Gen 3 Gen 4 Gen 5 Gen 6 Gen 7 Description

(Read Left to Right Across Spread)

Read/Write

BACNet ModBus N2 LON

Cooling Mode BV 54 R/W DI 77 BI 73 Special* ON X

Electric Heat Mode BV 57 R DI 16 BI 1 Special* OFF X

Electric Heat Demand BV 58 R DI 17 BI 2 Special* OFF X

Ext Occ/ Dirty Filt Sens BV 59 DI 76 BI 80 Special* OCC X

Dirty Filter Mode BV 60 R/W DI 76 BI 3 Special* TIME X

Archive Enable BV 62 R/W DI 75 BI 4 Special* OFF X

RNET Sensor 1 Enable BV 63 R/W DI 74 BI 70 Special* ON X

RNET Sensor 2 Enable BV 64 R/W DI 70 BI 78 Special* OFF X

RNET Sensor 3 Enable BV 65 R/W DI 71 BI 77 Special* OFF X

RNET Sensor 4 Enable BV 66 R/W DI 72 BI 76 Special* OFF X

RNET Sensor 5Enable BV 67 R/W DI 73 BI 75 Special* OFF X

EQ Touch Temp Enable BV 68 R/W DI 68 BI 72 Special* OFF X Network input that allows the use of the Equipment Touch Internal Sensors for Space Temperature .

Load Balance Select Mode AV 59 R/W Float 19 ADI 70 Special* 2 X Network Input used to select how the compressors are sequenced to balance Compressor Runtime.

32

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

This is used to disable cooling demand when it is desired to run Heating Mode only. ON=Cooling

Enabled, OFF=Cooling Disabled. Special feature in GEN6, Standard Feature in GEN7.

This enables Fulltime Electric Heating. Control (W) is used to enable heating element. "ON"= Full

Time Electric Heating, "OFF"= Heat Pump. (Heat Pump fucntion is shut down in the mode and

AUX provides output to drive external heating element. Requires external relay and heating

element). Special feature in GEN6, Standard Feature in GEN7.

Status signal is "ON" when a Heating Demand is present and in Fulltime Electric Heating Mode

( AUX_CTL = 15). Special feature in GEN6, Standard Feature in GEN7.

Selects between External Motion Sensor or Dirty Filter Air Pressue into BI:8. OCC= Occupancy,

DFS= Dirty Filter Sense. Special feature in GEN6, Standard Feature in GEN7.

Selects between Time Mode or DFS( Air Pressure )Mode as the method for determining the Dirty

Filter Interval. For DFS (Dirty Filter) Mode set (BV:59) to DFS. Special feature in GEN6, Standard

Feature in GEN7.

Network input used to Archive the current control program. Standard Feature in GEN7, not

present in previous generations.

Network input for enabling RNET Sensor 1 Present Alarm . Should be turned on if RNet1

Sensor is used

Network input for enabling RNET Sensor 2 Present Alarm . Should be turned on if RNet2

Sensor is used

Network input for enabling RNET Sensor 3 Present Alarm . Should be turned on if RNet3

Sensor is used

Network input for enabling RNET Sensor 4 Present Alarm . Should be turned on if RNet4

Sensor is used

Network input for enabling RNET Sensor 5 Present Alarm . Should be turned on if RNet5

Sensor is used

33

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC MultiProtoCol DDC Controls

November 19, 2018

Multi Generation Water-to-Air Points Matrix

AUX CFG Settings

AUX CFG Mode (AV:31) Value Gen 3 Gen 4 Gen 6 Gen 7

Electric Heat when Demand > 90% 1 X X X X

Cycle with Y1 2 X X X X

Cycle w/ G 3 X X X X

Slow Opening Water Valve 4 X X X X

High Speed Fan 5 X X X X

Alarm Relay 6 X X X X

Reheat ICM/DXM Std 7 X X X

Reheat ICM/DXM Rev 8 X X X

Reheat DXM Std 9 X X X

Reheat DXM Rev 10 X X X

Manual Control 11 X X X X

Humidity Control 12 X X

CO2 Control 13 X X

VOC Control 14 X X

Full time Electric Heat 15 X

Supply FAN Settings

SF CFG ( AV:33 ) Value Gen 3 Gen 4 Gen 6 Gen 7

Cycle with Compressor 1 X X X X

On during occupancy, cycle with

Compressor during unoccupancy

On all the Time 3 X X X X

2 X X X X

Compressor Load Balance Select Settings

Load Balance Select Mode (AV:59) Value Gen 3 Gen 4 Gen 6 Gen 7

Runtime Compare Mode 1 X

Manua Mode, C1 -Stage 1/ C2-Stage 2 2 X

Manua Mode, C2 -Stage 1/ C1-Stage 2 3 X

Time Toggle Mode- Toggles every 12 Hrs 4 X

Supply Fan Conguration Settings

SF CFG (AV:33) Value Gen 3 Gen 4 Gen 6 Gen 7

Supply Fan is ON anytime the

compressor is ON

Supply F an ON only when in occupied

hours and the compressor is ON

Supply Fan is ON all the time regardless

of occupancy or compressor state

1 X X X X

2 X X X X

3 X X X X

34

THE SMART SOLUTION FOR ENERGY EFFICIENCY

MPC Feature Conguration

MPC MultiProtoCol DDC Controls

November 19, 2018

Occupancy Settings: These control points are used

to set occupancy.

a. Occupancy (All Generations) – This point (BV:12)

controls whether the unit is in occupancy or

is unoccupied. It is normally defaulted to