Page 1

C

LIMATE

M

ASTER

¤

Flow Controller

GEOTHERMAL PUMPING MODULE

INSTALLED BY:

Flow Controller

Installation, Operation, &

Maintenance Instructions

12/98

TABLE OF CONTENTS

Flow Controller Description 2

Flow Controller Mounting 2

Piping Installation 3

Electrical Wiring 4

Flushing the Earth Loop 5

Antifreeze Selection 6

Antifreeze Charging 7

Heat Pump Freezestat Setting 8

Pressure Drop Tables 9

Earth Loop Pressurization 9

Flow Controller Start-Up 10

Pump Cartridge Replacement 10

Closed Loop Design 11

Polyethylene Pressure Drop 14

Rubber Hose Pressure Drop 15

Closed Loop Installation 16

Building Entry 18

1

Page 2

FLOW CONTROLLER DESCRIPTION

10.75"

Unit Side

13.75"

TTaacco

o

TTaacco

o

Loop Side

4.38"

8.75"

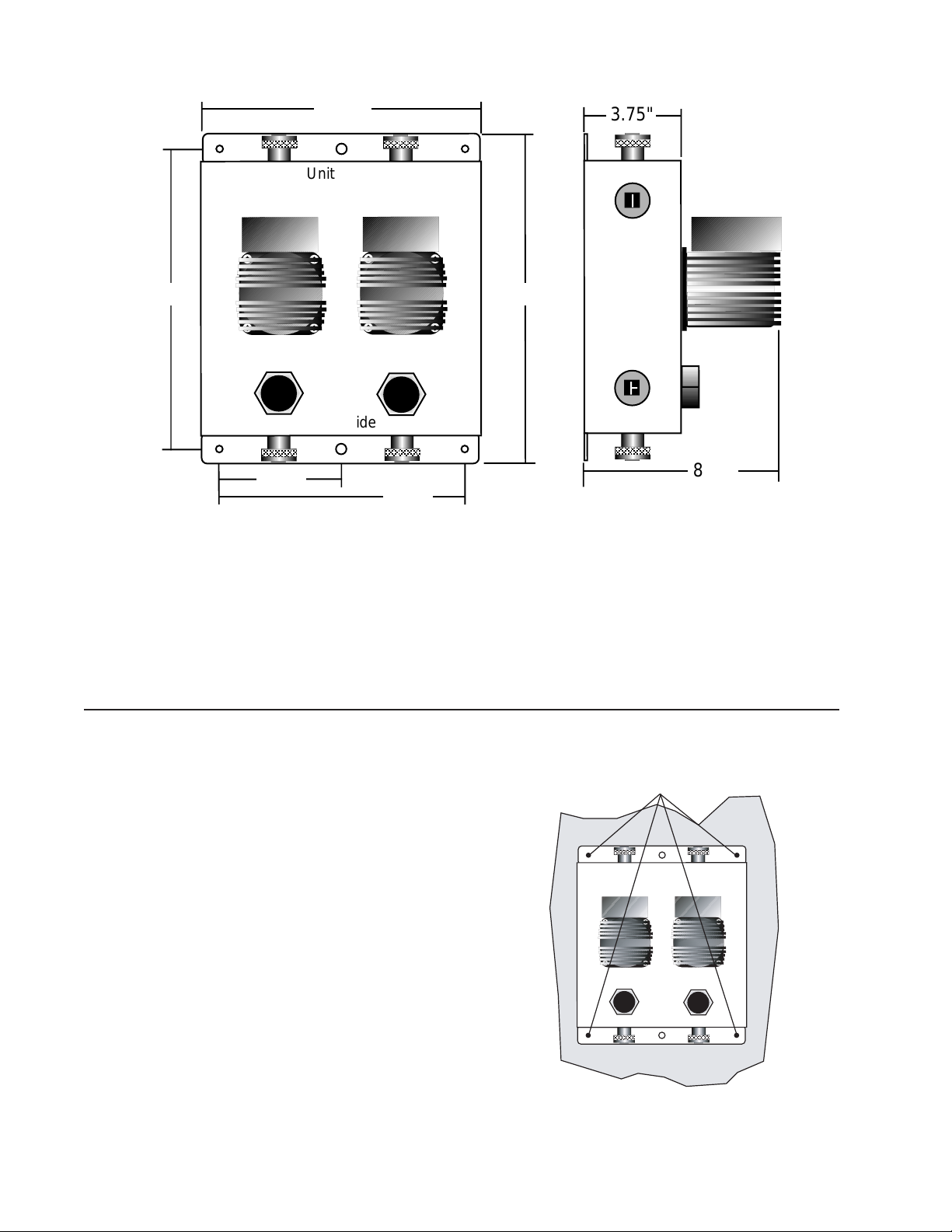

Figure 1 - Flow Controller Dimensions

The AFCS1A and 2A are insulated flow controllers

containing all flush, fill, and isolation connections for a

residential and light commercial geothermal closed loop

system that require a flow rate of no more than 20 gpm.

The AFCS1A and 2A are equipped with a large bore 1 1/

4" FPT swivel fittings for both earth loop and heat pump

unit connections. Either 1 (AFCS1A) or 2 (AFCS2A)

Taco 0013 chilled water rated cartridge type circulators

3.75"

15.00"

8.50"

are included with the flow controller. Included in this kit

are:

• 2 Lag bolts for mounting AFC onto stud walls

• 4 Self-drilling sheet metal screws for mounting AFC

onto heat pump

• 2 1" MPT PVC plug for sealing flush ports after

installation

FLOW CONTROLLER MOUNTING

General

The installation of the ClimateMaster Flow Controller

shall be made in accordance with all applicable codes.

Mounting the Flow Controller

The flow controller should be located as close to the unit

as possible to limit the length of the rubber hose kit and

thus its associated pressure drop. In general the flow

controller can be mounted in any orientation with the

exception of when the pump shafts are in a vertical

position as when it is laid flat on the floor or any similar

position. The controller is typically mounted in one of

three locations. Be certain there is adequate access to all

required flush ports and valves before mounting.

Stud Wall - Mounting on stud wall with or without

drywall can be accomplished by using the two supplied

lag bolts through the top and bottom center holes directly

into the studs as shown in Figure 2.

Self-drilling screws into sheet metal 4 places.

DO NOT PUNCTURE INTERNAL

COMPONENTS!

Unit Side

o

TTaacco

Loop Side

Heat Pump Cabinet

TTaacco

o

Figure 2 - Mounting Flow Controller on Stud Wall

2

Page 3

Side of Unit - Mounting on the side of the unit can be

accomplished by using the four self-drilling screws

directly into the sheet metal access panels or cabinet as

shown in Figure 3. Be careful not to puncture any

internal piping or other components with the screws. It

should be remembered that heat pump access will be

limited in this mounting position.

Tubing Insulation

brought up to cover

complete connection

1-1/4”

MPT

Remove

Cover

TTaacco

Unit Side

o

Loop Side

Figure 4 - AFCS1 Piping Detail

Figure 3 - Mounting Flow Controller on Side of Unit

Concrete wall - Mounting onto a concrete wall can be

accomplished by using 4 1/4" ‘Tapcon’ screws (supplied

by others) directly into the concrete wall.

Piping Installation

The Flow controller features 1 1/4" FPT swivel fittings

for flexible and easy installation. Table 1 illustrates the

connection options available for the AFCS1A and 2A.

Avoid using 3/4" piping on flows greater than 6 gpm.

Pressure drop in piping systems should be calculated to

insure adequate flow through the unit. All piping should

be insulated with closed cell insulation of 1/2" wall

thickness. Table 2 shows the insulation requirements for

typical piping materials. Piping insulation should be

glued and sealed to prevent condensation using closed

cell insulation glue. The swivel connectors on the flow

controller are designed to be hand tightened only.

Table 2 - Typical Piping Insulation Materials

Piping Material Insul Description

1" Hose Kit 1-3/8" ID - 1/2" wall

1" IPS PE 1-1/4" ID - 1/2" wall

1-1/4" IPS PE 1-5/8" ID - 1/2" wall

2" IPS PE 2-3/8" ID - 1/2" wall

Loop side piping is typically polyethylene piping

directly into the flow controller. Connection to the flow

controller can be accomplished by a fusion-to-brass MPT

adapter (GFMA66). In multiple flow controller systems

such as multifamily housing, PVC can also be used on

the loop side, remembering however that the transition

from PVC to PE should be accomplished by a flange

connection and PVC is approved for use only as an

indoor piping material in earth loops.

Unit side piping is typically connected using the

ClimateMaster hose kit (AHK5E) which contains all

fittings necessary for connection between the flow

controller and the unit as shown in Figure 5. In the

AFCS1A remove cover and make connections as shown

in Figure 4, remembering all areas of the piping should

be insulated to prevent condensation.

In multiple unit systems, PVC adapters (1 1/4" MPT x

PVC socket) to the flow controller and standard PVC

piping materials can be used to ‘tee’ more than one unit

into the flow controller. It is recommended that a hose kit

still be used at the end of the PVC piping run to facilitate

ease of installation and service of the units as shown in

Figure 6. Insulate all exposed piping. Plastic-to-metal

threads should not be used due to their leakage potential.

To Heat Pump 1"

Swivel Fitting

P/T Port

Rubber Hose Max of

15" Each Side

To Flow Controller 1 1/4"

Swivel Fitting

All Stainless

Hose Clamp

Figure 5 - AHK5E Hose Kit Typical Detail

Table 1 - AFCS1A and 2A Connection Materials

To Fittings

PVC 1-1/4" MPT x 1" PVC Glue Socket

PE Fusion 1-1/4" MPT x 1-1/4" PE Fusion

PE Barb 1-1/4" MPT x 1-1/4" insert barb*

Copper Sweat 1-1/4" MPT x 1" sweat**

Copper Thread 1-1/4" MPT x 1" MPT Nipple

* Use double all-stainless hose clamps

** Sweat before connecting to flow controller

From Flow Controller

1 1/4" MPT x Glue Socket

15" each side

1 or 1 1/2"

SCH 40 PVC

Insert Barb x Glue Socket

Rubber Hose Max of

15" each side

To Heat Pump #1 To Heat Pump #2

Rubber Hose Max of

Figure 6 - Two Units Utilizing One Flow Controller

(one side shown)

3

Page 4

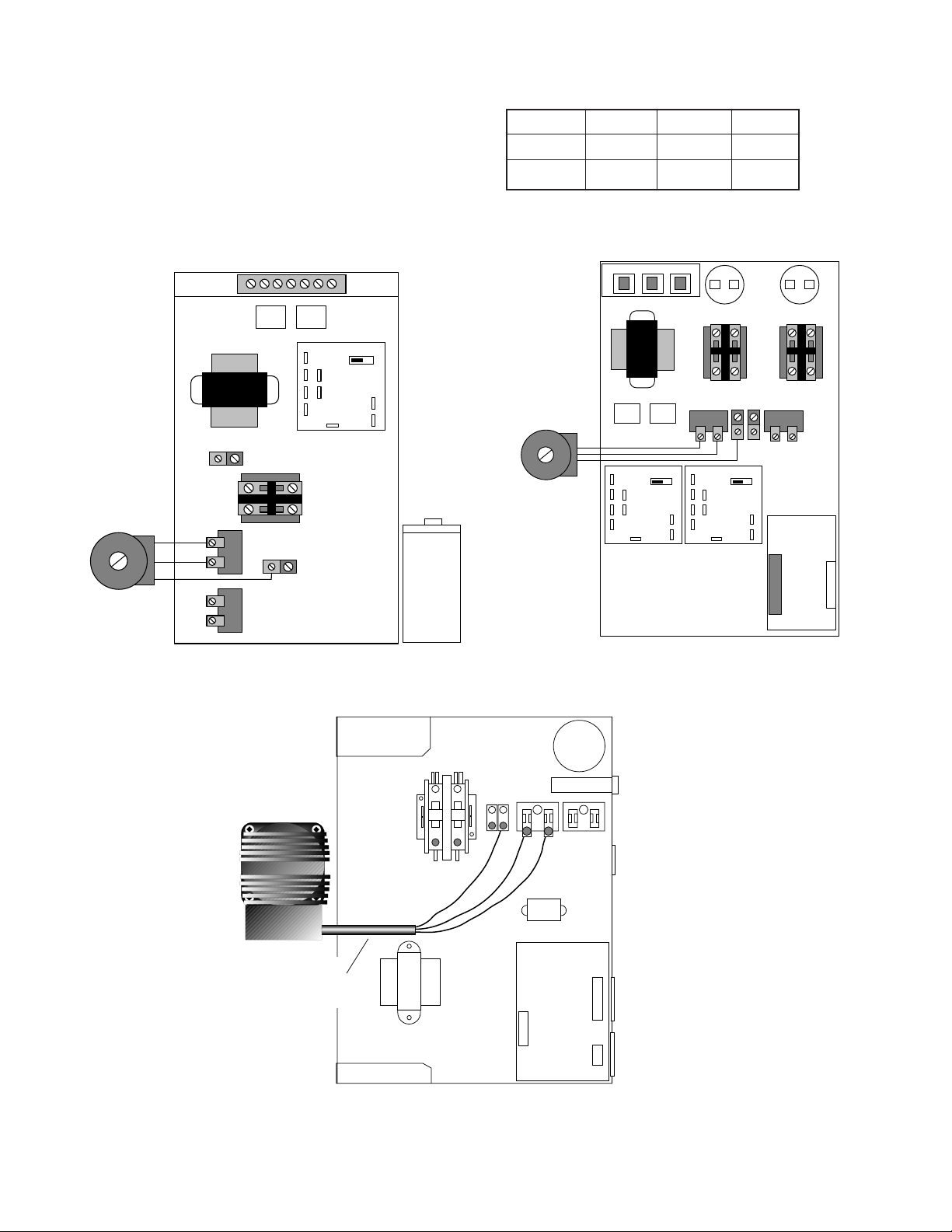

FLOW CONTROLLER ELECTRICAL WIRING

Power wiring to the flow controller should conform to all

applicable codes. Figure 7 illustrates the wiring required

for the Classic and Figure 8a and 8b for Genesis. Note

the flow controller is available in only in 230V single

phase voltage. Pumps are fused through a pair of circuit

breakers in the unit control boxes. See electrical table for

flow controller characteristics.

External Loop Pump(s)

208/230 Volt-4 Amp Max.

Transformer

L2 L1

CRR

Unit Ground

Loop Pump

Term Blk

HWG Pump

Term Blk

PR

CCM PCB

T1

HPS

LPS

Y

X

Compressor

Contactor

Pump Ground

Min Sec.

T

C

Electrical Table

Model Volts Amps HP

AFCS1A 230 .88 1/8

AFCS2A 230 1.76 1/4

Circuit Breakers

Transformer

External Loop Pump(s)

208/230 Volt-4 Amp Max.

CRR

T1

Y

CCM PCB

HPS

LPS

X

PR

Min Sec.

T

C

Compressor

Contactor

L2 L1

Loop Pump

Term Blk

T1

HPS

LPS

Y

X

Ground

CCM PCB

Min Sec.

T

C

Thermostat

Connection

Compressor

Contactor

HWG Pump

Term Blk

ICM2 Controller

Figure 7 - Power Wiring to Classic Series

o

TTaacco

External Pump

Power Supply

See electrical table for

wire and breaker size

Figure 8B - Power Wiring to Genesis Series

Contactor -CC

Transformer

Figure 8A - Power Wiring to Ultra Classic Series

Capacitor

Circ Brkr

HWG PB2

Loop PB1

T2

Grnd

L1

L2

BR

CXM Control

CB

Low Voltage

Connector

T1

T1

T2

4

Page 5

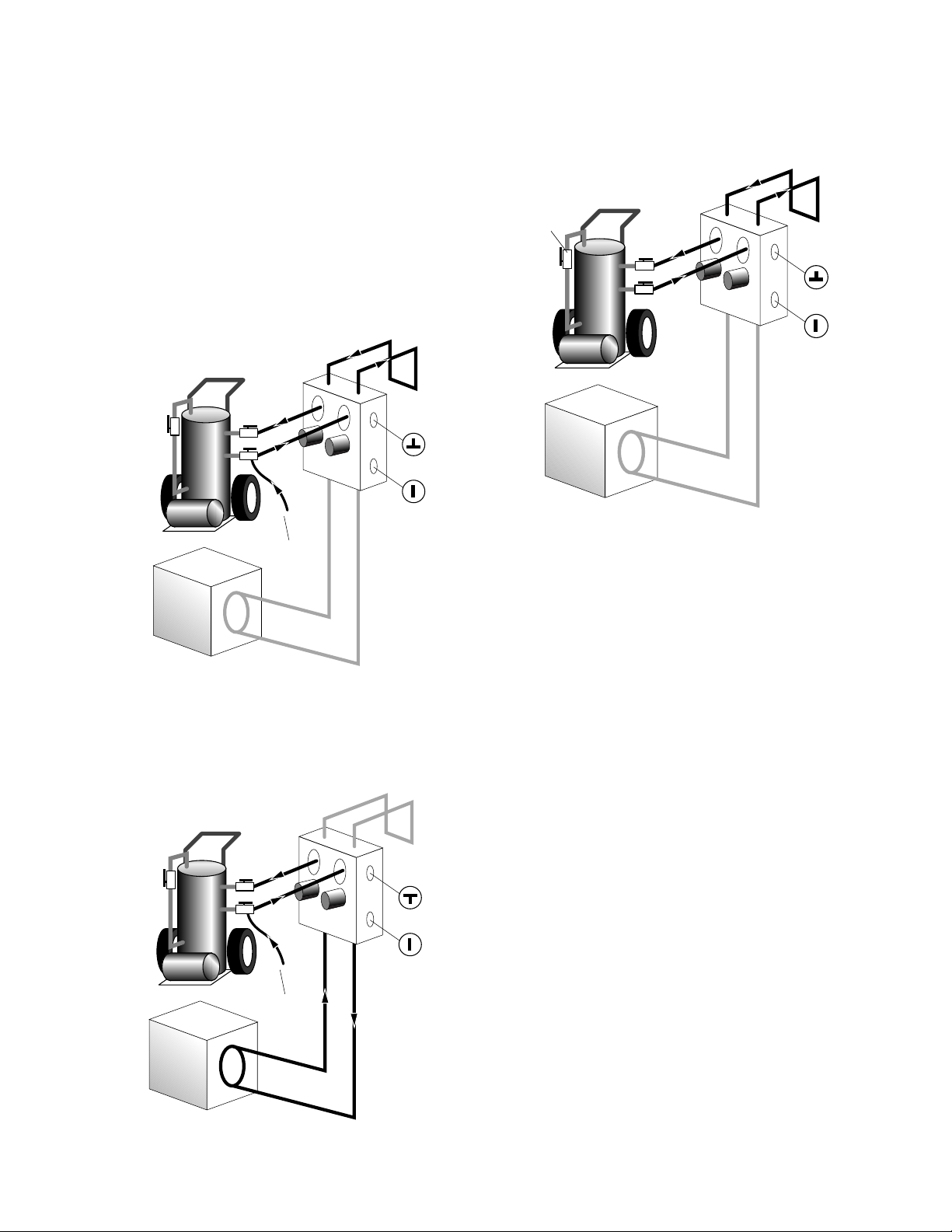

FLUSHING THE EARTH LOOP

Once piping is completed between the unit, flow controller, and the ground loop, final purging and charging of

the loop is needed.

A flush cart (at least a 1.5 hp pump) is needed to achieve

adequate flow velocity in the loop, to purge air and dirt

particles from the loop itself. Antifreeze solution is used

in most areas to prevent freezing. All air and debris must

be removed from the earth loop piping system before

operation. Flush the loop with a high volume of water at

a high velocity (2 fps in all piping) both directions, using

a filter in the loop return line of the flush cart to eliminate debris from the loop system. The steps below must

be followed for proper flushing.

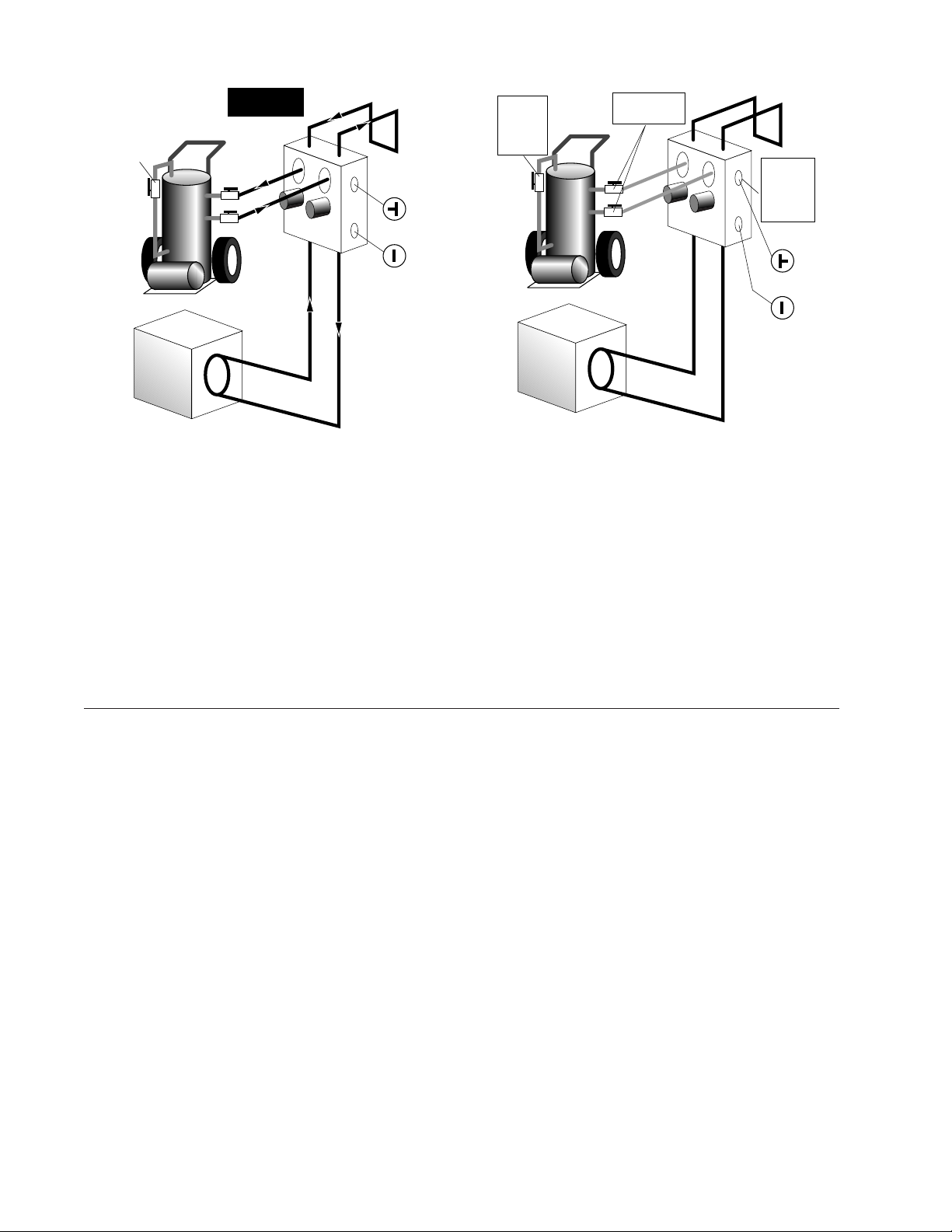

Loop

Flush Cart

Flow

Controller

Valve

Positions

Garden Hose

Unit

Figure 9A - Valve Position A - Loop Fill

Fill loop with water from a garden hose through flush

cart before using flush cart pump to ensure an even fill

and increase flushing speed. When water consistently

returns back to the flush reservoir switch to valve

position B.

Flush Cart

Loop

Flow

Controller

Valve

Positions

This position should be switched while filling, to fill the

unit heat exchanger and hose kit. This should be maintained until water consistently is returned into the flush

reservoir.

Loop

Dead Head

Pump Test

for Air

Unit

Flush Cart

Flow

Controller

Valve

Positions

Figure 9C - Valve Position C- Loop Flush

Switch to valve position C. The supply water may be

shut off and the flush cart turned on to begin flushing.

Once the flush reservoir is full, do not allow the water

level in the flush cart tank to drop below the pump inlet

line or air can be pumped back out to the earth loop. Try

to maintain a fluid level in the tank above the return tee

so that air cannot be continuously mixed back into the

fluid. 50 psi surges can be used to help purge air pockets

by simply shutting off the return valve going into the

flush cart reservoir. This ‘dead heads’ the pump to 50 psi.

To dead head the pump until maximum pumping pressure is reached, open the valve back up and a pressure

surge will be sent through the loop to help purge air

pockets from the piping system. Notice the drop in fluid

level in the flush cart tank. If all air is purged from the

system, the level will drop only 1-2" in a 10" diameter

PVC flush tank (about a half gallon) since liquids are

incompressible. If the level drops more than this,

flushing should continue since air is still being compressed in the loop fluid. Do this a number of times.

When the fluid level is dropping less than 1-2" in a 10"

diameter tank the flow can be reversed.

Garden Hose

Unit

Figure 9B - Valve Position B - Unit Fill

5

Page 6

Dead Head

Pump Test

for Air

Flush Cart

Add Antifreeze

Now if Needed

Loop

Flow

Controller

Valve

Positions

1

Dead Head

Pump to

Pressurize

to 50 PSI

Flush Cart

2

Close to Isolate

Flow Controller

Loop

3

Close Flow

Controller

Valves for

Operation

Mode

Valve

Positions

Unit

Figure 9D - Valve Position D - Full Flush

Now by switching both valves to this position water will

flow both through the loop and the unit heat exchanger.

Finally the "dead head" test should be checked again for

an indication of air in the loop. This fluid level drop is

your only indication of air in the loop. Antifreeze may

be added during this part of the flushing procedure

(see antifreeze section for details).

Close the flush cart return valve, and after pressurizing,

close the flush cart supply valve to pressurize the loop to

a static pressure of at least 50 psi. If water pressure is

ANTIFREEZE SELECTION

General

In areas where minimum entering loop temperatures drop

below 40°F or where piping will be routed through areas

subject to freezing, antifreeze is needed. Alcohols and

glycols are commonly used as antifreezes, however your

local representative should be consulted for the antifreeze

best suited to your area. Freeze protection should be

maintained to 15°F below the lowest expected entering

loop temperature. For example, if 30°F is the minimum

expected entering loop temperature, the leaving loop

temperature would be 25-22°F and freeze protection

should be at 15°F (30°F-15°F=15°F). All alcohols should

be premixed and pumped from a reservoir outside of the

building when possible or introduced under water level to

prevent fuming. Initially calculate the total volume of

fluid in the piping system using Table 3. Then use the

percentage by volume shown in Table 4 for the amount

of antifreeze. Antifreeze concentration should be checked

from a well mixed sample using a hydrometer to measure

specific gravity.

Unit

Figure 9E - Valve Position E - Pressurize and Operation

low, use an air compressor to bump the pressure up

through the P/T port. The loop may be isolated by

moving to valve position E keeping watch on the

pressure gauge of the flush cart for pressure greater than

50 psi. Loop static pressure will fluctuate with the

seasons and pressures will be higher in the winter months

than during the cooling season. This fluctuation is normal

and should be considered when charging the system

initially. Unhook flush cart from the flow controller.

Install counter sink plugs using sealant compatible with

PVC.

Antifreeze Characteristics

Selection of the antifreeze solution for ClimateMaster

closed loop earth coupled systems requires the consideration of many important factors which have long-term

implications on the performance and life of the equipment. Each area of concern leads to a different “best

choice” of antifreeze. The fact is that there is no “ideal”

antifreeze and any choice will require compromises in

one area or another. Some of the factors to consider are

safety, thermal performance, corrosiveness, local codes,

stability, convenience, and cost.

Methanol - Methanol or wood alcohol is considered

toxic in any form, good heat transfer, low to mid price,

flammable in concentrations greater than 25%, noncorrosive, and low viscosity. Methanol has delivered

outstanding performance in earth loops for over 10 years.

Its only drawbacks are toxicity and flammability.

Although methanol enjoys widespread consumer use as a

windshield washer fluid in even higher concentrations,

6

Page 7

some local codes may limit its use in earth loops. To

increase safety, a premixed form should be used on the

job site to increase the safety factor. Pure methanol can

be purchased from any chemical supplier.

Ethanol - Ethanol or grain alcohol exhibits good heat

transfer (slightly less than methanol), higher price, and is

flammable in concentrations greater than 10%. Ethanol is

generally non-corrosive and has medium viscosity.

Ethanol in its pure form is considered non toxic and

shows promise as a geothermal heat transfer fluid,

however, the U.S. Bureau of Alcohol, Tobacco, and

Firearms (ATF) limit its distribution. All non-beverage

ethanol is required to be denatured and rendered unfit to

drink. Generally this is done by adding a small percentage of toxic substances such as methanol, benzene, or

gasoline as a denaturant. Many of these denaturants are

difficult to identify by the casual user and many are not

compatible with polyethylene pipe. Only denatured

ethanol can be purchased for commercial use. CM does

not recommend the use of ethanol because of the unknown denaturants included and their possible toxicity

and damage resulting to polyethylene piping systems.

Ethylene glycol - Generally non-corrosive, expensive,

medium heat transfer, however is considered toxic. Its

toxicity has prevented its widespread use in the ground

source industry in spite of its widespread use in traditional watersource heat pump applications. CM does not

currently recommend ethylene glycol as a ground source

antifreeze.

Propylene glycol - Non toxic, non-corrosive, expensive,

hard to handle when cold, poorest heat transfer, has

formed “slime-type” coatings inside pipe. Poor heat

transfer has required its removal in some systems.

Propylene glycol (PG) is acceptable in systems anticipating loops temperatures no colder than 40°F. These

systems typically are antifreeze because of ambient

conditions (outside plumbing or cooling tower, etc.).

When loop temperatures are below 40°F., the fluid

becomes very difficult to pump, and heat transfer

characteristics suffer greatly. CM recommends only food

grade propylene glycol be used to prevent the corrosion

inhibitors (often present in other mixtures) from reacting

with local water and "coming" out of solution to form

slime type coatings inside heat exchangers and thus

hinder heat transfer.

GS4 (Potassium acetate) - Non toxic, good heat

transfer, high price, non-corrosive with added inhibitors,

low viscosity. Due to its low surface tension, GS4 has

been known to leak through mechanical fittings and

certain thread sealants. A variant of the salt family, it can

be extremely corrosive when exposed to air. CM does not

recommend the use of GS4 with its products due to the

leaking and ultimate corrosion problems associated with

it.

Contact the ClimateMaster Technical Services Department if you have any questions as to antifreeze selection.

ANTIFREEZE CHARGING

It his highly recommended to utilize premixed

antifreeze fluid where possible to alleviate many

installation problems and extra labor.

The following procedure is based upon pure methanol

and can be implemented during the Full Flush

procedure with three-way valves in the Figure 9D Valve Position D. If a premixed methanol of 15°F

freeze protection is used, the system can be filled and

flushed with the premix directly to prevent handling

pure methanol during the installation.

1) Flush loop until all air has been purged from system

and pressurize to check for leaks before adding any

antifreeze.

2) Run discharge line to a drain and hook up antifreeze

drum to suction side of pump (if not adding below

water level through approved container). Drain flush

reservoir down to pump suction inlet so reservoir can

accept the volume of antifreeze to be added.

3) Calculate the amount of antifreeze required by first

calculating the total fluid volume of the loop from

Table 3. Then use Table 4 for the appropriate freeze

protection level. Many southern applications require

freeze protection because of exposed piping and

flow controller ambient conditions. An extra 10°F

of freeze protection is needed in Paradigm outdoor

applications.

Table 3 - Fluid Volume of Common Piping Materials

Fluid Volume (gal/100' pipe)

Pipe Size Volume

1" 4.1

Copper 1.25" 6.4

1.5" 9.2

Rubber Hose 1" 3.9

Polyethylene 3/4" IPS SDR11 2.8

1" IPS SDR11 4.5

1 1/4" IPS SDR11 8.0

1 1/2" IPS SDR11 10.9

2" IPS SDR11 18.0

1 1/4" IPS SCH40 8.3

1 1/2" IPS SCH40 10.9

2" IPS SCH40 17.0

Unit Heat Exchanger Typical 1.0

Flush cart tank 10" diam x 3 ft 10.0

7

Page 8

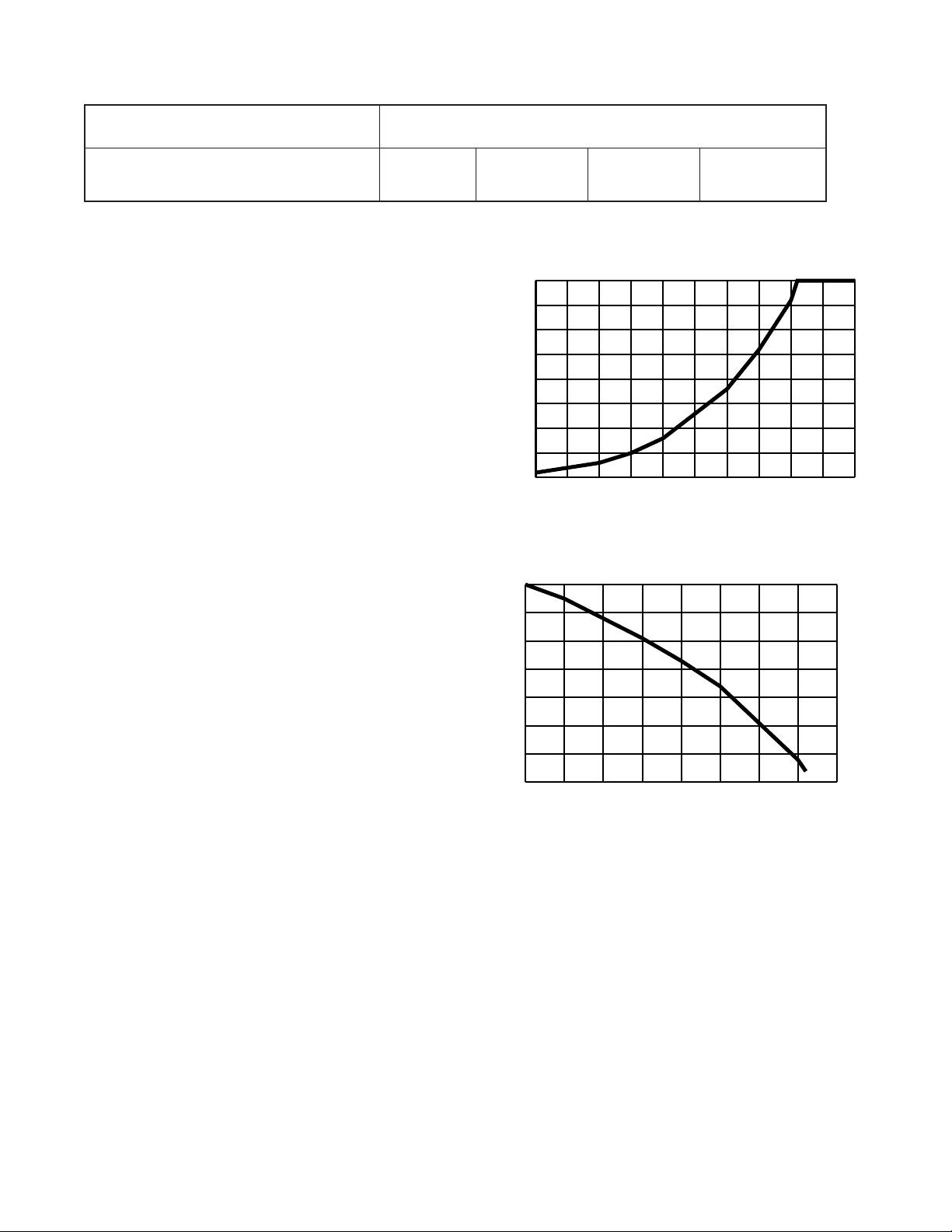

Table 4 - Antifreeze Percentages by Volume

-50 -40 -30 -20 -10 0 10 20 30 40 50

0.960

0.965

0.970

0.975

0.980

0.985

0.990

0.995

1.000

Freeze Protection - Degrees F˚

Specific Gravity

Type Minimum Temperature for Freeze Protection

10°F15°F20°F25°F

Methanol 25% 21% 16% 10%

100% USP food grade Propylene Glycol 38% 30% 22% 15%

4) Isolate unit and prepare to flush only through loop.

Start flush cart, and gradually introduce the required

amount of liquid to the flush cart tank (always

introduce alcohols under water or use suction of

pump to draw in directly to prevent fuming) until

attaining the proper antifreeze protection. Noting the

rise in flush reservoir level indicates amount of

antifreeze added. Some carts are marked with

measurements in gallons. A ten inch diameter, three

foot cylinder holds approximately eight gallons of

fluid. If more than one tankful is required, the tank

should be drained immediately by opening the waste

valve of the flush cart, noting the color of the

discharge fluid. Adding food coloring to the antifreeze can help indicate where the antifreeze is in the

circuit, which prevents the dumping of antifreeze out

the waste port. Repeat if necessary.

5) Be careful when handling methanol. The fumes are

flammable, and care should be taken with all

flammable liquids, such as alcohols. Open flush

valves to flush through both the unit and the loop;

flush until fluid is homogenous and mixed. It is

recommended to run the unit in the heating and

cooling mode for 15-20 minutes each to ‘temper’

the fluid temperature and prepare it for pressurization. Devoting this time to clean up can be

useful. This procedure helps prevent the periodic

“flat” loop condition.

6) Close the flush cart return valve; and immediately

thereafter, close the flush cart supply valve, leaving a

positive pressure in the loop of approximately 50psi.

This is a good time to pressure check the system as

well. Check the freeze protection of the fluid with

the proper hydrometer to ensure that the correct

amount of antifreeze has been added to the system.

The hydrometer can be dropped into the flush

reservoir and the reading compared to Figure 1A for

Methanol and 1B for Propylene Glycol to indicate

the level of freeze protection. Do not antifreeze more

8

than a +5°F freeze point. Specific gravity hydrometers are available from ClimateMaster. Repeat after

reopening and flushing for a minute to ensure good

second sample of fluid. Inadequate antifreeze

protection can cause nuisance freezestat lockouts

during cold weather.

Note: Always dilute alcohols with water (at least 50%

solution) before using (when possible).

Chart 1A - Methanol Specific Gravity

Chart 1B - Propylene Glycol Specific Gravity

1.07

1.06

1.05

1.04

1.03

1.02

Specific Gravity

1.01

1.00

-40 -30 -20 -10 0 10 20 30 40

Freeze Protection - Degrees F˚

7) Close the flush cart return valve; immediately

thereafter, close the flush cart supply valve, shut off

the flush cart leaving a positive pressure in the loop

of approximately 40-50 psi for summer and 50-75

psi for winter. Refer to Figure 9E for more details.

Heat Pump Freezestat Setting

When an antifreeze is used, the freezestat wires should be

switched to activate the low temperature freezestat

switch to avoid nuisance faults or lockouts. See the unit

installation manual for further details on switching

freezestat settings.

Page 9

Pressure/Temperature Ports

The pressure/temperature ports (P/T ports) supplied with

the earth loop connector kit are provided as a means of

measuring flow and temperature. The water flow (GPM)

through the unit can be checked by measuring the

incoming water pressure at the supply water P/T port

and subtracting the leaving water pressure at the return

water P/T port. Comparing the pressure differential to

the pressure drop/flow (Table 5) will determine the flow

rate through the unit. For reference, every 1 psi equals

2.31 feet of head, if conversion is needed.

ClimateMaster units require 2.25-3 gpm per nominal

cooling ton when installed in conjunction with an earth

loop. Note: Minimum flow for units is 2.25 gpm

per ton.

Example: A VP036 with a 3.8 PSI pressure drop would

be equivalent to 9 GPM on the chart. More flow will not

hurt the performance. However, insufficient flow can

significantly reduce capacity and possibly even cause

damage to the heat pump in extreme conditions. Digital

thermometers and pressure gauges needed for the P/T

ports are available from ClimateMaster.

Note: Pressure/temperature gauges should be pushed

gently into P/T ports to prevent internal damage to the

port.

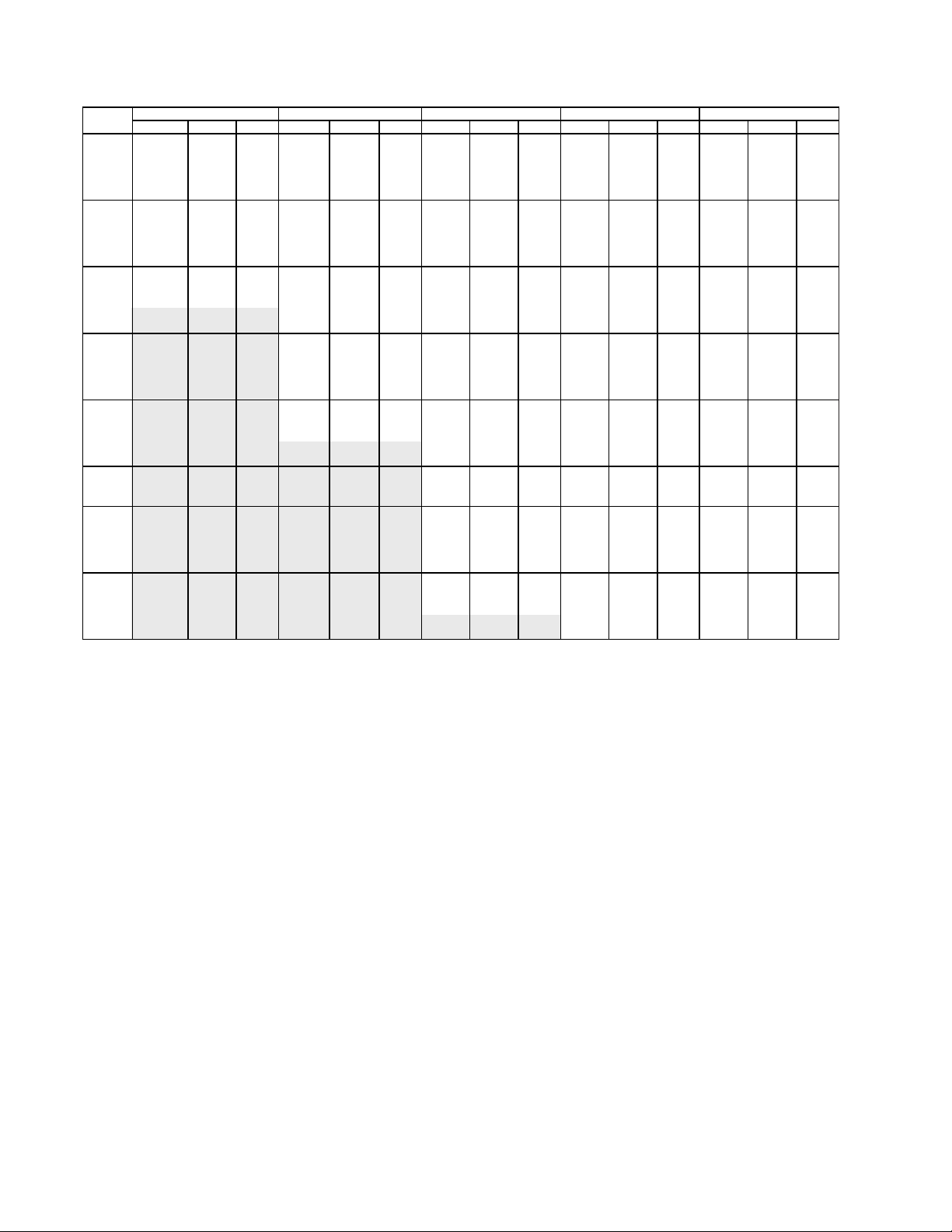

Table 5 - Classic, Ultra Classic, and Paradigm Pressure Drop

Earth Loop Pressure

The earth loop must have a slight positive pressure to

operate the pumps (>3 psi). The system pressure will

drop as the plastic earth loop pipe relaxes and will

fluctuate as the fluid temperature changes. Typical earth

loop pressures range from approximately 15-50 psi. At

the start-up of a system, you should leave the earth loops

with a (static) holding pressure of approximately 40-50

psi summer or 50-75 psi winter. Maximum operating

pressure should never exceed 100 psi under any

circumstance. It is recommended to run the unit in

the heating and cooling mode for 15-20 minutes each

to ‘temper’ the fluid temperature and prepare it for

pressurization. This procedure helps prevent the

periodic “flat” loop condition.

9

Page 10

FLOW CONTROLLER INITIAL START-UP

After pressurization, be sure to insure the loop flow

controller provides adequate flow through the unit by

checking pressure drop across the heat exchanger and

comparing it to the figures shown in Table 5. Flow

70

65

60

55

50

45

40

35

30

25

20

15

10

Total Head (ft. of hd.)

5

0

AFCS2A

AFCS1A

controller pump performance is shown in Chart 2.

Chart 2 - Flow Controller Performance

Start-Up of Flow Controller

1) Check to make sure that the loop and unit isolation

valves are completely open and the flush ports are

closed and sealed.

2) Check and record the earth loop pressure via the P/T

ports. Loop Pressure = In Out

3) Check and record the flow rate.

Flow Rate = gpm

4) Check performance of unit. Refer to unit installation

manual. Replace all caps to prevent pressure loss.

35302520151050

Flow Rate (gpm)

PUMP CARTRIDGE REPLACEMENT PROCEDURE

First isolate the pump in question as in Figure 10. Always

disable power to the pumps and remove pump power

wiring if needed. Close valves as in Step 1 of Figure 10.

Flow

Controller

Return Valve

Supply Valve

Bucket/Drain

Garden Hose Supply

Unit

Figure 10 - Cartridge Replacement Procedure

Loop

1

Close to isolate

pump tor

Cartridge change

2

Open to flush unit

with garden hose

and then pressurize

Valve

Positions

• Remove two allen head mounting bolts and lift off

pump stator housing. Lay out rags to soak up loop

fluid.

• Remove remaining two allen head mounting bolts and

remove cartridge, noting the large ‘o’-ring seal. Loop

fluid could spill from system.

• Replace with new cartridge, insuring the ‘o’-ring is in

place and install the two allen head mounting bolts.

• Reinstall the stator housing using the remaining allen

head mounting bolts.

• Place garden hose supply and return on flush ports as

shown in Figure 10 and open valves to flush through

the unit portion of loop. When water flows clear, close

return side to pressurize; finally, close the supply side

valve. Close 3-way valves to operation position Figure

9E. The loop can also be reflushed, using the complete procedure outlined for installation.

Remember, this procedure will dilute the antifreeze

mixture by a few gallons. If performed more than twice

on any earth loop, the antifreeze concentration should

be checked with a hydrometer and antifreeze added as

needed.

10

Page 11

GEOTHERMAL CLOSED LOOP DESIGN

Closed Loop Basics

Closed Loop Earth Coupled Heat Pump systems are

commonly installed in one of three configurations:

horizontal, vertical, and pond loop. Each configuration

provides the benefit of using the moderate temperatures

of the earth as a heat source/heat sink. Piping configurations can be either series or parallel.

Series piping configurations typically use 1-1/4 inch, 1-1/

2 inch, or 2 inch pipe. Parallel piping configurations

typically use 3/4 inch or 1 inch pipe for loops and 1-1/4

inch, 1-1/2 inch, or 2 inch pipe for headers and service

lines. Parallel configurations require headers to be either

“closed-coupled” short headers or reverse return design.

Select the installation configuration which provides the

most cost effective method of installation after considering all application constraints.

Loop design takes into account two basic factors. The

first is accurately engineered system to function properly

with low pumping requirement and adequate heat transfer

to handle the load of the structure. The second is to

design a loop with the lowest installed cost while still

maintaining a high level of quality. These factors have

been taken into account in all of the loop designs

presented in this manual.

In general terms, all loop lengths have been sized by the

ClimateMaster loop sizing software so that every loop

has approximately the same operating costs. In other

words, at the end of the year the home owner would have

paid approximately the same amount of money for

heating, cooling, and hot water, no matter which loop

type was installed. This leaves the installed cost of the

loop as the main factor for determining the system

payback. Therefore, this analysis says "install the most

economical system possible given the installation

requirements".

Pipe Fusion Methods

Two basic types of pipe joining methods are available for

earth coupled applications. Polyethylene pipe can be

socket fused or butt fused. In both processes the pipe is

actually melted together to form a joint that is even

stronger than the original pipe. Although when either

procedure is performed properly the joint will be stronger

than the pipe wall. ClimateMaster prefers socket fusion

in the fusion of 2" pipe or less because of the following:

• Allowable tolerance of mating the pipe is much

greater in socket fusion. According to general fusion

guidelines, a 3/4" SDR11 butt fusion joint alignment

can be off no more than 10% of the wall thickness

(0.01 in.). A hundredth of an inch accuracy while

fusing in a difficult position can be almost impossible to attain in the field.

• The actual socket fusion joint is 3 to 4 times the

cross sectional area of its butt fusion counterpart in

sizes under 2" and therefore tends to be more

forgiving of operator skill.

• Joints are frequently required in difficult trench

connections and the smaller socket fusion iron is

more mobile and operators will have less of a

tendency to cut corners during the fusion procedure

such as can happen during the facing and alignment

procedure of butt fusion.

In general, socket fusion loses these advantages in fusion

joints larger than 2", and of course socket fittings

become very expensive and time consuming in these

larger sizes as well. Therefore, butt fusion is generally

used in sizes larger than 2". In either joining method,

proper technique is essential for long lasting joints. All

ClimateMaster supplied pipe and fittings are IGSHPA

approved. All fusion joints should be performed by

certified fusion technicians. Table 6 illustrates the proper

fusion times for ClimateMaster Geothermal PE Pipe.

Table 6 - Fusion Times for ClimateMaster Polyethylene Pipe

Pipe Size Socket Fusion Butt Fusion

Time (sec.)- Time (sec.) Bead (in.)

3/4" IPS 8-10 8 1/16

1" IPS 10-14 12 1/16

1-1/4" IPS 12-15 15 1/16-1/8

1-1/2" IPS 15-18 15 1/16-1/8

2" IPS 18-22 18 1/8

Holding time of 60 sec.Cure time of 20 min.

Always use a timing device

Parallel vs Series Configurations

Initially, loops were all designed using series style flow

due to the lack of fusion fittings needed in parallel

systems. This resulted in large diameter pipe (>1 1/4")

being used to reduce pumping requirements, due to the

increased pressure drop of the pipe. Since the fusion

fittings have become available, parallel flow using (3/4"

IPS) for loops 2 ton and above, has become the standard

for a number of reasons.

• Cost of Pipe - The larger diameter (>1 1/4") pipe is

twice the cost of the smaller (3/4" IPS) pipe.

However, due to the reduced surface area of the

smaller pipe, the heat transfer capability is only

decreased by approximately 10-20%. In loop

designs using the smaller pipe the pipe length is

simply lengthened to compensate for the small heat

transfer reduction; however, it still results in around

50% savings in pipe costs over the larger pipe in

series. In some areas 1 1/4" vertical bores can be

more cost effective, where drilling costs are high.

• Pumping power - Parallel systems generally can

have much lower pressure drop and thus smaller

pumps, due to the multiple flow paths of smaller

pipes in parallel.

11

Page 12

• Installation ease - The smaller pipe is easier to

handle during installation than the larger diameters.

The "memory" of the pipe can be especially cumbersome when installing in cold conditions. Smaller

pipe takes less time to fuse and is easier to cut.

When Should Series Loops Be Used?

In smaller loops of two tons or less, the reasons for

parallel (listed above) may be less obvious. In these

cases, series loops can have some additional advantages:

• No header - Fittings tend to be more expensive and

require extra labor and skill to install.

• Simple design - No confusing piping arrangement

for easier installation by less experienced installers.

Loop Configuration - Determining the style of loop

primarily depends on lot size and "dirt" costs. For

instance, horizontal 1 pipe will have significantly (400%)

more trench than a horizontal 6 pipe. However the 6 pipe

will have about 75% more feet of pipe, therefore if

trenching costs are higher than the extra pipe costs, the 6

pipe is the best choice. Remember that labor is also a

factor in loop costs. The 6 pipe could also be chosen

because a small lot as well. Generally a contractor will

know after a few installations which configuration is the

most cost effective for him. Then this information can be

applied to later installations for a more overall cost

effective installation for his particular area. Depth of the

loop in horizontal systems generally does not exceed 5

feet because of trench safety issues and the sheer amount

of dirt required to move. In vertical systems, economic

depth due to escalating drilling costs in rock can sometimes require what is referred to as a parallel-series loop.

That is, a circuit will loop down and up through two

consecutive bores (series) to total the required circuit

length required.

Loop Circuiting - Loops should be designed with a

compromise between pressure drop and good turbulence

in the heat exchange pipe for heat transfer. Therefore the

following rules should be observed when designing a

loop:

• 3 gpm per ton flow rate (2.25 gpm per ton minimum). In larger systems 2.5 to 2.7 gpm per ton is

adequate in most cases. Overseeing the pumps to

attain exactly 3 gpm per ton is generally not cost

effective from an operating cost standpoint.

• One circuit per nominal equipment ton with 3/4" IPS

and 1/2 circuit per ton with 1 1/4" IPS pipe. This rule

can be deviated by one circuit or so for different loop

configurations.

Header Design - Headers for parallel loops should be

designed with two factors in mind, the first is pressure

drop and the second is flushability. The header shown in

Figure 11A is a standard header design through 15 tons

for polyethylene pipe with 2” supply and return runouts.

The header shown in Figure 11B is a standard header

2" IPS PE

Pipe

2" x 2" x 3/4" IPS

Supply/Return Line

3/4" IPS PE

Pipe

PE Tee

Circuit 9 - 15 Circuit 5 - 8

2" x 1 1/4" x 3/4"

IPS PE Tee

Figure 11A - Typical Header through 15 tons

1 1/4" IPS PE Pipe

1 1/4” x 1 1/4" x

3/4" IPS PE Tee

Supply/Return Line

3/4" IPS PE

Pipe

Circ uit 5

1 1/4" IPS PE

3/4" IPS PE

Pipe

11/4" x 3/4" x 3/4"

IPS PE Tee

Circ uit 4

Pipe

3/4" IPS PE

11/4" x 3/4" x 3/4"

IPS PE Tee

Circ uit 4

Pipe

Circ uit 3

3/4" IPS PE

Pipe

3/4" x 3/4" x 3/4"

IPS PE Tee

3/4" IPS PE

Pipe

3/4" x 3/4" x 3/4"

Circ uit 3

Circ uit

IPS PE Tee

3/4" IPS PE

Pipe

3/4" IPS PE

Pipe

Circ uit

2

Circ uit 1

3/4" IPS PE

Pipe

Circ uit 1

12

Figure 11B - Typical Header through 5 tons

Page 13

design through 5 tons for polyethylene pipe using 1-1/4”

supply and return runouts. Notice the reduction of pipe

from 2" IPS supply/return through circuits 12 to 8, and

then the line is reduced to 1 1/4" IPS pipe for circuits 7 to

4, and then finally the header line is reduced to 3/4" IPS

to supply circuits 3, 2, and 1. This allows minimum

pressure drop while still maintaining 2 fps velocity

throughout the header under normal flow conditions (3

gpm/ton), thus the header as shown is self-flushing under

normal flow conditions. This leaves the circuits themselves (3/4" IPS) as the only section of the loop not

attaining 2 fps flush velocity under normal flow conditions (3 gpm/ton & normally 3 gpm/circuit). 3/4" IPS

requires 3.8 gpm to attain 2 fps velocity; therefore to

calculate flushing requirements for any PE loop using the

header styles shown, simply multiply the number of

circuits by the flushing flow rate of each circuit (3.8 gpm

for 2 fps velocity). For instance on a 5 circuit loop the

flush flow rate is 5 circuits x 3.8 gpm/circuit = 19 gpm.

Headers that utilize large diameter pipe feeding the last

circuits should not be used. In PE1 1/4" IPS pipe requires

9.5 gpm to attain 2 fps and since increasing the flow

through the last circuit would also require increasing the

flow through the other circuits at an equal rate as well,

we can estimate the flush flow requirements by multiplying the number of circuits by 9.5 gpm (in 1 1/4" IPS) or

for instance a 5 circuit loop in PE would require 5

circuits x 9.5 gpm/circuits = 47.5 gpm to attain flush

flow rate. This is clearly an impossible flow to achieve

with a pump of any size.

Header Layout - Generally header layouts are more cost

effective with short headers. This requires centrally

locating the header to all circuits and then bringing the

circuits to the header. One of the easiest implementations

is to angle all trenches into a common pit similar to a

starburst. This layout can utilize the laydown or "L"

header and achieves reverse return flow by simply laying

the headers down in a mirror image and thus no extra

piping or labor. Figure 12 details a "laydown header".

Inside Piping - Polyethylene pipe provides an excellent

no-leak piping material inside the building. Inside, piping

fittings and elbows should be limited to prevent excessive pressure drop. Hose kits employing 1" rubber hose

should be limited in length to 10-15 feet per run to

reduce pressure drop problems. In general, 2 feet of head

pressure drop is allowed for all earth loop fittings which

would include 10-12 elbows for inside piping to the flow

controller. This allows a generous amount of maneuvering to the flow controller with the inside piping. 3/8 to 1/

2" closed cell insulation should be used on all inside

piping where loop temperatures below 50°F are anticipated. All barbed connections should be double clamped.

Flow Controller Selection - The pressure drop of the

entire ground loop should be estimated for the selection

of the flow controller. In general, if basic loop design

rules are followed, units of 3 tons or less will require

only one circulating pump (AFCS1A). Units from 3.5 to

6 tons will require a two pump system (AFCS2A). As a

caution, loop pressure drop calculation should be

performed for accurate flow estimation in any system

including unit, hose kit, inside piping, supply/return

headers, circuit piping, and fittings. Use Table 7A, B, and

C for pressure drop calculations, using methanol and

various piping materials. Tables showing other antifreezes are available from ClimateMaster Technical

Support.

Supply Line

Circuit 4 Circuit 3 Circuit 2

Figure 12 - Typical "Laydown" Header

2 foot wide trench

Return Line

Circuit 4 Circuit 3 Circuit 2

13

Page 14

Table 7A - Polyethylene Pressure Drop Table (using 20% methanol @ 30˚F per 100 ft. of pipe)

FLOW 3/4" IPS SDR 11 1" IPS SDR 11 1 1/4" IPS SCH 40 1 1/2" IPS SCH 40 2" IPS SCH 40

RATE PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re

1 0.36 0.55 1162 0.12 0.35 930 0.04 0.21 724 0.02 0.16 621 0.01 0.10 484

2 1.21 1.11 2325 0.42 0.71 1860 0.13 0.43 1449 0.06 0.32 1242 0.02 0.19 967

3 2.47 1.66 3487 0.85 1.06 2789 0.26 0.64 2173 0.13 0.47 1863 0.04 0.29 1451

4 4.08 2.21 4650 1.41 1.41 3719 0.43 0.86 2898 0.21 0.63 2484 0.06 0.38 1935

5 6.04 2.76 5812 2.09 1.77 4649 0.64 1.07 3622 0.31 0.79 3105 0.09 0.48 2418

6 8.30 3.32 6975 2.87 2.12 5579 0.88 1.29 4347 0.42 0.95 3726 0.13 0.57 2902

7 10.87 3.87 8137 3.76 2.48 6509 1.15 1.50 5071 0.55 1.10 4347 0.17 0.67 3386

8 13.74 4.42 9300 4.76 2.83 7439 1.45 1.72 5796 0.70 1.26 4968 0.21 0.77 3869

9 16.88 4.98 10462 5.84 3.18 8368 1.79 1.93 6520 0.86 1.42 5589 0.26 0.86 4353

10 20.30 5.53 11625 7.03 3.54 9298 2.15 2.15 7245 1.03 1.58 6209 0.32 0.96 4837

11 23.99 6.08 12787 8.30 3.89 10228 2.54 2.36 7969 1.22 1.73 6830 0.37 1.05 5320

12 27.93 6.63 13950 9.67 4.24 11158 2.95 2.58 8693 1.42 1.89 7451 0.43 1.15 5804

13 32.13 7.19 15112 11.12 4.60 12088 3.40 2.79 9418 1.63 2.05 8072 0.50 1.24 6288

14 12.66 4.95 13018 3.87 3.01 10142 1.86 2.21 8693 0.57 1.34 6771

15 14.29 5.30 13947 4.37 3.22 10867 2.10 2.37 9314 0.64 1.44 7255

16 16.00 5.66 14877 4.89 3.43 11591 2.35 2.52 9935 0.72 1.53 7739

17 17.79 6.01 15807 5.44 3.65 12316 2.61 2.68 10556 0.80 1.63 8222

18 19.66 6.37 16737 6.01 3.86 13040 2.89 2.84 11177 0.88 1.72 8706

19 21.61 6.72 17667 6.60 4.08 13765 3.17 3.00 11798 0.97 1.82 9190

20 23.64 7.07 18597 7.22 4.29 14489 3.47 3.15 12419 1.06 1.91 9673

21 25.75 7.43 19526 7.87 4.51 15214 3.78 3.31 13040 1.15 2.01 10157

22 27.93 7.78 20456 8.53 4.72 15938 4.10 3.47 13661 1.25 2.11 10641

23 30.19 8.13 21386 9.23 4.94 16663 4.44 3.63 14282 1.35 2.20 11124

24 9.94 5.15 17387 4.78 3.79 14903 1.46 2.30 11608

25 10.67 5.37 18111 5.13 3.94 15524 1.57 2.39 12092

26 11.43 5.58 18836 5.50 4.10 16145 1.68 2.49 12576

28 13.02 6.01 20285 6.26 4.42 17387 1.91 2.68 13543

30 14.69 6.44 21734 7.06 4.73 18628 2.16 2.87 14510

32 16.44 6.87 23183 7.91 5.05 19870 2.41 3.06 15478

34 18.28 7.30 24632 8.79 5.36 21112 2.68 3.25 16445

36 20.21 7.73 26080 9.71 5.68 22354 2.97 3.44 17412

38 22.21 8.16 27529 10.68 5.99 23596 3.26 3.64 18380

40 24.30 8.59 28978 11.68 6.31 24838 3.57 3.83 19347

42 26.46 9.02 30427 12.72 6.62 26080 3.88 4.02 20314

44 28.71 9.45 31876 13.80 6.94 27322 4.21 4.21 21282

46 31.03 9.88 33325 14.92 7.26 28564 4.55 4.40 22249

48 16.07 7.57 29806 4.91 4.59 23216

50 17.26 7.89 31047 5.27 4.78 24184

14

Page 15

Table 7B - Canadian Polyethylene (CSA) Pressure Drop Table (using 20% methanol @ 30˚F per 100 ft. of pipe)

FLOW 3/4" IPS CSA 160 1" IPS CSA 160 1 1/4" IPS CSA 100 1 1/2" IPS CSA 100 2" IPS CSA 100

RATE PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re

1 0.49 0.63 1242 0.17 0.41 996 0.04 0.21 713 0.02 0.16 623 0.01 0.10 498

2 1.66 1.26 2484 0.58 0.81 1992 0.12 0.42 1425 0.06 0.32 1245 0.02 0.20 995

3 3.38 1.89 3726 1.18 1.22 2987 0.24 0.62 2138 0.13 0.48 1868 0.04 0.30 1493

4 5.59 2.52 4968 1.96 1.62 3983 0.40 0.83 2850 0.21 0.63 2490 0.07 0.41 1991

5 8.26 3.15 6210 2.89 2.03 4979 0.59 1.04 3563 0.31 0.79 3113 0.11 0.51 2488

6 11.37 3.79 7452 3.98 2.43 5975 0.81 1.25 4275 0.43 0.95 3735 0.15 0.61 2986

7 14.89 4.42 8694 5.21 2.84 6970 1.06 1.45 4988 0.56 1.11 4358 0.19 0.71 3483

8 18.80 5.05 9935 6.58 3.24 7966 1.34 1.66 5701 0.71 1.27 4980 0.24 0.81 3981

9 23.11 5.68 11177 8.09 3.65 8962 1.65 1.87 6413 0.87 1.43 5603 0.30 0.91 4479

10 27.79 6.31 12419 9.73 4.06 9958 1.99 2.08 7126 1.04 1.59 6225 0.36 1.01 4976

11 32.83 6.94 13661 11.50 4.46 10953 2.35 2.28 7838 1.23 1.74 6848 0.43 1.11 5474

12 38.23 7.57 14903 13.39 4.87 11949 2.73 2.49 8551 1.44 1.90 7470 0.50 1.22 5972

13 43.98 8.20 16145 15.40 5.27 12945 3.14 2.70 9264 1.65 2.06 8093 0.57 1.32 6469

14 17.53 5.68 13941 3.58 2.91 9976 1.88 2.22 8715 0.65 1.42 6967

15 19.78 6.08 14936 4.04 3.12 10689 2.12 2.38 9338 0.73 1.52 7465

16 22.15 6.49 15932 4.52 3.32 11401 2.38 2.54 9960 0.82 1.62 7962

17 24.63 6.90 16928 5.03 3.53 12114 2.64 2.69 10583 0.91 1.72 8460

18 27.22 7.30 17924 5.55 3.74 12826 2.92 2.85 11205 1.01 1.82 8957

19 29.92 7.71 18920 6.10 3.95 13539 3.21 3.01 11828 1.11 1.92 9455

20 32.73 8.11 19915 6.68 4.15 14252 3.51 3.17 12450 1.21 2.03 9953

21 35.65 8.52 20911 7.27 4.36 14964 3.83 3.33 13073 1.32 2.13 10450

22 38.67 8.92 21907 7.89 4.57 15677 4.15 3.49 13695 1.43 2.23 10948

23 41.80 9.33 22903 8.53 4.78 16389 4.49 3.65 14318 1.55 2.33 11446

24 45.03 9.73 23898 9.19 4.98 17102 4.84 3.80 14940 1.67 2.43 11943

25 9.87 5.19 17814 5.19 3.96 15563 1.79 2.53 12441

26 10.57 5.40 18527 5.56 4.12 16185 1.92 2.63 12939

28 12.03 5.82 19952 6.33 4.44 17430 2.19 2.84 13934

30 13.58 6.23 21377 7.15 4.76 18675 2.47 3.04 14929

32 15.20 6.65 22803 8.00 5.07 19920 2.76 3.24 15924

34 16.90 7.06 24228 8.90 5.39 21165 3.07 3.44 16920

36 18.68 7.48 25653 9.83 5.71 22410 3.39 3.65 17915

38 20.53 7.89 27078 10.81 6.02 23655 3.73 3.85 18910

40 22.46 8.31 28503 11.82 6.34 24900 4.08 4.05 19905

42 24.46 8.72 29928 12.88 6.66 26146 4.45 4.25 20901

44 26.54 9.14 31354 13.97 6.97 27391 4.82 4.46 21896

46 28.69 9.55 32779 15.10 7.29 28636 5.21 4.66 22891

48 16.27 7.61 29881 5.62 4.86 23887

50 17.47 7.93 31126 6.03 5.06 24882

Table 7C - Rubber Hose Pressure Drop Table

(using 20% methanol @ 30˚F per 100 ft. of pipe)

FLOW 1" IPS RUBBER HOSE 1 1/2" IPS RUBBER HOSE 2" IPS RUBBER HOSE

RATE PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re PD (ft) Vel ft/s Re

1 0.18 0.41 1000 0.03 0.21 667 0.01 0.10 484

2 0.59 0.82 2000 0.09 0.43 1333 0.02 0.19 967

3 1.21 1.23 2999 0.18 0.64 2000 0.04 0.29 1451

4 2.00 1.64 3999 0.29 0.86 2666 0.06 0.38 1935

5 2.95 2.04 4999 0.43 1.07 3333 0.09 0.48 2418

6 4.06 2.45 5999 0.59 1.29 3999 0.13 0.57 2902

7 5.31 2.86 6998 0.77 1.50 4666 0.17 0.67 3386

8 6.71 3.27 7998 0.98 1.72 5332 0.21 0.77 3869

9 8.25 3.68 8998 1.20 1.93 5999 0.26 0.86 4353

10 9.92 4.09 9998 1.45 2.15 6665 0.32 0.96 4837

11 11.72 4.50 10997 1.71 2.36 7332 0.37 1.05 5320

12 13.64 4.91 11997 1.99 2.58 7998 0.43 1.15 5804

13 15.70 5.31 12997 2.29 2.79 8665 0.50 1.24 6288

14 17.87 5.72 13997 2.60 3.01 9331 0.57 1.34 6771

15 20.16 6.13 14996 2.94 3.22 9998 0.64 1.44 7255

16 22.57 6.54 15996 3.29 3.43 10664 0.72 1.53 7739

17 25.10 6.95 16996 3.66 3.65 11331 0.80 1.63 8222

18 27.74 7.36 17996 4.04 3.86 11997 0.88 1.72 8706

19 30.49 7.77 18995 4.44 4.08 12664 0.97 1.82 9190

20 33.36 8.18 19995 4.86 4.29 13330 1.06 1.91 9673

21 5.29 4.51 13997 1.15 2.01 10157

22 5.74 4.72 14663 1.25 2.11 10641

23 6.21 4.94 15330 1.35 2.20 11124

24 6.69 5.15 15996 1.46 2.30 11608

25 7.18 5.37 16663 1.57 2.39 12092

26 7.69 5.58 17329 1.68 2.49 12576

28 8.76 6.01 18662 1.91 2.68 13543

30 9.88 6.44 19995 2.16 2.87 14510

32 11.07 6.87 21328 2.41 3.06 15478

34 12.30 7.30 22661 2.68 3.25 16445

36 13.60 7.73 23994 2.97 3.44 17412

38 14.95 8.16 25327 3.26 3.64 18380

40 16.35 8.59 26660 3.57 3.83 19347

42 17.81 9.02 27993 3.88 4.02 20314

44 19.32 9.45 29326 4.21 4.21 21282

46 20.88 9.88 30659 4.55 4.40 22249

48 22.50 10.30 31992 4.91 4.59 23216

50 24.16 10.73 33325 5.27 4.78 24184

15

Page 16

CLOSED LOOP INSTALLATION

Prior to installation, locate and mark all existing underground utilities, piping, etc. Install loops for new

construction before sidewalks, patios, driveways, and

other construction has begun. During construction,

accurately mark all ground loop piping on the plot plan

as an aid in avoiding potential future damage to the

installation.

Loop Piping Installation

The typical closed loop ground source system is shown

in Figure 13. All earth loop piping materials should be

limited to only polyethylene fusion in inground sections

of the loop and galvanized or steel fittings should not be

used at any time due to their tendency to corrode by

galvanic action. All plastic-to-metal threaded fittings

should be avoided as well, due to their potential to leak in

earth coupled applications, and a flanged fitting substituted. P/T plugs should be used so that flow can be

measured using the pressure drop of the unit heat

exchanger in lieu of other flow measurement means.

Earth loop temperatures can range between 25-110°F and

2.25 to 3 gpm of flow per ton of cooling capacity is

recommended in any earth loop applications.

Horizontal Applications

To install Horizontal earth couplings, dig trenches using

either a chain-type trenching machine or a backhoe. Dig

trenches approximately 8-10 feet apart. Trenches must be

at least 5 feet from existing utility lines, foundations, and

property lines, and at least 10 feet from privies and wells.

Trenches may be curved to avoid obstructions and may

be turned around corners.

When multiple pipes are laid in a trench, space pipes

properly and backfill carefully to avoid disturbing the

spacing of the pipes in the trench. Figure 14 details

common loop cross-sections used in horizontal loops.

Flow

Controller

AFSC1 or 2

Unit Power

Disconnect

Concrete

block or

brick

Air Pad or Extruded

polystyrene insulation

board

AH5KE

Insulated

Hose Kit

Thermostat

Wiring

P/T Plugs

16

Figure 13 - Typical Closed Loop Application

Page 17

AA

AA

A

A

A

A

A

A

A

A

A

A

AAA

A

A

A

Vertical Bores

One Pair Series/Parallel One Pair

A

A

A

A

A

A

A

A

A

Avg Depth

Two Pair

A

A

A

A

A

A

A

A

A

Avg Depth

Avg Depth

A

A

A

A

A

A

A

A

A

A

When Loops are

shallower than

one ton per loop

A

2 ft

A

2 ft

Two-Pipe Four-Pipe Six-Pipe

Back-Hoe Loops

A

A

2 ft

A

Two-Pipe Four-Pipe

Trenched Loops

Figure 14 - Typical Horizontal Loop Configurations

Vertical Applications

To install Vertical earth couplings, drill boreholes using

any size drilling equipment. Regulations which govern

water well installations also apply to vertical ground loop

installations. Vertical applications typically require

multiple boreholes. Space boreholes a minimum of 10

feet apart. In southern or cooling dominated climates 15

feet is required.

The minimum diameter for 3/4 inch or 1 inch U-bend

well bores is 4 inches. Larger diameter boreholes may be

drilled if convenient, unless local code requires an

expensive method of backfilling. Assemble each U-bend

assembly, fill with water and pressure test prior to

insertion into the borehole.

To add weight and prevent the pipe from curving and

digging into the borehole wall during insertion, tape a

length of conduit, pipe, or reinforcing bar to the U-bend

end of the assembly. This technique is particularly useful

when inserting the assembly into a borehole filled with

water or drilling mud solutions, since a water filled pipe

is buoyant under these circumstances. Tape the pipes

together approximately every 10 feet to prevent the

assembly from separating under downward pressure and

bowing out against the borehole wall.

Carefully backfill the boreholes to within 10 feet of the

surface. Follow IGSPHA specifications for backfilling

unless local codes mandate otherwise.

When all U-bends are installed, dig the header trench 4

to 6 feet deep and as close to the boreholes as possible.

Use a spade to break through from ground level to the

bottom of the trench. At the top of the hole, dig a relief

to allow the pipe to bend for proper access to the header.

The “laydown” header mentioned earlier is a cost

effective method for connecting the bores. Figure 15

illustrates common vertical bore heat exchangers.

AA

AA

AA

2 ft

1 ft

AA

AA

2 ft

AA

2 ft

Extended Slinky

A

A

A

A

A

A

A

A

A

Figure 15 - Typical Vertical Loop Configurations

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Pond/Lake Applications

Pond loops are one of the most cost effective applications

of geothermal systems. Typically, 1 coil of 300 ft of PE

pipe per ton is sunk in a pond and headered back to the

structure. Minimum pond sizing is 1/2 acre and 8 feet

deep for an average residential home. Actual area can be

1500-3000 ft 2 per ton of cooling. In the north, an ice

cover is required during the heating season to allow the

pond to reach an average 39°F. Winter aeration or

excessive wave action can lower the pond temperature

preventing proper operation of the geothermal system.

Direct use of pond or lake water is discouraged because

of the potential problems of heat exchanger fouling and

pump suction lift. Heat exchanger may be constructed of

either multiple 300’ coils of pipe or slinky style (Figure

16). In northern applications, the slinky or matt style is

recommended due to its superior performance in heating.

Due to pipe and antifreeze buoyancy, pond heat exchanger will most likely need weighted down to prevent

floating. 300 foot coils require two 4” x 8” x 16” blocks

(19 lbs. each) or 8-10 bricks (4.5 lbs each) and every 20

ft of 1-1/4” pipe requires one three-hole brick. Coils are

supported off of the bottom by the concrete blocks or

bricks. The supply/return trenching should begin at the

structure and work toward the pond. Near the pond the

trench should be halted and backfilled most of the way.

A new trench should be started from the pond back

toward the partially backfilled first trench to prevent

pond from flooding back to the structure.

17

Page 18

A

Concrete

Blocks for

weight

Nylon Cable

Ties to secure

blocks

4 ft between

300 ft coil per

ton separated

by scrap pipe

coils

Reverse

Return

Header

3 foot

separation

Heavy Duty

Plastic Safety

matting

Nylon Cable

Ties to secure

Netting and

bricks

8-10 Bricks for

weight

300 ft slinky

coil per ton

Traditional Coiled

Pond Loop - Southern

Climates

Figure 16 - Typical Pond Heat Exchanger Configurations

BUILDING ENTRY

Seal and protect the entry point of all earth coupling

entry points into the building using hydraulic cement.

Slab on Grade Construction

New Construction: When possible, position the pipe in

the proper location prior to pouring the slab. To prevent

wear as the pipe expands and contracts, protect the pipe

with a layer of insulation as shown in Figure 17. When

the slab is poured prior to installation, create a chase

through the slab for the service lines with 4 inch PVC

street elbows and sleeves.

Insulation

Finished Grade

High Efficiency Slinky/Matt

Pond Loop - Northern

Climates

Retrofit Construction

Trench as close as possible to the footing. Bring the loop

pipe up along the outside wall of the footing until it is

higher than the slab. Enter the building as close to the

slab as the construction allows. Shield and insulate the

pipe to protect it from damage and the elements as shown

in Figure 18.

Enter Building As

Soon As Possible

Insulation Inside

Protective Shield

Finished Grade

18

4-6'

Loop Pipe

Figure 17 - Slab on Grade Entry Detail

4-6'

Loop Pipe

Figure 18 - Retrofit Construction Detail

Page 19

Pier and Beam (crawl space)

New and Retrofit Construction: Bury the pipe beneath the

footing and between piers to the point that it is directly

below the point of entry into the building. Bring the pipe

up into the building. Shield and insulate piping as shown

in Figure 19 to protect it from damage.

Horizontal Systems: Test individual loops as installed.

Test entire system when all loops are assembled.

Vertical U-Bends and Pond Loop Systems: Test Vertical

U-bends and pond loop assemblies prior to installation

with a test pressure of at least 100 psi. Either water or air

may be used as the testing medium.

Finished Grade

Insulation Inside

4-6'

Protective Shield

Loop Pipe

Figure 19 - Pier and Beam Entry Detail

Below Grade Entry

New and Retrofit Construction: Bring the pipe through

the wall as shown in Figure 20. For applications in which

loop temperature may fall below freezing, insulate pipes

at least 4 feet into the trench to prevent ice forming near

the wall.

Upon completion of the ground loop piping, pressure test

the loop to assure a leak-free system.

1-1/2” SDR21

1-1/2” PVC

repair coupling

2” hole &

Silcone Caulk

Hydraulic Cement

each side

Footer

Concrete Wall

Final Grade

Dirt Fill

Gravel backfill

PVC Sleeve

Undisturbed Earth

Figure 20 - Below Grade Entry Detail

1-1/4” x 1-1/2” Fernco

gasket coupling

1-1/4” SCH40

PE Pipe

19

Page 20

7300 S.W. 44th Street

Oklahoma City, OK 73179

Phone: 405-745-6000

*69197310*

69197310

ClimateMaster works continually to improve its products. As a result, the design and specifications of each product at the time of order may be changed

without notice and may not be as described herein. Please contact ClimateMaster’s Customer Service Department at 1-405-745-6000 for specific

information on the current design and specifications. Statements and other information contained herein are not express warranties and do not form the

basis of any bargain between the parties, but are merely ClimateMaster’s opinion or commendation of its products.

Rev.: 12/98 © ClimateMaster 1997

FAX: 405-745-2051

www.climatemaster.com

Loading...

Loading...