ClimaCool IOM FLEX User Manual

ClimaCool IOM

FLEX SERIES

Water-Cooled Modular Chillers

Installation, Operation &

Maintenance Manual

®

®

ClimaCool works continually to improve

its products. As a result, the design and

specifications of each product at the time for

order may be changed without notice and

may not be as described herein. Please contact

ClimaCool's Customer Service Department at

(405) 745-3185 for specific information on the

current design and specifications. Statements

and other information contained herein are not

express warranties and do not form the basis

of any bargain between the parties, but are

merely ClimaCool's opinion or commendation

of its products.

Refer to www.climacoolcorp.com for complete

warranty details.

2

www. cli mac ool cor p.c omwww. cli mac ool cor p.c om

®

CONTENTS PAGES

Model Numbers/Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Inspection

Site Preparation

Installation

Dimensional Data

Rigging and Lifting

Service Clearances

Vibration Isolation

Electrical Connection

Water Piping System

Water Piping Configurations

Hydronic Refrigeration (Drawing)

Filling the Water System

Water Treatment

Condenser Water Temperature Requirements

Strainer Systems

Stainless Steel Strainer Option

Automatic Timer Flush Package Option

Pressure Differential Alarm Package

Y Type and Basket Type Strainers

Pre-Start Up

Start Up

Pre-Start Up Check List

Start-Up and Warranty Registration Form

Chiller Operation and Maintenance

Heat Exchangers (Drawings)

Operation Limitations

Physical Data

Application Parameters

Compressor Information

Refrigeration Circuit (Drawings)

Refrigeration System Re-Processing

Sequence of Operation

Electrical Data

Power Distribution (Drawing)

Wiring Diagrams

Troubleshooting Guide

Warranty Information

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . . . . . . .10

. . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . .12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . 14

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . .18

. . . . . . . . . . . . . . . . . . . . . . 21

. . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

. . . . . . . . . . . . . . . . . . . 27

. . . . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

. . . . . . . . . . . . . . . . . . . . . . . . 34

. . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . 39

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

ClimaCool Modular Chillers

MODEL NUMBERS AND SPECIFICATIONS

Dimensions Refrigerant No. Of Nominal

Model No. L x W x H (in.) Voltage Circuits Compressors Tons

FLEX 30 41-7/8” x 29-1/2” x 77”* 208/230/3/60 2 2 30

FLEX 30 41-7/8” x 29-1/2” x 77 ”* 460/3/60 2 2 30

FLEX 30 41-7/8” x 29-1/2” x 77 ”* 575/3/60 2 2 30

FLEX 50 41-7/8” x 33-1/2” x 78 3/8”* 208/230/3/60 2 2 50

FLEX 50 41-7/8” x 33-1/2” x 78 3/8”* 460/3/60 2 2 50

FLEX 50 41-7/8” x 33-1/2” x 78 3/8”* 575/3/60 2 2 50

FLEX 65 43-5/8” x 33-1/2” x 78 3/8”* 208/230/3/60 2 2 65

FLEX 65 43-5/8” x 33-1/2” x 78 3/8”* 460/3/60 2 2 65

FLEX 65 43-5/8” x 33-1/2” x 78 3/8”* 575/3/60 2 2 65

* Dimensions with covers.

� SAFETY WARNING �

High voltage is used to operate this equipment. Failure to observe standard electrical safety procedures may result in serious

injury. Only persons qualified and / or properly trained should attempt to install, operate and maintain this equipment. These

chillers come fully charged with refrigerant. Installation, and start – up should be accomplished by technicians who are fully

certified to handle refrigerants, as required by 40 CFR Part 82, subpart F of the Recycling and Emissions Reduction Act. Scroll

compressors are used in this equipment. Phase verification is required for proper rotation direction. Incorrect rotation will

result in elevated sound and internal overload trip failure.

www. cli mac ool cor p.c om

1

®

Inspection

INSPECTION

Allow a sufficient amount of time to carefully follow these

instructions to assure warranty coverage.

During inspection of the equipment remove the top doors

to check the equipment for any damage during shipment.

Inspect wiring connections, lines from expansion devices,

thermostats, and pressure switches for damage.

General

During any correspondence concerning this machine, always

reference the full model and serial numbers of your modules.

Receipt of the ClimaCool Modules

Upon receipt of the equipment, carefully check the shipment

against the bill of lading. Make sure all modules ordered have

been received. Inspect the carton or crating of each module,

and inspect each module for damage. You must make

proper notation of any shortages or damage on all copies

of the freight bill for your records. Make sure the carrier

completes a common carrier inspection report listing any

shortages or damage.

Note: It is the responsibility of the recipient of the

modules to file all necessary claims with the carrier. In

addition, please notify the ClimaCool Customer Service

Department of all damage immediately. Refer to the

back cover for the Customer Service Department phone

number.

Handling of Modules

The packaging allows for handling by fork lift or pallet

jack (only lift the module from the side). See Lifting and

Transporting Modules (Fig. 3) on page 5. Caution: modules

ARE TOP HEAVY. Please use caution when rigging or

moving.

Rigging for Lifting

Each module should be lifted by using lift straps threaded

through each top header tube. See page 5 - Rigging and

Lifting Procedures.

� WARNING �

To avoid the release of refrigerant into the atmosphere,

the refrigerant circuit of this unit must be serviced only by

technicians who meet local, state and federal proficiency

requirements.

All refrigerant discharged from this unit must be recovered

WITHOUT EXCEPTION. Technicians must follow industry

accepted guidelines and all local, state and federal statutes for

the recovery and disposal of refrigerants.

If a compressor is removed from this unit, system refrigerant

circuit oil will remain in the compressor. To avoid leakage of

compressor oil, the refrigerant lines of the compressor must

be sealed after it is removed.

Storage

Equipment should be stored as shipped in a clean, dry area.

Store modules in an upright position at all times. Plastic wrap

should be left on until the module is ready to be installed.

2

www. cli mac ool cor p.c omwww. cli mac ool cor p.c om

®

Site Preparation/Installation

Preparing for Installation.

Prepare the modules for installation by carefully removing

the module's packaging, unbolt the module from the skid, and

lift the module with a crane or hoist into its final position.

Hardware kits are shipped in separate packaging along with

the modules. Make sure the hardware kits are on site when

connecting the modules.

SITE PREPARATION

Base Requirements

The minimum base requirement for the ClimaCool chiller

is a level surface which has been checked to ensure that it

is capable of bearing the combined operating weight of the

modules (see page 4).

Anti-Vibration Mountings

Although the compressors are installed on anti-vibration

mountings, further isolation of the chiller from the structure

can be achieved by installing vibration-eliminating springs or

pads under the base rails on which the chiller will rest. (see

page 7 - Vibration Isolation).

A factory supplied fastener kit is provided for the adjoining

of each module. Each kit contains (4) gaskets, (32) ¾” fully

threaded studs, (64) heavy duty hex nuts, (64) lock washers,

and (64) flat washers.

A ¾"-10 tap should be run through each weld nut located at

the bottom rear chiller header flange of each module. Screw

the fully threaded studs into these four weld nut locations.

At all other flange hole locations, insert fully threaded studs,

attach washers, lock washers, and nuts from the fastener kit.

The gasket should be placed between the first reference

module and the next module. Slide the next module into

position while guiding the fully threaded studs into the flange

holes of the next module. Finally, the washers, lock washers,

and nuts are applied to the other end of the fully threaded

studs to securely fasten the module flanges.

Tighten the flange bolts in a diametrically opposite pattern,

in such a way as to pull the modules together evenly. It will

be necessary to use a ¾" (12 point) box-end wrench when

tightening. As each module is added, the alignment of the

whole package should be confirmed.

Service Access

The minimum space required for electrical panel service is

36" in the front of each module. Allow 24" service clearance

in the back of the module for refrigeration access. Allow a

minimum of 18” of clearance above the module for service.

Allow 12” side clearance of any ClimaCool modular chiller

system (see Service Clearances page 6). Local building or

electrical codes may require additional clearance.

Draining

When performing standard maintenance procedures such

as flushing heat exchanger, it will be necessary to close off

a section of a module. ClimaCool modular chillers come

equipped with isolation valves for this purpose. Access to a

floor drain is helpful when performing standard maintenance

procedures.

INSTALLATION

Assembling Modules

Use of (2) 4” rails (minimum size) is required for ease of

installation. One of the end modules should be chosen as the

reference module and carefully located.

Header and Flange Insulation

Chilled water piping is pre-insulated on each module at the

factory with ¾” closed cell foam rubber. After the bolting the

modules together, the installer must apply insulation on site

over the chilled water header connection flanges.

3

www. cli mac ool cor p.c om

®

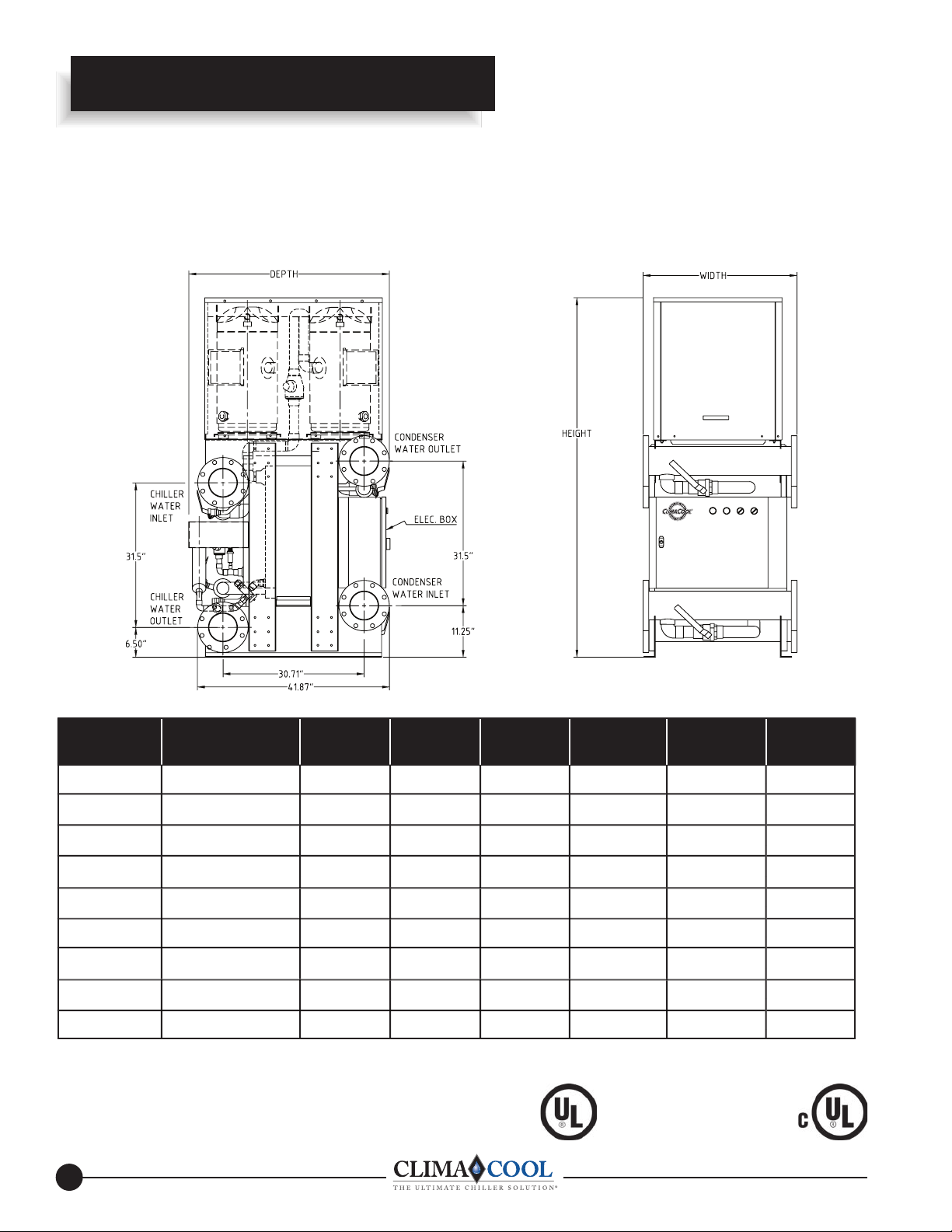

ClimaCool Dimensional Data

The ClimaCool® Modular Chiller -

Module Dimensional Data -

Models 30, 50 & 65 - FLEX Series

Model Voltage Depth Width Height Height (w/covers) Weight

FLEX (inches) (inches) (inches) (inches) (lbs.) (lbs.)

30 208/230/3/60 41-7/8 29-1/2 72-7/8 77 1,669 1,825

30

30

50

50

50

65

65 460/3/60 43-5/8 33-1/2 76-5/8 78-3/8 1,990 2,280

65 575/3/60

NOTES:

1. Unit shipping weight includes refrigerant charge, compressor oil, and shipping base skid. Add two inches to base dimensions

for shipping skid.

2. Operational weight includes refrigerant charge, compressor oil and water.

460/3/60 41-7/8 29-1/2 72-7/8 77 1,669 1,825

575/3/60 41-7/8 29-1/2 72-7/8 77 1,669 1,825

208/230/3/60 41-7/8 33-1/2 76-5/8 78-3/8 1,873 2,163

460/3/60 41-7/8 33-1/2 76-5/8 78-3/8 1,873 2,163

575/3/60 41-7/8 33-1/2 76-5/8 78-3/8 1,873 2,163

208/230/3/60 43-5/8 33-1/2 76-5/8 78-3/8 1,990 2,280

43-5/8 33-1/2 76-5/8 78-3/8 1,990 2,280

• ISO-9001 Certified

1

Oper. Weight2

• Meets NYC Fire Code

4

www. cli mac ool cor p.c omwww. cli mac ool cor p.c om

®

The ClimaCool®Modular Chiller -

Rigging and Lifting Procedures

Rigging (Figures 1 and 2)

Each module should be lifted by using lift straps threaded

through each top header tube.

ClimaCool Rigging and Lifting

A spreader bar should be utilized when rigging with

covers in place.

Lifting and Transporting Modules (Figure 3)

When lifting and transporting the module, it is very im-

for lifting and transporting may damage the module and

void the warranty.

CAUTION

Units are top heavy. Please use caution when

rigging or moving.

www. cli mac ool cor p.c om

snaemrehtoynafoesU.thgirtanwohssadeecorpottnatrop

5

®

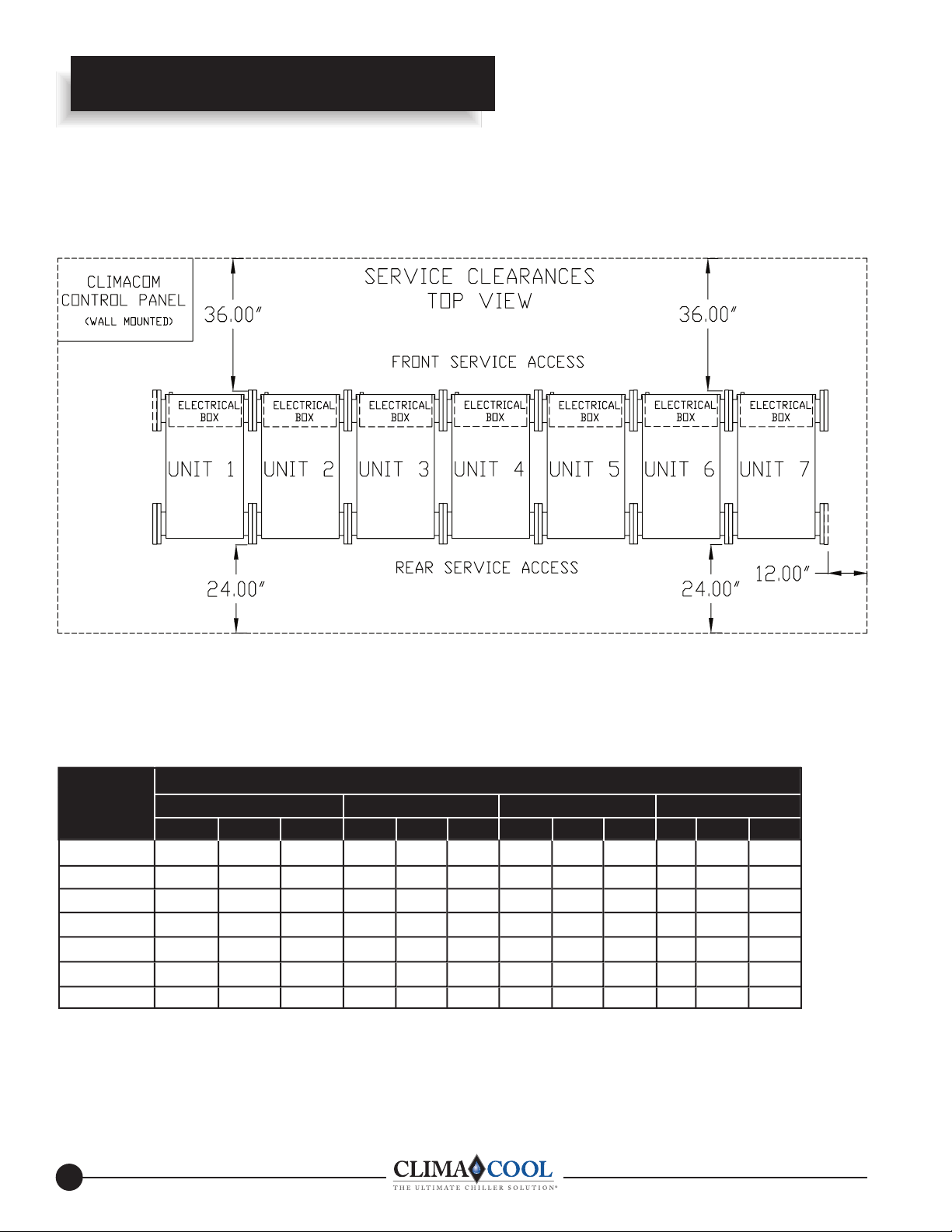

ClimaCool Service Clearances

The ClimaCool® Modular Chiller -

Service Clearances

Recommended Clearances

1. Allow 36” clearance for electrical panels and 24” clearance for rear service access to modules.

2. Allow a minimum of 18" height clearance for service and 12” for side clerances.

3. Local building or electrical codes may require additional clearance. Consult applicable codes.

Modular Chiller Bank Dimensions -

Model Dimensions

FLEX Width (ft./inches) Depth Height

30 50 65 30 50 65 30 50 65 30 50 65

1 module

2 modules

3 modules

4 modules

5 modules

6 modules

7 modules

NOTES:

1. Modular chiller bank width dimensions above include (1/8") between modules, plus (1-1/2") for required blank off plate fl anges

when piping for a direct return (Refer to Water Piping Confi guration - Figure 1). Example: (5) FLEX 65 modules

167-1/2" width + 1-1/2" (Blank off plates) + 5 x 1/8" (fl ange connection gaskets) = 169-5/8" (14' 1-5/8").

2. When piping 1 to 5 or more than 5 modules, use reverse return (Refer to Water Piping Confi guration - Figure 2).

Example: (7) FLEX 30 modules 206-1/2" width + 1-1/2" (Blank off plates left) + 1-1/2" (Blank off plates right) + 8 x 1/8"

(fl ange connection gaskets) = 210-1/2" (17' 6-1/2").

2’ 7-1/8” 2’ 11-1/8” 2’ 11-1/8”

5’ 3/4” 5’ 8-3/4” 5’ 8-3/4”

7’ 6-3/8” 8’ 6-3/8” 8’ 6-3/8”

10’ 0” 11’ 4” 11’ 4”

12’ 5-5/8” 14’ 1-5/8” 14’ 1-5/8”

15’ 7/8” 17’ 7/8” 17’ 7/8”

17’ 6-1/2”

19’ 10-1/2”19’ 10-1/2” 19’ 10-1/2”

w/Connnection Flange Gaskets and Blank Off Plates

(w/o panels) Height (w/ panels)

41-7/8” 41-7/8” 43-5/8” 72-7/8” 76-3/4” 76-3/4” 77” 78-3/8” 78-3/8”

41-7/8” 41-7/8” 43-5/8” 72-7/8” 76-3/4” 76-3/4” 77” 78-3/8” 78-3/8”

41-7/8” 41-7/8” 43-5/8” 72-7/8” 76-3/4” 76-3/4” 77” 78-3/8” 78-3/8”

41-7/8” 41-7/8” 43-5/8” 72-7/8” 76-3/4” 76-3/4” 77” 78-3/8” 78-3/8”

41-7/8” 41-7/8” 43-5/8” 72-7/8” 76-3/4” 76-3/4” 77” 78-3/8” 78-3/8”

41-7/8” 41-7/8” 43-5/8” 72-7/8” 76-3/4” 76-3/4” 77” 78-3/8” 78-3/8”

41-7/8” 41-7/8” 43-5/8” 72-7/8” 76-3/4” 76-3/4” 77” 78-3/8” 78-3/8”

6

www. cli mac ool cor p.c omwww. cli mac ool cor p.c om

®

The ClimaCool® Modular Chiller -

Mounting Rail and Vibration Isolation

Due to the low vibration of the modules, ClimaCool® does not

require the application of spring isolators or pads. Should

isolators or pads be desired, install in accordance with

Figs. 1 and 2.

Figure 1 - Spring Vibration Isolators Option

4” Rail Minimum

Required (by others)

ClimaCool Vibration Isolation

Figure 2 - Vibration Isolation Pads Option

4” Rail Minimum

Required (by others)

NOTE: la u div id ni rep reenigne larutcurts de fiilauq a yb denimreted eb ot si noitubirtsid thgiew dna eziS

job requirements.

7

www. cli mac ool cor p.c om

®

Electrical Connection

DANGER

!

• Electric shock hazard!

• May result in injury or death!

• Disconnect power supply(ies)

before servicing!

• Refer servicing to qualified

service personnel.

• Risque de choc électrique!

• Résultat de mai dans dommages

ou la mort!

• Debrancher avant d’entreprendre

le dépannage de l’appareil!

• Consulter un réparateur qualifie

pour le dépannage.

DANGER

!

Connecting the Water Piping to Modules

Water piping must be installed in accordance with

applicable codes and standards. Flexible connections and

supports should be installed to prevent load or stress on the

module's flange connections (see page 10 - Water Piping

Configurations).

ELECTRICAL CONNECTION

The compliance of the installation to relevant codes is

the responsibility of the installer. Before carrying out any

electrical work, confirm that the main supply is isolated.

The installer must ensure that the correct electrical drawing is

available.

Inter-Module Power Wiring

The power for all modules is taken from a fused supply

within the main panel. A typical power wiring is located on

page 43 - Power Distribution.

Inter-Module Control Wiring

After the power wiring has been run, the control wires can

then be connected. The wires should be carefully marked

and installed in the terminals shown on the wiring diagram.

External control wires should be connected to the relevant

terminals and devices. Wiring to the sensors should not be run

with the power wiring.

Control Wiring Sizes and Lengths

When running control wires, proper gauged wires should

be used. With 14 AWG the maximum distance allowed is

250 feet. With 16 AWG, 100 feet is acceptable. You should

not exceed 50 feet when using 18 AWG. These lengths and

gauges are for the use of 24 volt control circuits.

Incoming Power Wiring

Incoming power should be supplied from a suitable

disconnect switch. Proper grounding of the module is

mandatory.

Electrical Phase Sequencing

Proper clockwise rotation for scroll compressor motors is

important to prevent damaging the compressors. If you

have access to a phase sequence indicating instrument it

is recommended to use this following the manufactures

directions. If not, you may “bump test” the compressors

one at a time with pressure gauges attached to the high and

low gauge ports of the compressors to check for proper

rotation. Energize the compressor for a few seconds to

ensure the discharge pressure gauge increases significantly.

If the discharge pressure does not increase, proper rotation

is reversed. You can quickly reverse compressor rotation by

opening the main electrical disconnect and switching any two

of the main power supply leads feeding that compressor's

contactor.

Proper Voltage Balance

Occasionally, in three phase circuits, a voltage imbalance

occurs between phases. It is not recommended to operate

equipment when an imbalance greater than 2% occurs. This

causes motors to run at high temperatures and may affect

their longevity. The following example describes how to

calculate the average voltage of the three phases to see if the

imbalance is greater than 2%.

Example:

Line one = 226v Line two = 230v Line three = 228v

The average is: 226+230+228 = 228v

3

Next, 100(228-226) = 0.9%

228

The voltage imbalance of the three phase circuit is 0.9%.

This is well under the 2% range.

Checking

Before power is applied to the system, the wiring should be

visually inspected for loose connections or frayed terminal

connections. All control wiring should follow wiring

instructions supplied in the project submittal package.

8

www. cli mac ool cor p.c omwww. cli mac ool cor p.c om

®

Water Piping System

WATER PIPING SYSTEM

As with any water system, it is important that the system

is clean. Care should be taken to maintain a clean system.

The installing contractor should remove weld scale, rust and

contamination during the fabrication of the piping system.

We recommend the use of an alkaline flush of the piping

system prior to start-up.

Necessary Components

All items depicted in figure 1 and 2 on page 10, other than

the modules themselves, are provided by others as optional

accessories and must be installed with the hydronics system.

Several of these key components for both condenser and

chilled water systems are: water pump, strainer, isolation

valve, flow switch, temperature sensor wells, and pressure

taps.

Pressure Taps

The installer must provide access ports for connecting flow

switches (differential pressure or paddle style) for both the

condenser and chilled water systems (see page 10 - Water

Piping Configurations).

Isolation Valves

It is recommended to provide water isolation valves for proper

isolation and maintenance of the chiller, pump, and strainer

(see page 10 - Water Piping Configurations).

Flow Switch - Required

It is mandatory that differential pressure flow switches are

installed in both the chilled and condenser water circuits.

These flow switches are shown on page 10 - Water Piping

Configurations.

Temperature Sensor Wells

Four temperature sensors and wells are provided with each

ClimaCool chiller system (chilled water inlet, chilled water

outlet, condenser water inlet, condenser water outlet). The

installing contractor must install these temperature sensor

wells as shown in figures 1 and 2 on page 10.

Strainers - (Minimum 60 Mesh Screen Required)

ClimaCool chillers employ brazed plate heat exchangers

which are extremely sensitive to debris. Therefore, it is

mandatory that all condenser and chilled water systems

include a strainer with a minimum of 60 mesh screen for

proper filtration. The strainers must be installed as shown

in Water Piping Configurations (see page 10).

9

www. cli mac ool cor p.c om

®

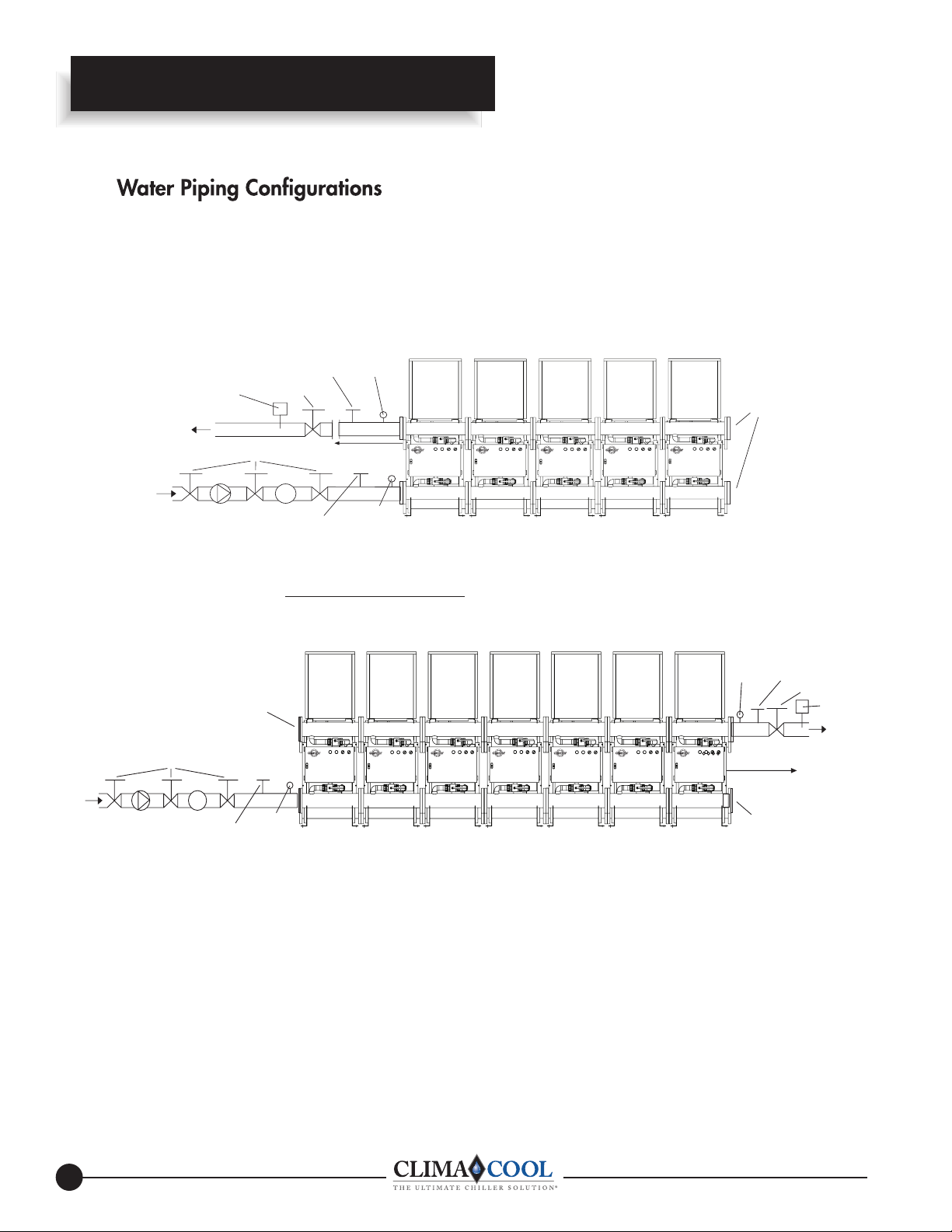

ClimaCool Water Piping Configurations

The ClimaCool® Modular Chiller -

Field Piping Direct Return - 1 to 5 Modules (Figure 1)

PressureTaps

with Shutoff Valves

& Gauges

60” Sensor Location

(Field-Installed)

PressureTap

w/Shutoff

Valve &

Gauge

Unit 1

Flow In

Flow Out

Flow Switch

Isolation Valves

Pump

Thermometer Well

Isolation Valve

Strainer

Thermometer Well

Unit 2 Unit 3 Unit 5Unit 4

Blank Off

Plates

Field Piping Reverse Return - (Preferred 1 to 5 modules) Required for 6 to 7 Modules (Figure 2)

Pressure Taps

with Shutoff Valves

Unit 1 Unit 2 Unit 3 Unit 7Unit 6Unit 5Unit 4

Blank Off

Plate

Isolation Valves

Pump

Flow In

Strainer

Thermometer Well

NOTES:

1. Figures 1 and 2 are required piping for proper water regulation and distribution through ClimaCool

PressureTap

w/Shutoff

Valve &

Gauge

®

modular chillers.

2. Module order and incoming/outgoing water fl ow as shown in both Figure 1 and 2 can be set up as either a left-to-right or

right-to-left confi guration.

3. Condenser Hydronic Circuit shown. Piping confi gurations are similar for the chilled water hydronic circuit.

4. For condenser and chilled water (evaporator) inlet/outlet location dimensions, refer to Module Dimensional Data.

5. A fl ow switch (supplied by others) is a required safety device for ClimaCool

®

modular chillers on the chilled and condenser

water circuits.

6. Maximum water fl ow rates for both evaporator and condenser water header systems in one bank of modules is 1000 GPM.

7. The chilled water piping on each module is pre-insulated at the factory with ¾” closed cell foam rubber. Insulation (3/4”)

on the chilled water header connection flanges is to be applied in the field by the installer, after the modules are bolted

together on site.

& Gauges

60” Sensor Location

(Field-Installed)

Blank Off

Plate

Thermometer Well

Isolation Valves

Flow Switch

Flow Out

10

www. cli mac ool cor p.c omwww. cli mac ool cor p.c om

®

The ClimaCool® Modular Chiller -

Figure 1 - Condenser Hydronic Circuit

ClimaCool Hydronic Refrigeration

Isolation Ball Valve (2 or 2-1/2”)

To Cooling Tower

Header

From Cooling Tower

Header

Isolation Ball Valve (2 or 2-1/2”)

Figure 2 - Chilled Water Circuit

Isolation Ball Valve (2 or 2-1/2”)

Chilled Water Inlet

Header

Pete’s Port

Service Port (3/4”)Pete’s Port

Service Port (3/4”)

Heat Exchanger

Service Port (3/4”)Pete’s Port

Refrigerant Circuit #1

Refrigerant Circuit #2

Refrigerant Circuit #1

Chilled Water Outlet

Header

Isolation Ball Valve (2 or 2-1/2”)

Cap Tube to Low Limit

Protection Thermostat

Pete’s Port

Service Port (3/4”)

Sensor Well (internal)

Heat Exchanger

NOTE: Figures 1 and 2 depict hydronic piping in each ClimaCool® chiller module.

www. cli mac ool cor p.c om

Refrigerant Circuit #2

11

®

Filling the Water System Pre-Start Up

FILLING THE WATER SYSTEMS

It is imperative that the water systems are free from

debris prior to initial operation. See the page 15 Water Treatment section for a comprehensive list of

precautions.

Filling, Purging and Leak Testing the System

After the water systems have been properly installed a visual

inspection should be made to all joints for tightness. If the

chiller is to be installed in an existing system, the cleanliness

of the existing system can be judged from the operating

conditions of the present machines. The cooling tower in

particular, should be inspected and cleaned if required. It is a

good practice to at least flush the existing system and ideally,

to acid wash the system before connecting a new chiller.

We recommend the following sequence to fill and leak check

the water systems:

1. Close all isolation valves inside each modular chiller.

2. Ensure that all drain valves are closed and that all water

main isolation valves are opened.

3. The system should be filled with clean water send through

a strainer and the system checked for leaks.

4. Once the main water lines and the chiller headers are

filled with clean water, purge and repeat the filling process

several times.

5. Open the isolation valves inside each modular chiller and

repeat the filling process, this time also checking for leaks

inside each module.

6. Following the final filling and leak checking procedure, air

should be purged from the system.

4. After several hours of operation, the strainer should be

isolated and cleaned.

5. Step 4 should be repeated until there is no more debris

being collected by the strainer.

6. Finally, open all isolation valves inside each modular

chiller and repeat step 4 and 5.

If it is not possible to install the bypass line in step 1 above,

it is recommended to drain out the initial fill of water to help

flush out debris. The chiller isolating valves should be closed

to prevent debris from being washed into the chiller as the

water drains out. Before refilling and purging the system

again, the strainers should be removed and cleaned. This

action should be repeated until there is no more debris being

collected by the strainer.

Starting the Pumps

Follow manufacturer's recommendations when staring the

pumps for the first time. The system should be checked

for leaks and air purged with the pumps in operation. The

pressure drop across the heat exchangers will give a good

indication of flow through the system (see page 34). This

should be immediately checked against the expected pressure

drop for the flow rate required. If the pressure drop begins to

fall and the flow rate is falling, this could indicate the need to

clean the strainers.

Cleaning the System

We recommend the following sequence to properly clean the

water systems:

1. If possible, install a temporary bypass line between the

supply and return water lines of both water systems prior

to cleaning the system.

2. Close all isolation valves inside each modular chiller

before engaging the main water pumps.

3. The pumps should be run with the strainer in place (see the

Starting the Pumps section for proper pump startup). All

external hydronic branches should be open to all devices in

the system.

12

www. cli mac ool cor p.c omwww. cli mac ool cor p.c om

®

Water Treatment

Table 1 - Water Quality Parameters

®

Application Parameters

WATER TREATMENT

Proper water treatment is a specialized industry. We

recommend consulting an expert in this field to analyze

the water for compliance with the water quality parameters

listed in Table 1 below. The material used in the ClimaCool

chiller exposed to the water are type 316 stainless steel,

pure copper, and carbon steel. Other materials may

exist external to the ClimaCool chiller. It is the users

responsibility to ensure these materials are compatible with

the treated water. Failure to provide proper water quality

will void the ClimaCool module's warranty.

It is further recommended to seek an experts advice to

specify the appropriate water treatment required. Typical

additives to hydronic systems include rust inhibitors,

scaling preventative, antimicrobial growth agents, and algae

preventatives. Anti-freeze solutions may also be used to

lower the freezing point.

Heavily-Contaminated Water

In such instances whereby the particulates in the water are

excessive it is recommended to install an intermediate plate

& frame heat exchanger to isolate the ClimaCool chiller

from the building water system.

Other Considerations

The following considerations are listed to help achieve

system longevity.

Cooling Tower

The cooling tower should be located away from sources of

external contaminates such as trees, dust, or grass cuttings.

Insect infiltration can be reduced by eliminating lights near

the tower. A periodic visual inspection of the tower system

should be made and contaminates removed as required.

Table 1 - Water Quality Parameters

WATER CONTAINING CONCENTRATION

Sulphate Less Than 200 ppm

pH 7.0 – 9.0

Chlorides Less Than 200 ppm

Nitrate Less Than 100 ppm

Iron Less Than 4.5 mg/l

Ammonia Less Than 2.0 mg/l

Manganese Less Than 0.1 mg/l

Dissolved Solids Less Than 1000 mg/l

CaCO3 Hardness 30 – 500 ppm

CaCO3 Alkalinity 30 – 500 ppm

CAUTION

• Excessive Chlorine, Undissolved Solids and

other improper water quality conditions

WILL DAMAGE the internal heat exchanger and

WILL VOID YOUR WARRANTY!

13

www. cli mac ool cor p.c om