ClimaCheck PA Pro III online Installation Manual

ClimaCheck Sweden AB, Box 46, SE-131 06 Nacka, Sweden

Visiting address: Gamla Värmdövägen 6, SE-131 37 Nacka Sweden

Tel.: +46 (0)8-50 255 250, Email: info@climacheck.com

Web: www.climacheck.com

Performance Analyser

ClimaCheck PA Pro III online

Installation Manual

2018-03-16

.

Installation Manual PA Pro III online – 2018-03-16 Page 2 of 30

Safety Precautions

Read the instruction manuals for all relevant equipment carefully before

starting to use ClimaCheck Performance Analysing systems.

ClimaCheck PA Pro III is a measuring and analysing system developed to give

detailed evaluation of refrigeration, air-conditioning and heat-pump systems in

development laboratories, production tests and in the field.

If equipment is used in a way not specified by producer the protection and safety provided may be

impaired.

Certifications/licenses are required in most countries for activities related to electrical systems,

pressurised systems and systems charged with refrigerants that have environmental impacts

and/or flammability.

ClimaCheck products are only intended for use by competent technicians/engineers complying with

local requirements for certifications/licenses.

Any work with electricity, pressurised systems or refrigerant involves potential dangers to human

health and system integrity if not conducted with caution. Always inspect the equipment for

damaged cables or other components before use. For many installations loss of product or

disturbances in operation incurs high costs. ClimaCheck assumes no responsibility for injuries or

costs that may occur as a result of failures in connection with measurements. The user must

evaluate whether an inspection can be carried out without risk of injury and/or damage.

Measurements should only be carried out when it can be done under safe working conditions and

without risks.

Installation Manual PA Pro III online – 2018-03-16 Page 3 of 30

Table of Contents

Safety Precautions ............................................................................................................... 2

1 Introduction .................................................................................................................. 5

2 Handling and safety ....................................................................................................... 6

3 Required documents and equipment ................................................................................ 7

4 Connection of power measurement .................................................................................. 8

4.1 Motor configurations ................................................................................................. 8

4.1.1 Part Winding ..................................................................................................... 8

4.1.2 Y/D (Star/Delta) ................................................................................................ 8

4.2 Systems with inverter ............................................................................................... 9

4.3 Differential protection ............................................................................................... 9

5 Connection of sensors ................................................................................................... 10

5.1 Mounting of pressure transmitters/transducers ........................................................... 10

5.2 Mounting temperature sensors .................................................................................. 10

5.2.1 Required insulation ........................................................................................... 10

5.2.2 Compensating for changes in temperature sensor cable length ............................... 11

5.3 1-wire temperature sensors ...................................................................................... 11

6 ClimaCheck PA Pro III Hardware ..................................................................................... 13

6.1 LED indicators ......................................................................................................... 13

6.2 Display ................................................................................................................... 14

6.3 Start ...................................................................................................................... 15

6.4 Menus .................................................................................................................... 16

6.5 Monitor .................................................................................................................. 16

6.5.1 View all values ................................................................................................. 17

6.5.2 Send interval / Intense send .............................................................................. 17

6.5.3 Signal level ...................................................................................................... 17

6.6 Setup ..................................................................................................................... 17

6.6.1 Reload configuration ......................................................................................... 17

6.6.2 Reboot ............................................................................................................ 18

7 Configuration of 1-wire sensors ...................................................................................... 19

7.1 Connecting sensors.................................................................................................. 19

7.2 Replace a 1-wire senor ............................................................................................. 19

7.3 Clear all 1-wire sensors ............................................................................................ 19

8 Configuration of PA Pro III ............................................................................................. 21

8.1 Change analog input mode (mA/V) ............................................................................ 21

8.2 Change communication mode ................................................................................... 21

9 Configuration of Power Meter EM24 ................................................................................. 23

9.1 Change CT-ratio configuration ................................................................................... 23

9.2 Change Modbus address ........................................................................................... 23

10 Configuration of Power Meter EM210 ............................................................................... 24

10.1 Change CT type configuration ................................................................................... 24

10.2 Change Modbus address ........................................................................................... 24

11 Configuration of IO module R560 .................................................................................... 25

11.1 Change Modbus address ........................................................................................... 25

11.2 Change Analog input mode ....................................................................................... 25

12 Troubleshooting ............................................................................................................ 26

12.1 Pressure readings .................................................................................................... 26

12.1.1 Required tools and spare parts ........................................................................... 26

12.1.2 Transmitter type ............................................................................................... 26

12.1.3 Supply voltage ................................................................................................. 26

12.1.4 Pressure signal ................................................................................................. 27

12.2 Temperature readings with PT1000 sensors ................................................................ 27

12.2.1 Required tools and spare parts ........................................................................... 27

12.2.2 Common issues ................................................................................................ 28

12.2.3 Temperature-resistance table ............................................................................. 28

Installation Manual PA Pro III online – 2018-03-16 Page 4 of 30

12.3 Temperature readings with 1-wire sensors ................................................................. 28

12.4 Power measurement ................................................................................................ 29

12.4.1 Supply voltage ................................................................................................. 29

12.4.2 Communication ................................................................................................ 29

12.4.3 Measurement ................................................................................................... 29

Note: Areas with red side marking are related to certification and should not be changed without

new date here log on changes are kept separately. Current date of changes is 2018-03-16.

Installation Manual PA Pro III online – 2018-03-16 Page 5 of 30

1 Introduction

ClimaCheck1 is a measuring and analysing system developed to give detailed evaluation of

refrigeration, air-conditioning and heat-pump systems in development laboratories, production

tests and in the field.

The method is based on measurements in the refrigeration circuit and does not require any fixed

installation of metering equipment in the system. The advantages of easy connection, immediate

and detailed information makes the ClimaCheck method superior for evaluating all refrigeration,

air-conditioning and heat pump systems.

An increased focus on energy efficiency can be seen in the EU Directive 2002/91/Ec on

the Energy Performance of Building and several other requirements on energy

performance on other markets. This directive requires annual inspections with

verifications of energy efficiency of all AC systems with more that 12 kW rated capacity.

Measuring with ClimaCheck gives and excellent foundation for performance inspections.

The ClimaCheck Performance Analysing method allows complete analysis of energy performance

as well as presenting all information to validate the individual components and their optimization

without the requirement of any fixed equipment making it possible to immediately identify and

locate any deficiencies in the system. The method was patented in 1986 and has since been used

in Sweden and internationally in the Product ETM 1500, ETM 2000, ClimaCheck PA 8:7 and now

ClimaCheck PA Pro.

The server based monitoring software is constantly logging the performance of the system and

uses the globally accepted equations for refrigerant properties in RefProp established by NIST

(National Institute of Standards and Technologies in USA). Anyone with the user name and

password can log in to the system from an Internet connected PC as well as have the server send

alarms when important parameters fall outside of their specified ranges.

The ClimaCheck method is suitable for almost all compressor-based refrigeration processes. All

suction or discharge gas cooled hermetic and semi hermetic compressors can be fully evaluated

without any compressor or system specific information. For open compressors the electrical motor

efficiency is given as input and for compressors with external cooling of air, water, oil or liquid

injection information on the cooling need to be entered to give a full capacity and COP accuracy.

For many types of systems data on compressor cooling are well known and necessary parameters

are known. ClimaCheck Specialists should be consulted to give advice on non-standard systems.

Installation Manual PA Pro III online – 2018-03-16 Page 6 of 30

2 Handling and safety

To ensure safe installation and operation the following instructions must be followed carefully:

- The equipment should be powered by either 90 – 264 V AC at 47 – 64 Hz or 120 – 370 V

DC. The maximum power consumption of the system is 25 W.

- An easily reachable external switch for breaking power to the installation has to be

available.

- Operating temperature range for the equipment is -20 to +50 °C.

- Operating humidity is R.H. 0 – 90 % non-condensing.

- Maximum operating altitude: 2000 m

- The equipment is designed for a maximum of Pollution Degree 2.

- The equipment enclosures have not been tested for UV-resistance and are thus not

approved for outdoor use.

- The enclosure must be mounted with at least three sides having a minimum clearance of

10 cm. The front must have a clearance of at least 30 cm.

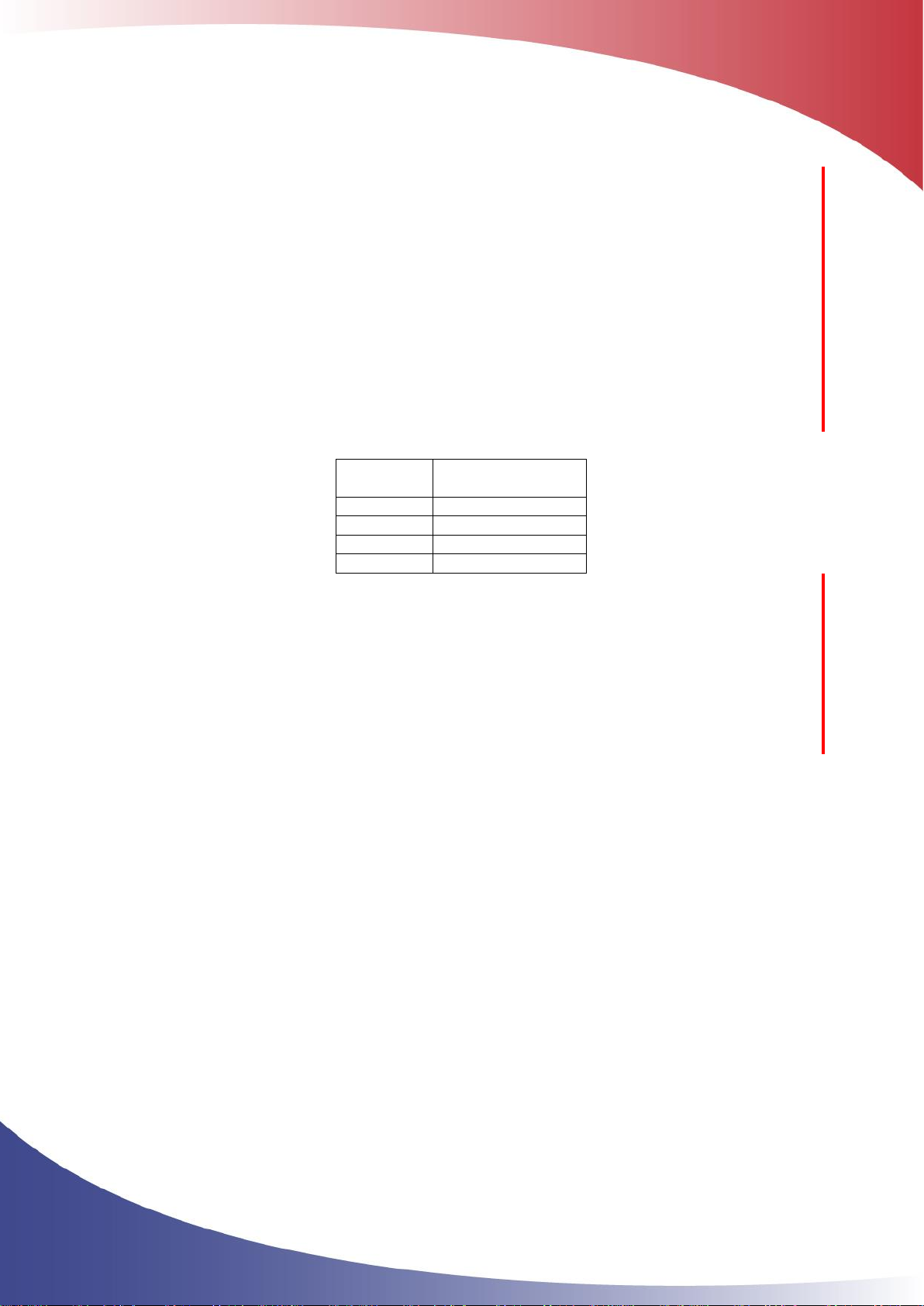

- Burned out fuses must be replaced in accordance to the table below. Use only UL/CSA

approved fuses.

Marking on

fuse holder

Fuse type

L

T 1 A L, 250 V

L1

T 500 mA L, 250 V

L2

T 500 mA L, 250 V

L3

T 500 mA L, 250 V

- See section 4 for important safety instructions when connecting the power measurement.

- For all electrical wires not included with the equipment, use UL1569 AWG20 or better. Not

that special considerations should be taken for the wiring of the power meters, see section

4.

- The standard enclosure is marked with protection class IP55, but the protection of the final

installation may be lower depending on several factors. ClimaCheck do not guarantee a

certain protection class.

- If the instructions in this section and the rest of the manual are not observed, the

protection provided by the equipment may be impaired.

Installation Manual PA Pro III online – 2018-03-16 Page 7 of 30

3 Required documents and equipment

In addition to this instruction a number of documents and equipment is required in order to

successfully complete the installation:

- Flow chart of the system with sensor placement, supplied with the attached configuration

document.

- Wiring diagram of the system, supplied with the attached configuration document.

- Small flathead screwdriver 2.5 x 0.5 mm.

- Aluminium tape.

- Insulation tape.

- A number of standard tools depending on the nature of the installation.

Installation Manual PA Pro III online – 2018-03-16 Page 8 of 30

4 Connection of power measurement

Important!

Improper use of ClimaCheck power meters may cause high voltage

build up that can be dangerous both for equipment and operators. Adhere to the

practices below to avoid this:

- Always connect the CTs to the power meter before they are attached around a live

wire.

- Always remove the CTs from the live wire before the cables to the power meter

are disconnected.

- Incorrect connection of voltage between phase and neutral will damage the

equipment.

- Never use the CTs on uninsulated wires or rails.

In addition, follow the steps below to assure proper power and energy readings:

- It is important to only measure the power to the compressor. Make sure the measurement

is done after the point where circulation pumps and fans are connected.

- Make sure that the voltage and current for each phase corresponds with the markings on

the measuring equipment and that the arrow on the current clamps are pointing in the

direction of the current.

- Make sure that the CTs are completely closed and that the contact areas are clean.

- Check that the connections are correct by reading the voltage, current and power on the

display of the power meter. If you find a problem remove the clamps and attach L1

followed by a control and the repeat the process for L2 and L3.

4.1 Motor configurations

Power measurements require good understanding of the electrical layout of the plant.

It is for example necessary to identify if a three-phase motor is part winding or Y/D (Star/Delta)

and connect accordingly.

4.1.1 Part Winding

Part winding means that the motor has two separate windings and the total current to these should

be measured. This can be done in several ways depending on the physical restrictions of cables and

CTs.

- Preferred choice is to measure before the contactors where the total current runs through

one lead. This can sometimes be physically impossible.

- One alternative is to put clamps around both L1 cables after the contactor or in the

connection box on the compressor if this can be done. This is repeated for L2 and L3.

- It is possible to measure with 6 clamps i.e. 2 in parallel to the instrument per phase.

- If there is no way to connect around the total current an acceptable approximation can be

achieved by measuring on one of the contactors (the one with largest power draw is

preferred) and adjusting the power scale in the ClimaCheck software Input tab. The ratios

are typically 50/50 or 60/40 and can be deduced by moving the clamp back and forth.

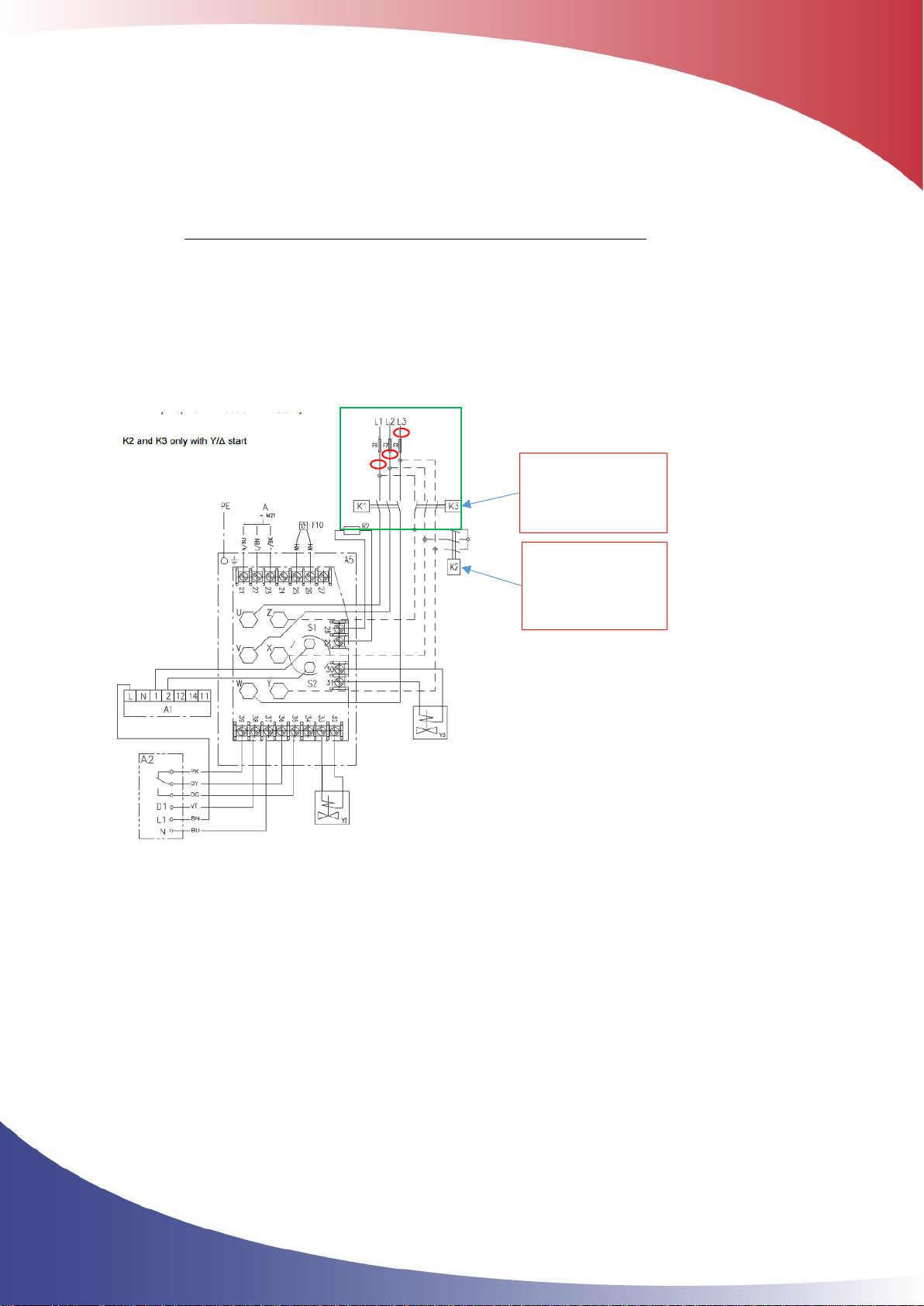

4.1.2 Y/D (Star/Delta)

Motor with Y/D start should preferably be measured before supply is split between the three

contactors this normally consist of e.g. at L1, L2 and L3.

Installation Manual PA Pro III online – 2018-03-16 Page 9 of 30

If measured after the split to K1 and K2/K3 both leads should be measured.

After the “Run” contactor K3 and the split to “Start” contactor K2 the cables to the motor will be

connected to different phases depending on position of K2 and K3.

If measured at motor correct cables must be matched so total L1, L2 respectively L3 feed is

measured but the reading will be incorrect during start when K2 is activated.

In picture below:

L1 is feeding U and Z

L2 is feeding V and X

L3 is feeding W and Y

If designation of poles is unknown the pairs can be identified by measuring voltage between poles

matching pairs will show zero voltage difference.

Figure 1 - Y/D (Star/Delta)

4.2 Systems with inverter

If inverters are used it is normally necessary to measure before inverter and use a loss factor of

typically 3-6% to compensate for the heat loss. Ensure that i.e. fans do not consume power from

the same feed. If so an offset can be added in the input tab

4.3 Differential protection

Differential protection is used to improve the security of the installation and will cut the supply if

any current is drawn outside the “protected loop”. As the EM210 is powered by the voltage line L1

and L2, differential protection must be taken into account when connecting.

Start contactor

Run contactor

Loading...

Loading...