Page 1

1

2

3

2800/2820/2850

Notebook Computer

Service Manual

4

5

6

7

8

i

Page 2

1

2

Preface

NOTICE

The company reserves the right to revise this publication or to change its contents without notice. Information contained herein is for reference only and does not constitute a commitment on the part of the manufacturer or any

subsequent vendor. They assume no responsibility or liability for any errors or inaccuracies that may appear in this

publication nor are they in anyway responsible for any loss or damage resulting from the use (or misuse) of this

publication.

This publication and any accompanying software may not, in whole or in part, be reproduced, translated, transmitted

or reduced to any machine readable form without prior consent from the vendor, manufacturer or creators of this

publication, except for copies kept by the user for backup purposes.

3

4

5

6

7

8

Brand and product names mentioned in this publication may or may not be copyrights and/or registered trademarks of

their respective companies. They are mentioned for identification purposes only and are not intended as an endorsement of that product or its manufacturer.

First Edition ©January, 2000

Trademarks

®

Intel

, Pentium® and Pentium® with MMX™ technology are registered trademarks of Intel Corporation.

IBM® and OS/2® are registered trademarks of IBM Corporation.

MS-DOS®, Windows®, Windows® 95 and Windows NT™ are registered trademarks of Microsoft Corporation.

SystemSoft® and CardWizard® are registered trademarks of SystemSoft Corporation.

Other brand and product names are trademarks and/or registered trademarks of their respective companies.

ii

copyrights

Page 3

ABOUT THIS MANUAL

This manual is intended for service personnel who have completed sufficient training to undertake the maintenance

and inspection of personal computers.

It is organized to allow you to look up basic information for servicing and/or upgrading components of the notebook

computer. The following information is included:

1

Chapter 1, Introduction, provides general information about the location of system elements and their specifications.

Chapter 2, Chipset, briefly describes the computer’s core logic, memory and supporting chipset.

Chapter 3, Disassembly, provides step-by-step instructions for disassembling parts and subsystems and how to up-

grade elements of the system.

Chapter 4, Troubleshooting, provides recommendations on how to solve possible system problems.

Appendix A, Part Lists

Appendix B, 2800 Circuit Diagrams

Appendix C, 2820/2850 Circuit Diagrams

2

3

4

5

6

7

8

the manual

iii

Page 4

Preface

RELATED DOCUMENTS

You may also need to consult the following manuals for additional information:

User’s Manual

1

2

3

4

5

6

7

8

The standard manufacturer’s configuration includes a printed Concise User’s Manual (usually in the language of the

destination market) and a complete ‘expanded’ User’s Manual on an accompanying CD-ROM.

Both the Concise User’s Manual and the CD-ROM based ‘expanded’ User’s Manual describe the notebook’s basic features and the procedures for operating the computer. The ‘expanded’ manual also describes the installation & operation of the utility programs and how to upgrade the system’s RAM and HDD.

Last Resort: The Manufacturer

If you can’t find the information you need in these documents or your up-line source, contact the manufacturer at:

www.clevo.com.tw

iv

related

Page 5

TABLE OF CONTENTS

Preface

Cover .................................................................................................................................................................................................... i

Notice .................................................................................................................................................................................................. ii

About This Manual ............................................................................................................................................................................ iii

Related Documents........................................................................................................................................................................... iv

Table of Contents................................................................................................................................................................................ v

Chapter 1: Introduction

System Specifications ......................................................................................................................................................................1-2

CPU .............................................................................................................................................................................................1-2

Memory ......................................................................................................................................................................................1-2

Core Logic ...................................................................................................................................................................................1-2

BIOS .............................................................................................................................................................................................1-3

Video ...........................................................................................................................................................................................1-3

Drives .......................................................................................................................................................................................... 1-3

Audio...........................................................................................................................................................................................1-3

I/O ...............................................................................................................................................................................................1-4

Interface ......................................................................................................................................................................................1-4

Power System .............................................................................................................................................................................1-4

Other Features (optional) ...........................................................................................................................................................1-5

Environment .....................................................................................................................................................................................1-5

Physical ............................................................................................................................................................................................1-5

External Locator ...............................................................................................................................................................................1-6

1

2

3

4

5

6

7

8

Chapter 2: Chipset

CPU - Intel Mobile Pentium III/Pentium II/Celeron....................................................................................................................... 2-4

Core Logic Chipset - Intel 440BX AGPset ..................................................................................................................................... 2-5

North Bridge, AGPset System Controller, 443BX.................................................................................................................... 2-5

table of contents

v

Page 6

Preface

South Bridge, PCI ISA IDE Xcelerator, 82371EB/MB (PIIX4E/M) .............................................................................................. 2-6

Supporting Chips ............................................................................................................................................................................ 2-8

Ricoh 5C475 PCI-CardBus Bridge............................................................................................................................................2-8

SMSC FDC37N869 PC 99 ....................................................................................................................................................... 2-10

Compliant 5V and 3.3V Super I/O Controller with Infrared Support .................................................................................. 2-10

1

ATI RAGE LT Pro Graphics Controller ....................................................................................................................................... 2-11

YAMAHA YMF744B DS-XG ..................................................................................................................................................... 2-12

2

3

4

5

6

7

8

Chapter 3: Disassembly

Connections ....................................................................................................................................................................................3-2

Maintenance Precautions ........................................................................................................................................................ 3-3

Battery Precautions ...................................................................................................................................................................3-3

Cleaning .................................................................................................................................................................................... 3-4

Maintenance Tools.................................................................................................................................................................... 3-4

General Disassembly: Under the Keyboard ................................................................................................................................3-5

Removing the Keyboard & Heat Plate .................................................................................................................................... 3-5

Changing the CPU .................................................................................................................................................................... 3-6

General Disassembly: Removing & Replacing the LCD Module................................................................................................ 3-8

Replacing the LCD ................................................................................................................................................................... 3-10

12.1” Disassembly .............................................................................................................................................................. 3-10

14.1 & 15.1” Disassembly ................................................................................................................................................... 3-10

Removing the Inverter Board ............................................................................................................................................ 3-10

General Disassembly: Top Cover Assembly .............................................................................................................................. 3-12

Separating the Top Cover Assembly ..................................................................................................................................... 3-12

General Disassembly: Top Cover Components......................................................................................................................... 3-14

TouchPad ................................................................................................................................................................................. 3-14

General Disassembly: Bottom Cover Assembly ........................................................................................................................ 3-16

HDD Module............................................................................................................................................................................ 3-16

FDD Module............................................................................................................................................................................. 3-16

Mainboard & Frame (not shown) .......................................................................................................................................... 3-16

Switches & Connectors ................................................................................................................................................................3-20

vi

table of contents

Page 7

Chapter 4: Troubleshooting

Before You Begin ............................................................................................................................................................................ 4-2

Tools ........................................................................................................................................................................................... 4-2

System Troubleshooting Chart ...................................................................................................................................................... 4-3

Pre-POST Assistant ......................................................................................................................................................................... 4-4

AC Power LED Fails ................................................................................................................................................................... 4-5

AC/DC Adapter .................................................................................................................................................................... 4-5

AC Power & Charge LEDs Fail ..................................................................................................................................................4-6

Checking the DC/DC Board ................................................................................................................................................4-6

Checking the Battery Pack and its Cabling ...................................................................................................................... 4-9

Checking the Battery Pack ............................................................................................................................................ 4-9

Checking the Cabling .................................................................................................................................................. 4-10

Checking the Mainboard ................................................................................................................................................. 4-10

LCD Screen Failure to Display.................................................................................................................................................. 4-11

Checking the LCD to Mainboard Connection................................................................................................................... 4-11

Checking the Inverter Board ............................................................................................................................................. 4-12

Checking the LCD Screen .................................................................................................................................................. 4-13

POST — Testing the System ......................................................................................................................................................... 4-14

No Errors Found During the POST .......................................................................................................................................... 4-14

POST Error Beeps & Screen Messages ................................................................................................................................. 4-15

Post-POST Problems..................................................................................................................................................................... 4-23

PC Card Socket Malfunction...................................................................................................................................................4-24

Sound Output Failure ..............................................................................................................................................................4-25

Checking the Software Configuration ..............................................................................................................................4-25

Checking the Volume ........................................................................................................................................................4-25

Checking the Speaker Cable ............................................................................................................................................4-26

Suspend Function Failure ....................................................................................................................................................... 4-27

Charge LED Failure.................................................................................................................................................................. 4-27

1

2

3

4

5

6

7

8

Appendix A: Part Lists

Appendix B: 2800 Circuit Diagrams

Appendix C: 2820/2850 Circuit Diagrams

table of contents

vii

Page 8

1 Introduction

This manual covers the information you need to service or upgrade the 2800/2820/2850 Notebook Computer.

Information about operating the computer (e.g. getting started, and the Setup utility) is in the User’s Manual. Information about drivers (e.g. VGA & audio) is also found in User’s Manual. That manual is shipped with the computer.

Operating systems (e.g. DOS, Windows 9x, Windows NT 4.0, OS/2 Warp, UNIX, etc.) have their own manuals as do

application software (e.g. word processing and database programs). If you have questions about those programs,

you should consult those manuals.

The notebook is designed to be upgradable. The 2800 supports Intel Pentium II & Celeron CPUs of different speeds

and 12.1” & 14.1” TFT color LCD screens. The 2820 supports Intel Pentium III & Celeron CPUs of different speeds

and 12.1” & 14.1” TFT color LCD screens while the 2850 supports Intel Pentium III & Celeron CPUs of different

speeds and 15.1” TFT color LCD screens. In addition, system memory, hard disk, and BIOS are also upgradable. See

Chapter 3, “Disassembly,” for a detailed description of the upgrade procedures for each specific component.

1

Please note the warning and safety information indicated by the “

The balance of this chapter reviews the computer’s technical specifications and external features.

M” symbol.

1 – 1

Page 9

Introduction

SYSTEM SPECIFICATIONS

CPU (2800) (2820 & 2850)

Package MicroPGA1 MicroPGA2

Type Pentium II, 300MHz~400MHz Pentium III, 450MHz or faster

1

Celeron, 300MHz~400MHz Celeron, 450MHz or faster

MEMORY

L1 cache (in CPU) 16KB code + 16KB data 16KB code + 16KB data

L2 cache Pentium II: 256KB SRAM Pentium III: 256KB SRAM

(on die) Celeron: 128KB SRAM Celeron: 128KB SRAM

RAM base 0MB (onboard) same

RAM expansion 2 S.O.DIMM sockets (144 pin) same

DIMM sizes: 32MB, 64MB, 128MB same

standards: 3.3-volt same

modes: SDRAM same

speed: 66MHz or faster speed: 100MHz or faster

use: singly, mixed* or identical pairs same

maximum expansion: 256MB same

*Both must be the same speed

CORE LOGIC

440BX AGPset, 66MHz 440BX AGPset, 100MHz

1 – 2

specifications

Page 10

BIOS

512KB Flash ROM, Plug ‘n Play 1.0a, LBA, APM 1.2, ACPI

VIDEO

memory 4MB/8MB SGRAM

chipset ATI 3D Rage LT Pro AGP (with 3D, AGP & ZV support/proprietary driver)

architecture 64-bit 2x AGP bus with Windows Acceleration

display TFT (active matrix)

12.1” SVGA, (800 x 600) at 24-bit color (TrueColor)

14.1” XGA, (1024 x 768) at 32-bit color (TrueColor)

15.1” XGA, (1024 x 768) at 32-bit color (TrueColor)

DRIVES

HDD module semi-removable 2½” (9.5mm) , PCI local bus IDE interface

FDD module 3.5”, 1.44MB (3-mode)

Device Bay

CD-ROM module 24X, full size (5.25”) ATAPI interface tray-loading mechanism,

access time below 100ms

or DVD module 4X or faster, full size (5.25”) ATAPI interface tray-loading mechanism,

access time below 100ms (with software MPEG support)

1

AUDIO

chipset Yamaha YMF744B (DS-XG), proprietary driver

architecture 32-bit PCI bus

type 64-voice dual-audio engine, AC-3 speaker virtualization, PnP, up to 20-bit ADCDAC

audio resolution, I

sampling max. record & playback up to 48 KHz stereo (WAVE audio)

3D HRTF 3-D positional audio under DirectX™ 5.0

compatibility Sound Blaster Pro™ legacy audio, MS Windows Sound System™

interface speakers (phones), microphone, line-in

speakers 2 built-in: 0.5W stereo amp.

2

S/zoomed video, high quality MIDI synthesis

specifications

1 – 3

Page 11

Introduction

I/O

USB 2 ports, compliant with UHCI 1.1, USB 1.0 & PCI 2.1

Serial 1 9-pin, 16C550 compatible

Serial 2 infrared, IrDA v 1.1, FIR, SIR compatible

Parallel 25-pin, ECP, output-only, bi-directional

CRT 15-pin VGA

PS/2 6-pin, mini-din, mouse or keyboard

1

PC Card one Type I or Type II socket, PC Card 3.0, ZV port & CardBus compliant

INTERFACE

keyboard 87-key or 90-key (depending on the language)

Windows 95 compliant with embedded numeric keypad

pointing device PS/2 TouchPad (built-in), MS-Mouse compatible

POWER SYSTEM

adapters (external) universal, auto-sensing switching

input: 90-240VAC @47- 63Hz

¯¯

Advanced Users

Actual battery life per

charge may differ from this

figure. It will vary depending on the system configuration, the condition of the

battery, the environment,

setup, and working habits.

battery pack(s) Li-Ion: smart battery with gauge circuit

battery charge time Fast (system off) approx. 2.5 hours per battery, 2000mA ±200mA

life per charge approx. 2.5hrs per battery (based on an Intel Pentium III 500 MHz CPU,

output: 60W, 20V, 3A

Ni-MH: dumb battery without gauge circuit

Slow (system on) approx. 7 hours per battery, 700mA ± 50mA

(based on a 3000mA smart battery)

running “ZD BatteryMark 3.0” software in the Windows 98 operating system)

1 – 4

management BIOS control, APM ver 1.2

levels: full-on, standby, suspend-to-RAM/suspend-to-disk (0 volt)

specifications

Page 12

OTHER FEATURES (OPTIONAL)

56K Fax/Data/Voice modem

10/100 Mbps PCI Ethernet Controller

ENVIRONMENT

operating temp. 0oC to 35oC (32oF to 95oF)

storage temp. -10

operating humidity 40% to 80%, non-condensing

storage humidity 10% to 90%, non-condensing

altitude 8000 feet

shock (unpacked) 5G (11 + 1 microsecond pulse)

o

C to 65oC (14oF to 149oF)

PHYSICAL

1

2800

dimensions 312mm(w) x 262mm(d) x 34.5mm(h)

weight 2.95Kg (with Li-Ion battery, FDD, HDD, CD-ROM & 14.1” LCD)

(12.1”/14.1” LCD capable):

2820 (12.1”/14.1” LCD capable):

dimensions 312mm(w) x 262mm(d) x 36/37.5mm(h)

weight 2.95Kg (with Li-Ion battery, FDD, HDD, CD-ROM & 14.1” LCD)

2850 (15.1” LCD):

dimensions 326mm(w) x 267mm(d) x 37.5mm(h)

weight 3.22Kg (with Li-Ion battery, FDD, HDD, CD-ROM & 15.1” LCD)

specifications

1 – 5

Page 13

Introduction

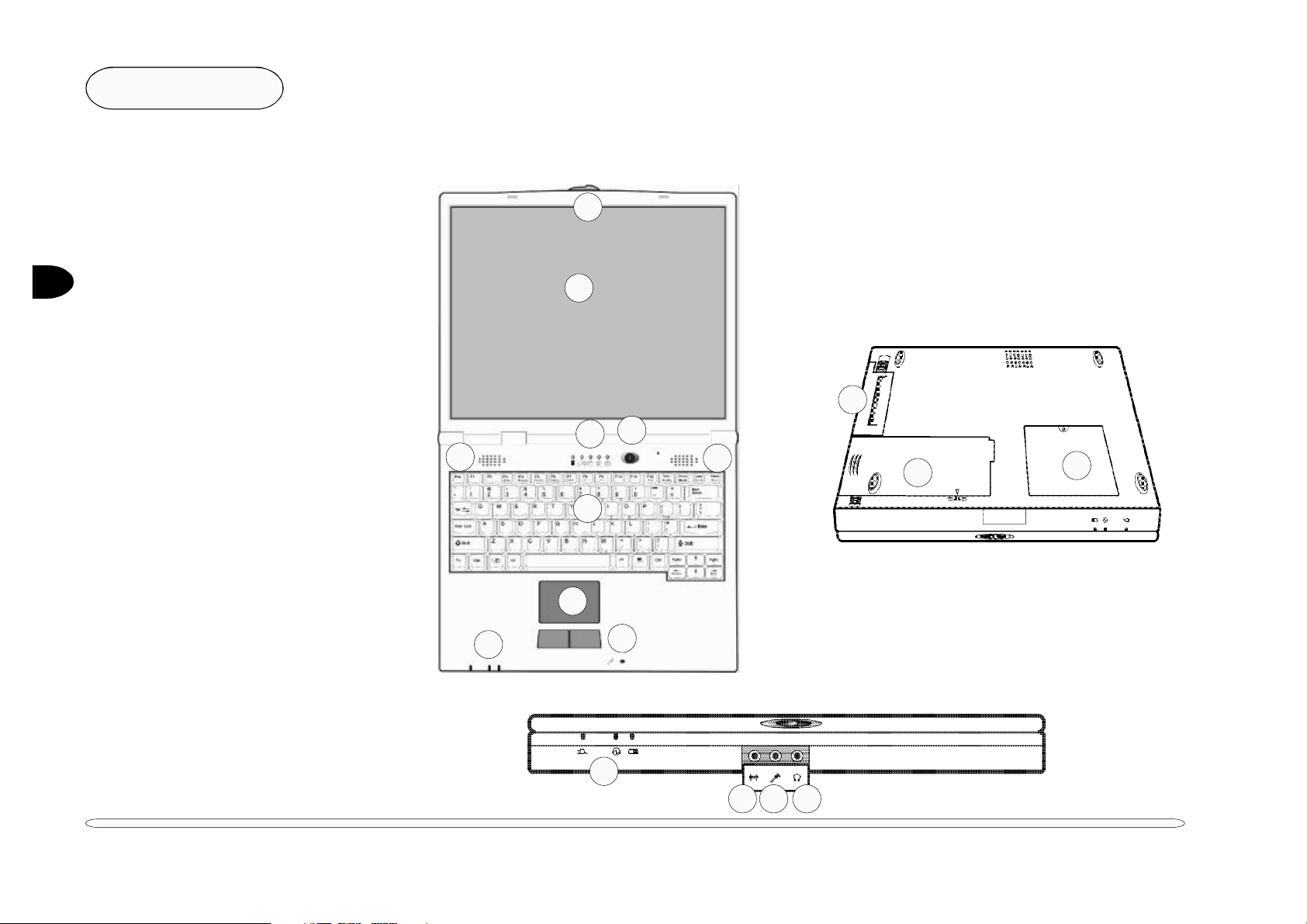

FRONT VIEW

FIG. 1 – 1

1

1. LCD

2. Cover latch

3. Speakers

4. On/Off switch

5. LED system status indicators

6. Keyboard

7. TouchPad & buttons

8. LED power status indicators

9. Microphone

10. Audio line-in jack

11. Mic jack

12. Phone jack

EXTERNAL LOCATOR

The following figures show the external locations of the computer’s main subsystems.

2

1

13

4

5

3

6

3

14

15

OTTOM VIEW

B

FIG. 1 - 2

13. Device bay

14. Battery bay

15. RAM bay

1 – 6

external locator

7

8

9

10811 12

Page 14

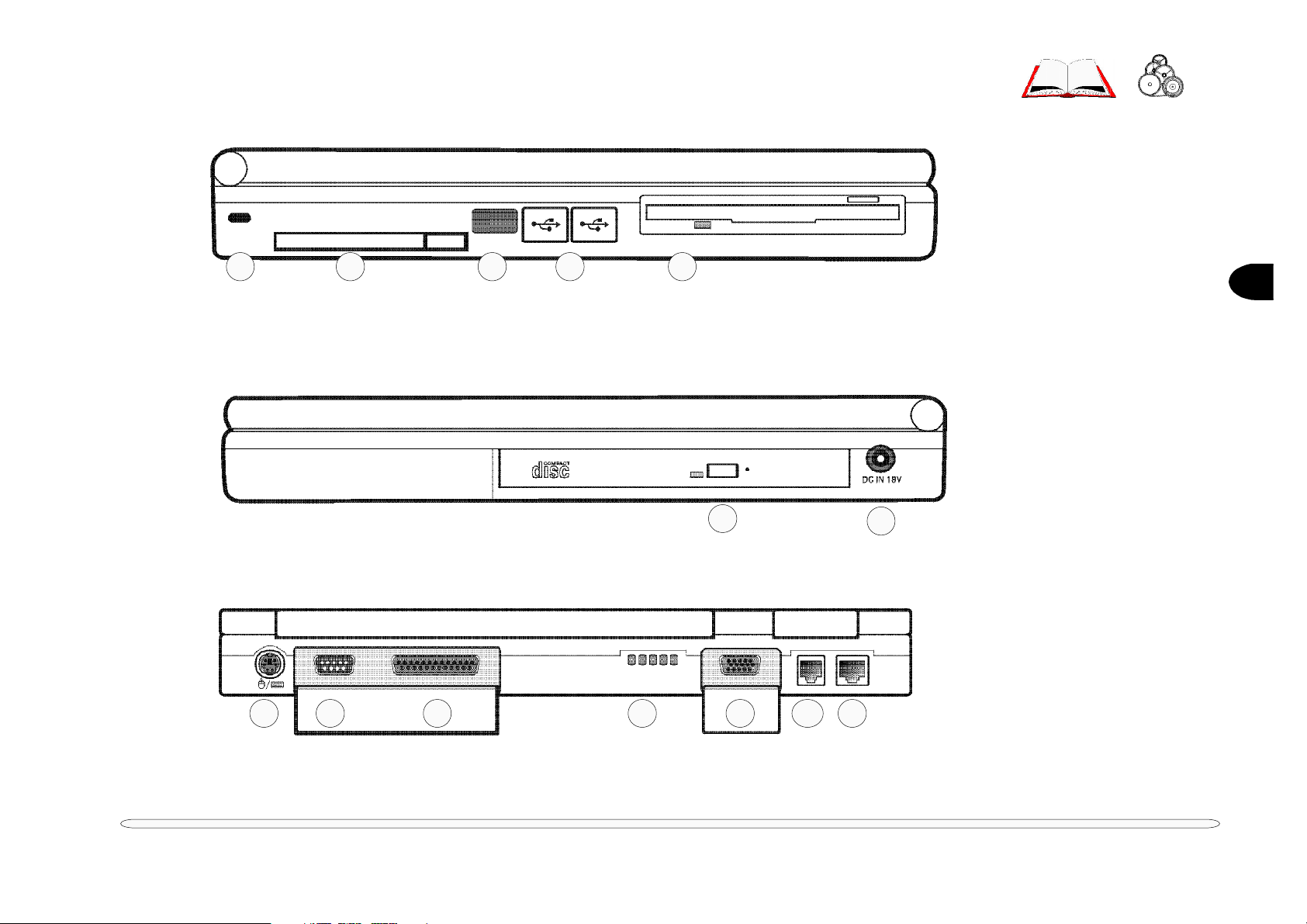

LEFT VIEW

FIG. 1 – 3

1. Kensington lock port

51 2 3 4

2. PC Card slot

3. IrDA (serial 2) port

4. USB ports

5. FDD

IGHT VIEW

R

FIG. 1 – 4

6. CD-ROM module (option)

or DVD ROM module (option)

7. Adapter port

1

6

8

9 12

10

11

13

14

7

EAR VIEW

R

FIG. 1 – 5

8. PS/2 port

9. COM (serial 1) port

10. Parallel port

11. Fan

12. External monitor port

13. Fax/Modem (option)

14. LAN port (option)

external locator

1 – 7

Page 15

Introduction

NOTES:

1

1 – 8

notes

Page 16

2 Chipset

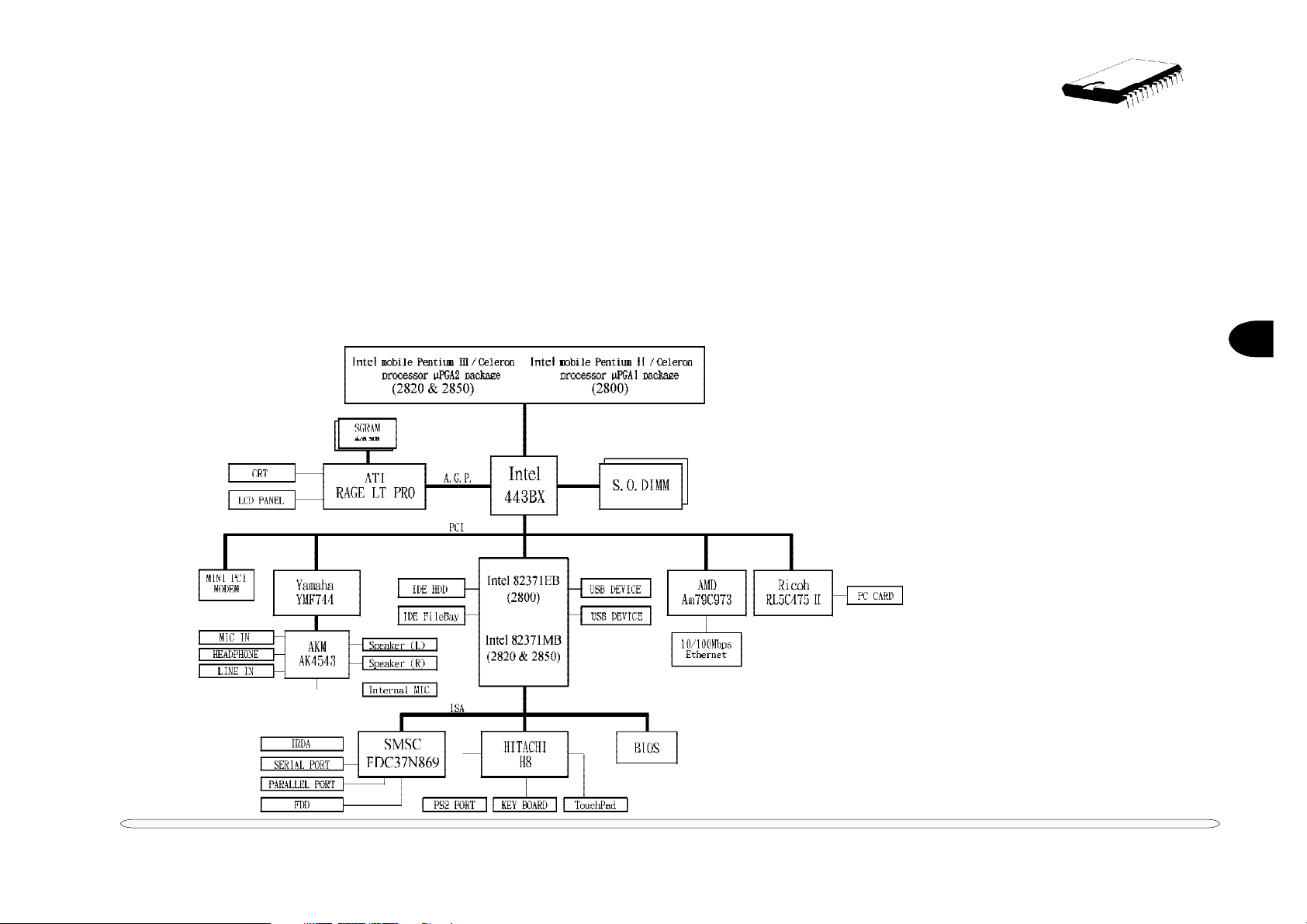

The computer is completely AT-compatible. Its chipset supports a high-performance PCI bus video interface and

state-of-the-art power management features. This chapter mainly describes the following major system components:

• CPU • Core logic chipset • Supporting chips

The following figures are the system block diagram and the chipset site diagram. These provide an overview of the

computer’s layout and a practical locator for chipset components.

2

SYSTEM BLOCK DIAGRAM

FIG. 2 – 1

2 – 1

Page 17

Chipset

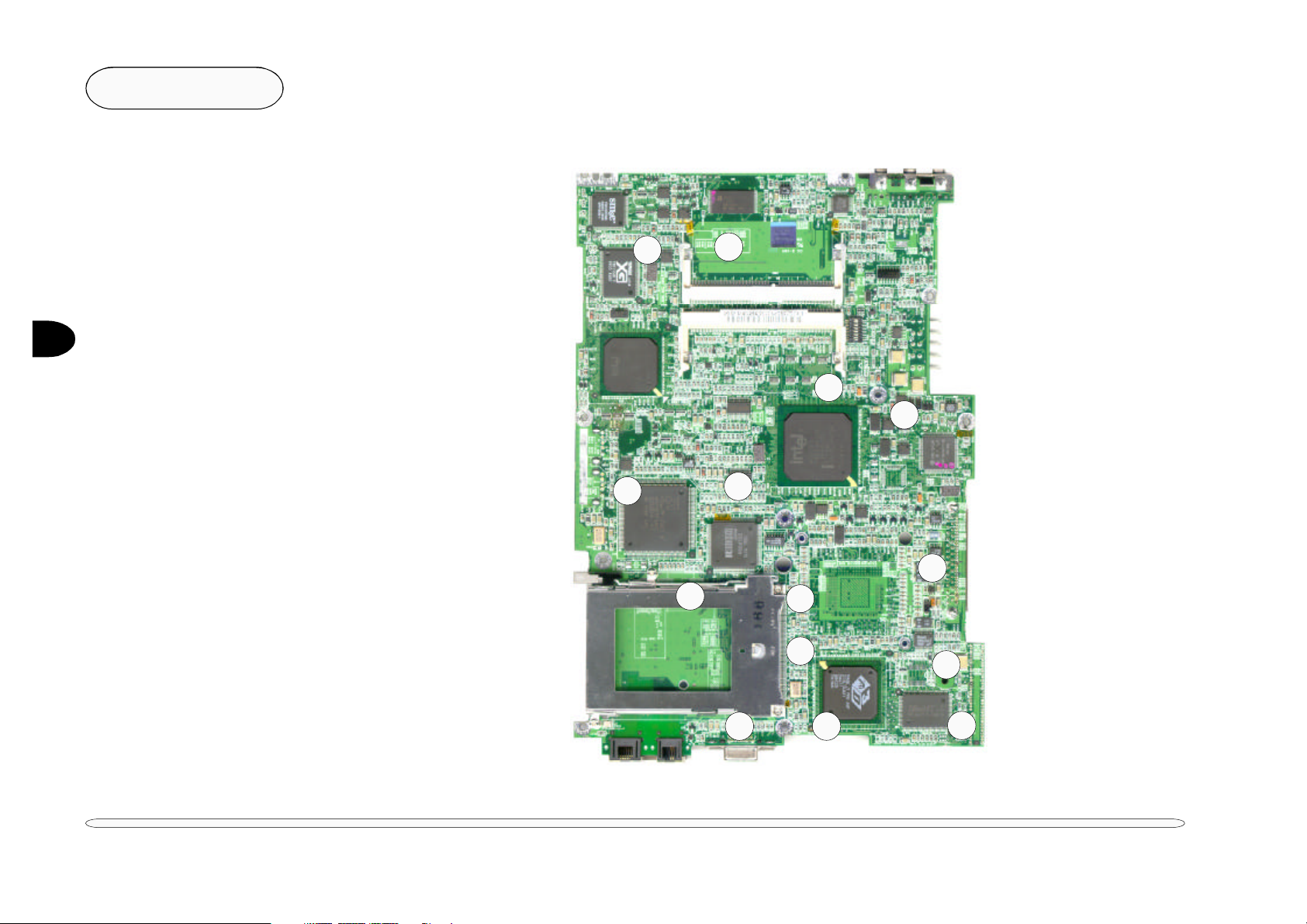

CHIPSET SITE DIAGRAM

1. Video SGRAM

2. Video Controller

2

ATI Rage LT Pro

3. PCI-CardBus Bridge

Ricoh 5C475

4. LAN Controller

AMD PCnet™ Fast III

AM79C973

5. Core Logic chip

82443BX

6. Keyboard Controller

Hitachi HB/3434

7. SW1 & SW2

8. CN28 DIMM socket “0”

9. CN29 DIMM socket “1”

10. Core Logic chip

82371EB (2800)

82371MB (2820 & 2850)

11. Audio controller

YAMAHA YMF744B

12. Super I/O controller

SMSC FDC37N869

13. 4MB FLASH ROM BIOS

AMD AM29LV004BT

14. Audio CODEC

AKM AK4543 VQ

FIG. 2 – 2

1

6

2

3

4

5

10

7

8

9

1314

11

12

2 – 2

component sites

Page 18

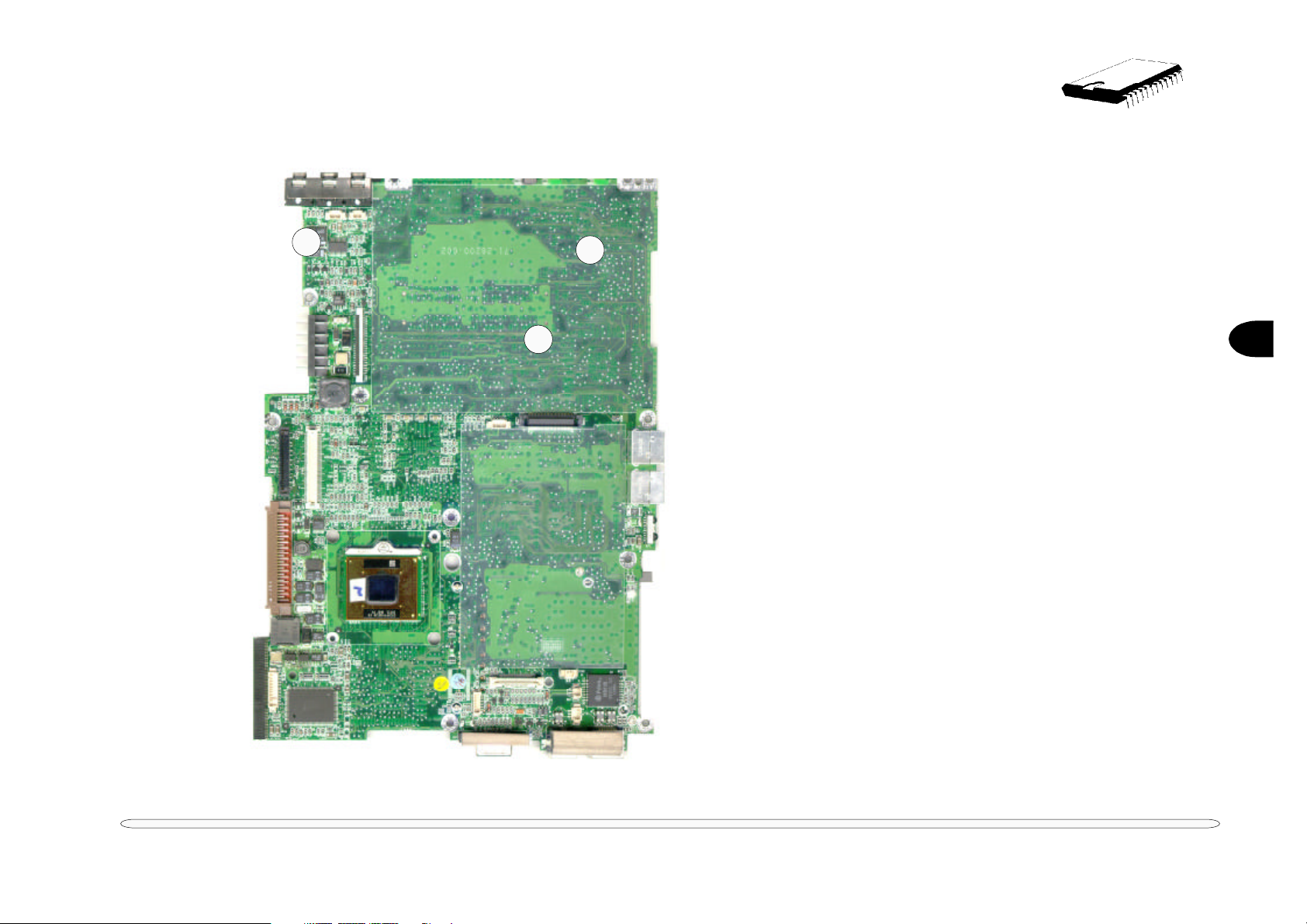

15

17

16

CHIPSET SITE DIAGRAM (CONT.)

IG. 2 – 2

F

15. LAN Transformer

LF-H71P

16. Video SGRAM

17. CPU

2

component sites

2 – 3

Page 19

2

Chipset

CPU - INTEL MOBILE PENTIUM III/PENTIUM II/CELERON

The 2800 uses the Intel Mobile Pentium II/Celeron processor in a microPGA1 package. The Intel Mobile Pentium

II/Celeron processor features an integrated L2 cache (256KB for Pentium II and 128KB for Celeron) and a 64-bit

high performance system bus.

The 2820 & 2850 use the Intel Mobile Pentium III/Celeron processor in a microPGA2 package. The Intel Mobile

Pentium III/Celeron processor features an integrated L2 cache (256KB for Pentium III and 128KB for Celeron) and

a 64-bit high performance system bus.

The Mobile Pentium III/Pentium II/Celeron processor’s 64-bit wide Low Power Gunning Transceiver Logic system

bus is compatible with the 440BX AGPSet and provides a glue-less, point-to-point interface for an I/O bridge/

memory controller.

The Intel Mobile PentiumIII/Pentium II/Celeron processors are fully compatible with all software written for the

Pentium processor with MMX technology, Pentium processor, Intel486 microprocessor, and Intel386 microprocessor. In addition, they provide improved multimedia & communications performance. They feature:

• Performance improved over existing mobile processors

- Supports the Intel Architecture with Dynamic Execution

- Supports the Intel Architecture MMX technology

• Integrated primary (L1) instructions and data caches

- 4-way set associative, 32-byte line size, 1 line per sector

- 16-Kbyte instruction cache and 16-Kbyte writeback data cache

- Cacheable range programmable by processor programmable registers

• Integrated second level (L2) cache

- 4-way set associative, 32-byte line size, 1 line per sector

- Operated at full core speed

- 128/256-Kbyte, ECC protected cache data array

• Low Power GTL+ system bus interface

- 64-bit data bus, 66-MHz operation

- Uniprocessor, two loads only (processor and I/O bridge/memory controller)

- Short trace length and low capacitance allows for single ended termination

• Voltage reduction technology

• Pentium III processor clock control

- Quick Start for low power, low exit latency clock “throttling”

- Deep Sleep mode for extremely low power dissipation

• Thermal diode for measuring processor temperature

2 – 4

CPU

Page 20

CORE LOGIC CHIPSET - INTEL 440BX AGPSET

The Intel 440BX AGPset consists of the BX System Controller (443BX) and the PCI ISA IDE Xcelerator (PIIX4E/

PIIX4M). The AGPset forms a Host-to-PCI bridge and provides the second level cache control and a full function

64-bit data path to main memory.

NORTH BRIDGE, AGPSET SYSTEM CONTROLLER, 443BX

The BX System Controller (443BX) integrates the cache and main memory DRAM control functions and provides

bus control to transfer between the CPU, cache, main memory, AGP bus and the PCI Bus.

Features

• Supports the host bus of the Pentium II & III processor families

at 66MHz and 100MHz at 3.3V respectively

• PCI 2.1 compliant

• Integrated Data Path

• Integrated DRAM controller

- 8Mbytes to 256Mbytes main memory

- 64Mbit DRAM/SDRAM technology support

- EDO and SDRAM DRAM support

- Integrated programmable-strength for DRAM interface

- CAS-Before-RAS refresh, extended CBR and self refresh for

EDO

- CAS-Before-RAS and self refresh for SDRAM

• Fully synchronous, minimum latency 30/33 MHz PCI bus interface

- Five PCI bus masters (including PIIX4)

- 10 DWord PCI-to-DRAM read prefetch buffer

- 18 DWord PCI-DRAM post buffer

- Multi-Transaction timer to support multiple short PCI transactions

• AGP Features

- AGP 1.0 compliant

- 66/133 MHz data transfer capability

- Supports concurrent CPU, AGP and PCI transactions

• Power Management Features

- Dynamic stop clock support

- Suspend to RAM (STR)

- Suspend to Disk (STD)

- Power On Suspend (POS)

- Internal clock control

- SDRAM and EDO self refresh during suspend

- ACPI support

- Compatible SMRAM (C_SMRAM) and Extended SMRAM

(E_SMRAM)

- SMM write-back cacheable in E_SMRAM mode up to 1MB

• Supports the Universal Serial Bus (USB)

• 492 Pin BGA 440BX AGPset with integrated data paths

2

core logic chipset

2 – 5

Page 21

2

Chipset

SOUTH BRIDGE, PCI ISA IDE XCELERATOR, 82371EB/MB (PIIX4E/M)

The 2800 uses the 82371EB (PIIX4E) while the 2820 & 2850 use 82371MB (PIIX4M). The PCI ISA IDE Xcelerator

(PIIX4E/PIIX4M) is a multi-function PCI device implementing a PCI-to-ISA bridge function, a PCI IDE function, a

Universal Serial Bus host/hub function, and an Enhanced Power Management function. As a PCI-to-ISA bridge, the

PIIX4E/PIIX4M integrates many common I/O functions found in ISA-based PC systems - a seven channel DMA

Controller, two 82C59 Interrupt Controllers, an 8254 Timer/Counter, and a Real Time Clock. In addition to compatible transfers, each DMA channel supports Type F transfers. The PIIX4E/PIIX4M also contains full support for

both PC/PCI and Distributed DMA protocols implementing PCI based DMA. The Interrupt Controller has Edge or

Level sensitive and programmable inputs and fully supports the use of an external I/O Advanced Programmable

Interrupt Controller (APIC) and Serial Interrupts. Chip select decoding is provided for BIOS, Real Time Clock,

Keyboard Controller, second external Microcontroller, as well as 2 Programmable Chip Selects. The PIIX4 provides

full Plug and Play compatibility. The PIIX4E/PIIX4M can be configured as a Subtractive Decode bridge. This allows

the use of a subtractive decode PCI-to-PCI bridge such as the 82380 chipset which implements a PCI/ISA docking

station environment.

The PIIX4E/PIIX4M supports two IDE connectors for up to four IDE devices providing an interface for IDE hard

disks and ROMs. Up to four IDE devices can be supported in Bus Master mode. The PIIX4E/PIIX4M contains

support for “Ultra DMA” synchronous DMA compatible devices.

The PIIX4E/PIIX4M contains a Universal Serial Bus (USB) Host Controller that is Universal Host Controller Interface (UHCI) compatible. The Host Controller’s root hub has two programmable USB ports.

2 – 6

core logic chipset

The PIIX4E/PIIX4M supports Enhanced Power Management, including full Clock Control, Device Management

for up to 14 devices, and Suspend and Resume logic with Power On Suspend, Suspend to RAM or Suspend to Disk.

It fully supports Operating System Directed Power Management via the Advanced Configuration and Power Interface (ACPI) specification. The PIIX4E/PIIX4M integrates both a System Management Bus (SMBus) Host and Slave

interface for serial communication with other devices.

Features

• Supports Pentium, Pentium II & Pentium III Microprocessors

- 440BX ISA kit

• Power Management Logic

- Global and local device management

- Suspend/resume logic

- Supports thermal alarm

- Support for external microcontroller

- Full support for Advanced Configuration and Power Interface (ACPI) Specification and OS Directed Power Management

• Multifunction PCI to ISA Bridge

- Supports PCI at 30 MHz and 33 MHz

- Supports PCI Rev 2.1 specification

- Supports Full ISA or Extended I/O (EIO) Bus

Page 22

- Supports full positive decode or subtractive decode of PCI

- Supports ISA/EIO at 1/4 of PCI frequency

• Supports both mobile and desktop deep green environments

- 3.3 V operation with 5 V tolerant buffers

- Ultra-low power for mobile environments

- Power-On Suspend and Soft-OFF for desktop environment

- All registers readable/restorable for proper resume from 0

V suspend

• Integrated IDE Controller

- Independent Timing of up to 4 drives

- PIO Mode 4 transfers up to 14 Mbytes/s

- Supports “Ultra 33” Synchronous DMA mode transfers up to

33 MBytes/sec

- Integrated 8 x 32-bit buffer for IDE PCI Burst

- Supports glue-less “Swap-Bay” option with full electrical isolation

• Enhanced DMA Controller

- Two 8237 DMA controllers

- Supports PCI DMA with 3 PC/PCI channels and Distributed

DMA protocols (simultaneously)

- Fast Type-F DMA for reduced PCI bus usage

• Interrupt Controller based on two 82C59

- 15 interrupt support

- Independently programmable for Edge/Level sensitivity

- Supports optional external I/O APIC

- Serial interrupt input

• Timers based on 82C54

- System Timer, Refresh Request, Speaker Tone Output

• USB

- Two USB 1.0 ports for serial transfers at 12 or 1.5 Mbit/sec

- Supports legacy keyboard and mouse software with USB-

based keyboard and mouse

- Supports UHCI Design Guide Revision 1.1 Interface

• SMBus

- Host interface allows CPU to communicate via SMBus

- Slave interface allows external SMBus master to control re-

sume events

• Real-Time Clock

- 256 Byte Battery-Pack CMOS SRAM

- Includes Date Alarm

- Two 8-byte Lockout Ranges

• Microsoft Win95/98 compliant

2

core logic chipset

2 – 7

Page 23

2

Chipset

SUPPORTING CHIPS

The following subsections describe major supporting chips:

• Ricoh 5C475II PCI-CardBus Bridge

• SMSC FDC37N869 PC 99 Compliant 5V and 3.3V Super I/O Controller with Infrared Support

• ATI RAGE LT Pro Graphics Controller

• Yamaha744B DS-XG Audio Controller

RICOH 5C475 PCI-CARDBUS BRIDGE

The R5C475II is a PC card controller offering a single chip solution as a bridge between PCI bus andCardBus. The

R5C475II includes a PC Card 95/97 compliant socket interface and a bridge function to the PCI bus of 33MHz. The

R5C475II can support the 32-bit CardBus(Card-32) and the 16-bit PC card(Card-16) without external buffers.

Concerning the 16-bit card control interface, the R5C475II‘s register is compatible with the Intel 82365SL and

Ricoh’s RF5C396/366 in order to maintain backward compatibility with the existing 16-bit PC Card compliant with

PCMCIA2.1/JEIDA4.2. All PC card interface signals are individually buffered to allow direct connection to CardBus

and Hot insertion/removal without external buffers. The R5C475II also allows direct connection to PCI bus.

The PCI and PC Card socket interfaces have their own power supply terminals that can be powered at either 3.3V

or 5V for compatibility with 3.3V and 5V signaling environments. The core logic is powered at 3.3V or 2.5V.

The R5C475II allows the system to be equipped with the high performance multimedia PC cards like the Video

capture card, and 100 BASE LAN card. It features:

2 – 8

•PC97/98/99 compliant

– PC99 Design Guide compliant (Subsystem ID, Subsystem

Vender ID)

– ACPI 1.0 and PCI Bus Power Management 1.0 compliant

– Global Reset support

• Low Power consumption

– Hardware Suspend

– CLKRUN#,CCLKRUN# support

– VCC-COREC

• High-performance

• Single Chip PCI-CardBus Bridge

supporting chip - PC Card

– PCMCIA PC-Card 95/97 sockets support

– CardBus(Card-32) Card and 16-bit(PCMCIA2.1/JEIDA4.2)

Card work at the same time

– Bridge function between PCI bus and CardBus

• PCI Bus Interface

– Complian t with PCI Local Bus Specification2.2

– The maximum frequency 33MHz

– PCI Master/Target protocol support

– Separated PCI configuration each socket

– Direct connection to PCI bus

– 3.3V interface (5V tolerant)

Page 24

• CardBus PC card Bridge

– PC Card Standard 95/97 compliant

– Compliant with Yenta register set Rev2.2

– The maximum frequency 33MHz

– CardBus Master/Target protocol support

– Transfer transactions

- All memory read/write transaction(bi-direction)

- I/O read/write transaction(bi-direction)

- Configuration read/write transaction(PCI ® Card)

- 2 programmable memory windows

- 2 programmable I/O windows

• PC Card-16 Bridge

– Compliant with PCMCIA PC Card 95/97 Standard Specification

– 5 programmable memory windows

– 2 programmable I/O windows

– Compliant with i82365SL compatible register set / ExCA

• System Interrupt

– INTA# support for PCI system interrupt

– IRQn support for ISA system interrupt (Non shared IRQn pins)

– Serialized IRQ support

• 3.3V/5V Mixed Voltage Operation at 33MHz

• GPIO support

• Posting Write and Prefetching Read support

• Plug and Play support

• 16-bit Legacy mode (3E0/3E2 I/O port) support

• Zoomed Video Port support

– Bypass type

• PCIway Legacy DMA support

2

supporting chip - PC Card

2 – 9

Page 25

2

Chipset

SMSC FDC37N869 PC 99 COMPLIANT 5V AND 3.3V SUPER I/O CONTROLLER WITH INFRARED SUPPORT

The FDC37N869 features:

• Serial ports

• 5 volt and 3.3 volt operation

• Intelligent auto power management

• 16 bit address qualification

• 2.88MB Super I/O Floppy Disk Controller

- Licensed CMOS 765B Floppy Disk Controller

- Software and register compatible with SMSC proprietary

82077AA compatible core

- Supports one Floppy Drive directly

- Configurable Open Drain/Push-Pull Output Drivers

- Supports Vertical Recording Format

- 16 byte data FIFO

- 100% IBM compatibility

- Detects all overrun and underrun conditions

- Sophisticated Power Control Circuitry (PCC) including

multiple power-down modes for reduced power

consumption

- DMA enable logic

- Data rate and drive control registers

- Swap drives A and B

- Non-burst mode DMA option

- 48 Base I/O address, 15 IRQ and 4 DMA options

- Forceable write protect and disk change controls

• Floppy disk available on parallel port pins ACPI compliant

• Enhanced digital data separator

- 2Mbps, 1Mbps, 500 Kbps, 300 Kbps, 250 Kbps data rates

- Programmable precompensation modes

- Two high speed NS16C550 compatible UARTs with send/

receive 16 Byte FIFOs

- Supports 230k and 460k baud

- Programmable baud rate generator

- Modem control circuitry

• Infrared communications controller

- IrDA v1.2 (4Mbps), HPSIR, ASKIR, Consumer IR Support

- 2 IR Ports

- 96 base I/O address, 15 IRQ options and 4 DMA options

• Multi-mode parallel port with ChiProtect

- Standard Mode

- IBM PC/XT PC/AT and PS/2 compatible bi-directional

parallel port

- Enhanced Parallel Port (EPP) compatible

- EPP 1.7 and EPP 1.9 (IEEE 1284 compliant)

- Enhanced Capabilities Port (ECP) compatible (IEEE 1284

compliant)

- Incorporates ChiProtect Circuitry for Protection Against

Damage Due to Printer Power-On

- 192 base I/O address, 16 IRQ and 4 DMA options

• Game port select logic

- 48 base I/O addresses

• General Purpose Address Decoder

- 16-byte block decode

2 – 10

supporting chip - super I/O

Page 26

ATI RAGE LT PRO GRAPHICS CONTROLLER

The RAGE LT Pro is a highly integrated graphics accelerator with superior support for 3D and motion video —

ideal for notebooks and LCD desktops. It incorporates comprehensive support for Intel’s Accelerated Graphics Port

(AGP), including 1X or 2X mode with sidebands.

Delivering superior 3D acceleration and comprehensive 3D support, the RAGE LT Pro includes a triangle set-up

engine, single-pass trilinear filtering, six perspectively correct texturing modes, video texturing, Gouraud and specular shading, and a host of 3D special effects.

The best choice for DVD notebooks and LCD desktops, the RAGE LT Pro’s DVD features include motion compensation, acceleration for soft DVD, integrated TV-out with Macrovision and support for third-party MPEG-2 decoders via the ATI Multimedia Channel (AMC).

Using Tri-View™ the RAGE LT Pro can output to LCD, CRT, and TV simultaneously. It also includes two output

controllers so that any two display devices can have different images and/or refresh rate.

It has the following main features:

2

• First mobile accelerator to use AGP 2X (133MHz) in AGP Texturing with sideband signals to realize all the benefits of AGP.

• First mobile accelerator to deliver full motion soft DVD using motion compensation circuitry.

• First mobile acccelerator with integrated LVDS transmitter.

• Innovative Dynamic Power Management with ACPI compliance.

• Superior 3D performance acheived through a hardware setup

engine and a 4KB on-chip texture cache.

• Superior 2D performance with support of 100MHz SGRAM.

• TFT and DSTN panel interface support for up to 1280x1024 resolutions.

• Integrated ImpacTV2-quality TV output provides optimal image quality via programmable 6 tap flicker filter, resolution

modes scale down from 1024x768 and 16:9 wide mode support. Direct YUV422 mode, Macrovision 7.01 and CGMS support.

• Support for 2, 4, or 8MB frame buffers, and integrated 230MHz

DAC.

• High quality ratiometric expansion that fits source images to

any panel resolution.

supporting chip - video

2 – 11

Page 27

2

Chipset

YAMAHA YMF744B DS-XG

The YMF744B (DS-1S) is a high performance audio controller for the PCI Bus. DS-1S consists of two separated

functional blocks. One is the PCI audio block and the other is the Legacy Audio block. PCI Audio block allows

Software Driver to handle maximum of 73 concurrent audio streams with the Bus Master DMA engine. The PCI

Audio Engine converts the sampling rate of each audio stream and the streams are mixed without utilizing the CPU

or causing system latency. By using the Software Driver from YAMAHA, PCI Audio provides 64-voice XG wavetable

synthesizer with Reverb and variation. It also supports DirectSound hardware accelerator, Downloadable Sound

(DLS) and DirectMusic accelerator.

Legacy Audio block supports FM Synthesizer, Sound Blaster Pro, MPU401 UART mode and Joystick function in

order to provide hardware compatibility for numerous PC games on real DOS without any software driver. To

achieve legacy DMAC compatibility on the PCI, DS-1S supports both PC/PCI and Distributed DMA protocols. DS1S also supports Serialized IRQ for legacy IRQ compatibility.

DS-1S supports the connection to AC’97s which provides high quality DAC, ADC and analog mixing, and it can

connect two AC’97. In addition, it supports consumer IEC958, Audio Digital Interface (SPDIF), to connect external audio equipment by digital. It has the following features:

2 – 12

• PCI 2.2 compliant

• PC’98/PC’99 specification compliant

• PCI Bus Power Management rev. 1.0 compliant (support D0, D2

and D3 state)

• Supports clock run

• PCI Bus Master for PCI audio

• Legacy audio compatibility

supporting chip - audio

- True full duplex playback and capture with different

sampling rate

- Maximum 64-voice XG capital wavetable

- Synthesizer including GM compatibility

- DirectSound Hardware Acceleration

- DirectMusic Hardware Acceleration

- Downloadable Sound (DLS) level-1

- FM synthesizer

- Hardware Sound Blaster Pro compatibility

- MPU401 UART mode MIDI interface

- Joystick

• Supports PC/PCI and Distributed DMA for legacy DMAC (8237)

emulation

• Supports serialized IRQ

• Supports I

• Supports Consumer IEC958 Output (SPDIF OUT)

• Supports Consumer IEC958 Input (SPDIF IN)

• Supports AC’97 Interface (AC-Link) Revision 2.1

• Multiple CODEC (Connectable two AC’97s)

• Hardware volume control

• EEPROM interface

• Single crystal operation (24.576Mhz)

• 3.3V power supply (5V tolerant)

2S

serial input for Zoomed Video Port

Page 28

3 Disassembly

This chapter provides step-by-step instructions for disassembling parts and subsystems. When it comes to reassembly, reverse the procedures (unless otherwise indicated).

We suggest you completely review any procedure before you take the computer apart.

The computer comes in two (2) models: 2800 and 2820/2850 and several “variations”:

The 280 is based on the P entium II CPU. Differ ent versions may have cosmetic and minor structural variations of the

top and bottom covers (mostly concerning LCD panel sizes). As appropriate, these differences are noted in the sidebars. When servicing, be sure to note the mainboard v ersion. This may affect CPU switch settings. Additional component information is available in Appendix A: Part Lists or Appendix B: Circuit Diagrams.

The 2820/2850 is based on the Pentium III. Like the earlier model, there may also be variations. However, unlike

the 2800, there are no CPU switch adjustments.

CPU Upgrades: To upgrade, you only need to remove the keyboard, heat plate and heatsink. For the 280 model, the

CPU switch settings can be accesed through the RAM bay opening.

Note: When re-assembling, make sure the heat plate is not “distorted” and is fastened securely.

LCD Upgrades (all versions): All switches are accessable throuth the RAM bay opening. Connections are under the status panel.

The LCD/ top cover assembly is anchored with four (4) externally accessable screws.

Illustrations: To enhance procedural clarity, the illustrations in this chapter do not include all components. Mylar

insulation and adhesive attachments are not shown unless they are critical to the disassembly

process. For information about these parts, please refer to

Appendix A: Part Lists

.

3

3 – 1

Page 29

Disassembly

The disassembly procedures appear in the following order:

• Keyboard – CPU upgrade/replacement

• LCD Module – LCD assembly, inverter

• Top Cover – TouchPad assembly

• Bottom Cover – HDD, FDD, mainboard, and DC/DC board

• Connector Locator

3

All disassembly procedures assume that the system is turned OFF, and disconnected from any power supply (the

battery is removed too). We also assume that the CD/DVD-ROM module is removed. All of these procedures are

described in the User’s Manual which accompanies the system.

CONNECTIONS

Connections within the computer are one of four types:

Locking collar sockets for ribbon connectors To release these connectors, use a small flat-head screwdriver

to gently pry the locking collar away from its base. When replacing the connection, make sure the connector is oriented in the

same way. The pin1 side is usually

Pressure sockets for multi-wire connectors To release this connector type, grasp it at its head and gently

rock it from side to side as you pull it out.

wires themselves.

force it. The socket only fits one way.

Pressure sockets for ribbon connectors To release these connectors, use a small pair of needle-nose

pliers to gently lift the connector away from its socket. When

replacing the connection, make sure the connector is oriented

in the same way. The pin1 side is usually

Board-to-board or multi-pin sockets To separate the boards, gently rock them from side to side as you

pull them apart. If the connection is very tight, use a small flathead screwdriver

When replacing the connection, do not try to

- use just enough force to start the separation.

not

indicated.

Do not pull on the

not

indicated.

3 – 2

procedures

Page 30

MAINTENANCE PRECAUTIONS

The following precautions are a reminder.

To avoid personal injury or damage to the notebook while performing a removal and/or replacement job, take the

following precautions:

1. Don't drop it. Perform your repairs and/or upgrades on a stable surface. If the computer falls, the case and other components

could be damaged.

2. Don't overheat it. Note the proximity of any heating elements. Keep the computer out of direct sunlight.

3. Avoid interference. Note the proximity of any high capacity transformers, electric motors, and other strong magnetic fields. These

can hinder proper performance and damage components and/or data. You should also monitor the position of magnetized tools

(i.e. screwdrivers).

4. Keep it dry. This is an electrical appliance. If water or any other liquid gets into it, the computer could be badly damaged.

5. Be careful with power. Avoid accidental shocks, discharges or explosions.

•Before removing or servicing any part from the notebook, turn the notebook off and detach any adapters (AC/DC or car adapter).

• To prevent the notebook from being turned on accidentally, remove the battery module

ment procedure.

• Only use a power adapter approved for use with this computer.

• Make sure the AC adapter has a steady, uninterrupted power supply and is grounded.

• When you want to unplug the power cord or any cable/wire, be sure to disconnect it by the plug head. Do not pull on the wire.

• Be sure the socket and any extension cord(s) you use can support the total current load of all connected devices.

6. Peripherals/Modules – Turn off and detach any peripherals. Remove all modules and power units.

7. Beware of static discharge. ICs, such as the CPU and main support chips, are vulnerable to static electricity. Before handling any

part in the notebook, discharge any static electricity inside the notebook. When handling a printed circuit board, do not use gloves

or other materials which allow static electricity buildup. We suggest that you use an anti-static wrist strap instead.

8. Beware of corrosion. As you perform your job, avoid touching any connector leads. Even the cleanest hands produce oils which

can attract corrosive elements.

9. Keep your work environment clean. Tobacco smoke, dust or other air-born particulate matter is often attracted to charged

surfaces, reducing performance.

10. Keep track of the components. When removing or replacing any part, be careful not to leave small parts, such as screws, loose

inside the notebook.

before

you start a removal or replace-

3

BATTERY PRECAUTIONS

Only use batteries designed for this computer. The wrong battery type may explode, leak or damage the computer.

Recharge the battery using an approved system. Incorrect recharging may make the battery explode.

Always dispose of batteries carefully. Batteries may explode or leak if exposed to fire, or improperly handled or discarded.

Do not try to repair a battery. Damaged or defective batteries should be replaced.

precautions

3 – 3

Page 31

3

Disassembly

CLEANING

Do not apply cleaner directly to the computer, use a soft clean cloth.

Do not use volatile (petroleum distillates) or abrasive cleaners on any part of the computer.

MAINTENANCE TOOLS

The following tools are recommended when working on the notebook:

M3 Phillips-head screwdriver

M2.5 Phillips-head screwdriver (magnetized)*

M2 Phillips-head screwdriver

Small flat-head screwdriver

Pair of needle-nose pliers

anti-static wrist-strap

* note Maintenance Precaution #3.

3 – 4

precautions

Page 32

GENERAL DISASSEMBLY: UNDER THE KEYBOARD

REMOVING THE KEYBOARD & HEAT PLATE

1. Make sure the computer is turned off.

2. Remove the rubber

caps and screws on

the status panel.

3. Carefully angle the

status panel up and

then the keyboard.

4. Flip the keyboard

face-down to expose

the HDD and

heatplate.

5. Use a flat-head

screw driver to pry up

the collar of the

keyboard’s ribbon

connector. Then set

the keyboard aside.

6. Using the philipshead screwdriver

again, remove the 5

screws anchoring the

heat plate.

2 2 2

""

"

""

%%

%

%%

4

""

"

""

##

#

##

3

$$

$

$$

""

"

""

3

3

RELEASING THE KEYBOARD & REMOVING

HEAT PLATE

THE

FIG. 3 – 1

!!

!

!!

Tip

This procedure involves:

Stop here if you only need to

replace /upgrade the CPU.

screws 8

connectors: 1

keyboard & heat plate

3 – 5

Page 33

3

Disassembly

CHANGING THE CPU

The CPU is further protected by cooling-fan/heatsink.

To remove it, again angle the status panel up. Lift the cooling-fan/heatsink up slightly and pull it forward. If you

want to completely remove the cooling-fan/heatsink, disconnect it from its power supply at connection CN7.

Note: the cooling-fan/heatsink has a small “lip” overhanging the mainboard.

The removable CPU fits into a µPGA socket.

When changing it, use a small flat-head screwdriver to carefully turn the pin-lock to the release position. As you

remove the old CPU, be sure to note the position of the CPU’s “Pin 1”. Make sure any replacement CPU is also

properly locked into position.

CPU settings for the Intel Pentium II -based 2800 are controlled from SW1 which is accessible from the RAM bay on

the notebook’s bottom.

The Pentium III-based 2820/2850 models auto-detect the CPU, so there are no CPU- switches to adjust.

Before making any changes, note the mainboard version and use the appropriate switch settings shown in Table 3-1.

3 – 6

CPU upgrades

Page 34

draobniaM 3rev

draobniaM 4rev

UPCsehctiwS1WS

deeps

)zHM(

332

662

003

333

663

epyT 1 2 3 4

ffoffo

no

nonono

/noxiD

noreleC

no

no no

no

ffo

no

ffo ffo

ffoffoffo

knaBhctiwS

UPC

1WS2WS

deeps

no

ffo

ffo

)zHM(

332

662

003

333

663

004 noreleC ffo

004 noxiD ffo

334noreleCffoffo

664noreleCffo

epyT 1 2 3 4 5 6 7 8 7

&noxiD

noreleC

ffoffo

no

nonono

ffo

no

no no

ffoffoffo

no

no no no no

no no no

no

no

ffo ffo

nono

ffo

nono

ffo

ffo

no

ffo

ffo

no

ffo

no

ffo

no

ffo

no

ffo

ffo ffo ffo

ffo

nono

ffo

nono

ffo

no

ffo

no

ffo

no

ffo

no

ffo

no

ffo

no

no

ffo

ffo

no

no

no

no

no

no

ffo

no

no

CPU SWITCH SETTINGS FOR 280

TABLE 3 - 1

3

CPU

FIG. 3 – 2

&&

&

&&

''

'

''

Note the Pin1 location

SW1

FIG. 3 – 3

CPU upgrades

3 – 7

Page 35

3

draobniaM082 3reV

sehctiwS2WS

epyTlenaP

dbk DI

erutaeF1234 5 6 7 8

lenaPDCL

ustijuFTFT-S"1.21

71-S6CVS13CLF

no

ffoffo

GLTFT-X"1.41

AN1A-AX141PL

nono

ffo

draobyeK

rehto&SU ffo ffo

esenapaJ

no

ffo

ynapmoC

DI

CTH ffo ffo ffo

ovelC

no

ffo ffo

draobniaM0082 4reV

2revdraobniaM0582/0282

sehctiwS2WS

epyTlenaP

dbkrwp DIUPC DI

erutaeFledoM123456*7 8

lenaPDCL

oynaSTFT-S"1.21

40L20-V5121MT

lla

no

ffoffo

ustijuFTFT-S"1.21

71-S6CVS13CLF

lla

no

ffoffo

ihcatiHTFT-X"1.41

CV58D63XT

lla

nono

ffo

GLTFT-X"1.41

AN1A-AX141PL

0082

nono

ffo

0282ffo

no

ffo

GLTFT-X"1.51

1X051PL

0582ffo

no

ffo

draobyeK

rehto&SU ]ffo[

esenapaJ

no

kcolretnI

rewoPCA

delbane

no

delbasid]ffo[

ynapmoC

DI

CTH ffo ffo

oynaS

no

ffo

ovelC

no no

sledom0582/0282rofdesuton,sdraobniam0082rofelbathctiwsUPCotrefeR*

gnittestluafedsetacidnI][

Disassembly

GENERAL DISASSEMBLY:

REMOVING & REPLACING THE LCD MODULE

The LCD module can be removed with only a little more disassembly after you’ve removed the keyboard and heat plate:

1. Lift the status panel up, disconnect the status panel board at CN8

(A) and the left speaker at CN12(B). Set it aside.

2. Remove the hinge covers (C, D & E). Use the flat-head screwdriver to flex the cover up and back slightly.

4. Disconnect controller connector CN11(F to G) and inverter connector CN6 (H to I).

5. Remove the two (2) rear screws (J ~ K), set them aside.

Note: On models 2800 & 2820 these are the upper rear screws.

6. Remov e the four (4) hinge scr e ws (L ~ O), set them aside and lift

the LCD module away from the body.

Note: On the 2850 model, screws M & O are on the bottom panel.

TABLE 3 - 2

LCD & MISCELLANEOUS

SWITCH SETTINGS

3 – 8

LCD module

If you are upgrading the LCD module to different size, stop here.

The entire module should be replaced, including the rear panel and

frame. The new module uses different components, but connects

in the same way as the original. Refer to Appendix A for specific

part numbers.

If you are only replacing the LCD panel with one of the same size,

continue to page 3-9.

Depending on your replacement module, you may need to adjust

SW2 settings in the RAM bay. Refer to Table 3-2:

Page 36

A

B

D

A

3

C

B

N

L

H

F

J

M

I

G

K

E

O

REMOVING THE LCD MODULE

FIG. 3 – 4

!!

!

!!

Tip

This procedure involves:

screws 6

connectors: 2

LCD module

3 – 9

Page 37

3

Disassembly

REPLACING THE LCD

The LCD module has two elements, the LCD itself, and its inverter card.

First separate the LCD module from the main body of the computer as described on pages 3-4 and 3-5.

If you are upgrading to a different LCD, this entire assembly, except for the side frame and hinge elements and

possibly the inverter card, will be replaced.

12.1” DISASSEMBLY (NOT SHOWN)

This LCD is attached directly to the rear panel of the LCD module.

1. Remove the 6 rubber caps and frame screws under them.

2 Snap off the LCD frame. As you do this, make sure the cover latch doesn’t spring out. There are snaps on all sides.

3. Disconnect the panel from the inverter board.

4. Remove the 4 LCD anchor screws, and lift the LCD away from the rear panel.

14.1 & 15.1” DISASSEMBLY (SHOWN)

This LCD is mounted in a frame, which in turn attaches to the rear panel of the module.

1. Remove the 7 rubber caps (A~G) and frame screws under them.

2 Snap off the LCD frame (H). As you do this, make sure the cover latches (I & J) doesn’t spring out. There are

snaps on all sides.

3. Disconnect the panel from the inverter board (K).

4. Remove the frame and hinge anchor screws (L ~Q) and lift the LCD panel (R) and frame away from the rear

panel (S).

6. Remove the frame screws (T~U)

3 – 10

REMOVING THE INVERTER BOARD

The inverter board is anchored to the rear panel of the LCD module with two screws. If you need to remove it for

testing or replacement, make sur e the system is disconnected from all po wer sour ces (including batteries). You should

disconnect all leads from the inverter befor e removing it from the LCD module. The inv erter board itself is housed in

protective mylar. This package is itself may be glued together, so separate it carefully to avoid tearing.

LCD module

Page 38

C

B

A

D

G

H

I

J

F

E

3

K

R

T

L

P

N

S

U

SEPARATING THE LCD & FRAME

FIG. 3 – 5

Q

!!

!

!!

O

This procedure involves:

screws 17

connectors: 2

Tip

15.1”

M

LCD module

3 – 11

Page 39

3

Disassembly

GENERAL DISASSEMBLY: TOP COVER ASSEMBLY

The Top Cover Assembly contains the TouchPad and daughterboards for the Status Panel LEDs and the Power

Switch. However other components are only accessible after the Top Cover Assembly is removed.

Remove the keyboard, status panel, heat plate and LCD module as described on pages 3-5 and 3-9.

SEPARATING THE TOP COVER ASSEMBLY

1. If you haven’t already done so, remove the battery and DVD/CD-ROM, or spacer module.

2. Remove the heat plate (A) and CPU fan (B) assembly (disconnect the fan at CN6).

3. Remove the LCD module (refer to pages 3-8 and 3-9).

4. Turn the notebook body upside-down.

For model 2850, remove 11 screws (C~M).

For models 2800 & 2820, remove 13 screws (C~O).

5. Remove the 2 screws on the rear panel (the lower outer corner screws 2800 & 2820 versions only).

6. Return the notebook to its upright position and disconnect the TouchPad to mainboard connector at

CN18 (P).

3 – 12

top cover & TouchPad

Page 40

A

TOP COVER D ISASSEMBLY

(BOTTOM SCREWS)

B

O

FIG. 3 – 6

D

E

M

C

F

G

L

K

J

I

P

H

N

This procedure involves:

screws 11 (2850)

or 13 (2800 & 2820)

This procedure involves:

connector(s) 1

!!

!

!!

Tip

TOP COVER D ISASSEMBLY

(TOP SCREWS)

FIG. 3 – 7

!!

!

!!

Tip

3

3 – 13top cover & TouchPad

Page 41

3

Disassembly

GENERAL DISASSEMBLY: TOP COVER COMPONENTS

The 2 TouchPad daughterboards in this assembly are unlikely to require any service.

TOUCHPAD

The TouchPad module is in 2 parts: the TouchPad itself and the “mouse” buttons.

To tak e them out of the top co v er assembly, first separate the top cov er assembly as described on pages 3-12 and 3-13.

1. Remove the 8 screws anchoring the TouchPad assembly (A~H)

2. Lift the TouchPad assembly away from the top cover.

3. To remove the TouchPad itself, remove the tape anchoring the ribbon connector, then release the connector

on the electronic component-side of the TouchPad (the connector’s collar flips up). (I)

4. The “mouse” button PC board is anchored to the assembly by two screws (J & K).

3 – 14

top cover assembly

Page 42

I

TOP COVER ASSEMBLY

A - H

J

FIG. 3 – 8

!!

!

K

The TouchPad module has:

screws 10

connectors 1

!!

Tip

3

3 – 15top cover assembly

Page 43

3

Disassembly

GENERAL DISASSEMBLY: BOTTOM COVER ASSEMBLY

The Bottom cover assembly includes the mainboar d, HDD module, FDD module, power board, PCMCIA socket, and

optional fax/modem module (not shown).

HDD MODULE

The HDD module (A) is held in place with two screws.

1. Remove the HDD module anchor screws (B & C).

2. Lift the HDD module away from the mainboard, disconnecting from pressure connector CN19 (D).

Note: The mylar insulation between the bottom of the module and the mainboard should remain attached to

the mainboard- there there are no serviceable components under it.

FDD MODULE

The FDD module (E) is held in place with two screws.

1. Remove the FDD module anchor screws (F & G). (front right & left rear)

2. Release the locking collar on the FDD’s ribbon connector, CN21 (H).

3. Lift the FDD module away from the mainboard.

Note: The mylar insulation between the bottom of the module and the mainboard should remain attached to

the mainboard- there there are no serviceable components under it.

4. If you are replacing the FDD, you should also r emov e the module’s side brackets (I & J), which ar e secured with

2 screws each.

3 – 16

MAINBOARD & FRAME (NOT SHOWN)

The mainboard & frame assembly also includes the DC/DC board. To remove them from the bottom cover,

1. Disconnect the onboard microphone at CN22 and the backup battery at CN23.

2. Remove 4 screws (left-rear corner, near battery terminal, behind PS/2 connector, and near drive-bay latch)

and the two stantion posts near the CPU.

3. Lift the mainboard & frame assembly up and away from the bottom cover.

To separate the mainboard, DC/DC board and frame, You only need to remove the hex nuts around the rear ports.

Then separate the mainboard and DC/DC board.

bottom cover

Page 44

""

"

""

B

D

''

'

''

C

""

"

""

G

A

E

H

F

3

BOTTOM COVER ASSEMBLY

FIG. 3 – 9

!!

!

!!

I

J

Separating the mainboard

from the bottom cover includes:

screws 3

connectors 2

Tip

bottom cover

3 – 17

Page 45

3

Disassembly

((

(

((

HDD

Jumper Warning

Some (usually older) HDDs

have a small jumper

switch. It must be set to

“master” or the system

may not correctly recognize the drive. Check your

drive’s documentation.

HDD MODULE ASSEMBLY

When you’re ready to install a new hard disk,

TAKING IT APART

After you’ve removed the HDD module,

1. Remove the four (4) bracket screws (A~D), and set them aside.

2. Remove screws E &F and carefully pull off the HDD adapter board (G).

3. Gently tilt the HDD up and pull it out of the frame.

A

3

##

#

##

B

HDD MODULE ASSEMBLY

FIG. 3 – 10

Note: This operation is conducted

with the electronics side face down.

3 – 18

HDD

))

)

))

C

D

3

G

E

2

**

*

**

F

Page 46

SETTING UP A NEW HDD FOR THE FIRST TIME

Before you can use a new HDD for the first time, you have to do two things:

• tell the computer about the HDD (refer to the User’s Manual Chapter 3: Firmware).

• prepare the HDD to accept data (refer to your operating system manual).

Use the following directions to prepare the new HDD for use.

HARDWARE

After you replace or upgrade the HDD, turn the system on and configure it for the newly-installed HDD

using Setup. R efer to the User’s Manual Chapter 3: Firmware.

528MB OR LARGER HDDS & LBA MODE

The notebook automatically assumes any HDD 528MB

or larger uses LBA Mode. If the HDD was formatted on

an older system which did not use LBA mode, use the

Setup utility to manually adjust the LBA setting for the

Primary Master. If you don’t, the system will not “see”

it correctly.

The default, “Auto” type setting uses LBA mode. Use

this if you’re preparing a “fresh” HDD.

SOFTWARE

A hard disk must be partitioned, and formatted before

use.

PARTITIONING

To partition the HDD, use the utility from your operating system (e.g. Microsoft’s fdisk command) to do this.

Note: If you want to use the Save to Disk Partition fea-

ture, refer to the User’s Manual’s Chapter 4: Power before you partition the HDD.

FORMATTING

To format, use the utility from your operating system

(e.g. Microsoft’s format/s command). Consult your operating system’s manual for more information on its partitioning and formatting utilities.

((

(

((

Save to Disk

Warning

Whenever you install a different hard disk that has

a Save to Disk partition on

it, make sure you follow

the procedures detailed in

the User’s Manual Chapter 3: Firmware and Chapter 4: Power.

3

HDD

3 – 19

Page 47

Disassembly

SWITCHES & CONNECTORS

These figures show the locations of the principal

switches and connectors.

SWITCHES & CONNECTORS

FIG. 3 – 11

Mainboard (top view)

1. CN1 LAN port

2. CN2 Fax/Modem port

3. CN3 VGA port

4. CN5 to Fax/Modem card

3

5. CN7 to CPU fan

6. CN12 to #35 (Status Panel)

7. CN11 to LCD panel

8. CN6 to #38 (Inverter)

9. CN8 to #33 (Status)

10. CN9 to #27 (DC/DC)

11. CN13 to CD/DVD-ROM

12. IrDA port

13. CN14 USB port

14. CN17 USB port

15. CN19 to HDD

16. CN18 to TouchPad

17. CPU socket

18. CN15 to Fax/Modem card

19. CN16 to keyboard

20. CN20 to main battery

21. CN21 to FDD

22. CN 22 to on-board mic

23. CN 23 to CMOS battery

24. CN24 line-in

25. CN25 microphone

26. CN26 phones

12

13

14

1

2

4

5

6

15

3

MAINBOARD (TOP)

8

7

17

16

21

22

23

18

9

19

20

10

11

28

27

DC/DC BOARD

29 30

31

(TOP)

3 – 20

24 25 26

switches & connectors

Page 48

37

31

34

30

33

STATUS PANEL (BOTTOM)

33

STATUS BOARD

(TOP)

DC/DC BOARD

(BOTTOM)

29

28

35

MAINBOARD (BOTTOM)

36

27

10C

SWITCHES & CONNECTORS

(CONT.)

FIG. 3 – 12

3

11

20

41

2

1

40

12

13

14

DC/DC Board

27. CN4 to #6 (Mainboard)

28. Parallel port

29. Serial 1 (COM1) port

30. PS/2 port

31. DC-in 19V

32. SW1 system power switch

Status Panel

33. CN2 to #9 (Mainboard)

34. Left speaker to

#6 (Mainboard)

35. CN3 to Close-cover switch

36. Close-cover switch

37. CN1 to Right speaker

Inverter Board

38. CN2 to #8 (Mainboard)

39. CN1 to LCD power

Mainboard (bottom)

40. CN27 PC Card

41. CN28 RAM slot “0”

42. CN29 RAM slot “1”

3

38

INVERTER BOARD (BOTTOM)

39

26

42

2425

switches & connectors

3 – 21

Page 49

3

Disassembly

NOTES:

3 – 22

notes

Page 50

4 Troubleshooting

1

2

3

4

4

6

If you are having trouble diagnosing and solving problems, this chapter has several tools which should help:

• Troubleshooting chart – a system flow chart indicating the location of possible system abnormalities.

• Pre-POST assistant – a rundown of possible problems before the POST and solutions.

• POST assistant – a listing of beeps and error messages and their definitions.

• Post-POST assistant – a rundown of possible problems after the POST and solutions.

This chapter does not tell you how to disassemble the notebook. For those procedures, go back to Chapter 3:

Disassembly.

7

8

4 – 1

Page 51

1

2

3

4

4

6

Troubleshooting

BEFORE YOU BEGIN

Before you start a troubleshooting job, be sure that:

• All peripheral devices are disconnected from the notebook. (They should be tested separately.)

• You have reviewed the safety precautions in the beginning of Chapter 3: Disassembly.

TOOLS

In addition to the tools listed in Chapter 3, troubleshooting jobs may call for some additional devices:

• Multimeter

• Transistor checker

• Oscilloscope (100 MHz)

• Soldering/de-soldering station (30W)

7

8

4 – 2

precautions & tools

Page 52

SYSTEM TROUBLESHOOTING CHART

Use the following troubleshooting flow chart to locate the problem areas systematically.

TROUBLESHOOTING FLOWCHART

FIG. 4 – 1

1

2

3

4

4

6

7

flow-chart

8

4 – 3

Page 53

1

3. The LCD screen has malfunctioned.

2

Troubleshooting

PRE-POST ASSISTANT

This section describes possible problems before the Power-On-Self-Test (POST) and ways to solve them.

Possible Problems Possible Causes

AC power LED fails The AC/DC adapter has malfunctioned.

3

4

4

6

7

8

TABLE 4 – 1

RE-POST PROBLEMS

P

AC power & charge LEDs fail

LCD screen fails to display

1. The DC/DC board has failed.

2. The battery pack has malfunctioned or its

connection to the DC/DC board is bad.

3. There is a short circuit in the mainboard.