Page 1

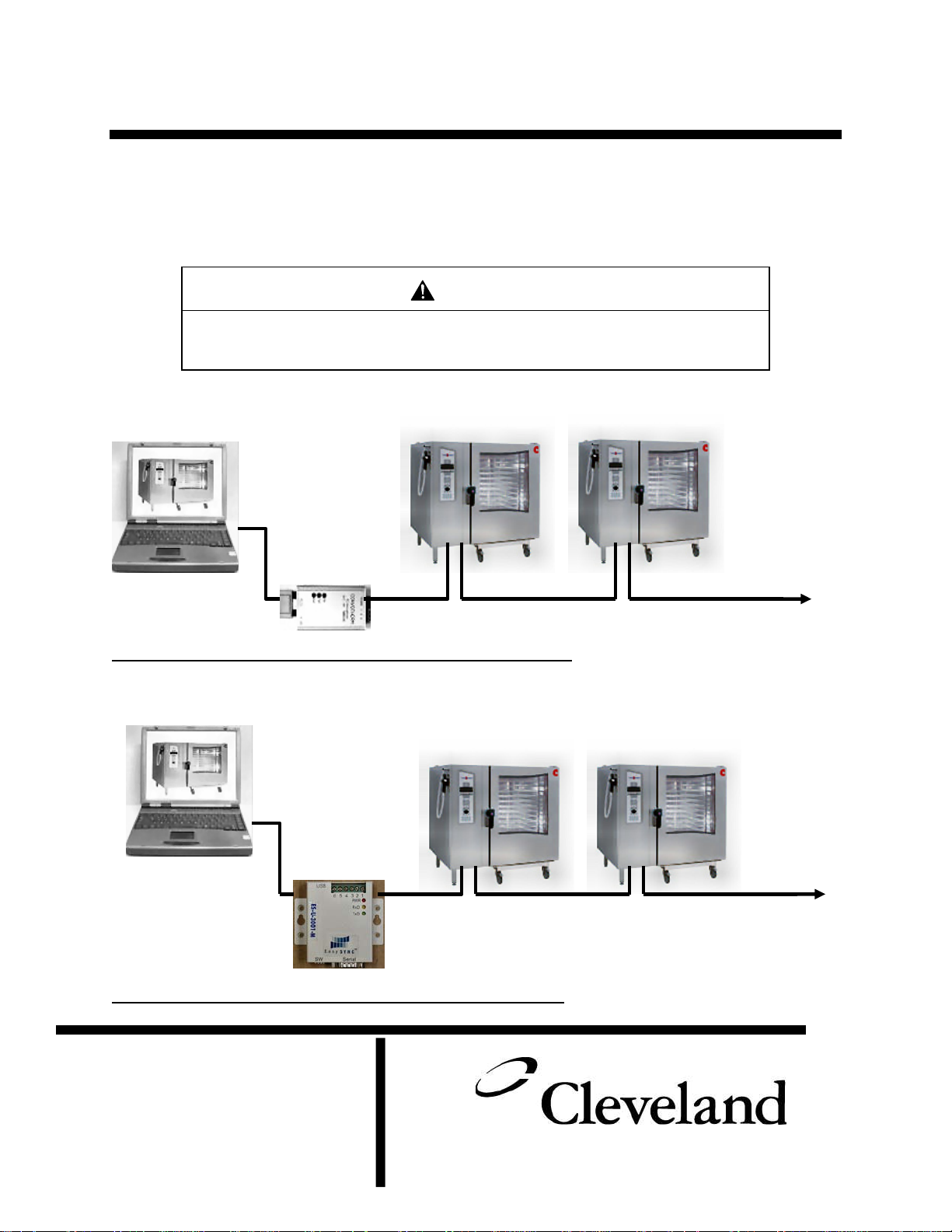

PC-Control / HACCP Network Installation

For Convotherm by Cleveland Combination Oven Steamers

This kit connects a PC to as many as 31 Combis at a maximum distance of 3280 Feet (1000 meters). The

software can download cooking programs, record HACCP information, and monitor the networked

Combis in real-time. This installation manual includes instructions for both RS232 and USB connections

for a PC. Choose the connection that works best for your application and follow the instructions that

apply. If any parts are missing from any kits, please contact Cleveland Range Service at 216-481-4900.

CAUTION

Turn off all power to Combis before installation of PC-HACCP Network.

Follow all Safety and Operating Instructions

Failure to do so can result in injury, and equipment and property damage.

RS232 Correct connection of a PC to Combis using the Communication Module with RS232 Port.

FOR RS232 connection use part number: CPC-HACCP-MU232

Correct connection of a PC to Combis using th e Communication Module with USB Port.

FOR USB connection use part number: CPC-HACCP-MUUSB

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481-4900

Fax: (216) 481 3782

www.clevelandrange.com

260AZH REV. B 3/06

Page 2

CAUTION

Read and understand this manual before using this PC-HACCP Kit.

NOTICE: In addition to the kit, the following wire is required for installation between each oven:

• For standard voltage units: 18/ 2 CPM/CL3P audio wire – e.g.: McMaster-Carr P/N- 71055K76.

• For 480 volt units use 18/2 UL AWM 2501 communication wire – e.g.: Allied Electronics

USB TO RS 232/485 ADAPTER 300555 included only with kit number CPC-HACCP-MUUSB

Failure to do so can result in injury, and equipment and property damage.

P/N – 708-1301. (Can be used with all voltage ovens.)

2

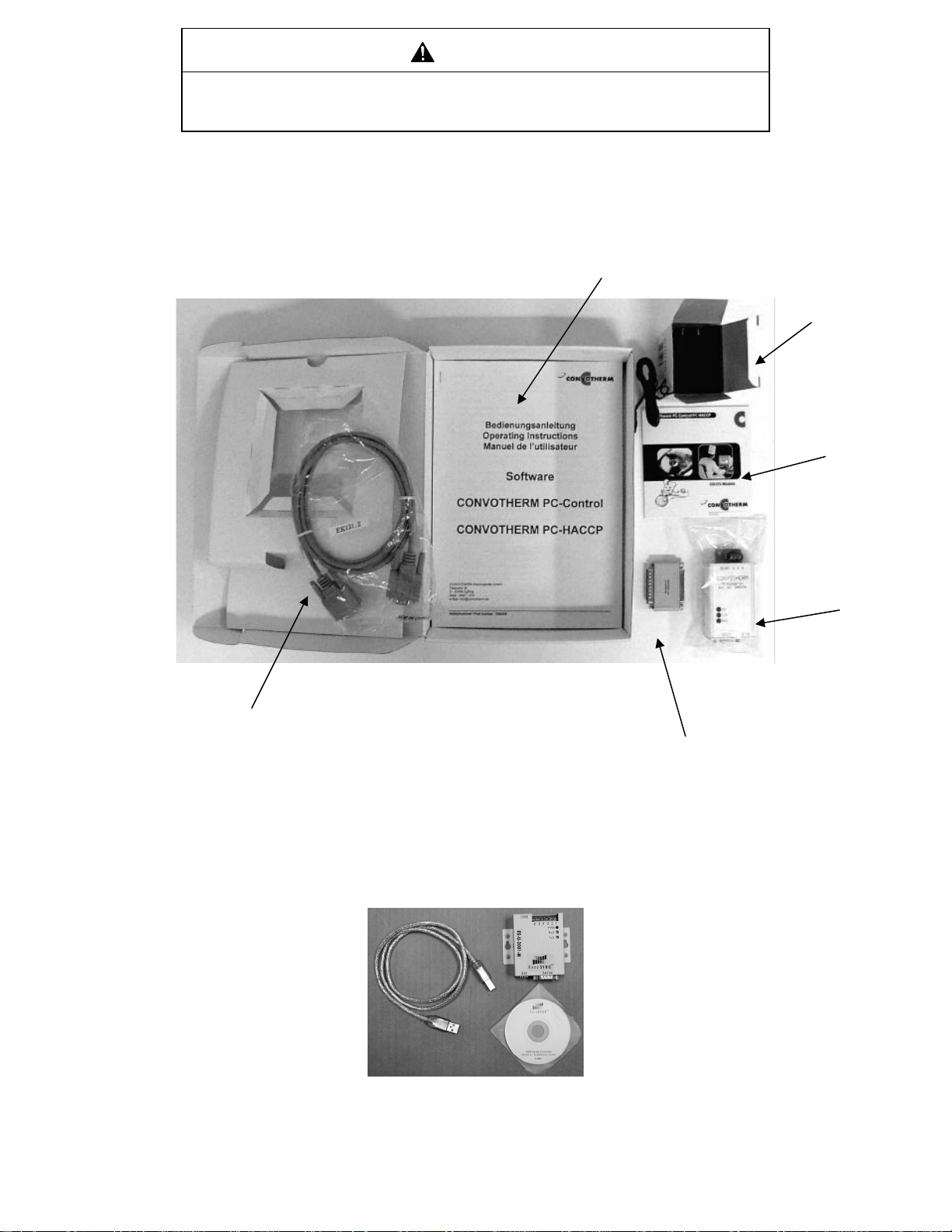

1 Software-CD - 300550

2 Network Connection Cable – 300551

3 Dongle - C5009210

4 PC Interface Converter - C5009156

5 9 Volt Power Supply for Converter – 300548

6 Operating Instructions – 260AZV

USB Cable

Follow all Safety and Operating Instructions

PC–HACCP KIT CONTENTS

Photo 1

(included only w/ 232 kit)

(included only w/ 232 kit)

Photo 2

6

(included only w/ 232 kit)

USB Adapter

See Page 20 for

Installation Instructions

3

Software-CD

5

1

4

2

Page 3

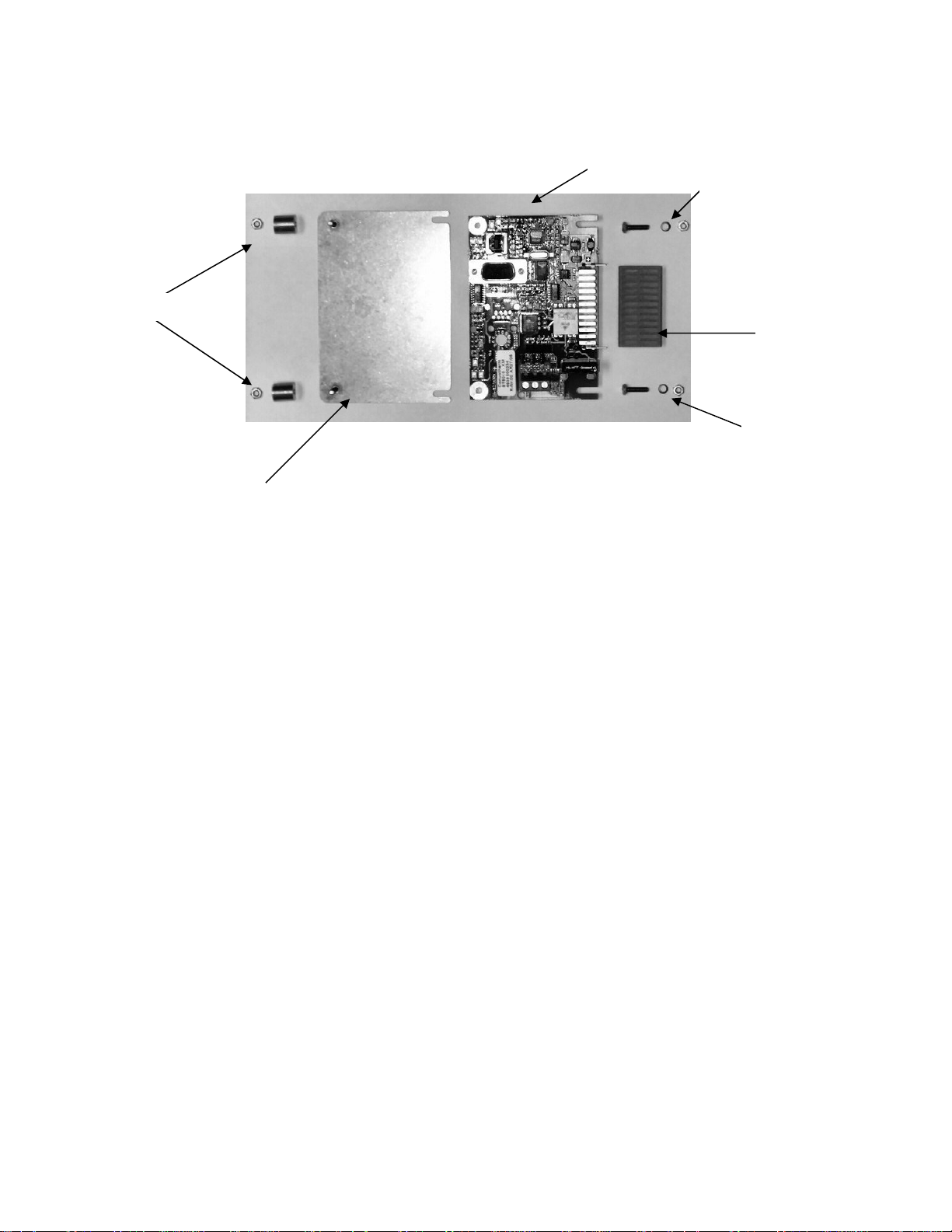

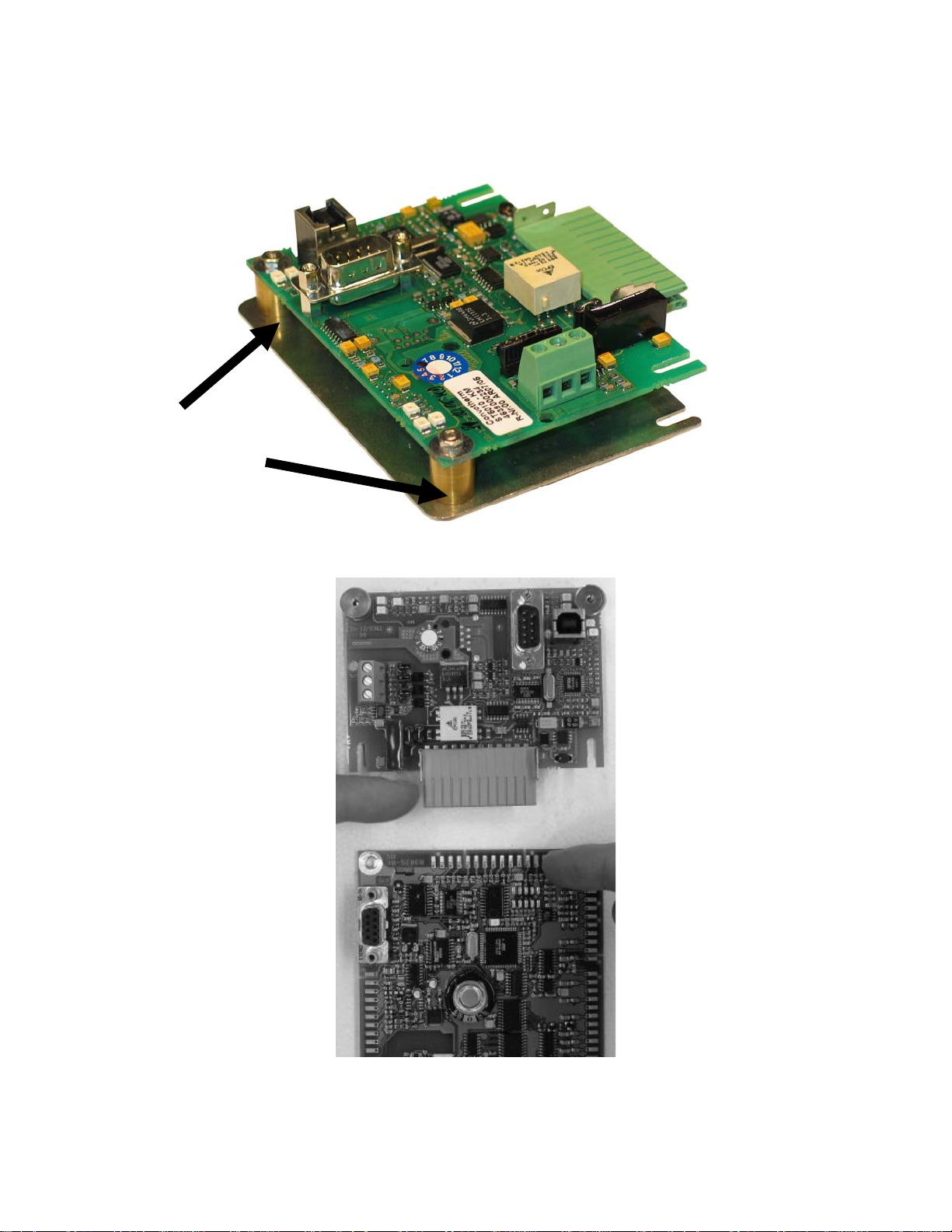

4,7

RS485 Communication Module p/n C-RS485

1

5, 6, 7

2

5, 6, 7

PHOTO 3

3

1 Electronic Board (1) – C5019104

2 Connector (1) – C5002091

3 Bracket with Studs (1) – C2114799

4 Control Panel Spacers (2) – C8009030

5 Screws – M3 (2) - 111633

6 Lock Washers (2) – C8016001

7 Hexagon Nuts – M3 (4) – C8004012

3

Page 4

TO CONNECT THE RS232 CONVERTER TO THE PC

Photos 4, 5, and 6 show the correct cable connections from the PC to the PC Converter

for RS232. Note the position of the Dongle on the PC in Photo 5. Make sure the PC

Converter is connected to the 9-volt DC power supply as shown in Photo 7.

Photo 4

Photo 5

Photo 6

Photo 7

4

Page 5

RS232 CABLE CONNECTION FOR CONVERTER TO RS485 ONLY

Photo 8 shows the cable connections for the PC Converter.

The PC Converter wiring is connected to the FIRST Combi in the Chain.

Photo 8

A: RED WIRE

B: BLACK WIRE

GROUND: GROUND OR SHIELD WIRE

NOTE:

5

Page 6

TO CONNECT USB CONVERTER TO RS485 ONLY

IMPORTANT

ALWAYS USE THE SAME USB PORT WHEN REATTACHING THE USB CABLE TO THE PC!

:

See Page 20 for instructions for USB hardware and software installation and setup.

The USB software must be installed on the PC before using the USB adapter.

Photos 9, 10, and 11 shows the correct USB cable connections from the PC to the

Converter in Photo 12.

Note the position of the Dongle on the PC in Photo 11.

Photo 9

Photo 10

Photo 11

Photo 12

6

PHOTO 12 SHOWS WIRE

CONNECTIONS PIN 1, PIN 2,

AND GROUND (PIN 6).

Page 7

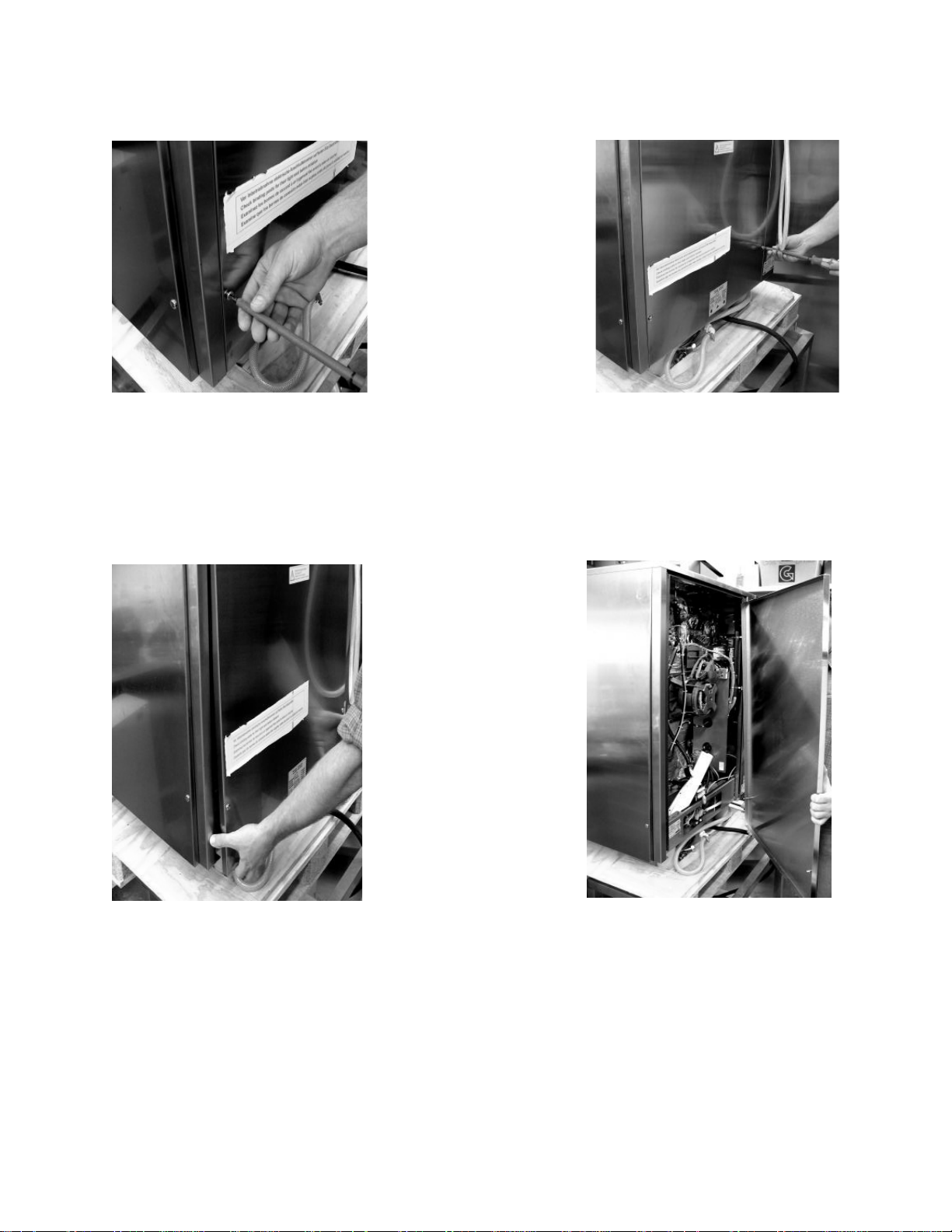

Remove the Control Side Cover

Photo 13

Photo 14

Turn the 1/4 turn quick-locks to loosen.

Photo 15

Photo 16

From the bottom edge of the side panel, push up and pull out.

Remove the side panel and set it aside.

7

Page 8

Remove the Control Panel

Photo 17

Press down and turn counterclockwise to remove the Operation Panel retention screw.

Photo 18

Remove the Operation Panel out from the rear. Be careful not to drop it.

Disconnect the computer cable from the Operation Panel and set the panel aside.

Photo 19

Remove the Control Panel and place it on a work surface as shown.

8

Page 9

Attaching the Base Plate to the Communication Module

1. Mount the board to the panel using the spacers, nuts and washers included in the kit.

Photo 20

Photo 21

Press the Communication Module Interface onto the Control Module.

Tighten the screws holding the Communication Module to the Control Module.

9

Page 10

Attaching the Base Plate to the Communication Module

Mount the board to the panel using the spacers and nuts included in the kit.

Photo 22 Photo 23

Photo 24

Complete Assembly of Communication Module Interface and Control Module.

10

Page 11

Inserting the Communication Module Cable into the Oven

Photo 30

Remove the sanitary seal plug from the underside of the Combi.

Photo 31

Insert the new bushing, P/N 111751 into the opening.

Pull the Communication Module cable through the Bushing.

Pull enough wire through the bottom of the oven to allow ample movement while

attaching the wires to the network boards.

11

Page 12

Connect the Network Cable to the Communication Module

Take care to match the wire ends or colors to the connections throughout the network to

avoid miswiring.

For RS232 Converter: Attach the wire to the Converter at connection “A” and attach the

other end to connection “A” on the Communication Module. Attach the wire to the

Converter at connection “B” and attach the other end to connection “B” on the

Communication Module. Connect drain/shield as ground

For USB: Attach the network wire to connection 2 on the Converter and attach the other

end to connection “A” on the Communication Module. Attach the network wire to

connection 1 on the Converter and attach the other end to connection “B” on the

Communication Module. Connect drain/shield as ground

The network module in the first oven and all others in the network but the last all has

identical wiring

A

B Ground

Photo 25

Connection in the

FIRST and all but the

last Combis in the

Network.

“A” to “A”

“B” to “B”

12

Page 13

Setting the Jumpers on the Communication Module

Photo 27

Jumper setting for the first Combi and all Combis in the Network.

To set the jumpers: gently pull them from the board and install them as shown.

Photo 28

Wire Connection and jumpers positions for last communication module in the Network.

Photo 29

Wires Connected to Communication Module Interface and Control Module Assembly.

13

Page 14

Photo 33

Secure cable to the upper right spacer as shown in Photo 36.

Photo 35

Place Control Board and Module back into the Combi.

Use wire ties to secure cable away from high voltage, sharp corners and edges, and

moving parts.

Make sure the Control Board can still be removed from the Combi once the Network

Board and cables are attached.

14

Page 15

Replace the Operation Panel

Photo 36

Remount the Operation Panel back into the Combi.

Photo 37

Press down and turn clockwise to tighten the Operation Panel retention screw.

15

Page 16

Replace the Control Side Panel

Photo 38 Photo 39

Push up and in from the bottom edge of the side panel.

Photo 40 Photo 41

Turn the 1/4 turn quick-locks to tighten.

See the PC-HACCP Instructions to use the PC-HACCP Network.

16

Page 17

Directions for Installing the USB Adapter

1. Plug the USB connector into the adapter and connect to one of the USB ports on

the back of your computer.

2. Install the USB drivers onto your computer using the CD provided in the kit.

3. Follow the instructions that are on the CD to configure the COM ports so the

computer can recognize the USB adapter.(See configuration pages for data

speeds and other settings)

4. Configure the USB for COM 2-4 only. The PC-HACCP will only recognize those

COM ports.

5. Record which COM port the USB is connected to and always plug the adapter

into that port when using the PC-HACCP controls.

Select “No not at this time.”

17

Page 18

Select install from a list of specific location (advanced)

Ignore this screen if it appears:

18

Page 19

Uncheck “Include this location in the search.”

Click Next. Let search

19

Page 20

The Hardware wizard will appear a second time:

20

Page 21

Follow the directions in each screen.

21

Page 22

Allow search for CD

22

Page 23

Click Finish to close the screen.

Configure your serial device:

1. Right click My Computer, select properties:

Then select the “Hardware tab” and click on the “Device Manager” button.

23

Page 24

Expand the Ports (COM & LPT) device

24

Page 25

Right click on the “USB Serial Port (COM??)” item.

The ?? will be a number greater than 0 and less than 255.

Select the Port Settings tab.

25

Page 26

Note the COM setting. Only COM1, COM2, COM3, and COM4 can be used by the

HACCP software. To change the COM number, click the Advanced button.

26

Page 27

If needed click the COM Port Number: drop menu and select and acceptable port

number. If all are marked as (in use) then change one of the other serial devices to a

COM port number higher than 4. Click OK.

27

Page 28

6. Once the computer recognizes the USB adapter, the dip switches in the adapter

have to be set up for RS485 or RS232 data transfer; chose the correct setting to

match the configuration you are using.

For USB to RS232

Switches 2, 3, 4 are ON

For USB to RS485

Switches 1 and 4 are ON

28

Page 29

SHOWS WIRE CONNECTIONS PIN 1, PIN 2, AND GROUND (PIN 6).

7. For the adapter to output data for RS485, a jumper inside the metal case must be

positioned correctly. This photo shows the position of the #1 jumper. All other

jumpers should be in the original position.

Place

connect

jumper #1

Jumper #1 Position

8. Place the metal cover back on the adapter and secure the screws.

9. The adapter is now ready for use with the PC-HACCP.

29

Page 30

This Page for Internal Record Only, Not for Printing

Cleveland Range, LLC

1333 East 179th St, Cleveland, Ohio 44110

Drawing No. 260AZH

Revision Index Page

REV

A 260AZH Production Release Per EO # C-6947 12-12-05 ERB

B Added new part number for HACCP instruction PER EO # C-7022 04-16-06 ERB

REVISION HISTORY

DATE BY

116 March 2006

Rev Page

260AZH REV. B

Loading...

Loading...