Cleveland Range SD-1600-K 12 12, SD-1600-K2020, SD-1050-K 6 6, SD-1600-K 620, SD-1200-K 612 User Manual

...Page 1

SE95008 Rev. 6

Operators Manual

Installation, Operation & Service

Direct Steam Table Top Kettles

Table-Top Direct

Steam Kettles

MODELS: KDT- 1- T

KDT- 3- T

KDT- 6- T

KDT-12- T

KDT-20- T

SD Stands

MODELS: SD- 450

SD- 650

SD- 760

SD-1050

SD-1200

SD-1600

SD-1800

Kettles on

SD Stands

MODELS: SD-450 - K 6

SD-650 - K12

SD-760 - K12

SD-760 - K20

SD-1050- K 6 6

SD-1200- K 6 12

SD-1600- K 6 20

SD-1600- K 12 12

SD-1600- K 12 20

SD-1600- K 20 20

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Phone: (216) 481-4900 Fax: (216) 481-3782

Visit our web site at www.clevelandrange.com

d

Enodis

™

Clev elan

Page 2

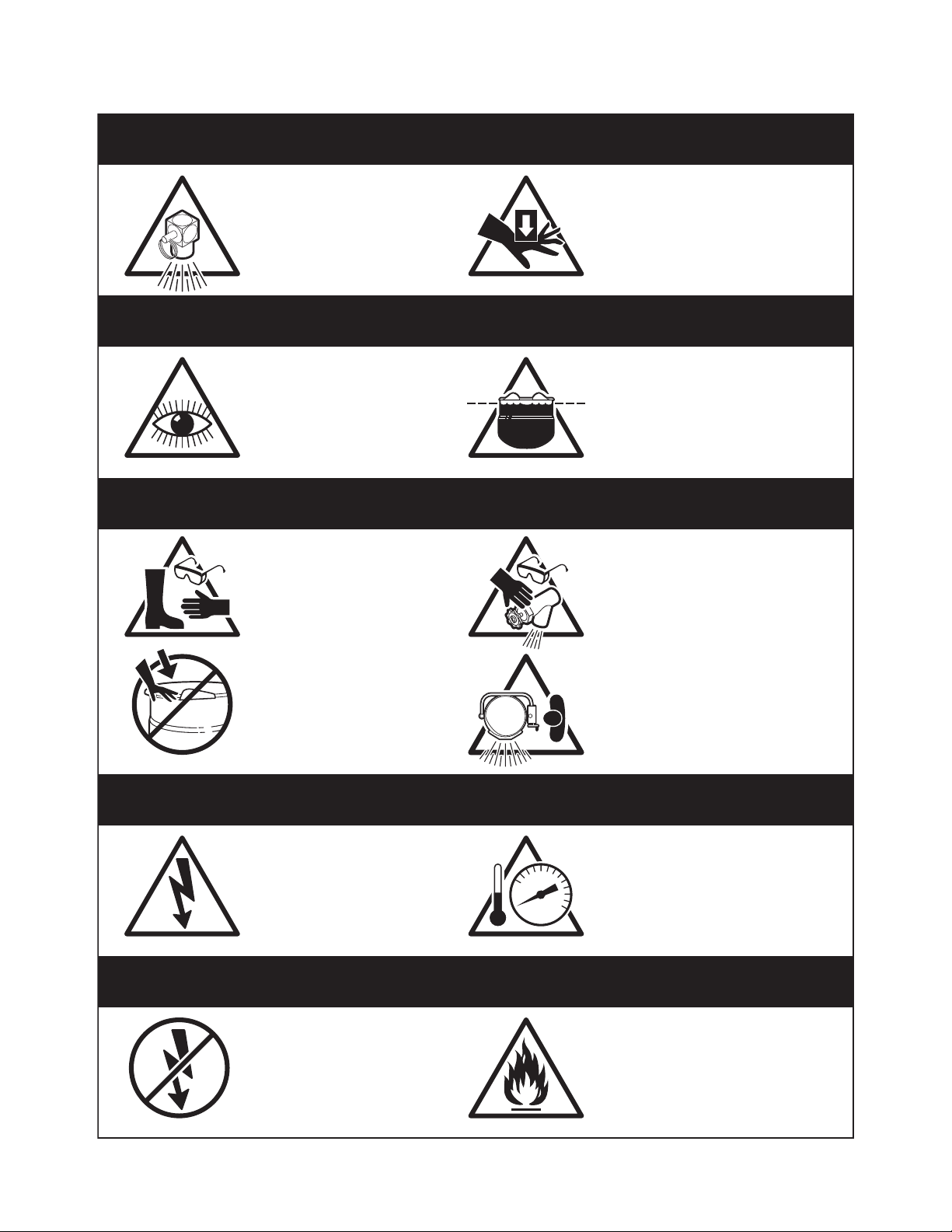

For your safety

DANGER

Keep clear of pressure

relief discharge.

IMPORTANT

Inspect unit daily for

proper operation.

CAUTION

Surfaces may be

extremely hot! Use

protective equipment.

Keep hands away from

moving parts and pinch points.

Do not fill kettle above

recommended level

marked on outside of kettle.

Wear protective equipment

when discharging hot product.

Do not lean on or place

objects on kettle lip.

SERVICING

Shut off power at main

fuse disconnect prior

to servicing.

GAS APPLIANCES

Do not attempt to operate

this appliance during a

power failure.

Stand clear of product

discharge path when

discharging hot product.

Ensure kettle is at room

0

temperature and pressure

gauge is showing zero or less

prior to removing any fittings.

Keep appliance and area free

and clear of combustibles.

Page 3

GENERAL

Installation of the unit must be accomplished by

qualified installation personnel working to all

applicable local and national codes. Improper

installation of product could cause injury or damage.

This unit is built to comply with applicable

standards for manufacturers. Included among

those approval agencies are: UL, NSF,

ASME/Ntl.Bd., CSA, ETL, CE, and others. Many

local codes exist, and it is the responsibility of the

owner/installer to comply with these codes.

INSPECTION

Before uncrating, visually inspect the unit for

evidence of damage during shipping. If damage

is noticed, do not unpack the unit, follow shipping

damage instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or the

reason for suspecting damage as soon as it is

discovered. This will help in filling out the claim

forms later. If possible, take a polaroid picture.

2. As soon as damage is discovered or suspected,

notify the carrier that delivered the shipment.

3. Arrange for the carrier's representative to

examine the damage.

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

CLEARANCE REQUIREMENTS

The first installation step is to refer to the

SPECIFICATION DRAWINGS at the back of this manual

in order to determine the exact location of the kettle.

CLEARANCE REQUIREMENTS TO

COMBUSTIBLE AND NONCOMBUSTIBLE

SURFACES:

RIGHT LEFT BACK

KDT-1-T 4" 0" 0"

KDT-3-T & KDT-6-T 4" 4" 1"

KDT-12-T & KDT-20-T 4" 4" 1.75"

Note: For SD Stands (with or without kettles) zero

clearance is required on the sides and back.

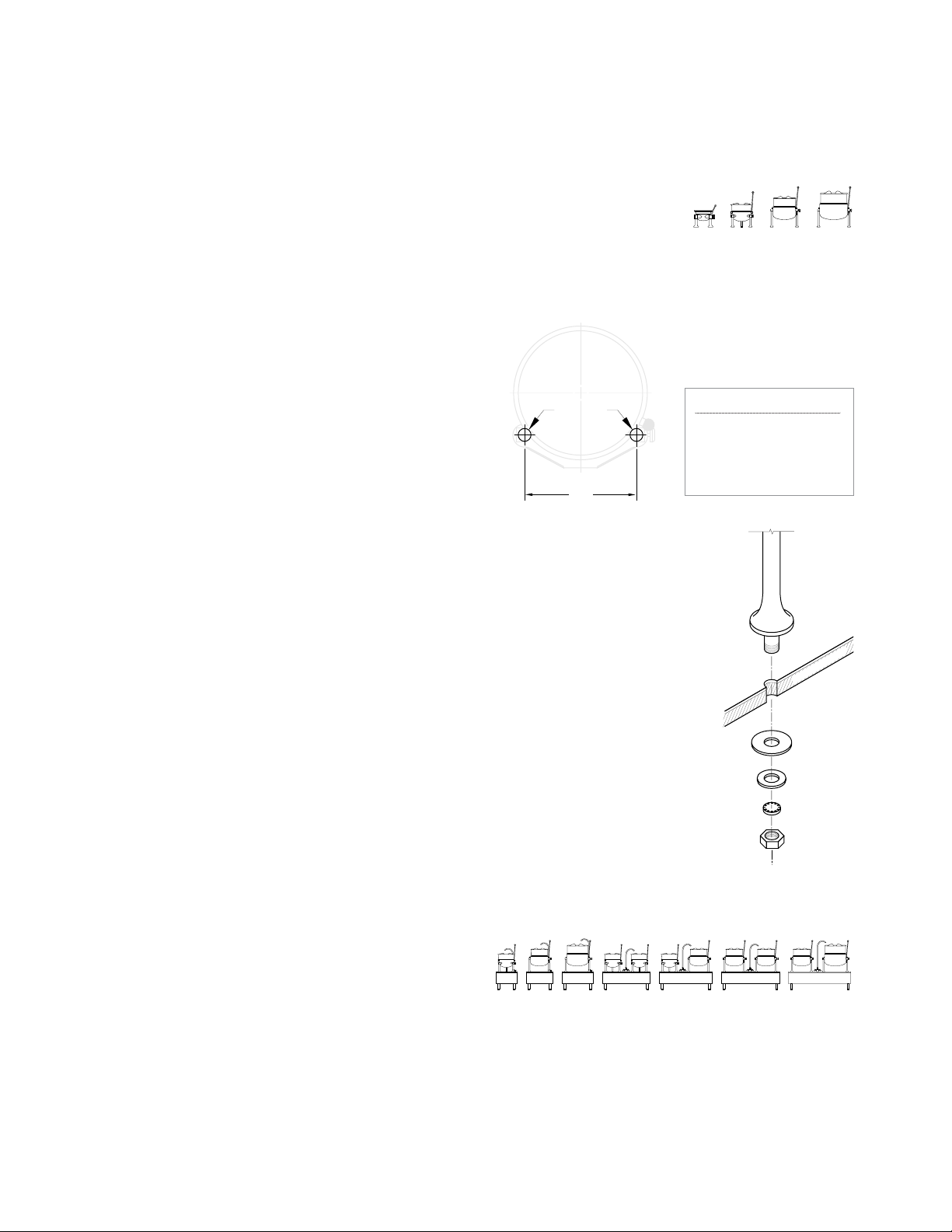

KETTLES

Table-top models must be positioned on a firm stand

or existing counter top and secured in place. An

optional modular cabinet base (SD Stand), with

level-adjustable legs is available .

1. Make two 1" holes for

the kettle legs.

2. Remove the leg mounting

locknuts and washers from

the kettle's legs.

3. Install the legs into the two

1" holes.

4. Position washers as

illustrated and secure

the kettle to its' base by

refastening the locknut

from underneath the

cabinet or countertop.

5. Once the kettle is secure,

screw the tilt handle into

the mounting block welded

to the side of the kettle.

6. Install service requirements

as required.

KETTLES c/w SD STAND

1. Place unit in desired location.

2. Place a carpenter's level on the kettle rim and

level the stand using the level adjustable feet.

3. Install service requirements as required.

INSTALLATION

A

KDT-1-T 8 1/8"

KDT-3-T 10"

KDT-6-T 12"

KDT-12-T 19 1/2"

KDT-20-T 23 3/4"

DRILL TWO

1" HOLES

A

COUNTERTOP

Page 4

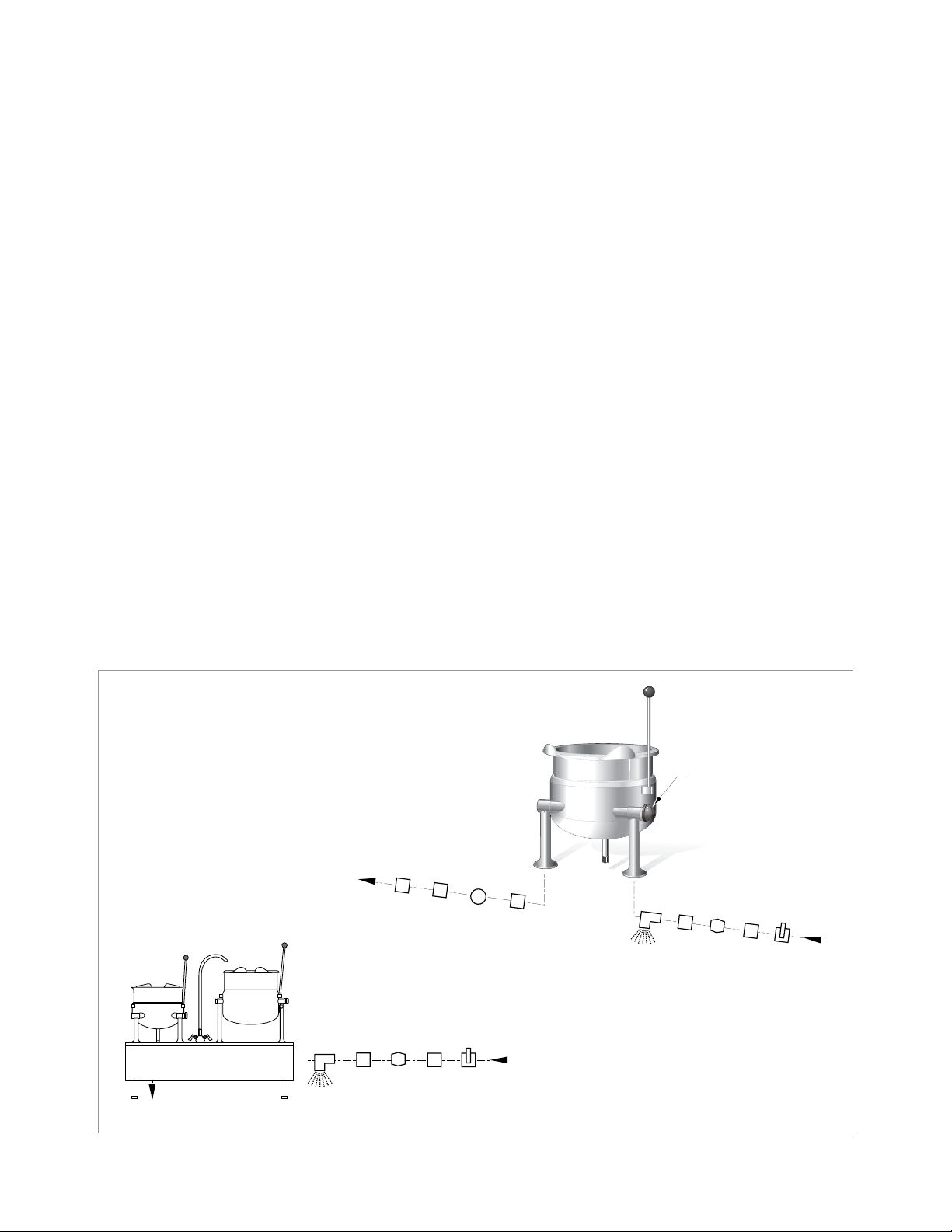

STEAM

All steam plumbing to and from the kettle and

steam boiler should be thoroughly cleaned and

inspected for dirt and debris before final

connection to the kettle are made.

Generally, kettles require 1/2" i.p.s. pipe, 10-45 psi

steam pressure. If the steam supply pressure

exceeds 45 psi, a pressure reducing valve is

required. The steam inlet is at the right side of the

kettle, as n from the front.

A pressure reducing valve is required on the

incoming line as shown below. The relief valve

should have a capacity of 300 lb/hr (136 kg/hr).

CONDENSATE (Kettles without SD Stands)

Maximum pressure rating on table-top kettles is

50psi. It is highly recommended that a pressure relief

valve equal to or less than this pressure be installed

on the incoming steam line close to the kettle.

A steam condensate trap must be plumbed to a drain,

using minimum 1/2" NPT plumbing. The condensate line

is limited to a maximum rise of 10 feet in order for the

steam pressure to adequately force the condensate

through the plumbing. Any higher rise requires a pump.

If the steam boiler to which this kettle is installed has a

condensate return (closed loop system), a 1/2" steam

strainer, a 1/2" steam trap, and a 1/2" check valve must

be installed on the output (condensate) side of the kettle.

CONDENSATE (Kettles c/w SD Stands)

The stand comes factory plumbed so the condensate

is connected to the stands drain manifold.

POTABLE WATER

The water faucet (optional on kettles purchased

without SD stands) with swing spout, requires 1/2

inch O.D. copper tube plumbing for hot or cold water

supplies to the faucet (SPK - cold water connection

only, DPK - hot and cold water connection).

FINAL INSTALLATION CHECK

1. Partially fill the kettle with water.

2. Slowly turn the steam supply valve's knob to

the open position.

3. Release the safety valve, ensuring that the

steam escapes freely. Stay clear of steam

exhaust when releasing the safety valve.

4.

Observe that the water in the kettle comes to a boil.

5. Close the steam supply valve.

6. Drain off the water by tilting the kettle.

KETTLES

RECOMMENDED PIPING

SCHEMATICS

(all service connections shown supplied by others)

KETTLES c/w

SD STANDS

TO DRAIN OR BOILER

CONDENSATE LINE

RELIEF

VALVE

STRAINER

TO DRAIN (CONDENSATE RETURN PLUMBED TO 1 1/2" DRAIN MANIFOLD)

CONDENSATE RETURN

UNION

CHECK

PRESSURE

REDUCING

VALVE

UNION

VALVE

STEAM

TRAP

SHUT OFF

VALVE

STRAINER

STEAM

MANUAL

STEAM

VALVE

STRAINER

RELIEF

VALVE

IN

PRESSURE

REDUCING

VALVE

UNION

STEAM

SHUT OFF

VALVE

IN

Page 5

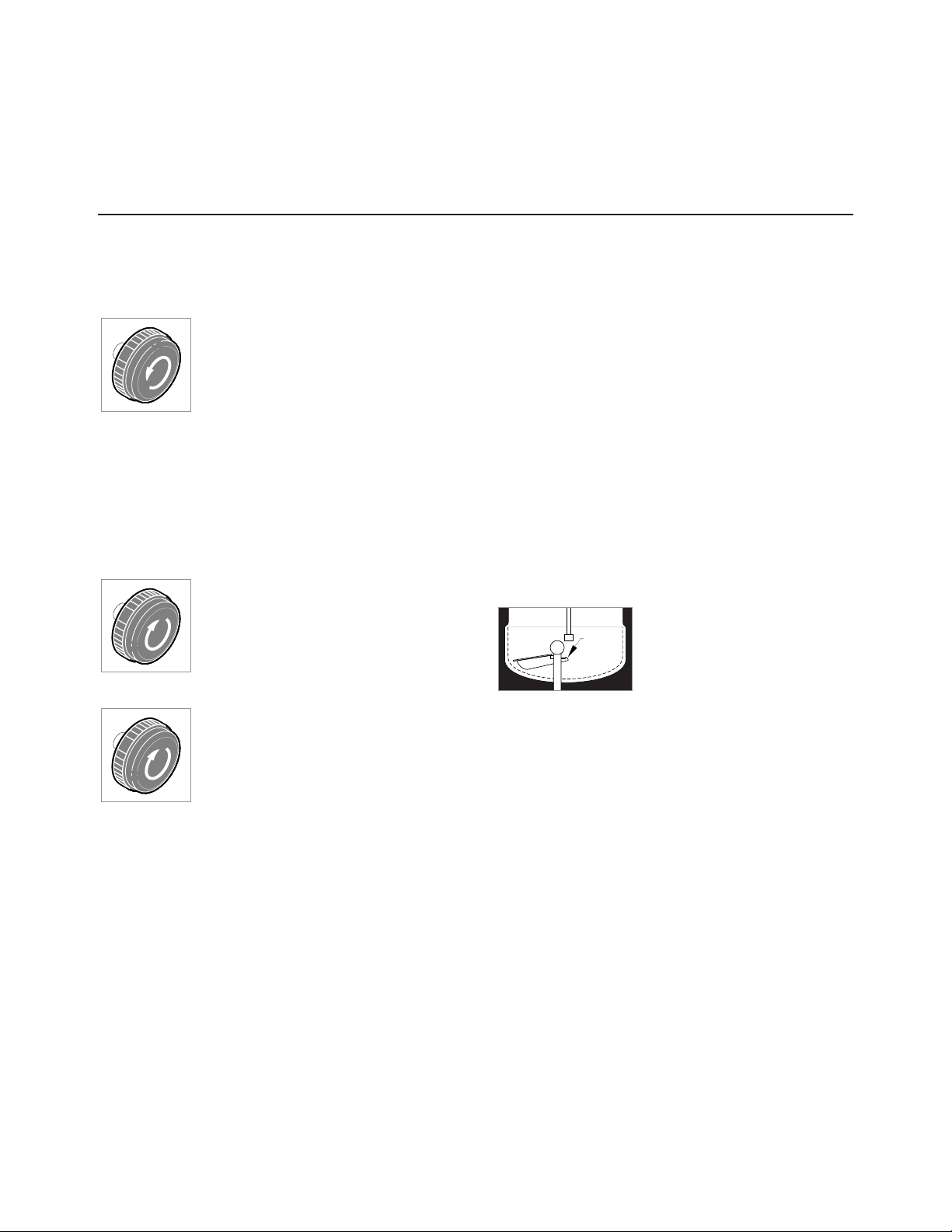

OPERATION

1. Ensure that there is an adequate steam

supply to the kettle.

2. Turn the steam control valve to

the open position by turning the

knob counter-clockwise, then allow

the kettle to preheat.

NOTE: When cooking egg and milk products, the

kettle should NOT be preheated, as products of

this nature adhere to hot cooking surfaces. These

types of foods should be placed in the kettle

before heating is begun.

3. Fill kettle with product to desired level.

4. When the product has reached

the desired temperature, regulate

the heat, as required, by turning

the steam control valve clockwise

for less steam, and therefore, a

lower temperature.

5. When cooking is complete,

close the steam control valve by

turning the knob clockwise.

FOR KETTLE/STEAMER COMBINATIONS:

If the boiler in a steamer is supplying steam to a

kettle, always heat the kettle first. After the kettle

contents are heated, and the boiler's steam

pressure returns to normal, the steamer may be

used. Pressure steamer compartments should be

sequentially started, and preheated before

cooking.

NOTE: As with cleaning food soil from any

cookware, art important part of kettle cleaning is

to prevent food from drying on. For this reason,

cleaning should be completed immediately after

cooked foods are removed. . Please read the

"Care and Cleaning" instructions for detailed kettle

washing procedures

Marine Lock (12 & 20 gal. models only)

If your unit is equipped with

a marine lock to prevent

accidental tilting, it must be

inspected daily to insure it

moves freely and

automatically locks into place when kettle is

returned to upright position.

Use the following procedure to tilt the kettle.

1. Securely grasp the tilt handle.

2. Push the marine lock button down to unlock

tilting mechanism.

3. Pull the handle to tilt the kettle.

4. When you return the kettle to its' original upright

position the marine lock will latch automatically.

OPERATING INSTRUCTIONS

CLEVELAND STEAM COOKING EQUIPMENT IS INTENDED FOR

COMMERCIAL USE ONLY BY PROFESSIONALLY TRAINED PERSONNEL.

MARINE

LOCK

Page 6

CARE AND CLEANING

Cooking equipment must be cleaned regularly to

maintain its fast, efficient cooking performance and

to ensure its continued safe, reliable operation. The

best time to clean is shortly after each use (allow

unit to cool to a safe temperature).

WARNINGS

➩ Do not use detergents or

cleansers that are chloride

based or contain quaternary

salt.

➩ Do not use a metal bristle

brush or scraper.

➩ Steel wool should never be

used for cleaning the stainless

steel.

➩ Unit should never be cleaned

with a high pressure spray

hose.

➩

Do not leave water sitting in unit

when not in use.

CLEANING INSTRUCTIONS

CAUTION

SURFACES MAY

BE EXTREMELY HOT!

CLEANING INSTRUCTIONS

1. Turn unit off.

2. Remove drain screen (if applicable). Thoroughly

wash and rinse the screen either in a sink or a

dishwasher.

3. Prepare a warm water and mild detergent solution in

the unit.

4. Remove food soil using a nylon brush.

5. Loosen food which is stuck by allowing it to soak at

a low temperature setting.

6. Drain unit.

7. Rinse interior thoroughly.

8. If the unit is equipped with a

TTaannggeenntt DDrraaww--OOffff

VVaallvvee

, clean as follows:

a) Disassemble the draw-off valve first by turning

the valve knob counter-clockwise, then turning

the large hex nut counter-clockwise until the

valve stem is free of the valve body.

b) In a sink, wash and rinse the inside of the valve

body using a nylon brush.

c)

Use a nylon brush to clean tangent draw-off tube.

d) Rinse with fresh water.

e) Reassemble the draw-off valve by reversing the

procedure for disassembly. The valve's hex nut

should be hand tight only.

9. If the unit is equipped with a

BBuutttteerrffllyy VVaallvvee

, clean

as follows:

a) Place valve in open position.

b) Wash using a warm water and mild detergent

solution.

c) Remove food deposits using a nylon brush.

d) Rinse with fresh water.

e) Leave valve open when unit is not in use.

10 . Using mild soapy water and a damp sponge, wash

the exterior, rinse, and dry.

NOTES

➩ For more difficult cleaning applications one of the

following can be used: alcohol, baking soda, vinegar,

or a solution of ammonia in water.

➩ Leave the cover off when the kettle is not in use.

➩ For more detailed instructions refer to the Nafem

Stainless Steel Equipment Care and Cleaning manual

(supplied with unit).

Chloride Cleaners

Wire Brush &

Steel Pads

High Pressure

Spray Hose

Stagnant

Water

Page 7

STAINLESS STEEL EQUIPMENT CARE AND CLEANING

(Suppied courtesy of Nafem. For more information visit their web site at www.nafem.org)

Contrary to popular belief, stainless steels ARE susceptible to rusting.

Corrosion on metals is everywhere. It is recognized quickly on iron and

steel as unsightly yellow/orange rust. Such metals are called “active”

because they actively corrode in a natural environment when their atoms

combine with oxygen to form rust.

Stainless steels are passive metals because they contain other metals, like

chromium, nickel and manganese that stabilize the atoms. 400 series

stainless steels are called ferritic, contain chromium, and are magnetic;

300 series stainless steels are called austenitic, contain chromium and

nickel; and 200 series stainless, also austenitic, contains manganese,

nitrogen and carbon. Austenitic types of stainless are not magnetic, and

generally provide greater resistance to corrosion than ferritic types.

With 12-30 percent chromium, an invisible passive film covers the steel’s

surface acting as a shield against corrosion. As long as the film is intact

and not broken or contaminated, the metal is passive and stain-less. If the

passive film of stainless steel has been broken, equipment starts to

corrode. At its end, it rusts.

Enemies of Stainless Steel

There are three basic things which can break down stainless steel’s

passivity layer and allow corrosion to occur.

1. Mechanical abrasion

2. Deposits and water

3. Chlorides

Mechanical abrasion means those things that will scratch a steel surface.

Steel pads, wire brushes and scrapers are prime examples.

Water comes out of the faucet in varying degrees of hardness. Depending

on what part of the country you live in, you may have hard or soft water.

Hard water may leave spots, and when heated leave deposits behind that

if left to sit, will break down the passive layer and rust stainless steel. Other

deposits from food preparation and service must be properly removed.

Chlorides are found nearly everywhere. They are in water, food and table

salt. One of the worst chloride perpetrators can come from household and

industrial cleaners.

So what does all this mean? Don’t Despair!

Here are a few steps that can help prevent stainless steel rust.

1.

Use the pr

oper tools.

When cleaning stainless steel products, use non-abrasive tools. Soft

cloths and plastic scouring pads will not harm steel’s passive layer.

Stainless steel pads also can be used but the scrubbing motion must

be in the direction of the manufacturers’ polishing marks.

2.

Clean with the polish lines.

Some stainless steel comes with visible polishing lines or “grain.”

When visible lines are present, always scrub in a motion parallel to the

lines. When the grain cannot be seen, play it safe and use a soft cloth

or plastic scouring pad.

3.

Use alkaline, alkaline chlorinated or non-chloride containing cleaners.

While many traditional cleaners are loaded with chlorides, the industry

is providing an ever-increasing choice of non-chloride cleaners. If you

are not sure of chloride content in the cleaner used, contact your cleaner

supplier. If your present cleaner contains chlorides, ask your supplier if

they have an alternative. Avoid cleaners containing quaternary salts; it

also can attack stainless steel and cause pitting and rusting.

4.

Treat your water

.

Though this is not always practical, softening hard water can do much

to reduce deposits. There are certain filters that can be installed to

remove distasteful and corrosive elements. To insure proper water

treatment, call a treatment specialist.

5.

Keep your food equipment clean.

Use alkaline, alkaline chlorinated or non-chloride cleaners at

recommended strength. Clean frequently to avoid build-up of hard,

stubborn stains. If you boil water in stainless steel equipment,

remember the single most likely cause of damage is chlorides in the

water. Heating cleaners that contain chlorides have a similar effect.

6.

Rinse, rinse, rinse.

If chlorinated cleaners are used, rinse and wipe equipment and

supplies dry immediately. The sooner you wipe off standing water,

especially when it contains cleaning agents, the better. After wiping

equipment down, allow it to air dry; oxygen helps maintain the

stainless steel’s passivity film.

7.

Never use hydrochloric acid (muriatic acid) on stainless steel.

8.

Regularly restore/passivate stainless steel.

Recommended cleaners for specific situations

Job Cleaning Agent Comments

Routine cleaning Soap, ammonia, Apply with cloth or sponge

detergent, Medallion

Fingerprints & smears Arcal 20, Lac-O-Nu Provides barrier film

Ecoshine

Stubborn stains & Cameo, Talc, Zud, Rub in direction of polish lines

discoloration First Impression

Grease & fatty acids, Easy-off, De-Grease Excellent removal on all finishes

blood, burnt-on-foods It Oven Aid

Grease & oil Any good Apply with sponge or cloth

commercial detergent

Restoration/Passivation Benefit, Super Sheen

Review

1. Stainless steels rust when passivity (film-shield) breaks down as a

result of scrapes, scratches, deposits and chlorides.

2. Stainless steel rust starts with pits and cracks.

3. Use the proper tools. Do not use steel pads, wire brushes or scrapers

to clean stainless steel.

4. Use non-chlorinated cleaners at recommended concentrations. Use

only chloride- free cleaners.

5. Soften your water. Use filters and softeners whenever possible.

6. Wipe off cleaning agent(s) and standing water as soon as possible.

Prolonged contact causes eventual problems.

To learn more about chloride-stress corrosion and how to prevent it,

contact the equipment manufacturer or cleaning materials supplier.

Developed by Packer Engineering, Naperville, Ill., an independent testing

laboratory.

Page 8

STEAM CONTROL ASSEMBLY

SERVICE PARTS

1

15

16

2

3

4

5

5

22

6

7

8

9

10

1

13

14

21

20

19

18

17

25

4

23

24

12

4

5

3

21

20

19

18

17

5

6

7

8

9

4

23

7

8

9

23

6

7

8

9

4

23

13

12

5

26

28

27

29

11

Page 9

STEAM CONTROL ASSEMBLY

ITEM NO. PART NO. DESCRIPTION QTY.

1. FA11056 Binding Head Screw, 6-32 x 1/2" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. KE50458 End Cap, condensate return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE50455-1 Trunnion, condensate return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. FA05002-35 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

5. FA05002-37 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

6. KE50460-1 Trunnion, steam inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. FA11089 Binding Head Screw, 8-32 x 1/4" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. KE51713 Washer, steam valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE50459 Operating Stem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE50457 End Cap, steam inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. SE00028 Steam Control Knob Assembly (c/w Item No. 12, 13 & Knob) . . . . . . . . . . . . . .1

12. KE51888 Retaining Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. FA11092 Binding Head Screw, 8-32 x 1/2" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. KE50151-E Knob, threaded (after 07/94) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50151 Knob, non threaded (prior to 06/94) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. KE50886-1 Handle, KDT-1-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50886-2 Handle, KDT-3-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50886-3 Handle, KDT-6-T & KDT-12-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50886-4 Handle, KDT-20-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. KE50475 Plug Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. KE52697 Lock Nut, 1/2" NPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

18. FA32500 Lockwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

19. FA30502 Washer, satin coat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

20. KE50467 Washer, Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

21. KE50465 Service Pipe, KDT-1-T & KDT-3-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

KE52030 Service Pipe, KDT-6-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

KE50463 Service Pipe, KDT-12-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

KE50464 Service Pipe, KDT-20-T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

22. T40272 Leg Assembly, KDT-1-T (c/w Item No. 17-21) . . . . . . . . . . . . . . . . . . . . . . . . . .2

T40218 Leg Assembly, KDT-3-T (c/w Item No. 17-21) . . . . . . . . . . . . . . . . . . . . . . . . . .2

KE00896 Leg Assembly, KDT-6-T (c/w Item No. 17-21) . . . . . . . . . . . . . . . . . . . . . . . . . .2

KE00203 Leg Assembly, KDT-12-T (c/w Item No. 17-21) . . . . . . . . . . . . . . . . . . . . . . . . .2

KE00204 Leg Assembly, KDT-20-T (c/w Item No. 17-21) . . . . . . . . . . . . . . . . . . . . . . . . .2

23. FA05002-12 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

24. KE01115-1 Right Hand Marine Lock Latch, KDT-12-T & KDT20-T only . . . . . . . . . . . . . . . .1

24. KE01115 Left Hand Marine Lock Latch, KDT-12-T & KDT20-T only . . . . . . . . . . . . . . . . .1

25. KE52632 Crown Nut, KDT-12-T & KDT20-T only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

26. SE00096 Steam Outlet Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

27. SE00011 Trunnion Assembly, steam inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

28. SE00029 Operating Stem Assembly, steam inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

29. SE00030 Steam Inlet Control Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Requires Knob -

Item No.

KE50151-E

00908 O Ring Lubrication

Page 10

3

4

7

6

5

11

10

9

8

16

12

13

15

14

22

21

19

18

20

See Steam

Control Drawing

2

1

1

1

24

28

1

25

26

27

30

See Steam

Control Drawing

23

17

Steam In Configuration for

SD Stand with Two Kettles

2

2

CONDENSATE

RETURN

STEAM

IN

STEAM

IN

CONDENSATE

RETURN

See Steam

Control Drawing

STEAM

STEAM

29

PLUMBING ASSEMBLY

(for SD Stands)

Page 11

PLUMBING ASSEMBLY (for SD Stands)

ITEM NO. PART NO. DESCRIPTION QTY.

1. FI00169 Tee, 1/2" NPT. (single kettle units) . . . . . . . . . . . . .1

(twin kettle units) . . . . . . . . . . . . . . .3

2. KE54941-5 Safety Valve, 50 PSI, 1/2" (North America) (single kettle units) . . . . . . . . . . . . .1

(twin kettle units) . . . . . . . . . . . . . . .2

KE54941-31 Safety Valve, 50 PSI, 1/2", (Europe) (single kettle units) . . . . . . . . . . . . .1

(twin kettle units) . . . . . . . . . . . . . . .2

3. FA95010 Jam Nut, #3/4-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4. KE51340 Leg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

5. SD50000 Strainer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. SD50042 Radiator Hose, 4" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. FI05131 Hose Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. SD50043 Nipple, threaded one end only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE51367 Check Valve, 1 1/4" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. FI00670 Nipple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. FI00136 90° Street Elbow, 1 1/4" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. FI00191 Cap, 1 1/2" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. KE00648 Drain Pipe Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. FI00044 90° Elbow, 1 1/2" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. FI05027 Pipe Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

16. FI05047 Reducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. FI05077 Compression Elbow (single kettle units) . . . . . . . . . . . . .1

18. SD50027 Steam Trap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

19. FI05049 Male Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

20. KE51249 Strainer, 1/2" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

21. FI00596 Nipple, 1/2" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

22. FI00266 Coupling, 1/2" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

23. FI05048 Compression Tee (twin kettle units) . . . . . . . . . . . . . . .1

24. FI00586 Nipple . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

25. FI05029 Hose Fitting, 1/2" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

26. KE51391 Hose Clamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

27. SD50034 Hose, 20" (SD1050K66) . . . . . . . . . . . . . . . . . .1

SD50035 Hose, 17" (SD1200K612) . . . . . . . . . . . . . . . . .1

SD50036 Hose, 27" (SD1600K620, 1212, 12,20 & 2020) .1

28. FI05028 90° Swivel Elbow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

29. SDP Sliding Drain Pan Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

30. Front Access Panels

SD50067 (SD450 series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SD50068 (SD650 series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SD50106 (SD760 series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SD50069 (SD1050 series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SD50070 (SD1200 series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SD50071 (SD1600 series) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Page 12

6

7

8

4

5

1

4

2

3

1

2

3

11

12

9

11

12

10

FAUCET ASSEMBLIES

Page 13

FAUCET ASSEMBLIES

ITEM NO. PART NO. DESCRIPTION QTY.

1.

KE50825-8 6 gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50825-1 12 gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50825-1 20 gallon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.

FA95022 Retaining Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3.

FA05002-19 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4.

KE51736 Long Faucet Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. SD50097 Flanged Nut, 3/4" NPT, Chrome Plated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE51585 Faucet Spout Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. SD50098 Locknut, 3/4" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

8. FI00266 Coupling, 1/2" NPT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE51899 Double Pantry Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

(c/w Item No. 11&12)

10.

KE51403 Double Pantry Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

(c/w Item No. 11&12)

KE51401 Single Pantry Control Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

(c/w Item No. 12)

11.

SE50020 Hot Water Stem Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12.

SE50021 Cold Water Stem Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Page 14

STEAM CONTROL ASSEMBLY -

FOR KETTLES WITH GEARBOX

See Tilting

Gearbox Assembly

1

2

3

4

5

6

5

6

7

8

9

10

11

11

12

14

15

16

17

19

18

20

21

22

10

13

Page 15

STEAM CONTROL ASSEMBLY -

FOR KETTLES WITH GEARBOX

ITEM NO. PART NO. DESCRIPTION QTY.

1. KE52697 Lock Nut, 1/2" NPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

2. FA32500 Lockwasher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

3. FA30502 Washer, satin coat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4. KE50467 Washer, Foot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

5. KE50463 Service Pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

6. KE00203 Leg Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

7. FA11056 Binding Head Screw, 6-32 x 1/2" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. KE50458 End Cap, condensate return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE50455-1 Trunnion, condensate return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. FA05002-35 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. FA05002-37 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

12. KE54752 Trunnion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. FA11509-1 Bolt, 1/2-13 x 3/4" lg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. FA11089 Binding Head Screw, 8-32 x 1/4" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. KE51713 Washer, steam valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. FA05002-12 "O" Ring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. KE54753 Operating Stem . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

18. KE51888 Retaining Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

19. SE00028 Steam Control Knob (includes Item #18 & 20) . . . . . . . . . . . . . . . . . . . . . . . . . .1

20. FA11092 Binding Head Screw, 8-32 x 1/2" lg. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

21. KE54729 Gear Box Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

22. FA11146 Binding Head Screw, 8-32 x 3/8" . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Page 16

3

3

5

6

4

7

8

7

9

12

13

12

2

11

14

16

15

10

1

14

1

NOTE: Item #14 to be tack welded

flush outside in the gearbox

housing (item #1). Do not damage the outside

edges of the gearbox

housing when

tack welding.

2

See Steam

Control Assembly

TILTING GEARBOX ASSEMBLY

-

FOR KETTLES WITH GEARBOX

Page 17

TILTING GEARBOX ASSEMBLY

-

FOR KETTLES WITH GEARBOX

ITEM NO. PART NO. DESCRIPTION QTY.

1.-16. KE02062-1 Tilting Gearbox Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1. KE02060 Gearbox Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE50198 Bearing, trunnion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

3. KE54739-2 Bearing, tilt shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

4. KE54737 End Housing Spacer, tilt shaft, bronze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE54738-3 Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. KE50306-1 Tilt Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. KE52192 Bearing Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. KE52191 Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. KE50426-3 Spacer, Tilt Shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. KE50315 Worm Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. FA95005 Tension Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. KE54738-1 Washer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

13. KE02059 Segment Gear and Spacer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. KE02061 Trunnion Bearing Housing Holder Assembly c/w Bearing . . . . . . . . . . . . . . . . .1

15. FA10485 Hex Head Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. FA20008 Hex Nut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Page 18

PRESSURE RELIEF VALVE

TESTING PROCEDURE

The pressure relief valve (optional on kettles) must

be checked at least twice a year as part of the

normal maintenance performed.

1. Open steam valve and preheat kettle.

2. Stand to the side of the pressure relief valve

discharge tube and pull ring three or four

times to insure free movement. Hold valve

open for two seconds each time, insuring

there is rapid steam escape each time.

3. If valve appears to be sticking replace

pressure relief valve. If foreign material is

discharged, replace pressure relief valve and

eliminate the source of contamination.

STEAM TRAP

To remove line condensate that forms inside the

steam jacket, each kettle should be equipped with

a steam trap in the line of the kettle outlet to the

drain. A good steam trap at startup releases air

and wet steam into the drain line for a few

minutes, then holds the steam jacket. During

cooking, the trap periodically releases

accumulated condensate. If the kettle's cooking

performance becomes inadequate after long use,

replacement of the steam trap with a new one may

restore kettle operation to peak efficiency.

MARINE LOCK

Inspect lock at least twice yearly.

1. Check for excessive play or wear on pivot.

Adjust or replace as required.

2. Insure lock is catching over the centre of the

stop pin and not bent to one side or the other.

Adjust or replace as required.

WARRANTY

Our Company supports a worldwide network of

Maintenance and Repair Centers. Contact your

nearest Maintenance and Repair Centre for

replacement parts, service, or information

regarding the proper maintenance and repair of

your cooking equipment

In order to preserve the various agency safety

certification (UL, NSF, ASME/Ntl. Bd., etc.), only

factory-supplied replacement parts should be

used. The use of other than factory supplied

replacement parts will void warranty.

WARNING

Kettle will be hot. Use gloves for protection.

MAINTENANCE

ALL SERVICE MUST BE PERFORMED BY A

QUALIFIED SERVICE TECHNICIAN.

This kettle requires very little preventative maintenance other than daily cleaning.

The pressure relief valve must be tested twice a year.

Page 19

TROUBLESHOOTING GUIDE

This section contains information intended for use by Authorized Service Personnel only.

PROBLEM

A/ Kettle heats too slowly or does not come to a boil.

Probable Cause Remedy

1. Inadequate steam flow. Check for correct steam using chart below.

If kettle is connected to a steamer and powered by a

generator the units should be operated sequentially

(kettle boiling first, then start steamer).

2. Steam trap not operating properly. The trap should open periodically to

dump condensate, then close.

If it does not open or close it should be

cleaned or replaced.

3. Food batches are not always the same. When checking make certain that the original state (ie.

fresh or frozen) and quantity of food product is the same.

PROBLEM

B/ The trunnion housing leaks steam.

Probable Cause Remedy

1. Trunnion "O" rings are worn. Replace "O" rings (see STEAM CONTROL ASSEMBLY

drawing).

Gas Input Steam Output Boiler

BTU/Hour Lbs./Hour H.P.

100,000 60 1.7

160,000 95 2.8

200,000 125 3.6

250,000 150 4.4

300,000 180 5.2

Electric

KW Input

18 60 1.7

24 70 2.0

27 90 2.6

36 120 3.5

48 150 4.4

Capacity Fast Medium Stock

Gal./Lit. Cooking Cooking Kettle

5/17 11 9 6

10/42 22 18 11

25/95 55 44 28

40/151 88 70 44

60/227 132 105 66

Electric: Above shows lbs. per hour with 10-15

psig steam at the kettle. The use of

higher steam pressures (20-25 psig) will

reduce heat-up time 5-20%.

STEAM FLOW RATING

OF STEAM GENERATORS

STEAM FLOW RATING

REQUIREMENTS FOR KETTLES

Page 20

SPECIFICATION DRAWINGS

KDT-1-T

CLEARANCE REQUIREMENTS TO

COMBUSTIBLE AND

NONCOMBUSTIBLE SURFACES:

Right - 4" Left - 0 Back - 0

8.00"

203mm

9.38"

238mm

3.50"

89mm

9.31"

236mm

1.56"

40mm

1/2" NPT

CONDENSATE

RETURN

9.88"

251mm

8.13"

207mm

12.25"

311mm

1/2" NPT

STEAM

INLET

12.50"

318mm

Page 21

F

G

NOTE:

INLET AND RETURN

NOT INTERCHANGABLE

C

A

B

WALL

E

D

H

1/2" NPT

STEAM

INLET

1/2" NPT

CONDENSATE

RETURN

STEAM

CONTROL

VALVE

K

M

L

N

J

1.00"

25mm

1.25"/32mm

WALL

2.25"

57mm

GAL. LITRE A B C D E F G H J K L M N

311

IN 14.00 10.00 15.13 12.50 8.25 10.00 12.50 23.00 7.00 4.00 11.00 15.00 21.00

mm 356 254 384 317 210 254 317 584 178 102 279 381 533

623

IN 17.50 13.38 15.13 15.31 11.00 12.00 14.50 24.50 6.75 6.00 14.50 21.19 27.50

mm 445 400 384 389 279 305 368 622 171 152 368 538 699

KDT-3-T & KDT-6-T

CLEARANCE REQUIREMENTS TO

COMBUSTIBLE AND

NONCOMBUSTIBLE SURFACES:

Right - 4" Left - 4" Back - 1"

Page 22

GAL. LITRE A B C D E F G H J K L M

311

IN 20.50 16.75 23.00 22.25 13.50 19.50 22.00 29.00 6.00 8.75 11.50 29.50

mm 521 425 584 565 343 495 559 737 152 222 292 749

623

IN 25.25 21.00 27.25 18.00 11.00 23.75 26.25 33.00 6.50 10.50 13.25 36.75

mm 641 533 692 457 279 603 667 838 165 267 337 960

KDT-12-T & KDT-20-T

CLEARANCE REQUIREMENTS TO

COMBUSTIBLE AND

NONCOMBUSTIBLE SURFACES:

Right - 4" Left - 4" Back - 1.75"

WALL

A

E

D

B

C

H

STEAM

CONTROL

VALVE

1.75"

45mm

MARINE

LOCK

WALL

2.25"

57mm

J

1.25"

1/2" NPT

CONDENSATE

RETURN

F

G

NOTE: INLET AND RETURN

NOT INTERCHANGABLE

32mm

1/2" NPT

STEAM

INLET

K

M

L

Page 23

SD STANDS WITH

KETTLES

CLEARANCE REQUIREMENTS TO

COMBUSTIBLE AND

NONCOMBUSTIBLE SURFACES:

Right - 0 Left - 0 Back - 0

MODEL A B C

SD-450 - K 6

SD-650 - K12

SD-760 - K12

SD-760 - K20

SD-1050- K20

SD-1050- K 6 6

SD-1200- K 6 12

SD-1600- K 6 20

SD-1600- K 12 12

SD-1600- K 12 20

SD-1600- K 20 20

17.70 4.00 10.00

450 102 254

25.56 4.00 13.75

650 102 349

29.94 5.22 15.00

760 133 381

29.94 3.10 15.00

760 79 381

41.32 6.50 34.75

1050 165 883

41.32 4.91 20.66

1050 125 525

47.19 4.10 19.84

1200 104 504

63 9.88 25.63

1600 251 651

63 8.25 31.50

1600 210 800

63 6.13 29.38

1600 156 746

63 4.00 31.50

1600 102 800

5.00"

127mm

D

H C

13.75"

349mm

16.88"

429mm

3.25"

83mm

SLIDING

DRAIN PAN

B

C

SLIDING

DRAIN PAN

38.75"

984mm

MARINE

LOCK

A

27.75"

706mm

22.00"

610mm

6.00"

152mm

18.00"

457mm

1.47"

37mm

1.47"

37mm

4.44"

113mm

33.50"

851mm

1.47"

37mm

Loading...

Loading...