Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COOK CHILL SYSTEMS

Cook/Chill Systems

GAS FIRED STEAM BOILERS

Cleveland Standard Features

I Complete skid-mounted and piped, gas fired Steam Boiler with

Vertical Return System and Blow Down Separator

I Available for Pressure Ratings from 15 to 150 psi (specify

required operating pressure)

I Vertical Tubeless design

I Fully insulated Boiler with top mounted, down-fired burners

I High Temperature Insulation assists thermal efficiency of 80%

I Spinning Cyclonic Flame travels down the entire length of the

Combustion Chamber

I Top Flame Retainer increases occupancy time of flue gases to

complete combustion process

I Operating Pressure Control and High Limit Pressure Control

with Manual Reset

I Water Column with Water Gauge Assembly

I All necessary valves are included

I Automatic Water Feed System with probe type Water Level

Controls and single phase Motor for Pump

I Steam Outlet conveniently located at top of Boiler

I Control Panel factory mounted and wired, ready for power con-

nection

I Built and stamped to A.S.M.E. Code

I Registered with the National Board of Boiler & Pressure Vessel

Inspectors

I Accepted for use in U.S.D.A. Inspected Facilities

Options & Accessories

Ë Stainless Steel outer Jacket

Ë Automatic Boiler Blow-down Controls

Ë Applicable Controls to meet the various special insurance,

local, state or federal code requirements

Ë Electric heated Steam Boilers

Ë Oil-fired Steam Boilers

Ë Cooling Kit for boiler drain

Ë Aquastat automatic drain cooling kit

Ë Larger models availabe on request

MODELS:

GFB-6

GFB-10GFB-20

GFB-15

GFB-30GFB-60

GFB-50

Short Form Specifications

Shall be CLEVELAND Model GFB -____, gas-fired, vertical, tubeless LARGE STEAM BOILER System, _____H.P. (horse power);

Complete with Power Burners; Skid mounted and piped with

Vertical Condensate Return System and Blow-Down Separator

Package; Factory assembled as a self-contained unit, in accordance to U.L. requirements, and A.S.M.E. Section 1 (one) Code;

Guaranteed production of _______ pounds of Steam per hour at

212˚F.

SECT. XIV PAGE 53

0907

Page 2

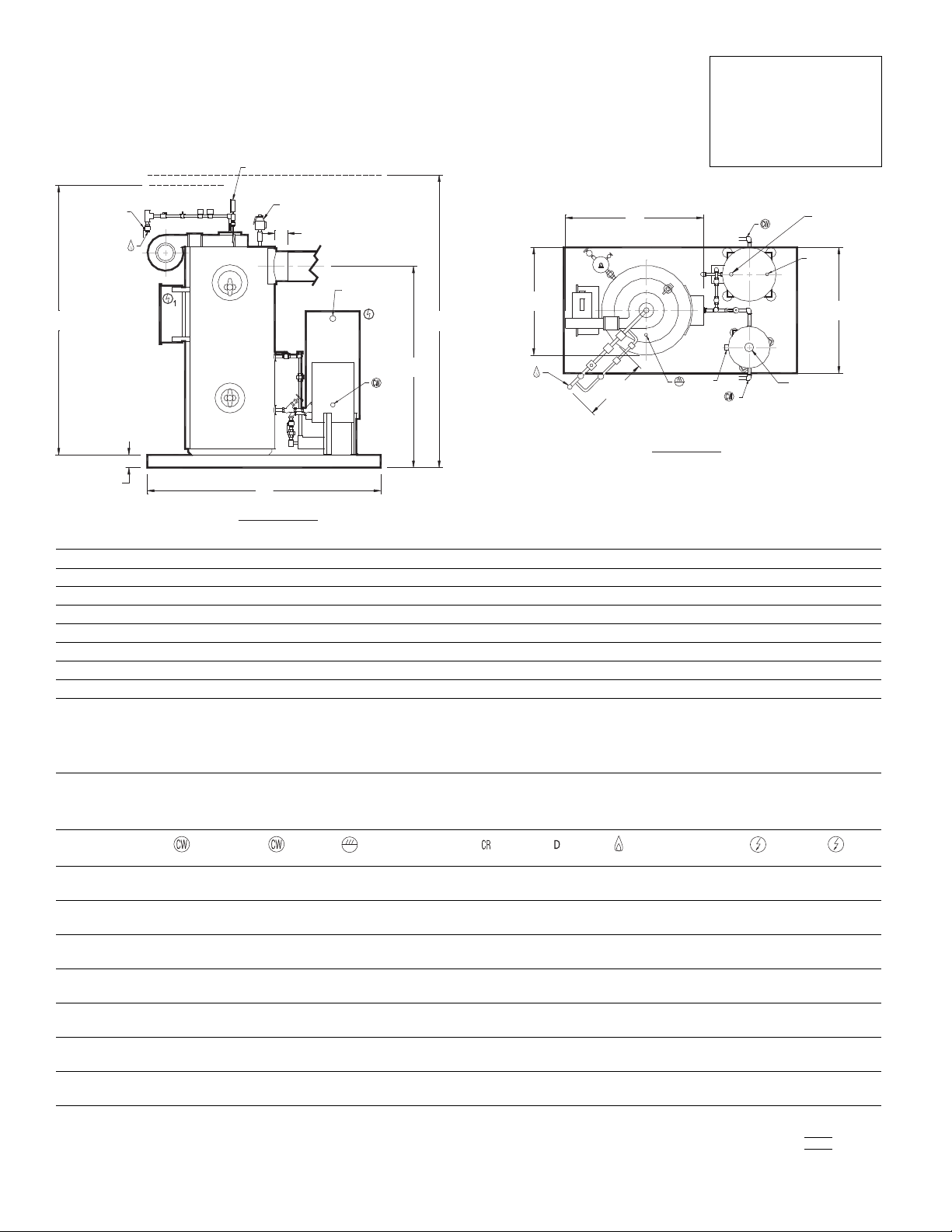

F

H

CAN PIVOT 360∞

GAS HEAD

E

(TO OUTSIDE

1

-1/4" DIA. VENT

3

" DIA. VENT

(TO OUTSIDE

O

F BUILDING)

G

C

D

4 1/4"

B

(PIPE TO DRAIN)

O

VERFLOW

OVERALL

REMOVAL

B

URNER

S

AFETY VALVE

E

XHAUST

4 1/4"

STEAM GAGE ASSEMBLY

A

B

OILER HEIGHT

W

ITH TRIM

(NOT SUPPLIED)

SHUTOFF VALVE

G

AS INLET

G

AS INLET

OF BUILDING)

FRONT VIEW

PLAN VIEW

2

1

2

CR

D

MINIMUM CLEARANCE

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

FRONT 18"

SIDES 18"

REAR 18"

TOP - see dimension "C"

DIMENSIONS

MODEL ABC DEF GH

GFB-6 75" 72" 86 1/4" 56 1/4" 48" 33" 44" 22 1/2"

GFB-10 80 1/2" 78" 90 1/4" 62 1/4" 54" 33 1/2" 46" 21 1/2"

GFB-15 86 1/2" 84" 96 1/4" 67 1/4" 54" 35 1/2" 47" 20 1/2"

GFB-20 92 1/2" 90" 100 1/4" 70 1/4" 54" 43" 60" 25"

GFB-30 102" 96" 110 1/4" 77 3/4" 60" 49" 67" 27"

GFB-50 106 1/2" 114" 118 1/4" 83 1/4" 66" 57" 78" 22 1/2"

GFB-60 120" 114" 128 1/4" 89 1/4" 66" 57" 78" 34"

UTILITY CONNECTIONS

120 /1PH

BOILER BLOW DOWN STEAM CONDEN

FILL COLD OUTPUT

MODEL COLD WATER WATER

1

GFB-6 1/2" NPT 1" NPT 3/4" 207 1" 1 1/2" 1" 260 5.2 10

STEAM LBS/HR

2

-SATE

BLOWDOWN

RETURN DRAIN GAS FT3/HR TRICAL PUMP

NPT NPT NPT NPT AMPS AMPS

GFB-10 1/2" NPT 1" NPT 1" 345 1 1/4" 1 1/2" 1" 420 5.2 10

GFB-15 1/2" NPT 1 1/4" NPT 1 1/4" 518 1 1/4" 1 1/2" 1 1/4" 630 5.2 15

GFB-20 1/2" NPT 1 1/4" NPT 1 1/2" 690 1 1/4" 1 1/2" 1 1/4" 840 9.2 15

GFB-30 1/2" NPT 1 1/4" NPT 2" 1035 1 1/4" 1 1/2" 1 1/2" 1260 9.2 20

GFB-50 3/4" NPT 1 1/2" NPT 3" 1725 2" 1 1/2" 1 1/2" 2100 **4.4 **11

NPT NPT NPT NPT AMPS AMPS

NPT NPT NPT NPT AMPS AMPS

NPT NPT NPT NPT AMPS AMPS

NPT NPT NPT NPT AMPS AMPS

NPT NPT NPT NPT AMPS AMPS

GFB-60 3/4" NPT 2" NPT 3" 2070 2" 1 1/2" 2" 2520 **4.4 **16.7

NPT NPT NPT NPT AMPS AMPS

** 208V / 3PH

NOTE: It is the owners/operators responsiblity to meet the recommended minumum water quality requirements.

Cleveland Range reserves right of design improvement or modification, as warranted.

NATURAL GAS

CONSUMPTION

EL1 EL2

ELEC- FOR

12

SECT. XIV PAGE 54

(NOT TO SCALE)

0907

Litho in USA

Loading...

Loading...