Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

U

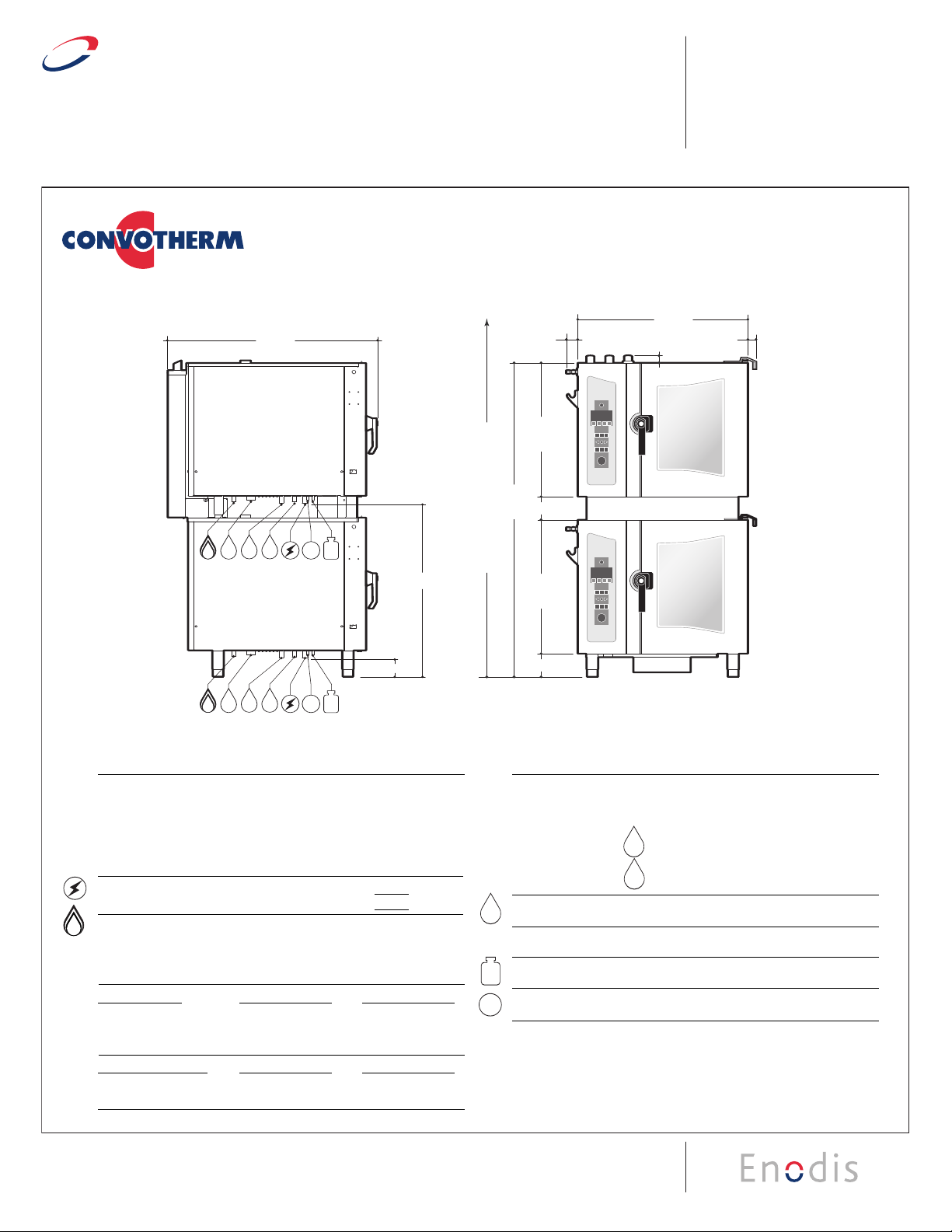

NIT A

UNIT B

6.00"

NOTE: Overall height of unit does not change for units with casters.

RC

CS

W1 W2

D

G

4

.38"

NOTE: Overall height of unit does not change for units with casters.

RC

CS

W1W

2

D

G

RC

CS

W1 W2

D

G

4.38"

38.08"

3

9.21"

L

EFT SIDE VIEW

6.10

on 6.10

GAS

U

NIT A

UNIT B

3

6.70"

1.58"

28.43

5

.00"

1

.82"

67.8 5 "

28.43

6.00"

78.00” (MIN.HOOD REQUIREMENT)

2

.52"

W1

W2

D

W1

W2

D

RC

S

CS

AV

G

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

W1

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.10 on OGB 6.10 or OGS 6.10 on OGS 6.10)

Model # Description

CSTK-610 for mounting two 6.10 models

STK-610CA for mounting two 6.10 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factor

y ser

vice department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

ype:

Gas T

Gas Flow Pressure:

BOILER MODELS UNIT A - OGB-6.10 UNIT B - OGB-6.10

otal Connected Load:

T

Steam Generator:

Hot Air: 45.400 BTU 45.400 BTU

BOILERLESS MODELS UNIT A - OGS-6.10 UNIT B - OGS-6.10

otal Connected Load:

T

Hot Air:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

UNIT A UNIT B -

11.7 amps

11.7 amps

Natural Gas (Propane optional)

Natural Gas - Min. 5.5" WC / Max. 14" WC

Propane Gas - Min. 11" WC / Max. 14" WC

45.400 BTU

45.400 BTU

45.400 BTU

45.400 BTU

45.400 BTU

45.400 BTU

45.400 BTU 45.400 BTU

Water Connections: Cold Water (drinking water quality)

Flow Pressure:

ater Inlets: 3/4" GHT-F (Female Garden Hose Connection)

W

30 - 60 PSI

reated W

T

ater for Steam Generator

Untreated Water for Condenser

Drain Connection: 2" Tube

enting:

V

*Connection for Cleaning Solution

*Connection for Rinse Cycle

Exhaust Hood required

*

Available as an option

Note: For additional connection details, see spec sheet for each

individual combi model to be stacked.

SECT. IIB PAGE 5A

0707

Page 2

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

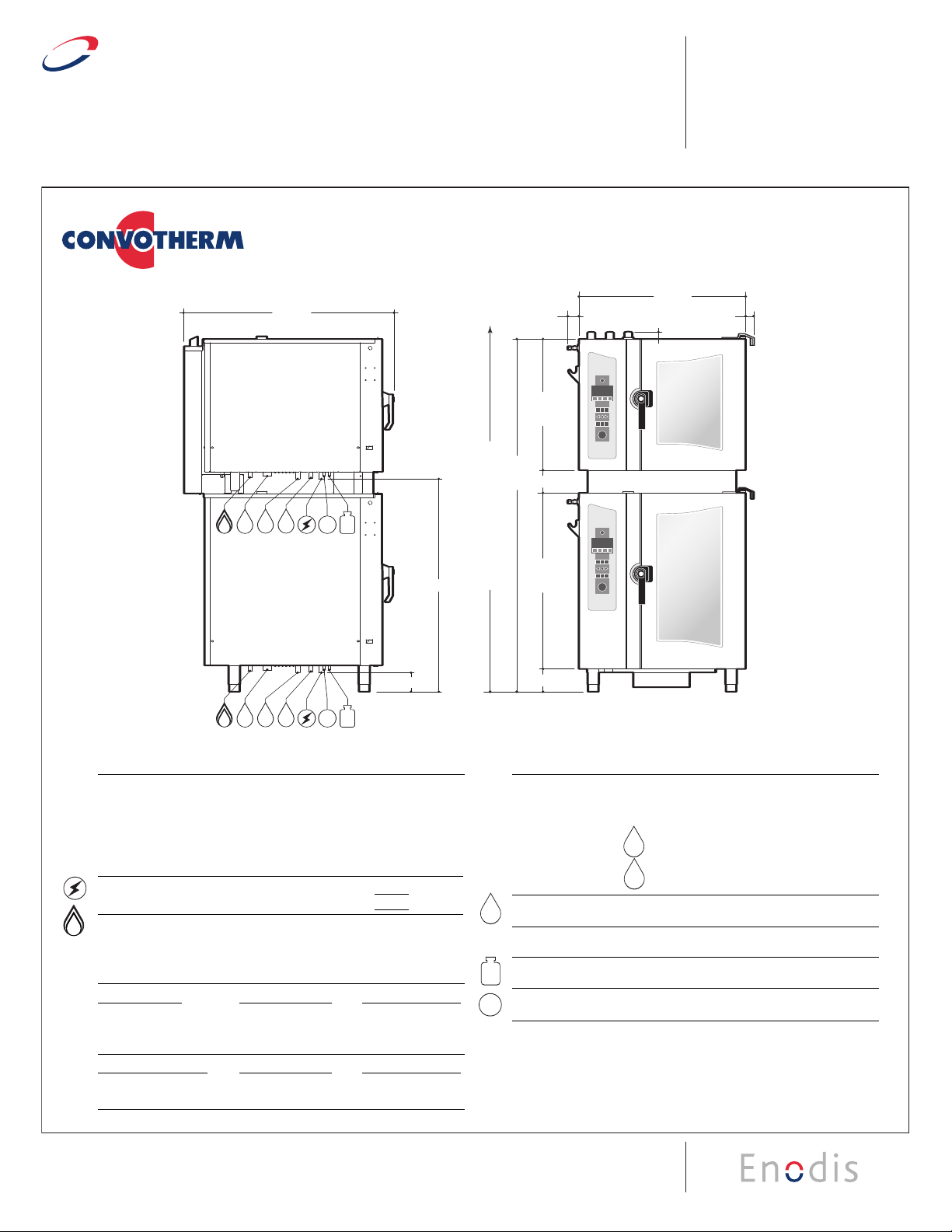

UNIT A

UNIT B

6.00"

R

C

C

S

W1W

2

D

G

4.38"

NOTE: Overall height of unit does not change for units with casters.

U

6.10

on 10.10

GAS

RC

CS

W1 W2

D

G

RC

CS

W1 W2

D

G

4.38"

48.54”

39.21"

NOTE: Overall height of unit does not change for units with casters.

UNIT A

UNIT B

L

EFT SIDE VIEW

78.41"

36.70"

1.58"

1

.82"

28.43

5.00"

38.98"

6.00"

80.00” (MIN.HOOD REQUIREMENT)

2.52"

W1

W2

D

W1

W2

D

RC

S

CS

AV

G

W1

W1

W2

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.10 on OGB 10.10 or OGS 6.10 on OGS 10.10)

Model # Description

CSTK-1010 for mounting one 6.10 model on top of one 10.10 model

CSTK-1010CA for mounting one 6.10 model on top of one 10.10 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

Rear - 2", Left Side - 4", Right Side - 2 1/2"

Water Connections: Cold Water (drinking water quality)

Flow Pressure:

ater Inlets: 3/4" GHT-F (Female Garden Hose Connection)

W

• Allow for sufficient clearance on left side for service access (contact the

factor

y ser

vice department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

ype:

Gas T

Gas Flow Pressure:

BOILER MODELS UNIT A - OGB-6.10 UNIT B - OGB-10.10

otal Connected Load:

T

Steam Generator:

Hot Air: 45.400 BTU 75,700 BTU

BOILERLESS MODELS UNIT A - OGS-6.10 UNIT B - OGS-10.10

otal Connected Load:

T

Hot Air:

120 volt, 60 Hz, single phase,

Natural Gas (Propane optional)

Natural Gas - Min. 5.5" WC / Max. 14" WC

Propane Gas - Min. 11" WC / Max. 14" WC

45.400 BTU

45.400 BTU

45.400 BTU

UNIT A UNIT B -

75,700 BTU

68,200 BTU

75,700 BTU

11.7 amps

11.7 amps

Drain Connection: 2" Tube

enting:

V

*Connection for Cleaning Solution

*Connection for Rinse Cycle

*

Available as an option

Note: For additional connection details, see spec sheet for each

individual combi model to be stacked.

45.400 BTU 75,700 BTU

30 - 60 PSI

ater for Steam Generator

reated W

T

Untreated Water for Condenser

Exhaust Hood required

SECT. IIB PAGE 5B

0707

Page 3

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

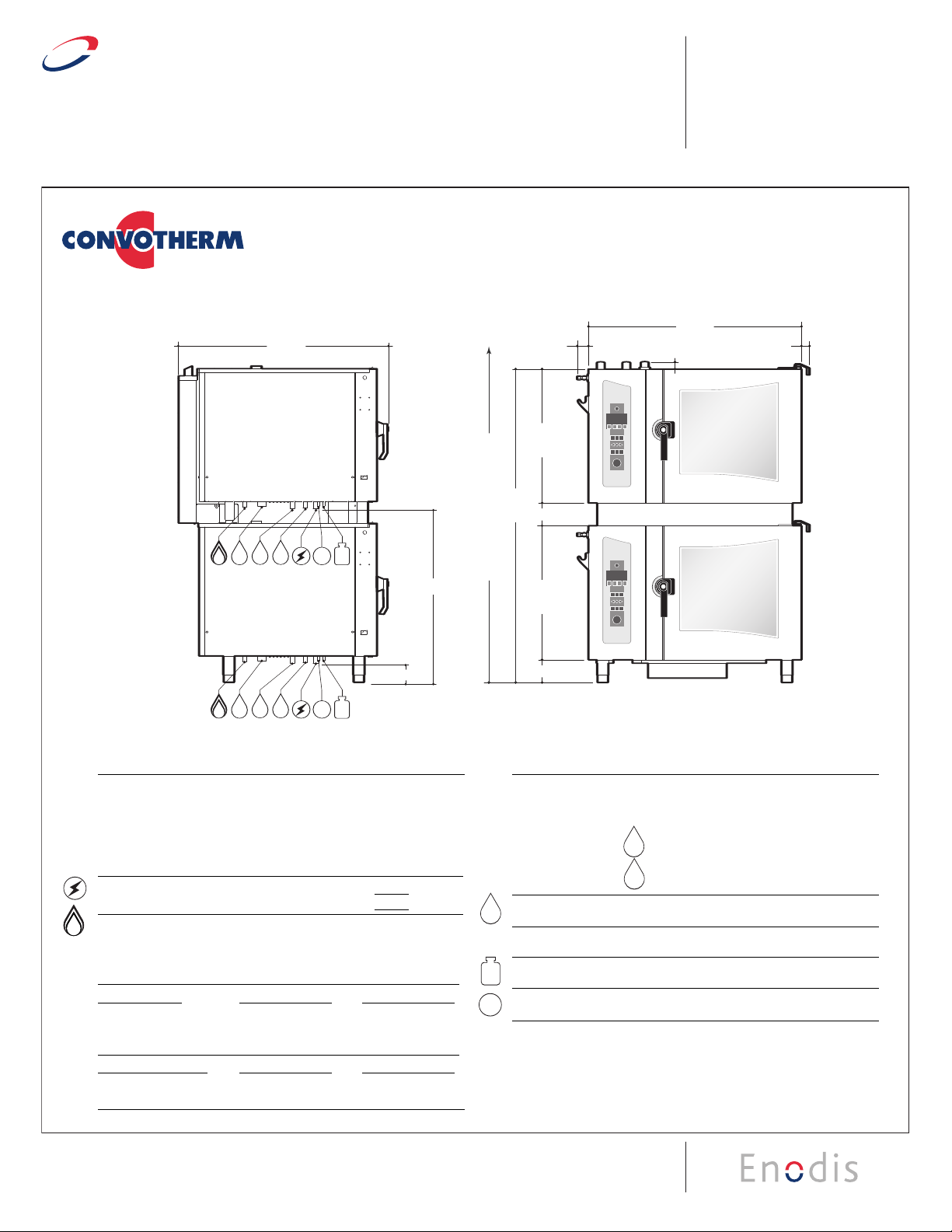

2.52"

30.12"

5.00"

30.12"

6.00"

47.92"

1.58"

1

.82"

71.24"

NOTE: Overall height of unit does not change for units with casters.

78.00” (MIN.HOOD REQUIREMENT)

RC

CS

W1W

2

D

G

RC

CS

W1 W2

D

G

4.38"

39.50"

47.72"

U

NIT A UNIT A

UNIT B

UNIT B

L

EFT SIDE VIEW

F

RONT VIEW

6.20

on 6.20

GAS

W1

W2

D

W1

W2

D

RC

S

CS

AV

G

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

W1

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.20 on OGB 6.20 or OGS 6.20 on OGS 6.20)

Model # Description

CSTK-620 for mounting two 6.20 models

STK-620CA for mounting two 6.20 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factor

y ser

vice department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

ype:

Gas T

Gas Flow Pressure:

BOILER MODELS UNIT A - OGB-6.20 UNIT B - OGB-6.20

otal Connected Load:

T

Steam Generator:

Hot Air: 75,700 BTU 75,700 BTU

BOILERLESS MODELS UNIT A - OGS-6.20 UNIT B - OGS-6.20

otal Connected Load:

T

Hot Air:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

Natural Gas (Propane optional)

Natural Gas - Min. 5.5" WC / Max. 14" WC

Propane Gas - Min. 11" WC / Max. 14" WC

75,700 BTU

68,200 BTU

75,700 BTU

75,700 BTU 75,700 BTU

UNIT A -

11.7 amps

UNIT B -

11.7 amps

75,700 BTU

68,200 BTU

75,700 BTU

Water Connections: Cold Water (drinking water quality)

Flow Pressure:

ater Inlets: 3/4" GHT-F (Female Garden Hose Connection)

W

30 - 60 PSI

reated W

T

ater for Steam Generator

Untreated Water for Condenser

Drain Connection: 2" Tube

enting:

V

Exhaust Hood required

*Connection for Cleaning Solution

*Connection for Rinse Cycle

*

Available as an option

Note: For additional connection details, see spec sheet for each

individual combi model to be stacked.

SECT. IIB PAGE 5C

0707

Page 4

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

6.20

on 10.20

GAS

80.09"

47.92"

2

.52"

1.58"

1.82"

30.12"

5.00"

38.98"

6.00"

81.00” (MIN.HOOD REQUIREMENT)

RC

CS

W1 W2

D

G

RC

CS

W1 W2

D

G

4.38"

48.32"

47.72"

NOTE: Overall height of unit does not change for units with casters.

U

NIT A UNIT A

UNIT B

UNIT B

L

EFT SIDE VIEW

FRONT VIEW

W1

W2

D

W1

W2

D

RC

S

CS

AV

G

W1

W1

W2

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.20 on OGB 10.20 or OGS 6.20 on OGS 10.20)

Model # Description

CSTK-1020 for mounting one 6.20 model on top of one 10.20 model

CSTK-1020CA for mounting one 6.20 model on top of one 10.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

Rear - 2", Left Side - 4", Right Side - 2 1/2"

Water Connections: Cold Water (drinking water quality)

Flow Pressure:

ater Inlets: 3/4" GHT-F (Female Garden Hose Connection)

W

• Allow for sufficient clearance on left side for service access (contact the

factor

y ser

vice department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

120 volt, 60 Hz, single phase,

UNIT A UNIT B -

11.7 amps

15.9 amps

Drain Connection: 2" Tube

Gas Connection: 3/4" NPT

ype:

Gas T

Gas Flow Pressure:

BOILER MODELS UNIT A - OGB-6.20 UNIT B - OGB-10.20

otal Connected Load:

T

Steam Generator:

Hot Air: 75,700 BTU 132,700 BTU

BOILERLESS MODELS UNIT A - OGS-6.20 UNIT B - OGS-10.20

otal Connected Load:

T

Steam Generator:

Natural Gas (Propane optional)

enting:

V

Natural Gas - Min. 5.5" WC / Max. 14" WC

Propane Gas - Min. 11" WC / Max. 14" WC

75,700 BTU

68,200 BTU

75,700 BTU

75,700 BTU 132,700 BTU

132,700 BTU

113,600 BTU

132,700 BTU

*Connection for Cleaning Solution

*Connection for Rinse Cycle

*

Available as an option

Note: For additional connection details, see spec sheet for each

individual combi model to be stacked.

30 - 60 PSI

ater for Steam Generator

reated W

T

Untreated Water for Condenser

Exhaust Hood required

SECT. IIB PAGE 5D

0707

Page 5

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

6

.00"

78

RC

CS

W1 W2

D

4.38"

39.50"

4

NOTE: Overall height of unit does not change for units with casters.

U

37.83"

LEFT SIDE VIEW

36.70"

1.58"

1

.82"

2.52"

RC

CS

W1 W2

D

RC

CS

W1 W2

D

NOTE: Overall height of unit does not change for units with casters.

4.38"

3

8.08"

28.43

5.00"

67.8 5 "

28.43

6.00"

78.00” (MIN.HOOD REQUIREMENT)

U

NIT A

UNIT B

U

NIT A

UNIT B

6.10

on 6.10

ELEC

W1

W2

D

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

W1

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.10 on OEB 6.10 or OES 6.10 on OES 6.10)

Model # Description

CSTK-610 for mounting two 6.10 models

STK-610CA for mounting two 6.10 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB-6.10 UNIT B - OEB-6.10

MODELS

Total Connected Load:

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 8.6 KW 11.4 KW 9.1 KW 10.2 KW

Steam Generator: 7.7 KW 10.2 KW 8.6 KW 10.2 KW 7.7 KW 10.2 KW 8.6 KW 10.2 KW

Amps per Phase: 27.3 30.8 15.2 16.3 27.3 30.8 15.2 16.3

BOILERLESS

MODELS

Total Connected Load:

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 8.6 KW 11.4 KW 9.1 KW 10.2 KW

Amps per Phase: 27.3 30.8 15.2 16.3 27.3 30.8 15.2 16.3

Rear - 2", Left Side - 4", Right Side - 2 1/2"

.I. outlet.

Do not connect to a G.F

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

9.9 KW 12.8 KW 11 KW 13.1 KW 9.9 KW 12.8 KW 11 KW 13.1 KW

UNIT A

- OES-6.10 UNIT B - OES-6.10

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

9.9 KW 12.8 KW 11 KW 13.1 KW 9.9 KW 12.8 KW 11 KW 13.1 KW

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 30 - 60 PSI

ater Inlets:

W

-F (Female Garden Hose

3/4" GHT

Connection)

Treated Water for Steam Generator

Untreated Water for Condenser

Drain Connection: 2" Tube

enting:

V

Exhaust Hood required

*Connection for Cleaning Solution

*Connection for Rinse Cycle

*

Available as an option

Note: For additional connection details,

see spec sheet for each individual

combi model to be stacked.

SECT. IIB PAGE 5E

0707

Page 6

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

UNIT A

UNIT B

6.00"

R

C

C

S

W1W

2

D

4

.38"

NOTE: Overall height of unit does not change for units with casters.

RC

CS

W1 W2

D

RC

CS

W1W

2

D

3

7.83"

NOTE: Overall height of unit does not change for units with casters.

LEFT SIDE VIEW

U

NIT A

UNIT B

4.38"

48.54"

6.10

on 10.10

ELEC

78.41"

36.70"

1.58"

1.82"

28.43

5.00"

38.98"

6.00"

80.00” (MIN.HOOD REQUIREMENT)

2.52"

W1

W2

D

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

W1

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.10 on OEB 10.10 or OES 6.10 on OES 10.10)

Model # Description

CSTK-1010 for mounting one 6.10 model on top of one 10.10 model

CSTK-1010CA for mounting one 6.10 model on top of one 10.10 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

vice department for recommendations).

ser

Installation must comply with all local fire and health codes.

•

Electrical Requirements:

BOILER UNIT A - OEB-6.10 UNIT B - OEB-10.10

MODELS

otal Connected Load:

T

Hot Air: 8.6 KW

Steam Generator: 7.7 KW

Amps per Phase: 27.3 30.8 15.2 16.3 45.5 51.8 24.2 26.4

BOILERLESS

MODELS

otal Connected Load:

T

Hot Air: 8.6 KW

Amps per Phase: 27.3

Do not connect to a G.F.I. outlet.

480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

440/3/60

240/3/60

208/3/60

12.8 KW 11 KW 13.1 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

9.9 KW

11.4 KW 9.1 KW 10.2 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

10.2 KW 8.6 KW 10.2 KW 12.8 KW 17.1 KW 14.3 KW 17.1 KW

UNIT A

- OES-6.10 UNIT B - OES-10.10

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

12.8 KW

9.9 KW

11.4 KW

30.8

11 KW

9.1 KW

15.2

13.1 KW

10.2 KW

16.3

21.6 KW 18.5 KW 22 KW

6.4 KW

19.6 KW 16.5 KW 19.6 KW

14.7 KW

51.8 24.2 26.4

45.5

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 30 - 60 PSI

ater Inlets:

W

-F (Female Garden Hose

3/4" GHT

Connection)

Treated Water for Steam Generator

Untreated Water for Condenser

Drain Connection: 2" Tube

enting:

V

*Connection for Cleaning Solution

Exhaust Hood required

*Connection for Rinse Cycle

*

Available as an option

Note: For additional connection details,

see spec sheet for each individual

combi model to be stacked.

SECT. IIB PAGE 5F

0707

Page 7

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

71.20"

47.92"

2

.52"

1.58"

1.82"

30.12"

5.00"

30.12"

6.00"

78.00” (MIN.HOOD REQUIREMENT)

RC

CS

W1 W2

D

RC

CS

W1W

2

D

4.38"

39.50"

4

6.34"

NOTE: Overall height of unit does not change for units with casters.

U

NIT A UNIT A

UNIT B

UNIT B

L

EFT SIDE VIEW

F

RONT VIEW

6.20

on 6.20

ELEC

W1

W2

D

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

W1

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.20 on OEB 6.20 or OES 6.20 on OES 6.20)

Model # Description

CSTK-620 for mounting two 6.20 models

STK-620CA for mounting two 6.20 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

• Allow for sufficient clearance on left side for service access (contact the factory

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB-6.20 UNIT B - OEB-6.20

MODELS

Total Connected Load:

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Steam Generator: 12.8 KW 17.1 KW 14.3 KW 17.1 KW 12.8 KW 17.1 KW 14.3 KW 17.1 KW

Amps per Phase: 45.5 51.8 24.2 26.4 45.5 51.8 24.2 26.4

BOILERLESS

MODELS

Total Connected Load:

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Amps per Phase: 45.5 51.8 24.2 26.4 45.5 51.8 24.2 26.4

Rear - 2", Left Side - 4", Right Side - 2 1/2"

the unit.

service department for recommendations).

Do not connect to a G.F

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

16.4 KW 21.6 KW 18.5 KW 22 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

UNIT A

- OES-6.20 UNIT B - OES-6.20

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

16.4 KW 21.6 KW 18.5 KW 22 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

.I. outlet.

Water Connections: Cold Water (drinking water quality)

Flow Pressure:

Water Inlets: 3/4" GHT-F (Female Garden Hose

30 - 60 PSI

Connection)

Treated Water for Steam Generator

Untreated Water for Condenser

Drain Connection: 2" T

ube

Venting: Exhaust Hood required

*Connection for Cleaning Solution

*Connection for Rinse Cycle

Available as an option

*

Note: For additional connection details,

see spec sheet for each individual

combi model to be stacked.

SECT. IIB PAGE 5G

0707

Page 8

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

by

Cleveland

80.09"

47.92"

2.52"

1.58"

1.82"

30.12"

5.00"

38.98"

6.00"

81.00” (MIN. HOOD REQUIREMENT )

RC

CS

W1 W2

D

RC

CS

W1 W2

D

4.38"

4

8.32"

46.34"

NOTE: Overall height of unit does not change for units with casters.

UNIT A UNIT A

UNIT B

UNIT B

LEFT SIDE VIEW

F

RONT VIEW

6.20

on 10.20

ELEC

W1

W2

D

W1

W2

D

W1

W2

D

RC

W1

W2

D

RC

CS

W1

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.20 on OEB 10.20 or OES 6.20 on OES 10.20)

Model # Description

CSTK-1020 for mounting one 6.20 model on top of one 10.20 model

CSTK-1020CA for mounting one 6.20 model on top of one 10.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER

MODELS

otal Connected Load:

T

Hot Air: 14.7 KW

Steam Generator: 12.8 KW

Amps per Phase: 45.5

BOILERLESS UNIT A - OES-6.20 UNIT B - OES-10.20

MODELS

Total Connected Load:

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 25.8 KW 34.3 KW 28.8 KW 34.3 KW

Amps per Phase: 45.5 51.8 24.2 26.4 77.8 88.8 41.4 44.9

Do not connect to a G.F.I. outlet.

UNIT A

- OEB-6.20 UNIT B - OEB-10.20

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

21.6 KW

16.4 KW

19.6 KW

17.1 KW

51.8

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

16.4 KW 21.6 KW 18.5 KW 22 KW 26.3 KW 34.9 KW 29.4 KW 34.9 KW

22 KW

18.5 KW

19.6 KW

16.5 KW

17.1 KW

14.3 KW

26.4

24.2

26.3 KW 34.9 KW 29.4 KW 34.9 KW

25.8 KW 34.3 KW 28.8 KW 34.3 KW

20.5 KW 27.3 KW 22.9 KW 27.3 KW

77.8 88.8 41.4 44.9

Water Connections: Cold Water (drinking water quality)

Flow Pressure:

Water Inlets: 3/4" GHT-F (Female Garden Hose

30 - 60 PSI

Connection)

Treated Water for Steam Generator

Untreated Water for Condenser

Drain Connection: 2" T

Venting: Exhaust Hood required

*Connection for Cleaning Solution

*Connection for Rinse Cycle

Available as an option

*

Note: For additional connection details,

see spec sheet for each individual

combi model to be stacked.

ube

SECT. IIB PAGE 5H

0707

Loading...

Loading...