Page 1

Installation Manual

a

)

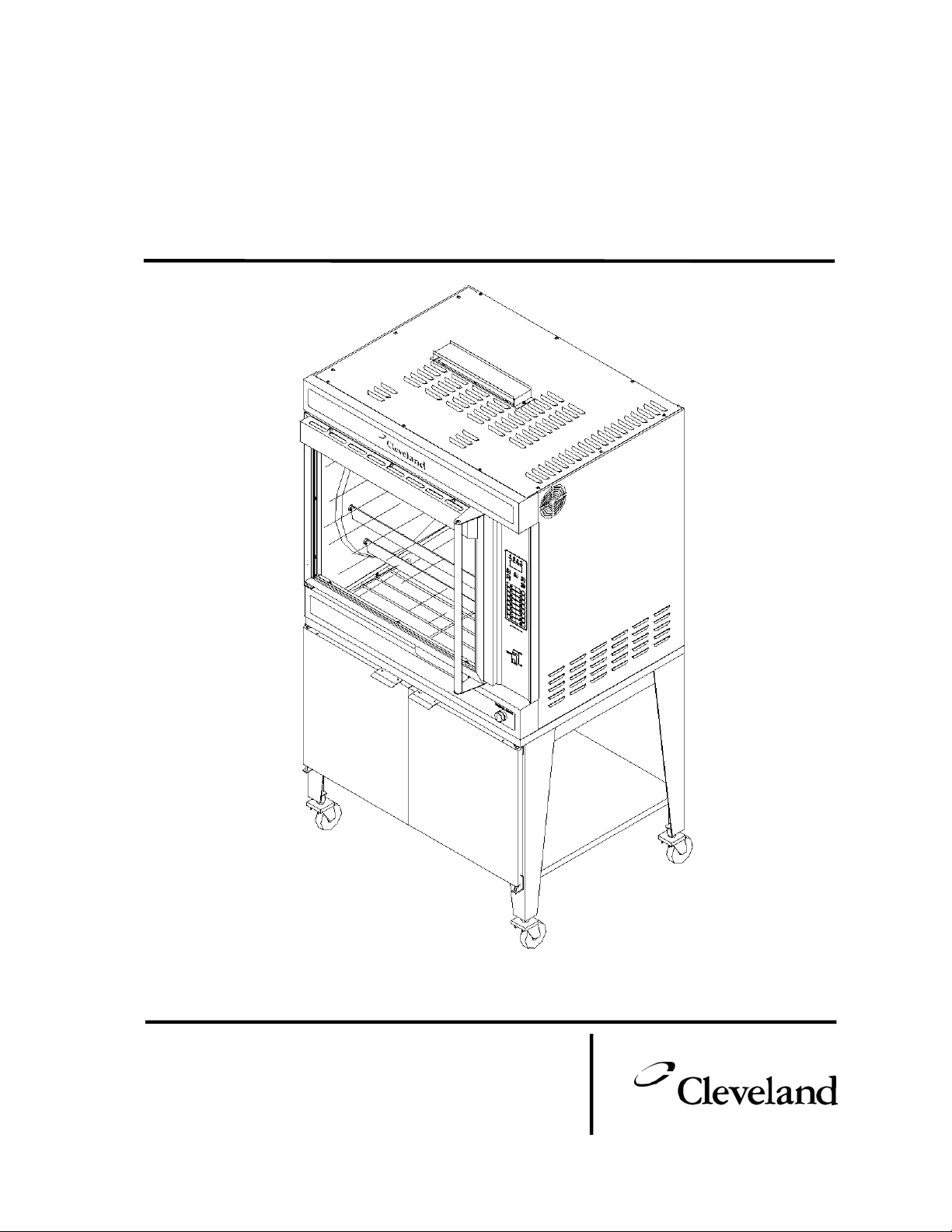

Installation Instructions

Gas Convection Rotisserie and Holding Oven

Models: CR32, CR32-DD, CR32-FP, CR32-FFP

CR28, CR28-DD, CR28-FP, CR28-FFP (CR32 Shown

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481-4900

F

x: (216) 481 3782

Part No. CR-INM REV. A 06/01

Page 2

FOR THE INSTALLER

FOR YOUR SAFETY

Do not store or use gasoline

or other flammable vapors or

liquids in the vicinity of this

or any other appliance.

WARNING

Disconnect power before servicing

Improper installation, adjustment,

alterations, service or maintenance can

cause property damage, injury or death.

Read the installation, operating and

maintenance instructions thoroughly

before installing or servicing this

equipment

.

WARNING

IMPORTANT

IT IS IMPORTANT, TO POST INSTRUCTIONS, WHICH ARE TO BE

FOLLOWED IN THE EVENT THE USER SMELLS GAS. THESE

INSTRUCTIONS SHOULD BE LOCATED IN A PROMINENT LOCATION, AND

BE FULLY UNDERSTOOD BY ALL USERS OF THIS EQUIPMENT. THIS

INFORMATION SHOULD BE OBTAINED FROM YOUR LOCAL GAS

SUPPLIER.

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED CLEVELAND

RANGE AUTHORIZED TECHNICIAN.

The wiring diagram is located on the back of the right side panel.

RETAIN THIS MANUAL FOR YOUR REFERENCE

Page 3

Installation Manual

Rotisserie Oven and CBS-32 Stand

or CR-334 Warming Cabinet

Important SAFETY

Information

WARNING:

Improper installation of the rotisserie could result

in BODILY INJURY or DEATH as well as

EQUIPMENT DAMAGE. Improper installation

also will void the equipment warranty.

Limit of Liability

In no event shall Cleveland Range assume any

liability for consequential damage or injury resulting

from installations which are not in strict compliance

with our instructions, and with applicable codes.

Specifically, Cleveland Range will not assume any

liability for damage resulting from improper

installation of equipment including, but not limited

to, temporary installations.

Ensure Safe Installation

The rotisserie is designed and built to comply with

all applicable national certification codes.

Cleveland Range is not responsible for loss of

certification if installed contrary to any prevailing

codes.

When NOT to Install

To remain safe to operate, the unit MUST NOT be

installed:

Contradictory to our instructions, requirements,

•

and specifications.

In violation of any applicable national, state or

•

local codes.

In temporary locations.

•

If the equipment is damaged or suspected of

•

damage during shipment or storage.

If the equipment has been altered from its

•

original factory configuration.

If the equipment has undergone any improper

•

and unauthorized repair, maintenance, or

service.

Ensure Safe Operation – All Personnel

Must Be Properly Trained

Qualified Persons

Cleveland Range products are intended for

installation, operation, care and maintenance by

professionally trained personnel only.

DO NOT allow unqualified persons to install,

operate, maintain, or repair the rotisserie. Any

repair of the rotisserie must be done by a Cleveland

Range Authorized Service organization.

Proper Training

All rotisserie operators must be trained according to

the operation and cleaning procedures provided in

the Rotisserie Operation Manual. Those

procedures must be supplemented with any

additional actions consistent with the safe operation

and care of professional food preparation

equipment.

Introduction

This guide describes how to install a Rotisserie

Convection Oven.

Proper support for the oven consists of either the

CBS-32 stand or the CR-334 Warming cabinet.

(Instructions for installing the warming cabinet are

in a separate guide, shipped with the unit.) The

oven must be properly bolted to the stand or

cabinet. A drain kit is supplied so the drip pan at

the bottom of the oven can be plumbed through the

stand or cabinet to a bucket or basin.

The cabinet and stand have 4 casters (2 lockable

casters up front). Caster shims are supplied to

level the unit. The stand and cabinet are equipped

with a metal eye for restraining the unit to the wall

(required for movable gas appliances).

CONTENTS:

Note to the Owner About Safety and Warranty

•

Note to the Installer

•

Preparing the Site

•

Assembling the Oven to the Stand

•

Installing the Drain Kit

•

• Leveling and final Connections

1 Cleveland Range, Inc.

Page 4

About the Warranty

Installation Manual

Protect Your Warranty Coverage

The Cleveland Range warranty reprinted in this

manual requires the rotisserie to be properly

installed, maintained, and operated.

If these responsibilities are not met, the Limited

and/or Extended Limited Warranty coverage may

be adversely affected.

Notes for the Installer:

Before you Begin

Understand Installation Requirements

Read this installation guide completely before

beginning installation. Follow all safety precautions

and instructions. Comply with all applicable

national, state and local codes.

This guide must be used together with your

professional experience and a thorough

understanding of the codes.

The instructions given in this guide are for qualified

trade professionals only: we do not include all the

procedures that are in the common domain of

licensed plumbers, pipefitters, electricians, and

experienced food service equipment installers.

Factors That May Void or Adversely Affect

Warranty Coverage

Several installation and operation factors have in

the past affected warranty coverage, most

commonly those listed below. Make sure these

factors are properly resolved before placing the unit

into operation.

Incorrect electrical and gas Supply

•

Equipment Not Properly Leveled

•

Inadequate Cooling and Ventilation

•

Inadequate Side and Back Clearances

•

The National Electrical Code, ANSI/NFPA No. 70

(latest edition) or the Canadian Electrical Code,

CSA C22.2 as applicable, the Food Service

Sanitation Manual of the Food and Drug

Administration (FDA) and all applicable state and

local codes and regulations.

Unpack, Inspect, and Store the Equipment Until

Ready to Install

After receiving each piece of Cleveland Range

equipment for the installation, the shipping carton(s)

should be inspected. If no damage is found or

suspected, the units should be stored in a dry, outof-the-way location, in their protective cartons, until

the site has been prepared for installation.

The installation of this oven must conform with the

Basic Plumbing Code of the Building Officials and

Code Administrators International, Inc. (BOCA), the

National Fuel Gas Code, ANSI Z223.1 (latest

edition) or the Natural Gas Installation Code

CAN/CGA-B-149.1 or the Propane Installation Code

CAN/CGA-B-149.2 as applicable.

Save This Manual

Keep This Manual for Future Reference

Fill in the information at right and keep this manual

(along with a copy of the Operation Manual) in the

owner’s files.

DO NOT Install Damaged Equipment

If shipping damage is discovered or suspected,

prepare a shipping damage claim:

Notify the delivery carrier.

•

Write down a damage description right

•

away, for use with claim forms later.

Arrange for the carrier representative to

•

examine the damage.

Fill out all appropriate claim forms; get

•

examining carrier’s signature and date.

Model:___________ Ser. #:_______________

Installed By: ___________________________

Installing

Date: ___________Organization:__________

Startup By: ____________________________

Startup

Date: ___________Organization: __________

Rotisserie Oven 2

Page 5

Installation Manual

Preparing the Site – General Information

Assure Sufficient Clearances

Clearances specified for the oven on the rating

label are required for the proper cooling,

ventilation, and combustion air supply. Make sure

nothing obstructs the flow of combustion and

ventilation air. Depending on the number of units

being installed, make sure there is enough

clearance between each unit, and from walls to the

sides and to the rear. Failure to provide the

necessary clearance may void the manufacturer’s

warranty. A proper air supply for combustion and

ventilation is critical to safe, efficient operation of

the oven.

Equipment Leveling

For proper operation and water pan drainage, the

equipment must be level. Use the leveling spacers

provided with the casters.

spacers

into its final location.

Restraining Cables

Restraining cables must be installed to limit the

movement of the appliance and protect flexible gas

lines from breakage on gas appliances with

so that equipment is level when rolled

Install leveling

casters. Anchor the cables into wall studs and

connect them to the eyelets provided in the stand

or warming cabinet. The installation shall be made

with a connector that complies with the Standard

for Connectors for Movable Gas Appliances, ANSI

Z21.69 or Connectors for Moveable Gas

Appliances, CAN/CGA-6.16, and a quickdisconnect device that complies with the Standard

for Quick-Disconnect Devices for Use With Gas

Fuel, ANSI Z21.41, or Quick Disconnect Devices

for Use with Gas Fuel, CAN1-6.9.

Provide a Powered Exhaust Hood

Code requires an exhaust hood. The hood must

meet dimension requirements, and must have

adequate exhaust capacity, based on the

combined BTU output of the ovens.

a direct connection to the oven exhaust vent

Fire Safety

Do not store or leave combustible materials near

the oven. Consult your local codes for fire

protection requirements

must be posted. Your gas utility can supply a sign

or the appropriate wording for a sign.

. Gas Leak Instructions

Never make

.

Preparing the Site – Gas and Electrical Services

Gas Pressure

Test the building’s gas supply pressure. It must

meet Cleveland Range’s specifications. (See

pages 5-8.) If gas pressure is too high, install a

pressure regulator (excess pressure will damage

the equipment) – if too low, notify the gas company

to raise pressure to specs.

Gas Flow

Sufficient gas flow is important to oven

performance. During peaks hours of operation gas

flow may be insufficient if pipe diameter is too

small. Feed a multiple-oven installation with a

manifold-type gas supply line sized properly for

good flow.

Gas Plumbing

Provide a shut-off valve, drip leg, and flexible

supply line for each oven. Use appropriate ¾-inch

IPS plumbing components. Follow applicable

codes. Seal all threaded joints with suitable joint

compound, resistant to the action of liquefied

petroleum gases.

Gas Leak Tests

After completing the gas plumbing, close all oven

shut-off valves and test all upstream joints under

pressure, using a soap-rich water solution. Repair

all leaks and retest. The steamer must be isolated

from the gas supply system during any pressure

testing as follows: (1) The appliance and its main

manual shut-off valve must be disconnected from

the gas supply piping system during any pressure

testing of the system at test pressures in excess of

14” water column (1/2 psi or 3.45 kPa). (2) The

appliance must be isolated from the gas supply

piping system by closing its main manual shut-off

valve during any pressure testing of the gas supply

piping system at test pressure equal to or less than

14” water column (1/2 psi or 3.45 kPA).

Electrical Supply: Oven

Each oven is equipped with a 120V/15A-power

cord, with a three-prong (grounding) plug for

protection against shock hazard. It should be

plugged directly into a properly grounded threeprong receptacle. Do not cut off or remove the

grounding prong from the plug. (Some local codes

may require a different form of disconnect.)

Electrical Supply: Optional Warmer

The CR-334 warming cabinet can draw up to 30

amps, and must be provided with a suitable

grounded branch circuit and outlet. The power

3 Cleveland Range, Inc.

Page 6

Installation Manual

cord supplied with the warmer has a NEMA type

L5-30P plug.

3 Cleveland Range, Inc.

Page 7

Assembling the Oven to Stand

(If not pre-assembled, see dwgs. 260AMT & 260ANN)

Installation Manual

Note: Instructions for assembling the oven to

the optional CR-334 warming cabinet are in a

separate guide, shipped with that unit.

Before beginning to assemble the 2 components,

inspect the equipment for damage. Do not install

damaged equipment.

Remove all tape and protective film from the oven

and the stand.

Find – and set aside – all packaged components,

such as the installation/Drain kit, rotisserie spits,

baskets, tools, etc. Locate the Installation/Drain Kit

(P/N 107442) and unpack all parts. (Drawing

260ANN has a list of all drain kit parts.)

Installing the Drain Kit

(If not pre-installed, see dwg. 260ANN)

The oven is equipped at the factory with an elbow

on the drain pan. It is angled downward and

toward the rear, and is sealed against leaks.

During installation of the drain kit, be careful not to

break this seal. When assembling the drain kit

components, use a suitable sealant on all threaded

joints.

Install the 1-by-4 inch pipe nipple (item #3) to the

drain pan elbow.

Install the 4 casters to each leg of the stand – put

the 2 locking casters at the front of the unit. (After

the assembly is in place, caster spacers will need

to be installed to level the unit.

With a lift truck, or other safe means, lift the oven

onto the stand. Position the oven so that the

mounting holes in the stand and the oven line up.

(The oven overlaps the stand at the sides and rear

by 1/8-inch and at the front by 1-3/4-inch.)

Bolt the 2 units together with the 3/8-inch hardware

provided. Insert the hardware from below, through

the stand. Thread the bolts into the weldnuts in

the bottom of the oven and tighten.

Install the hose barb fitting (item #5) into the drain

valve (item #4). Next, install the drain valve onto

the nipple. Position the valve for easy operator

access from the front of the stand. Make sure it

can be opened and closed without obstruction.

Assemble the drain tube (item #8) and the hose,

using the double wire hose clamp (item #6). Then

connect the hose to the hose barb, using the other

hose clamp.

Apply a bead of RTV adhesive/sealant around the

top surface perimeter of the drain blockoff plate

(item #2), and slide over the nipple. Position the

plate to block the opening between the stand and

the interior of the oven, and adhere it to the base.

This blockoff is required to maintain sanitary

certification.

Rotisserie Oven 4

Some CBS-32 stands will be shipped with 1 or 2

optional side panels. Install these if supplied.

Page 8

Installation Manual

5 Cleveland Range, Inc.

Page 9

Installation Manual

Rotisserie Oven 6

Page 10

Installation Manual

7 Cleveland Range, Inc.

Page 11

Installation Manual

Rotisserie Oven 8

Page 12

Installation Manual

9 Cleveland Range, Inc.

Page 13

Move Unit Into Place, Level It,

and Finish the Installation

Installation Manual

Move the unit into its desired location, no closer

than 3-inches from the rear wall for single door

units and 36-inches for double door units, and 3

inches from another unit or a side wall. For hearth

installation, back of unit may be in contact with

non-combustible hearth wall opening.

If right side clearance is limited to 3”, there must be

adequate space to roll unit out for service access.

Using a level and the caster spacers provided in

the drain installation kit, (if drain kit is pre-installed,

caster spacers will be supplied in rotisserie cooking

cavity), level the unit. Do not shim any caster more

than 7/8-inch. Be sure to tighten the caster

retaining bolts.

Safety Precautions Before

Startup and Checkout

CAUTION

The Performance Checkout consists of tests to

make sure the oven is functioning properly and

safely. It should be performed only by qualified

Cleveland Range authorized technicians, familiar

with the operation, troubleshooting, and repair of

the Rotisserie oven. This service is provided by

Cleveland Range, Inc. at no cost. Contact either

your local distributor or the factory for information

on who the closest Cleveland Range authorized

service agency is to schedule the performance

checkout and start-up.

Install the gas appliance restraining cable (not

supplied by Manufacturer). Make sure the cable is

short enough to prevent the flexible gas line from

ever being pulled tight and being subject to

rupture.

Make Sure Electrical Power Stays Off Until

Startup Procedure is Initiated

If power is supplied from a standard wall outlet,

leave the unit unplugged. If the electrical power is

supplied through a disconnect, make sure the

disconnect is securely off.

Rotisserie Oven 10

Page 14

LIMITED WARRANTY

CLEVELAND RANGE products are warranted to the original purchaser to be free from defects in materials

and workmanship under normal use and service for the standard warranty period of one year from date of

installation or 18 months from date of shipment, which ever comes first.

CLEVELAND RANGE agrees to repair or replace, at its option, f.o.b. factory, any part which proves to be

defective due to defects in material or workmanship during the warranty period, providing the equipment has

been unaltered, and has been PROPERLY INSTALLED, MAINTAINED, AND OPERATED IN ACCORDANCE WITH

THE CLEVELAND RANGE OWNER’S MANUAL.

CLEVELAND RANGE agrees to pay any FACTORY AUTHORIZED EQUIPMENT SERVICE AGENCY (within the

continental United States, and Hawaii) for reasonable labor required to repair or replace, at our option, f.o.b.

factory, any part which proves to be defective due to defects in material or workmanship, during the labor

warranty period. This warranty includes travel time not to exceed two hours and mileage not to exceed 50 miles

(100 miles round-trip), BUT DOES NOT INCLUDE POST START-UP, TIGHTENING LOOSE FITTINGS, MINOR

ADJUSTMENTS, MAINTENANCE, CLEANING OR DESCALING.

The standard labor warranty allows factory payments of reasonable labor required to repair or replace such

defective parts. Cleveland Range will not reimburse the expense of labor required to repair or replacement of

parts after the standard warranty period, unless an Extended Labor Warranty Contract has been purchased to

cover the equipment for the balance of the warranty period from the date of equipment installation, start-up, or

demonstration.

PROPER INSTALLATION IS THE RESPONSIBILITY OF THE DEALER, THE OWNER-USER, OR INSTALLING

CONTRACTOR, AND IS NOT COVERED BY THIS WARRANTY. Many local codes exist, and it is the

responsibility of the owner and installer to comply with these codes. Cleveland Range equipment is built to

comply with applicable standards for manufactures, including UL, A.G.A., NSF, ASME/Ntl. Bd., CSA, CGA, ETL,

and others.

Boiler (Steam Generator) MAINTENANCE IS THE RESPONSIBILITY OF THE OWNER-USER AND IS NOT

COVERED BE THIS WARRANTY. The use of good quality feed water is the responsibility of the Owner-User

(see Water Quality Recommendations below). THE USE OF POOR QUALITY FEED WATER WILL VOID

EQUIPMENT WARRANTIES. Boiler maintenance supplies, including boiler hand gaskets, are not warranted

beyond the first 90 days after the date the equipment is placed into service. Preventive maintenance records

must be available showing descaling per the applicable Cleveland Operators Manual for Boiler Proration

Program considerations.

WATER QUALITY RECOMMENDATIONS

TOTAL DISSOLVED SOLIDS Less than 60 parts per million

TOTAL ALKALINITY Less than 20 parts per million

SILICA Less than 13 parts per million

CHLORIDE Less than 30 parts per million

pH factor Greater than 7.5

The foregoing shall constitute the sole and exclusive remedy of original purchaser and the full liability of

Cleveland Range for any breach of warranty. THE FOREGOING IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES, WHETHER WRITTEN, ORAL, OR IMPLIED, INCLUDING ANY WARRANTY OF PERFORMANCE,

MERCHANTABILITY, OR FITNESS FOR PURPOSE, AND SUPERSEDES AND EXCLUDES ANY ORAL

WARRANTIES OR REPRESENTATIONS, OR WRITTEN WARRANTIES OR REPRESENTATIONS, NOT

EXPRESSLY DESIGNATED IN WRITING AS A “WARRANTY” OR “GUARANTEE” OF CLEVELAND RANGE MADE

OR IMPLIED IN ANY MANUAL, LITERATURE, ADVERTISING BROCHURE OR OTHER MATERIALS.

CLEVELAND RANGE’S liability on any claim of any kind, including negligence, with respect to the goods or

services covered hereunder, shall in no case exceed the price of the goods or services, or part thereof, which

gives rise to the claim. IN NO EVENT SHALL CLEVELAND RANGE BE LIABLE FOR SPECIAL, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, OR ANY DAMAGES IN THE NATURE OF PENALTIES.

LIMITED EXTENDED WARRANTY COVERAGE

The purchase of a Limited Extended Warranty Contract extends the standard warranty coverage to the

purchased period of time (one to two years) from the date of installation, start-up, or demonstration, whichever

is sooner.

An additional two years Parts and Labor Warranty can be purchased with each piece of Cleveland

equipment for an additional 2% of the List Price per year. The 2% of list price charge will be the net invoice

amount for each year of extended warranty purchased.

-

Extended warranty must be purchased at the same time the equipment is purchased.

-

Extended Warranty has the same exclusions as stated in our standard warranty.

Loading...

Loading...