Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

CLASSIC CONVECTION STEAMERS

15 PSI BOILER BASE STYLE

C

Cleveland Classic Series

TWO COMPARTMENT, PRESSURELESS

PLUS ONE 6 GALLON KETTLE

24, 36 OR 48 KW ELECTRIC STEAM GENERATOR

42” WIDE CABINET BASE DESIGN

Cleveland Standard Features

n

Cooking Capacity for up to six 12˝ x 20˝ x 21⁄2˝ deep Cafeteria Pans.

n Pressureless cooking with forced convection steam, permitting

doors to be opened while cooking continues.

n

Solid State Controls operate water level and safety functions.

n

Each compartment is equipped with a 60 minute mechanical

timer, separate bypass switch for constant steaming and a

cold water condenser for superior cooking results.

n Instant Steam Standby Mode: Holds generator at steaming

temperature. Allows unit to start cooking instantly.

n Durable 14 Gauge Stainless Steel Construction:

For Compartment Door and Steam Cooking Cavity.

n Separate Main Power Switch for “On/Off”

n Exclusive Steam Cooking Distribution System:

sive Convection Jets produce a high velocity convection steam

without fans. Coved Corner design in cooking compartment distributes heat evenly and is easy to keep clean. Creased top & bottom enhance drainage. Cold Water Condenser for each

compartment maintains a dry steam. Fully insulated cooking compartment for thermal efficiency. Removable Stainless Steel Slide

Racks for easy cleaning.

n Exclusive “Cool to the Touch” Compartment Door Design:

Free floating inner door with reversible door gasket provides

an air tight seal. Stainless Steel Slam/Latch Door Latch mechanism provides greater reliability.

n Left Hand Door Hinging: Compartment Doors hinged left,

controls on the right.

n Modular Cabinet Base with Hinged Door.

n

Electric Steam Generator: Automatic W

n Automatic Generator Drain at shutdown: Contains a “Water

Jet” Spray Rinse Cleaning Cycle to keep drain clear.

n Automatic Water Level Control System with Low Water

Power Cut-of

n

Steam generator equipped with High Limit Pressure Safety Switch,

f Circuit.

15 psi Safety Valve, and Steam Generator Pressure Gauge.

n Secondary Low Water Cut-Off, factory installed (CALE)

(Required for AZ. AR. CA. CO. CT. DE. FL. GA. HI. IL. IA. KS. MD. MA. MI. MN.

MT. NE. NV. NM. NC. OK. OR. PR. RI. TN. UT. VA. WA. WV., Buffalo, NY, Wash. DC)

n NSF Certified 6˝ Stainless Steel Legs with adjustable

flanged feet for a one inch level adjustment.

n Standard voltage 208 or 240 volts, 60 Hz, 3 phase.

able Top includes 2˝ deep Drain Trough with

n

T

n 6 gallon Tilting Kettle made of type 304 Stainless Steel,

2

⁄3 jacketed

Kettle includes:

n Trunnion Mounted Steam Control Valve

n 50 psi kettle Steam Jacket Pressure Rating

n Lift Of

n Double Pantry Faucet with Swing Spout

f Cover

ater Fill on start up.

STEAMERS

3

⁄4˝ Drain &

ONVECTION

The exclu-

Grate

MODELS:

c 42-CKEM-24 c 42-CKEM-48

c 42-CKEM-36

Shown with optional

Electronic Timer

Shall be Two Compartments, CLEVELAND Convection Steamer, plus one 6

gallon Direct Steam, tilting, kettle, Model 42-CKEM- _____ , Electric

_____ volts, _____phase, 3 wire. Solid State Controls operate timing, water level

and safety functions. Electric Steam Generator with Automatic Water Fill on

start-up and Automatic Blowdown with additional Manual Drain Valve. For

each cooking compartment: 60 minute Mechanical Timer, Manual Operation

Mode and Cold Water Condenser. Type 304 Stainless Steel cooking compartment.

Options & Accessories

p Right Hand Door Hinging, Controls on the Left (DHR)

p Electronic Timer with Compensating Load Feature (ETC)

p ON/OFF Steam Switch only for compartment controls (MC)

p Cafeteria pans in depths of 1˝, 21⁄2˝, 4˝ and 6˝

p Compartment Door Steam Shut Of

oltages other than standard (see back page)

p V

p Correctional Packages

p Power

p Stainless Steel Base Frame (FSS)

ype 316 Stainless Steel Liner for high acid products (316-6G)

p T

p Boiler Descaling Pump Kit (107142)

ater Filters

p W

Short Form Specifications

f Switch (SCS)

ake Off Kit (EPTO), Kettle Interconnecting Kit (IMK)

T

SECT. III PAGE 17

0707

Page 2

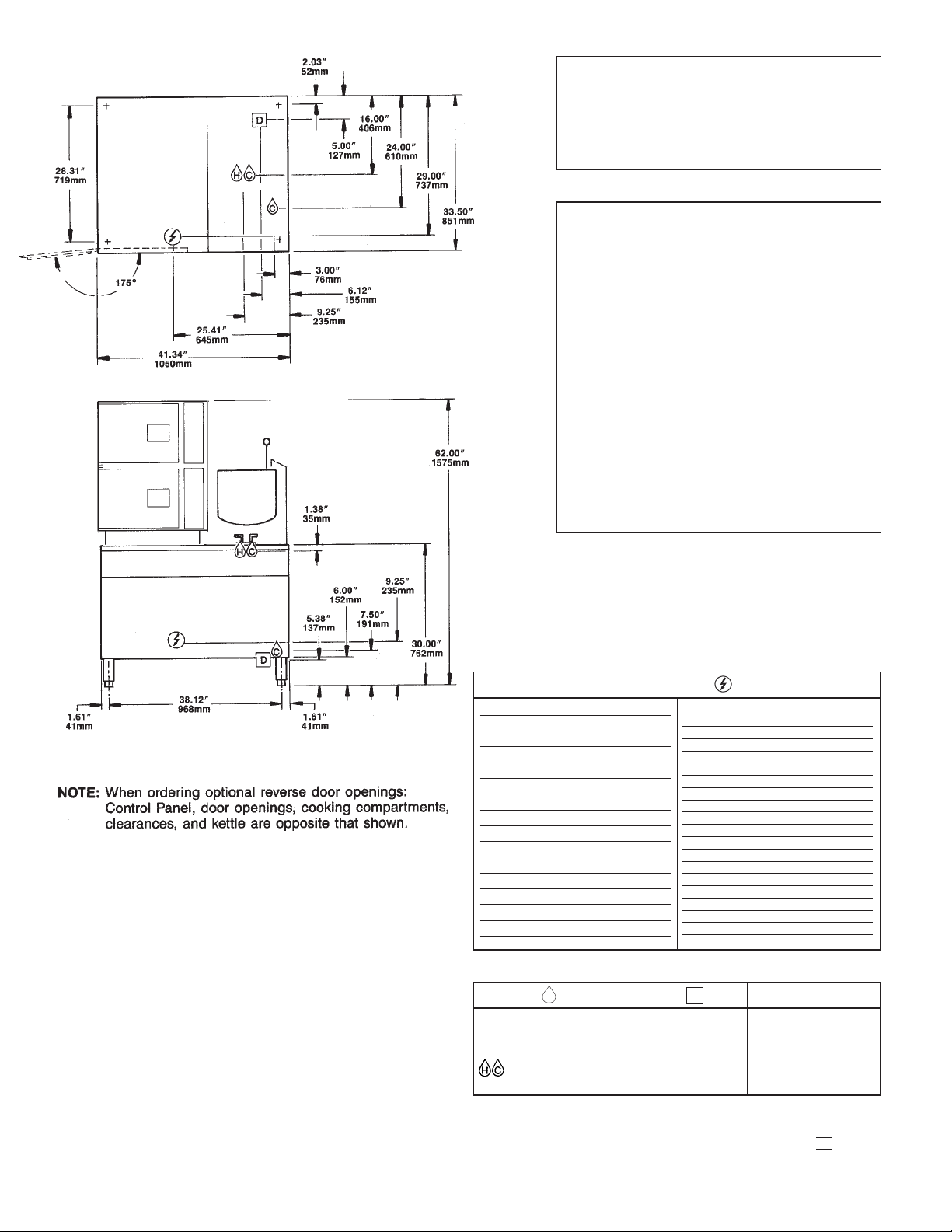

C

ACTUAL CAPACITIES:

Kettle 6 gallons/23 liters or 192, 4 oz. servings.

Other size servings may be calculated.

•

Each compartment has capacity for:

Three, 12˝ x 20˝ x 2

•

1

or six, 12˝ x 20˝ x 1˝

⁄2˝

deep Cafeteria Pans.

WATER QUALITY REQUIREMENT

The recommended minimum water quality stan-

ards whether untreated or pre-treated, based

d

upon 10 hours of use per day, and a Daily

Blowdown, are as follows:

TOTAL DISSOLVED

SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

pH FACTOR greater than 7.5

CHLORINE less than 30 parts per million

Consult a local water treatment specialist for an on

site water analysis for recommendations concerning

steam generator feed water treatment (if required),

in order to remove or reduce harmful concentrations

of minerals. The use of highly mineralized water will

mean that more frequent servicing

generator will be necessary. The fact that a water

supply is potable is not proof that it will be suitable

for the generator.

of the steam

ELECTRIC

KW Volts

24 208 21,500 1 103.4 2

WATER DRAINAGE CLEARANCE

1/4˝ NPT , Cold Water

Inlet, 35 psi minimum,

60 psi maximum

TES

NO

:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are ASME/N. Bd, UL, NSF and CSA.

Watts Ph Amps Wire

220 24,000 1 109.1 2

240 24,000 1 100.0 2

440 20,200 1 45.9 2

480 24,000 1 50.0 2

208 21,500 3 59.7 3

220 24,000 3 63.1 3

240 24,000 3 57.8 3

440 20,200 3 26.5 3

24,000 3 28.9 3

480

600 24,000 3 23.1 3

360

21,500 3 34.5 4

380 24,000 3 36.5 4

415 24,000 3 33.4 4

The Floor Drain must be located

outside the confines of the

1/4" NPT hot

and cold water

for swing spout

equipment base.

1 1/2˝ I.P.S. common drain.

Do not connect other units to this drain.

Do not use PVC pipe for drain.

KW Volts

36 208 32,200 3 89.5 3

48 208 42,900 3 119.2 3

D

Watts Ph Amps Wire

220 36,000 3 94.6 3

36,000 3 86.7 3

240

440 30,200 3 39.7 3

480

600 36,000 3 34.7 3

360 32,200 3 51.7 4

380 36,000 3 54.8 4

415 36,000 3 50.1 4

220 48,000 3 126.1 3

240 48,000 3 115.6 3

440 40,300 3 52.9 3

480 48,000 3 57.8 3

600 48,000 3 46.2 3

360 42,900 3 68.9 4

380 48,000 3 73.0 4

415 48,000 3 66.9 4

3 43.4 3

36,000

Right - 3”, Left - 3”, Rear - 3”

(12” on control side if

adjoining wall or equipment

is over 30” high for service

acess)

Contact factory for

ariances to clearances.

v

T

(NOT

.

SECT

III P

Litho in U.S.A.

O SCALE)

AGE

18

0707

Loading...

Loading...