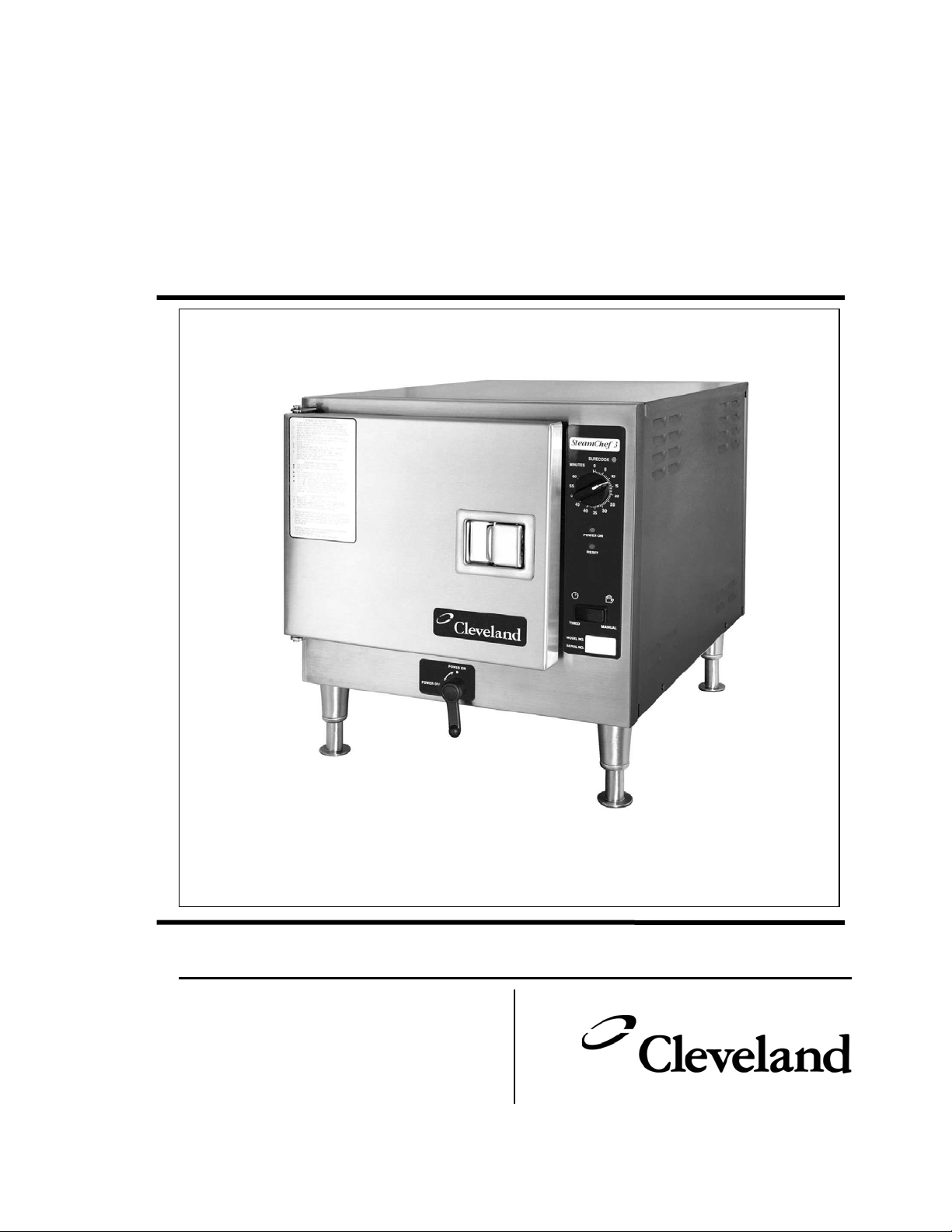

Page 1

Operators Manual

Installation, Operation, Use & Care

Steam Cooker and Rethermalization Unit

Series: SteamChef¥ 3 Model 22CET3A Series

1333 East 179th Street

Cleveland, Ohio 44110

Phone: (216) 481-4900

Fax: (216) 481 3782

22CET3-OPM A 2/03

Page 2

FOR THE USER

FOR YOUR SAFETY

Do not Store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

WARNING

Disconnect power before servicing

Improper installation, adjustment, alterations,

services or maintenance can cause property

damage, injury or death. Read the

installation, operating and maintenance

instructions thoroughly before installing or

servicing this equipment.

WARNING

IMPORTANT

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED CLEVELAND

RANGE TECHNICIAN.

RETAIN THIS MANUAL FOR YOUR REFERENCE

Page 3

Operators and Installation Manual

SteamChef¥ 3 Steam Cooker and Rethermalization Unit

Table of Contents

CHAPTER PAGE

CHAPTER 1. INTRODUCTION …………………………………………..……………………….… 1

A. OPERATIONAL SAFETY…………………………………………………………….…..……………… 1

B. PRODUCT INFORMATION …………………………………..……………………………………….. 2

1. Model Number……………………………………………………………………………………..…. 2

2. Serial Number …….…………………………..……………………………………………..……… 2

3. Product information Plate ………………………………………..………………………….……… 2

4. “SteamChef¥ 3” Model No. 22CET3A Product View ……………..………….…..…………...… 3

CHAPTER 2. OPERATION ………………………………………..…………….……………………… 4

A. GENERAL OPERATION ………………………………………..…………………….………………… 4

1. Main External Power Switch ……………………………….……………………………………….. 4

2. Door Interlock Switch …………………………………………………………………………….….. 4

3. KleanShield¥ ………………………………………………….………………………………….….. 4

4. Inspecting the Cooking Compartment ……………..……………………………….…………….. 5

5. Power ON (Auto Water Fill/Automatic Preheat) ………………….…………….………………… 6

6. Preheating the Steamer…………………………………………………………………………..…. 6

7. High Limit Reset ……………………………………………………………………………….….…. 6

8. Energy/Water Saver Feature ………………………………………………………….……..….…. 6

B. CONTROL PANELS ……………….……………………………….……………………………..….… 7

1. Dial Timer Control Panel ………………………………………………………………….………… 7

a. General Operation………………………………………………………………………….….… 7

b. Manual and Timed Modes …………………….……………………………….………….…… 7

(1) Manual Mode ………………………..….………………………………….……………..… 7

(2) Timed Modes …………………………………………………………………….………..… 7

2. “ON/OFF” Control Panel …………………………………….……………………….……………. 8

a. Cooking Operations – ON/OFF Control Panel ……………………………….…………..… 8

b. Operating the ON/OFF Control …………………………………….…………………….…… 9

C. COOKING WITH THE STEAMCHEF¥ 3 ……………………………………………………….….…. 9

1. Operating and Cooking Procedure – Timed Cook Mode ……………….………………….…… 10

2. Operating Procedure – Manual Mode …………………………………………………………….. 11

3. Using the SteamChef¥ 3 to Rethermalize Food ……………..…………………………………. 12

D. SHUTDOWN AND CLEANING PROCEDURE..……………………………………………………… 13

CHAPTER 3 – PREVENTATIVE MAINTENANCE AND TROUBLESHOOTING….. 14

A. MAINTENANCE………………………………………………………………………………………….. 14

1. Maintenance Records……………………………………………………………………………….. 15

2. Daily Maintenance………………………………………………………………………………….… 15

a. Checking and Changing the Water……………………………………………………………. 15

b. Cleaning the Steamer…………………………………………………………………………… 15

3. Yearly Maintenance – Cleaning the Water Strainers ……………..……………….………….… 15

B. OPERATORS TROUBLESHOOTING GUIDE………………………………………………………… 16

CHAPTER 4 – INSTALLATION……………………………………………………….….

A. GENERAL………………………………………………………………………………………………… 19

B. INSTALLATION OF THE STEAMCHEF¥ 3 …………………………………………………………. 19

19

(Continued on Following Page)

Page 4

Table of Contents (continued)

CHAPTER

1. Locating the Steamer……………………………………………………………………………….. 20

Location and Clearance Requirements of the Steamer ………………………………………... 20

2. Installation Using Cleveland Range Stand Model No. ES222834 …………………………….. 21

3. Installation of SteamChef¥ Steamers on the Model No. ES222824S Sacking Stand …..….. 22

4. Installing the Legs …………………………………..……………………………………………… 24

5. Positioning and Leveling the Steamer …………………………………..….……………………. 25

6. Installation of the KleanShield¥ ……………………………………..…..….……………………. 25

7. Installing the Fan Guard ………………………………………………..…..….…………………… 25

8. Install Slide Racks and Rear Vent ………………………………………………………………… 25

9. Install the Free Air Vented Drain Lines ……………………………………………………………. 26

10. Water Supply Requirements and Installation ……………………………………………………. 27

a. Water Supply Requirements …..…….………………………………..…………………..…. 27

b. Install Water Supply Lines …..…….……………………………………………………...…. 27

c. Testing Water Supply Lines …………………………………………………………..……… 29

11. Install Electric Power Lines………………………………………………………………………… 29

C. STARTUP AND CHECKOUT…………………………………………………………………………... 30

1. Installation Checkout ……………………………………………………………………..………… 30

Notes on Installation ……………………………………………………………………..……… 30

2. Operating Test and Final Checkout Procedure………………………………………………….. 31

a. Startup Procedure……………………………………………………………………………… 31

b. Drain Rinse Inspection ……………………………………………………………………….. 32

c. Operating Tests and Final Checkout Procedure (Sequence of Operation) ….…………. 32

PAGE

CHAPTER 4 – STEAM COOKING GUIDE …………..……………………………..…. 35

A. INTRODUCTION ………………………………………………………………………………………… 35

B. SIZING UP PAN CAPACITY ………………………………………………………………..……..…. 36

1. Serving Sizes – How Much? How Many? …………………………….………………..………… 36

2. Reference Charts for Typical Pan Capacities …………………………………..……………….. 36

C. CONVECTION STEAMER – SUGGESTED TIMER SETTING GUIDELINES …………………... 37

D. STEAMING TIPS – LOBSTER – CRAB - SHRIMP ………………………………………………... 39

1. Live Lobster and Crabs …………………………….………………………………..…..………… 39

2. Lobster Tail 8 oz. …………………………………..……………………………………………….. 39

3. King Crab Legs …………………………….……………………………………………..………… 39

4. Shrimp …………………………………..…………………………………………………………... 39

Page 5

CHAPTER 1 – INTRODUCTION

To use a SteamChef¥ 3 steamer safely and effectively, each operator must read and understand this

section completely before starting operation. The owners and operators of the steamer should retain these

instructions in an easily accessible location for future reference and training.

The owner(s) and operator(s) of the steamer must be aware that steam can cause serious injuries and

equipment damage. Pay particular attention to the Operational Safety section of this chapter, and the

WARNINGS and CAUTIONS displayed in this manual and on the equipment.

WARNING

DO NOT ATTEMPT TO START OR OPERATE a SteamChef¥ 3 steamer during a

power outage.

DEATH, INJURY, AND EQUIPMENT DAMAGE could result from the improper

installation of a steamer.

Before starting a recently installed or repaired steamer, be sure it has been installed by

qualified personnel according to the instructions found in CHAPTER 4 of this Manual.

A. OPERATIONAL SAFETY

The safe and effective operation of any steamer depends upon proper installation, use, maintenance, and

repair. Operational safety must encompass all of these factors. This Operational Safety section outlines the

minimum safety policies that should be considered when using one or more SteamChef¥ 3 steamers. It is

assumed that any operational safety program must be tailored to the specific site and use of the equipment.

Burn hazards are present in any professional food service operation. When using the steamer, observe the

following precautions.

x

The SteamChef¥ 3 is a constantly cooking appliance and is in some cooking or standby mode

whenever it is turned ON. As such parts of this appliance will ALWAYS BE HOT.

x

Remember at all times that steam can cause severe burns.

x

Never operate a SteamChef¥ 3 steamer without the KleanShield¥ properly installed in the bottom

of the water reservoir or the fan guard installed over the fan.

x

When checking inside the steamer always open the door slowly and stand to the side and back

away from the steamer.

x

Open the door slightly to allow steam to vent before looking or reaching into cooking compartment.

x

Do not reach into the cooking compartment until the steam has cleared and the cooking fan has

ceased rotating.

x

Do not reach into steamer or handle hot items without wearing heatproof gloves. Wet or damp

gloves conduct heat, and may cause burns when touching hot items.

x

Do not use anything but your hands to operate the controls of the steamer.

x

Do not block the vents on the side or rear of the unit or obstruct the flow of ventilation air to the

steamer. Do not store articles on top of the unit.

x

Do not ever tilt the unit if the main external power to the unit is on, or if the drain is closed.

The steamer requires a minimum of service if properly operated and maintained by trained personnel. The

following steps will help keep the steamer in a safe, efficient operating condition.

1. Do not store or leave combustible materials near the steamer. Keep the area around and under the

steamer free of combustible materials.

2. Non slip draining mats should be on the floor in front of the steamer to prevent slipping accidents from

spilled water.

3. Train all personnel who will use the steamer. Make sure personnel know how to operate the steamer,

clean the interior and exterior, and drain the unit.

1

Page 6

4. Operating personnel must be able to recognize problems, and report them so that corrective actions

can be taken by trained personnel as outlined in the troubleshooting charts found in Chapter 3 of this

manual.

5. Conduct regular steamer inspections. Check for water line leaks, door seal, drain and drain valve leaks,

clogged drain or KleanShield¥, dirty water level sensors, and steamer control malfunctions.

6. Follow the instructions for steamer maintenance found in this manual.

7. Remove spilled food from the surface of the KleanShield¥ and the inside of the steamer reservoir.

Never push solid food remnants down the KleanShield¥ opening or the reservoir drain opening.

8. Before each use of the steamer, inspect the drain and KleanShield¥ for blockage. Inspect the door

gasket assembly, water level sensors, KleanShield¥, fan guard and slide racks for proper installation

and cleanliness.

9. Allow only Cleveland Range authorized service representatives to service the steamer.

10. Use only factory authorized repair parts.

11. Maintain written records of steamer maintenance and service. Each record should include at least:

x

The date of the service or maintenance.

x

A description of the service, maintenance or repair performed. Include part numbers if applicable.

x

Copies of purchase order(s) and invoice(s) for repair parts and service.

x

The name and signature of the person performing the maintenance or service.

B. PRODUCT INFORMATION

Cleveland Range, LLC assigns two product identification numbers to each steamer: a model number and a

serial number. The model number identifies the product characteristics. The serial number identifies the

individual unit. The Model Number and Serial Number are also located on the control panel as well as the

product information plate for your convenience in accessing this information.

1. Model Number

This manual covers the SteamChef¥ 3 Model No. 22CET3A Steam Cooker and Rethermalizer. Each

character of this model number identifies a characteristic of the steamer. The SteamChef¥ 3 Model No.

22CET3A is 22 inches wide, is a Convection Steamer, an Electric Tabletop Model, cooks up to 3

standard 2 ½” pans of food and A equipped with Auto fill/drain option. This manual covers all standard

features and options available on SteamChef¥ 3 electric steamers.

Other than selection of options, there are presently no significant design, parts, or operating differences

among steamers with this model number. Figures 1-2 and 1-3 illustrate the major external features.

2. Serial Number

During manufacture, SteamChef¥ 3 Steamers are assigned individual serial numbers. Whenever any

inquiry is made with Cleveland Range regarding a steamer the serial number should be referenced.

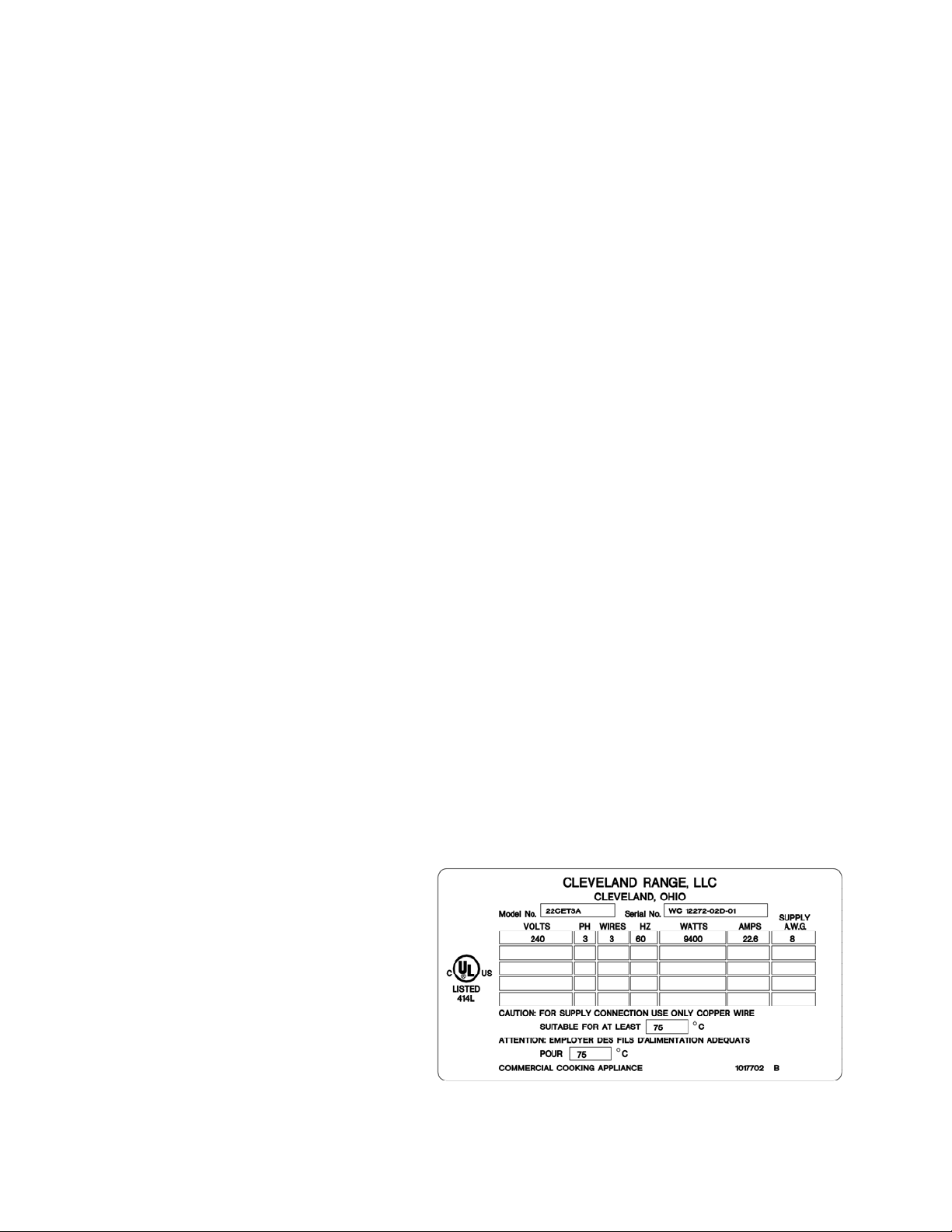

3. Product Information Plate

The Product Information Plate on

the rear of the unit lists the model

and serial number as well as the

power and wiring requirements of

the steamer. Refer to Figure 1-3 for

the location of the plate. Figure 1-1

illustrates a typical SteamChef¥ 3

Product Information Plate.

Figure 1-1 SteamChef¥ 3 Product Information Plate

2

Page 7

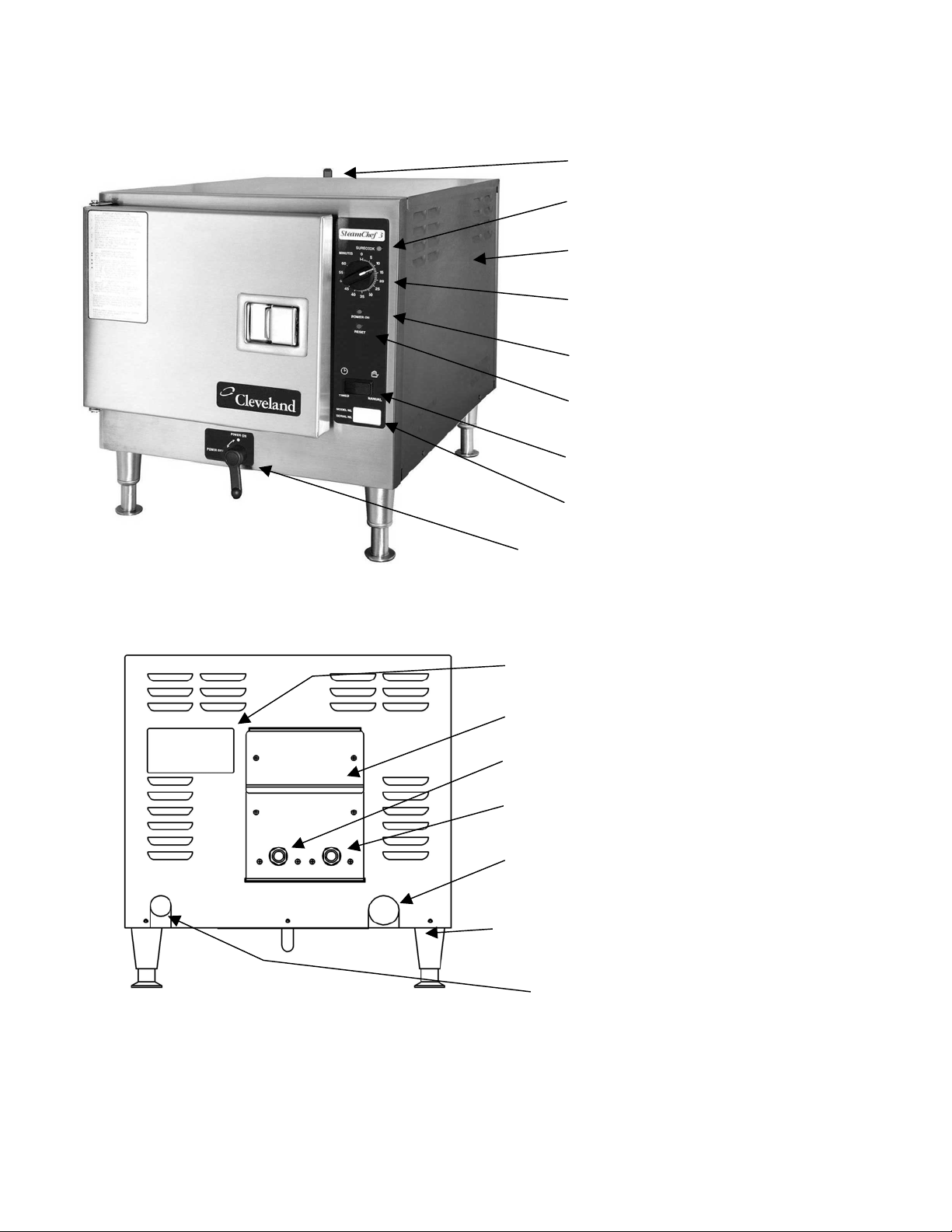

4. “SteamChef¥ 3” Model No. 22CET3A Product Views

Cavity Vent from Drain

“SureCook” Indicator

Removable Side Panel

Timer Control with Thermostatic

Control Feature

Power ON Indicator

Hi Limit Reset Indicator

Manual/Timed Selector Switch

Model/Serial Number Insert

Drain Valve/ Main Power ON/OFF Lever

-

Figure 1-3 SteamChef¥ 3 Steam Cooker Rear View

¥

Product Information Plate

Includes Serial/Model

Number Information

Rear Access Panel for Fan

Water Fill Connection

Condenser Connection

Outlet for Drain/Vent

Assembly

4” (102mm) Adjustable

Legs with Skid Resistant

Flanged feet

Opening for Electrical

Conduit Connection

3

Page 8

CHAPTER 2 – OPERATION

A. GENERAL OPERATION

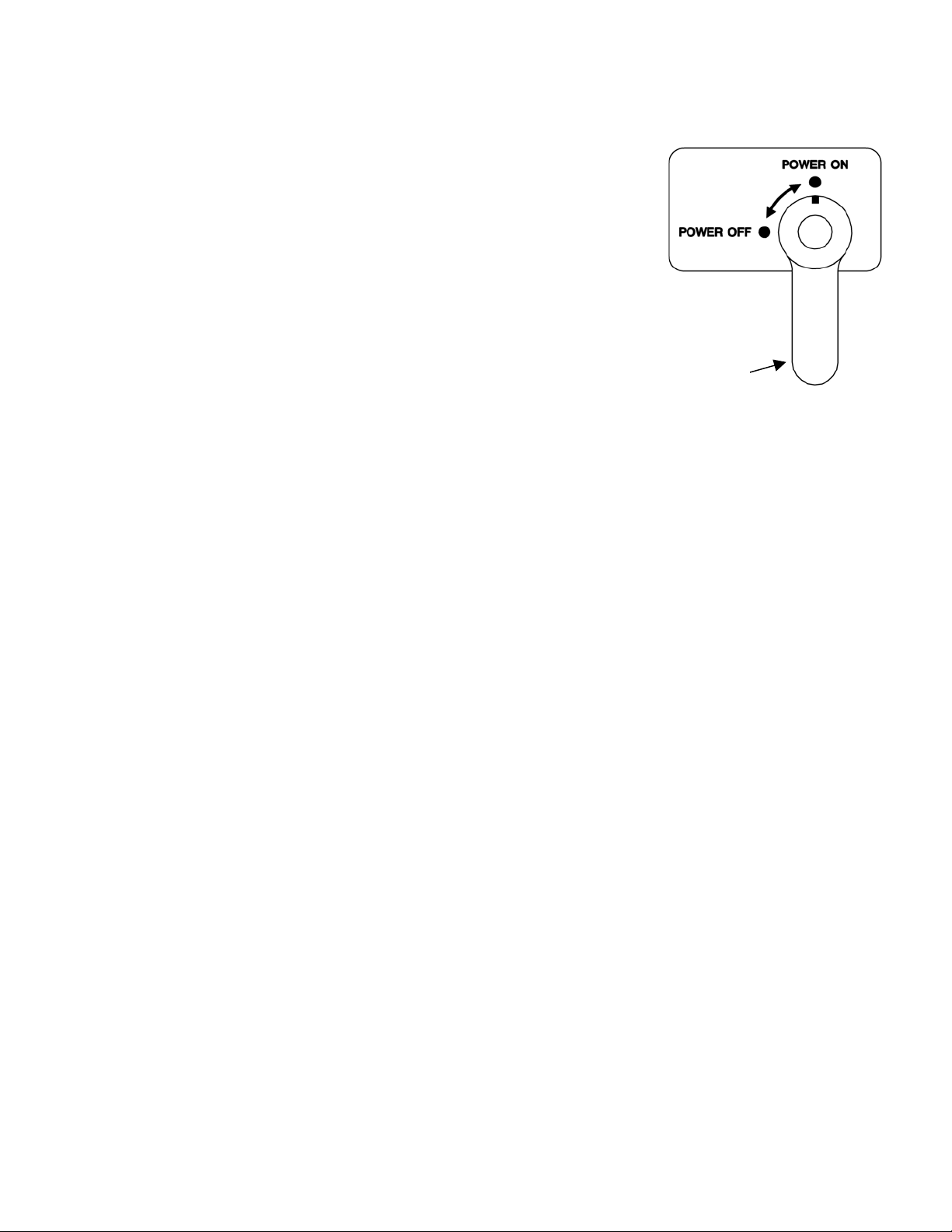

1. Main External Power Switch

MAIN POWER SWITCH

Usually the steamers main external power switch is left ON. If

the main power switch was left in the OFF position, turn it ON

as follows.

a. Turn the ON/OFF lever/switch to the OFF position.

b. The control settings are not important in this

procedure. The control panel circuits are not powered

while the ON/OFF lever/switch is set to OFF.

c. Refer to the main power switch in Figure 2-1, and turn

on electric power to the steamer.

2. Door Interlock Switch

The steamer compartment of the SteamChef¥ 3 is equipped with an automatic steam cutoff switch, which

turns OFF the production of steam and shuts down the convection fan and condenser whenever the door to

the compartment is opened. NOTE: That even though the continued production of additional heat ends as

soon as the door is opened, it may take up to a minute for residual heat in the system to stop producing

steam in the cooking compartment and for the fan to stop rotating. To avoid possible injury always wait until

this residual steam has cleared and the convection fan has stopped rotating before reaching into the

cooking compartment. Remember the SteamChef¥ 3 is always heating in either the standby heat

mode or steam cooking mode, whenever the main power switch is in the ON position and the

steamer door is closed.

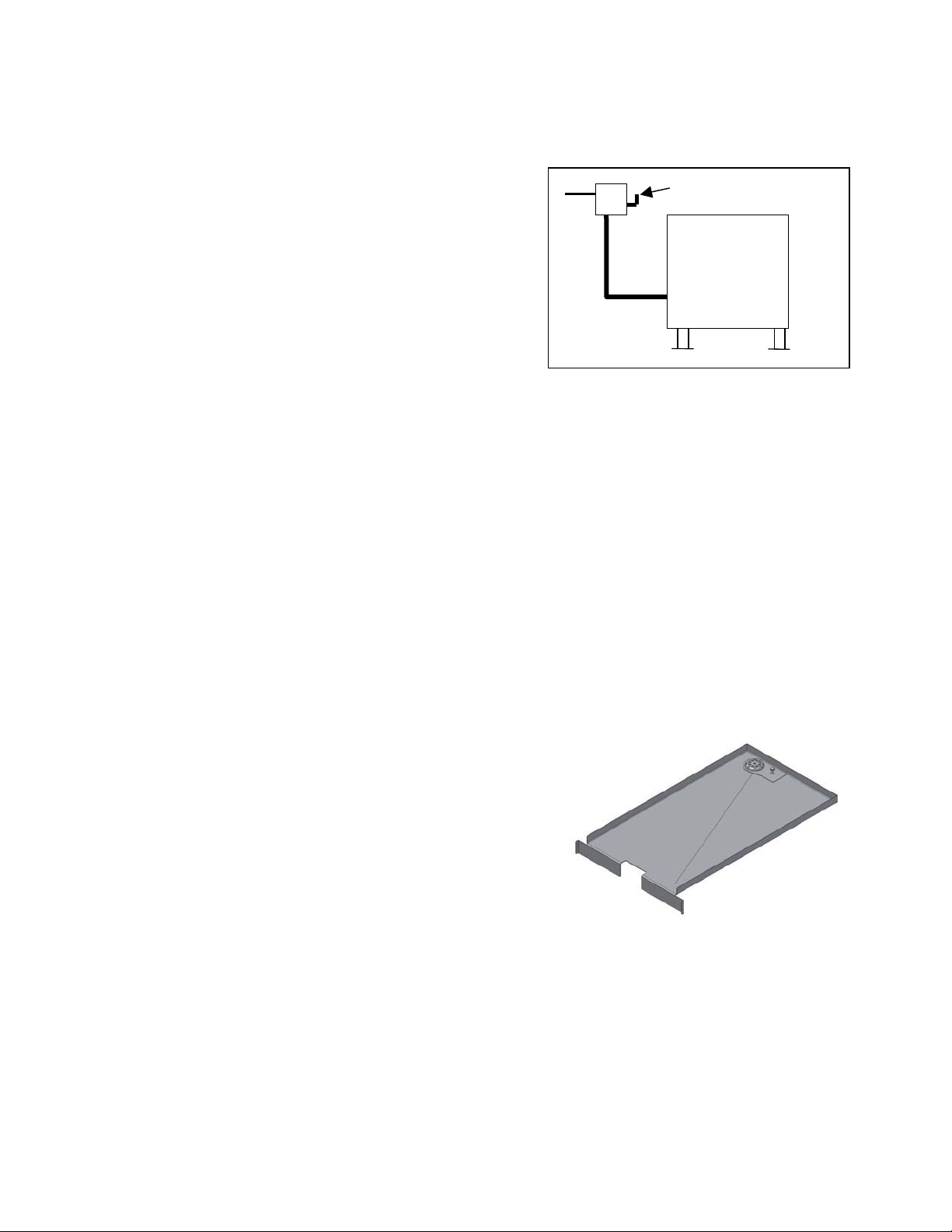

3. KleanShield¥

This unit is equipped with the KleanShield¥ for improved maintenance, cooking and safety performance in

the steam cooking of food. The KleanShield¥ (See Figure 2-2) is located in the bottom of the water

reservoir of Cleveland Range SteamChef¥ Cookers and provides the following benefits to the

owner/operator:

Figure 2-1 Main Power Switch

SteamChef¥ 3

x By collecting all of the drippings of food being

cooked from entering and contaminating the

reservoir water.

x By keeping the water cleaner, less maintenance is

needed in the daily operation and cleaning of the

interior of the steamer.

x It directs the steam being produced around the sides

of the pans to insure more even distribution of the

steam.

x It prevents the operator from accidentally coming in

contact with the reservoir water during the placing or

removal and food from the cooking compartment.

x It also prevents spilled food from pans from falling directly into the reservoir and splashing out

scalding water.

x The KleanShield¥ is removable and dishwasher safe allowing for easy cleaning.

Please read the following Important Use and care Instructions for the KleanShield¥

a. Never operate a SteamChef¥ Steamer without a properly installed KleanShield¥.

b. To install the KleanShield¥, the side pan racks must first be removed from the steamer.

Figure 2-2 the KleanShield¥

4

Page 9

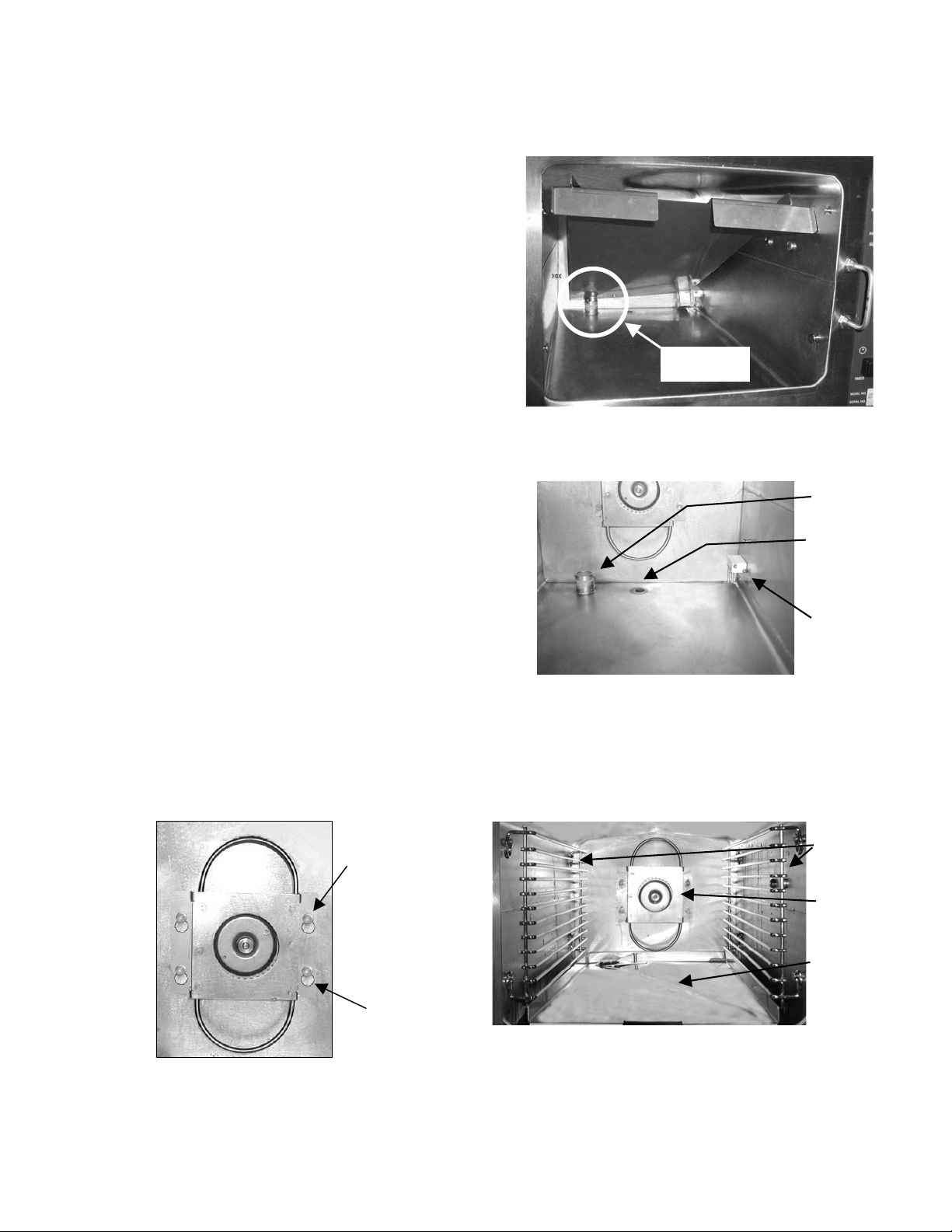

c. Place the KleanShield¥ into the steamer with

pipe extension towards the back and facing

down. Set the KleanShield¥ in place over the

corresponding pipe extending out of the bottom of

the steamer reservoir. See Figure 2-3.

d. The KleanShield¥ is installed properly when the

pipe from the KleanShield¥ is fitted into the

corresponding pipe in the bottom of the steamer

and its legs are flush against the bottom of the

steamer. See Figure 2-6.

4. Inspecting The Cooking Compartment

a. Before turning ON the power switch/lever to the

FIT UP OF

KLEANSHIELD¥

SteamChef¥ 3, the entire inside of the steamer

must be thoroughly cleaned.

b. All food debris should be wiped clean and the

drain openings and the water level sensors shall

Figure 2-3 KleanShield¥

Installation

be inspected and cleaned of any residue or

debris (See Figure 2-4).

c. The door gasket assembly, KleanShield¥, fan

guard and slide racks should be inspected for

proper installation and cleanliness. See Chapter

2, Section A, Part 3 for proper installation of the

KleanShield¥.

x To properly install the fan guard, hold the fan

guard so that the large ends of the keyholes

are towards the bottom of the steamer. Place

all four openings over the mounts located on

the rear wall of the steamer and pull it down

so that the narrow ends of the slots are pulled

Figure 2-4 Inspecting

Compartment drains

tight over the mounts. See Figure 2-5.

d. Make sure that the KleanShield¥ drain is clear. See Figure 2-6.

e. It is also recommended that a small amount of water (about a quart) be poured through the

KleanShield¥ drain. Check that water flows out the drain.

OVERFLOW

DRAIN

RESERVOIR

DRAIN

OPENING

WATER

LEVEL

SENSOR

ASSEMBLY

FAN GUARD

SHOWN PULLED

DOWN TO LOCK IT

Figure 2-5 Fan Guard Shown in

Installed Position

IN PLACE

LARGE END OF

KEYHOLE AT

BOTTOM

REMOVABLE

PAN RACKS

FAN

GUARD

KLEANSHIELD¥

Figure 2-6 Inspecting Compartment

Interior Accessories

5

Page 10

5. Power ON (Auto Water Fill/Automatic Preheat)

(

)

a. Check that the water supply valves to the unit are open.

b. Set the timed manual switch to timed (dial timer models) or set

the selector switch to OFF (ON/OFF control models).

c. Turn ON power to the steamer by turning the drain valve lever

clockwise (down) to close the drain (see Figure 2-7). The power

ON indicator will light and the unit will begin to fill automatically.

d. Close the door. Once the unit has filled to the minimal operating

level the heater will come ON, and the steamer will begin to

automatically heat the water supply to the standby cooking

temperature.

e. When the “SureCook” indicator light goes off the steamer has

completed its Preheat (this only applies for units equipped with a

timer). For ON/OFF control units it will take approximately 10 to

15 minutes for the unit to reach the standby heating temperature

ON/OFF LEVER

Figure 2-7 ON/OFF Lever

Shown in ON Position

depending on the wattage of the Steamer and the incoming

temperature of the water.

6. Preheating The Steamer

Preheating the steamer can help insure that the best productivity and consistent cooking is obtained. To

preheat the SteamChef¥ 3, simply turn the unit on approximately 15 minutes before you are ready to cook.

The unit will automatically go into the preheat mode and prepare the unit for cooking.

x

BEFORE PREHEATING, inspect and clean the compartment. After preheating, the compartment will

be too hot to inspect and clean safely.

7. High Limit Reset

This unit is protected by a high limit lockout, which acts to protect the unit from overheating. If the reset

light should come ON, a buzzer will sound continuously, the heating circuit of the steamer will be locked

out by the over-temperature circuit, and the steamer will not be able to be used for cooking until the unit is

reset. To reset the high limit use the following procedure:

a. If the reset indicator lights, turn OFF power to the unit at the ON/OFF lever.

b. Wait 15 minutes for the unit to cool and refill the unit with water according to the Power ON

instructions found in Chapter 2, Section A, Part 5.

c. If the condition should repeat itself see the operators troubleshooting section of this manual,

Chapter 3, Section B for further instructions.

8. Energy/ Water Saver Feature

This unit is equipped with an internal timer system, which automatically switches the unit to the standby

heat temperature if the unit is left in the Manual Mode (timer models) or the unit is left ON (ON/OFF

Control Models) for more than 60 minutes without opening the door. This feature has the following

benefits:

x It saves water by reducing steam loss and condenser water.

x By maintaining a lower temperature and not constantly producing steam, energy usage is reduced.

x Increases the steamer life.

x Because the unit automatically returns to the cooking temperature the next time the door is opened,

this feature has almost no effect on the operation of the equipment.

6

Page 11

B. CONTROL PANELS

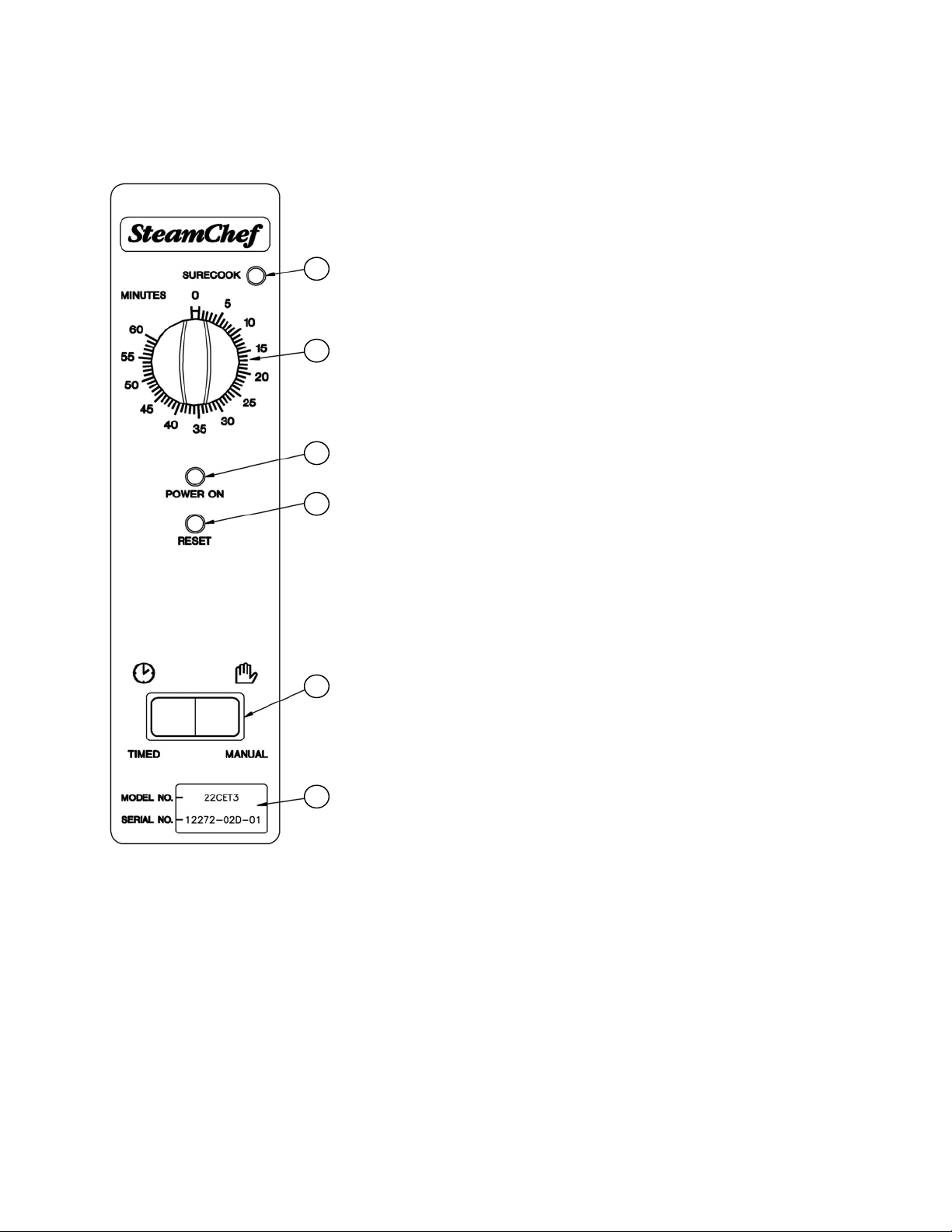

The standard dial timer control panel (illustrated in Figure 2-8) has a mechanical timer that uses a

“SureCook” temperature compensation circuit, which allows the timer to count down only while the cooking

compartment is at cooking temperature. An optional ON/OFF control panel (illustrated in Figure 2-9) is also

available. The ON/OFF Control Panel, operates exactly like the dial timer control model in manual mode,

except a selector switch is used to change the steamer from the standby heat mode to the cooking mode.

1. Dial Timer Control Panel

a. Cooking Operations – Dial Timer Control Panel

For safe, efficient operation of the steamer, the operator must, at a minimum, comply with all

cautions, warnings and instructions in the detailed operating procedures and be familiar with the

control panel shown in Figure 2-8. The operator must be familiar with all the operating features

explained in this manual before attempting to operate the steamer.

b. Manual and Timed Modes

The steamer has two operating modes: manual and timed. The TIMED/MANUAL rocker switch

selects the operating mode. Pressing the MANUAL end of the switch selects the manual operating

mode. Pressing the TIMED end of the switch selects the timed operating mode. Cooking

procedures are slightly different for each mode.

1). Manual Mode

The manual mode provides continuous steaming operation. The operator starts and stops steaming

operations manually. See the Operating and Cooking Procedure – Manual mode in Chapter 2,

Section C, Part 2 for more information. A thermostat controlled “SureCook” indicator light located on

the control panel indicates that the cooking compartment has not yet reached optimum cooking

temperature.

2). Timed Mode

x

The timer provides timed control of steaming operations. The timer starts and stops

steaming operations.

x

The mechanical timer control uses a “SureCook “ temperature compensation circuit that

effects only the timer. When operating, the timer ONLY COUNTS DOWN WHILE THE

COOKING COMPARTMENT IS AT AN EFFICIENT COOKING TEMPERATURE. This

provides totally automatic control of the steaming operation and assures uniform cooking

as the timer automatically compensates for food product defrosting and/or compartment

heat up time. Whenever the steamer is not at an efficient cooking temperature, the

compensation feature interrupts the countdown of the timer and the “SureCook” light is

illuminated.

x

To use the timer, simply set the timer to the desired time. The steamer will begin cooking

as soon as the timer is set. When the timer reaches zero the steaming functions will

automatically end and a buzzer will sound for 3 seconds to alert the operator that cooking

is complete. The cooking compartment will then revert to the standby-heating mode until

the next timing cycle is started.

x

Note the mechanical timer will not function when the Timed/Manual switch is set to

Manual, although the “SureCook

compartment is not yet at optimum cooking temperature.

” light will still illuminate to indicate that the cooking

7

Page 12

1. “SureCook” Indicator Light

This Amber light is lit whenever the cooking

compartment has not yet reached the optimum cooking

1

temperature. Note: when in the timed mode the timer

will not count down as long as this light is ON.

2. TIMER

2

This dial timer sets the operating time from 0 to 60

minutes. Turn the dial clockwise until it points to the

required number of minutes. When it reaches 0, a

buzzer sounds for 3 seconds.

3

3. POWER ON Indicator Light

When the Green indicator light is ON, power is ON to

4

the operating controls.

4. RESET Indicator Light

When this light is lit, it indicates that the high limit

circuit of the steamer has opened. This light will remain

ON, and a buzzer will sound until power to the unit has

been reset. See High Limit Reset in Chapter 2, Section

A, Part 7 for additional details.

5

5. TIMED/MANUAL Switch

The TIMED/MANUAL switch selects the manual or

timed operating mode.

x

6

Pressing the MANUAL end of the switch selects the

manual mode.

x

Pressing the TIMED end of the switch selects the

timed mode.

6. Serial Number/Model Number Display

Figure 2-8 Dial Timer Control Panel

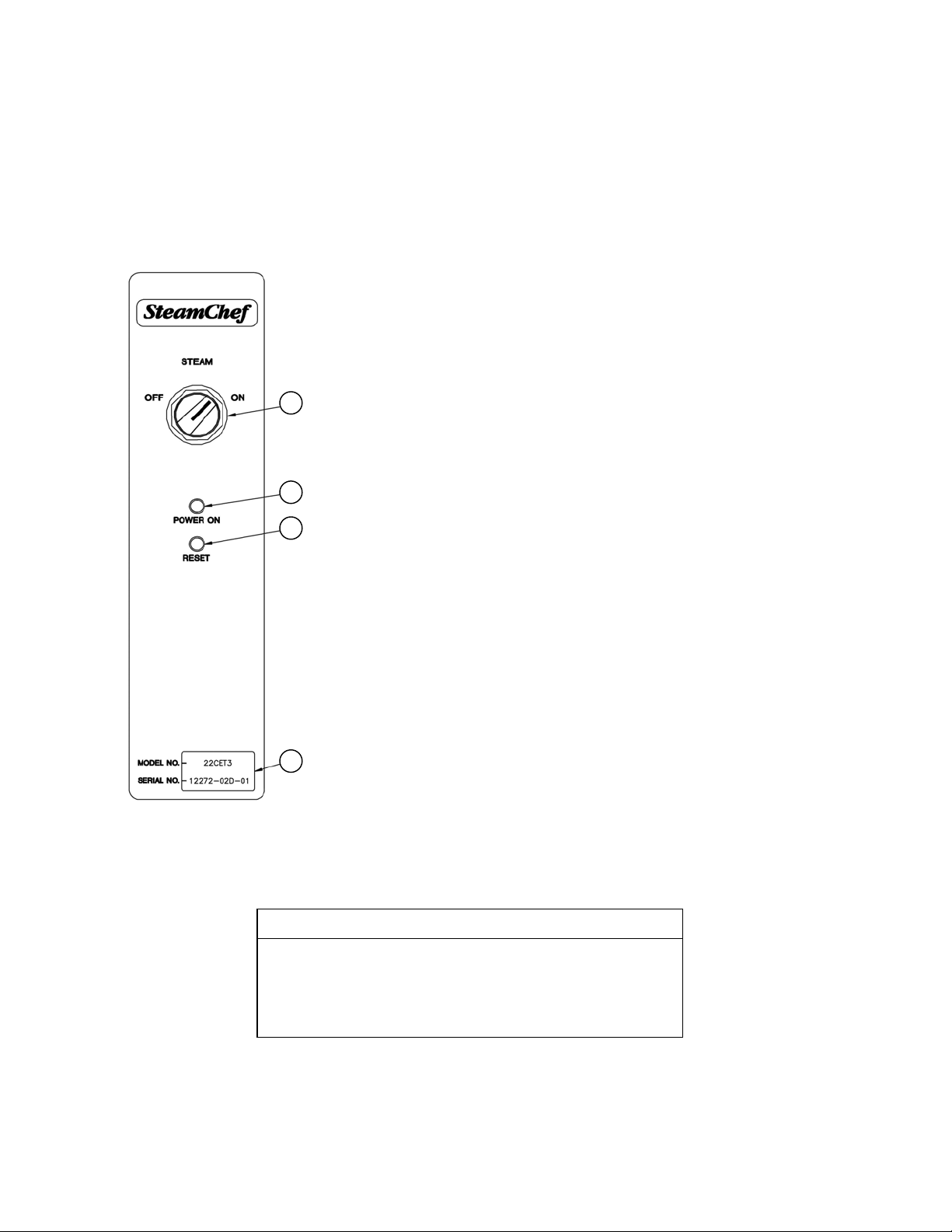

2. ON/OFF Control Panel

a. Cooking Operations – ON/OFF Control Panel

For safe, efficient operation of the steamer, the operator must, at a minimum, comply with all

cautions, warnings and instructions in the detailed operating procedures and be familiar with the

control panel shown in Figure 2-9. The operator must be familiar with all the operating features

explained in this manual before attempting to operate the steamer.

8

Page 13

b. Operating the ON/OFF Control

This unit leaves all control of the cooking up to the operator. When turned ON cooking with this

steamer is the same as cooking with a dial timer control unit in the Manual Steam Mode.

NOTE: This unit is constantly in a hot mode whenever the main power lever is ON, the door is

closed and the unit is filled with water. When the selector switch of this unit is turned to the

OFF position, this unit will maintain the Standby Heat temperature in the compartment.

1. ON/OFF Selector Switch

When turned to the ON position the steamer will go

into the Constant Steam Mode and maintain the

compartment temperature at the cooking level for 1

1

hour unless the door is opened. When turned to the

OFF position the unit will be maintained at the

standby heating temperature.

2. POWER ON Indicator Light

2

When the Green indicator light is ON, power is ON

3

to the operating controls.

3. RESET Indicator Light

4. Serial Number/Model Number Display

4

Figure 2-9 On/Off Control Panel

C. COOKING WITH THE STEAMCHEF¥ 3

The SteamChef¥ 3 is a continuously operating appliance

and is constantly standing by and ready to cook whenever

the ON/OFF lever of the power control panel is in the ON

position.

When this light is lit, it indicates that the Hi-limit

circuit of the steamer has opened. This light will

remain ON, and a buzzer will sound until power to

the unit has been reset. See High Limit Reset in

Chapter 2, Section A, Part 7 for additional details.

IMPORTANT

9

Page 14

WARNING

When checking inside the steamer always open the door slowly

and stand to the side and back away from the steamer. Water

leaking from the door gasket can be a sign of a blocked drain. If

the drain is blocked, hot water can accumulate inside the

compartment and spill out when the door is opened.

1. Operating and Cooking Procedure – Timed Cook Mode

WARNING

Even though the heating elements are de-energized as soon as a door is opened, it

may take up to a minute for production of steam to end and residual steam in the

system to clear from the cooking compartment. To avoid possible injury always wait

until this residual steam has cleared before reaching into the cooking compartment.

Never operate a SteamChef¥ 3 Steamer without the KleanShield¥ properly

installed in the bottom of the water reservoir or the fan guard installed over the fan.

In timed mode, the timer starts and stops the cooking operation. When in the timed mode and the

compartment door is closed, the unit will maintain the compartment at the standby heat temperature

whenever the unit is not performing a timed cook operation.

(1) Refer to Inspecting the Cooking Compartment in Chapter 2, Section A Part 4. Inspect and clean the

drain, KleanShield¥ and cooking compartment as required.

(2) Refer to the Power ON instructions in Chapter 2, Section A, Part 5 and turn ON and fill the unit.

(3) If necessary, refer to Preheating the Steamer, in Chapter 2, Section A Part 6, and preheat the

cooking compartment.

(4) Slide the pans of food into the slide racks inside the steamer. Do not place pans or anything else on

the bottom of the compartment.

CAUTION

Some foods drip juices and food debris. Use a solid catch

pan under perforated pans when steaming food that will drip

excessive juices and debris. Failure to use a catch pan can

cause a clogged drain or KleanShield¥.

x

For best cooking results, use shallow, 2-1/2 inch deep, perforated pans without covers. These

give the best heat transfer and shortest cooking time.

(5) Close the steamer door.

(6) Check the control panel settings. At this point the settings should be:

x

The ON/OFF Lever is in the ON (down) position and the Power indicator light is lit.

x

The TIMED/MANUAL switch is in the TIMED (left) position.

10

Page 15

(7) Set the required cooking time. The timer will start counting down as soon as the compartment

reaches the minimum cooking temperature.

(8) When the timer reaches zero, a buzzer will sound for 3 seconds; the cooking circuit will turn OFF

and the unit will revert to the standby heat mode. The cooking cycle is complete.

WARNING

SEVERE BURNS may result from exposure to steam.

Do not open the steamer door before steam generation stops.

Stand back when opening the compartment door. Open the

door slightly to allow steam to vent before looking or reaching

into cooking compartment. Do not reach into cooking

compartment until the steam has cleared.

Do not reach into steamer or handle hot items without wearing

heatproof gloves. Wet or damp gloves conduct heat, and may cause

burns when touching hot items.

(9) Carefully open the cooking compartment door, and remove the pans from the slide racks.

x

If the steamer will be used again shut the door to maintain the cooking compartment

temperature.

x

If the steamer is not being used again during this shift, perform the Shut Down and Cleaning

Procedures, found in Chapter 2, Section D.

2. Operating and Cooking Procedure – Manual Mode

Manual mode allows the operator to personally control the cooking functions. The operator starts and

stops the steaming operations, and sets the cooking time including time for cooking compartment and

food heat-up time. Use the manual-cooking mode for:

x

A continuous supply of steam.

x

Maintaining the compartment temperature between cooking batches.

x

Remember that this unit is equipped with an energy saving feature. This automatically drops the

compartment into the standby heat mode, after an hour of operating in the manual mode without

interruption (such as opening the door). If Cooking times longer than the 60 minutes are desired, it

will be necessary to reset this timer circuit. To reset the timer without interrupting the continuous

cooking of the unit either quickly open and close the cooking compartment door, or switch the

TIMED/MANUAL switch to timed and back to manual.

Manual Cooking Procedure

Follow this procedure when cooking with the steamer in manual mode.

WARNING

Even though the heating elements are de-energized as soon as a door is opened, it

may take up to a minute for production of steam to end and residual steam in the

system to clear from the cooking compartment. To avoid possible injury always wait

until this residual steam has cleared before reaching into the cooking compartment.

Never operate a SteamChef¥ 3 Steamer without the KleanShield¥ properly

installed in the bottom of the water reservoir or the fan guard installed over the fan.

11

Page 16

(1) Inspect and clean the drain and cooking compartment as required. Refer to Inspecting the

Cooking Compartment in Chapter 2, Section A, Part 4.

(2) Refer to the Power ON instructions in Chapter 2, Section A, Part 5 and turn ON and fill the

unit.

(3) In manual mode, the operator can bring the compartment to cooking temperature by either

preheating or increasing the cooking time. If the operator chooses to preheat the cooking

compartment manually, refer to Chapter 3, Section A, Part 6, Preheating The Steamer.

(4) Slide the pans of food into the slide racks inside the steamer. Do not place pans or anything

else on the bottom of the compartment.

CAUTION

Some foods drip juices and food debris. Use a solid catch

pan under perforated pans when steaming food that will drip

excessive juices and debris. Failure to use a catch pan can

cause a clogged drain or KleanShield¥.

x

For best cooking results, use shallow, 2-1/2 inch deep, perforated pans without covers.

These give the best heat transfer and shortest cooking time.

(5) Close the steamer door. Select the manual mode by pressing the MANUAL end of the

TIMED/MANUAL rocker switch. The steaming cycle starts as soon as the switch is pressed.

Shortly after the door is closed, steam fills the cooking compartment.

(6) To stop manual mode steaming, press the TIMED end of the TIMED/MANUAL rocker switch

and verify that the timer is at zero. The cooking circuit is de-energized, and steam flow to the

cooking compartment gradually stops.

WARNING

SEVERE BURNS may result from exposure to steam.

Do not open the steamer door before steam flow stops. Stand back when

opening the compartment door. Open the door slightly to allow steam to vent

before looking or reaching into cooking compartment. Do not reach into

cooking compartment until the steam has cleared.

Do not reach into steamer or handle hot items without wearing heatproof gloves.

Wet or damp gloves conduct heat, and may cause burns when touching hot items.

(7) Carefully open the cooking compartment door, and remove the pans from the slide racks.

x

If the steamer will be used again shut the door to maintain the cooking compartment

temperature.

x

If the steamer is not being used again during this shift, perform the Shut Down and

Cleaning Procedures, found in Chapter 2, Section D.

3. Using the SteamChef¥ 3 to Rethermalize Food

The SteamChef¥ may also be used to reheat/rethermalize previously cooked and/or refrigerated

foods to serving temperature in minutes. To use the SteamChef¥ 3 to rethermalize food, use the

following procedure:

x Use the SteamChef¥ 3 in the Manual Cooking Mode as outlined in Chapter 2, Part C, Section 2,

and cook the food to a safe serving temperature, 160-170 ˚F for most foods.

12

Page 17

x Depending on initial food temperature and density, most foods should be rethermalized to a serving

temperature in 10 to 40 minutes.

x Always check internal temperature of food with a thermometer to determine when it has been

rethermalized to a safe temperature (160° to 170°F).

x Remember that this unit is equipped with an energy saving feature. This automatically drops the

compartment into the standby heat mode, after an hour of operating in the manual mode without

interruption (such as opening the door). If Cooking times longer than the 60 minutes are required to

rethermalize a particular load of food, it will be necessary to reset this timer circuit. To reset the

timer without interrupting the continuous cooking of the unit either quickly open and close the

cooking compartment door, or switch the TIMED/MANUAL switch to timed and back to manual

NOTE: Cooking times may be longer for some foods and/or larger loads, especially when using 6

kW SteamChef¥ 3 models.

D. SHUTDOWN AND CLEANING PROCEDURE

This procedure should be performed at the end of each day or shift.

WARNING

Do not use a hose or water jet to clean this appliance.

CAUTION

When cleaning do not pick up or tilt the SteamChef¥ 3. If it is absolutely

necessary to move a SteamChef¥ 3 for cleaning, turn OFF power at the main

external power supply switch.

Catastrophic damage can result from shifting the SteamChef¥ 3 more than 10˚

out of level while power is turned on at the main external power supply switch.

The steamer MUST BE LEVEL BOTH FRONT TO BACK AND SIDE TO SIDE in

all mounting arrangements.

1. Open the steamer door and allow steamer to cool.

2. Turn the ON/OFF lever counter-clockwise (up) so that the white reference marker on the lever is

pointing directly left to turn the power OFF, de-energize all controls and drain the steamer. The

steamer will begin a 3-minute drain rinse cycle to clean the drain system.

WARNING

Inside of steamer stays hot for a long time. Be careful

when cleaning inside steamer compartment.

3. Remove any spilled food from the surface of the KleanShield¥. Never push solid food remnants

down the KleanShield¥ opening or the reservoir drain opening.

4. Remove the slide racks, fan guard and KleanShield¥. Wash and rinse slide racks, fan guard and

KleanShield¥ separately or clean them in a dishwasher according to health requirements.

5. Remove any spilled food from inside compartment and clear any residue from the drain valve and

the KleanShield¥ drain opening. Clean the interior of the compartment thoroughly, to remove all

13

Page 18

food particles. Use a soft bristle brush to clean the water sensor, temperature probe and to remove

stubborn food particles. Do not use abrasive cleaning compounds or steel wool.

6. After all the particulate matter has been removed, wipe down the interior of the cooking

compartment, particularly below the normal operating level, with a vinegar solution. When done

daily this will prevent the buildup of calcium and other mineral deposits left over from the boiling of

water, and prevent scale buildup in the steamer. Rinse the inside of steamer compartment and

drain valve thoroughly with clean water.

7. Inspect the probe assembly and clean it with a vegetable brush or similar non-abrasive cleaning

means. If detergent has been used to clean the inside of the steamer, be sure and thoroughly rinse

off the probe assembly with a vinegar solution. If detergent residue is not completely rinsed from the

probe assembly the film residue can prevent the water level control from properly operating.

8. Clean the door assembly.

x

Remove the door gasket assembly (see Figure 2-10).

x

Note the keyhole slots on the door and the retaining pins

on the gasket assembly. Grasp the gasket assembly at

the sides and lift up and towards you to remove the

assembly.

x

Clean all surfaces of the gasket assembly, as well as the

inside of the door, by wiping with a damp cloth.

x

Rotate the liner assembly 180q and replace the gasket

assembly by sliding the retaining pins into the keyhole

slots. Either long edge of the gasket assembly can be

positioned at the top. Periodic rotating of the door

assembly will increase the door gasket life.

Figure 2-10 Door Gasket Assembly

9. Replace the cleaned KleanShield¥ (See Chapter 2, Section A, Part 3), slide racks and fan guard.

WARNING

Never operate a SteamChef¥ 3 Steamer without the

KleanShield¥ properly installed in the bottom of the

water reservoir or the fan guard installed over the fan.

10. Wipe the exterior with a damp cloth only. NEVER HOSE DOWN THE STEAMER. Electrical

components inside the unit will not function correctly if wet or damp and may cause a shock hazard.

11. After cleaning, leave the steamer door open until the next steamer operation. This prevents

compartment odor buildup and increases gasket life.

CHAPTER 3. PREVENTATIVE MAINTENANCE AND

TROUBLESHOOTING

A. MAINTENANCE

Maintenance on the steamer must be performed on a regular basis to keep the unit running properly and

efficiently. By following the simple maintenance instructions in this chapter and cleaning the equipment

regularly as outlined in Chapter 2, Part D, problems with the steamer will be kept to a minimum. As with any

preventative maintenance schedule, the frequency of steamer maintenance may need to be increased,

depending on equipment usage and water quality. If problems do occur, refer to the Troubleshooting Guide

in this chapter. For more information on product and services, contact your sales representative.

14

Page 19

1. Maintenance Records

Make a file solely for maintenance and repair records. Keep a written record of daily, weekly, monthly, and

yearly maintenance. These records will protect warranty coverage, help personnel to know when to perform

various maintenance procedures, help keep the SteamChef¥ 3 cooking properly and assist service

personnel.

2. Daily Maintenance

a. Checking and Changing the Water

When using the SteamChef¥ 3 frequently check the water, especially if cooking with perforated

pans. Although, most food drippings will be caught by the KleanShield¥, the water may still become

soiled from occasional spilled food that falls over the edge of pans or when removing and loading

food into the steamer. Replace the water as outlined below whenever the water becomes cloudy or

heavily contaminated with food particles. At the very least CHANGE THE WATER IN THE

STEAMCHEF¥ 3 AT LEAST EVERY DAY IN ORDER TO MAINTAIN FOOD QUALITY AND

KEEP THE STEAMER SANITARY.

Note: It may be necessary to change the water several times a shift, especially if cooking strong

flavored foods or with perforated pans.

1) Open the steamer door and allow steamer to cool.

2) Turn the ON/OFF lever counter-clockwise (up) so that the white reference marker on the

lever is pointing directly left to turn the power OFF, deenergize all controls and drain the

steamer.

3) Remove the KleanShield¥. Remove any food particles and rinse the KleanShield¥ with clean

water.

WARNING

Inside of steamer stays hot for a long time. Be careful

when cleaning inside steamer compartment.

4) Remove any spilled food from inside compartment and rinse any residue from the drain valve

and the KleanShield¥ drain.

5) Replace the KleanShield¥ (see Chapter 2, Section A, Part 3).

6) Turn ON power to the steamer by turning the drain valve lever clockwise (down) to close the

drain (see Figure 2-7). The power ON indicator will light. The steamer will automatically begin

filling with water to the normal operating level.

7) Close the door. The “SureCook” indicator will light (timer models only), and the steamer will

begin to automatically heat the water supply to the standby cooking temperature.

8) When the “SureCook” indicator turns OFF (timer models only) the Steamer is now ready to

begin cooking.

b. Cleaning the Steamer

Clean interior and exterior of the steamer according to the shutdown instructions in Chapter 2, Part

D at least once per day if not at the end of each shift.

3. Yearly Maintenance – Cleaning the Water Strainers

Clean the water line strainers at least once a year as follows:

15

Page 20

NOTE: When the steamer is first installed, check the strainer more frequently to find out how often it must

be cleaned.

1. Turn OFF power to the streamer at the main electrical disconnect switch/breaker.

2. Close the valves in the steamer water supply lines.

3. Unscrew the hoses from the inlet fittings located on the rear of the

steamer.

4. Remove the filter washers (Figure 3-1) from the outlet of the hoses

and wash them with clean water.

5. Check the filter washer for wear and replace it if necessary.

6. Put the filter washers into each of the water inlets and reconnect the

hoses to the back of the steamer. Note if treated water is used to

supply water to the reservoir, make sure that it is connected to the

left inlet at the rear of the steamer (See Figure 4-1), which provides

feed water for the production of steam.

7. Open water supply valve(s) and check for water leaks.

8. Turn back on power to the steamer at the main electrical shutoff/breaker.

B. OPERATORS TROUBLESHOOTING GUIDE

The Troubleshooting guide includes a list of symptoms that may be encountered during routine operation

and maintenance. The first column on the left (PROBLEM) describes these symptoms. The second column

lists the possible causes for the problem in column one. The third column lists possible remedies for the

problems and causes in columns one and two. The causes and remedies are listed in the order they should

be checked, with the least costly and easiest to repair listed first. The third column also refers to notes that

are grouped at the end of the troubleshooting guide. Refer to these notes when instructed to do so.

Figure 3-1 Filter

Washer Assembly

PROBLEM POSSIBLE CAUSE REMEDY/REFERENCE

Power indicator light does not

turn ON when ON/OFF lever

is in the ON position.

Power ON and steamer does

not fill

Control panel power indicator

light ON, and steamer does

not come up to cooking

temperature or produce

steam.

Table 3-1 Trouble Shooting Guide

Power turned OFF at main external

power switch.

ON/OFF lever not fully turned to the ON

position.

Inoperative controls or indicator. See note #1

Water supply to steamer shut OFF Open water supply lines.

Water line strainer and/or external filter

system clogged.

Water sensor is grounded. Rinse water sensor assembly thoroughly

Inoperative controls or solenoids. See notes #1 and #5

Door interlock switch not engaged. Close door completely.

Water supply to steamer shut OFF Open water supply lines.

Water line strainer and/or external filter

system clogged.

Unit is in the timed mode and timer is not

set (Dial timer control models only)

Hi-limit switch has tripped. Reset steamer according to instructions

Inoperative controls. See note #1.

(Continued on next page)

Turn ON power at main power switch.

Turn lever to the full ON position.

Clean water supply strainer and/or filter

system.

with vinegar solution.

Clean water supply strainer and/or filter

system.

Change to manual mode or set the timer.

found in Chapter 2, Section A, Part 7. If

condition repeats itself see note #1.

16

Page 21

PROBLEM POSSIBLE CAUSE REMEDY/REFERENCE

Steam and/or water draining

around the compartment door.

See Warning under note #7.

Abnormal amount of steam

coming from drain or vent.

Abnormal amount of steam

coming from drain during

draining of steamer

Compartment bottom dirty

with food drippings.

Table 3-1 Trouble Shooting Guide (Continued)

Either the vent, the drain to the vent or

the KleanShield¥ opening is clogged or

covered.

Door gasket or door parts worn. See note #1.

Hot water instead of cold water

connected to the condenser water line

External drain or vent not properly

installed, should be free air vented and

pitched down.

Steamer not level. See note #2.

Condenser not operative See note #1.

Hot water instead of cold water

connected to the condenser water line

External vent is not installed in drain tee See notes #2 and #3.

Inoperative controls See note #1

ON/OFF lever/switch is not turned fully to

the OFF position

Water line strainer and/or external filter

system clogged.

Hot water instead of cold water

connected to reservoir fill line

Inoperative controls. See note #1.

KleanShield¥ not installed Install KleanShield¥ to catch food

Juices and/or food leaking from pans

during loading and unloading of steamer.

Clear vent or collector opening and/or

clean the drain with USDA approved drain

cleaner and flush drain thoroughly with

fresh water as applicable. If condition

persists see note #1.

See note #2 and #3.

See notes #2 and #3.

See note #2 and #3.

Turn lever/switch to the fully OFF position

to activate drain cooling feature.

Clean water supply strainer and/or filter

system.

See note #2 and #3.

drippings

Put a solid pan under perforated pans to

catch drippings, or put less food in pan.

Food takes too long to cook.

To verify the steamers

proper operation see

note #8.

Control panel Power indicator

is on, buzzer is buzzing

continuously and Reset

indicator is lit.

Steam coming out of the

exhaust.

Pans too close to the bottom of cabinet. Put pans in racks near top of cabinet.

Compartment overloaded with too much

food.

Suggested cooking times are usually

listed for cooking at sea level.

Convection fan inoperative See note #1.

Voltage too low for unit. See note #4.

High limit has been tripped. Reset steamer according to instructions

Inoperative controls. See Note #1.

A small amount of steam may issue from

the exhaust whenever the unit is in the

cooking mode.

Water line strainer and/or external filter

system clogged.

Hot water instead of cold water

connected to reservoir fill line

Inoperative controls. See note #1.

Put less food into pan. Use fewer pans.

Extend cooking times for altitudes above

2500 feet.

found in Chapter 2, Section A, Part 7. If

problem repeats itself, see Note #1.

This is normal operation of the steamer

NO action is necessary.

Clean water supply strainer and/or filter

system.

See note #2 and #3.

17

Page 22

TROUBLESHOOTING NOTES

1. A qualified service technician must repair problem or do the appropriate maintenance

2. Proper installation of the steamer is the responsibility of the owner or installer. A qualified installer or

technician should be contacted to correct the installation

3. Repairs to external plumbing should be done by a Licensed Plumber.

4. Repairs to external wiring should be done by a Licensed Electrician.

5. Should the automatic fill system fail for any reason the steamer will eventually stop heating when the

water level drops below the minimum operating level. Should this happen, the unit can continue to be

operated by manually filling the water reservoir with about a gallon of water approximately every halfhour, until service can be scheduled.

6. For more information on products and services, contact your nearest Authorized Sales Representative.

Call factory for a preventative maintenance program and water treatment systems: USA: (800)

338-2204, Canada: (800) 427-6668.

7. Whenever opening door, especially when water or steam is leaking around gasket heed the warning

below.

WARNING

When checking inside the steamer always open the door slowly and stand to the

side and back away from the steamer. Water leaking from the door gasket can be a

sign of a blocked drain. If the drain is blocked, hot water can accumulate inside the

compartment and spill out when the door is opened.

8. To evaluate whether a SteamChef¥ steamer is producing normal cooking performance, conduct the

Egg Test as follows (NOTE: this test is not valid for pressure steamers). A properly operating steamer

will produce cooked eggs as follows.

Turn on the steamer, and set the selector switch to the manual mode (or for ON/OFF models set the

selector to the ON position) so that steam is being produced. When wisps of steam has begun to exit

the steam vent, preheat the steamer by leaving it ON for ten minutes. After the compartment is

preheated follow the instructions as listed below.

x Place a fresh egg on a perforated steamtable pan in the middle of the cavity.

x Close the door and set the timer as directed by the size chart below

Size

Medium 12 minutes

Large 14 minutes

Extra Large 14 minutes

x When time is complete, carefully remove the egg and place in a container with cold water running

over it.

x Let cool under cold running water for 5 minutes.

x After cooling, crack egg shell and peal.

The result will be a perfectly hard boiled egg.

SteamChef¥

18

Page 23

CHAPTER 4. INSTALLATION INSTRUCTIONS

A. GENERAL

This equipment should only be installed by qualified, professional plumbers, pipe fitters and electricians.

x

The installation of this steamer must conform with the Basic Plumbing Code of the Building Officials and

Code Administrators International, Inc. (BOCA) as applicable, The National Electrical Code, ANSI/NFPA

No. 70-(latest edition) or the Canadian Electrical Code, CSA C22.2 as applicable, the Food Service

Sanitation Manual of the Food and Drug Administration (FDA) and all applicable state and local codes

and regulations.

x

The installation instructions must be read in their entirety before starting the installation of this steamer.

WARNING

Improper installation, adjustment, alteration, service or maintenance

can cause property damage, injury or death. The Installation,

Operating and Maintenance instructions should be read thoroughly

before installing or servicing this equipment

DO NOT INSTALL a SteamChef¥ 3 steamer suspected of damage.

Install the SteamChef¥ 3 steamer according to the policies and procedures

outlined in this manual.

x In order to properly install this steamer, the following requirements must be considered when selecting a

location.

a. A suitable electrical supply must be available matching the power requirements found on the rating

plate.

b. The location must have sufficient space to meet the clearance requirements of the steamer as

outlined in Chapter 4, Section B, Part 1, “Locating the Steamer”.

c. A potable cold water supply meeting the requirements outlined in Chapter 4, Section B, Part 10

“Water Supply Requirements and Installation” must be available

d. A suitable drain must be available within 12 ft. of the steamer.

B. INSTALLATION OF THE STEAMCHEF¥ 3

After selecting the steamer’s operating location the steamer can be positioned, and installed. After Startup

and Checkout, the SteamChef¥ 3 steamer will provide years of reliable operation.

CAUTION

Malfunctions and equipment damage may result from improper mounting.

The steamer MUST BE LEVEL BOTH FRONT TO BACK AND SIDE TO

SIDE in all mounting arrangements.

Catastrophic damage can result from shifting the SteamChef¥ 3 more than

10˚ out of level while power is turned on at the main external power supply

switch.

19

Page 24

1. Locating the Steamer

Location and Clearance Requirements of the Steamer

(1) Do not locate the steamer directly over a floor drain.

(2) Observe the following criteria when selecting an operating location for the SteamChef¥ 3

steamer.

x

Maintain a 3-inch operating clearance at the sides of the unit, and at least a 4-inch

clearance at the back.

x

A 12 in clearance is recommended on the right side for servicing the steamer.

x

Approximately 24 inches of clearance is recommended in front of the unit for opening the

door and standard pan clearance.

22.500

3.000

18.500

4.000

21.640

17.434

12.000

33.826

30.167

31.750

24.000

C1 Feed Water Reservoir

C2 Condenser Water

Electrical

6-kW Units

VOLTS WATTS

208 6400 30.8 17.8

220 5440 25 14.3

240 6400 26.7 15.4

9-kW Units

VOLTS WATTS

208 9400 45.2 26.1

220 7960 36.1 20.9

240 9400 39.2 22.6

Right – 12.00”

1-PH 3-PH

AMPS AMPS

1-PH 3-PH

AMPS AMPS

Clearances

Left – 3.00”

Rear – 4.00”

Figure 4-1 SteamChef¥ 3 Dimensions and Clearances

20

Page 25

21

Page 26

(3) The steamer is typically installed with four adjustable mounting legs, as shown in the dimension

quip

drawing. The steamer must be level both front to back and side to side. Select an operating

surface that is level enough to allow leveling the unit without extreme adjustment of the legs

or shimming of surface mounts.

(4) The counter area selected must be capable of

supporting an operating weight of approximately 260

pounds to include the weight of water and food.

(5) Do not block the vents on the side or rear of the unit. Do

not store articles on top of the unit.

(6) If a satisfactory counter location is not available,

consider using a Model ES222834 Equipment Stand.

This stand, illustrated in Figure 4-2, is designed to

support the SteamChef¥ 3, and meets all necessary

support and safety criteria. A stacking stand, Model No.

ES222824S, is also available. The Model ES222834S

stacking stand allows the installation of two SteamChef

¥ 3 Steamers one on top of the other. See Section 1, Part

B and C for the installation instructions for installing

SteamChef¥ 3 steamers on Cleveland Range Stands.

2. Installation Using Cleveland Range Stand Model No. ES222834.

a. Move the stand (Figure 4-2) to the selected location. We recommend that the feet with round

mounting pads be at the rear of the steamer.

Figure 4-2 ES222834

E

ment Stand

WARNING

INJURY AND EQUIPMENT DAMAGE could result from improper lifting. A

Model Number 22CET3 weighs approximately 250 pounds. Use enough

workers with experience lifting heavy equipment to place the steamer on the

supporting surface.

b. Set the unit on the stand with the front of the unit flush with the front edge of the stand. Mount the

unit to the stand from below using the 1/2 x 0.750 lg. bolts and fender washers provided with the

Stand Kit (Figure 4-3, on following page) installed into the rear leg mounts of the steamer.

c. Seal the unit to the stand around the edge as shown in Figure 4-3, with a suitable RTV sealant.

Note: Be careful not to seal the side panels to the steamer.

Figure 4-3 Mounting the Steamer on the Equipment Stand

22

Page 27

d. Complete the installation of the steamer in accordance with the remaining instructions of this

manual. Once the unit has been leveled using the adjustable feet provided on the stand, it is

recommended that the unit be secured to the floor using the two Anchorable legs.

3. Installation of Cleveland Range SteamChef¥ 3 Steamers on the Model No. ES222824S

Stacking Stand

The Cleveland Range Model ES222824S Stacking Stand includes the stand and all the necessary

hardware to connect the two units plumbing into a common drain outlet and a common set of water

inlets.

a. Beginning Installation of the Cleveland Range Model No. ES222824S Stacking Stand

1). Move the stacking stand base (Item 1, Figure 4-4) to the selected location. We recommend

that the feet with round mounting pads be at the rear of the steamer.

b. Mount the lower unit to the stand base

2). Remove the side panels of the lower steamer and set it into place on the Stacking Stand

base (Item 1, Figure 4-4).

3). Mount the lower unit to the stand from below using the 1/2 x 0.750 lg. bolts and the fender

and locking washers provided installed into both rear leg mounts as shown (See Figure 4-4).

4). Seal any gaps between the stand and the steamer with suitable RTV sealant (not provided).

c. Install the stand spacer onto the lower unit

5). Set the studded spacers (Figure 4-5 Item 2) on top of the lower unit lengthwise with the

nearer stud on the end towards the front of the steamer. Next set the spacer retainer (Figure

4-5 Item 1) over the studded spacer and the steamer (see Figures 4-4 and 4-5). The studs

from the spacer will go through the corresponding openings in the retainer, and the lower

edges of the retainer will extend over the top of the lower unit (See Figures 4-4 and 4-5).

6). Seal between the lower steamer and the spacer retainer with suitable RTV sealant (not

provided).

1

2

Figure 4-4 Installing Lower Unit

Figure 4-5 Positioning the

Studded Spacer

23

Page 28

d. Mounting the Upper Unit

7). Before setting the upper steamer into place over the spacer studs, place a bead of RTV

around the edge of the entire spacer outline.

8). Remove the side panels from the upper unit and set it onto the spacer. The ¼-20 studs of the

spacer should go through the ½” welded nuts normally used to secure the legs to the

steamer.

9). Secure the upper unit to the stand at the front pair of studs using the ¼-20 Lock Nut and

Washer provided (Figure 4-6).

Figure 4-6 Mounting the upper unit

e. Installing the Drain Between the Two Steamers

10).Assemble the drain fittings onto the steamers as shown in the schematic. Be sure to use a

suitable pipe dope compound or Teflon tape at all threaded pipe connections.

11). Lay the Drain hose (Figure 4-7 Item 8) out between the upper and lower hose fittings as it

may be necessary to shorten the length slightly depending on the fit-up of pipe

Drain Parts

Item

Part

No.

1

2 02573 Bushing, Hex, 1 ½” NPT x 1” NPT 2

3 111008 Nipple, ¾” NPT x 14”, Toe 1

4 03616 Coupling, Reducing, 1 ½” NPT x ¾” NPT,

5 20220 Tee, 1 ½” NPT, Male Run, Black Iron 1

6 110985 Fitting, 1 ½” Hose x 1 ½” NPT(M), Plated 2

7 102018 Clamp, Hose, Worm Drive 2

8

9 20221 Tee, 1 ½” NPT, Black Iron 1

Supplied with the steamer not part of the kit

Description Qty

No.

14369 Nipple, 1” NPT, Close, Black Iron 2

Black Iron

Hose, Black EPDM, 1 ½” ID x 13” long 1

110984

1300

1

Figure 4-7 Drain Assembly

12).Put the Worm drive clamps over the hose and then install the hose between the two hose

fittings.

24

Page 29

NOTE: It may be easier to install the hose over the upper fitting first, and then loosen the lower

fitting (by turning the lower drain plumbing assembly counter clockwise) to get the hose started

over the lower hose fitting. Once started in this manner the hose will then slide over the hose

fitting when the pipe assembly is turned back into its final position as shown in Figure 4-7.

13).Tighten the hose onto the hose fittings with the worm drive clamps.

f. Installing the Plumbing

14).Assemble the water trains for the condenser and feed water as shown in Figure 4-8. Be sure

and use pipe dope at all threaded pipe connections and that a suitable washer or washer

strainer is located at each National Hose threaded (GHT, garden hose thread) connection (DO

NOT USE PIPE DOPE ON NATIONAL HOSE THREAD CONNECTIONS).

NOTE: The national hose thread (also known as garden hose thread) inlets of the

SteamChef¥ 3 steamers water connections, come supplied with strainer washers (not

shown). These washers must be used at the steamer water inlet connections.

Drain Parts

Item

No.

Part

No.

Description Qty

1 110998 Hose Assembly, GHT(F) x GHT(F), 2 Ft.

Long

2 110977 Fitting, ½” NPT (M) x ¾”GHT (F), Brass 2

3 20229 Tee, ½” NPT, Brass 2

4 110986 Fitting, ½” NPT (M) x ¾” GHT(M), Brass 4

110987 Strainer, Filter Washer, Garden Hose Inlet 4

5

These parts are installed in the steamer, and should be left in the

units as part of the final installation.

Figure 4-8 Plumbing Assembly

g. Complete the Installation of the Steamer

15).Complete the installation of the steamer in accordance with the remaining instructions of

this manual. Once the unit has been leveled using the adjustable feet provided on the

stand, it is recommended that the unit be secured to the floor using the two Anchorable

legs.

4. Installing the Legs

The legs on the SteamChef¥ 3 are used for installing the steamer, except when it is installed with any

of the Cleveland Range stands.

(1) Check that the feet are fully retracted into the legs. Do not over tighten. The feet should easily

screw in and out using fingers only.

(2) Place the SteamChef¥ 3 on its left side.

2

(3) Screw the four legs into the weldnut mounting holes. All four legs must be installed for proper

mounting of the SteamChef¥ 3.

(4) Place the steamer upright on the four legs

25

Page 30

5. Positioning and Leveling the Steamer

WARNING

INJURY AND EQUIPMENT DAMAGE could result from improper

lifting. A Model Number 22CET3 weighs approximately 250

pounds. Use enough workers with experience lifting heavy

equipment to place the steamer on the supporting surface.

Move the steamer into position. Using a level, adjust the adjustable legs of the unit or the Cleveland

Range stand as applicable until the unit is level.

6. Installation of the KleanShield¥

a. Never operate a SteamChef¥ Steamer without a properly installed KleanShield¥.

b. Note the KleanShield¥ must be installed before the side pan racks.

c. Place the KleanShield¥ into the steamer with pipe

extension towards the back and facing down. Set

the KleanShield¥ in place over the corresponding

pipe extending out of the bottom of the steamer

reservoir. See Figure 4-9.

d. The KleanShield¥ is installed properly when the

pipe from the KleanShield¥ is fitted into the

corresponding pipe in the bottom of the steamer

and its legs are flush against the bottom of the

steamer. See Figure 2-6 in Chapter 2 showing an

installed KleanShield¥.

7. Installing the Fan Guard

Figure 4-9 KleanShield¥

Installation

To properly install the Fan Guard, hold the fan guard

so that the large ends of the keyholes are towards the

bottom of the steamer. Place all four openings over the

mounts located on the rear wall of the steamer and pull

FAN GUARD

SHOWN PULLED

DOWN TO LOCK IT

IN PLACE

it down so that the narrow ends of the slots are pulled

tight over the mounts. See Figure 4-10.

8. Install Slide Racks and Rear Vent

a. Refer to Figure 4-11. Each rack has four loops:

two at the top and two at the bottom. Hold the

slide rack so the ends of the hanger loops are

LARGE END OF

KEYHOLE AT

BOTTOM

towards the cavity wall, as shown in the figure.

b. Slide one rack into the compartment with loops

toward one side.

Figure 4-10 Fan Guard Shown

in Installed Position

c. Hook the loops over the top and bottom pins.

d. Repeat steps a. through c. for the other racks.

e. Using pipe sealant (not provided), install the drain tee into the rear of the steamer using the close

nipple provided, as shown in Figure 4-12. (Note: For Steamers installed on a Cleveland Range

Model ES222824S Stacking Stand refer to the instructions found in Section B, Part 3 of this

Chapter, for proper vent installation).

26

Page 31

f. Install the threaded end of the Vent stack into the ½” outlet of the drain tee using pipe sealant.

g. The unit is now ready for connection to a drain, see Chapter 4, Section B, Part 9.

VENT STACK

DRAIN TEE

Figure 4-11 Slide

Rack Installation

Figure 4-12 Steam Vent

Assembly Installation

9. Install the Free Air Vented Drain Lines

Furnishing and installing the drain line is the responsibility of the owner and/or installer. Figure 4-13

illustrates a drain layout recommended by Cleveland Range.

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE could result from improper installation of the

drain outlet lines.

Improper installation of these lines could void the SteamChef¥ 3 Steamers warranty. The

following restrictions are critical to the safety of personnel and equipment, and must not be violated

under any circumstances.

Do not connect the drain line into PVC or any drain material that cannot sustain 180

Do not connect drains from any other equipment to the drain line of the SteamChef¥ 3 Steamer.

Do not connect the drain outlet extension line directly to a floor drain or sewer line.

The drain line must be free air vented, have gravity flow from the steamer, and terminate outside

the perimeter of the unit.

a. The drain lines must be installed in compliance with the Basic Plumbing Code of the Building

Officials and Code Administrators International, Inc. (BOCA), and the Food Service Sanitation

Manual of the Food and Drug Administration (FDA) and any state, provincial or local codes.

o

F.

b. Do not install the steamer directly over a drain. Steam rising up out of the floor drain will

adversely affect operation, cooling air ventilation and may damage electrical components. (See

Figure 4-13)

c. The total length of pipe and number of bend fittings required to reach the open drain determines

the pipe size used to extend the drain line to an open drain.

x

If the drain outlet extension requires 6 feet or less of pipe, and no more than two elbows are

required, 1inch (or larger) pipe and fittings are acceptable.

x

If the drain outlet extension requires 6 to 12 feet of pipe, or requires three or more elbows, or is

installed on a Cleveland Range Model ES222824S stacked stand, 2 -inch (or larger) pipe and

fittings are required.

d. The drain line must have a gravity flow from the steamer drain outlet to the floor drain. Do not install

a trap in the drain line.

27

Page 32

e. Free air venting requires a minimum of 1 inch of

clearance between the end of the drain line and the top

of the floor drain.

f. Do not connect the steamer drain directly to drains or

plumbing of any other equipment. (Except when using a

Cleveland Range designed application such as is used

with the Model ES222824S Stacking Stand)

g. Refer to Figure 4-13 and connect the drain to the

steamer as described below:

x

The steamer is supplied with a 1-inch pipe

connection at the bottom of the drain tee.

x

When assembling the pipes and fittings of the

drain outlet extension, apply a hardening type pipe

sealant to the threads, and thread them together

FINGER TIGHT ONLY. DO NOT USE A

WRENCH.

10. Water Supply Requirements and Installation

a. Water Supply Requirements

1). Water Quality

Unlike most steam utilizing equipment, the water quality can vary significantly without any

undue loss of performance of a SteamChef¥ steamer. Even exceedingly hard, mineral laden

water will not affect the operation of a SteamChef¥ 3 as long as it is cleaned with vinegar daily

as outlined in Chapter 2, Section D.

TABLETOP (MOUNTING SURFACE)

1” CLEARANCE

MINIMUM

Figure 4-13 Typical Drain

Connection SteamChef

DRAIN TEE

DRAIN LINE

FLOOR DRAIN

¥ 3

2). Water Supply System

A potable water supply system must be available providing a minimum dynamic pressure of 35

psi (2.4 kg/cm

2

) and a maximum static pressure of 60 psi (4.1 kg/cm2).

b. Install Water Supply Lines

The installer/owner is responsible for the correct water connection of the unit. When connecting the

water supply lines observe the following instructions and all national and local codes and

regulations:

1). Never connect the unit to HOT WATER. The condenser system of the steamer will not work

properly if it is connected to HOT or WARM water.

2). The water supply should have a minimum flow pressure of 35-psi (2.4 kg/cm²) and a maximum

static pressure of 60-psi (4.1 kg/cm²). If the static pressure is above 60 psi, a pressure regulator

must be used set at approximately 50 psi. Pressure above 60 psi can damage the solenoid

valves.

3). The SteamChef¥ steamers are supplied with two connection points for incoming water, one

feeds the condensers and the second supplies feed water to the reservoir. Although, the

SteamChef¥ is very tolerant of water conditions a customer may want to use conditioned water

to supply the feed water to the reservoir. In the case of using a separate conditioned water

supply, use the layout shown in Figure 4-15.

4). Pay attention to the following requirements and recommendations when connecting the

steamer to the water supply:

a) Cleveland Range recommends the plumbing layout illustrated in either Figure 4-14, for

installations using a single water supply or Figure 4-15 if a separate conditioned water

supply is being used for the steam reservoir feed. Note: If using a single water feed to the

28

Page 33

system the supply piping to the tee fitting should be of at least the next largest size of pipe

to the connection provided at the steamer.

b) The steamer has two 3/4-inch NHT fittings (Standard Garden Hose fitting) for the water

connections to the water reservoir and to the condenser. These fittings are detailed as C1

and C2 in Figure 4-1. NOTE: The hose connector used must be NSF or FDA rated for food

grade service.

c) Install a manual water valve between the main cold water supply line(s) and the steamer

supply lines.

d) The National Sanitation Foundation (NSF) requires installation of a check-valve in all supply

lines in accordance with and as required by local plumbing codes.

e) The water supply line(s) should be designed so that the unit can be moved for service.

SteamChef¥ 3

Condenser Solenoids

Steam Resevoir

Solenoid

Water Connection C2 on

Dimension Diagram

Strainer

Water Connection C1 on

Dimension Diagram

Air/Water Column

(if required)

Check Valve

Pressure Reducer

(if required)

Figure 4-14 Cleveland Range Single Water Supply Arrangement

The strainers for this unit are preinstalled in the water inlet)

(

SteamChef¥ 3

Condenser Solenoids

Steam Reservoir

Solenoids

Water Connection C2 on

Dimension Diagram

Water Connection C1 on

Dimension Diagram

Strainer

Check Valve

Pressure Reducer