Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

STEAMCRAFT®GENERATOR STYLE

HIGH SPEED CONVECTION STEAMERS

SteamCraft®Ultra 5

COUNTER TYPE DESIGN

PRESSURELESS CONVECTION STEAMER

GAS STEAM GENERATOR, 70,000 BTU

Cleveland Standard Features

n Cooking Capacity for up to five 12˝ x 20˝ x 2

Pans (OR) 10 - 1” Cafeteria Pans.

n Innovative PowerPak Gas Steam Generator:

n

Naturally Fired 70 MBTU Generator is 72% Efficient

n

Strong 14 Gauge Stainless Steel Construction

n

Fully Automatic Electronic Spark Ignition (pilotless)

n Simple ON/OFF Start Switch: Ignites Burners and Water Fills

into Pressureless Generator with ease.

n Easy Access Cleaning Port: Generator Cleaning Port

located on the outside, top of the unit. Not necessary to

remove hot panels or pan rack guides.

n Generator Cleaning Light: Indicator Light located on the

front of the unit warns operator it is time to delime generator.

n Steam Generator Stand By Mode: Holds generator at a

steaming temperature. Allows unit to start cooking instantly.

n One 60 Minute Electro-Mechanical Timer and Switch for

manual operation:

Audible signal for cooking time

completion. (MCS)

n 4˝ Adjustable Legs.

n Durable 14 Gauge Stainless Steel Construction:

For compartment door, cavity, and steam generator.

n Automatic Generator Drain with a “Water Jet” drain clean-

ing feature.

n Exclusive Automatic Remote Float Type Water Level

Control:

n Exclusive Steam Cooking Distribution System:

Separate from the generator for easy access.

Maintenance Free Exclusive Brass Steam Jets produce a high

velocity convection steam without fans. Coved Corner design

in cooking compartment distributes heat evenly, and is easy to

keep clean. Creased top & bottom enhance drainage. Cold

water condenser behind drain maintains a dry steam. Fully

Insulated cooking compartment for thermal efficiency.

Removable Stainless Steel Slide Racks for easy cleaning.

n Exclusive “Cool to the Touch”Two-Piece Compartment

Door Design:

Free floating inner door with reversible gasket

provides an air tight seal. Stainless Steel Slam/Latch Door

Latch mechanism for reliability.

n Standar

n Left Hand Door Hinging: Compartment door hinged on left,

d with Cord & Plug for 115 volt controls.

controls on the right.

Options & Accessories

1

⁄2˝ deep Cafeteria

MODEL: c 21-CGA-5

Shown with optional

onic Timer

Electr

Short Form Specifications

Shall be CLEVELAND,

Counter-Type Steamer, Model 21-CGA-5, 70 M BTU, heavy duty all

Stainless Steel constr

Generator with Remote Probe Type Water Level Controls and

Automatic Steam Generator Blowdown with “Water Jet” Drain

Cleaning feature.

p 34" (864mm) High Stainless Steel Economy Stand, for one 21-

CGA-5 (UniStand34)

p POSK Pull-Out Shelf Kit for UniStand (P/N 1

p URK Pan Rack Kit UniStand (P/N 1

p Compartment Door Steam Shut Of

p Cafeteria Pans in depths of 1˝, 21⁄2˝, 4” and 6”

p Dissolve®Descale Solution, 6 one gallon container w/quart

markings (106174)

p Propane Gas option (PG)

p Water Filters

SteamCraftUlt ra 5

uction; r

ear mounted, insulated Steam

11726)

f (SCS)

, one compartment,

1724)

1

p Electronic Timer with Compensating Load Feature (ETC)

p Simple ON/OFF Switch for Compartment Controls (MC)

SECT. IV PAGE 7

0707

Page 2

C

C

C

WATER QUALITY

REQUIREMENTS

The quality of water varies

greatly from region to

region. Steam equipment

generators must be

drained daily and chemically descaled periodically

o ensure proper operation.

t

o minimize service prob-

T

ems caused by the accu-

l

mulation of minerals and

chemicals in water review

the following quality guidelines with a local water

treatment specialist. Inlet

water that is beyond these

specified guidelines should

be treated to achieve these

acceptable limits. Total

Dissolved Solids less than

60 ppm, Alkalinity less than

20 ppm, Silica less than 13

ppm, pH factor greater

than 7.5, Chlorine less

than 30 ppm.

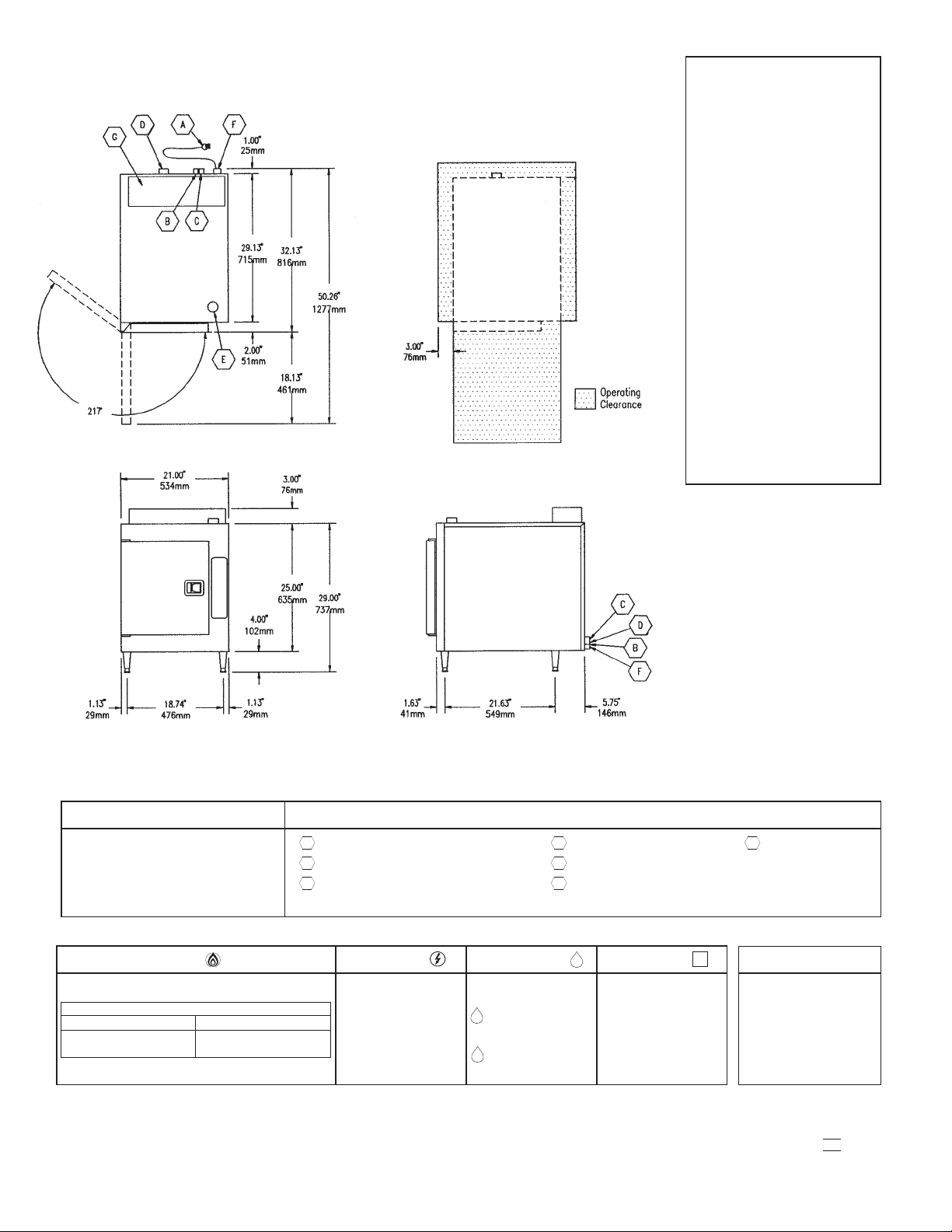

TOTAL CAPACITY

1

NA

TURAL

⁄2˝ Cafeteria Pans or

GAS COLD WATER DRAINAGE

SUPPLY PRESSURE

PROP

ANE

A

Electrical Supply Drain: 1-1/4˝ Dia. IPS Flue Gas Exhaust

B

Cold Water Supply for Condenser 1/4˝ Dia. NPT Inlet for Generator Deliming Solution

C

ater Supply for Generator. Gas Su pply 1/2˝ Dia. IPS

Cold W

1/4˝ Dia. NPT (for water treatment conn.)

Unit comes with a 40 Mesh Water Strainer

ELECTRIC

115V - 1 Phase

35 Watts

4 Amps

15 — 12˝ x 20˝ x 2

10 — 12˝ x 20˝ x 1˝ Cafeteria Pans or

23 — 12˝ x 20˝ x 4˝ Cafeteria Pans

1/2˝ Dia. IPS

4.00˝ W.C. minimum 12.00˝ W.C. minimum

14.00˝ W.C. maximum 14.00˝ W.C. maximum

Manufacturer must be notified if unit will be used above 2,000

ft. altitude.

TES

NO

:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are UL/NSF#4 and CSA (AGA, CGA).

UTILITY CONNECTIONS

D

E

F

35 psi minimum

60 psi maximum

1

⁄4˝ Dia. NPT for

Generator (for w ater

treatment connection)

1

⁄4˝ Dia. NPT for

Condenser

D

1

1

⁄4˝ Dia. IPS

Do not connect any other

units to this drain.

Drain line must be vented.

No PVC pipe for drain.

G

from Generator

CLEARANCE

Right - 3”, Left - 3”, Rear - 3”

(12” on control side if adjoining wall or equipment is over

30” high for service access)

Contact factor

or v

f

y

ariances to c

(NOT TO SCALE)

SECT. IV PAGE 8

learances.

Litho in U.S.A.

0707

Loading...

Loading...