Page 1

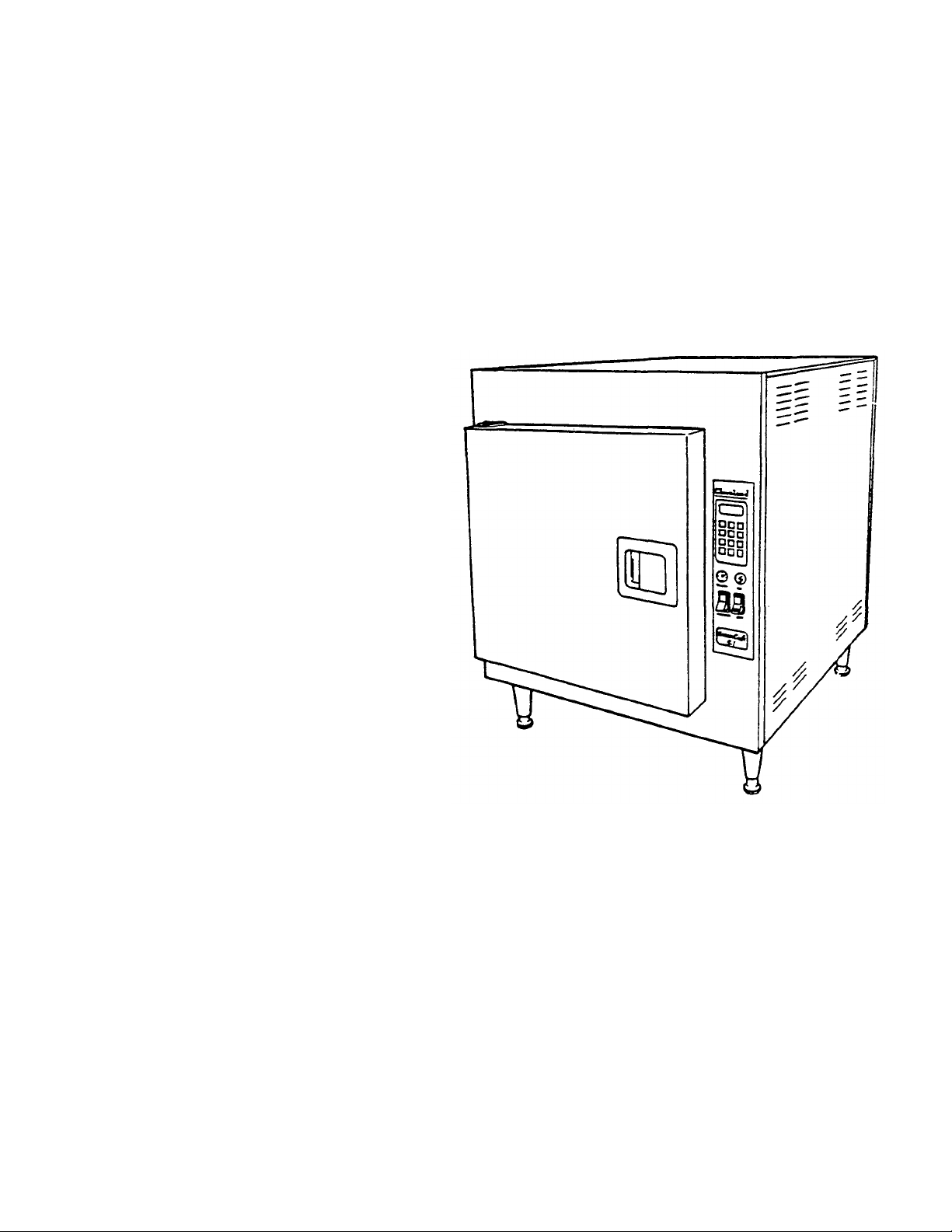

Steam Craft

SERVICE

5.1

COUNTER TYPE CONVECTION

STEAMER

MANUAL

Model21-CET-16

Printed 12/90

Cleveland Range, Inc.

•UNITED STATES CANADA

1333 East. 79th St. Garland Commercial Ranges • 1177 Kamato Rd. Cleveland.Olno-

UlHI Mi',sissauua. Ontariu CM.4\V 1X4 Phone: (216) 4Sl-4y(ll» • 1 cle \: ^.1)54^

• FAX: (216) 4S1-37S2 Phone: (416) 64-026» • FAX: 1416) 624-(1623

CTS-02

Page 2

PROTECTING WARRANTY COVERAGE

Electrical Power Requirements and Line Voltage

6 and 17

Water Quality Require

ments and Analysis

6 Water Pressure

18 Vented Drain

14 Level Operation

10 Blowdown Frequency

41

and

52 Steam Generator Maintenance and Maintenance Records

55 Descaling Frequency and Procedure

56 Approved Chemical Cleaners

56

The warranty printed to the left specifies the owner/user's responsibility for proper

installation, operation, and maintenance of the SteamCraft 51 If these responsibilities are not met, the Limited Warranty and/or Extended Limited Warranty

coverage may be adversely affected The following table is provided to assist the

owner/user in meeting these responsibilities In addition, the warranty advantages of

installing a SteamerGard water treatment system are explained after the table

The Warranty Protection Table lists installation, operation, and maintenance fac tors

that have in the past adversely affected warranty coverage The owner/user of a

SteamCraft 51 should pay particular attention to these factors to protect his warranty

coverage This table is not a comprehensive list of the owner/user's responsibilities

Cleveland Range steam products are intended for use only by professionally trained

personnel To meet his responsibilities, the owner/user must supplement this guide

with any additional actions consistent with the operation of steam generating food

preparation equipment by a trained professional

Warranty Protection Table

SUBJECT PAGE

Authorized Maintenance and Repair 61

REFERENCE

SteamerGard Water Treatment System

A Steamer Gard water treatment system protects the SteamCraft 51 from impurities

contained in regular tap water, especially Total Dissolved Solids (TDS) which cause

lime and scale deposits in steamer equipment The protection is so effective that

Cleveland Range increases the warranty coverage on a SteamCraft 51 installed in

conjunction with a SteamerGard system to five years for parts and three years for

labor on water related components, elements, valves, generators, piping, etc Howe'ver, even with a SteamerGard system installed, the owner/user should follow the

guidance of the Warranty Protection Table

Page 3

Model 21-CET-16 Service Manual Page i

MODEL NUMBER

1 SERIAL NUMBER

1 PRODUCT INFORMATION PLATE

1

INTRODUCTION

3 INSTALLATION POLICIES

3

INSTALLATION OVERVIEW

4

PREPARATION

FOR

INSTALLATION

6

Electric Power Requirements

6 Water Quality Requirements

6 Water Supply System

7 Selecting The Operating Location

7 INSTALLATION INSTRUCTIONS

9

Unpacking and Inspection

9 Shipping Da

mage Instructions

10 Position and Level The Steam Craft 51

10 Leg Mounting and Leveling

10 Surface Mounting and Leveling

11 Stand Mounting and Leveling

12 Install Slide Racks

14 Install the Free Air Vented Drain Lines

14 Connect Drain Lin

e

16 Install Electric Power Lines

16 Connect

Electrical Line

17 Install Water Supply Lines

18 Connect Water Supply Lines

20

General Connection Requirements

21

Untreated Water Connection (Without SteamerGard)

21

Treated Water Connection (With St

eamerGard)

21 Testing Water Supply Lines

21 Final Setup and Checkout

22

Setup and Blowdown Inspection

- All SteamCraft

51's 22 Operating Tests

- Key Pad Control Panel

24 Operating Tests

- Dial Timer Control Panel

26

Table of Contents

CHAPTER PAGE

CHAPTER 1 PRODUCT IDENTIFICATION 1

CHAPTER 2 INSTALLATION INSTRUCTIONS 3

Page 4

Page ii Model 21 -CET-16 Service Manual

Table of Contents (continued)

CHAPTER PAGE

CHAPTER 3 OPERATION 29

INTRODUCTION 29

OPERATIONAL SAFETY 29

CONTROL, PANELS 30

KEY PAD CONTROL PANEL SUMMARY 31

COOKING OPERATIONS -KEYPAD CONTROL PANEL 32

Manual and Timed Modes 32

Main Power Switch 32

Power ON (Automatic Fill) 34

Inspect the Cooking Compartment 34

Preheating the SteamCraft 51 35

Operating Procedure - Timed Mode 36

Operating Procedure - Manual Mode 39

Manual Timer 39

Temperature Compensation 39

Manual Cooking Procedure 40

Power OFF (Automatic Blowdown) 41

Blowdown Frequency 41

Blowdown Procedure 42

Shut Down and Cleaning (At end of day or shift) 42

DIAL TIMER, CONTROL PANEL SUMMARY 44

COOKING OPERATIONS-DIAL TIMER CO NTROL PANEL 44

Manual and Timed Modes 46

Main Power Switch 46

Power ON (Automatic Fill) 46

Inspect the Cooking Compartment - 47

Preheating the SteamCraft 5-1 47

Operating Procedure - Timed Mode 48

Operating Procedure - Manual Mode 50

Manual Timer 50

Manual Cooking Procedure 50

Power OFF (Automatic Blowdown) 52

Blowdown Frequency 52

Blowdown Procedure 52

Shut Down and Cleaning (At end of day or shift) 53

Page 5

Model 21-CET-16 Service Manual Page iii

INTRODUCTION

55 MAINTENANCE RECORDS

55 DAILY MAINTENANCE

55

Clean SteamCraft

51

55 WEEKLY MAINTENAN

CE 55 MONTHLY MAINTENANCE

56 YEARLY MAINTENANCE

59 TROUBLESHOOTING NOTES

61

INTRODUCTION

63

Figure

s

And Illustrations

63 STEAMCRAFT 51 ELECTRICAL CIRCUITS

63

High Voltage Circuit

63 120

VAC Circuit

63 Timer

Circuits

64 CIRCUIT OPERATION

64

MANUAL Mode Circuit Operation

64 TIMED Mode, Circuit Operation

67 Electronic Key Pad Timer Units

68 Mechanical Dial Timer Unit

68 Shutdown, Steam Generator Blowdown and Float Cylinder Rinse

68 ELECTRICAL CIRCUI

T COMPONENTS

70 Terminal Block

(4,

Figure

6-7) 70 Heater Element

(4,

Figure

6-9) 70 Dryer Element

(7,

Figure

6-8) 71 Fuses

(8,

Figure

6-7) 71 ON/OFF Switch

(10,

Figure

6-

5) 71 TIMED/MANUAL Switch

(11,

Figure

6-5) 72 Relay K1

(9,

Figure

6-5) 72 3 Minute Timer

(14,

Figure 6

-5 ) 73 Rinse Solenoid Valve

(1,

Figure

6-11) 73 Drain Solenoid Valve

(4

Figure

6-12) 73 Fin Solenoid Valve

(1,

Figure

6-11) 73 Condenser Solenoid Valve

(1,

Figure

6-11) 74 Timer

74 Electronic Key Pad Timer

(3,

Figure

) 74 Compartment Thermal Switch (electronic key pad units only)

(17,

Figure

) 75

Table of Contents (continued)

CHAPTER PAGE

CHAPTER 4 PREVENTATTVE MAINTENANCE AND TROUBLESHOOTING 55

CHAPTER 5- ELECTRICAL SYSTEM 63

Page 6

Page iv Model 21-CET-16 Service Manual

3-Second Timer and Buzzer

(mechanical timer units only)

(11,15,

Figure

6-6) 75 High Tempera

ture Limit Switch

(1,

Figure 6

-9) 75 Float Assembly (Figure

6-10) 75 COMPONENT TESTING GUIDE INTRODUCTION

77

Nominal Voltage

77 FUNDAMENTAL COMPONENT TESTING

77 Visual Check

77

Fuses

78

Connection Points and Wiring

78 Solenoid Valves

78 Tim

ers

79 Thermostatic Snap Switches

79

Heater Element

80 Resistance Measurements

80

Insulation Resistance Measurements

80

Voltage Measurements

80 COMPONENT TEST PROCEDURES

81

Initial conditions for all testing

81 Fuses

81

Transformer

82 ON/O

FF Switch

83 Relay K1

83 Fill Solenoid Valve

84

3-Minute Timer

85 Drain Solenoid Valve

-

86 Rinse solenoid

-

valve

-

87 Condenser Solenoid Valve

88 TIMED/MANUAL Switch

89 High Temperature Limit Switch

90 Electronic Key Pad Timer

90 Compartme

nt Thermal Switch (key pad timer units only)

92 Mechanical Timer

93 Heater Contactor

93 Heater and Dryer Elements

95 Float Assembly

96 3-Second Timer and Buzzer (mechanical timer units only)

99

Table of Contents (continued)

CHAPTER PAGE

CHAPTER 5 ELECTRICAL SYSTEM (continued)

Mechanical Timer (3, Figure 6-6) 75

Page 7

Model 21 -CET-16 Service Manual Page v

INTRODUCTION

101 Parts Differences Among SteamCraft

5.1

Steamers

101 Electrical Schematics and Wiring Diagrams

101

Table of Contents (continued)

CHAPTER PAGE

CHAPTER 6. ILLUSTRATED PARTS LISTS 101

Page 8

Page 9

MODEL NUMBER

SERIAL NUMBER

Model 21-CET-16 Service Manual Page 1

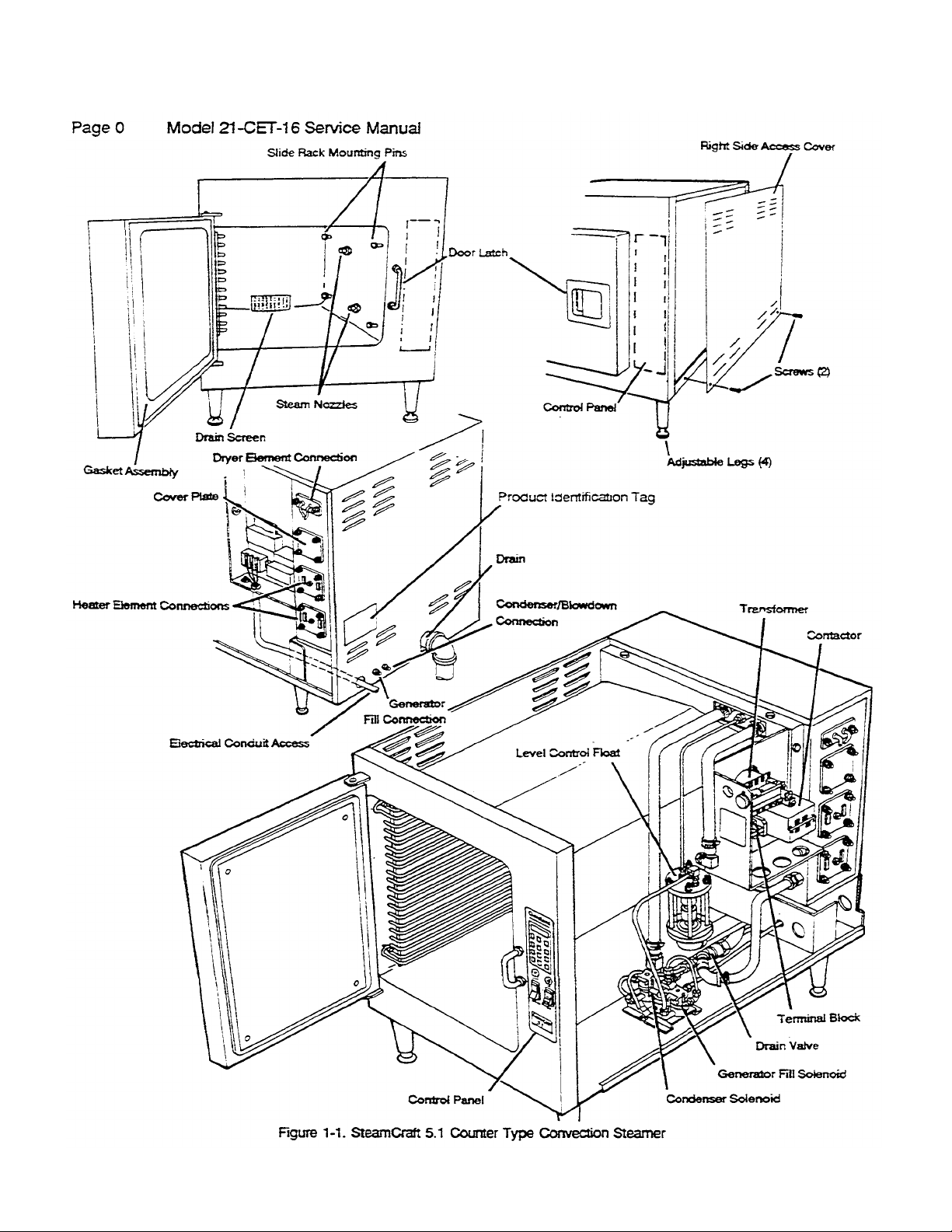

CHAPTER 1. PRODUCT IDENTIFICATION

Cleveland Range, Inc. assigns two product identification numbers to each

SteamCraft 5.1: a model number and a serial number. The model number

identifies the product characteristics. The serial number identifies the individual

unit.

All-SteamCraft 5.1 steamers are identified by the same model number,

21-CET-16. Each character of this model number identifies a charac teristic of the steamer. The SteamCraft 5.1 is a Convection steamer,

.Electric powered, and Table-mounted with an input energy rating of 16.5

kW. This manual covers all standard features and options available on

SteamCraft 5.1 steamers.

Other than selection of options, there are presently no significant design,

parts, or operating differences among steamers with this model number.

Figure 1-1 illustrates the SteamCraft 5.1 and identifies the major components.

During manufacture, SteamCraft 5.1's are assigned individual serial

numbers. A typical SteamCraft 5.1 serial number is: WC-7350-90G-02.

The left half of the number carries design information. The right half of the

number contains the manufacturing date and the unit of the manufac turing lot The date of our sample number is 90G-02:90= 1990, G=July.

02=the second unit of the manufacturing lot. Serial numbers are used

when explaining differences in design, parts, or operation among units

with the same model number. For example: a particular part may be used

on SteamCraft 5.1's with serial numbers before WC-7350-90G-02, and a

different part used on steamer WC-7350-90G-02 and those manufac tured

after it

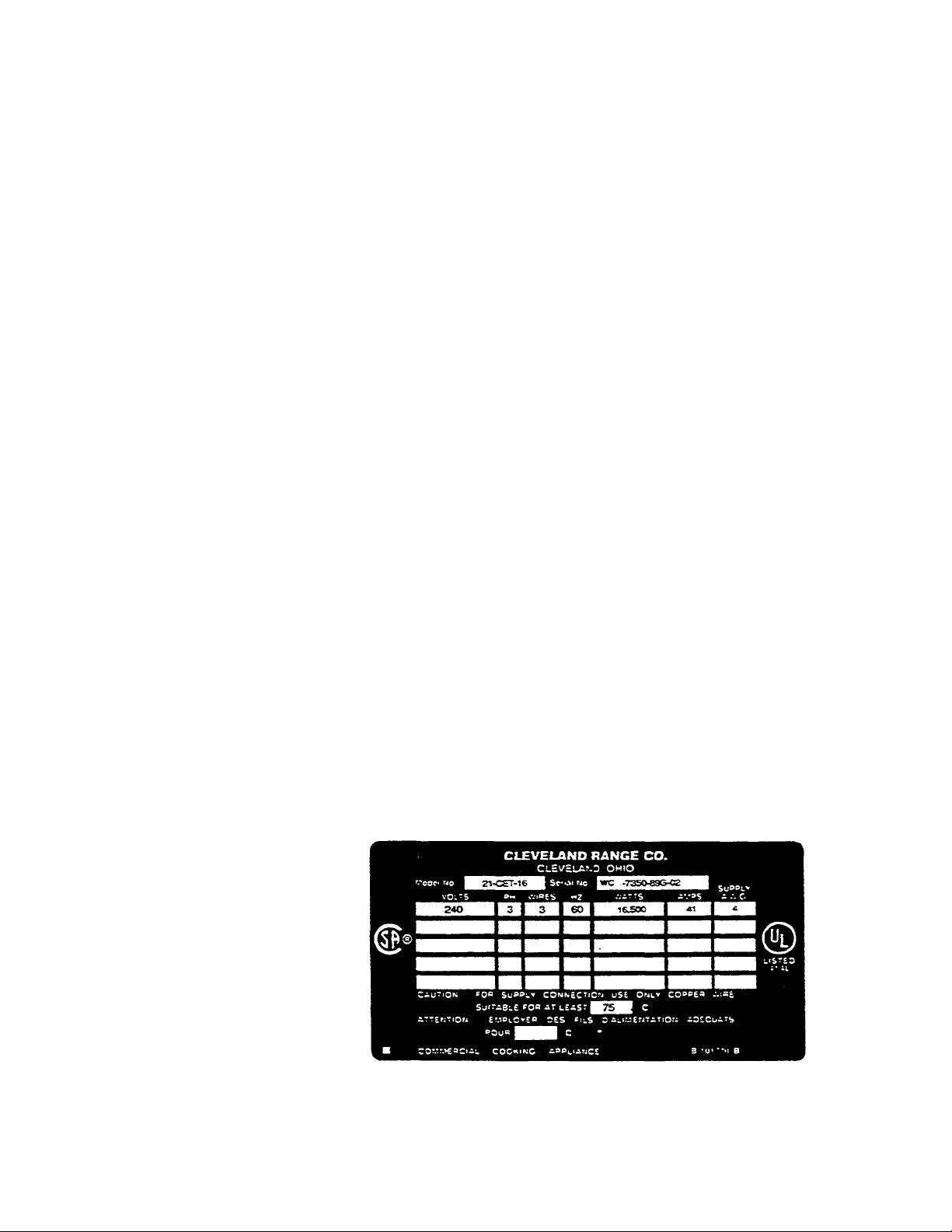

PRODUCT INFORMATION PLATE

The Product Information Plate on the back of the unit lists the model and

serial number of the steamer. Refer to Figure 1-1 for the location of the

plate. Figure 1-2 illustrates a typical SteamCraft 5.1 Product Information

Plate. The plate also fists power and wiring requirements.

Figure 1-2. SteamCraft 5.1 Product Information Plate

Page 10

INTRODUCTION

Model 21-CET-16 Service Manual Page 3

CHAPTER 2. INSTALLATION INSTRUCTIONS

This chapter is a guide for installation of the SteamCraft 5.1, model

number 21-CET-16. The instructions are written for qualified, profes sional

plumbers, pipe fitters, and electricians. This guide does not include all

procedures and precautions in the common domain of licensed plumbers,

pipe fitters, and electricians, or experienced food service equipment

installers.These instructions must be used in conjunction with a thorough

understanding of the Basic PIumbing Code of the Building Officials and

Code Administrators International, Inc. (BOCA), the National Fuel Gas

Code, ANSI Z223.1-1984, and the Food Service Sanitation Manual of the

Food and Drug Administration (FDA).

Before starting installation, the owner and the installer should read

through this chapter and thoroughly understand and agree upon:

• The installation policies of Cleveland Range, Inc. as stated in

Installation Policies.

• Responsibility for electric power requirements as described in

Preparation for Installation, Electric Power Requirements.

• Responsibility for feed water quality and its testing as described in

Preparation For Installation, Water Quality Requirements.

INSTALLATION POLICIES

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE

could result from improper installation of the

SteamCraft 5.1, or from installation of a unit

damaged during shipment or storage- Either of

these conditions could also void the equipment

warranty.

DO NOT INSTALL a SteamCraft 5.1 suspected of

damage.

Install the SteamCraft 5.1 according to the policies

and procedures outlined in this manual.

The SteamCraft 5.1 must be installed by qualified plumbing and

electrical personnel, working to all applicable national and local codes.

Equipment installation must comply with the Basic Plumbing Code of

the Building Officials and Code Administrators International, Inc.

(BOCA) and the Food Service Sanitation Manual of the Food and Drug

Administration (FDA).

Cleveland Range designs and manufactures equipment to comply with

applicable standards for manufacturers. Included among these

certification agencies are: UL, A.G.A., ASME/N.Bd., NSF, CSA, CGA,

ETL, and others.

Page 11

Page 4 Model 21 -CET-16 Service Manual

Unpack and inspect SteamCraft 5.1

9

Install and connect water supply lines.

18-21

• This equipment is designed and certified for safe operation only when

permanently installed in accordance with local and/or national

codes.Many local codes east, and it is the responsibility of the owner and

installer to comply with these codes.

• In no event shall the manufacturer assume any liability for damage or

injury resulting from installations which are not in strict compliance with

the Installation Instructions and the codes cited above.Specifically, the

manufacturer will not assume any liability for damage or injury resulting

from improper installation of equipment, including, but not limited to,

temporary or mobile installations.

INSTALLATION OVERVIEW

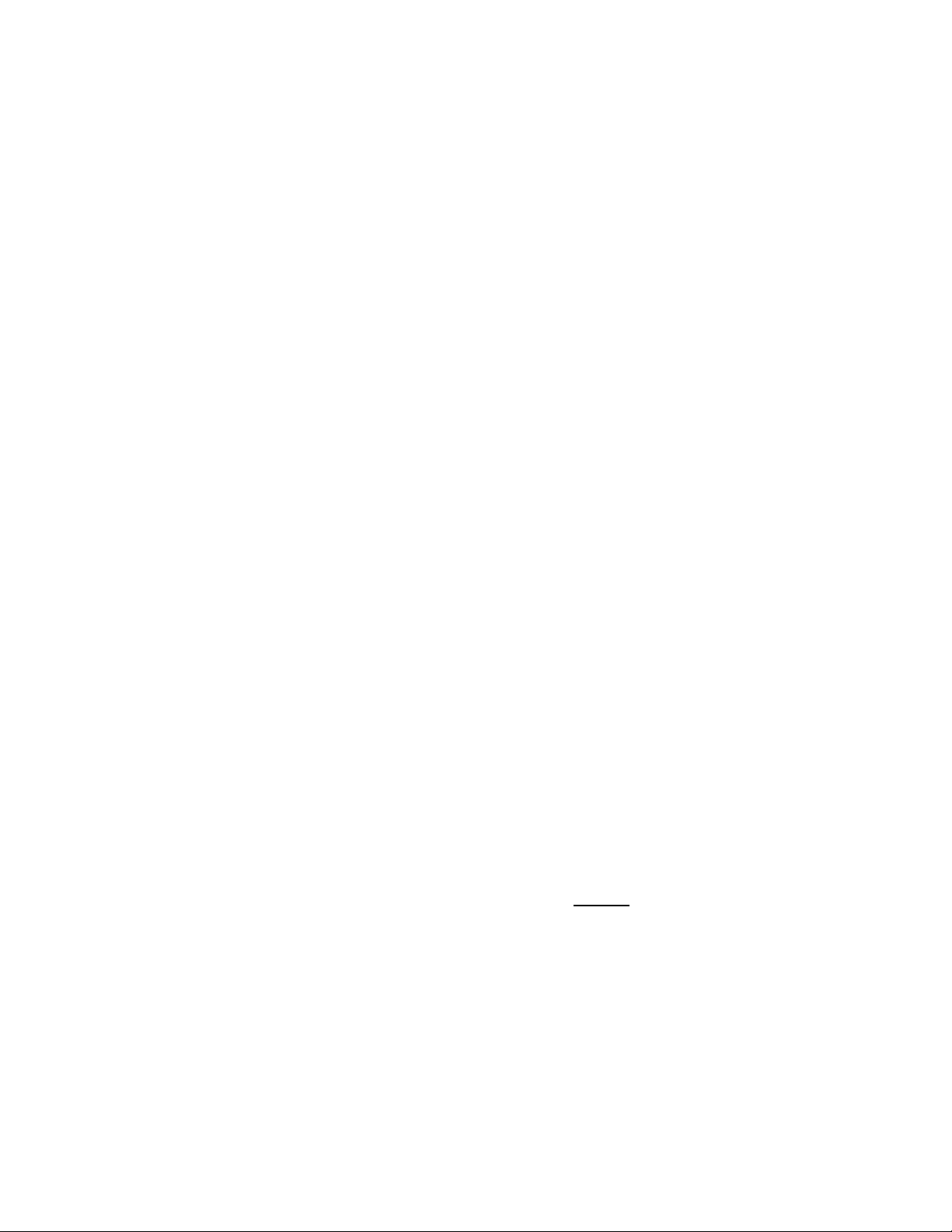

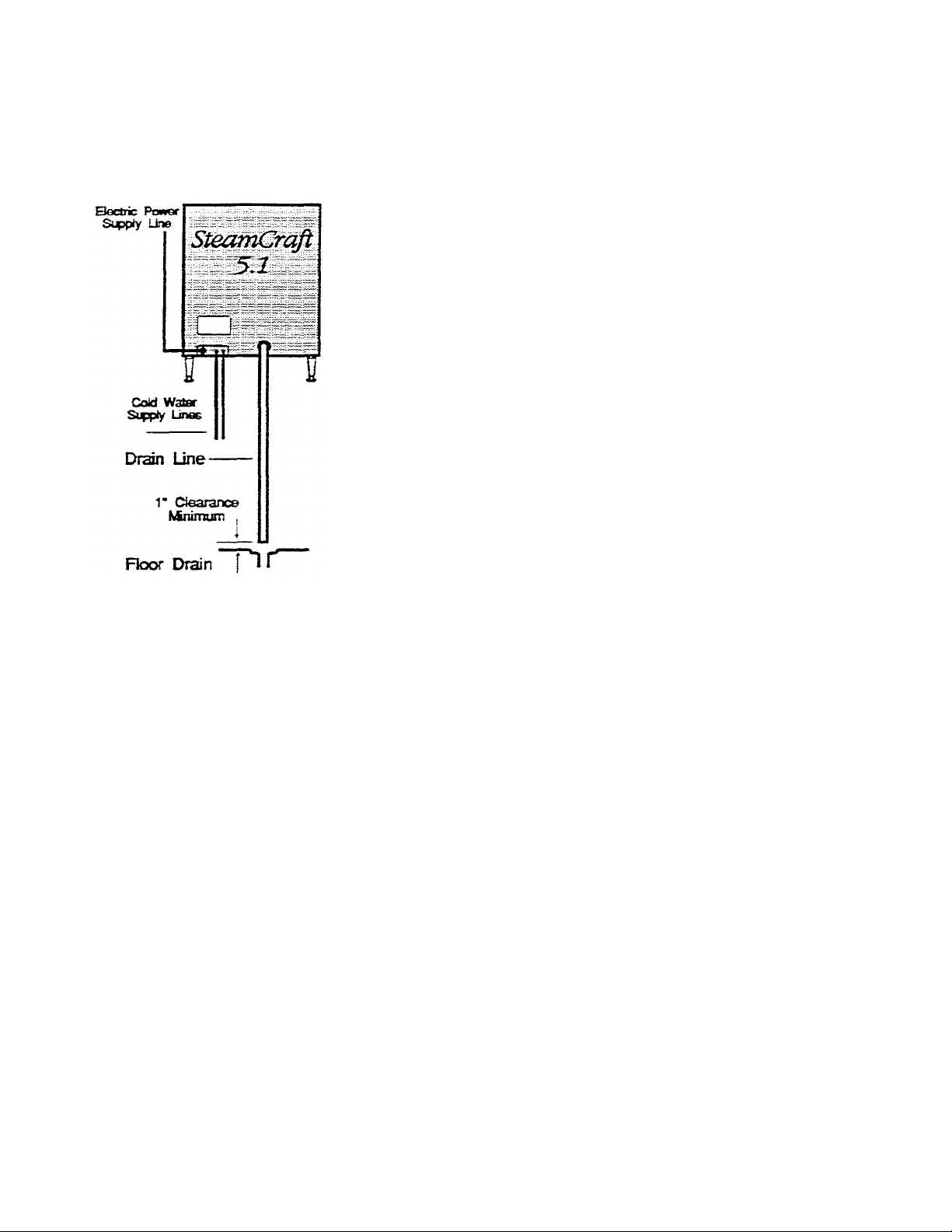

Schematic Installation Diagram, Figure 2-1, illustrates the various drain,

electrical, and water lines required; and their connection points on the

SteamCraft 5.1. Table 2-1, Installation Check List, outlines the overall

installation process in a recommended sequence; the instructions referenced provide details. Installation requirements may vary from site to site;

adapt the check list accordingly.

Table 2-1. Installation Check List

TASK REFERENCE COMPLETED

Preparation

Check Electric Power Requirements. 6

Test supply water quality. 7

Select water supply system- 7

Install water treatment system- 7

Select operating location. 7

Installation

Position and level steamer. 10

Install and connect drain line. 14-16

Install and connect electrical lines. 16-18

Test water supply lines. 21

Perform final setup and checkout. 22

PAGE

Page 12

Model 21-CET-16 Service Manual Page 5

INSTALLATION DIAGRAM NOTES

1. The Product Identification Plate located on the back

panel specifies the electric power requirements.

2. For each unit, the installer must provide a ground

connection and a separate fused disconnect switch.

3. Catastrophic damage will result from shifting the

SteamCraft 5.1 more than 10° out of level while

power is turned on at the unit's main power switch.

4. The unit must have a cold water supply, NOT HOT.

The water supply must meet the quality requirements

of Table 2-2, and the pressure requirements on page

18.

5. A SteamerGard system is recommended when water

quality does not meet the Table 2-2 requirements.

Figure 2-1. Schematic Installation Diagram

6. A manual shut off valve must be installed between

the main water supply and the steamer supply fines.

Refer to figures 2-18 and 2-19 for the recommended

component arrangements.

7. Run a single water fine between the main cold water

supply and the tee. The separate steam generator

and condenser/blowdown supply fines are

comparatively short.

8. The drain One must have a gravity flow away from

the steamer, and must not be connected to the dram

lines of any other equipment.

9. The drain line must be free air vented- If the line

empties into a floor drain, there must be a one inch

minimum clearance between the drain fine and the

floor drain openings.

Page 13

Page 6 Model 21-CET-16 Service Manual

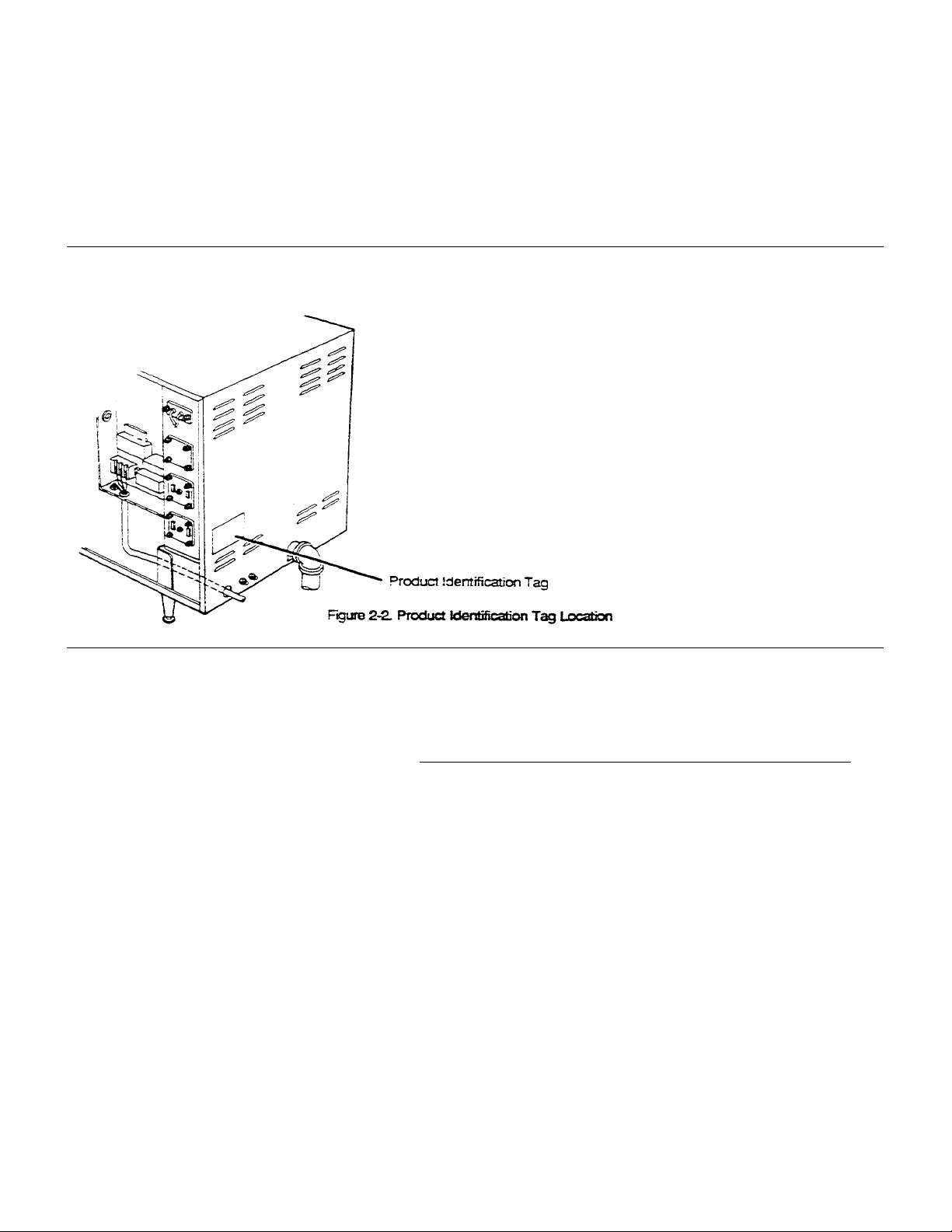

The characteristics of the e

lectric power supply must match the power

Water Quality Requirements

CAUTION

PREPARATION FOR INSTALLATION

Before unpacking the SteamCraft 5.1, check the electric power and water quality

requirements and select the operating location-

Electric Power Requirements

requirements specified on the SteamCraft 5.1 product identification plate.

The plate is located on the back of the unit as illustrated in Figure

2-2.

Using water not within the limits specified in this manual could

void or adversely affect Cleveland Range's warranty

coverage of the SteamCraft 5.1.

As with any steam generating equipment, poor water quality degrades

SteamCraft 5-1 performance. If feed water is low in Total Dissolved Solids

(TDS) and free of particulate matter, the steam generator, heating element,

and valves of the SteamCraft 5.1 will give years of trouble-free service with

a minimum of maintenance.

In some areas, even potable tap water contains a variety of impurities that

can cause costly problems in steam generating equipment. Of primary

concern are mineral salts and other impurities which remain behind as lime

or scale deposits during the steam generating process. Th ese deposits

have caused components to fail, including heating elements, probes and

solenoid valves. Of equal importance is the decrease in heat transfer

efficiency caused by lime and scale deposits. Decreased heat transfer

increases water and power consumption. Use of the SteamCraft 5.1 in

areas with poor water quality requires installation of a SteamerGard water

treatment system or increased frequency of maintenance, cleaning, and

descaling.

Page 14

Model

21 -

CET-16 Service Manual

Page

7 For safe and efficient operation, observe the following criteria when

Check the quality of supply water as described below

before starting construction

Alkalinity

less than

20

parts per million

of the water supply lines. If a SteamerGard water treatment system must be

installed to achieve acceptable water quality, install it before connecting the water

supply lines to the SteamCraft 5.1.

Contact a local water treatment specialist for an on-the-premises water analysis.

The recommeoded minimum feed water quality requirements for the SteamCraft

5.1 are listed in Table 2-2.

Table 2-2. Minimum Water Quality Requirements

Total Dissolved Solids

Silica less than 13 parts per million

ph factor greater than 7.5

less than 60 parts per million

Water Supply System

Select a water supply system that fulfills the requirements of the limits

listed in Table 2-2. The supply must provide a minimum dynamic pressure

of 35 psi (2.4 kg/cm2) and a maximum static pressure of 60 psi (4.1

kg/cm). Refer to page 18 for detailed pressure and fitting requirements,

and recommended plumbing layouts.

• If analysis shows that the supply water is within the required limits, a

single line water system can be installed. A single water line system is

illustrated in Figure 2-18 on page 18,

• If analysis shows that the supply water is NOT within the required limits,

install a SteamerGard water treatment system- Figure 2-19 on page 19

illustrates a treated water supply arrangement.

• If analysis shows that the supply water is NOT within the required limits,

and it is not possible to install a SteamerGard water treatment system;

plan on increasing the frequency of maintenance, cleaning, and

descaling beyond that recommended in the maintenance schedule

(Chapter 4).

Selecting The Operating Location

selecting an operating location for the SteamCraft 5.1.

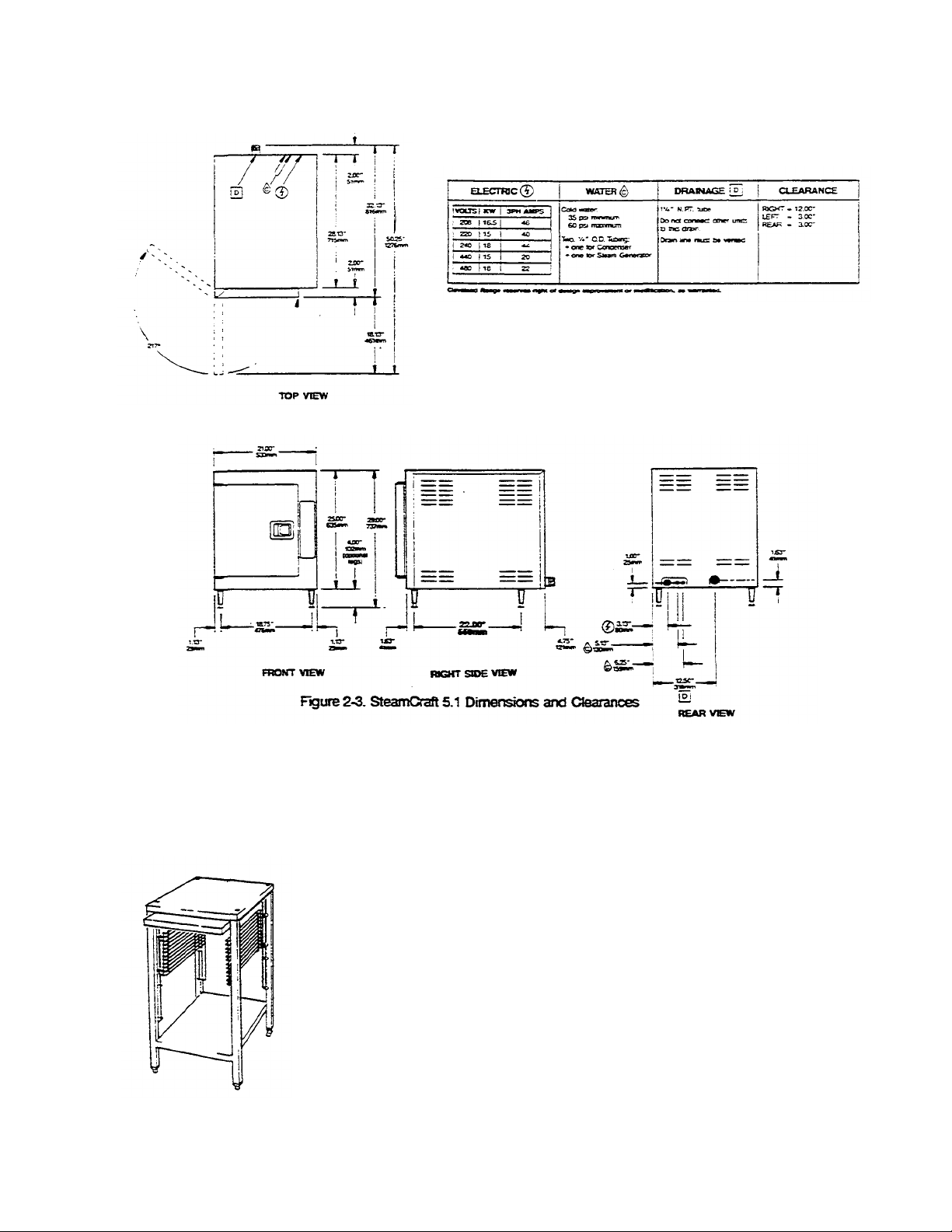

1. The SteamCraft 5.1 fits in a small counter space- Figure 2-3 illustrates

the dimensions and clearances required. Maintain the following

minimum dimensions around the unit for safe and efficient operation,

maintenance and service.

• A 3 inch clearance around the unit for ventilation.

• A 12 inch clearance on the right side for removing the service panel

during descaling, maintenance and repair.

• A 3 inch clearance at the rear for the water inlet fittings, and the

maximum size (2-inch NPT) drain fittings.

• Approximately 22 inches in front of the unit for opening the door and

cafeteria pan clearance.

Page 15

Page 8 Model 21 -CET-16 Service Manual

Figure 2-4. Equipment Stand

2. The SteamCraft5.1 is typically installed with four adjustable mounting

legs, as shown in the dimension drawing. If clearance above the unit is

limited, it can be installed 'without legs, surface mounted directly to the

counter top.

3. The SteamCraft 5.1 must be level both front to back and side to side.

Select an operating surface that is level enough to allow leveling the

unit without extreme adjustment of the legs or shimming of surface

mounts.

4. The SteamCraft 5.1 weighs approximately 155 pounds. The counter

area selected must be capable of supporting an operating weight of

approximately 200 pounds to include the weight of water and food.

5. The SteamCraft 5.1 has capacity for three 12" x 20" x 2-5' Cafeteria

Pans (model # SP-2.5 or PP-2J). Convenient storage for pans should

be considered when selecting the operating location.

6- Do not block the vents on the side or rear of the unit. Do not store

articles on top of the unit.

If a satisfactory counter location is not available, consider using a model

ES-2130 Equipment Stand. This stand, illustrated in Figure 2-4, is

designed to support the SteamCraft 5.1, and meets the above criteria.

Page 16

Model 21 -CET-16 Service Manual Page 9

INSTALLATION INSTRUCTIONS

Unpacking and Inspection

After selecting the SteamCraft 5.1 operating location, the steamer can be

unpacked, positioned, and installed. After Final Setup and Checkout, the

SteamCraft 5.1 will provide years of reliable operation.

1. Before unpacking the shipping carton, visually inspect it for damage.

• If the shipping carton appears damaged, do not open the carton.

Refer to the Shipping Damage Instructions on page 10.

• If the shipping carton is undamaged, proceed with step 2.

2. Slit the four comers of the carton and peel carton sides away from the

SteamCraft 5.1. The slide racks and legs are shipped in separate

packing on top of the unit. Be careful not to damage or throw away

these unassembled parts.

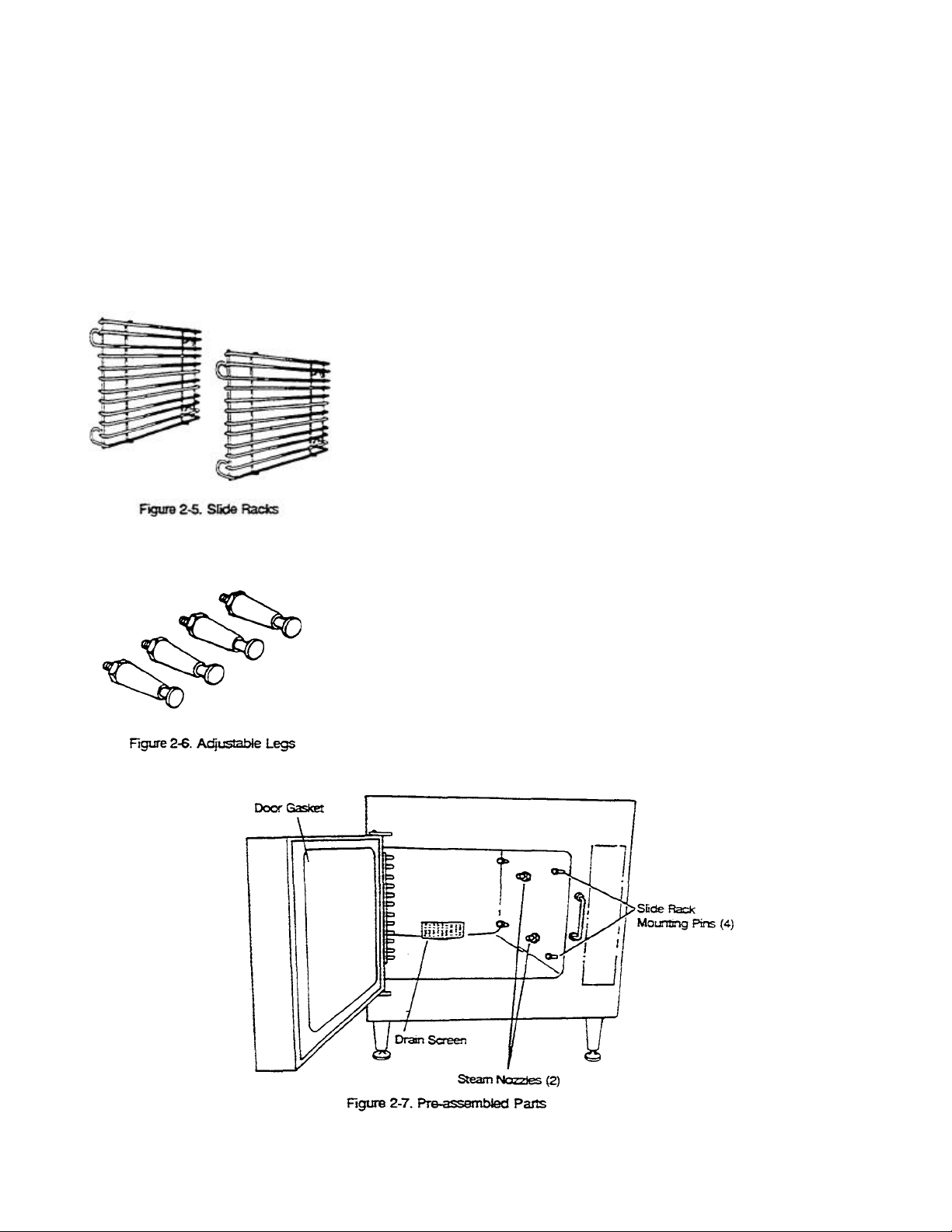

3. Remove the carton from the top of the unit The package contains two

slide racks as illustrated in Figure 2-5. These racks are snipped in

separate packing on top of the unit

4. The SteamCraft 5.1 adjustable legs are also shipped on top of the unit

in pockets at the edges of the packing. Refer to Figure 2-6.

5. Open the door of the SteamCraft 5.1. Several pre-assembled parts can

be seen inside the unit Refer to Figure 2-7. Do not remove the Drain

Screen, Steam Nozzles, and Slide Rack Mounting Pins.

6. Inspect the SteamCraft 5.1 and parts for damage or loss.

• If you discover or suspect shipping damage or loss, refer to the

Shipping Damage Instructions on page 10.

• If all items are accounted for and undamaged, place the packaged

slide rac ks inside the cooking compartment, and proceed to Position

and Level The SteamCraft 5.1.

Page 17

Page 10 Model 21 -CET-16 Service Manual

Shipping Damage Instructions

If shipping damage to the SteamCraft 5.1 is discovered or suspected,

observe the following guidelines in preparing a shipping damage claim.

• Write down a description of the damage or the reason for suspecting

damage as soon as it is discovered. This will help in filling oat the claim

forms later.

• As soon as damage is discovered or suspected, notify the carrier that

delivered the shipment.

• Arrange for carrier representative to examine damage.

• Fill out all appropriate claims forms and have the examining carrier sign

and date each farm.

Position and Level

The SteamCraft 5.1

The SteamCraft 5.1 is typically counter top mounted on four adjustable

legs. To compensate for height limitations, the steamer can be surface

mounted directly to the counter top. If a suitable counter is not available,

the unit can be secured to a Cleveland Range ES-2130 Equipment Stand.

The following instructions cover each of these mounting methods.

CAUTION

Malfunctions and equipment damage may result from

improper mounting. Malfunctions and/or damage

resulting from improper mounting are not covered by the

equipment warranty.

The SteamCraft 5.1 MUST BE LEVEL BOTH FRONT

TO BACK AND SIDE TO SIDE in all mount ing

arrangements.

Catastrophic damage will result from shining the

SteamCraft 5.1 more than 10° out of level while power is

turned on at the unit's main power supply switch.

Leg Mounting and Leveling

The supporting legs of the SteamCraft 5.1 are four inches long when the

adjustable feet are fully retracted. This provides the four inch space below

the unit required by NSF sanitary standards. The adjustable feet can be

extended approximately two inches for leveling the steamer.

Assembly

1. Check that the feet are fully retracted into the legs. Do not overtighten. The feet should easily screw in and out using fingers only.

Page 18

Model 21 -CET-16 Service Manual Page 11

Surface Mounting and Leveling

WARNING

INJURY AND EQUIPMENT DAMAGE could result

from improper lifting. The SteamCraft 5.1 weighs

approximately 135 pounds. Use enough workers with

experience lifting heavy equipment to place the

SteamCraft 5.1 on the counter.

2. Be sure electric power is turned off at the main power switch. Place

the SteamCraft 5.1 on its left side.

3. Screw the four legs into the weldnuts mounting holes - All four lees

must be installed for proper mounting of the SteamCraft 5.1.

4. Place the steamer upright on its four legs.

Positioning and Leveling

1. Thoroughly clean the counter top area that will support the steamer.

2. Using a level, determine and mark the highest comer of the counter

top area that will support the steamer.

3. Lift the SteamCraft 5.1 into position on the counter.

4. Do not adjust the retractable foot of the leg in the highest comer

(marked in step 2). Using a level, adjust the other three legs until the

unit is level both front to back and side to side.

5. After the SteamCraft 5.1 has been positioned and leveled, refer to

page 14, and install the slide racks.

Figure 2-8. Counter Top Mounting Holes

When a SteamCraft 5.1 is surface mounted (without legs), NSF standards

require a sanitary counter top seal between the counter surface and the

bottom of the unit. This seal closes any gap between the unit and counter

top. A sanitary seal closing a gap greater than 1/4 inch may not meet NSF

sanitation standards. Therefore, do not surfac e mount the SteamCraft 5.1

to a surface out of level more then 1/4 inch over the length or width of the

unit. Shimming the unit level may leave a gap too large to seal within NSF

standards.

1. Thoroughly dean the bottom perimeter of the steamer and the counter

top area that will support the steamer.

2. Using a level, determine and mark the highest comer of the counter top

area that will support the steamer- At each of the other three comers,

measure and note the shim thickness required to level the SteamCraft

5-1 both front to back and side to side.

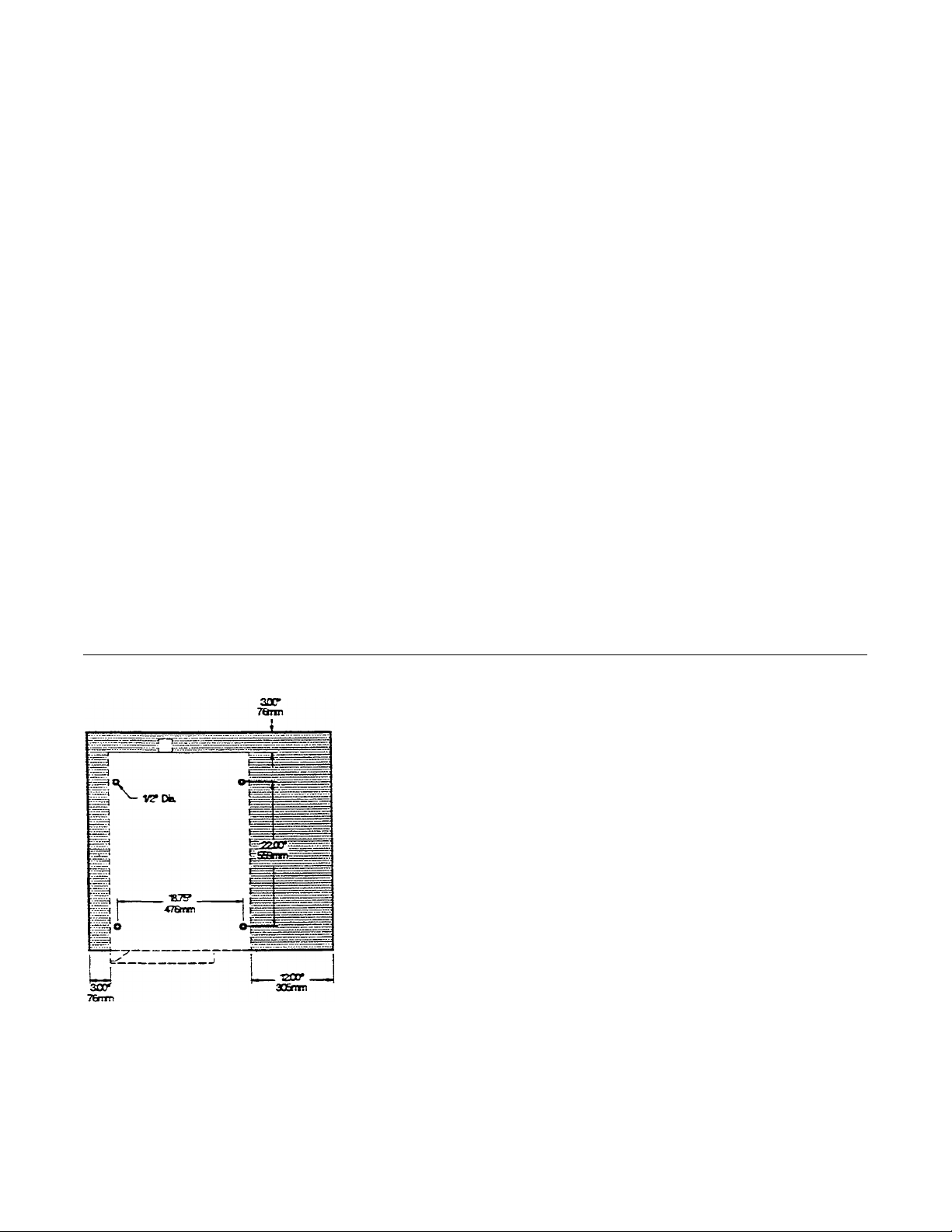

3. Refer to Figure 2-8. Leaving the required clearance (shaded area)

around the unit, determine the exact front, back, and side lines of the

SteamCraft 5.1 on the counter top. From these lines, locate and drill

four 1/2 inch diameter mounting holes in the counter, as shown in the

diagram.

Page 19

Page 12 Model 21 -CET-16 Service Manual

4. Lift the SteamCraft 5.1 into position on the counter and align the

steamer mounting holes with the counter mounting holes. The steamer

mounting holes are the holes with the 3/8" -16 weldnuts usually used to

mount the adjustable legs -

NOTE: If there is not enough clearance behind the steamer to install the

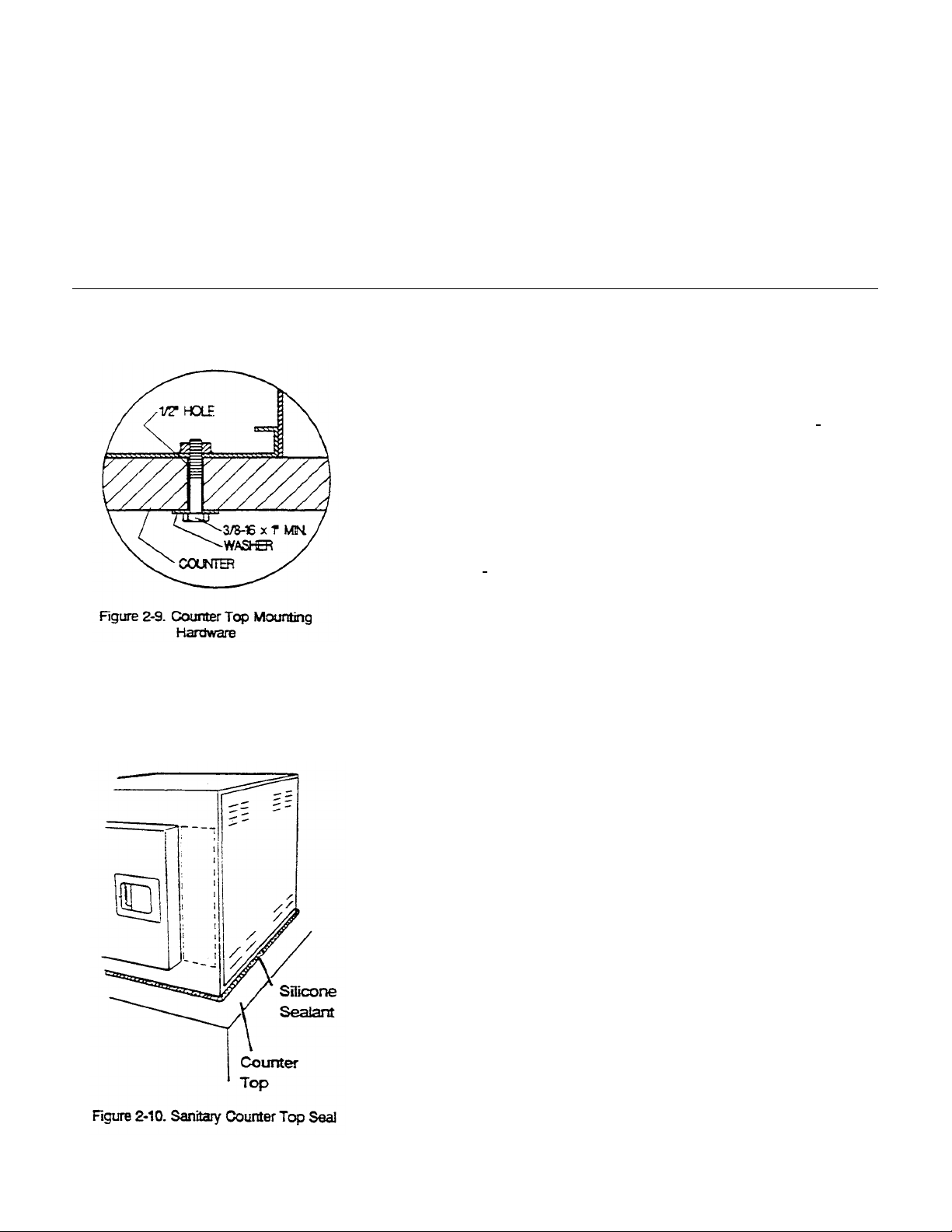

5. Install 3/8"-16 mounting screws and washers as shown in Figure 2-9.

The screws should be long enough to pass through the washer,

counter, shims, and weldnut without projecting more than 1/2 inch

above the weldnut. Thread the screws only a few turns into the

weldnuts, leaving enough play for leveling the unit and sealing the

mounting holes -

6- Do not shim at the highest corner (marked in step 2). Shim the ot her

three comers until the unit is level both front to back and side to side.

7. Inject enough silicone sealant into each mounting hole in the counter to

seal the hole as the hardware is tightened.

8. Tighten the mounting hardware enough to secure the unit in place but

not change the level. After hardware is tightened, verify that the

SteamCraft 5.1 is level front to back and side to side.

9. Seal the gap between the SteamCraft 5.1 and the counter top. Lay a

generous bead of silicone sealant under the entire perimeter of the

steamer bottom. See Figure 2-10.

10. Smooth the silicone seal into the crevice with finger or tool to provide a

cove seal.

11. After the SteamCraft 5.1 has been positioned and leveled, refer to page

14, and install the slide racks.

WARNING

INJURY AND EQUIPMENT DAMAGE could result from

improper lifting. The SteamCraft 5.1 weighs

approximately 135 pounds. Use enough workers with

experience lifting heavy equipment to place the

SteamCraft 5.1 on the counter.

drain, electrical, and water lines; skip the remainder of this

procedure and go to page 14, Install the Free Air Vented Drain

Lines- After installing all necessary drain, electrical, and water

lines, proceed with step 5 of these instructions and mount the

steamer to the counter top.

Stand Mounting and Leveling

The Cleveland Range ES-2130 Equipment Stand provides a stable, level

mounting base for the SteamCraft 5.1. In addition, the stand has a slideaway work surface, and storage for five cafeteria trays. When mounting a

SteamCraft 5.1 on the ES-2130, first install and level the stand, then

surface mount the steamer to the top of the stand. Because the stand is

level and designed to support the SteamCraft 5.1 it is not necessary to

place shims or seals between the stand and steamer.

Page 20

Model 21 -CET-16 Service Manual Page 13

Equipment Stand Installation

1. The equipment stand is shipped assembled except for the slide racks. The

racks and the steamer mounting hardware are shipped in separate packing

within the equipment stand packing. Refer to the Unpacking and Inspection

instructions on page 9, and unpack the equipment stand,

NOTE: If there is not enough clearance behind the stand and steamer to install

2- Thoroughly clean the floor area that will support the equipment stand.

3. Using a level, determine and mark the highest corner of the floor area that will

4- Move the stand into position and level it. Do not adjust the retractable foot of

5. Once the stand is level, secure the rear two feet to the floor.

6. After the stand has been positioned, leveled, and secured in place;

Mount the Steamcraft 5.1 on the Stand

1. Thoroughly clean the bottom perimeter of the steamer and the mounting

the drain, electrical, and water lines; skip the remainder of this

procedure and go to page 14, Install the Free Air Vented Drain Lines.

After installing all necessary dram, electrical, and water lines, proceed

with step 2 of these instructions and install the equipment stand.

support the equipment stand.

the leg in the highest comer (marked in st ep 3). Using a level, adjust the feet

on the other three legs until the unit is level both front to back and side to side.

install the slide racks. The racks are mounted to the stand in the same manner

as the slide racks are mounted inside the steamer. Refer to Install Slide Racks,

below.

surface of the equipment stand.

WARNING

INJURY AND EQUIPMENT DAMAGE could result from

improper lifting. The SteamCraft 5.1 weighs

approximately 135 pounds. Use enough workers with

experience lifting heavy equipment to place the

SteamCraft 5.1 on the stand.

2. Lift the SteamCraft 5.1 onto the equipment stand and align the

steamer mounting holes with the stand mounting holes. The steamer

mounting holes are the holes with the 3/8" -16 weldnuts usually used

to mount the adjustable legs .

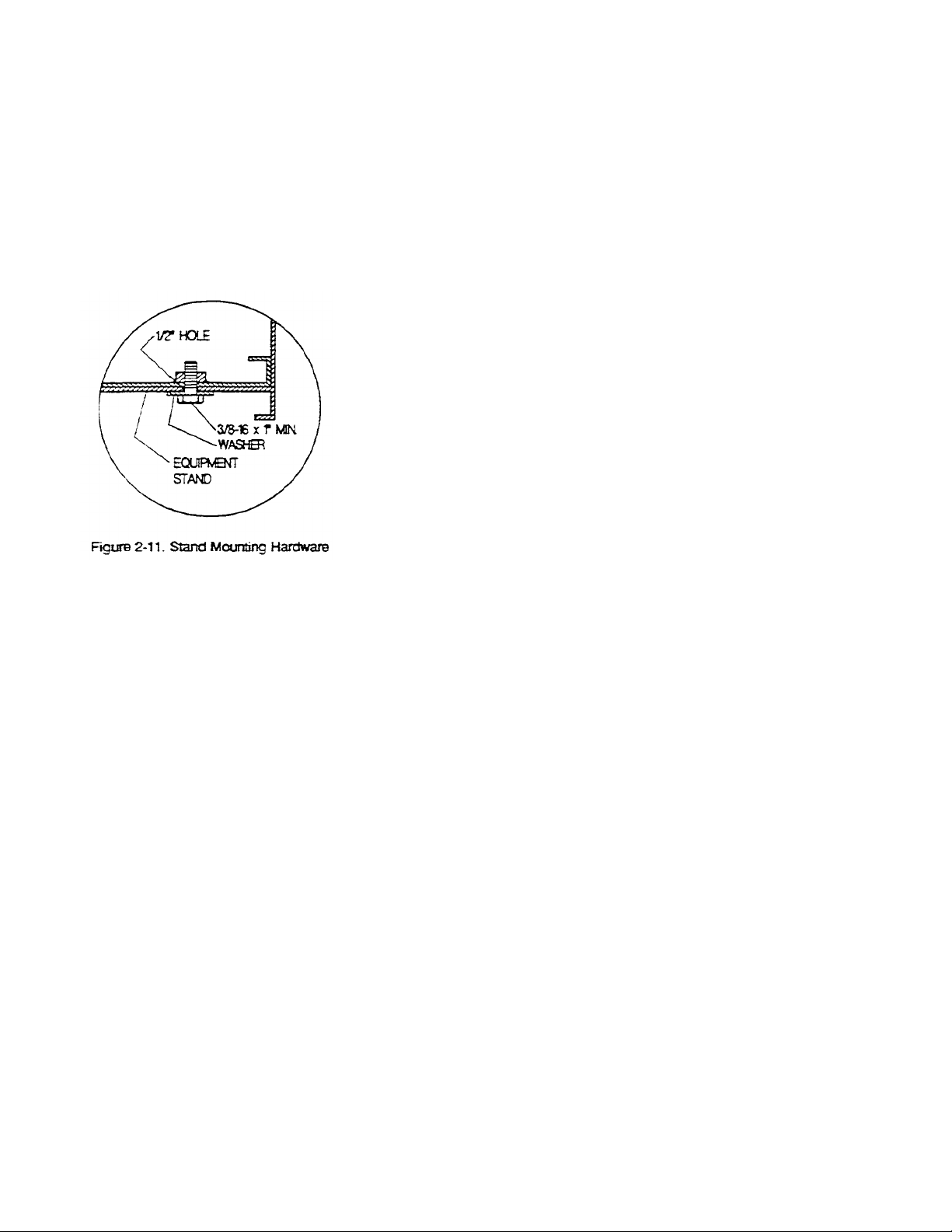

3. Install mounting screws and washers supplied with the stand, as

illustrated in Figure 2-11.

4. Tighten the mounting hardware to secure the steamer to the stand,

and verify that the SteamCraft 5.1 is level front to back and side to

side. If the steamer is not level, re-adjust the STAND level. DO NOT

place shims between the stand and the steamer.

Page 21

Page 14 Model 21-CET-16 Service Manual

Install the Free Air Vented

WARNING

5. After the steamer and stand have been positioned and leveled. install the slide

racks in the steamer as explained below.

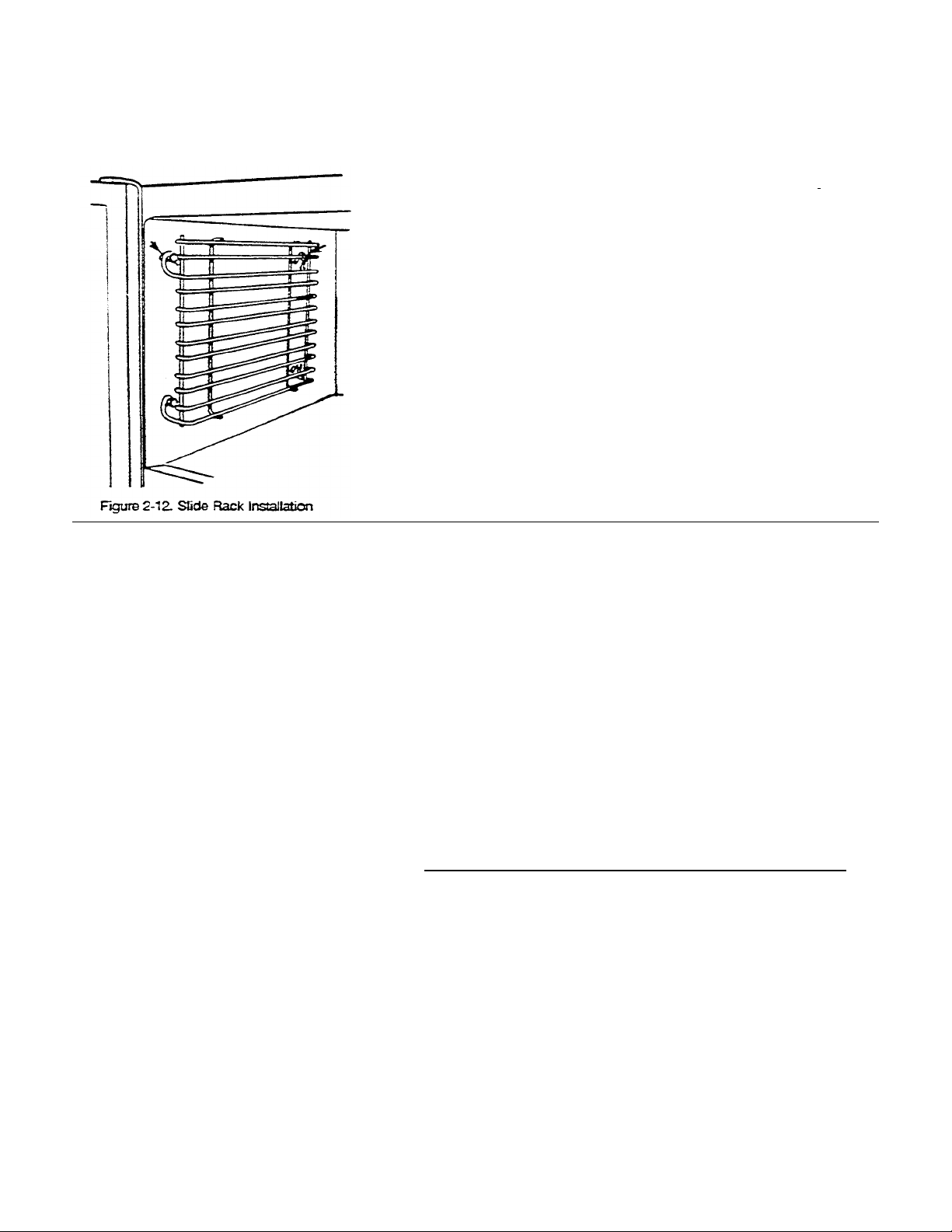

Install Slide Racks

1. Refer to Figure 2-12. Each rack has four loops: two at the top and two

at the bottom- Hold the slide rack so the ends of the hanger loops point

down, as shown in the figure.

2. Slide one rack into the compartment with loops toward one side.

3. Hook the loops over the top and bottom pins.

4. Repeat steps 1 through 3 for the other rack.

Drain Lines

DEATH, INJURY, AND EQUIPMENT DAMAGE could

result from improper installation of the drain outlet lines.

Improper installation of these lines could void the

SteamCraft 5.1 warranty. The following restrictions are

critical to the safety of personnel and equipment, and

must not be violated under any circumstances.

Do not connect the drain fine into PVC pipe, or any other

drain material that cannot sustain 180° F.

Do not connect drains from any other equipment to the

SteamCraft 5.1 drain line.

Do not connect the drain outlet extension line directly to a

floor drain or sewer line.

Furnishing and installing the drain line is the responsibility of the owner

and/or installer. Figure 2-13 illustrates a drain layout recommended by

Cleveland Range. Observe the following instructions to determine the

pipe size, the number of fittings required, and the layout of the drain line.

Page 22

Model 21-CET-16 Service Manual Page 15

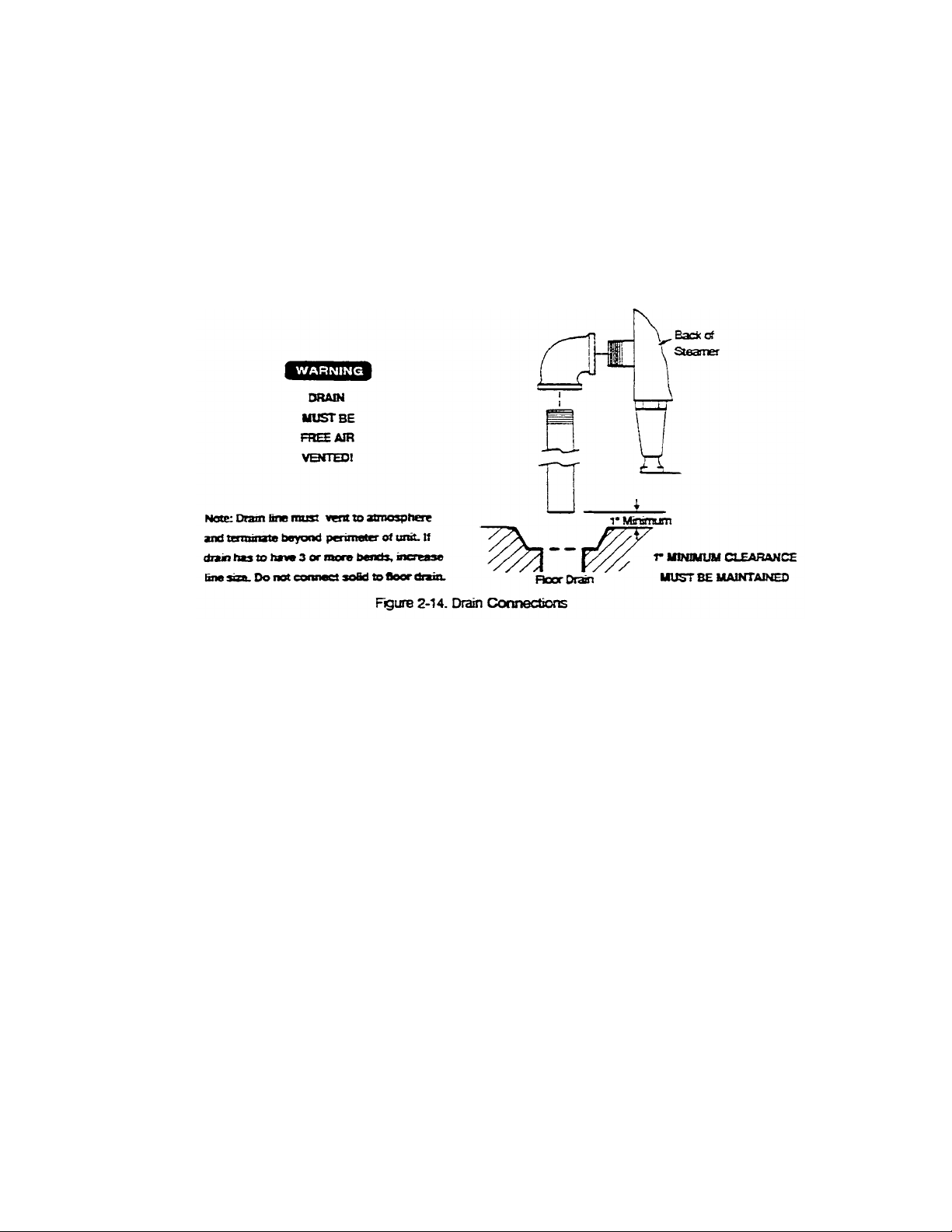

NOTE: The drain line must be free air vented, have gravity flow

from steamer, and terminate outside the perimeter of the

unit

The one inch minimum clearance between the drain opening

and floor drain provides the SteamCraft 5.1 with free air venting.

The drain outlet discharges exhaust steam and hot condensate

from the steamer. The drain outlet must be free air vented to

equalize the pressure in the SteamCraft 5.1 with the

atmosphere. Without a free air vent, either high or low pressure

in the compartment will cause malfunction or damage.

• Pressure build up in the steamer will cause steam and hot

water leakage around the door.

• A vacuum will implode the steamer and cause permanent

damage.

Figure 2-13. Drain Lay out

1. The drain lines must be installed in compliance with the Basic Plumbing Code of the Building Officials and Code Administrators International, Inc. (BOCA), and the Food Service Sanitation Manual of the

Food and Drug Administration (FDA).

2. The tot al length of pipe and number of bend fittings required to reach

the open drain determines the pipe size used to extend the drain line

to an open drain.

• If the drain outlet extension requires six feet or less of pipe, and no

more than two elbows are required, use 1-1/4-inch pipe and fittings.

• If the drain outlet extension requires six to twelve feet of pipe, or

requires three or more elbows, use 2-inch pipe and fittings -

3. The drain line must have a gravity flow from the SteamCraft 5.1 drain

outlet to the floor drain. Do not install a trap in the drain line.

4. Free air venting requires a minimum of one inch clearance between

the end of the drain line and the top of the floor drain.

5. Do not connect the steamer drain to drains or plumbing of any other

equipment. If drains of two or more units are connected together

• Low pressure can develop, causing an implosion and physical

collapse of the steamer-

• Drainage from another unit can flow back into compartment of the

steamer.

Page 23

Page 16 Model 21 -CET-16 Service Manual

Connect Drain Line

Connect the drain to the steamer as described below.

1. The SteamCraft 5.1 is supplied with a 1-1/4-inch pipe connection at the rear of

the unit (Figure 2-14).

2. When assembling the pipes and fittings of the drain outlet extension, apply a

hardening type pipe sealant to the threads, and thread them together FINGER

TIGHT ONLY. DO NOT USE A WRENCH-

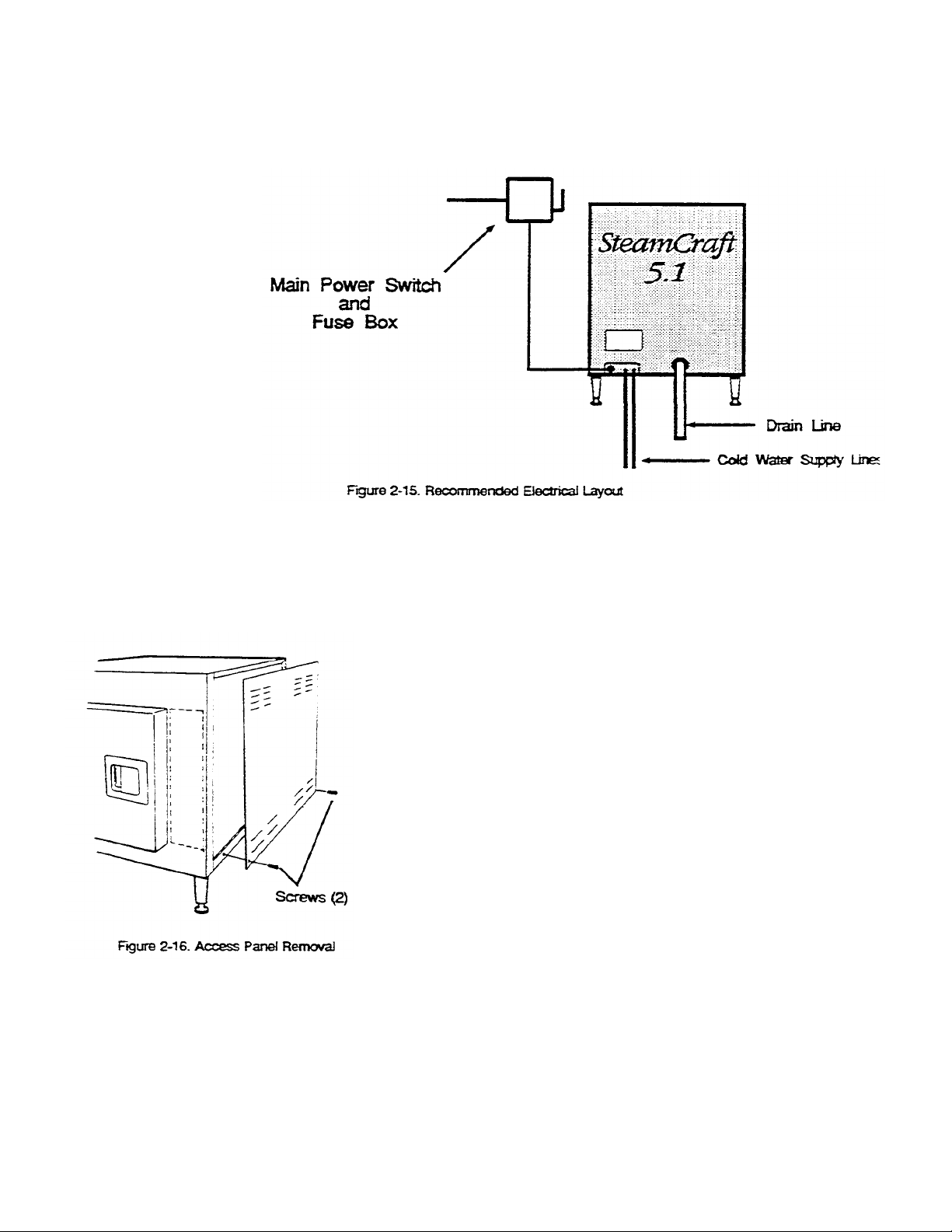

Install Electric Power Lines

Furnishing and installing the electrical power lines, switches, fuse box es,

connectors and accessories is the responsibility of the owner and/or

installer. Figure 2-15 illustrates an electrical layout recommended by

Cleveland Range. When installing the electrical power lines and acces sories, observe the following instructions .

1. In the United States, install the electrical power lines in accordance with

local codes and/or the National Electric Code, ANSI/NFPA No. 70-1990

(USA).

2. In Canada, install the electrical power Lines in accordance with local

codes and/or the Canadian Electrical Code, CSA Standard C22.1

(Canada).

3. Install the proper size disconnect switch, circuit breaker or fuses, and

wire and conduit to conform to all local codes and the national codes

cited above. See Table 2-3 for wire requirements.

4. install a separate disconnect switch and fuses or breakers sized to meet

the line amps required by the SteamCraft 5.1 (see Table 2-3). The

fuses or breakers maybe an integral part of the disconnect switch or in

a separate fuse box. Install the disconnect switch for easy access as

needed for daily startup and shutdown. Throughout the remainder of

this manual the fused disconnect switch is referred to as the main

power switch.

Page 24

Model 21 -CET-16 Service Manual Page 17

5. There should be a sufficient length of flexible conduit between me Steam

Craft 5.1 connector and the wall so the unit can be moved for service.

6. Each steamer must be electrically grounded by the installer.

7. The characteristics of the electric power supply must match the power

requirements specified on the SteamCraft 5.1 product identification plate.

The plate is located on the back of the unit (refer to Figure 2-2).

Table 2-3. Minimum Wire Requirements

Connect Electrical Line

VOLTS KILO-

WATTS

208 165 46.8 16.2 87 4

220 14.4 37.2 19.8 106 6

240 16.5 40.7 19.8 106 4

440 14.4 18.6 79 423 10

480 165 203 79 423 10

380 16.5 25.6 54 289 8

415 16.5 235 65 344 10

AMPS 3

Phase

HEATER

OHMS/COIL

DRYER

OHMS

WIRE

SIZE*

*Use solid copper wire rated for 75°C, wet location-Connect the electrical

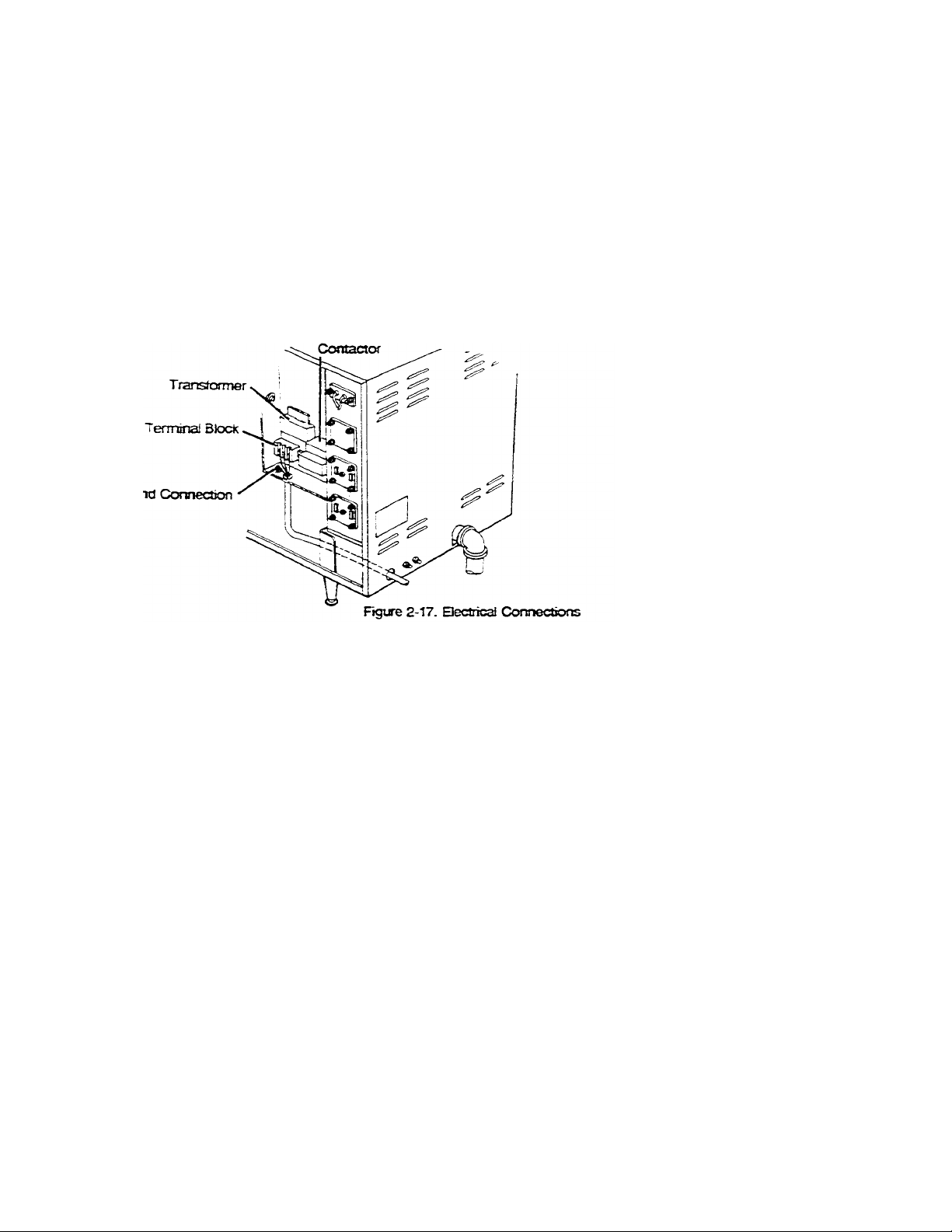

lines to the terminal block inside the right side cover as described below.

1. Remove the side panel by removing two screws (Figure 2-16) that hold it in

place. Save the screws.

Page 25

Page 18 Model 21 -CET-16 Service Manual

2.

Mechanically secure the flexible conduit to the electrical access hole (Figure

2

-

Furnishing and plumbing the water supply lines is the responsibility of the

17).

3. The terminal block and ground connection are near the center of the side

opening

4. Refer to the connection diagrams in Figure 2-17, and connect the wires to the

terminal block and ground connector accordingly.

5- The steamer must be electrically grounded by the installer.

6- If no further work inside the side panel is required at this time, such as plumbing

and leak checks, secure the side panel with the two mounting screws (Figure

2-16).

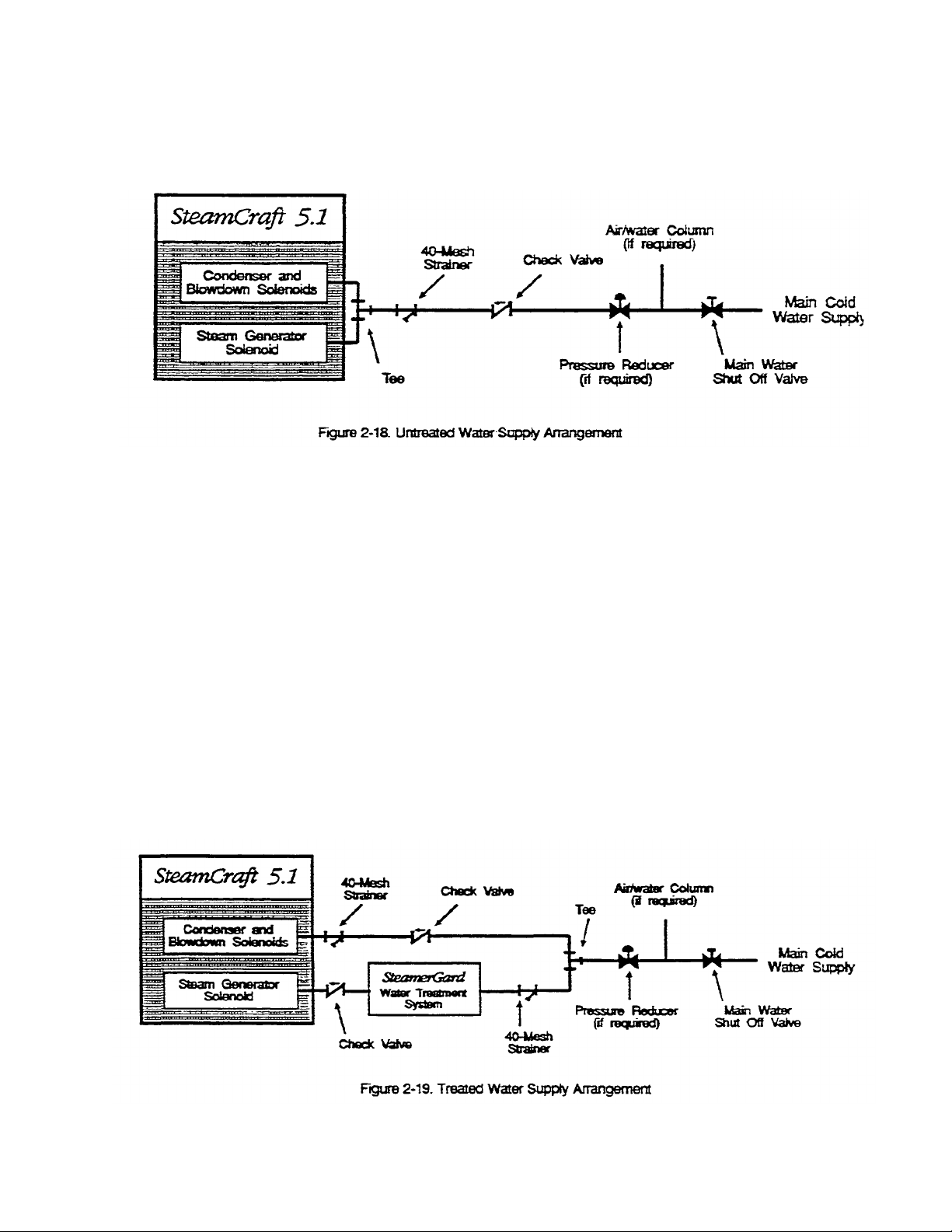

Install Water Supply Lines

owner and/or installer. This section illustrates plumbing layouts

recommended by Cleve land Range. When installing water supply lines,

observe the following instructions.

1. Always connect a cold water supply to the SteamCrart5.1 water supply

lines.DO NOT USE HOT WATER. The steamer will not function properly

or within design safety limits if hot or warm water is supplied to either the

condenser connection or the steam generator fill connection.

2. Supply water must have a minimum dynamic pressure of 35 psi (2.4

kg/cm2) and a maximum static pressure of 60 psi (4.1 kg/cm2). If static

pressure exceeds 60 psi, a pressure regulator must be installed in the

supply lines. For best results, set the regulator for 50 psi dynamic

pressure. Water pressure greater than 60 psi will cause damage to the

solenoid valves. Local water pressure can be 100 psi or more. If

possible, check supply pressure at non-peak demand time. A local water

company can assist in this check.

3. Refer to the recommended plumbing layouts in Figures 2-18 and 2-19,

and install the water supply lines and fittings in accordance with all local

and national codes. Pay particular attention to the following

requirements and recommendations.

Page 26

Model 21 -CET-16 Service Manual Page -19

a. When installing a water supply system without a Steamer Gard.

Cleveland Range recommends the plumbing layout illustrated in

Figure 2-18. This is a single water line from the main cold water

supply to the tee just outside the SteamCraft 5.1- The two separate

lines from the tee to the steam generator and condenser/blowdown

connections are comparitively short.

b.When installing a water supply system with a SteamerGard,

Cleveland Range recommends the plumbing layout illustrated in

Figure 2-19. Note the following details:

• This is a single water line from the main cold water supply to the

tee just before the SteamerGard. The two separate lines from the

tee to the SteamerGard intake connection and the Steam Craft

5.1 condenser/blowdown connection are comparatively short.

• The water supply to the condenser connection can be untreated.

• The treated water supply connects to the steam generator fill

connection.

Page 27

Page 20 Model 21-CET-16 Service Manual

The water supply connections are located at the rear of the SteamCraft

5.1,

c. Install 1/4-inch IPS water supply lines to match the 1/4-inch com-

pression fittings mounted on the rear of the SteamCraft 5.1. If larger

lines are used, a pressure regulator must be installed in the supply

line to maintain the pressure specified in step 2.

d.Install a manual water valve between the main cold water supply line

and the SteamCraft 5.1 lines.

e. The National Sanitation Foundation (NSF) requires installation of a

check-valve in all supply lines in accordance with and as required by

local plumbing codes.

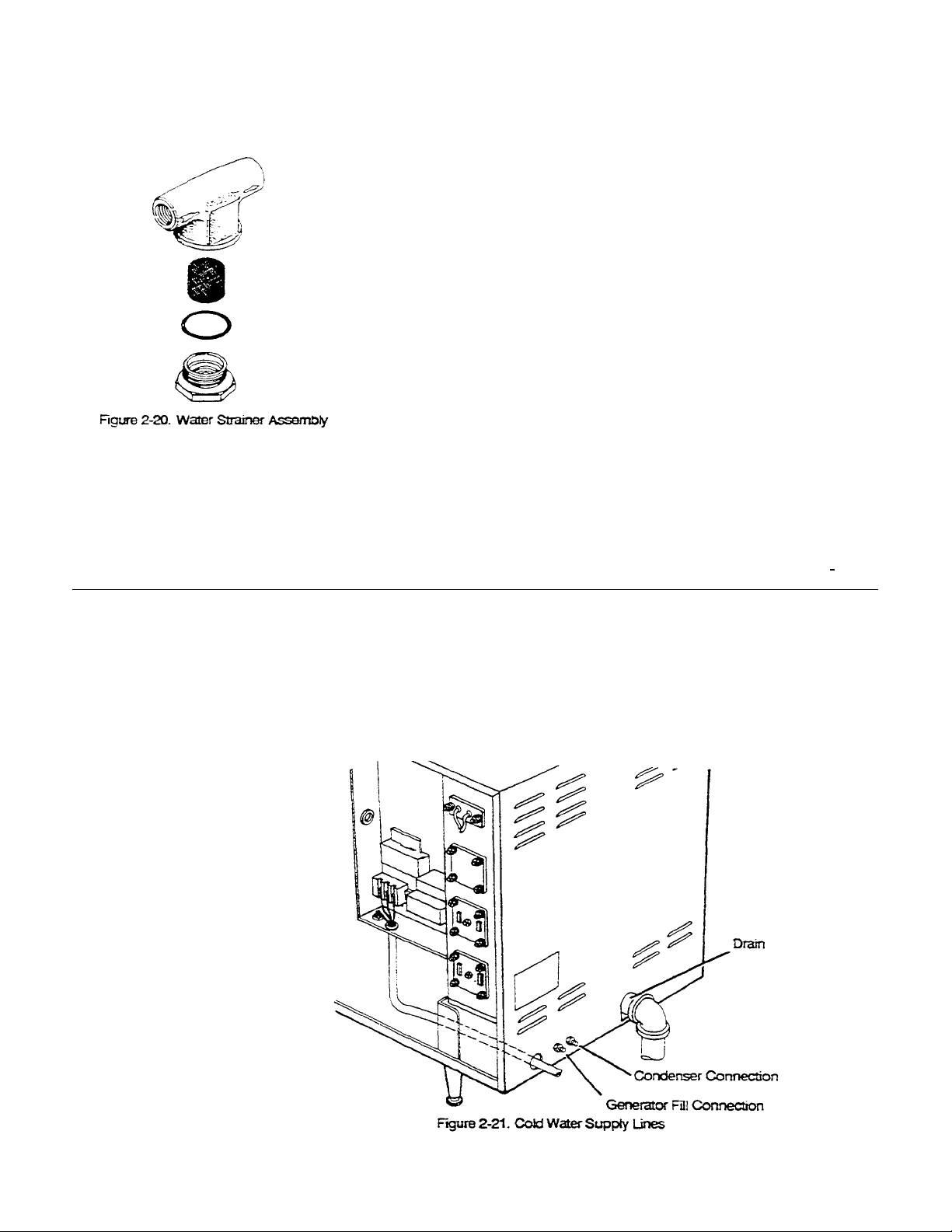

f. At the points indicated in the recommended plumbing layouts, install a

40-mesh water strainer of the type and construction illustrated in

Figure 2-20, Cleveland Range part number 102383.

4. Construct all supply lines up to the point of installing the strainer(s)

illustrated in the recommended plumbing layouts. Rush the water

supply lines before connecting the strainer(s).

• If the remaining water supply lines and/or SteamerGard are not

immediately installed and connected after flushing, temporarily cap

the water supply lines

• If the final installation and connections are performed immediately,

Connect Water Supply Lines

refer to the connection instructions in the SteamerGard manual, and

Connect Water Supply Lines, on page 20.

as shown in Figure 2-21- Connect the water supply lines to the SteamCraft

5.1 by following both the general connection requirements and those

requirements specific to the type of supply system, either untreated water

supply (Figure 2-18) or water supply treatment system (Figure 2-19).

Page 28

Figure

2-22- Water Strainer installation

General Connection Requirements

Testing Water Supply Lines

Untreated

Water Connection (Without SteamerGard)

Model 21 -CET-16 Service Manual Page 21

1. Apply pipe dope or teflon tape to any threaded connection.

2. Flush the water supply lines before connecting the strainer(s), and again before

connecting the lines to the SteamCraft 5-1 connections.

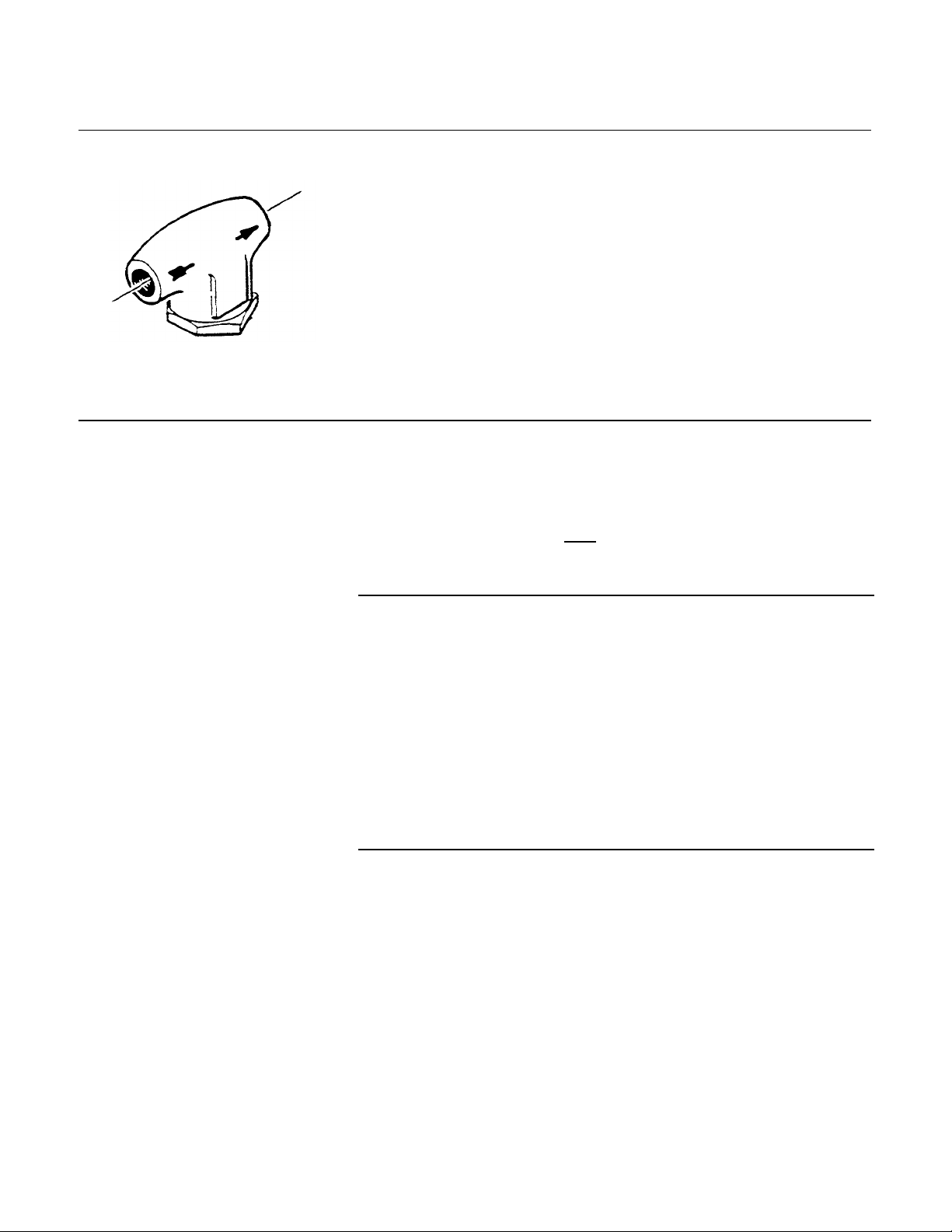

3. When installing water strainer(s), use a strainer with a 40 mesh screen as

illustrated in Figure 2-22.

• Make sure the arrow on the strainer body points in the direction of flow into

the steamer.

• Install the strainer so the access nut points down-

4. If incoming line pressure exceeds 60 psi static pressure, install a pressure

regulator to maintain the SteamCraft 5.1 pressure requirements specified in

Install Water Supply Lines (page 18).

1. Refer to Figure 2-18. Verify that a suitable check valve is installed according to

NSF and local codes.

2. Look. at the flow indicating arrows on the strainer and check valve and verify

that flow is toward the steamer.

3. Install the tee and connecting Iines Hush these ones before connecting them to

the water supply fittings on the steamer.

Treated Water Connection (With SteamerGard)

1. Verify that the SteamerGard water treatment system has been installed

according to the SteamerGard installation manual The 40-mesh strainer

supplied with the SteamerGard must be installed at the SteamerGard water

inlet.

2. Refer to Figure 2-19. Verify that suitable check valves are installed according to

NSF and local codes. The condenser line check valve should be installed

between the tee and the steamer. The steam generator line check valve should

be installed between the SteamerGard and the steamer.

3. Look at the flow indicating arrows on the strainers and check valves. Verify that

flow is toward the steamer.

4. Install the connecting lines and flush them before connecting them to the water

supply fittings on the steamer. Be sure the line from the SteamerGard water

treatment system connects to the steam generator fitting on the SteamCraft

5.1.

1. Check all connections for proper tightness. Remove the side panel to inspect

water connections inside the steamer (Figure 2-16).

2. Open the water supply valves.

Page 29

Page 22 Model 21 -CET-16 Service Manual

3- Check all lines and connections for leakage, both inside and outside the

steamer.

4. If Final Setup and Checkout win be performed next, leave the right side panel

off; otherwise, replace the side panel and se cure it to the unit with the two

screws (Figure 2-16).

NOTE: If the steamer has not been mounted yet:

Final Setup and Checkout

The Final Setup and Checkout procedures prepare a recently installed or repaired

SteamCraft 5.1 for operation- The procedures check proper electrical, water, and

drain connections to the SteamCraft 5.1, and verify basic steamer operation.

Model 21-CET-16 SteamCraft 5.1's have an electronic control panel with a key

pad timer control. This control panel is illustrated in Figure 2-23 on page 23. An

electro-mechanical control panel is also available. This panel has a dial timer

control, as illustrated in Figure 2-24 on page 26. There are a few operating

differences between steamers with the dial timer controls and steamers with the

key pad controls. To avoid confusion during testing, there are two sets of testing

instructions: one labeled Operating Tests - Key Pad Control Panel for the

electronic control panel, and one labeled Operating Tests-Dial Timer Control Panel

for the electro-mechanical control panel. After performing the setup procedure,

perform the test procedure appropriate to the control panel on the SteamCraft 5.1

being tested.

For surface mounting, return to page 12, step 5, and finish the mounting

procedure.

For equipment stand installation and steamer mounting, return to page

13, step 2, install the stand and mount the steamer.

Setup and Slowdown Inspection - All SteamCraft 5.1 's

This procedure is appropriate for SteamCraft 5.1's with either key pad control

panels or dial ti mer control panels. Read through all steps of this procedure before

starting. Complete this setup procedure before starting the operating tests.

1. Check that the water supply line valves are open.

2. If using a SteamerGrard water treatment system, refer to the Steamer -Gard

manual and start the system. Check that all valves between the SteamerGard

and the SteamCraft 5.1 are open.

3. Open the steamer door. Check for proper installation of the drain screen, slide

racks, and door gasket assembly. Be sure the drain is not blocked. Shut the

steamer door.

4. Refer to electrical layout, Figure 2-15, and Table 2-3. Be sure the main power

switch is in the off position. Verify installation of proper size fuses or

breakers.

Page 30

Model 21 -CET-16 Service Manual Page 23

5. Set the control panel as follows:

a. Press the OFF (bottom) end of the ON/OFF switch.

b. Press the TIMED (top) end of the TIMED/MANUAL switch.

c. The timer setting is not important while the ON/OFF switch is in the OFF

position.

• The key pad timer display is blank without power.

• Even if the dial timer is not zeroed (pointing to the 0 mark), the timing

circuits are not powered.

6. Remove the right side access cover (see Figure 2-16).

WARNING

Death, severe electrical shock or equipment damage

can result from touching any component inside unit

when main power switch is in the on position. Use

extreme caution during testing with the access cover

removed.

7. Turn on electric power to the SteamCraft 5.1 at the main power switch. The

steamer will immediately start a blowdown cycle. During blowdown, the

condenser and drain valves are fully open while the steam generator and float

assembly are flushed with fresh water. The blowdown cycle lasts 3 minutes

During the automa tic blowdown cycle, make the following checks.

• Look at the top of the float control. There should be a steady flow of water

entering the top of the float chamber through the spray nozzle.

• Look at the one inch vent gap between the steamer drain pipe and the floor

drain- A steady stream of water should be draining from the steamer.

* After about 3 minutes, the cycle is complete- Check the two points listed

above; there should be no water flow at any of the points.

NOTE: If it is necessary to stop the blowdown cycle before it is finished, do so by

pressing the ON end of the ON/OFF switch.This energizes the

operating control circuits, the red ON/OFF indicator lights, blowdown

stops, and the steam generator fills with water. When the ON/OFF

switch is tamed OFF. the blowdown cycle will start again.

8. If operating tests will be performed next, leave the right side panel off and

perform step a below; otherwise perform step b.

a- Begin the operating tests appropriate to the control panel on the

SteamCraft 5.1 being tested. The key pad control panel tests start after

this procedure. The dial timer control panel tests start on page 26.

Page 31

Page 24 Model 21-CET-16 Service Manual

b. Turn off electric power to the SteamCraft 5.1 at the main power switch.

Operating Tests - Key Pad Control Panel

This procedure is followed for SteamCraft 5.1's with key pad control

panels (Figure 2-23). The test consists of observing and timing various

steamer functions in the MANUAL operating mode, and in the TIMED

operating mode. To become familiar with the functions observed and

timed, read through all steps of the procedure before starting the steamer.

The times listed in the procedure are approximate and may vary with the

temperature of the equipment, the temperature and pressure of the supply

water, heater supply voltage, and pipe lengths. A stopwatch. wrist watch

with a second hand, or one with a digital readout in seconds is required

for timing the functions.

1. Remove the right side access cover.

2. Perform the Setup and Blowdown Inspection procedure. Leave the

control settings as they are at the end of the procedure.

• The main power switch is ON.

• The ON/OFF switch is OFF (indicator not lighted).

• The TIMED/MANUAL switch is in the TIMED (top) position.

• The timer display is blank while the ON/OFF switch is set to OFF.

3. If the timer is not zeroed (00:00) when power is turned on in step 4,

press and hold the CLEAR key on the key pad control panel to zero

the timer.

4. When the ON/OFF switch is turned ON, the steam generator compartment fills with water. Start timing upon pressing the top of the

ON/OFF switch to ON. Check and time the following functions.

• Immediately: The red ON/OFF switch light turns on. The fill valve

• After 3 Minutes : Water appears in the bottom of the float cylinder as

• After 4 Minutes: The fill valve closes (click sound). Water level in the

Install the right side access cover and secure it to the unit with the two

screws (Figure 2-16).

opens and water begins to fill the steam generator.

the water level in the steam generator rises. Check that no water

flows from the drain opening. Check for plumbing leaks.

float cylinder stops rising, about one inch from the top of the cylinder.

If the water level continues to rise above the top of the float cylinder,

have a qualified service representative check the float circuit.

Page 32

Model 21 -CET-16 Service Manual Page 25

5. When the TIMED/MANUAL switch is set to MANUAL, the steam

generating cycle starts. Start timing upon pressing the MANUAL end

of the TIMED/MANUAL switch- Check and time the following

functions-

• Immediately: Th e condenser solenoid clicks open and condenser

flow starts- With the float cylinder water level above one inch, the

heater coil turns on.

• After 2-5 seconds: A small stream of water flows from the drain pipe.

If no drain water flows, check that the water supply valves are

open.

• After 2 minutes: A dull roaring sound indicates the heater is working

and the unit is beginning to generate steam

• After 3-4 minutes: Steam begins to enter the compartment from the

nozzles. A small quantity of water may drip from the nozzles until

steam clears the lines -

• After 4-5 minutes: Steam from nozzles begins to fill compartment:

6. When the TIMED/MANUAL switch is set to TIMED (timer zeroed). the

steam generating cycle stops. Press the TIMED end of the

TIMED/MANUAL switch.

• Immediately: The heaters turn off, and the condenser flow stops.

• After about 30 seconds: Steam stops entering the cooking

compartment.

7. Open the cooking compartment door to vent the steam and allow the

compartment to cool slightly. After 2 or 3 minutes, close the door and

continue testing.

8. With the TIMED/MANUAL switch set to TIMED, use the timer key pad

to set the timer for 10 minutes. press the number keys 1 0 0 0 in

sequence. The display reads 10:00 (ten minutes and zero seconds).

9. When the START/STOP key is pressed, the steam generating cycle

starts. This is the same sequence observed in steps 5 and 6, except:

• The electronic timer controls the cycle.

• The elapsed times are shorter because the water in the steam

generator and the cooking compartment were preheated during

step 5.

• The electronic timer automatically starts the step 6 functions after

counting down to zero.

10. Press the START/STOP key and observe the following steam

generating functions.

a. The timer display changes to PAUS unt il the cooking compartment

reaches cooking temperature. When it does, the timer begins

counting down to zero.

b. The condenser solenoid clicks open and condenser flow starts. A

small stream of water flows from the drain pipe.

Page 33

Page 26 Model 21 -CET-16 Service Manual

d. As the unit generates steam, the water level fluctuates and a clicking sound

f. When the timer counts down to zero (00:00), the heaters turn off, the

g. After about 30 seconds, steam stops entering the cooking compartment

11. Turn the SteamCraft 5.1 off by pressing the OFF (bottom) end of the ON/OFF

switch. The red indicator on the switch turns off immedi ately, and the

automatic blowdown cycle starts. DO NOT turn off the power at the main

power switch until blowdown is complete. The cycle takes about 3 minutes.

12. When blowdown is complete, turn the steamer off at the main power

c. If the float cylinder water level drops below the initial fill level, the water

fill valve opens and fills the generator. When the float cylinder water level

is above one inch, the heater coil turns on. A dull roaring sound indicates

the heater is working and the unit is beginning to generate steam -

is heard as the solenoid opens and closes the fill valve. The level in the float

cylinder rises and falls about 1/4 inch as the fill valve operates.

e. Check for steam leaks around the door.

condenser flow stops, and the buzzer sounds continuously. Press the

START/STOP key to silence the buzzer.

switch. 13. Install the side panel and secure it in place with two screws (see

Figure 2-16). After completing the Initial Setup and Blowdown Inspection

procedure, and the Operating Test procedure; the SteamCraft 5.1 is ready for

service. Refer to Chapter 3 for complete operating instruc-tions.

Operating Tests - Dial Tuner Control Panel

This procedure is followed for SteamCraft 5.1's with dial timer control panels

(Figure 2-24). The test consists of observing and timing various steamer functions

in the MANUAL operating mode, and in the TIMED operating mode. To become

familiar with the functions observed and timed, read through all steps of the

procedure before starting the steamer.

The times listed in the procedure are approximate and may vary with the

temperature of the equipment, the temperature and pressure of the supply water,

heater supply voltage, and pipe lengths. A stopwatch, wristwatch with a second

hand, or one with a digital readout in seconds is required for timing the functions.

1. Remove the right side access cover.

2. Perform the Setup and Blowdown Inspection procedure. Leave the control

settings as the are at the end of the procedure.

• The main power switch is ON.

• The ON/OFF switch is OFF (indicator not lighted).

Page 34

Model 21 -CET-16 Service Manual Page 27

• The TIMED/MANUAL switch is in the TIMED (top) position.

• The Timer is zeroed, dial pointing to the 0 mark.

3- If the Timer is not zeroed, turn the dial counter clockwise until it points to the 0

mark.

4- When the ON/OFF switch is turned ON, the steam generator compartment fills

with water. Start timing upon pressing the top of the ON/OFF switch to ON.

deck and time the following functions.

• Immediately: The red ON/OFF switch light turns on. The fill valve opens and

water begins to fin the steam generator. The buzzer sounds for 3 seconds.

• After 3 Minutes: Water appears in the bottom of the float cylinder as the

water level in the steam generator rises. Check that no water flows from the

drain opening. Check for plumbing leaks.

• After 4 Minutes: The fill valve closes (click sound). Water level in the float

cylinder stops rising, about one inch from the top of the cylinder. If the

water level continues to rise above the top of the float cylinder, have a

qualified service representative check the float circuit.

5. When the TIMED/MANUAL switch is set to MANUAL, the steam generating

cycle starts. Start timing upon pressing the MANUAL end of the

TIMED/MANUAL switch- Check and time the following functions.

• Immediately: The condenser solenoid clicks open and condenser flow starts.

With the float cylinder water level above one inch, the heater coil turns on.

• After 2-5 seconds : A small stream of water flows from the drain pipe. If no

drain water flows, check that the water supply valves are open.

• After 2 minutes: A dull roaring sound indicates the heater is working and the

unit is beginning to generate steam.

• After 3-4 minutes: Steam begins to enter the compartment from the nozzles.

A small quantity of water may drip from the nozzles until steam clears the

lines.

• After 4-5 minutes: Steam from nozzles begins to fill compartment.

6. When tile TIMED/MANUAL switch is set to TIMED (timer at 0), the steam

generating cycle stops. Press the TIMED.) end of the TIMED/MANUA L

switch.

• Immediately: The heaters turn off, the condenser flow stops, and the buzzer

sounds for 3 seconds.

• After about 30 seconds: Steam stops entering the cooking compartment.

7. Open the cooking compartment door to vent the steam and allow the

compartment to cool slightly. After 2 or 3 minutes, close the door and continue

testing.

Page 35

Page 28 Model 21 -CET-16 Service Manual

8. With the TIMED/MANUAL switch set to TIMED, turn the dial of the timer

to 10 minutes.

9. As soon as the dial is released, the steam generating cycle starts. This is

the same sequence observed in steps 5 and 6, except:

• The dial timer controls the cycle.

• The elapsed times are shorter because the water in the steam

generator and the cooking compartment were preheated during step

5.

• The dial timer automatically starts the step 6 functions after counting

down to zero.

10. After setting and releasing the timer dial, observe the following steam

generating functions.

a. The dial timer immediately begins counting down to zero.

b.The condenser solenoid clicks open and condenser flow starts. A

small stream of water flows from the drain pipe.

c. If the float cylinderwater level drops below the initial fill level, the

water fill valve opens and fills the generator. When the float cylinder

water level is above one inch, the heater coil turns on. A dun roaring

sound indicates the heater is working and the unit is

beginning to generate steam

d. As the unit generates steam, the water level fluctuates and a clicking

sound is heard as the solenoid opens and closes the fill valve. The

level in the float cylinder rises and falls about 1/4 inch as the fill valve

operates.

e. Check for steam leaks around the door.

f. When the timer counts down to zero, the heaters turn off, the

condenser flow stops, and the buzzer sounds for 3 seconds.

g. After about 30 seconds steam stops entering the cooking compart

ment.

11. Turn the SteamCraft 5.1 off by pressing the OFF (bottom) end of the

ON/OFF switch. The red indicator on the switch turns off immediately,

and the automatic blowdown cycle starts. DO NOT turn off the power at

the main power switch until blowdown is complete. The cycle takes

about 3 minutes.

12. When blowdown is complete, turn the steamer off at the main power

switch.

13. Install the side panel and secure it in place with two screws (see Figure

2-16). After completing the Initial Setup and Blowdown Inspection

procedure, and the Operating Test procedure; the SteamCraft 5.1 is

ready for service. Refer to Chapter 3 for complete operating instruc tions.

Page 36

Model 21 -CET-16 Service Manual Page 29

CHAPTER

3.

OPERATION

INTRODUCTION

The SteamCraft

5.1

is as safe and easy to operate as a touch tone phone

OPERATIONAL SAFETY

The safe and effective operation of an

y steamer depends upon proper installation,

or a kitchen timer. To use the steamer safely and effectively, each

operator must read and understand this chapter completely before start ing operation. The owners and operators of the SteamCraft 5.1 should

retain these instructions in an easily accessible location for future reference and training.

The owner(s) and operators) of the Steam Craft 5.1 must be aware that

steam can cause serious injuries and equipment damage. Pay particular

attention to the Operational Safety section of this chapter, and the

WARNINGS and CAUTIONS displayed in this manual and on the

equipment.

WARNING

DEATH, INJURY, AND EQUIPMENT DAMAGE could

result from the improper installation of a SteamCraft

5.1.

Before starting a recently installed or repaired steamer,

be sure it is installed according to the instructions in

Chapter 2.

use, maintenance, and repair. Operational safety must encompass all of these

factors. This Operational Safety section outlines the minimum safety policies that

should be considered when using one or more SteamCraft 5.1 's. It is assumed

that any operational safety program must be tailored to the specific site and use of

the equipment. Such a program will pay handsome dividends in equipment life,

performance. and reduced down-time.

Bum hazards are present in any professional food service operation. This is

especially so when steam is used in the cooking process. When using the

SteamCraft 5.1 steamer, observe the following precautions.

• Remember at all times that steam can cause severe burns.

• Do not open the steamer door before steam flow stops.

• Stand back when opening the compartment door. Open the door slightly to allow

steam to vent before looking or reaching into cooking compartment.

• Do not reach into the cooking compartment until the steam has cleared.

• Do not reach into steamer or handle hot items without wearing heat -proof gloves.

Wet or damp gloves conduct heat, and may cause bums when touching hot

items.

Page 37

Page 30 Model 21 -CET-16 Service Manual

OPERATIONAL SAFETY (continued)

The SteamCraft 5.1 requires a minimum of service if properly operated and

maintained by trained personnel. The following steps will help keep the

steamer in a safe, efficient operating condition.

1- Train all personnel who will use the steamer. Make sure personnel

know how to operate the steamer, clean the interior and exterior, drain

the unit, and descale the steam generator.

2. Operating personnel must be able to recognize problems and know how

to take corrective action as outlined in the Chapter 4 troubleshooting

chart

3. Conduct reguIar steamer inspections. Check for water line leaks, door

seal and drain leaks, clogged drain, steam generator scale buildup, and

steamer control malfunctions.

4. Follow the instructions for steamer maintenance in Chapter 4.

5. Before each use of the SteamCraft 5.1, inspect the drain and screen for

blockage. Inspect the door gasket assembly, and slide racks for proper

installation and cleanliness.

6. Allow only Cleveland Range authorized service representatives to

service the SteamCraft 5.1.

7. Use only factory authorized repair parts. This will maintain Underwriters

Laboratories (UL) and/or Canadian Standards Association (CSA)

certification, and all approvals to protect warranty coverage.

8. Maintain written recordsof steamer maintenance and service. These

records will be helpful if warranty coverage is ever in question. Each

record should include at least:

• The date of the service or maintenance.

• A description of the service, maintenance or repair performed.

Include part numbers if applicable.

• Copies of purchase order(s) and invoice(s) for repair parts and

service.

• The name and signature of the person performing the maintenance

or service.

CONTROL PANELS

The standard SteamCraft 5.1 control panel, illustrated in Figure 3-1 has an

electronic key pad timer with a temperature compensation circuit. The

circuit allows the timer to count down only while the cooking compartment

is at cooking temperature. An optional electro-mechanical control panel,

illustrated in Figure 3-6 on page 44, is also available. This panel has a dial

timer without a temperature compensation feature. The timer starts

counting down when set. Operating details and cooking procedures differ

between units with standard and optional panels. For clarity, two sets of

operating instructions are provided. The standard key pad control

instructions start on page 31. Instructions for the optional dial timer control

panel start on page 44.

Page 38

KEY PAD CONTROL PANEL SUMMARY

1. TIMER Display

This four-digit display indicates the minutes and seconds remaining in the

count down. The display reads from zero (00:00) to 99 minutes and 99

seconds (99:99). It reads pause (PAUS) when the count down is halted either

by the START/STOP key or by the temperature compensating circuit.

2. Number Pad Keys

These keys set the number of minutes and seconds in the timer count down.

Pressing the number keys 12 3 4 in this sequence, sets the timer for 12

minutes and 34 seconds (12:34).

3. START/STOP Key

This key starts and stops the timer. In TIMED mode the steaming functions are

linked to the timer. In MANUAL mode, the steaming functions are independent

of the timer.

4. CLEAR Key

This key resets the timer to zero (00:00), after it has been stopped. The timer

must be zeroed by pressing this key before a new time can beset.

5. TIMED/MANUAL Switch

The TIMED/MANUAL switch selects the manual or timed operating mode.

• Pressing the MANUAL (bottom) end of the switch selects the manual mode.

• Pressing the TIMED (top) end of the switch selects the timed mode.

6. ON/OFF switch

The ON/OFF switch controls electric power to the control panel.

• Pressing the ON (top) end of the switch energizes the steamer control panel.

• Pressing the OFF (bottom) end of the ON/OFF switch turns the steamer

Model 21 -CET-16 Service Manual Page 31

CAUTION

Press switches with finger tips only. Do not use kitchen

utensils or anything sharp to operate the switches.

A red indicator on the switch lights, and water fills the steam generator.

control panel OFF. The red indicator goes out, and the 3-minute blowdown

cycle starts.

Page 39

Page 32 Model 21 -CET-16 Service Manual

COOKING OPERATIONS - KEY PAD CONTROL PANEL

SteamCraft 5.1 cooking operations are simple and direct. Figure 3-3, to the right,

shows the operations that can be performed during a four-hour shift. Each

operation in the diagram is covered in a procedure in this chapter. The diagram, in

conjunction .with the control panel summary on page 31, contains enough

information for rudimentary (quick start) operation of the SteamCraft 5.1. However,

to maintain full warranty coverage, and for safe, efficient operation of the

SteamCraft 5.1. the operator must, at a minimum, comply with all cautions,

warnings and instructions in the detailed operating procedures. The operator must

be familiar with all the operating features explained in this chapter before

attempting to operate the SteamCraft 5.1 steamer.

Manual and Timed Modes

Main Power Switch

The SteamCraft 5-1 has two operating modes: manual and timed. The

TIMED/MANUAL rocker switch selects the operating mode. Pressing the MANUAL

end of the switch selects the manual operating mode. Pressing the TIMED end of

the switch selects the timed (automatic) operating mode.

• Manual Mode provides continuous steaming. The operator starts and stops

steaming operations manually.

• Timed Mode provides automatic control of steaming operations. The timer control

starts and stops steaming operation, and monitors cooking time and

compartment temperature for accurate, efficient uniform steam cooking.

Cooking procedures are slightly different for each mode. The diagram in Figure 3-3

illustrates which procedures are common to both modes and which are specific to

each mode.

Usually the SteamCraft 5.1 main power switch is left ON. If the main power switch

was left in the OFF position, turn it ON as follows.

1. Check that the water supply valves are open.

2. Press the OFF (bottom) end of the ON/OFF switch.

3. The TIMED/MANUAL switch and timer settings are not important in this

procedure. The control panel circuits are not powered while the ON/OFF switch

is set to OFF.

4. Refer to the main power switch in Figure 3-2, and turn on electric power to the

SteamCraft 5.1. The steamer will immediately start a blowdown cycle. The

blowdown cycle lasts 3 minutes.

NOTE: If it is necessary to stop the blowdown cycle before it is finished, turn

the ON/OFF switch to ON. (Refer to Power ON and Preheat.)

Page 40

Model 21 -CET-16 Service Manual Page 33

Figure 3-3. SteamCraft 5.1 Cooking Operations

Keypad Control Panel

Page 41

Page 34 Model 21 -CET-16 Service Manual

When the SteamCraft

5.1

is turned on, it automatically fills the steam

Power ON (Automatic Fill)

generator with water. Use this procedure at the beginning of a shift to

prepare the steamer for operation without starting steam generation.When

ready to start steam cooking, begin either the Timed or Manual Operating

Procedure,

1. At the beginning of this procedure the ON/OFF switch is in the OFF

(bottom) position. The control panel circuits are not powered and the

timer display is blank.

2. Press the TIMED (top) end of the TIMED/MANUAL switch.

3. Press the ON (top) end of the ON/OFF switch to energize the

SteamCraft 5.1 control panel. The red indicator on the switch lights, and

water fills the steam generator.

4. During the fin cycle, check the timer display. If the timer is not zeroed

(00:00), clear the timer by pressing and holding the CLEAR key on the

key pad control panel.

5. When the generator is full, the SteamCraft 5.1 automatically stops water

flow.

Inspect the Cooking Compartment

CAUTION

Steam leaks around the door, cooking oompart -ment

flooding, reduced cooking performance, and