Cleveland Motion Controls

INSTRUCTION MANUAL

(MAN-70434-0)

FOR

U

LTRA ISC SERIES SLIM CELL

TRANSDUCER

REVISION

AA

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

REVISION HISTORY

Rev ECO Author Date Description of Change

AA XXX WGW As Released

This documentation may not be copied, photocopied, reproduced, translated, or reduced to

any electronic medium or machine-readable format without explicit written permission from

CLEVELAND MOTION CONTROLS.

Copyright

©

2007 by ITT, Cleveland Motion Controls

Burny/AMC Division

7550 Hub Parkway

Cleveland, Ohio 44125-5794

Tele: 216.524.8800

Fax: 216.642.2199

PAGE 2 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

WARRANTY AND LIMITATION OF LIABILITY

All equipment is sold subject to the mutual agreement that it is warranted by the company to

be free from defects of material and workmanship but the company shall not be liable for

special, indirect or consequential damages of any kind under this contract or otherwise. The

company’s liability shall be limited exclusively to replacing or repairing without charge, at its

factory or elsewhere at its discretion, any material or workmanship defects which become

apparent within one year from the date on which the equipment was shipped, and the

company shall have no liability for damages of any kind arising from the installation and/or

use of the apparatus by anyone. The buyer by the acceptance of the equipment will assume

all liability for any damages which may result from its use or misuse by the buyer, his or its

employees, or by others.

The warranties of the company do not cover, and the company makes no warranty with

respect to any defect, failure, deficiency, or error, which is:

Not reported to the company within the applicable warranty period, or

Due to misapplication, modification, disassembly, abuse, improper installation by others,

abnormal conditions of temperature, dirt, or corrosive matter, or

Due to operation, either intentional or otherwise, above rated capacities or in an otherwise

improper manner.

There are no other warranties, expressed or implied including the implied warranties of

merchantability and fitness for a particular purpose.

PAGE 3 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

BLANK

PAGE 4 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

TABLE OF CONTENTS

1 PRODUCT OVERVIEW ......................................................................................................9

1.1 GENERAL DESCRIPTION ......................................................................................................................9

1.2 FEATURES........................................................................................................................................10

1.3 HOW IS THE ULTRA ISC USED...........................................................................................................10

1.4 CE EMC RESPONSIBILITY.................................................................................................................10

1.5 GENERAL SPECIFICATIONS ................................................................................................................11

1.6 PHYSICAL SPECIFICATIONS ...............................................................................................................11

1.7 ENVIRONMENTAL REQUIREMENTS......................................................................................................11

1.8 OPERATING CONDITIONS...................................................................................................................12

1.9 EMC TECHNICAL RATINGS................................................................................................................12

1.10 EMISSION SPECIFICATIONS ..............................................................................................................12

1.11 SPECIFICATIONS .............................................................................................................................12

1.12 SLIM CELL FORCE RATINGS............................................................................................................13

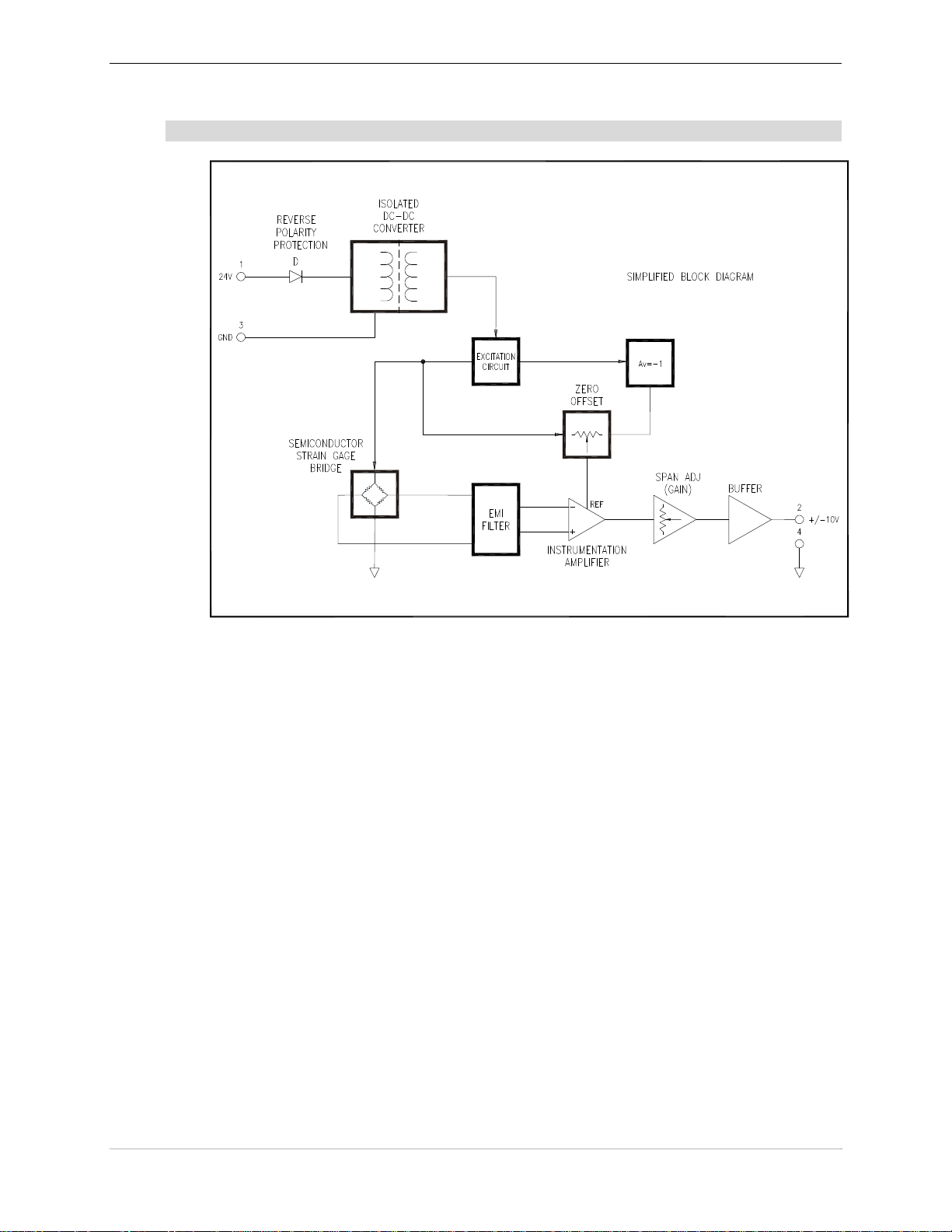

1.13 BLOCK DIAGRAM OF ULTRA SERIES ISC AMPLIFIER MODULE ..........................................................14

2 PRODUCT COMPONENTS ...............................................................................................15

2.1 M12 MATING CONNECTOR ................................................................................................................16

2.2 ELECTRICAL CONNECTIONS AND WIRING ...........................................................................................17

2.3 CABLING ..........................................................................................................................................18

2.4 POWER SUPPLY REQUIREMENTS .......................................................................................................19

2.4.1 Interface wiring ..................................................................................................................................... 19

2.5 POTENTIOMETERS ADJUSTMENTS (IF NEEDED) ..................................................................................20

2.5.1 Correct Adjustment Tools .....................................................................................................................20

3 PRODUCT APPLICATION ................................................................................................21

3.1 FINAL CALIBRATION ..........................................................................................................................21

3.2 SUMMING..........................................................................................................................................22

3.3 SUMMING BY “SERIES STACKING” ....................................................................................................23

4 INSTALLATION ..............................................................................................................24

4.1 RECEIVING AND UNPACKING..............................................................................................................24

4.2 BEFORE INSTALLING THE TRANSDUCER.............................................................................................24

4.2.1 Safety Considerations...........................................................................................................................24

4.2.2 Mounting Hardware and Recommended Fastener Torque...................................................................25

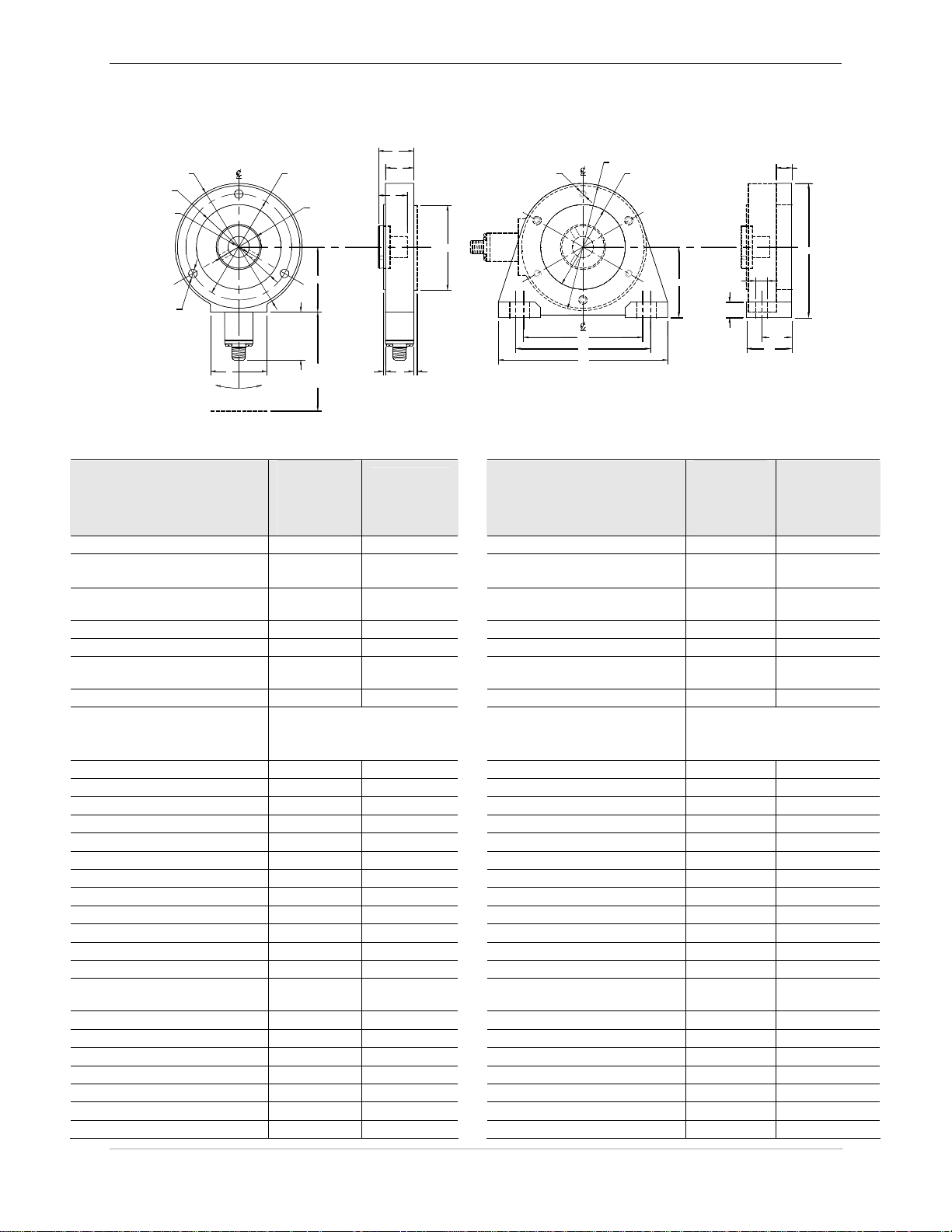

4.2.3 Mounting Dimensions ...........................................................................................................................26

4.2.4 Selecting a Mounting Location..............................................................................................................28

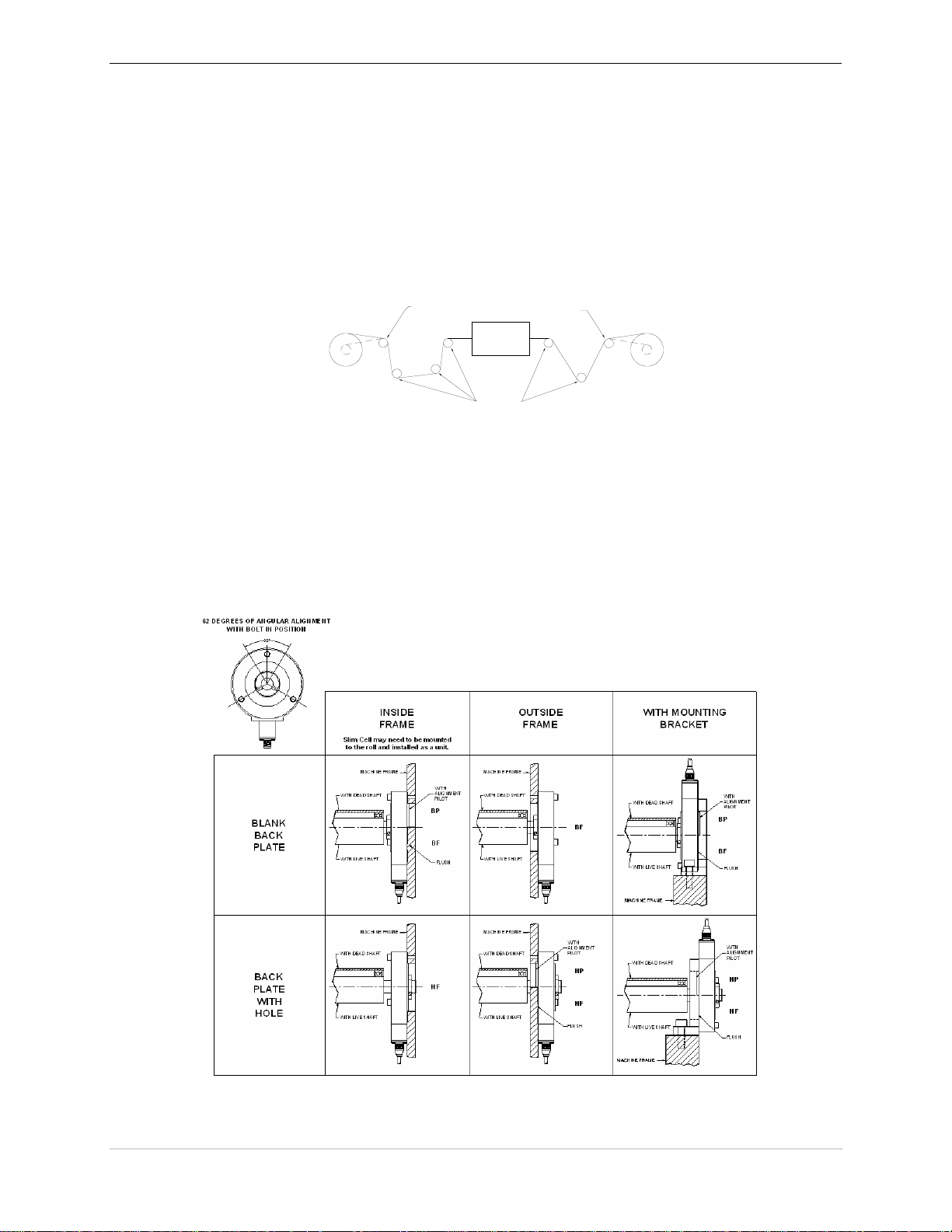

4.2.5 Determine a Mounting Style..................................................................................................................28

4.3 PRE-INSTALLATION PRECAUTIONS.....................................................................................................29

4.3.1 Shipping................................................................................................................................................29

4.3.2 Roll Balance..........................................................................................................................................29

4.3.3 Critical Roll Speed ................................................................................................................................29

4.3.4 Avoiding Damage to the Transducers...................................................................................................29

4.4 INSTALLATION PRECAUTIONS ............................................................................................................30

4.5 MOUNTING THE SLIM CELL TRANSDUCER TO THE MACHINE FRAME......................................................30

4.6 POSITIONING THE SLIM CELL TRANSDUCER .......................................................................................31

4.7 MOUNTING THE SENSING ROLL..........................................................................................................32

4.8 CHECKING THE TRANSDUCER MOUNTING ..........................................................................................32

4.9 POWER-UP AND TESTING...................................................................................................................33

4.9.1 Before Applying Power .........................................................................................................................33

4.9.2 Power Application.................................................................................................................................33

PAGE 5 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4.10 ADJUSTMENT TOOLS (ONLY IF NOT USING NUMERICAL CORRECTION)..............................................34

4.11 GAIN AND ZERO CALIBRATION ........................................................................................................34

4.12 PROPER PRACTICES FOR APPLYING CALIBRATION FORCES..............................................................35

4.13 CALIBRATION ACCURACY CONSIDERATIONS....................................................................................36

4.14 FINAL CALIBRATION........................................................................................................................37

4.15 EMC CONNECTIONS AND INSTALLATION..........................................................................................38

4.16 CABLE GLANDS..............................................................................................................................39

5 TROUBLESHOOTING ......................................................................................................40

5.1 TRANSDUCER BENCH TESTING..........................................................................................................41

6 MANUFACTURERS DECLARATION OF CONFORMITY..........................................................42

PAGE 6 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

WARRANTY

Cleveland Motion Controls warrants the goods against defects in design, materials and workmanship for the period

of 12 months from the date of delivery on the terms detailed in the Cleveland Motion Controls, Inc. Terms and

Conditions of Sale, document number AO-90131.

Cleveland Motion Controls, Inc. reserves the right to change the content and product specification without notice.

© 2004 in this document is reserved to:

Cleveland Motion Controls, Inc.

7550 Hub Parkway

Cleveland, OH 44125

216-524-8800 Phone

216-642-2199 Fax

INTENDED USERS

This Instruction Manual is to be made available to all persons who are required to configure, install or service the

tension transducer equipment described in this manual or any other related activity.

FURTHER INFORMATION

For the latest product information, technical literature etc., visit our website at www.cmccontrols.com

ATTENTION: The following information is provided merely as a guide for proper installation. Cleveland Motion

Controls cannot assume responsibility for the compliance (or failure to comply) to any code (national, local or other)

that prescribes the proper installation of this electro-mechanical device or associated equipment. A hazard of

personal injury and/or property damage can exist if applicable codes are not adhered to.

CONTACT INFORMATION AND SERVICE ASSISTANCE

For service assistance, have the following information available:

Type of Slim Cell Transducer

Maximum Working Force

Purchase Order Number

To contact us, visit our website at www.cmccontrols.com

Phone: 216.524.8800

Fax: 216.642.5159

or use the following numbers:

Disassembly by improperly trained personnel may result in additional damage to these units. Should

repairs be required or for warranty repairs, contact the Customer Service Department for a return

authorization number before returning the units.

PAGE 7 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

BLANK

PAGE 8 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

1 PRODUCT OVERVIEW

1.1 GENERAL DESCRIPTION

The Ultra Series Integrated Signal Conditioning (ISC) tension transducer (see Figure 1) outputs a

+/- 10 VDC signal for reporting signals from strain gage-based load cells.

include an Integrated Signal Conditioner (ISC) amplifier that is coupled directly to the “Ultra”

type load cell employing semiconductor strain gages. This local processing reduces the signal

degradation due to long wires to the driving displays or recording devices.

Because the output stage is free to float, be aware of voltage differences on the output

side of the tension transducer with respect to protective earth ground.

Ultra ISC transducers

Figure 1 Ultra Series Integrated Signal Conditioning (ISC) Tension Transducer

The Integrated Signal Conditioning (ISC) tension transducer has a separate ground reference

(common) for the output signals. The ground used by the output circuits is electrically separate from

the ground return for the fixed 24Vdc supply. The 24Vdc supply inpu t is protected against reverse

polarity.

The Integrated Signal Conditioning (ISC) tension transducer uses an embedded Instrumentation

Amplifier (IA) to amplify the millivolt level signals generated by the strain gage bridge, while

effectively rejecting common-mode noise. Low drift Surface Mount Technology (SMT)

components, Multi-layer Printed Circuit Boards (PCB) and optimum circuit topologies are

incorporated to promote load cell signal integrity.

The Amplifier gain is adjustable over a 9.6:1 range to allow span calibration of the analog outputs.

A precision low voltage excitation source is provided for exciting the strain gage elements in the

internal strain-gage bridge.

The use of galvanic isolation can aid in reducing noise pickup caused by ground loops in the field

wiring and accommodates limited voltage gradients between input and output sections of the

application wiring.

PAGE 9 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

1.2 FEATURES

Ultra ISC tension transducer features are:

Factory Calibration promotes interchangeability

Tension controller observation of individual loadcell signals provides increased oppo rtunity

for advanced diagnostics and calibration.

Self contained precision excitation circuit eliminates the need for the expense and

complication of remote sense

24V supply has reverse polarity protection

Analog output buffer designed to accommodate capacitive cable loads.

Floating strain-gage and output stage allows “stacking” ISC outputs for simple summing.

Sealed enclosure and M12 connector provide environmental protection

Industry standard M12 allows use of readily available molded cordsets

1.3 HOW IS THE ULTRA ISC USED

The Ultra ISC load cell has been developed for those customers who desire to send the amplified

transducer signal directly into their Controller, PLC, PAC, Drive, or Local I/O.

The signal outputs are zeroed, scaled, and summed (if a pair of transducers is used) by

software. It is the responsibility of the customer to write this software.

The Ultra ISC load cell is shipped preset from CMC with 0 volts representing no load, and 10 volts

representing the 100% full rating of the transducer. (Example: A 100 lb Ultra ISC transducer with no

load outputs 0 volts. With a 100 lb. load the output is 10VDC when loaded in one direction and 10VDC when loaded in the opposite direction.)

1.4 CE EMC RESPONSIBILITY

The Integrated Signal Conditioning (ISC) Amplifier MO-13333-10ISC Ultra Series module

embedded in the transducer can be considered a component performing a direct function and

therefore is subject to the provisions of the EMC Directive.

To assist manufacturers, suppliers, and installers of relevant apparatus, this amplifier module is

compliant to EN61326:1997 when installed according to these instructions. Manufacturers,

suppliers, and installers of relevant apparatus may use this compliance as a contributing basis for

their own justification of overall compliance with the EMC Directive.

Before installing the Ultra Series ISC Amplifier you must clearly understand who is legally

responsible for conformance with the EMC Directive. Misappropriation of the CE mark is a criminal

offense.

PAGE 10 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

1.5 GENERAL SPECIFICATIONS

Item Specification Comments

Input Supply

Power Supply Requirements 21.6-26.4 VDC @ 50mA Basic Isolated Amplifier

Load Cell (Transducer)

Transducer Excitation (Vexc) 3.0 VDC FIXED Internally supplied.

Amplifier

Calibration Range Min. 0.9 - Max. 9 Multi-turn Gain adjustment provided.

Zero Adjustment Output Zero Preset at CMC – Accessible

by user if absolutely necessary

Span (Gain) Adjustment Preset at CMC – Accessible by user if

absolutely necessary

Amplifier Output Signal +/-10 VDC @ 2 mA

Isolation

Isolation +/- 50 V max. output circuit potential not to exceed

0V=Zero force on beam

Adjustments provided

+/-10 is undamped signal

50 V from protective earth potential

1.6 PHYSICAL SPECIFICATIONS

Item Specification Comments

Integrated Signal Conditioning mountable

Enclosure Type

Enclosure Size

Weight – Basic Amplifier 50 Grams 2.5 ounces

Connector 4 Pin M12 Quick-connect M12 Quick-connect 4 Pin, DC Keyed

with special adjustments accessible from

the surface. Remove sticker or screw to

access the setup potentiometers.

Base: 26 mm wide by 26 mm high

length:43 mm

Aluminum enclosure just behind the

M12 connector.

1.0 inches (width) by 1.0 inches

(height) 1.7 inches (depth)

1.7 ENVIRONMENTAL REQUIREMENTS

Requirement Description

Enclosure

Operating temperature

Humidity

Altitude

Atmosphere

Storage temperature range

Transport temperature range

IP65

0 to 70 degrees C

32 to 158 degrees F

Non-condensing

85% at 55 degrees C

85% at 132 degrees F

1000 meters

3300 feet

Non-flammable, non-corrosive and dust free

-30 to 90 degrees C

-22 to 194 degrees F

-40 to 80 degrees C

-40 to 176 degrees F

PAGE 11 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

1.8 OPERATING CONDITIONS

Condition Isolated Signal Conditioning Amplifier

Installation category Category III

Pollution Pollution Degree 2

Input supply Earth (Ground) referenced

Protection Enclosure mounted

1.9 EMC TECHNICAL RATINGS

Port Phenomenon Test Standard Level From Test Standard

Enclosure ESD EN 61000-4-2: 8KV AD, 1KV CD EN 61326:1997

Enclosure RF Field EN 61000-4-3 10V/m,1 Khz AM EN 61326:1997

Output Leads

DC Supply

Leads

DC Supply

Leads

Output Leads

Fast

Transient

Burst

Fast

Transient

Burst

Conducted

Immunity

Conducted

Immunity

EN 61000-4-4 1kV EN 61326:1997

EN 61000-4-4 1kV EN 61326:1997

EN 61000-4-6 3V/m EN 61326:1997

EN 61000-4-6 3V/m EN 61326:1997

1.10 EMISSION SPECIFICATIONS

Port Phenomenon Test Standard Level Generic Standard

Enclosure Radiated EN 61326:

The levels of performance indicated are achieved when the Isolated Signal Conditioning Amplifier is

installed by using the instructions and specifications outlined in this document.

1997

Class A EN 61326:1997

1.11 SPECIFICATIONS

Item: Specification:

Slim Cell 1 Slim Cell 2

Transducer Weight

Weight + Bracket

Material Body and Side Plates – Stainless Steel 410

Bridge Resistance 135-147 Ohms @ 20

2.8 lbs.

1.3 kg

Slim Cell 1 Slim Cell 2

5.5 lbs.

2.5 kg.

o

6.6 lb.

3.0 kg.

11.6 lb.

5.3 kg.

C

Gage Type Semi-conductor strain gage, gage factor equals 95 (nominal)

Excitation Voltage 5.6 VDC maximum

Nominal Output Signal at Rated

MWF

(Excess voltage can cause permanent damage)

+/- 100 mV per Transducer (with 5 VDC excitation voltage)

PAGE 12 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

Output Impedance Approximately 64 Ohms per Bridge leg

Maximum Voltage, Gage to

Beam or Base (Ground)

Operating Temperature Range 0o F to +200 o F

Maximum RPM 2500 (without derating)

Alignment +/- 2 degrees angular displacement

Break-away torque 0.6 lb-in

1.12 SLIM CELL FORCE RATINGS

Size MWF (lb.) Linear Overload (%)* Ultimate Overload (%) **

10 400 800

25 400 800

UltraSlim 1

UltraSlim 2

*Linear overload: Maximum force applied on the transducer before hitting the safety stop (the output is linear up to that

point).

** Ultimate Overload: Maximum force applied on the transducer with out risking permanent deformation.

50 400 1000

100 300 1000

250 300 1000

500 150 500

500 200 1000

1000 150 500

50 Volts peak

PAGE 13 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

1.13 BLOCK DIAGRAM OF ULTRA SERIES ISC AMPLIFIER MODULE

Figure 2 Block Diagram of Ultra Series ISC Amplifier Module

PAGE 14 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

2 PRODUCT COMPONENTS

The Ultra Series ISC Slim Cell Tension Transducer (see Figure 3) consists of a housing that

contains the amplifier and power supply boards that are coupled directly to an “Ultra” type load

cell. There is an M12 connector to send amplified transducer signals into a tension controller,

PLC, PAC, drive or local I/O. This housing has two access holes for gain and zero potentiometer

adjustments if necessary.

Figure 3 Ultra Series ISC Slim Cell Tension Transducer

PAGE 15 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

2.1 M12 MATING CONNECTOR

The M12 connector used on the Ultra Series ISC amplifier is a four-pin, DC keyed, male

connector that mates directly with the molded cordset offered by Cleveland Motion Controls.

col

Table A lists the pin numbers, signal, function, wire

When mating the connector, align the keying

mechanism and pins so that they enter the socket

without you having to apply excessive force. Use

your fingers to sufficiently tighten the coupling nut

enough to ensure an adequate seal and to

discourage accidental loosening.

ors and any notes that apply:

Figure 4 - Front View of M12 Connector

Supply

1 24 VDC

2 +/- 10V OUT

3 0V RET Power Supply Return Blue Must not exceed 25 volts from P.E.

4 COMMON Output signal Return Black

Signal Function

Power Supply source 24

Vdc

Voltage Signal Output

Undamped bi-polar tension

signal

If you choose to make your own cables or need to repair damaged connectors, you can purchase a separate

mating connector from Cleveland Motion Controls. To order, use CMC part number, X43-34338.

A fuse with a rating of 0.25A must be used in the fixed 24 VDC supply lead to limit potential damage to the

amplifier in the event of circuit malfunction. Example: Bussman GMA-250-R

Transducers (load cells) use strain gages which have limited insulation levels to ground (earth). This requires that

the COM terminals be referenced to ground (earth) to prevent damage to the transducers (load cells).

Table A M12 Connector Pin #s and Signals

Wire

Color

Brown

White max. load 2 mA

+24 VDC

@ 35 mA max

Common for +/- 10V an analog output

Must not exceed 25 volts from P.E.

Notes

PAGE 16 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

2.2 ELECTRICAL CONNECTIONS AND WIRING

Refer to Figure 5 for making the transducer to power supply and tension controller connections.

Make certain that:

The cables do not interfere with the web path, and that they are away from power

transmission gearing or other moving part s.

You exercise care when routing the cables to avoid pick-up from noise-radiating power

cabling (motor armature leads, AC main wiring, etc).

In environments with severe electromagnetic noise, it may be necessary to route the

cables inside metallic conduit.

Polarity changes are accommodated by reversing the physical orientation of the

transducer, by interchanging the black and white output wires or by changing the settings

in the user’s application software.

Figure 5 Installation Wiring Diagram

PAGE 17 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

2.3 CABLING

Important: Most start-up problems are the result of mis-wiring or failure to reference the detailed

information in this manual. Additional information details can be found in the subsequent sections of this

manual and should be referenced before actual installat i on begins.

The connector for the ISC is a standard 4-pin M12 quick-connect connector keyed for DC operation.

Molded cordsets are readily available (see Table B) that can provide a direct conn

equipped Tension Transducer, the required 24 VDC sup ply and tension controller (PLC, Tension Indicator,

Analog Input Module, etc). Ready-made PUR (polyurethane) jacketed cordsets are available in different

lengths and different connector orientation (straight or right-angle) from Cleveland-Motion Controls. It is

advisable to employ an overall outer shield (or place cable in a metallic conduit) for noise rejection in

environments with high levels of electromagnetic interference.

The wire gage should be a minimum of 24 AWG to aid in minim i zi ng un desi rable voltage drops. An

overall outer shield is required, with the shield connected to ground at the tension controller through as

short a connection as possible. The short connection is essential in minimizing parasitic inductance and

thereby maximizing the shielding effectiveness at high frequencies.

Exercise care in routing the cable to minimize electromagnetic interference from noise generating wiring

and equipment.

ailable cordsets (Get from Web marketing):

Table B lists the part numbers and descriptions for these a

v

ection between the ISC

Length

Cordset Part

Number

Connector

Orientation

Cordset Part

Number

Connector

Orientation

3M X44-33975-010 Straight X44-33976-010 Right-Angle

8M X44-33975-026 Straight X44-33976-026 Right-Angle

16M X44-33975-052 Straight X44-33976-052 Right-Angle

24M X44-33975-078 Straight X44-33976-070 Right-Angle

32M X44-33975-105 Straight X44-33976-105 Right-Angle

48M X44-33975-157 Straight X44-33976-157 Right-Angle

Table B Cordset Part Numbers

PAGE 18 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

2.4 POWER SUPPLY REQUIREMENTS

For best performance, a regulated DC power supply that provides a nominal 24 VDC and at least 50 mA per

ISC should be used.

Important: Pay particular attention to the power supply for susceptibility to the effects of condu c ted and

radiated energy from noise sources. Every effort should be made to provide stable voltage to the amplifier

using correct wiring practices and filters. To protect against circuit damage, include a 0.25 Amp fuse in the

power supply output lead to each amplifier in case of amplifier or power supply malfunction.

The power source for the power supply shall be fused at the proper rating to prevent over current in

the supply leads due to a power supply failure.

Output voltage from the supply should be within +/- 10% of 24 VDC. Component stress due to excessive

supply voltage may damage components and prolonged operation with a higher than necessary voltage will

increase the internal temperature of the circuitry within the ISC. Supply voltages that are excessively low (

either due to a low supply set-point or excessive IR drop of voltage arising by long cable runs ) can result in

“brown-out” of internal regulated supply voltages. This “brown-out” may be evident by the +/- 10V analog

output being clipped at some voltage below 10V. Keep in mind that voltage drops due to long cable runs

may drop the voltage by nearly a half a Volt (250 feet of 24 AWG cable carrying 30 mA will loose 0.4 V).

Although the amplifier provides limited galvanic isolation between the 24 VDC supply circuit and the straingage amplifier circuit, it is only intended as a mechanism to avoid “ground loop” interference. The 24 VDC

supply should always have its output return referenced to P.E. (protective earth), so that uncontrolled

potentials are not imposed between the 24 VDC supply circuit and the load cell case.

For optimum performance, the DC supply voltage should be free from excessive ripple voltage or transient

excursions.

2.4.1 INTERFACE WIRING

The load in this connection may be an indicator, recorder, data acquisition device or the analog input

terminals of a control device such as a DC drive or a programmable logic controller. The output signal at this

terminal is undamped and provides a direct response to changes in the transducer (load-cell) load. Note that

the cable’s shield drain wire should be connected at only one end, preferably at the “receiving end” (i.e.

common ground at the PLC Analog Input etc.)

The pair of wires associated with the amplified transducer signal are generally separated out from the 24VDC

supply wires at the point where they get routed toward the tension controller.

For most M12, DC keyed molded cordsets, the wire colors associated with the #1 and #3 pins is BRN and

BLU respectively.

For most M12, DC keyed molded cordsets, the wire colors associated with the #2 and #4 pins are WHT and

BLK respectively. These WHT and BLK wires provide the amplified tension signal transmitted as a +/- 10

VDC Full.Scale. analog signal from an internal op-amp (operational amplifier) buffer stage. The BLK wire

has the signal return and the WHT wire is the amplifier output. Resistive loads drawing up to 5 mA of

current are allowable.

The most common way of reversing the sense of the load cell signal is to invert the mechanical orientation of

the loadcell body itself. If this is impractical, it is possible to interchange the BLK and WHT signal wires, as

the loadcell amplifier and output stage is essentially floating with respect to the 24 VDC supply ground. Note

however that the voltage potential cannot be allowed to float “unbounded”, and that connection to line

potential drive circuits is not permissible (and potentially hazardous).

PAGE 19 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

2.5 POTENTIOMETERS ADJUSTMENTS (IF NEEDED)

The gain and zero adjustments are factory preset but accessible by the user for adjustment if

absolutely necessary. Adjustment holes to access these potentiometers are visible on the side of the housing.

Adjustments can be made by removing the sticker around the amplifier enclosure. Use Figure 3 to locate the

an

d gain adjustment holes

zero

The Table C lists these potentiometers, their reference designator, and a description of their functions. For

info

rmation on the correct adjustment tool to use, refer to section 2.5.1 in this document.

Potentiometer

GAIN P2

ZERO P1

Reference

Designator

Function

This potentiometer is preset but accessible by the user for adjustment if

absolutely necessary. It provides a 10:1 “vernier” adjustment of the amplifier

gain. It is a multi-turn potentiometer, with clockwise rotation causing an

increase in amplifier gain. When turned fully counter clockwise, the

potentiometer causes the amplifier stage to provide the minimum gain.

This potentiometer is preset but accessible by the user for adjustment if

absolutely necessary. It provides a zero (offset) adjustment. It is a multiturn potentiometer, with clockwise rotation causing a positive shift in the

analog outputs. It should be set mid-way prior to setting the ZERO

adjustment.

Table C Potentiometers Adjustments

2.5.1 CORRECT ADJUSTMENT TOOLS

A small flat-bladed “jeweler’s” screwdriver is required. The overall diameter should be no larger than 0.062”

The thickness of the blade flat should be no greater than 0.012”. Ideally, a non-conductive tool (plastic or

ceramic) provides the safest approach for minimizing the generation of minute metallic shards that are made

when a metal blade accidentally scuffs the aluminum housing.

The Zero is normally adjusted first while the loadcell is in the No-Load condition (i.e. with no tension in the

web). The calibration forces are then applied to the transducer and then the gain potentiometer adjusted to

achieve the desired scale factor. It is advisable to look for a particular step change between load and no-load

conditions and adjust the step size independent of a particular zero point. Only after the desired scale factor

is achieved, is it then best to adjust the final zero point using the Zero adjustment.

Following adjustment, it is important to seal the adjustment holes for continued protection from

contamination. A small piece of adhesive backed tape can be used to reseal.

PAGE 20 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

3 PRODUCT APPLICATION

The Ultra Series Slim Cell Transducer utilizes a twin sensing beam. Conversion from mechanical

strain to an electrical signal is accomplished using semiconductor-based, piezoresistive strain gage

elements. The Full Wheatstone Bridge configuration provides an electrically balanced output

yielding twice the amount of signal swing as half-bridged transducers operated at the same

excitation voltage. Integral span compensation is used to correct for temperature induced gain

changes.

MACHINE FRAME

SLIM CELL TRANSDUCERS

Figure 6- Slim Cell Transducer Incorporating Shaft Bearing Function

Slim Cell Transducers can be used with either rotating (live) shaft rolls (RS type) or, stationary

(dead) shaft rolls (SS type) that incorporate their own low friction bearings. For more information

on transducer type selection refer to Section 4.2.5 .

t

The Ul

ra ISC has been developed for those customers who desire to send the transducer signal

directly into their Controller, PLC, PAC, Drive, or Local I/O. When a pair of transducers is used,

the signal outputs can be zeroed, scaled, and summed by software. It is responsibility of the

customer to write this software.

3.1 FINAL CALIBRATION

When calibration is done though application software within the target controller, the greatest

calibration accuracy is achieved though the use of individual gain and offset parameters for each

of the two transducers (which generally are used in pairs). By using separate analog inputs and

separate gain and offset parameters, you can correct for any transfer function differences arising

from subtle mounting variations intrinsic to transducer output variations. If however the loadcells

are summed first and then digitized, the matching of loadcell outputs (as affected by such things as

loadcell orientation relative to the wrap angle) becomes more critical.

The tradeoff between hardware cost and accuracy will impact the decision as to which approach

users decide to take.

PAGE 21 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

3.2 SUMMING

In the majority of applications, loadcells are used in pairs. The net tension of the web must

therefore be represented by the summation of the two loadcell signals. As described above, th e

summation can be done in software, so long as both analog channels can be independently

observed. When only a single analog input is available, some other form of summer is required.

Two simple approaches are described below.

In the most common approach, a pair of equal-valued resistors are used in the classic resistive

summer circuit. A third resistor acts as a ground referred load which receives the combined signal

from each of the loadcells. The load resistance may be part of the analog input circuit’s input

impedance, but may also be supplemented by a fixed resistance for improved load resistance

stability.

In the following schematic using the resistance values shown, the equation for the summed signal

is:

= 2/5 (V

V

sum

The resultant voltage for 10 volts applied to V

left

left

and V

+ V

)

right

would therefore be 8V.The maximum

right

load impedance experienced by each loadcell’s output stage would be 7.5K ohm, necessitating that

each loadcell amplifier be capable of 1.3 mA of load current.

Figure 7 ISC Summing Amplifier

The final approach to be discussed is to “stack” the two loadcell outputs by wiring the analog

outputs to be “series aiding”.

PAGE 22 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

3.3 SUMMING BY “SERIES STACKING”

The final interface approach to be discussed is to “stack” the two loadcell outputs by wiring the

analog outputs to be “series aiding”. Note that with each loadcell outputs at a maximum of 5VDC,

the sum would be 10 VDC. As should be obvious, loadcell signals greater than 5 VDC each will

likely take most PLC analog inputs over-range.

Figure 8 Stacking the Two Loadcell Outputs

Here is a simple example of software scaling and summing

Command Description

Sample (digitize) LCH and store

Sample RCH and store

ADD LCH_OFSET to LCH parameter

Multiply offset corrected LCH parameter by

LCHGAIN

ADD RCH_OFSET to Digitized RCH parameter

Multiply offset corrected RCH param. by RCHGAIN

Add resultant LCH and RCH parameters

; Store digitized LCH.

; Concurrent samples are best.

; LCH_OFSET is the zero correction constant.

; This scales the Left Channel for span

; RCH_OFSET is the zero constant

; This scales the Reft Channel for span.

; This is the composite tension feedback

Note that sometimes, over-sampling and filtering can be used to generate a robust tension

feedback parameter despite brief disturbances (either mechanical or electrical).

PAGE 23 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4 INSTALLATION

4.1 RECEIVING AND UNPACKING

After receiving the Ultra ISC Slim Cell Transducer you should:

Carefully unpack and handle the equipment

Compare the received shipment with the packing list

Report any damage to the carrier and your CMC representative

Store equipment that will not be used in a clean, dry location

Take appropriate precautions to prevent moisture, dust and dirt from accumulating in storage

and installation areas

4.2 BEFORE INSTALLING THE TRANSDUCER

Before you install the Ultra ISC Slim Cell Transducer you should perform the following steps:

Review the safety considerations (Section 4.2.1 )

Assem

R

Determ

Determ

le the mounting hardware and review the torque fastener information (Section 4.2.2 )

b

ference the mounting dimensions (Sectio n 4.2.3 )

e

e a mounting location (Section 4.2.4 )

in

ine an a

ppropriate mounting style (Section 4.2.5 )

4.2.1 SAFETY CONSIDERATIONS

Don’t let safety be an afterthought. Before installing, servicing or calibrating review and follow

applicable policies and procedures to ensure worker safety. Machinery must be in a safe state and

be aware of any additional hazards that can arise when installing and calibrating higher force

transducers.

The following points are important to remember:

When “dead-weights” are used to produce calibration forces, always wear steel-toed

shoes.

When manually handling weights, use safe lifting practices to avoid injury.

Size cordage or straps with an ample safety factor to reduce the chances of failure and

falling weights.

Consider where the cords and weights will travel should a failure occur.

Check that all hardware is mounted with appropriate fasteners (thread size and pitch,

fastener grade, length of thread engagement).

PAGE 24 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

4.2.2 MOUNTING HARDWARE AND RECOMMENDED FASTENER TORQUE

UltraSlim 1: Torque:

¼ - 20 x 1-3/8 “(typical)

SAE grade 8

M6 - 1.0 x 35 mm L,

Property Class 10.9

Setscrews

10 - 32 (Inch Hub)

M5 - 0.8 (Metric Hub)

UltraSlim 2: Torque:

3/8-16 x 2 (typical)

SAE grade 8

M10 - 1.5 x 50 mm L,

Property Class 10.9

Setscrews

¼ - 20 (Inch Hub)

M6 - 1.0 (Metric Hub)

10 lb-ft

8 N-m

24 lb-in

4.7 N-m

32 lb-ft

45 N-m

7.5 lb-ft

6 N-m

Mechanisms used for industrial automation can tax even the best threaded fasteners. You can

improve the likelihood that bolts and shafts remain secure by using suitable anaerobic “thread

lockers” during the final assembly.

Trademark Information

Loctite is a registered trademark of Henkel Loctite Corp.

Kidder is a registered trademark of Cleveland Motion Controls

PAGE 25 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4.2.3 MOUNTING DIMENSIONS

G

A

C

E

B

D

H

N

S

RY

T

C

M (BOLT DIA)

K

62 ° OF ANGULAR ALIGNMENT

WITH BOLT IN POSI TI ON

L

AA1

OR

AA2

SLIM CELL

J

O

P

FI

Q

MOUNTING BRACKET ( WITH SLIM CELL)

Z

X (BO LT DIA)

U

Mounting Dimensions for English Hardware: Mounting Dimensions for Metric Hardware:

Designator:

A 4.50 5.80

AA1

(mating conn. at right angle)

AA2

(mating conn. straight)

B 3.75 4.75

BB 1.08 1.33

C 2.996 -

D 1.50 2.46

E 0.625 1.250

F 0.12 0.14

G 1.31 1.70

H 1.02 1.32

I 0.07 0.10

J 2.30 3.05

K 2.00 2.50

L 1.275 1.275

M .28 (3) .40 (3)

N 1.02 1.36

O 4.22 5.50

P 4.78 6.5

Q 6.00 8.00

R 3.000 -

S 4.50 5.80

T 0.55 0.65

U 0.55 0.65

V 1.60 2.1

W 4.75 6.2

X 3/8 (2) ½ (2)

Y 1/4 - 20 3/8-16

Dimension

in

Slim Cell

Transducer

1:

Dimension in

Slim Cell

Transducer

2:

1.3 1.3

2.5 2.5

4.196 -

3.000

4.200

0.750 1.500

1.000 1.750

4.200 -

3.006

4.206

Designator:

A 114.3 174.3

AA1

(mating conn. at right angle)

AA2

(mating conn. straight)

B 95.3 120.7

BB 27.4 33.8

C 76.10 -

D 38.1 62.5

E 15 30

F 3.0 3.6

G 33.3 43.2

H 25.9 33.5

I 1.8 2.5

J 58.4 77.5

K 50.8 63.5

L 32.625 32.625

M 6 (3) 8 (3)

N 25.9 34.5

O 107.2 139.7

P 121.4 165.1

Q 152.4 203.2

R 76.20 -

S 114.3 174.3

T 14.0 16.5

U 14.0 16.5

V 40.6 50.8

W 120.6 157.5

X 10 (2) 12 (2)

Y 1/4-20 3/8-16

Dimension

in

Slim Cell

Transducer

1:

33 33

64 64

76.20

20 35

25 40

76.35

W

BB

V

Dimension in

Slim Cell

Transducer 2:

106.58 -

106.68

106.68 -

106.83

PAGE 26 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

NC (3) NC (3)

Z 2.50 3.30

Table D Transducer and Mounting Bracket Dimensions

NC (6) NC (6)

Z 63.5 83.8

PAGE 27 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4.2.4 SELECTING A MOUNTING LOCATION

Select the mounting location for the transducer keeping the following points in mind:

The transducer can be mounted to either inside or outside of the machine frame.

The tension-sensing roll must not be mounted where the web wrap angle can vary, or the

transducer will not interpret the tension properly as the angle varies. If a variance in the

wrap angle occurs, it is sensed by the transducer as a tension change and the change is

indicated on the tension indicator. In cases where it is impossible to mount the transducer

where the wrap angle does not vary, the change in indicated tension that results should be

calculated and if small, can be disregarded.

WRAP VARIESWRAP VARIES

PROCESS

OK FOR TENSION SENSING

Figure 9 Example of Varying Wrap Angles

4.2.5 DETERMINE A MOUNTING STYLE

The Ultra ISC Slim Cell Transducer can be mounted in several different ways (Figure 10). When

choosing a mounting style, evaluate your options by taking the following points into consid eration:

Safety

Machine Frame orientation

Ease of Assembly

Figure 10- Slim Cell Transducer Mounting Styles

PAGE 28 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

4.3 PRE-INSTALLATION PRECAUTIONS

4.3.1 SHIPPING

Shock and vibration transmitted to the transducers by the sensing roll during transportation can

damage the transducers. It is essential that you remove the sensing roll when the machine is

shipped with the transducers mounted.

4.3.2 ROLL BALANCE

The sensing roll must be adequately balanced. Understand that the balance of the sensing roll will

be more demanding than that typically needed in general rotating machinery. The goal goes

beyond just limiting the force to which bearings will be subjected, but rather to minimize the

generation of an unintended noise component in the transducer tension signal. The centrifugal

force caused by imbalance can be estimated using the following formula:

-6

F = (1.77 x 10

Where:

F = centrifugal force (in units of lb-f)

W = weight imbalance (in units of ounces)

R = radius of displacement, distance of imbalance weight from roll axis of rotation (in inches)

RPM = Revolution per minute

The force increase is equal to the square of the RPM or in other words, doubling the RPM causes

four times the imbalance force. Because rolls tend to have a high length-to-diameter ratio, twoplane (dynamic) balancing is recommended. Balancing is particularly needed where higher RPMs

and lower web forces are involved.

) x W x R x (RPM)2

To illustrate how much imbalance induced “noise” could be generated, Table E shows the force

di

sturbance for various ISO balance grades for an illustrative case of a 20 pound roll (4” diameter

x 36” long, aluminum ) rotating at 1500 RPM.

Table E Force Disturbance For Various ISO Balance Grades

Balance Grade

(ISO 1940/1):

G16 1.25 oz-in +/- 5 lb-f at 25 Hz

G6.3 0.5 oz-in +/- 2 lb-f at 25 Hz

G2.5 0.2 oz-in +/- 0.8 lb-f at 25 Hz

G1 0.08 oz-in +/- 0.3 lb-f at 25 Hz

4.3.3 CRITICAL ROLL SPEED

Even with a balanced roll, a vibration can be set up in a stationary shaft. If this vibration (in cycles

per minute) occurs at the harmonic frequency of the shaft, the transducers can be damaged. To

determine the critical roll speed, use the following formula:

Critical roll speed in RPM = 4.8 x 106 x Shaft O.D.

(Shaft Length)

(Dimensions are in inches)

To assure that this issue is avoided, the critical roll speed should be at least 20% above the roll

speed attained at maximum web speed.

Residual Imbalance:

Resultant Force due to

Residual Imbalance:

2

4.3.4 AVOIDING DAMAGE TO THE TRANSDUCERS

To avoid damaging the transducers, refrain from repetitive overloading above the maximum

working force or severe overloading.

PAGE 29 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4.4 INSTALLATION PRECAUTIONS

To ensure proper installation and operation of the system, keep the following points in mind:

Do not apply shock loads to the Slim Cell bearing assembly when mounting or

dismounting rolls.

Exercise care to avoid overstressing the transducer when handling partially mounted rolls.

Even relatively short rolls can afford an impressive mechanical advantage over the

sensitive transducer.

Bolting the transducer to a non-flat surface can cause deformation of the transducer body

and degrade the quality of the tension signal.

Failure to follow these precautions can result in serious damage to the Slim Cell Transducers and

possibly void the warranty!

4.5 MOUNTING THE SLIM CELL TRANSDUCER TO THE MACHINE FRAME

The Slim Cell Transducer can be mounted directly to the machine frame or mounted using the optional

mounting bracket.

The mounting surfaces for the Slim Cell Transducer should be flat and parallel to each other. Remove any

loose paint, rust or scale from the machine frame before mounting.

When Mounting the Slim Cell Transducer Directly to

the Machine Frame:

The Slim Cell can be mounted on either

the inside or outside of the machine

frame. Refer to Figure 10 to help

eterm

ine the arrangement that best suits

d

your application.

Before drilling and tapping the mounting

holes in the machine frame, refer to

section 4.6 to ensure proper alignment of

e Slim

th

Cell.

Mount the Slim Cell Transducer into

place with three bolts. For properly

positioned bolt hole centers and sizes,

refer to the dimensions listed for letters B

and M in Error! Reference source not

found.. The bolt hole centers are evenly

spaced on a circle and 120 degrees from

each other.

When Mounting the Bracket to the Machine Frame:

The transducers can be mounted on either

side of the bracket. Refer to Figure 10 to

p

determine the arrangement that best

hel

suits your application.

Drill and tap two mounting holes in the

machine frame for each bracket. Refer to

dimension X, O and P in Table D for

r

ect dimensions for the bolt holes.

cor

PAGE 30 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

4.6 POSITIONING THE SLIM CELL TRANSDUCER

Use the following steps when positioning the transducers for mounting:

1. Before bolting the transducer in place, be sure that it is generally aligned with the tension force (load

direction). The transducer is properly aligned when the load direction (bisector of the wrap angle) is

pointing along a line connecting the “+” and “-“signs located on the sides of the load cell

2 Insert and finger-tighten the bolts.

3 Rotate the slim cell outer ring so that the load direction is precisely aligned with the “+/-“ axis. the outer

ring can be rotated 60 degrees in either direction to achieve the proper alignment position.

4 Tighten the mounting bolts to the recommended torque (refer to section 4.2.2 ). It is a good practice to

tighten e

5 Note the alignment of the force. If the force points to the “+” sign, the output signal of the transducer is

positive. If the force points to the “-“ sign, the output is negative. This information is important to know

when wiring the transducer to the indicator or controller terminals. Interchanging the black wire and

white wire at the amplifier terminals (connections) may be required to provide the proper signal polarity

for the device.

ach bolt increm

entally, and in succession.

Figure 11 – Positioning the Slim Cell Transducers for Mounting

PAGE 31 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4.7 MOUNTING THE SENSING ROLL

Be sure to exercise care during this portion of the installation, as it easy to produce excessive force on the

transducer sensing beams. To mount the roll, use the following steps:

1. Loo sely fit the roll into the transducer to verify that the shaft and the adapter fit without excessive

interference or clearance. For reference, the bore diameter of the hub is +0.0007 and +0.0017 in.

(+0.018 and +0.043 mm) from the nominal diameters listed in Section 4.2.3 .

2 Che

3 Secure o

4 Tighten the set screws while preloading the hub.

ck to see if the transducer has a blank back plate (without a hole). If it is a blank plate, be sure that

the roll shaft does not extend too deep inside of the Load Cell and rub against the back plate. Refer to

letter N in Section 4.2.3 of this document.

ne end of the roll shaft into either of the Slim Cell Transducer shaft hubs by tightening the two

set screws.

Preloading of the adapter shaft hub allows for expansion and contraction of the roll shaft. Because of

the affects of thermal gradients and differing material, both expansion and contraction must be

accommodated.

To preload the hub, push the hub inward against the resistance of the internal spring prior to tightening

the set screw on the remaining shaft hub.

During final assembly, you can use Loctite® #609 retaining compound on the roll journal to

transducer hub interface, and Loctite’s #242 (removable strength) thread locker on the set screws.

4.8 CHECKING THE TRANSDUCER MOUNTING

Before preparing to apply force to the transducer(s) and calibrating th e amplifier, inspect the load cell to

confirm that it is oriented and mounted in accordance to the installation instructions. Common problems

include:

Failure to mount transducers on flat (machined) surface.

Poor shaft alignment that exceeds allowable limits.

Fastener torque either excessive or insufficient.

Transducer mis-oriented so that the axis of sensing is not true to the applied force vector

(bisector of the wrap angle).

Roll is mounted without allowance for shaft expansion/contraction at transducer hub.

The transducer is positioned in the web path so that the wrap angle is not constant.

PAGE 32 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

4.9 POWER-UP AND TESTING

4.9.1 BEFORE APPLYING POWER

Before applying power, check the wiring to the amplifier. Pay particular attention to the following:

Double check the transducer cabling to ensu re that th e 24V power supply is within limits

4.9.2 POWER APPLICATION

and polarity is correct.

Use an approved anti-static wrist strap when adjusting any potentiometers on the amplifier.

Use the appropriate tool when making any adjustments to the potentiometers on the

amplifier. Damage to the circuitry may occur if excessive force is used or a conductive tool

accidentally contacts internal voltages.

As soon as practical after connecting power to the ISC, verify that the 24 VDC supply is

operational and not overloaded by any mis-wiri n g.

polarity is correct and that the voltage is within the prescribed limits. Promptly identifying any

over-voltage condition can help minimize potential damage to the circuitry internal to the

transducer.

With 24 VDC supply confirmed, check the DC output voltage reported by the ISC and see if it

responds as expected when small test forces are applied to the Tension Transducer.

Use a DC voltmeter to confirm that the supply

PAGE 33 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4.10 ADJUSTMENT TOOLS (ONLY IF NOT USING NUMERICAL CORRECTION)

Using the correct tools simplifies the setup process and necessary adjustments. Keep the following

points in mind:

The Integrated Signal Conditioning Amplifier utilizes two different potentiometers. The

Gain and Zero adjustments are located on the side of the amplifier (under the sticker).

The adjustment tool should have dimension on the order of 0.5mm (.020 inches) blade

thickness and be 2.5 mm wide (0.1inches).

Important: Use a non-conductive tool to alter potentiometer positions. Be sure that

adjustment tool does not touch any part of PCB circuit to avoid accidentally damaging it.

4.11 GAIN AND ZERO CALIBRATION

The gain and zero adjustments are preset but accessible by the user for adjustment if

absolutely necessary. To make your final calibration adjustments, use the following steps:

1. Verify Zero on the analog Outputs for the “unloaded” (no web force applied) condition and

adjust the Zero potentiometer to correct for any minor offset voltage.

2. Apply the calibration force to the transducer(s) and adjust the Gain potentiometer to

achieve the desired span.

3. Verify linear operation of the transducer and amplifier by applying a series of forces that

falls somewhere between the zero and full-scale endpoints. The intent is not to re-execute

any calibration per se, but to confirm the hardware’s ability to accurately report a measured

force without non-linearity.

We recommend that you focus only on achieving a particular voltage “span” between the load and

unloaded forces by alternating between the two force levels. Avoid repeatedly adjust the Zero

potentiometer between measurements unless the offset voltage becomes excessive and interferes

with achieving a valid output signal on the analog output. You should only adjust the final Zero

after the desired Gain setting has been achieved.

These final calibration steps represent the minimal adjustments that might be required at

periodic calibration intervals and

accessible through the small holes in the front cover.

typically involve only the Zero and Gain potentiometers

PAGE 34 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

4.12 PROPER PRACTICES FOR APPLYING CALIBRATION FORCES

Seldom is a transducer oriented such that the calibration can be done by simply hanging a true

dead weight from the roll. By generating a tension force that follows the same web path across the

roll, you avoid the necessity of making manual (numerical) calculations to correct for the details of

different wrap angle, transducer orientat i o n, et c.

The following diagrams show the correct and incorrect techniques to use when applying

calibration forces.

Examples of Inaccurate Wrap Angles

In this example, there was a disregard for maintaining the

correct wrap angle. The dotted line indicates the proper

web path.

Example of Correct Wrap angles and Anchor Point

In this example, the anchor point and the wrap angle have

been correctly achieved and closely follow the actual web

path.

In this example, the true web path was difficult to access

and an incorrect path was implemented using a

convenient, but incorrect anchor point.

PAGE 35 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

Examples of Force Loss due to Friction at Driven Roll

In this example, only a fraction of the test force is

transferred to the transducer due to drag from the

driven roll.

4.13 CALIBRATION ACCURACY CONSIDERATIONS

The application of an accurate calibration force requires careful attention to minimizing the nonideal effects of the real world. Keep the following points in mind:

When conducting a calibration that involves a large mass, it is often practical to use a series of smaller masses

added in succession. Consider performing an initial Zero and Gain adjustment when the first 20% of the

weights have been applied. By performing the calibration using this method, the Zero and Gain adjustments

can be made approximately correct earlier in the calibration effort (before many weights have been handled).

When the full calibration load is applied, there is a better chance that only minor adjustments will be needed.

Allow the transducer and amplifier to reach thermal equilibrium before conducting

calibration. Ideally, the temperature should reflect the expected operating cond itions.

The test force should be a moderate percentage of the intended working force of the

transducer and never over the 100% Maximum Working Force (MWF) or, you risk

calibrating with an overloaded (“clipped”) transducer signal.

Cycle the load on the transducer a number of times with the test force to pre-condition or

“set” the transducer prior to calibration. Repeat this procedure again before calibrating if

the transducer has been disturbed (i.e. roll remounted or any mounting bolts re-torqued).

With very low force transducers consider that connecting a test mass involves some finite

cord mass.

When two transducers support a roll, calibrate with the cord in the exact center of the roll.

Passing a cord over a roll on its way to the transducer inevitably causes some amount of

friction. The worst case scenario involves passing the working part of a cord over a roll

that doesn’t readily freewheel. A test was conducted to determine the loss on a stationary

4” diameter anodized roll with a 90 degree wrap angle. It exhibited a 25 to 30% loss in

force due to friction!

When all else is done correctly, the largest remaining contributor to error is friction. If

friction cannot be reduced, consider determining the magnitude of the friction through

measurement and then making first order corrections numerically.

In this example, by rearranging the anchor point

and the force location as well as utilizing the idle

roll, the frictional losses are minimized.

PAGE 36 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

Always apply and remove the test load in a continuously increasing or decreasing

manner, so that the force changes are monotonic. This helps to avoid disturbing any

hysteresis component of the transducers force signal.

When calibrating for a particularly wide roll that will always have a narrower product

tracking to one side, consider applying the calibration force at the roll position that

represents the center of the product. This will automatically cancel some of the affects of

transducer gain imbalance without the need to actually re-balance the transducers gains

within the amplifier.

It is a good practice to verify linear operation of the transducer and amplifier by applying

a final test force that falls somewhere between the zero and full-scale endpoints. The

intent is not to conduct calibration, but to confirm the hardware’s ability to accurately

report a measured force.

4.14 FINAL CALIBRATION

Even though the ISC transducer is factory calibrated, calibration is still usually required to

accommodate application variables such as wrap angle and transducer orientation. The customer

then accesses these software parameters using an HMI, keypad, or other device. The transducer is

still calibrated using weights as is done currently.

Final calibration is usually required to take in to account particular application circumstances of

roll weight, wrap angle and loadcell orientation. The final zero and span calibration is most easily

accomplished by numerical scaling within the digital processor of the tension controller. Because

each ISC equipped tension transducer has been factory adjusted for uniform transfer function,

loadcell inter-changeability when calibrated this way is readily promoted.

Field calibration still consists of applying known force conditions in the web, but instead of

adjusting a potentiometer, the observed loadcell offset is determined at the controller and then

numerically subtracted from the reported loadcell signal.

In the case of Span calibration, a known web force (equal to a moderate portion of the expected

operational force) is applied using test cords routed through the expected web path past the

transducer pair. An appropriate numerical scaling factor is then determined and used as a scaling

factor within the tension controller.

Hint

An interesting approach to slightly attenuating the loadcell output by purely mechanical means can

be used with those loadcell styles which accommodate slight rotation relative to the bisector of the

wrap angle (i.e. Cartridge transducers and Slim Cells).

Consider taking advantage of the Cosine relationship (noting that a 10 degree mechanical shift

will reduce the output span by 1.5%). The deflection of CMC’s strain gage based loadcell is

sufficiently small that tracking will not usually be adversely affected.

PAGE 37 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

4.15 EMC CONNECTIONS AND INSTALLATION

Compliance with the specified EMC directive for immunity in a heavy industrial environment and

emissions in a light industrial environment requires correct installation and wiring of the Ultra ISC

Tension Transducer. The most important precaution to be taken in the wiring is to use double

screened (shields) cabling for the cables from the transducers (load-cells) to the controller, and

from the 24VDC Power Supply to the transducer load. The outer screen of each cable must be

firmly bonded to the enclosure that contains the amplifier, the transducer (load-cell) housing and

the enclosure of the output load device. Large loops of unshielded cables must be avoided and

effective cable glands providing 360 degree grounding of the outer screen of the transducer and

output cables to the enclosure must be used.

Figure 12 EMC Connections and Installation

PAGE 38 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

4.16 CABLE GLANDS

Several manufacturers provide cable glands that can be used to ensure the integrity of the EMC

requirements when installing this equipment in the enclosure. The objective of the cable gland is

to provide a good mechanical entry into the enclosure to protect the cable and also provide an

electrical bond the outer shield (screen) of the cable to the enclosure.

The following is a list of cable gland venders and the range of cable sizes that each vender can

provide. This is not an endorsement or promotion of any particular vender or manufacturer; the

information is provided only to assist you in the application of the product described in this

document.

Cable Gland Vendor Cables

EMI-Proof Grounded Nickel Plated Brass Liquid Tight

Sealcon

14853 E. Hinsdale Ave., Suite D

Englewood, CO 80112, U.S.A.

Tel: (303)699-1135 Fax: (303)680-5344

Tel: (800)456-9012

GlobTek, Inc.

186 Veterans Drive

Northvale, NJ 07647

Tel: (207)784-1000 Fax: (210)784-0111

Email: globtek1@idt.net

URL: www.globtek.com

Wiedmuller

Tel: (800)849-9343 Fax: (800)794-0252

Belden

Strain Relief Fittings

Standard and Feed-through types

Cable diameters from 0.11 inches to 1.38 inches

Metric (PG) or NPT thread types

Optional metric (PG) to NPT adapters

Standard, IP68 protection

Index EMC Cable Glands

Cable diameters from 6.0 mm to 20.0 mm

Metric threads

Bulkhead Cable Glands for Braid/Armour Termination

Standard types KGC 1 Series

Cable diameters from 1.8 mm to 39.9 mm

Metric threads

Optional washers and locknuts

Braided “overshield” wire; Belden #8669 (0.5” I.D.)

braided shielding and bonding wire

PAGE 39 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

5 TROUBLESHOOTING

Do no let safety be an afterthought! Before installing, servicing or calibrating review and follow applicable policies and

procedures to ensure worker safety. Machinery must be in a safe state and be aware of any additional hazards that

can arise when installing and calibrating higher force transducers.

The Table F provides you with a list of typical issues that you may encounter and possible solutions:

If you are having this issue: Then:

Check to be sure that all connections have been made completely and properly.

Inspect the connecting cables for crimps or cuts.

Verify that the appropriate 24VDC voltage supply is being applied to the ISC tension

No Output Signal

Low Output Signal

Wrong Polarity of Output Signal

Excessive Output Signal with

Minimal or No Load

Poor Linearity

transducer. Check fuses in supply.

Disconnect the ISC transducer output wires from the tension controller’s input terminals (to

eliminate any potential for accidental loading) and check the amplified output signal using a

voltage meter.

The ISC transducer may have too large a maximum working force (MWF) in relation to the

force to be sensed, or the wrap angle may be insufficient and is not able to generate an

optimum resultant force on the transducer.

Or

The transducer may be improperly orientated such that the transducer’s axis of sensitivity is

not aligned with the bisector of the wrap angle.

Or,

Check that the signals from each ISC transducer will combine additively. Otherwise, the two

signals will work against each other, and only minute differences between signals appear.

Transducers may have been incorrectly oriented. Refer to section 4.6 for proper load

direction. Alternately, change the signal sense by

transducer leads into the tension controller. Compliment (invert) signal sense in controller

software.

There may be a high degree of misalignment of the transducers causing a severe pre-load.

Or

The sensing guide roll assembly may be excessively heavy. The sensing guide roll should

not weigh more than ½ the maximum working force of the transducers in most cases.

Or

The transducer may have too small a maximum working force for the application. Replace

with a higher maximum working force transducer or decrease the web wrap angle.

Also,

Check cables and connectors for intended connections using an ohm-meter or continuity

checker. Inspect not only for continuity where expected, but also disconnect connectors and

check for unintended resistances (shorts) between conductors.

Inspect the transducers for mechanical reasons why there is a reported overload.

Possibilities include, debris wedged in the transducer’s shaft seal area, a roll shaft bottoming

inside the transducer body or a transducer otherwise poorly mounted.

Check for mechanical reasons such as rubbing or binding that interferes with the force being

properly transmitted to the load cell.

Or

Your calibration efforts may have been conducted while either the transducer or the amplifier

was in a non-linear mode (i.e. under the effects clipping or saturation). Try and recalibrate

the amplifier using a lower force.

To determine whether the clipping is being caused by the transducer or the amplifier, apply

a series of intermediate forces and record the tension signal.

interchanging the white and black

Table F Troubleshooting Guidelines

PAGE 40 OF 42

MAN-70434-0 REV AA ULTRA ISC SERIES SLIM CELL TRANSDUCER

5.1 TRANSDUCER BENCH TESTING

Because the strain gage signal conditioning is completely internal to the transducer, it is impractical

to directly measure the resistance of the stain gage elements. This complicates the task of bench

testing.

However, there are measurable indications of the potential functionality.

1. Measure the DC load current powering the ISC. An in-line Digital Multi-meter (DMM) set up

to measure DC milliamps can be used. With a 24 VDC supply applied, the current into PIN 1

of the M12 connector should be between 25 and 45 milliamps. If no discernable current is

observed, check the applied polarity (the voltage to the ISC could be reverse, and the internal

polarity protection diode could be blocking current flow). Also check that the DMM is set for

DC and not AC milliamps.

2. If the current is reasonable, check the transducer output voltage for zero. Set the DMM back

to measuring voltage and amplified output voltage at PIN 2 with respect to PIN 4. With no

force being applied to the transducer, the voltage should be within part of a volt of ground.

For an un-mounted cartridge style transducer, the ideal “no force” condition can be

accomplished by orienting the loadcell so that the roll journal bore faces “skyward”. If the

transducer is still machine mounted, and there is a roll mounted, the dead-weight of the roll

can be negated by slightly loosening the mounting to allow the loadcell body to be rotated so

that the axis of loadcell force sensing is parallel to the ground. With heavy rolls, exercise care

before loosening any mounting so that an unsafe condition does not resu lt.

3. If the transducer is of limited M.W.F. , it should be possible to apply forces by hand and

observe ( in a qualitative way ) the amplified output swing to different positive and negative

voltages.

If the transducer has a high M.W.F. capacity, the full amount of force may not by readily

applied “by hand”, and the following approach can be used to observe the capab ility of the

analog output stage.

It is generally not advisable to needlessly alter the factory calibration of the loadcell, but if

necessary, the ZERO potentiometer setting can be used as a way to temporarily drive the

transducer output to arbitrary positive and negative voltag es to prov e that the output stage of

the transducer is operational.

After changing the ZERO potentiometer, return it to the desired output voltage with no force

applied.

4. Because the ISC is a true analog design, there is no “quantization” of the analog signal and

the output has (theoretically) infinite resolution. It is therefore possible that high MWF

transducers can be checked with a DMM set to the millivolt scale and series of relatively

small test forces applied with either masses or a hardware store variety “fish scale”. For

example, a 1000 lb transducer should have a calibrated slope of 1.6 oz / mV. With just a

handful of appropriately weighted items (quantified using a shipping scale) it is possible to

conduct a crude test of a transducer to verify that it exhibits an essentially rational transfer

function.

5. Using a DMM set to measure high resistances, test between the M12-3 and M12-4 pins to

verify that the 24 VDC supply is galvanically isolated from the analog signal conditio ning

stage as evidenced by a resistance above 20 Mohm.

6. As a final electrical test, a DMM should be used to check the resistance between each of the

M12 connector pins and the metallic case of the transducer. No pins should have less than 20

meg-Ohm (this is a typical measurement limit of most Multimeters). DO NOT use a high

voltage insulation tester (i.e. “megger”) to test for the high resistance, as this can cause

damage to the internal circuitry. Exercise care that ungloved fingers do not simultaneously

contact the two meter probes, or the resistance measurement will be falsely low due to the

conductance of human skin.

PAGE 41 OF 42

ULTRA ISC SERIES SLIM CELL TRANSDUCER MAN-70434-0 REV AA

6 MANUFACTURERS DECLARATION OF CONFORMITY

Figure 13 EC Declaration of Conformity

P

AGE 42 OF 42

Loading...

Loading...