Page 1

QUANTUM

USER MANUAL

Cleveland Motion Controls

MAN-70421

Page 2

www.cmccontrols.com

Congratulations on your Cleveland Motion

Controls Quantum digital controller!

You have just acquired the most user friendly

and powerful digital controller in its

category.

This user manual has been designed to give

you all the information you need for

installation and commissioning.

CONTENTS

Dimensions - Mounting 3

Basic wiring 4

Setting up - Overview 4

Typical application examples 5

Wiring for l or z transducers - Classic or Ultra 9

Keyboard basics 10

Full programming principles with front face keyboard 11

PC software - Installation and Use 13

Parameter Setup; Menu Selection; Digital I/0; Help notes: 14

-1.0 Parameters

-2.0 Menu Inputs

-3.0 Menu Display

-4.0 Menu Functions

-5.0 Menu PID

-6.0 Menu Outputs

-7.0 Digital Inputs

-8.0 Data Capture

2

TENSION CONTROL

Page 3

3

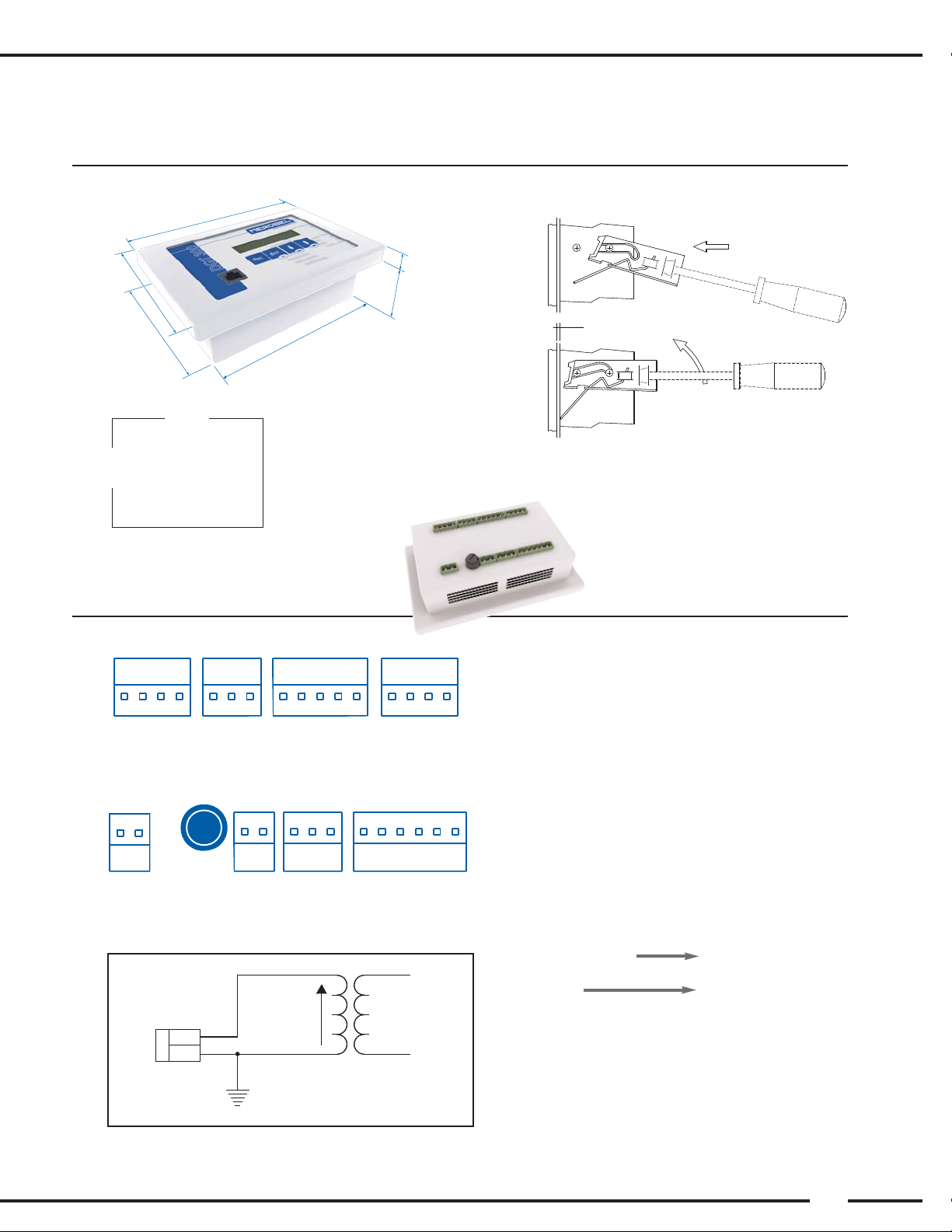

DIMENSIONS - FIXING

166

111

152

38

100

4

Front panel

cutout

156

101

1 - 5 mm

analog

outputs

set

point

tacho /

diameter

measurements

supply

output

control

alarms

logic

inputs

ComCom

A01 A01

ComCom

A02 A02

ComCom

SetPSetP

+10V+10V

ComCom

TCTC

ComCom

DMDM

+24V +24V

S1-

ComCom

S1+

+5V

+5V

ComCom

+24+24

C1C1

C2C2

ALAL-

AL1AL1

AL2AL2

V+V+

A

B

V+

V+

initinit

RegReg

F

Com : 0 V

A01 : analog output control 1 (-10 to +10 V)

A02 : analog output control 2 (-10 to +10 V)

SetP : set point input (0 to 10V, or potentiometer)

+10V : potentiometer supply

TC : tachometer input (0 to 10 V)

DM : diameter input

+24V : Ultrasonic sensor supply

S1- : Signal (-)

S1+ : Signal (+)

+5V : load cell or sensor supply

+24 : supply (24 V AC or DC)

C1-C2 : PWM output (brakes direct supply) 1.5 Amp max.

AL- : ouptut logic reference

AL1 : logic output 1

AL2 : logic output 2

V+ : logic input voltage remote control

A : logic input 1

B : logic input 2

init : INIT

reg : REG

process configuration

regulator configuration

BASIC WIRING

Note :

When grounding the secondary of the transformer, please

refer to the opposite sketch.

All Com / 0V are linked to the ground

Supply

Com

+24

Secondary

Primary

fuse

3.15A T

Page 4

www.cmccontrols.com

4

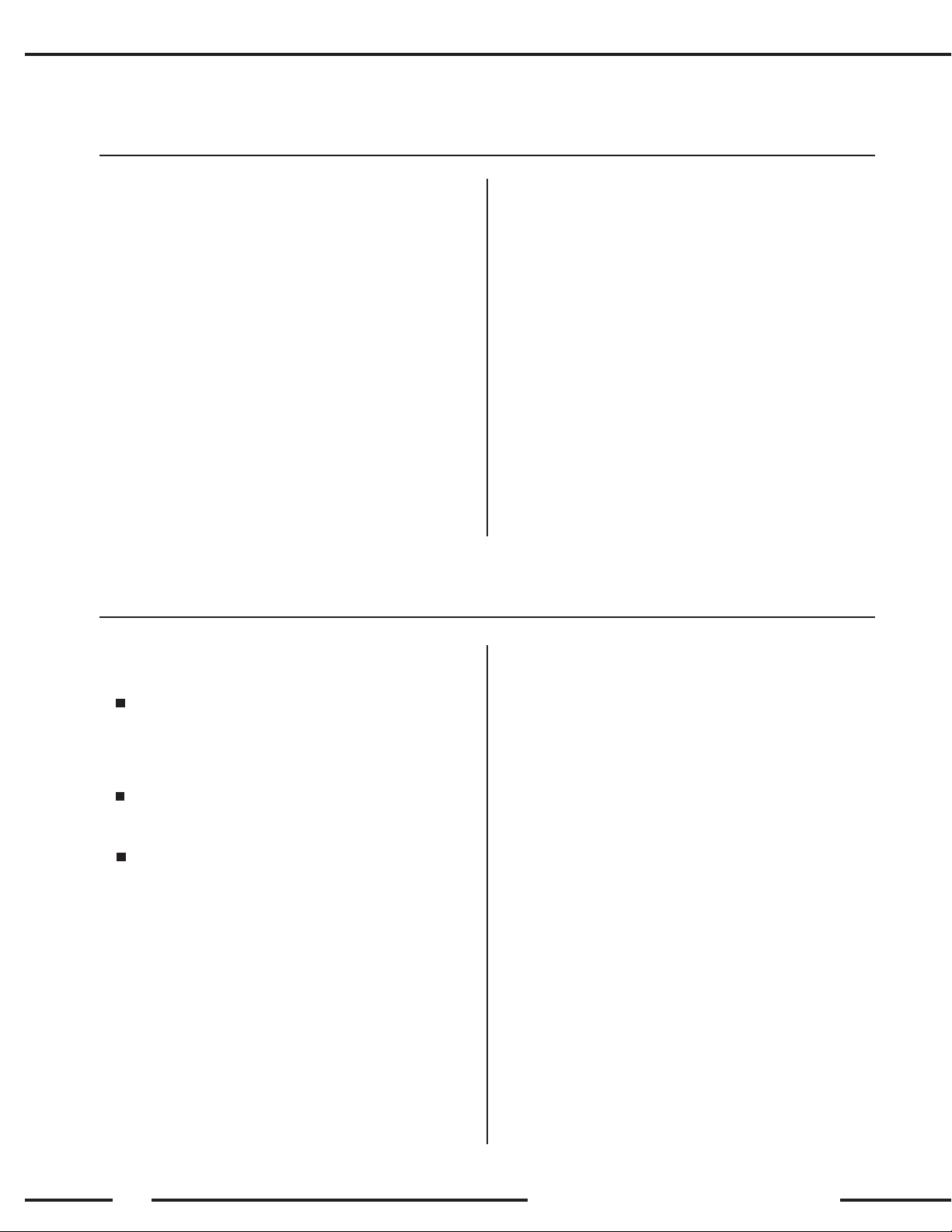

SETTING UP

Keypad : Follow -> Input > Measure > ... (load cells)

Follow -> Input > Diameter > ... (US

sensor)

2 - Set point value

Open loop: enter a percentage of the full scale

Closed loop: enter directly the target value

Note: The Set Point value can be adjusted at any

time from the front panel keypad

3 - Input/Output definition

Software: See -> Input and Output Menus and

enter the data fields related to the

chosen application

Keypad: Enter the parameters shown on the table

4 - Dynamic parameters (regulation and stability)

Software: See -> Regulation Menu and enter the

data fields related to the chosen

application

Keypad: Enter the parameters shown on the table

OVERVIEW

Fully compatible with

Any current load cell technologies

One or two, half or full bridge load cells

US sensors (direct input available)

Built-in PWM Power Supply

Up to 1.5 Amp available as PWM output voltage

No need for external power supply with EMAG Brakes

All details about these advanced features are

fully available in the Help file included with the

PC software supplied with the unit.

User friendly

Selectable language (En / Fr / Ge / It)

Selectable Metric or Imperial units

HOLD and RELEASE on front panel keyboard

Advanced regulation capabilities

Automatic P.I.D. parameters variation function

Closed loop + open loop mode

Inertia compensation control

Smooth start-up with programmable slope

E-stop torque proportional to the set point

Adjustable tapper function available

No-Stop web turrets management function

Five complete built-in memories

Motors & Drives specific settings available

PC software sett-up and debugging

Unlimited configuration records by software

Real time full control panel available

Unlimited real time data record by software

Two different ways are offered for system set-up of

your QUANTUM:

Using the exclusive user friendly set-up software

(QUANTUMsoft on a computer.)

Choose the required type of application, fill in

the datafields with your own data, and upload

the file to the QUANTUM.

At any point in the set-up you can click on help

in the toolbar, which gives you more details

about the procedure.

Using the front face keypad when there is no

computer available (password requested, see

p10).

The procedure is based on the “Initial set of

parameters” related to each type of application

(on pages 5-8). Enter the data as per the drawing

on p10.

System set up procedure to be followed

1 - Sensor(s) calibration

Follow the automatic calibration procedure

Software : Download the related “.prm” file

See -> Input Menu in the

QUANTUMsoft and enter the data

fields related to the chosen

application

Page 5

5

TYPICAL APPLICATION EXAMPLES

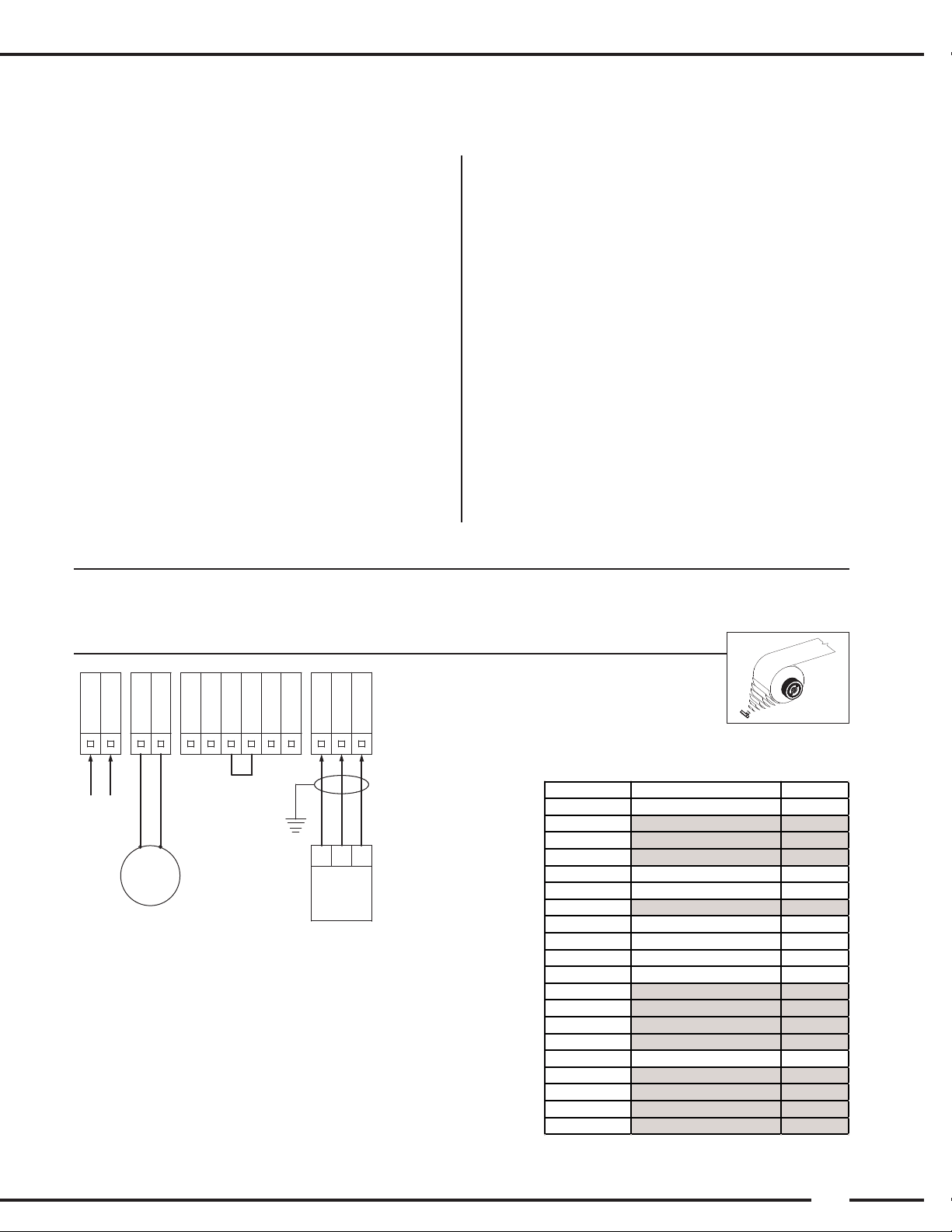

WIRING UNWIND WITH EMAG BRAKE AND ULTRASONIC SENSOR

OPEN LOOP

Initial set of parameters

File : Diameter_measurement.prm

DISPLAY Line 1 Set Point

Line 2 Diameter

FUNCTIONS Time Delay Start

Time Delay Stop

Hold

INPUTS Set Point 50

Diameter Filtering 1000

Tachymeter Filtering

OUTPUTS Upper Limit 0

Bottom Limit 10

Power Gain 100

REGULATION Max Effort 100

PID

Measurement Filtering

Open Loop Gain 100

Closed Loop Gain

Speed Gain

Coeff Speed

Overspeed

Note : all Com / 0V are linked to the ground

Troubleshooting

Check: All wiring, in particular ensure cable

shields are properly connected

Ensure the parameter settings are in

full accordance with the related

applications tables

Stability: When necessary adjust the parameters

(*) to improve the system stability

Note: Variable PID (coefficients are

proportional to the diameter) is also

available when system stability cannot

be obtained (diameter measurement

must be available).

Detailed features about the Variable

PID are fully available in the Help file

included to the PC software

CAUTION: Ensure the required “Process” (link

to the machine automation) is

active before starting the system

(logic input B)

Reg

Com

+24 V

AC / DC

EMAG

Brake

V+

A

Jumper

C2

C1

+24

Init

V+

B

Com

Yellow

Blue

Bleu

S

-

NR7

Ultrasonic

Sensor

DM

Jaune

+24

Brown

+

Brun

Page 6

www.cmccontrols.com

6

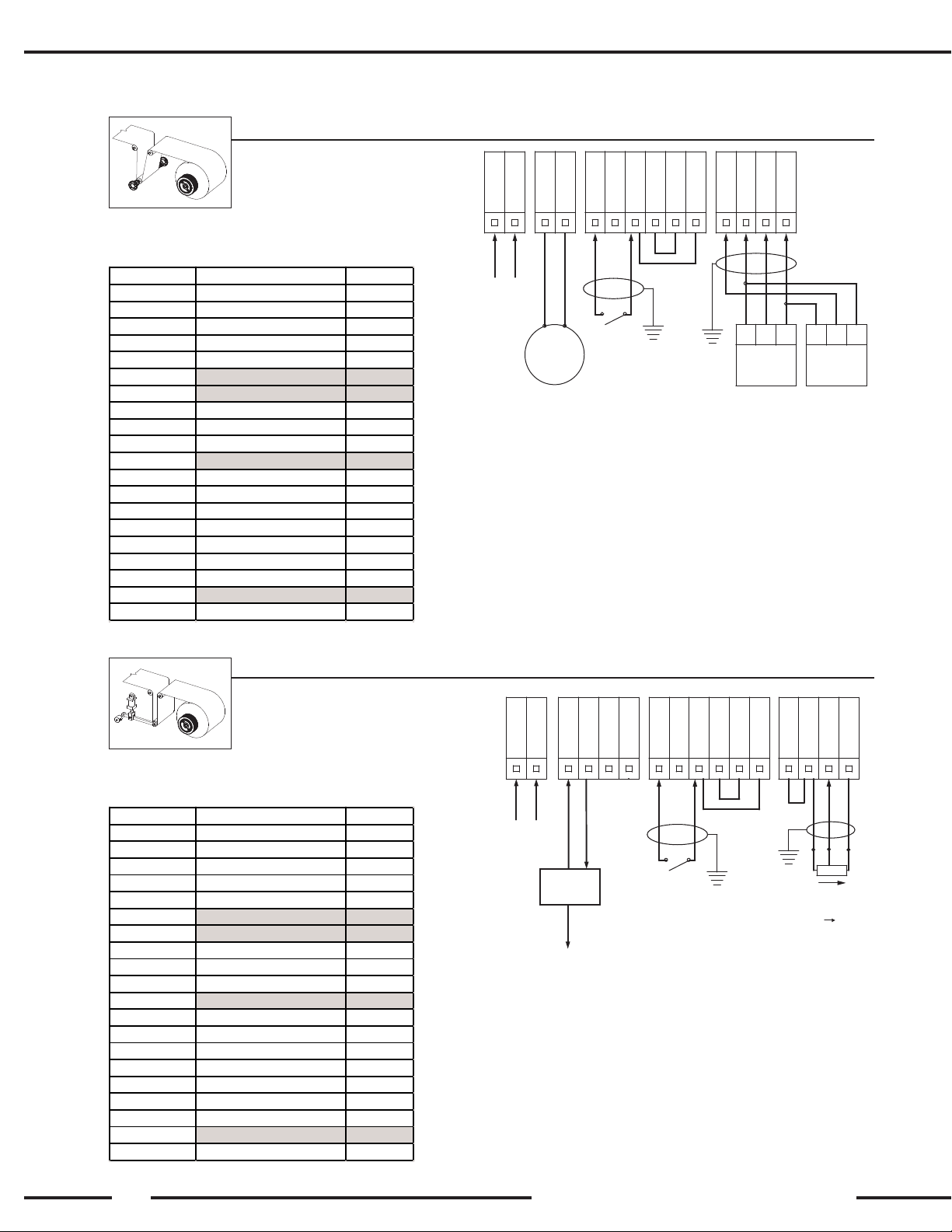

Initial set of parameters

File : Dancer.prm

Machine / product stopped : B = 0V (OPEN)

Web Tension = HOLD value (Open Loop)

Machine / product running : B = 24V (CLOSED)

Web Tension = SET POINT value (Closed Loop)

Process

Machine / product stopped : B = 0V (OPEN)

Web Tension = HOLD value (Open Loop)

Machine / product running : B = 24V (CLOSED)

Web Tension = SET POINT value (Closed Loop)

Process

Wiring

Note : all Com / 0V are linked to the ground

Note : all Com / 0V are linked to the ground

Initial set of parameters

File : Force_feedback.prm

Wiring

DISPLAY Line 1 Set Point

Line 2 Measure

FUNCTIONS Time Delay Start 1

Time Delay Stop 300

Hold 10

INPUTS Set Point 50

Diameter Filtering

Tachymeter Filtering

OUTPUTS Upper Limit 0

Bottom Limit 10

Power Gain 100

REGULATION Max Effort

P 100 (*)

I 20 (*)

D 0

Measurement Filtering 100 (*)

Open Loop Gain 0

Closed Loop Gain 100

Speed Gain 0

Coeff Speed

Overspeed 0

DISPLAY Line 1 Set Point

Line 2 Measure

FUNCTIONS Time Delay Start 1

Time Delay Stop 300

Hold 100

INPUTS Set Point 50

Diameter Filtering

Tachymeter Filtering

OUTPUTS Upper Limit 0

Bottom Limit 10

Power Gain 100

REGULATION Max Effort

P 100 (*)

I 5 (*)

D 100 (*)

Measurement Filtering 5

Open Loop Gain 0

Closed Loop Gain 100

Speed Gain 0

Coeff Speed

Overspeed 0

UNWIND WITH DANCER AND EMAG BRAKE

CLOSED LOOP

UNWIND WITH LOAD CELLS AND EMAG BRAKE

CLOSED LOOP

*

Other load

cells

configuratios,

see page 9

Com

+24

C1

C2

V+

+5V

S1+

Com

S1-

Reg

Init

V+

B

A

+24 V

AC / DC

EMAG

Brake

Logic

input B

Jumpers

N.O.

WH

BK

Load cell

Classic

R

WH

BK

Load cell

Classic

R

Reg

Com

+24 V

AC / DC

+24

E/P

Transducer

Air Brake

Com

AO1

Com

AO2

V+

Logic

input B

N.O.

A

Init

V+

B

Jumpers

Com

S1-

Position

Potentiometer

4.5 10 kΩ

S1+

+5V

Page 7

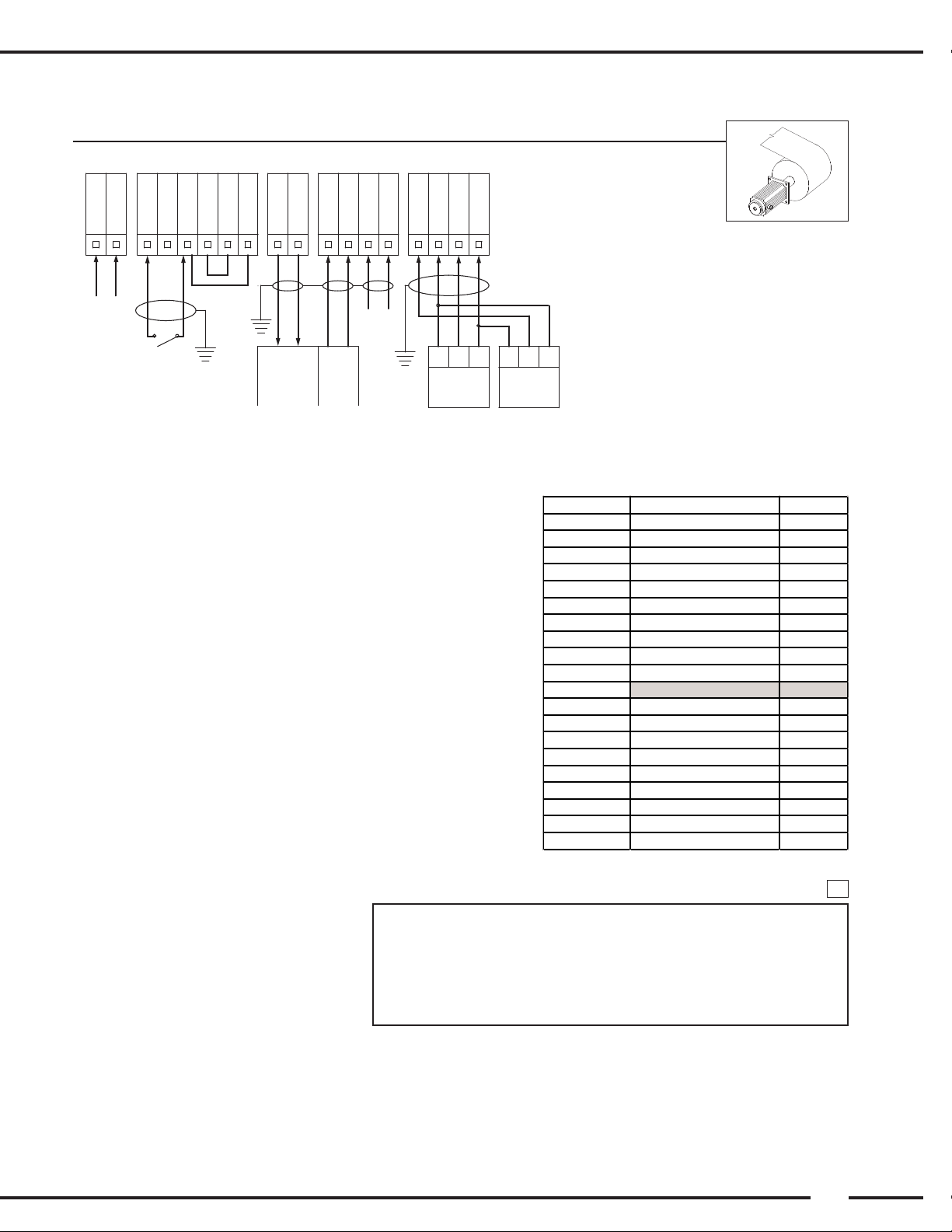

7

Machine / product stopped : B = 0V (OPEN)

Web Tension = HOLD value (Open Loop)

Machine / product running : B = 24V (CLOSED)

Web Tension = SET POINT value (Closed Loop)

Process

Regulation Speed Gain = (D

min

x V

l

) / V

r

D

min

[m] Min web diameter

Vl[m/min] Linear speed for 10V output from tachometer

Vr[RPM] Max speed of the drive motor

(when set point output =10 V on AO1)

1

Wiring

UNWIND WITH MOTOR AND LOAD CELLS

CLOSED LOOP

Initial set of parameters

File : Force_motor.prm

DISPLAY Line 1 Set Point

Line 2 Measure

FUNCTIONS Time Delay Start 1

Time Delay Stop 300

Hold 10

INPUTS Set Point 100

Diameter Filtering 1000

Tachymeter Filtering 100

OUTPUTS Upper Limit 0

Bottom Limit 10

Power Gain 100

REGULATION Max Effort

P 10 (*)

I 5 (*)

D 0

Measurement Filtering 100 (*)

Open Loop Gain 0

Closed Loop Gain 100

Speed Gain Calcul 1

Coeff Speed 100

Overspeed 0

Note : all Com / 0V are linked to the ground

Com

+24

V+

DM

A

Com

AO1

Reg

Init

V+

B

Com

TC

Com

S1-

Com

S1+

+5V

N.O.

Jumpers

Drive

Output

-10 - +10V

Web

rotation

Tachometer

0 - 10V

+24 V

AC / DC

Logic

input B

Diam.

Input

0 - 10V

WH

BK

Load cell

Classic

BK

WH

Load cell

Classic

R

R

Page 8

www.cmccontrols.com

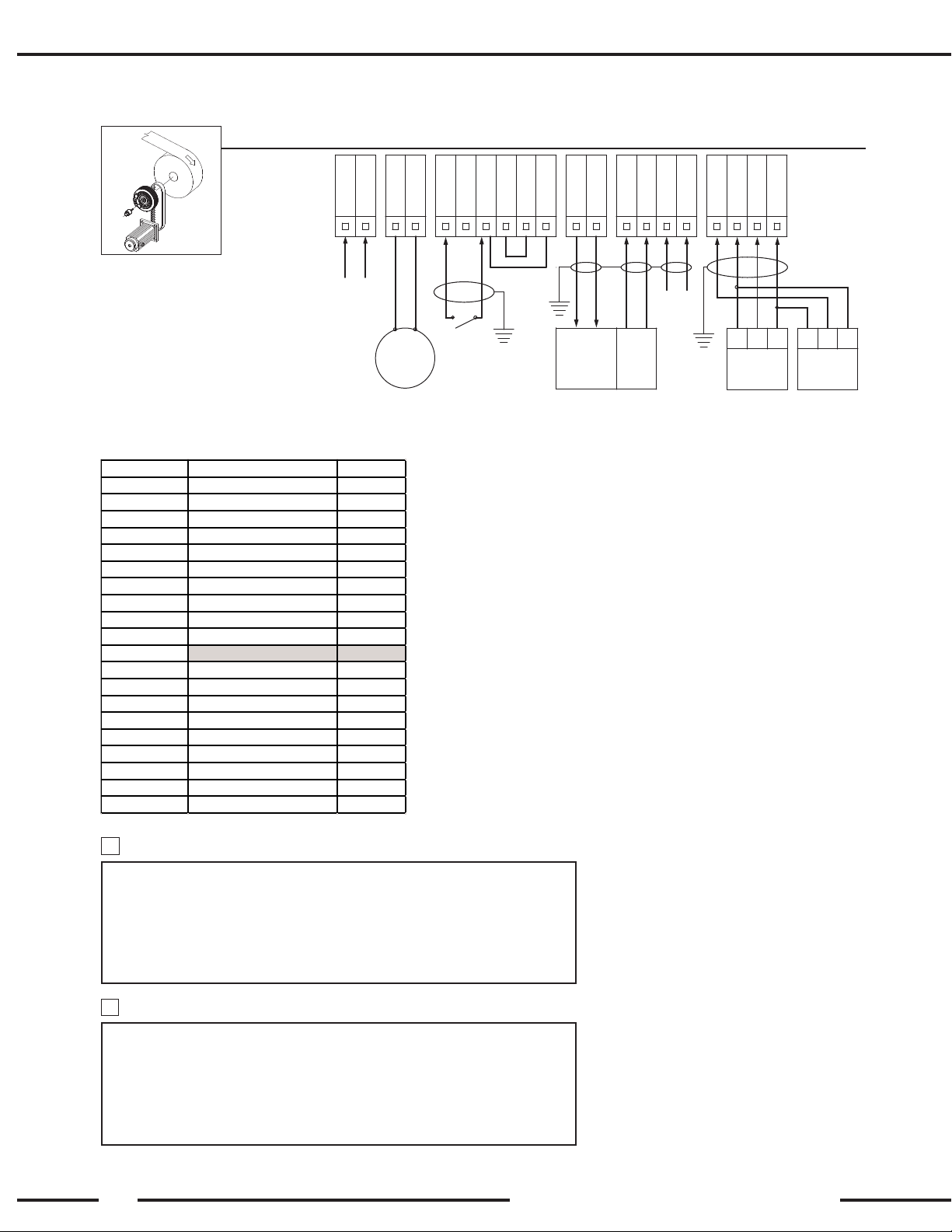

8

Machine / product stopped : B = 0V (OPEN)

Web Tension = HOLD value (Open Loop)

Machine / product running : B = 24V (CLOSED)

Web Tension = SET POINT value (Closed Loop)

Process

Wiring

REWIND WITH LOAD CELL + CLUTCH/MOTOR

CLOSED

LOOP

Initial set of parameters

File : Force_clutch_motor.prm

DISPLAY Line 1 Set Point

Line 2 Measure

FUNCTIONS Time Delay Start 1

Time Delay Stop 300

Hold 10

INPUTS Set Point 100

Diameter Filtering 1000

Tachymeter Filtering 100

OUTPUTS Upper Limit 0

Bottom Limit 10

Power Gain 100

REGULATION Max Effort

P 100 (*)

I 20 (*)

D 0

Measurement Filtering 100 (*)

Open Loop Gain 0

Closed Loop Gain 100

Speed Gain Calcul 1

Coeff Speed 0

Overspeed Calcul 2

Regulation Speed Gain = (D

min

x V

l

) / V

r

D

min

[m] Min web diameter

Vl[m/min] Linear speed for 10V output from tachometer

Vr[RPM] Max speed of the drive motor

(when set point output =10 V on AO2)

1

Overspeed = (S

s

x AO2

max

) / V

r

S

s

[RPM] Slipping speed (60 RPM recommended)

AO2

max

[V] Max output from AO2 : 10 V

V

r

[RPM] Max speed of the drive motor

(when set point output =10 V on AO2)

2

DM

Com

+24

C1

C2

V+

A

Com

AO2

Reg

Init

V+

B

Com

TC

Com

S1-

Com

S1+

+5V

+24 V

AC / DC

EMAG

Brake

Logic

input B

N.O.

Jumpers

Diam.

Input

Drive

Output

-10 - +10V

Web

rotation

Tachometer

0 - 10V

0 - 10V

BK

Load cell

Classic

WH

R

WH

BK

Load cell

Classic

R

Page 9

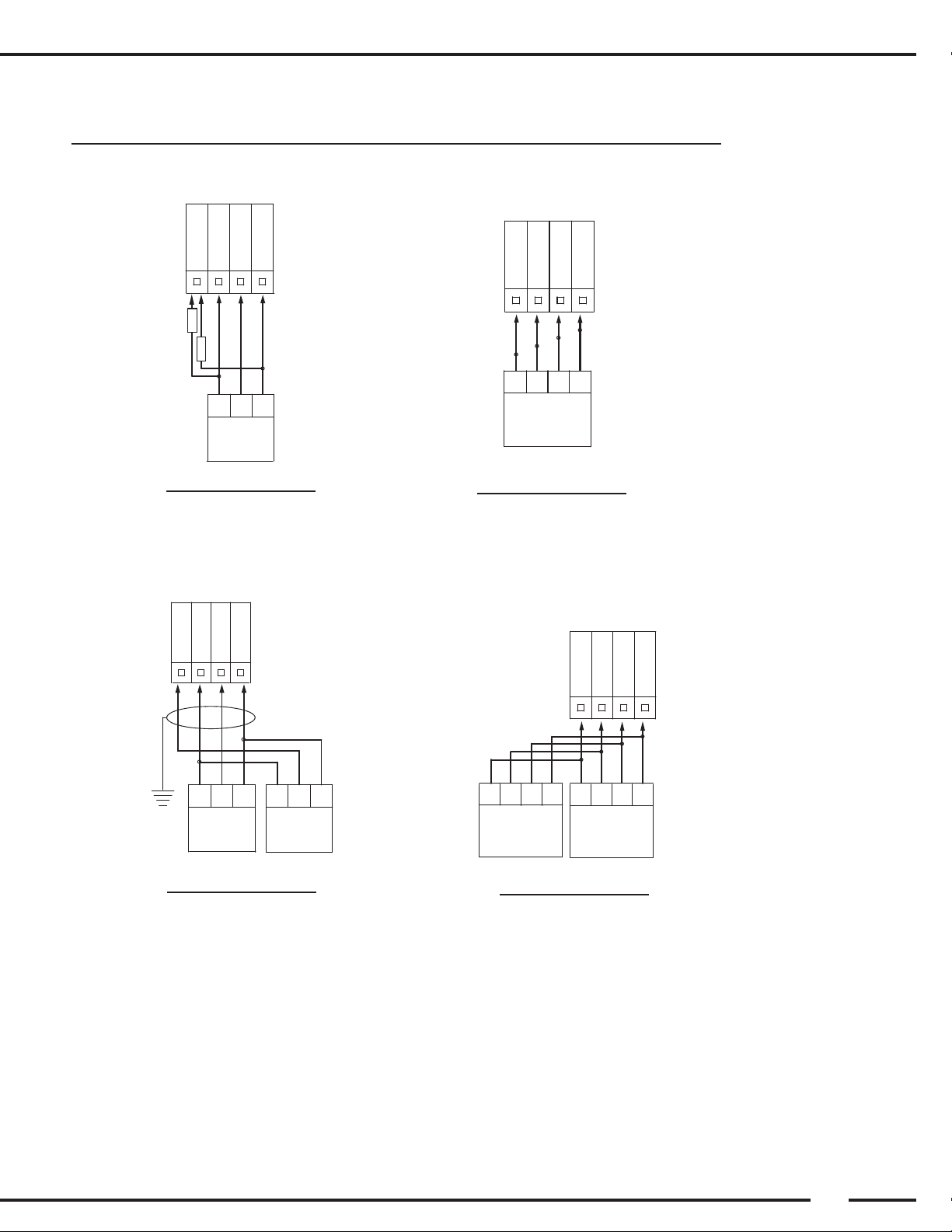

OTHER LOAD CELL CONFIGURATIONS

Wiring

One Load Cell

Half-Bridge

Classic - Series

Two Load Cells

Half-Bridge

Classic - Series

One Load Cell

Full-Bridge

Ultra- Series

Two Load Cells

Full-Bridge

Classic - Series

9

10 kΩ

S1-

Com

S1+

+5V

+5V

S1+

Com

S1-

10 kΩ

R

WH

BK

Load cell

Classic

+5V

S1+

Com

S1-

R

WH

BK

Load cell

Classic

WH

BK

Load cell

Classic

WH

-

Full bridge

Load cell

BLU

0

Ultra

BLK

+

BRN

V

+5V

S1+

Com

S1-

BLK

R

WH

-

Full bridge

Load cell

BLU

0

Ultra

BRN

+

V

WH

BLU

0

-

Full bridge

Load cell

Ultra

BLK

+

BRN

V

Page 10

10

Ent

Ent

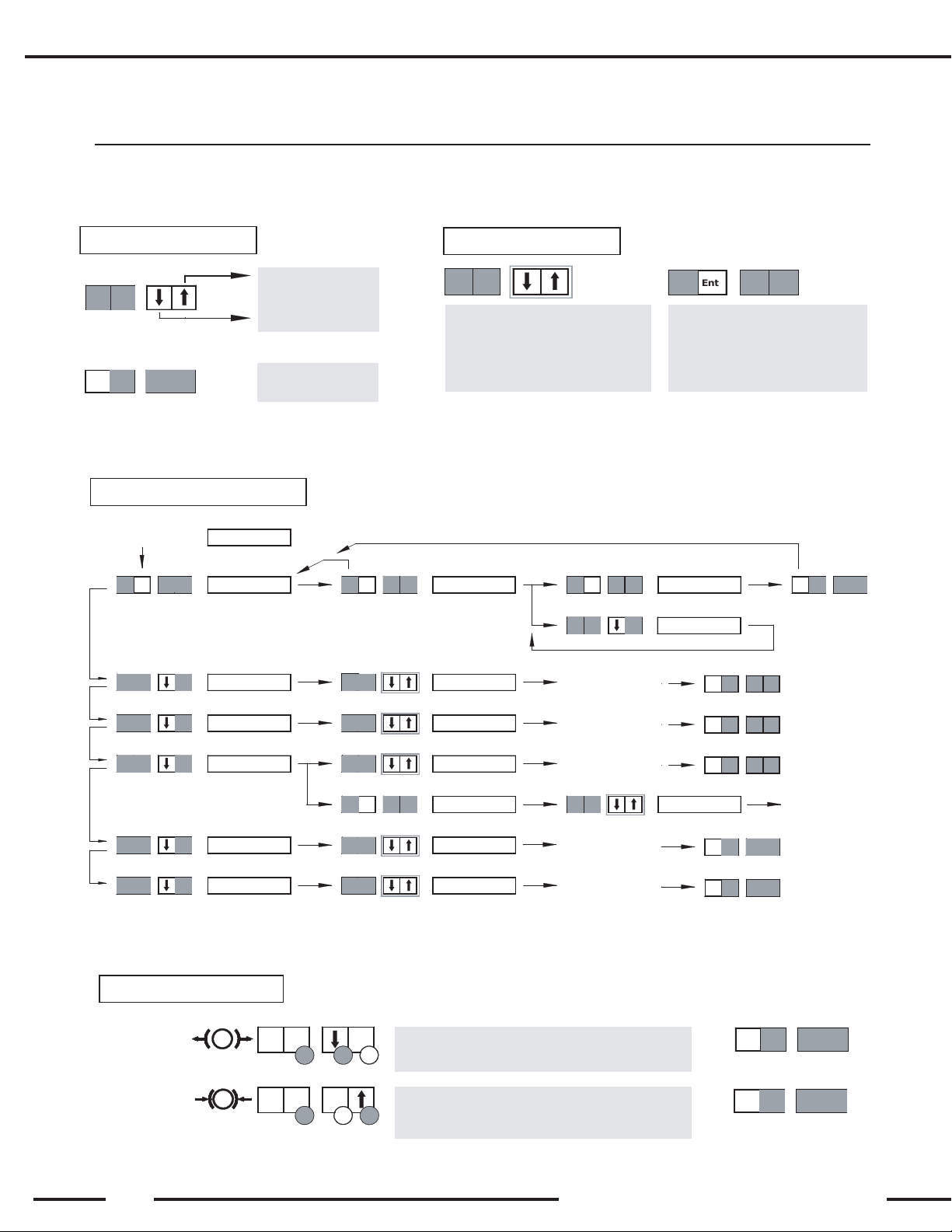

1– SET POINT Setting

4– System General Settings

2–Variable Setting

Hold for increase

Hold for decrease

Ent

•

Press both buttons simultaneously

to enter the Data field (visible

underscore)

• Press once to increase/decrease

one digit

• Press to validate each digit

• Last digit validation sends the

complete value to the system

(underscore disapears)

3– Additional functions

Press both buttons simultaneously to release the

system (Output = 0)

Press both buttons simultaneously to block the

system (Output = Max)

This value may be adjusted (see « SET POINT settings »)

Esc

Escape from releasing

Esc

Escape from Hold

Releasing Mode

Hold Mode

Esc

Escape from

Setting mode

MOTOR DIRECTION

- -> + / + -> -

MOTOR DIRECTION

- -> +

WIDTH COEFF

0 0 0

1 0 0

TAPER COEFF

0 0 0 , 0

HOLD

WIDTH COEFF

Ent

0 0 0

TAPER DIAM.

0 0 , 0 0 0

TAPER COEFF

1 0 0

0 0 0 , 0

_

HOLD

Initial readout

Ent

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - -

RECALL MEMORY

Ent

M1

Variable setting

Esc

Variable setting

Variable setting

Variable setting

TAPER DIAM.

0 0 , 0 0 0

Esc

Esc

Esc

Variable

setting

Ent

M2 ... / ... M3 , M4, M5

MEMORY READ

Esc

0 0 0 , 0

DISPLAY FILTER

0 0 0 , 0

DISPLAY FILTER

Variable setting

Esc

KEYPAD BASICS

www.cmccontrols.com

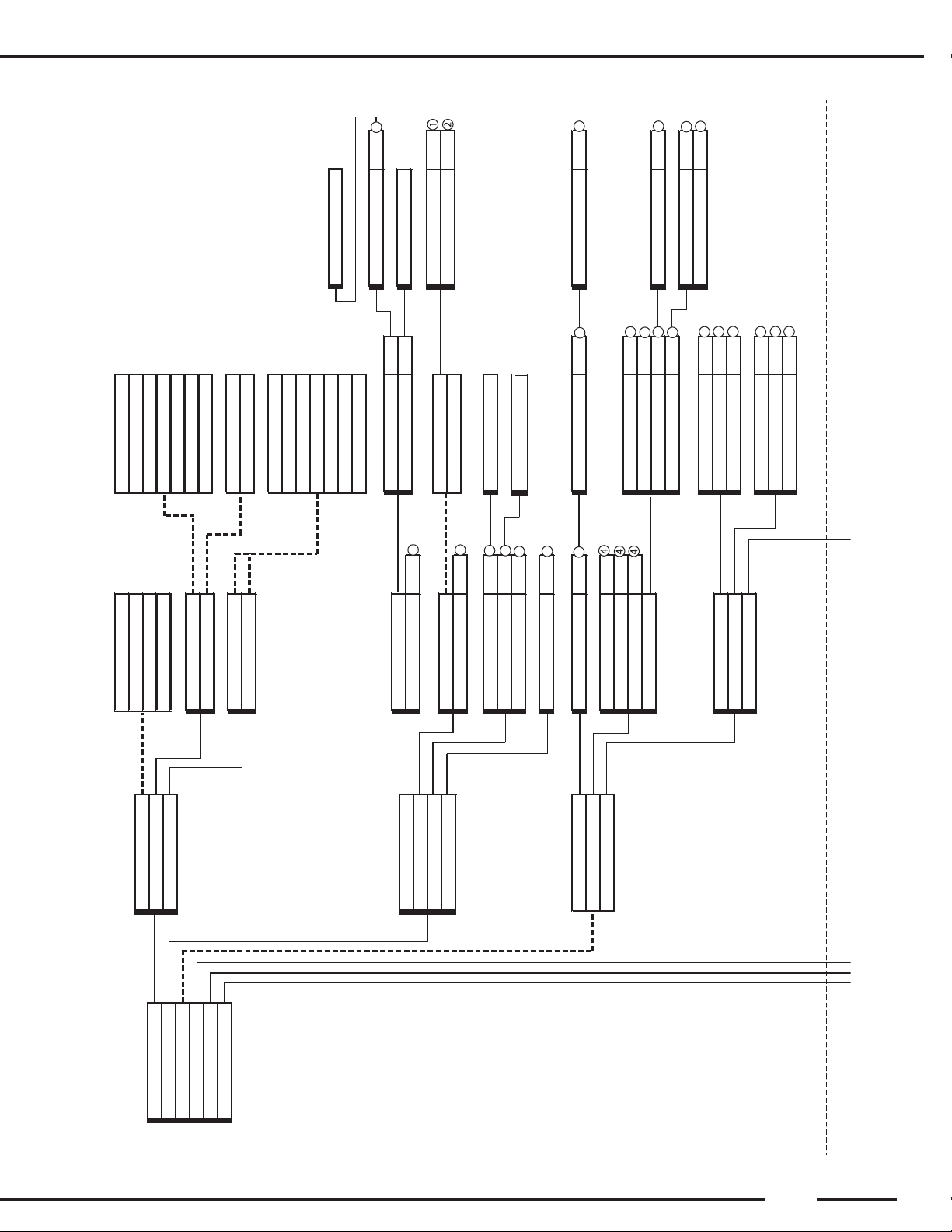

Page 11

display

language

french N

inputs

units

english kg

regulation type

display config.

italiano lb

functions

deutsch Nm

outputs

PLI

memories

measure

Ftlb

diameter%line 1mline 2

in

AO1 output

AO2 output

set point

diameter

measure

AO1 config

AO2 config

measure

calibration

upper level val.

100.0

full scale %

100.0

set point

filtering

0

bottom level val

0.0

diameter

validate

tachymeter

internal

set point value

0.0

set point option

external 0-10V

slope duration

1

filtering0Dmax value

0.1

validate

Dmin value

0.01

filtering0filtering

0

open loop max. effort

1

inertia gain

0.0

web width coeff.

100

basic PID

variable PID P (proportional)

0

I (Integral)0D (derivative)0loop coeff

OL coeff.

0

CL coeff.

100

inertia gain

0.0

web width coeff.

100

speed gain

0.000

coeff speed0overspeed

0.0

max Diam. coeff.

P (proportional)

0

min Diam. coeff.

I (Integral)

0

loop coeff.

D (derivative)

0

p (proportional)

0

i (Integral)0d (derivative)

0

validate

validate

display

inputs

regulation type

7

7

7

7

7

7

7

7

7

7

5

8

9

9

9

3

3

3

3

3

3

3

3

11

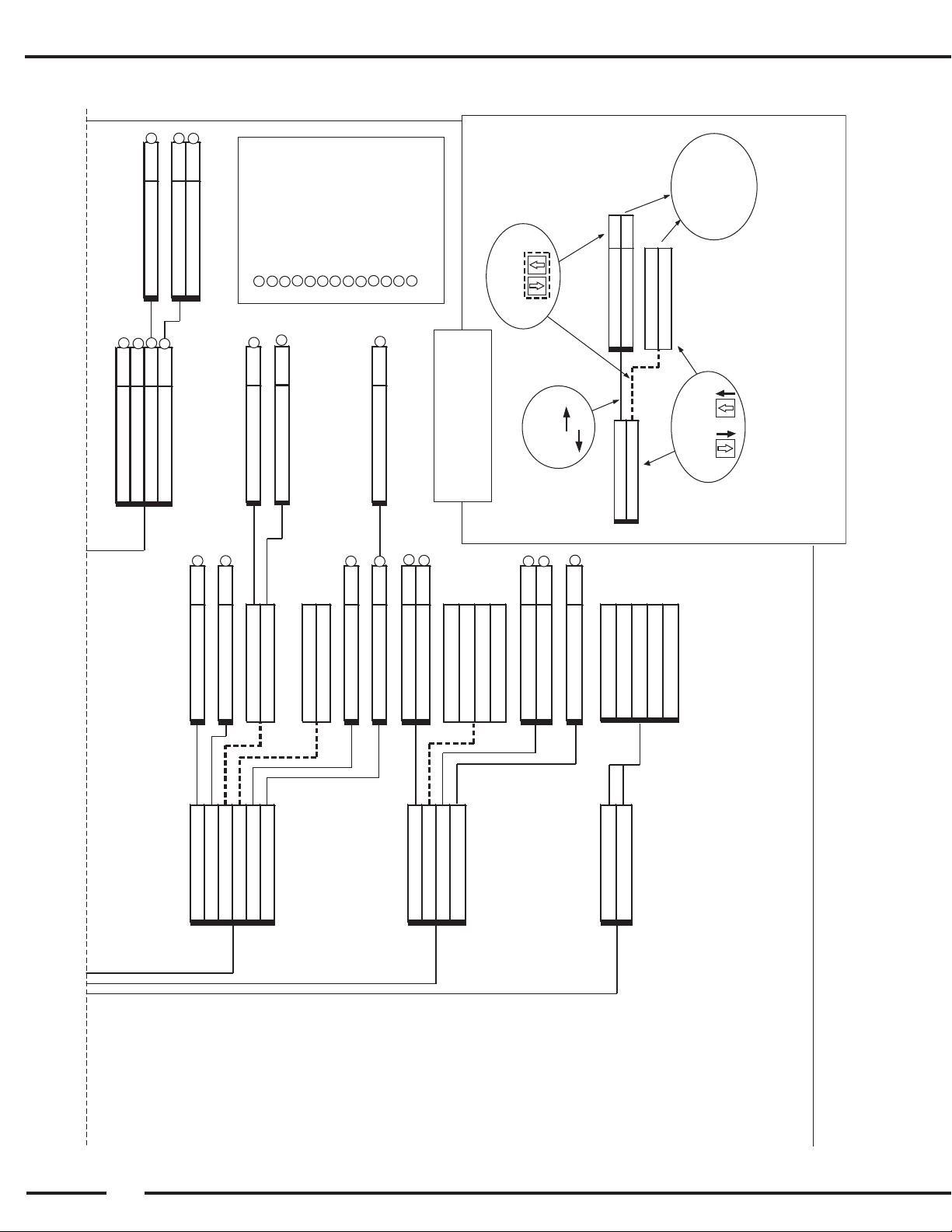

Page 12

www.cmccontrols.com

time delay start duration (* 10ms)

1

time delay stop

E-stop option duration (* 10ms)

1

no-stop

hold fixed fixed0taper

proportional

enable

disable

hold0taper (%)

0

taper diameter

0.01

thresholds

upper limit

10.0

AO2 readout

bottom limit

0.0

logical outputs

power output

set point

measure

diameter

rotation speed

AL1 : error range

100

AL2 : Diam. limit

0

gain

1

save M1

call M2

M3M4M5

proportional

100

functions

outputs

memories

thresholds

upper limit

10.0

AO2 readout

bottom limit

0.0

set point

measure

Ent

Esc

Choice in

a list

Entering in

data selection

Choice or

parameter

validation

Ent

QUANTUM

Set-up using Keypad

1 Between 0 and max. effort

2 1 unit. = 10 ms

3 000 --> 100

4 000 --> 100 (valeur entière)

5 00 --> 10 (V )

6 0.01 --> 1.00

7 0000 --> 9999

8 0001 --> 9999

9 0.010 --> 99.000

OL coeff.

0

CL coeff.

100

inertia gain

0

web width coeff.

100

speed gain

0

coeff speed0overspeed

0.0

10 001 --> 999

11 100 --> 500

12 -10.0 --> +10.0

13 001 --> 100

5

8

9

10

13

3

3

3

12

12

11

9

3

3

3

3

3

3

3

Menu

Exploration

PASSWORD :

Esc , Ent , Esc , Ent , Esc

(in less than 2 s)

12

Page 13

13

PC SOFTWARE - INSTALLATION AND USE

The CD-Rom delivered with your box contains a PC software dedicated to the QUANTUM, called

QUANTUMsoft.

Launch the “Setup” file to automatically install the software on your PC in:

“C:\ProgramFiles\cmc\quantum\”

During the installation process, a shortcut is automatically created in Run\Programs

The application is launched by a double click on the icon.

To open a pre-set application parameter file, two possibilities are offered:

- click on the thumb index in 'parameter' then 'new' and choose the application type which is

appropriate to you.

- click on 'File' then 'open parameters files…'and under C:\ProgramFiles\merobel\DGT3Soft, open

the file .prm related to your application.

- for direct access to the related help, click the right mouse button.

If you meet problems when installing the QUANTUMsoft on your computer, ensure the

following points:

- the operating system is Windows XP.

- In the event of defect of COM during the launching of the application, make sure that the

cable is properly connected to the COM1 of the PC.

If COM1 is not available, configure the application to work on an alternative port (ex. COM2),

according to following instructions :

. create a shortcut on the desktop for the QUANTUMSoft.exe application.

. click in the properties of the shortcut (right click on the shortcut icon).

. in the thumb index shortcut, write in the target after the access path - com2

(ex. : "C:\Program Files\Program Files\cmc\QUANTUM\quantum.exe" - com2 ).

Page 14

NOTES

www.cmccontrols.com

14

Page 15

15

1.0

Parameter

1.1 Communicate parameters to regulator

Save or load a set of parameters on the PC

To save a set of parameters, click in the thumb index 'file' then choose 'save as…' for recording

in a new file (file..PRM.), or 'recording' to record the set of parameters in the file in progress.

To open a set of parameters, click in menu 'file', then choose 'open…'. The set of parameters

will automatically load in the right interface.

The banks of memories of the regulator

There are five internal memories M1 to M5 in the QUANTUM. The memory in progress is

selected by the front panel.

Read the parameters of the regulator

PC software can read these 5 memory banks by clicking on 'read parameter' or in the thumb

index 'regulator' then 'read from regulator' and select the memory.

Send the parameters to the regulator

-To send a set of parameters, you can use the menu 'Regulator,' then 'send to regulator.' Then

select the memory bank in which you want to record the parameters. There is a direct access to

the memories in the icon bar (button 1 to 5).

Page 16

www.cmccontrols.com

16

Parameter

1.2 Begin a new parameter setting

Choose the type of parameter setting

Before beginning a new parameter setting, you must select the application type:

Click in menu 'Parameter,' or in the thumb index 'Parameter' then 'New,' choose your application.

-Open loop

Tension control application by measurement of the diameter

Inertia compensation with analogical line speed information

-Closed loop

Tension control application by measurement of the tension or the torque.

Dancer application (control of the dancer roll position)

-Inertia compensation

Tension control application when inertia becomes dominating in the transitional phases.

-Motor command

Use for intermediate tension control or rewinding application with motor speed control

-Speed follower

Use for rewinding application with motorized clutch. The goal is to control the tension

with the clutch and to control the slipping speed in the clutch to undersize it

Each of these application types requires a different set of parameters, choose the category

corresponding to your use of the QUANTUM.

Modify the parameters

The parameters are divided into three or four menus (according to the application type). Click

on the button of one of these menus to modify the contents of it.

Once the parameter setting is finished, you can save it or send to the regulator.

Caution! If you do not save, the set of parameters will be lost when you close the interface.

Page 17

17

2.0

Menu INPUTS

2.1 Measure Menu

This menu appears when choosing closed loop, inertia correction,motor command or speed

follower. It allows calibration for any type of measurement, from a few mV to 10V.

Measure calibration

% full scale: Type in the percentage of full scale corresponding to the upper point used

during calibration (this percentage must be more than 20%).

Valid high level: Type in the value for the upper point.

Valid low level: Type in the value for the lower point.

Procedure:

Fill the 3 parameters and then click on the memory used. Then physically simulate the upper

point and click "valid high level," wait 5 seconds (yellow button), physically simulate the lower

point and click "valid low level," wait 5 seconds (yellow button); calibration is complete.

Page 18

www.cmccontrols.com

18

Menu INPUTS

2.2 Set Point Menu

Two types of set points are available

-Internal set point: type in the chosen value, it can be modified by the operator with the

arrows on the keyboard. A ramp can be used for soft start. The ramp is activated when the

switch Regulator is turned on.

-External 0-10V set point: Potentiometer or PLC connected to "set point" pin.

The set point unit is given in menu DISPLAY.

Open loop case:

In this case, the parameter Max Effort must be given. It corresponds to the max product

tension.

This parameter is used to calibrate the system since there is no measure.

Example: CMC Magnetic Particle Brake (EMAG 26)

Nominal torque = 35 Nm at 1 A.

Bobine max diameter = 1 m.

Max current in brake = 0.5 A.

1/ from the EMAG 26 torque vs current, we obtain 0.5A = 22.5Nm.

2/ Max Effort = 22.5Nm / 0.5m = 45N.

Max Effort = 45N (or 4.5kg).

Page 19

19

Menu INPUTS

2.3 Diameter Menu

Diameter calibration

With an analog diameter measure, the signal must be calibrated from physical values (upper point

= max diameter, lower point = min diameter).

Valid max diameter: Type in the max diameter value.

Valid min diameter: Type in the min diameter value.

The diameter unit is chosen in the DISPLAY menu.

Procedure: Fill the values and click on memory used, then physically simulate the max diameter

and click on the button "valid max diameter," wait 5 seconds and do the same with min

diameter and the button "valid min diameter."

Page 20

www.cmccontrols.com

20

Menu INPUTS

2.2 FILTERING

All the inputs can be filtered. Filtering makes the regulation less sensitive to electric and

mechanical disturbances but generates a delay in the system response time.

A few rules:

Measure : Filtering depends on the application and product.

Converting force from 100.

Converting force on elastic product from 400.

Dancer from 0.

Set point: Useful for external set point to filter the signal or simulate a ramp.

Diameter: It is recommended to use filtering on this signal because diameter is changing

slowly.

The recommended initial value is 100.

Tachymeter: Try to find a compromise between noise reduction and quick response. The

recommended initial value is 10

The QUANTUM uses a first order digital filter, the larger the number you give, the lower the cut

off frequency (Fc) will be and therefore the more filtering you will obtain.

Fc 18 20 22 25 29 34 40 50 70 110 150 240

numbers seize 51 45 40 35 30 25 20 15 10 5 3 1

Fc 1 2 3 4 5 6 7 8 9 10 12 15

numbers seized 1000 500 330 245 195 162 138 120 106 95 78 62

Page 21

21

3.0 Menu DISPLAY

3.1 Units / Display

The front panel is used to display measurement values as well as different data used by the

Controller. These two menus (Units / Display) have to be used to choose what will be displayed

on the two available16 digits lines.

Units

This menu is used to choose the units for the measurement and for the diameter values.

Display

This menu is used to choose what information will be displayed on the two lines. On each line

it is possible to choose between the following options :

Display AO1 (idem AO2): Shows the analogic voltage output on AO1 output (resp. AO2).

Set point / Diameter / Measure: Shows the actual Set point / Diameter / Measure, using the

chosen unit.

Shows AO1 status (idem AO2): Shows the logic inputs configuration viewed by the Controller

(according to A / B digital inputs state), meaning HOLD mode, REGUL mode, RELEASING mode,

Estop mode.

Page 22

www.cmccontrols.com

22

4.0 Menu FUNCTION

4.1 E-STOP function

Principle

The E-stop function could be used for the Emergency stop or for any other particular process.

Two different options are available: Fixed E-Stop value and Proportional E-Stop value. The last

one sends an output voltage related to the last current output (before switching to the HOLD

mode)

How does it work

Fixed HOLD value: by entering a value between 0 - 100% , a proportional value between 010V will be sent on the output (i.e. with 50%, 5V will be sent on AO1 output during the HOLD

mode).

Proportional HOLD value: input the gain value (100 - 500%).

The last calculated output value before switching to the HOLD mode will be multiplied by the

chosen gain (i.e. with an actual output value of 3 V (during the normal regulation), the

controller will send 9 V to the ouptut if the gain has been set to 300%.

Process

The E-stop mode is managed by the following digital inputs:

external switch A closed - external switch B closed

Page 23

23

Menu FUNCTION

4.2 Time Delay Menu

Principle

When the machine process management (motor start and stop) is not synchronized with the

controller logical inputs remote control (external switches Reg and B), some regulation troubles

can appear. The synchronizing problems can be solved with the time delay options available in

the Controller functions.

How it works

Starting time delay: Entering a time delay value (tens of milliseconds), means that the system

will wait for that delay before the controller starts the actual calculation (after switching Reg

from open to closed position).

Stopping time delay: Entering a time delay value (tens of milliseconds), means that the

system will wait for that delay before the controller stops the actual calculation (after switching

Reg from closed to open position).

The same effect will be applied on the delay to switch from Regulation mode to Hold mode

Process

It is usually necessary to manage the switches Reg and B simultaneously.

Page 24

www.cmccontrols.com

24

Menu FUNCTION

4.3 HOLD function

Principle

The Hold function can be used by the operator for the machine settings (out of regulation

mode). It allows the operator to directly manage a constant ouptut voltage level (parameter

always available on the controller front panel).

How does it work

Hold value: Entering 0-100% means 0-10V proportional output voltage

Process

Two different ways are available to manage this function:

External switch A open - external switch B open by the front panel operator menu (priority

access)

Page 25

25

Menu FUNCTION

4.4 Inertia

This menu is available for open loop configuration when inertia compensation is required.

Inertia compensation function

The inertia compensation function allows the controller to increase or decrease the output

during the acceleration/deceleration periods. This coefficient (inertia gain) is related to the roll

inertia (proportional to the actual diameter measurement) and to the actual line speed

(tachometer input). When the web width is not constant, it is possible to adjust the calculated

inertia term by entering the coefficient Web width (also always available to the operator on the

controller front panel).

Calculation - Inertia gain GI:

Data:

Max roll weight M (Kg)

Max roll diameter D (m)

Max line speed VL (m/s)

Decceleration duration T (s)

Rated current for the chosen Brake IC (A)

Max current adjusted on the power supply board IR (A)

Rated torque for the chosen Brake CN (Nm)

Formula : GI = M x VL x D x IC x 100

240 x T x CN x IR

Adjustment procedure:

Proceed with the first tests with the maximum web width (Coeff. Web width = 100 %).

Temporarily disable the open loop control (Closed loop gain = 0 %) to avoid interactions during

the adjustment procedure.

- Apply a high filtering coefficient on the diameter input (slow variation input): Diameter

filtering = 500

- Enter a low filtering coefficient on the Tachy measurement input to avoid fast transient

troubles

- Apply the calculated inertia gain (above formula)

- Start the machine and adjust the inertia gain value to stabilize the actual measurement

during acceleration/deceleration periods.

Page 26

www.cmccontrols.com

26

Menu FUNCTION

4.5 NO-STOP function

Principle

This function is used to manage two independent outputs (one which is the calculation result

output and the second one which is fixed - hold value). This is usually very useful to manage

the automatic splice turrets systems.

How does it work

Click in the "No-Stop" special function box to enable the function.

The ouptut currently not affected by the calculation is automatically delivering the Hold or the

E-stop value, depending on the status chosen for logical inputs A and B.

Process

See the following table:

A B AO1 AO2

0 0 Regulation Hold

0 1 Regulation E-Stop

1 0 Hold Regulation

1 1 E-Stop Regulation

0 means Open / 1 means Closed

NOTE:

When using this "No-Stop" function, the "Demagnetization" function is not available.

The Operator control panel (front face keyboard functions) remains the priority control.

That means that "Hold" or "Freewheel" modes are sent simultaneously on both AO1 and AO2.

Page 27

27

5.0 Menu PID

5.1

Coefficients Menu

This menu is available for both closed loop and inertia compensation configurations.

5.2 Closed loop + Open loop Control function

When using a closed loop configuration, this function allows integration with an open loop control by using

a specific coefficient for each of these control modes; open loop gain and closed loop gain. This function

allows additional closed loop control around the result of an open loop control, in order to limit the Measure

- Set point difference, to improve the system stability as well as the accuracy.

Calculation - Open loop gain CBO

DATA :

Max Force range F (N)

Max web diameter D (m)

Rated current for the chosen Brake IC (A)

Max current adjusted on the power supply board IR (A)

Rated torque for the chosen Brake CN (Nm)

Formula: CBO = F x D x IC x 100

2 x CN x IR

The result gives the open loop true coefficient. This value can be modified to optimize the system stability.

5.3 Inertia compensation function

The Inertia compensation function allows an additional open loop control to the calculated currrent closed

loop result during the acceleration/deceleration periods. This coefficient (inertia gain) is related to the roll

inertia (proportional to the actual diameter measurement) and to the actual line speed (tachometer input).

When the Web width is not constant, it is possible to adjust the calculated inertia term by entering the

coefficient Web width (also available to the operator on the controller front panel).

Calculation - Inertia gain GI:

Data:

Max roll weight M ( Kg )

Max roll diameter D ( m )

Max line speed VL ( m/s )

Decceleration duration T ( s )

Rated current for the chosen Brake IC ( A )

Max current adjusted on the power supply board IR ( A )

Rated torque for the chosen Brake CN ( N.m )

Formula: GI = M x VL x D x IC x 100

240 x T x CN x IR

Adjustment procedure:

Proceed with the first tests with the maximum Web width (Coeff. Web width = 100%). Temporarily

disable the open loop control (Closed loop gain = 0 %) to avoid interactions during the adjustment

procedure. Apply a high filtering coefficient on the diameter input (slow variation input): Diameter

filtering = 500. Enter a low filtering coefficient on the Tachy measurement input to avoid fast transient

troubles. Apply the calculated Inertia gain (above formula). Start the machine and adjust the inertia

gain value to stabilize the actual measurement during acceleration/deceleration periods.

Page 28

www.cmccontrols.com

28

5.0 Menu PID

5.4 PID Menu

Principle

The P.I.D. is the heart of the controller calculation system when using the Closed loop mode.

P , I , and D parameters are the coefficients which give the actual output result from the

Measurement - Set point difference .

CAUTION : the PID calculation must be disabled during the machine rest periods to avoid that

a static Measurement - Set point difference increases the output value to the maximum (giving

a very high overshoot for the next machine restart) .

The following process has obviously to be managed by the global machine management system

! (using the external switches Reg and Init) .

How does it work

There are two options for the PID calculation principle :Fixed PID (coefficients) or Variable PID

(coefficients) which have to be chosen in the PID Menu (" click in the box " choice mode) .

The Variable PID option is very useful when the Fixed PID is unable to keep the same stability

level for the whole range of the Web diameter variation .

The Variable PID option offers to define a P, I and D specific value for the min. diameter, and a

different one for the max. diameter . the three P, I, and D parameters will be automatically

updated in relation to a diameter measurement input (linear variation between min. and max.

for each parameter)

P parameter: This parameter is the direct gain on the Measurement - Set point difference .

The P coefficient will directly affect the global system response time .

CAUTION : The higher the value, the higher the response time, but with a lower stability .

I parameter: This parameter is used to cancel the " static error " by the accumulation of this

error from the beginning, and by adding this error to the set point until reaching the equality .

When the Measurement - Set point difference becomes null, the Integral value is stabilized.

A high coefficient value will make the system more reactif by decreasing the time for the

Measure to reach the Set point actual value .

D parameter: This parameter is used to help the system to react for fast transients.

It is generally only used for the Dancer applications, in order to stabilize the dancer position

when the web speed is variable .

CAUTION : this parameter is used for react to transients, but it means that it could be highly

sensitive to the electric interferences on the measurement signal .Be very careful to connect the

wiring shields at the best .

Process

The PID calculation is managed by the external switches Reg and Init.

Init Reg PID calcul mode

0 0 Stopped (blocked)

1 0 initialisation

0 1 processing

1 1 processing

CAUTION : when using the diameter calculation (counters inputs), the initialisation of diameter

calculation is managed by the same external switches (Reg = 0 , Init = 1)

Page 29

29

5.0 Menu PID

5.5 Motor

This menu is available in motor command configuration.

Tension control for motorized rewinder in speed regulation.

In this case, we need linear speed (tacho) and diameter information to calculate the rotation

speed of the motor.

Motor gain is then the coefficient linking the different parameters:

Motor gain calculation:

Parameters : 10v on diameter input = D ( m )

10v on tacho input = Vl (m/min)

10v on output AO1 = speed set point for the drive = Vr (rpm)

Calculation : Motor gain = Pi x D x Vr

Vl

With this rotation speed calculation, we have an open loop system on the speed control.

To control the tension on the product, the DGT regulates the open loop calculation with a

closed loop (PID adjustement) on tension measurement.

For this application, Coefficient motor = 100%

Note : In this configuration, Overspeed = 0.

Special case: Tension control through clutch and speed follower on rewinder

This model is done to solve dissipation problem in clutch on the rewinding side.

The goal is to drive tension on the product with the clutch and drive the motor speed to keep

low slipping in the clutch.

AO1 input : dedicated to clutch control (PID regulation with tension control).

AO2 input :dedicated to motor speed control. The DGT calculates the rotation speed with linear

speed and diameter information. Motor gain is calculated like here above.

To ensure a minimum slipping for the right working of the clutch, it is necessary to add an

overspeed constant (usually equivalent to 60rpm).

Overspeed calculation:

Parameter : 10v on AO2 output = speed set point for the drive = Vr (rpm)

Calculation : overspeed = 60(rpm) * 10(V)

(de 0.0Và 10.0V)

Vr (rpm)

For this application, Coefficient motor = 0% (generate automatically AO2 as speed output).

Important note: If motor gain =0, motor configuration is not validated and settings are

memorized as closed loop configuration.

Page 30

6.0 Menu OUTPUTS

6.1 Working range

Principle

This function defines the two limits for the actual regulation voltage output AO1 (or AO1 and

AO2 when using the No-Stop mode) inside the global output range (-10 / + 10 V). Useful

function when using the controller with a device which only uses 0 - +10V input.

How does it work

Min. threshold: Means the minimum voltage allowed to the controller regulated output

(enter the threshold value between -10V et +10V).

Max. threshold: Means the maximum voltage allowed to the controller regulated output

(enter the threshold value between -10V et +10V - must be higher than the Min. threshold

already defined).

www.cmccontrols.com

30

Page 31

Menu OUTPUTS

6.2 DISPLAY output function (AO2)

This function is used to select one of the following four items to be displayed:

-Set point (0 to 10V = whole measurement range as it has already been calibrated)

-Measure (-10V to +10V = whole measurement range as it has already been calibrated)

-Diameter (0 to 10V = 0 to the Max diameter)

-Linear speed for the speed follower menu

31

Page 32

Menu OUTPUTS

6.3 Current limitation

Principle

This function limits the current in the coil when using EMAG brakes and EMAG clutches directly.

As the supply of the coil is done by a pulse width modulation on the rectified supply of the

QUANTUM, the parameter drives the duty cycle of the PWM.

How does it work

Enter a value between 1-100% corresponding to the maximum current for the application.

Example

Case of an EMAG 50 (65Nm - 1A nominal current-200hm impedance) used for a 50Nm

maximum torque application (equivalent to 0.7A).

1. QUANTUM supply with a 24Vac transformer.

The supply of the coil is done on the 24V rectified meaning around 34Vdc.

The impedance is 20Ohm, so the max available current is 1.7A.

To limit the current at 0.7A, the duty cycle is 41%.

2. QUANTUM supply with a 24Vdc converter.

The supply of the coil is done on the 24Vdc

The impedance is 20Ohm, so the max available current is 1.2A.

To limit the current at 0.7A, the duty cycle is 58%.

This parameter is useful for dancer applications by limiting the current at the lowest value

needed to pull the dancer for the max roll with the max tension.

www.cmccontrols.com

32

Page 33

Menu OUTPUTS

6.4 ALARM management function

Principle

Two digital outputs have been designed to provide two different alarm signals:

Regulation fault: When the Measurement - Set point difference is over the pre-set tolerance, it

means that there is something wrong in the process.

Min. Diameter: Diameter measurement threshold available to alert the operator before the real end

of the bobbin.

How does it work

Error range parameter: The digital output AL1 will be closed for an actual Measurement - Set

point difference higher than the chosen percentage.

Diam Threshold parameter: The digital output AL2 will be closed for an actual Diameter

measurement below the chosen percentage of full scale diameter.

Example

Error range:

For a 5 kg set point and 10 % Error range, the AL1 output will be closed for a measurement out of

the 4.5 to 5.5 kg range ( +/- 10 % of the current set point)

Diam Threshold :

Diameter range = 0.2 to 1.0 m

Actual working range = 1.0 - 0.2 = 0.8 m

For 5 % Diam threshold, the AL2 output will be closed as soon as the actual diameter is lower

than 0.24 m

Alarm diameter = core diameter + (Actual working range x Diameter threshold) 0.2 + (0.8 x 5%)

= 0.24m

Process

AL1 and / or AL2 digital outputs remain closed until the time that the related measurements are

out of the correct range.

CAUTION: AL1 and AL2 are driven by optocoupling components. The common (0 V) point for both

is ALMax output capability: Vceo = 300 V

33

Page 34

7.0 Digital Inputs

7.1 Digital Inputs A and B

Principle

The digital inputs A and B are dedicated to the management of the controller’s global status. It

provides the user the ability to create an automatic relationship between the machine process

and the controller status (i.e. to manage the E-Stop needs).

How does it work

The following table shows the controller’s main status for any different combination of A and B

switch positions, as long as the No-Stop mode is not activated (see SPECIAL FUNCTIONS Menu /

No-Stop Function).

A B Output AO1

0 0 Hold

0 1 Regul

1 0 Release

1 1 E-Stop

0 means: Switch Open / 1 means: switch closed (to the 24Vdc terminal)

The operator control panel (front face keyboard functions) remains the priority control.

www.cmccontrols.com

34

Page 35

Digital Inputs

7.2 Logical inputs Reg and Init

Principle

The digital inputs Reg and Init are dedicated to the management of the P.I.D. calculation

process.

How does it work

The following table shows the calculation process status for any different combination of Reg

and Init switches positions:

Init Reg PID calculation

0 0 calculation stopped

1 0 calculation initialization

0 1 calculation in process

1 1 calculation in process

0 means: Switch Open / 1 means: switch closed (to the 24Vdc terminal)

35

Page 36

8.0 Data Capture

8.1 DATA CAPTURE Menu

Starting a Data Capture

The PC software includes a Data capture function, allowing to visualize and to record each

Controller input/output actual value/status, four times/sec. To start a data capture, go to the

REGULATOR / Start Acquisition option.

To record the data on the computer, enter a new File name (ext., .acq). The data capture will

start and the data will be saved in the related file. To look at the data without recording,

choose ‘Cancel.’ The data capture will be started without recording. In both cases, press ‘Stop’

to end the data capture process.

Using the recording option during the data capture allows you to store the data on the disk as

a data file (ext., .acq). The data is displayed as a text file (columns separator = Tab) which can

be read by any spreadsheet software.

NOTE: The data is collected 4 times / sec, meaning the time base between two lines is 250 ms

(1/4s) .

How to display the acquired file

To display the curves of the acquired file, click on the menu 'acquisition' then select 'visualize' or

click directely in the icon bar. A new window opens and you have to load the acquired file.

Select the curves you want to see. A multi-curves option can be selected when clicking in

'customize'.

www.cmccontrols.com

36

Page 37

7550 HUB PARKWAY

CLEVELAND, OH 44125

216.524.8800 or 800.321.8072

www.cmccontrols.com

MAN-70421

Loading...

Loading...