Cleveland Motion Controls MWP – 12662 - 0 User Manual

UNWIND BRAKE TENSION CONTROLLER

MWP – 12662 - 0

Instruction Manual

AO-70173 (Rev BA)

Table Of Contents

General Description .............................................................................................................4

Unwind Brake System ..........................................................................................................................4

Motor Powered Unwind System ...........................................................................................................4

Quickstart ............................................................................................................................. 5

Installation ............................................................................................................................ 6

Cabinet Installation ...............................................................................................................................6

Electro-Pneumatic ( E/P ) Converter Installation ..................................................................................6

High Current Driver ( HCD ) Installation .............................................................................................6

PCB Link Positions ..............................................................................................................7

Controller Connections........................................................................................................ 7

Transducer Connections ..................................................................................................... 9

Intrinsically Safe Transducer Connections for Hazardous Area Installations.......................................9

Machine Sequence Logic and Connections, Digital Inputs ................................................................10

Digital Output Connections .................................................................................................................10

Power Supply Connections.................................................................................................................11

Tacho Connections .............................................................................................................................11

Encoder Connections .........................................................................................................................11

Length Counter ...................................................................................................................................11

Batch Hold ..........................................................................................................................................12

System Set Up .................................................................................................................... 12

Machine Parameters........................................................................................................... 13

Language ............................................................................................................................................14

Unit system .........................................................................................................................................14

Unwind type ........................................................................................................................................14

Output range .......................................................................................................................................14

Start in control screen .........................................................................................................................14

Enable MAN / AUTO / OFF keys........................................................................................................14

Dual tension range..............................................................................................................................14

Minimum tension.................................................................................................................................15

Output level bias .................................................................................................................................15

Output level limit .................................................................................................................................15

Diameter adjustment...........................................................................................................................15

Set point ramp rate .............................................................................................................................15

Soft stop time ......................................................................................................................................15

Display damping time .........................................................................................................................15

Display precision.................................................................................................................................15

Right transducer..................................................................................................................................15

Line Tacho or Encoder * .....................................................................................................................16

Winder Tacho or Encoder * ................................................................................................................16

Calibrate Tension ...............................................................................................................16

Calibration of the Total Tension Analog Output............................................................... 17

Calibrate Speed .................................................................................................................. 17

Product Parameters ........................................................................................................... 18

Controller Tuning - Unwind Brake Mode .......................................................................... 18

Output Level Bias ...............................................................................................................................18

Output Level Limit ...............................................................................................................................18

PI Stability Settings .............................................................................................................................18

Inertia Compensation..........................................................................................................................19

AO-70173 2 Revision BA

Table Of Contents

"Soft Start”.......................................................................................................................... 19

Operating ............................................................................................................................ 20

Adjusting the screen contrast .............................................................................................................20

Change Passwords ............................................................................................................ 20

Safety and EMC ..................................................................................................................20

Additional Information ....................................................................................................... 21

External tension set point input...........................................................................................................21

Tension set point output .....................................................................................................................21

Diameter calculation ...........................................................................................................................21

Troubleshooting .................................................................................................................21

Installation Record Sheet................................................................................................... 22

AO-70173 3 Revision BA

WebPro Unwind Brake Tension Controller

General Description

The WebPro Digital Tension Controller is part of a closed loop tension control system with transducer

feedback. The Controller continuously controls the web tension to the TENSION SET POINT value and

displays the true web tension on an LCD screen, either as a percentage or in engineering units. The

screen will display the tension applied to each transducer separately by pressing the < LEFT tension or

> RIGHT tension key. The sum of the LEFT and RIGHT tensions is displayed when the < > TOTAL key is

pressed. The Controller will control to the TOTAL tension value even when the LEFT or RIGHT tension is

being displayed. The Controller also has a dual range tension indication feature.

The measurement of actual web tension is made by sensing, with strain gauge transducers (sometimes

referred to as "load cells"), the force on a sensing roller caused by the tension in the web. The electrical

signal from the transducers is a combination of tension force and sensing roller weight. The weight of the

sensing roller is zeroed out electrically, leaving the tension force only to be displayed on the screen.

For wide web applications two transducers are recommended, one on each end of the sensing roller; for

narrow web, wire, cable and filaments one transducer can usually be used.

Unwind Brake System

The Controller may be used with an Electropneumatic converter for pneumatic brakes

or a High Current Driver for electric brakes.

The torque of a center coupled unwind

brake must be reduced as the reel diameter

reduces in order to maintain constant

tension. It is the tension force alone which

pulls the web from the reel and overcomes

the unwind reel inertia on start up from rest

and during acceleration. The residual drag

torque of the brake added to any losses in

the machine will result in a minimum

operating tension. When the LOW tension

range is selected the Controller LOW output

may be used to disconnect pads from a

multipad brake for optimum performance.

Motor Powered Unwind System

1

0

0

N

Motor powered unwind systems can operate at tension levels lower than those of a brake system and can

generate tension when the machine is at rest (stall tension) provided the machine is designed to allow

this. The motor and drive must be suitable for continuous regenerative operation. The Controller requires

either tachogenerators ( tachos ) or encoders or a combination of both, for the unwind reel speed and for

the line speed. These speed signals are used by the Controller to calculate the reel diameter.

The Unwind Brake Controller has the software loaded for motor powered unwind control. If the Controller

is to be used for these applications contact CMC Inc for the AO-70172 handbook for these systems.

AO-70173 4 Revision BA

WebPro Unwind Brake Tension Controller

Quickstart

The Controller is supplied with the software loaded for the application as ordered but it will require

commissioning before use.

For more detailed information refer to the various sections later in this manual.

1. Carefully unpack the Controller, remove the rear cover and detach the bag containing the accessories.

Attach the cable gland to the large hole in the rear cover. Mount the Controller in the operators panel

using the two keyhole brackets provided.

2. Position the links LK1 to LK5 on the Printed Circuit Board correctly for the type of transducer used.

Ensure that the mains voltage selector is set correctly.

3. Thread the mains supply cable through the gland and connect to the orange two part connector.

Thread the transducer cables, machine interlock cables, output cable and any other cables through the

most convenient of the four smaller holes and connect to the terminal strips. If an encoder is to be used,

thread the encoder cable through the rear cover and connect to the header using the crimps provided.

Additional holes may be drilled and extra glands for the cables may be fitted by the user.

Ensure that the encoder is connected correctly to prevent damage to the power supply.

4. Fix the rear cover to the Controller and tighten the gland to retain the mains cable for safety purposes.

5. Switch on, the POWER LED will light, the company logos will be shown briefly then the Introduction

screen will be shown.

6. Press 4, Commissioning, enter the default password, by pressing 5678 then press the ENTER key.

Press 1, Machine parameters, then scroll through and enter the parameters for the installation.

By default only one transducer, the LEFT transducer, is enabled. For installations with two transducers,

which is the normal situation for web applications, the RIGHT transducer must be enabled.

If a tacho is used the MAXIMUM input voltage is +10V DC.

If an encoder is used the number of pulses per second at maximum machine speed must be entered.

To accept and save the Machine parameters the CONFIRM key MUST be pressed.

7. Calibration for the sensing roller weight and maximum tension to be used is required; calibration for the

speed of the machine may also be required.

8. The default Product number is 1 with a PI stability of SLOW. This should be sufficient to put the

machine into service. To change the stability, open the Adjust PI stability screen from the Commissioning

menu, start the machine and observe the bar graph. Reduce the PI stability to MEDIUM or FAST until the

bar graph fluctuations just start to increase, then press CONFIRM.

AO-70173 5 Revision BA

(

)

WebPro Unwind Brake Tension Controller

Installation

The following parts are supplied:-

1. Controller, with software loaded for the application but requiring commissioning by the user.

2. Two keyhole mounting brackets.

3. Cable gland to be fitted to the rear cover and header connector kit for encoders.

4. Cabinet, if ordered.

5. Electro-pneumatic (E/P) Converter kit or High Current Driver, if ordered.

6. Manual (this document).

Transducers and cables may also be supplied to complete the system

The Controller should be installed using 'best practice' and in accordance with all relevant regulations.

The Controller must be installed in a dry, non-hazardous location. A panel cut out 8.27in (210mm) wide X

7.01in (178mm) high is required. The Controller is 3.94in (100mm) deep, additional space for the cables

is needed.

The Controller is retained by two mounting brackets. Remove the four screws securing the mounting

brackets to the Controller. Insert the Controller into the cut out in the panel. Refit the four screws, attach

the mounting brackets to the Controller and tighten the two nylon screws to retain the Controller.

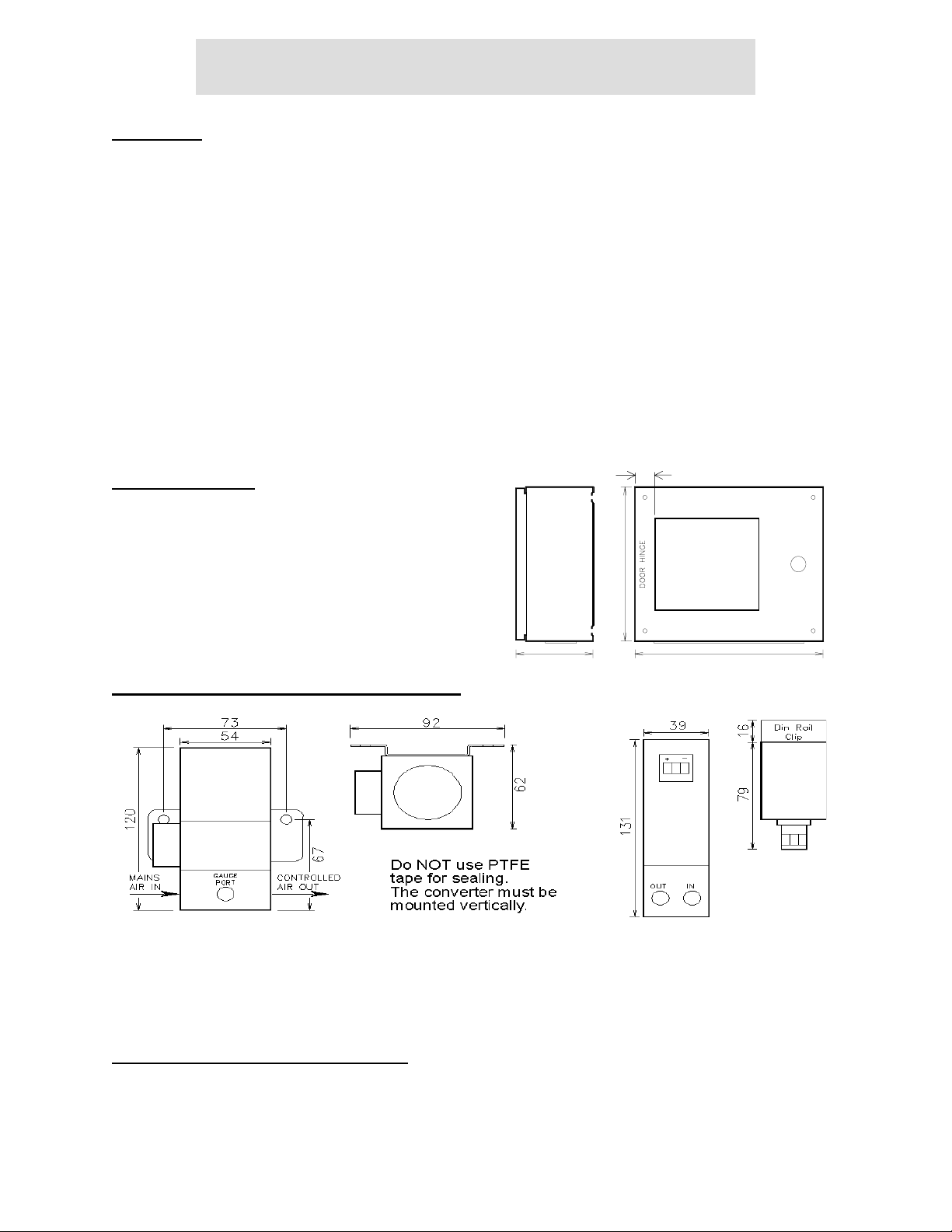

Cabinet Installation

2 in. (50mm)

The cabinet has rear mounting holes for M8 fixing.

When the Controller is supplied as a cabinet version the

mains supply is terminated inside the cabinet on a three

way terminal block. The incoming mains cable should be

securely fastened by the gland plate cord grip.

11.8 in

300mm

CUT OUT

8.27 in. x 7.01 in.

210 X 178

(210x178mm)

LOCK

Electro-Pneumatic ( E/P ) Converter Installation

IMI 101X converter

6 in.

(155mm)

Fairchild TA6000-406 converter

ENTRY GLAND PLATE

15 in.

(380mm)

CLEAN DRY OIL-FREE air of instrument quality, maximum supply pressure 100 PSI/7 Bar, filtered to 5

micron or better is required. The air line distance between the E/P Converter and the brake or clutch

should not exceed 5 metres or degradation of performance may occur.

High Current Driver ( HCD ) Installation

Use an HCD when the WebPro is used to drive a magnetic brake. Consult the manufacturer of the

magnetic brake for HCD recommendations. The HCD must be capable of delivering the rated brake

current and also be capable of supplying the rated brake voltage – usually 24 or 90 volts. Control of the

HCD output current must be controllable with a 0 to +10 volt signal.

AO-70173 6 Revision BA

WebPro Unwind Brake Tension Controller

Before connecting the HCD to the mains supply, ensure that the mains voltage matches the HCD

requirements. Connect the HCD control input common to the WebPro controller “0V analog” mTB4 and

the HCD control + signal input to the WebPro controls “control out 0/+10V” or TB4.

Caution: The HCD controller signal input connections must be isolated from the mains supply

connections or damage to the WebPro and the HCD will occur.

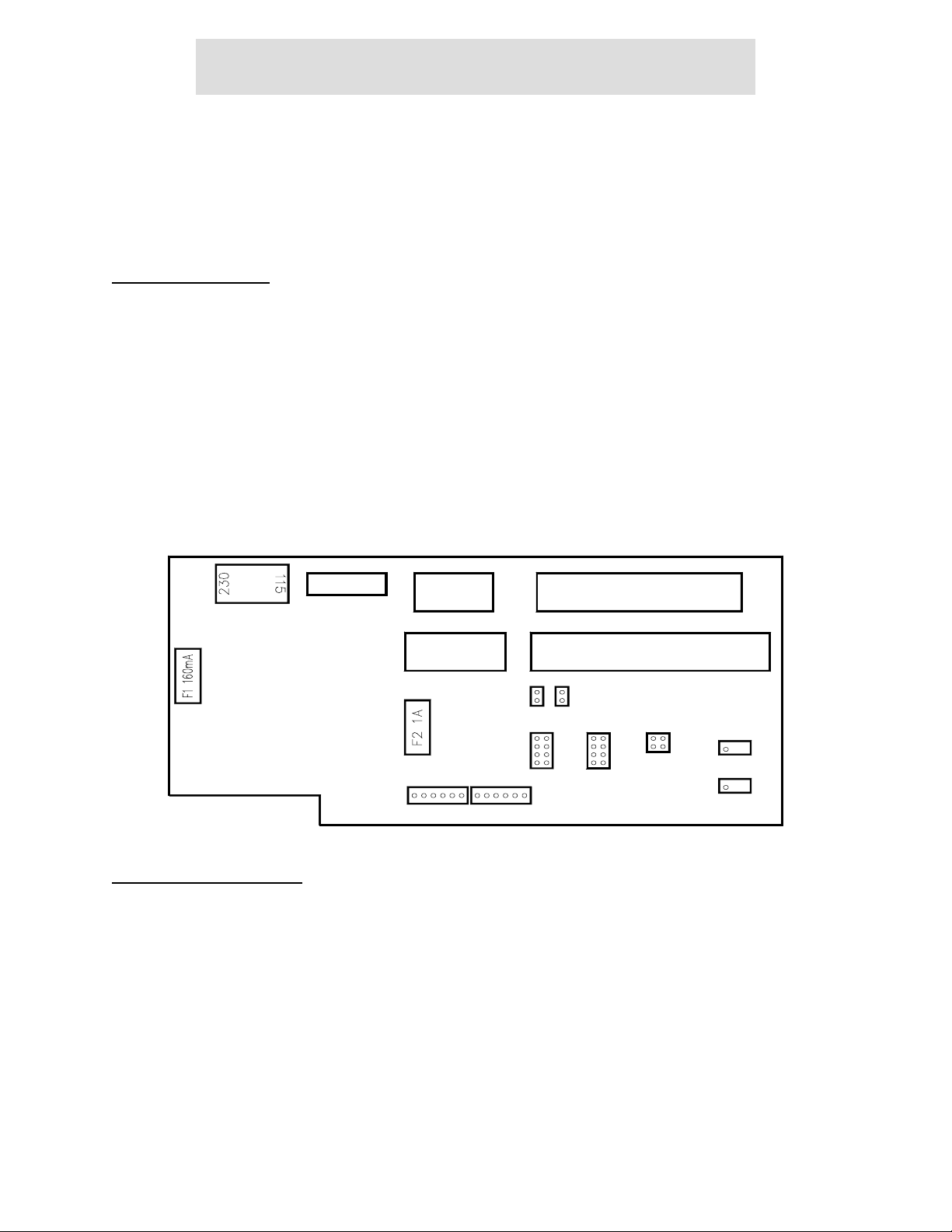

PCB Link Positions

The links LK1 to LK5 MUST be in the proper positions for correct operation.

It may be found more convenient to position the links before connecting the Controller.

LK1 Excitation Voltage Position B This gives 5.6V for Cleveland-Kidder transducers

LK1 Excitation Voltage Position A This gives 10V for ACDF and foil transducers

LK2 and LK3 IN For Cleveland-Kidder transducers to complete the bridge

LK2 and LK3 OUT For full bridge transducers, the bridges are complete

LK4 and LK5 Gain Position A Normal gain for Cleveland-Kidder transducers

LK4 and LK5 Gain Position B High gain for Cleveland-Kidder transducers

LK4 and LK5 Gain Position C Normal gain for ACDF and foil transducers

LK4 and LK5 Gain Position D High gain for ACDF and foil transducers

The high gain positions providing three times the normal gain are used if the transducers are oversized

and there is insufficient signal level for accurate calibration.

TB1

LEN 312 541

TB2

1

3245687 9 10 1411 12 13 15

132 456

TB3

LK2

LK3

LK4

A

B

C

D D

HD2 HD1

6 16 1

A

B

C

TB5

TB4

LK1LK5

AB

10965423 87131211

VR2 SPAN

VR1 ZERO

Controller Connections

WARNING - Disconnect the Controller completely before any electric welding is undertaken on the

machine. Failure to carry out this precaution could damage the Controller and will invalidate the warranty.

WARNING - The PCB uses devices sensitive to electrostatic voltages. Do NOT touch any components

without first using proper electrostatic discharge ESD precautions.

The Controller uses Wago Cage Clamp terminals, it is recommended that the correct tool is used when

inserting the cables. Wago part number 210-120 is available from Wago or CMC Inc.

Do NOT strain the terminals or the PCB. The terminals are suitable for cable sizes 12-24 AWG, 0.1-

2.5sqmm. The cable ends should be terminated with ferrules or crimp tags.

It is necessary to remove the rear cover to connect the Controller, set the links and select the mains

supply voltage. Remove the rear cover and fit the cable gland (supplied loose) to the rear cover. Feed the

mains cable through the cable gland and connect to the two part connect as shown. Feed the transducer

AO-70173 7 Revision BA

Loading...

Loading...