CLEVELAND-KIDDER® UNDER PILLOW BLOCK

WASHDOWN-DUTY

LOAD CELL

INSTRUCTION MANUAL . . . TYPE UPB WASHDOWN-DUTY

7550 Hub Parkway

Cleveland, Oh 44125-5794

Phone: 216-524-8800

Or 800-321-8072

Fax: 216-642-2100

Visit Us: www.cmccontrols.com

INSTRUCTION NUMBER: AO-70136 BA 1 of 9

1.0 GENERAL INFORMATION

1.1 RECEIVING AND UNPACKING

Handle and unpack the equipment carefully.

Immediately upon arrival, check the shipment against

the packing list. Any damage should be reported

immediately to the carrier and to the nearest CMC

representative.

Equipment that will not be installed immediately

should be stored in a clean, dry location. Precautions

should be taken to prevent moisture, dust and dirt

from accumulating in storage and installation areas

1.2 PRECAUTIONS

1.2.1 Shipping

roll be removed when the machine is shipped with the

transducers mounted. The shock and vibration

transmitted to the transducers by the sensing roll

during transporting can damage them.

1.2.2 Roll Balance

balanced to prevent forces caused by imbalance.

These forces cause a noise signal to be superimposed

on the tension signal. The centrifugal force (F) caused

by imbalance can be calculated using the equation

below.

F = 28.6 x 10

W = Weight of roll in pounds

R = Displacement of mass of roll from the

axis of rotation in inches

RPM = Revolution per minute

It is recommended that the force (F) be less than 5%

of the resultant web force at the maximum web speed

for most applications.

1.2.3 Critical Roll Speed

vibration can be set up in a stationary shaft. If this

vibration (in cycles per minute) occurs at the

harmonic frequency of the shaft, the transducers can

be damaged. To determine the critical roll speed, use

the following formula:

- It is recommended that the sensing

- The sensing roll should be

-6

x W x R x (RPM)2 Lbs.

- Even with a balanced roll, a

Critical roll = 4.8 x 10

speed in RPM (Shaft Length)

6

x Shaft O.D.

2

Dimensions are in inches.

To assure that this problem is avoided, the critical roll

speed should at least be 20% above the roll speed

attained at maximum web speed.

1.2.4 Overloading

- Repetitive overloading above the

maximum working force or severe overloading should

be avoided because it will damage the transducers.

1.3 SPECIFICATIONS

Gage Resistance - End to end resistance 440-480

Ohms

Gage Factor - 100 nominal

Excitation Voltage -10 VDC or VAC (RMS)

maximum

Output Signal

at Rated MWF - 100 mV nominal per

Transducer (1/2 bridge)

200 mV nominal per

Transducer pair (full bridge)

Output Impedance - Approximately 880 Ohms for

UPB2 and UPB3

Approximately 120 for UPB 1

Required Input

Impedance of

Tension Amplifier - 5K ohms per Transducer (1/2

bridge)

Maximum Voltage,

Gage to Beam or

Base (Ground) - 50 VDC

Operating

Temperature Range - 0

F to +200 F

Compliant

INSTRUCTION NUMBER: AO-70136 BA 2 of 9

1.4 DESCRIPTION

The Cleveland-Kidder Washdown Duty UPB

transducers utilize a sensing twin beam to which

semiconductor strain gages are bonded. With these

high output signal gages a very small force on the

sensing beam will be shown as a change in the tension

signal.

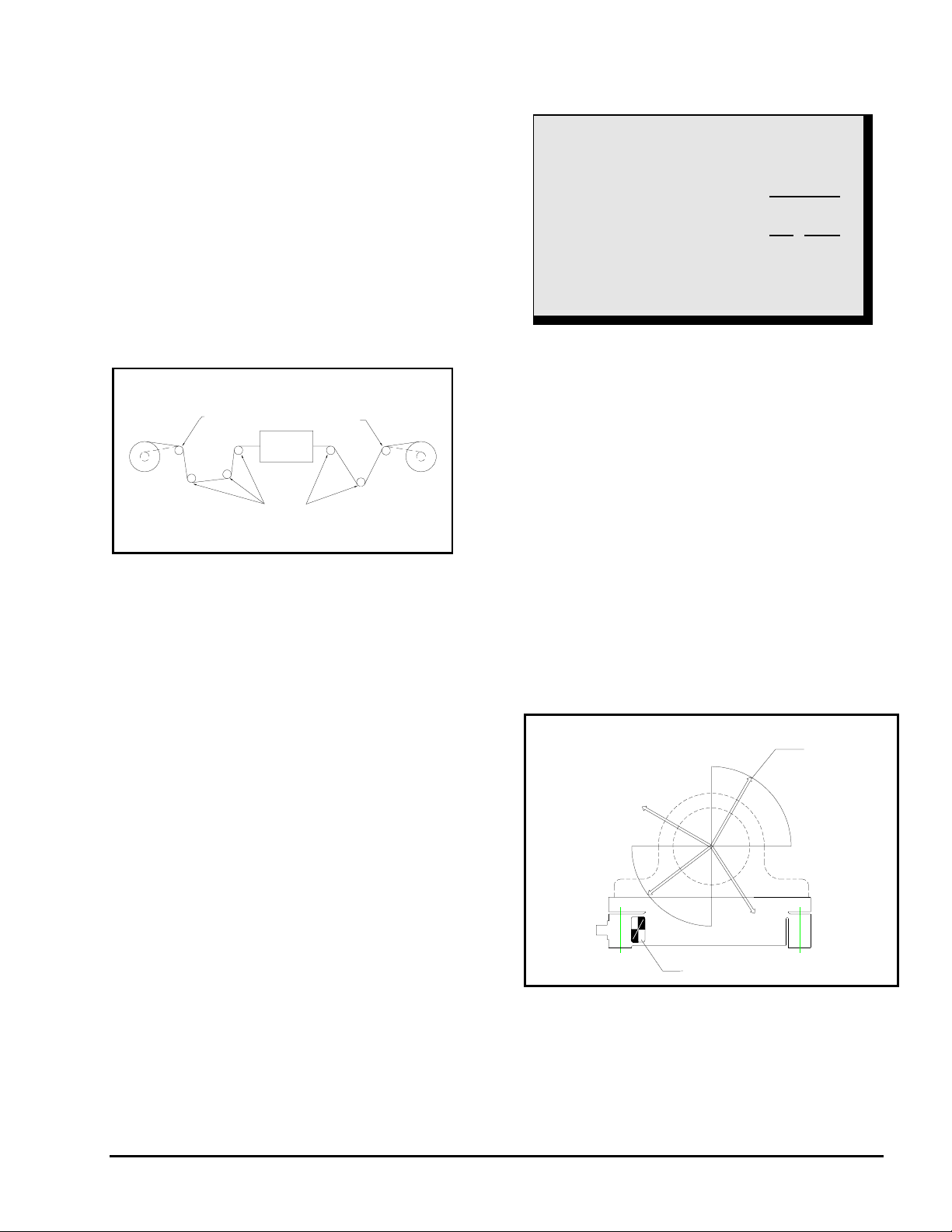

The type UPB transducers are for use with shafts that

are mounted in Pillow Block Bearings. See Figure 1.

For mounting dimensions see Figure 2.

Pillow Block Bearing

Washdown UPB Transducer

Figure 1

BM N

A

F G

PILLOW BLOCK

MOUNTING PLATE

LOAD CELL

C

L

J

E

H

K

D

W

No.

Size

No.

*Allow 2.5 inches (64 mm) clearance for connector

**Approximate rating in Newtons

A B C D E F(Max.) G H J (Max.) K L M N W

1 1.5 0.55 5.8 1.5 5/16 (4) 5.8 1.6 1.95 ½ (2) 1.40 6.5 1.3 2.2 2.2 25, 50, 100, 250, 500, 1000

2 3 0.80 10.0 3.0 ½ (4) 10.0 3.0 2.5 ¾ (4) 1.71 11.0 3.3 3.95 4.0 1000, 2500, 5000, 10000, 20000

3 4.5 1.63 15.0 4.5 1 (4) 15.6 5.0 4.2 1-1/8 (4) 2.80 17.0 4.8 5.2 6.5 10000, 20000, 30000

A B C D E F(Max.) G H J (Max.) K L M N W

1 38 14 147.5 38 M8 147 40.5 49.5 M12 (2) 35.5 165 33 56 56 110, 225, 450, 1100, 2250, 4500

2 76 20 254 76 M12 254 76 63.5 M20 (4) 43.5 279.5 84 100 101.5 4500, 11000, 22000, 45000, 9000

3 114 41.5 381 114 M24 396 127 106.5 M30 (4) 71 432 122 132 165 45000, 9000, 13500

Dimensions in Inches* Size

Dimensions in Millimeters*

Figure 2

Maximum Working Force (lb.)

Maximum Working Force (N.)**

INSTRUCTION NUMBER: AO-70136 BA 3of 9

2.0 INSTALLATION

2.1 SELECTION OF TRANSDUCER

MOUNTING LOCATION

When selecting a transducer mounting location,

keep in mind that the tension-sensing roll must

NOT be mounted where the web wrap angle can

vary. Any change in the wrap angle will be sensed

by the transducers as a change in tension, and

indicated as such on the tension indicator.

WRAP VARIESWRAP VARIES

PROCESS

OK FOR TENSION SENSING

Figure 3

In some cases, it may be impossible to find a

location for the transducers where the wrap angle

does not vary. The change in indicated tension that

will result can be calculated and, if small, may not

be significant.

2.2 MOUNTING SURFACE

PREPARATION

The mounting surfaces for the transducers should

be flat and parallel. Prepare the machine frames or

mounting surfaces by removing any loose paint,

rust, scale, etc.

2.3 INSTALLATION PRECAUTIONS

To insure proper installation and operation of the

system, the following steps should be performed in

sequence. Failure to do so could seriously

damaged the Transducers and void the warranty.

PRECAUTION

Always install, orient and firmly bolt

down the transducers BEFORE

installing the tension-sensing roll. When

disassembling or installing, DO NOT

remove the transducer and the tensionsensing roll as an assembly - remove the

roll first, before loosening the transducer

mounting bolts.

2.4 INSTALLATION OF TYPE

UPB TRANSDUCERS

Instructions for Mounting the UPB Load Cell to

the Machine Frame (see Figure 6)

Remove the pillow block mounting plate (it is held

in place by four stainless steel corner bolts) in order

to gain access to the four load cell mounting holes.

Drill and tap the machine frame to match the load

cell mounting holes (refer to section 2.5 to properly

position the load cell). Bolt the load cell in place.

The UPB load cell is designed so that either

imperial or metric mounting bolts can be used when

mounting the load cell to the machine frame. Refer

to E in the Figure 2 above for the proper bolt size.

Before remounting the pillow block mounting plate,

refer to section 2.6.

WEB FORCE

INCORRECT

CORRECT

INCORRECT

CORRECT

LOAD ZONE DIRECTION LABEL

Figure 4

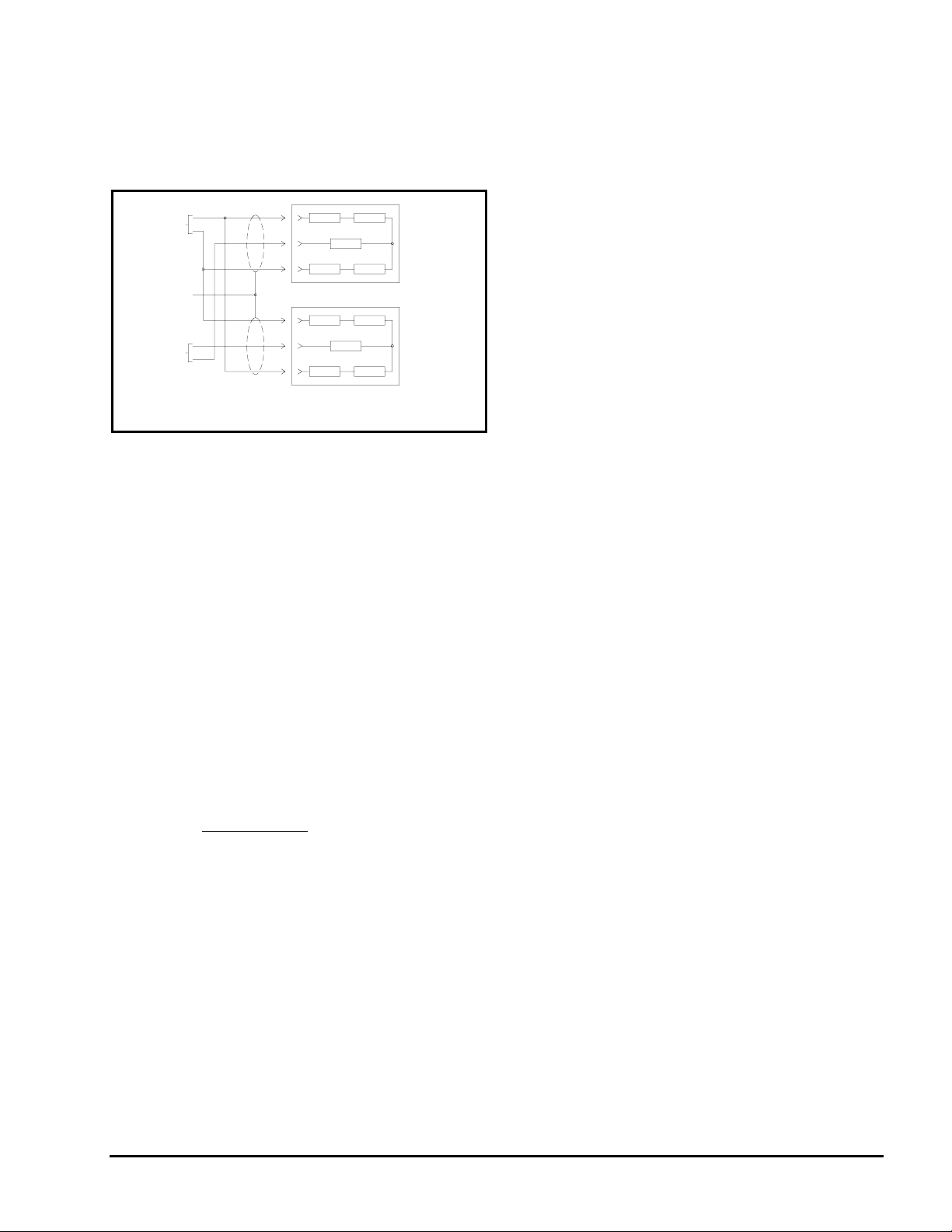

2.5 POSITIONING THE TRANSDUCER

Once the four tapped holes have been drilled, you

need to orient the UPB load cell properly to obtain

INSTRUCTION NUMBER: AO-70136 BA 4of 9

a good tension measurement. See Figure 4 for

details.

Note: the UPB must be oriented so that the

resultant tension force direction (bisector of the

wrap angle) is in the same quadrant as the load

direction arrow on the side of the UPB.

Once the correct orientation is selected, you need

to tighten four locking bolts (not supplied)

accordingly to Figure 5.

English Metric

UPB

Length

min. (in.)

Torque

(ft.-lbs.)

Length

min. (mm)

Torque

(N-m)

1 1.00 10 25 15

2 1.50 30 40 40

3 2.50 150 65 200

Figure 5

2.6 INSTALLATION OF PILLOW BLOCK

BEARING

Remove the mounting plate, then drill and tap it to

match the pillow block mounting dimensions. A

centerline mark is provided on the mounting plate.

The plate is to be drilled and tapped by utilizing

this centerline mark to insure that the pillow block

bearing is centered on the plate. Remount the plate

and bolt the pillow block bearing to it. The

mounting plate is 304 Stainless Steel, which is

amenable to drilling but offers corrosive and

chemical resistance. Refer to J in the table above

for the maximum bolt diameter recommended for

bolting the pillow block bearing to the mounting

plate.

2.7 EXTREMELY SEVERE APPLICATIONS

For applications that can create major build-ups of

material (paint, glue…), it is recommended to close

the exposed gaps of the transducer. A good way to

do this is to use Electrical Tape all around the side

of the UPB Transducer (See figure 7).

Figure 7

Figure 6

Instructions for Mounting the Pillow Block

Bearing to the UPB Load Cell (see Figure 6)

Mounting the pillow block bearing to the UPB is

2.8 SHAFT EXPANSION

If the roller is subjected to higher temperatures after

installation, thermal shaft expansion may damage

the transducers. To prevent damage to the

transducers, an expansion type pillow block bearing

should be used.

simple and convenient. The UPB is shipped with a

pillow block mounting plate. The mounting plate

is held in place by four stainless steel corner bolts.

INSTRUCTION NUMBER: AO-70136 BA 5of 9

3.0 ELECTRICAL CONNECTION

EXCITATION

VOLTAGE

SHIELD

OUTPUT

SIGNAL

(-)

(+)

(-)

(+)

WIRING DIAGRAM FOR TRANSDUCERS

BLK

WHT

RED

BLK

WHT

RED

Figure 8

Refer to the installation wiring diagrams supplied

with the Cleveland-Kidder tension indicator or

controller for making the transducer connections.

Make certain that the cables do not interfere with

the web path and that they are away from gearing

or other moving parts.

Many of the Cleveland-Kidder indicators and

controllers use only half bridge transducer inputs

and then sum the two transducer signals internally.

See the applicable installation wiring diagrams for

the tension indicator or controller.

3.1 MATING CONNECTORS FOR

TRANSDUCERS

USE CMC P/N

Mating Straight Connector,

Boot and Clamp Kit MO-09854

Mating 90

Angle Connector,

Boot and Clamp Kit MO-09855

These are not sealed for washdown duty. For

washdown duty mating connector consult CMC.

3.2 INTRINSICALLY SAFE

TRANSDUCERS

These transducers are intrinsically safe only when

they are part of a complete intrinsically safe

TENSION GAGE

B

TEMP. COMPENSATION

NETWORK

A

COMPRESSION GAGE

C

TENSION GAGE

B

TEMP. COMPENSATION

NETWORK

A

COMPRESSION GAGE

C

NO. 1

TRANSDUCER

NO. 2

TRANSDUCER

system using the TIX-1 tension indicator or wired

per CMC control drawings.

Barrier block assemblies and/or the individual

barrier blocks may be purchased from CMC. Please

contact CMC for part numbers and pricing.

4.0 TEMPERATURE

COMPENSATION

The transducers are supplied with a temperature

compensation network (except size 1 which don’t

require it) which is in series with the output signal

lead. The compensation circuit is designed to be

used with a tension amplifier which has an input

impedance of 10K Ohms when a pair of transducers

connected as a full bridge is used. If only one

transducer is used, the tension amplifier impedance

should be 5K Ohms. If other than the input

impedances given above are used, drift will occur

in the tension amplifier output when the transducer

temperature changes.

5.0 SINGLE TRANSDUCER

OPERATION

For those applications where only one transducer is

required, a dummy circuit may or may not be

required depending upon the input circuit of the

tension amplifier. Consult the factory for this

information. The dummy circuit consisting of two

resistors is substituted in place of the second

transducer. The resistors should have a resistance

value between 100 and 150 Ohms and should be

matched to within 1%. Dummy circuits are

available from the factory for connecting to tension

indicators or controllers.

6.0 TROUBLESHOOTING

6.1 EXCESSIVE OUTPUT SIGNAL

WITH NO LOAD

There may be a high degree of misalignment of the

transducers causing a severe pre-load.

Or

The sensing guide roll assembly may be

excessively heavy. The sensing guide roll should

INSTRUCTION NUMBER: AO-70136 BA 6of 9

not weigh more than ½ the maximum working

force of the transducers in most cases.

Or

The surface under the UPB is not flat enough.

Or

The bolting torque is not in accordance with

Figure 5 (especially for UPB with MWF under

250 lb.).

6.2 LOW OUTPUT SIGNAL

The transducer may have too large a maximum

working force for the application. Replace with a

lower maximum working force transducer or

increase web wrap angle.

6.3 WRONG POLARITY OF OUTPUT

SIGNAL

Transducers may have been incorrectly oriented.

See Section 2.4 for proper load direction.

Alternately, change the transducer excitation

voltage by interchanging the B and C connections.

6.4 OUTPUT SIGNAL NOT LINEAR,

ZERO SHIFTS DURING

OPERATION

Check transducer and tension roll mounting. All

mounting bolts must be tight. Check that there is

no dirt or foreign matter interfering with the

transducer mounting. Check that mounting surface

is flat and rigid.

6.5 NO OUTPUT SIGNAL

Check to see that all connections have been made

completely. Check for places where the

connecting cables might be crimped or cut.

6.6 VERY HIGH OUTPUT WITH NO

LOAD

Check cables and connectors for good connections

and check continuity of cables with an ohmmeter.

Check for proper wiring to transducers. Check

transducer gage resistance as given in the

following chart at room temperature with no load

applied.

TRANSDUCER GAGE RESISTANCE CHECK

Resistance

(ohms)

Pin C to B 420±20 420±20

Pin A to B 210±10 900-1100

Pin A to C 210±10 900-1100

UPB 1 UPB 2/3

7.0 SERVICE ASSISTANCE AND

REPAIR

For additional service assistance, please obtain the

Type, MWF, and Serial Number from the

nameplate. Contact the Factory Service

Department.

Phone: 216-524-8800

Or 800-321-8072

Fax: 216-642-2100

Visit Us: www.cmccontrols.com

Disassembly by improperly trained personnel may

result in additional damage to these units. Should

repairs be required or for warranty repairs, contact

the Customer Service Department for a return

authorization number before returning the units.

INSTRUCTION NUMBER: AO-70136 BA 7of 9

8.0 USEFUL SPECIFICATIONS

8.1 WEIGHT

Complete

Unit

Without

mounting plate

8.2 RATINGS

SIZE RATING (LB) * ULTIMATE OVERLOAD (%)

UPB 1 25 to 1000 500

UPB 2

UPB 3 10000 to 30000 500

* Ultimate overload: Maximum force applied on the

transducer without risking permanent deformation. For

the Washdown duty UPB the output is linear up to the

point of the ultimate overload.

1000 to 10000 500

8.3 SIZING CALCULATION

T = Max Tension

A = Wrap Angle (degrees)

W = Roll Weight

B = Angle of tension force

K = Overload for Transients

(Nominally 1.4 for most applications)

MWF = Maximum Working Force

(This is used to select the proper force rating of the

transducer)

C = Mounting Angle

H = Bearing Height + D

SIZE L (in) D (in)

UPB 1 2.5 0.98

UPB 2 4.5 1.25

UPB 3 6.5 2.10

See figure 9.

∗

=

MWF

SIZING CALCULATION:

* The MWF calculation defines the force on each

individual load cell.

** If Angle b is below horizontal use + in calculation

If Angle b is above horizontal use - in calculation

Weight lb. (kg.) Each

UPB 1 UPB 2 UPB 3

3.7 (1.7) 22 (10) 102 (47)

1.5 (0.7) 12 (5.4) 59 (27)

20000 250

A

[][]

sin 2KT

2

±+

2L

∗∗

sinC H-cosC LWB LcosBHsin

Note: Consult CMC for assistance in sizing the load cell

to your specific application.

A

A/2

T

C

B

L

T

W

H

D

Figure 9

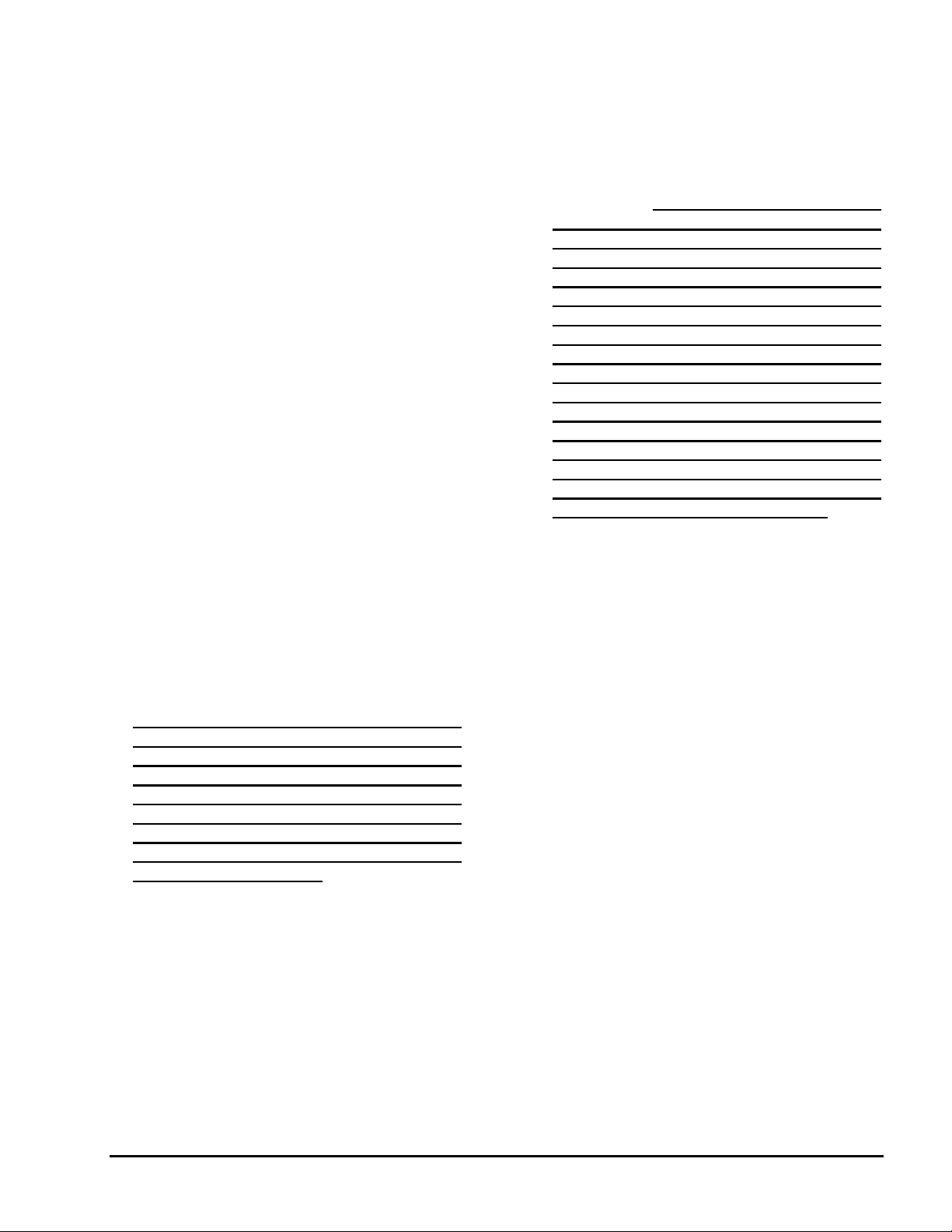

8.4 SELECTION CHART

Transducer MWF (lbs.)

UPB1

UPB2

UPB3

Ordering procedure:

1. Calculate the Maximum Working Force

2. From the Selection Chart, determine the part

3. Obtain pricing and delivery information by

Rating 25 50 100 250 500 1000

M846-12171- 000 100 200 300 400 500

Rating 1000 2500 5000 10000 20000

M846-12172- 000 100 200 300 400

Rating 10000 20000 30000

M846-12173- 000 100 200

(MWF) rating based upon your calculations

from the sizing calculation equation.

number for the UPB Washdown-Duty LC.

Select a MWF rating that equals or exceeds the

MWF from your sizing calculation. Then, make

sure that your pillow block bearing fits the UPB

type that you selected (UPB 1, 2 or 3).

Example: If you calculate a MWF of 2,204

lbs., select a UPB 2 rated at 2500 lbs. MWF

from the Selection Chart. You part number

is M846-12172-100. Then, from Figure 2.

make sure that you pillow block bearing fits

on the Size 2 transducer. If it does not,

please consult factory.

contacting a CMC sales representative,

distributor, or the factory.

INSTRUCTION NUMBER: AO-70136 BA 8of 9

LIMITED WARRANTY.

ALL GOODS ARE SOLD SUBJECT TO

THE MUTUAL AGREEMENT THAT

THEY ARE WARRANTED BY THE

COMPANY TO BE FREE FROM

DEFECTS IN MATERIAL AND

WORKMANSHIP FOR ONE YEAR

FROM THE DATE OF SHIPMENT. THE

COMPANY'S WARRANTY DOES NOT

COVER, AND IT MAKES NO

WARRANTY WITH RESPECT TO ANY

DEFECT, FAILURE, DEFICIENCY OR

ERROR WHICH IS:

A) NOT REPORTED TO THE

COMPANY WITHIN THE

APPLICABLE WARRANTY

PERIOD; OR

B) DUE TO MISAPPLICATION,

MODIFICATION, DISASSEMBLY,

ABUSE, MISUSE, IMPROPER

INSTALLATION, UNAUTHORIZED

REPAIR, IMPROPER

MAINTENANCE OR ABNORMAL

CONDITIONS OF TEMPERATURE,

DIRT OR CORROSIVE MATTER;

OR

C) DUE TO OPERATION, EITHER

INTENTIONAL OR OTHERWISE,

ABOVE RATED CAPACITIES OR

IN AN OTHERWISE IMPROPER

MANNER.

THE FOREGOING WARRANTY IS IN

LIEU OF ALL OTHER WARRANTIES.

THE PARTIES AGREE THAT THE

IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE AND

ALL OTHER WARRANTIES, EXPRESS

OR IMPLIED, ARE EXCLUDED FROM

THE SALE OF GOODS.

LIMITATION OF REMEDY AND

LIABILITY.

THE REMEDY PROVIDED HEREIN IS

BUYER'S SOLE AND EXCLUSIVE

REMEDY. THE BUYER'S REMEDY

AND THE COMPANY'S LIABILITY

(WHETHER UNDER THE THEORIES

OF BREACH OF WARRANTY,

CONTRACT, TORT INCLUDING

NEGLIGENCE OR STRICT LIABILITY

OR ANY OTHER LEGAL THEORY)

SHALL BE LIMITED EXCLUSIVELY

AT THE COMPANY'S OPTION TO

REPLACING OR REPAIRING

WITHOUT CHARGE AT THE

COMPANY'S FACTORY OR

ELSEWHERE ANY MATERIAL OR

WORKMANSHIP DEFECTS WHICH

BECOME APPARENT WITHIN ONE

YEAR FROM THE DATE ON WHICH

THE GOODS WERE SHIPPED. THE

COMPANY SHALL NOT BE LIABLE

FOR SPECIAL, INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY

KIND INCLUDING BUT NOT LIMITED

TO DAMAGES FOR LOSS OF USE,

INCOME OR PROFIT, OR LOSSES

SUSTAINED AS A RESULT OF INJURY

(INCLUDING DEATH) TO ANY

PERSON OR DAMAGES TO

PROPERTY. THE COMPANY SHALL

HAVE NO LIABILITY FOR DAMAGES

OF ANY KIND ARISING FROM THE

INSTALLATION AND/OR USE OF THE

GOODS BY ANYONE. BY THE

ACCEPTANCE OF THE GOODS, THE

BUYER SHALL ASSUME ALL

LIABILITY FOR ANY DAMAGES

WHICH MAY RESULT FROM USE OR

MISUSE BY THE BUYER, ITS

EMPLOYEES OR BY OTHERS.

INSTRUCTION NUMBER: AO-70136 BA 9of 9

Loading...

Loading...