Cleveland XVI 9-PCSM-L, XVI 9-PCGM-300-L, XVI 9-PCGM-250-L, XVI 9-PCEM-48-L, XVI 9-PCDM-L User Manual

Page 1

CLEVELAND

SteamPro™ XVI

PRESSURE / CONVECTION

STEAMER

OWNERS

MANUAL

Models: 9-PCEM -48-L

9-PCGM -250-L

9-PCGM -300-L

9-PCDM -L

9-PCSM -L

R

e

v

.

1

P

{

r

Printed 01/90

PCS-02

Page 2

Cleveland ALCO

PUBLICATION IMPROVEMENT RECOMMENDATION

Users of this publication are encouraged to report errors, omissions and

their recommendations for improving the publication. This sheet is

provided for that purpose. To file a Publication Improvement

Recommendation, fill in the information requested below, fold, tape and

mail this prepaid business reply form.

This Publication Improve ment

Recommendation pertains to manual __________________________ _____________

__________________________ Publication Date

of Manual

The following information Installation

was discovered during: (check one) Other (specify)__________________

Recommendation:_____________________________________________

(Be specific by referencing your remarks to page numbers, step numbers, etc.)

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

(Continue on back if needed)

Your name _____________________________________

(Please print)

Service office ___________________________________

(City) (State)

Telephone _____________________________________

(Area code) (Number)

Page 3

TABLE OF CONTENTS

Specification Information Page

9-PCEM-L (Electric) 3-4

9-PCGM-L (Gas) 5-6

9-PCDM-L (Direct Steam) 7-8

9-PCSM-L (Steam Coil) 9-10

Inspection and Unpacking 11

Installation Instructions 11

Installation Policies 11

Installation Ins tructions for all models 11-13

Installation Check 13

Introduction to SteamPro XVI Ownership 14

Operational Safety 14-15

Operational Functions 15-17

Control Panel Overview 16-17

Timer Information 16-17

Timer Programming 17

Timer Bypass

Operating Mode Selection

Basic Sequence of Operation 17-18

Start-Up and Preheat 18-19

Steaming Operation 19

Preventative Maintenance 20-21

Steamer Timer Programming Guide 22-23

Parts Breakdown 24-38

Electrical Wiring Diagram 39-40

Maintenance and Repair Center Information 41

Page 4

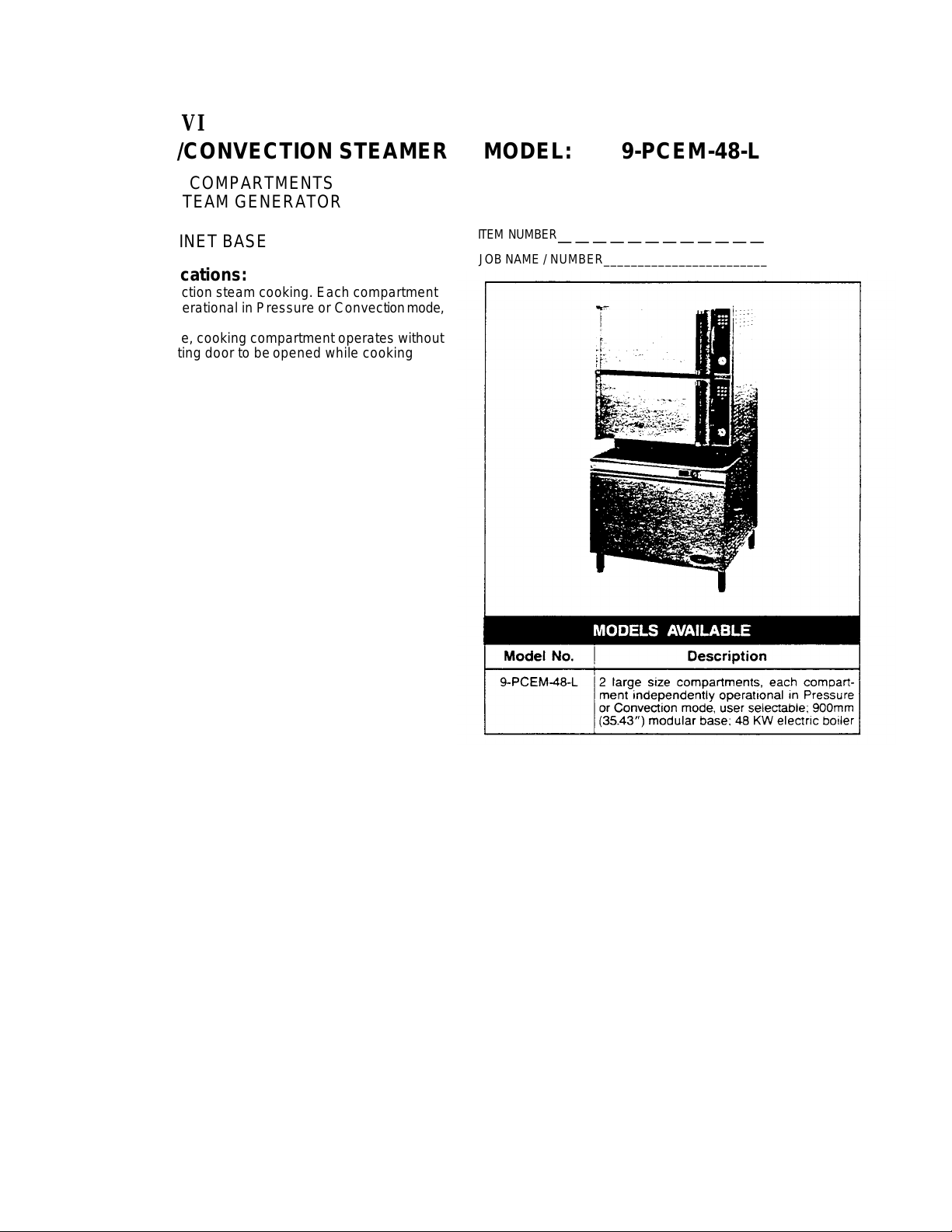

SteamPro® XVI

PRESSURE/CONVECTION STEAMER MODEL: 9-PCEM -48-L

• TWO LARGE COMPARTMENTS

• ELECTRIC STEAM GENERATOR

48 KW

• 900mm CABINET BASE

General Specifications:

• Pressure or Convection steam cooking. Each compartment

independently operational in Pressure or Convection mode,

user selectable

• In Convection mode, cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for safety

• Solid state, digital timer with wipe clean touch control panel:

one per compartment, each with 99 minute capacity plus

selectable "Repeat Cycle" feature

• High speed cooking with 10 psi operating pressure

• Standard voltage is 208V, 60 Hz, 3 phase, 3 wire

• Automatic temperature compensated timing action for

consistent product results

• Alternate manual operation mode (Convection only)

• "Clean Cove" corners in cooking compartments — easy to

clean

• Solid state controls for boiler and steam flow

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors,

table top

• Exterior sheathing is type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, all boiler controls and components, compartment drain lines and steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

(none furnished standard)

• Single cold water connection

• Boiler empties under pressure (blows down) automatically

upon each shut -down, automatic water fill upon start-up —

single button control*

• Standard control panel languages are English, French and

Spanish

ITEM NUMBER

JOB NAME / NUMBER__________________________________

———————————————

Options and Accessories:

"California Code" boiler controls compliance kit factory

installed. Single button control replaced by two button

controls

Voltages other than standard a

Cooking pans

8", 10" or 12" adjustable legs

Stainless Steel base frame (FSS)

3.

Page 5

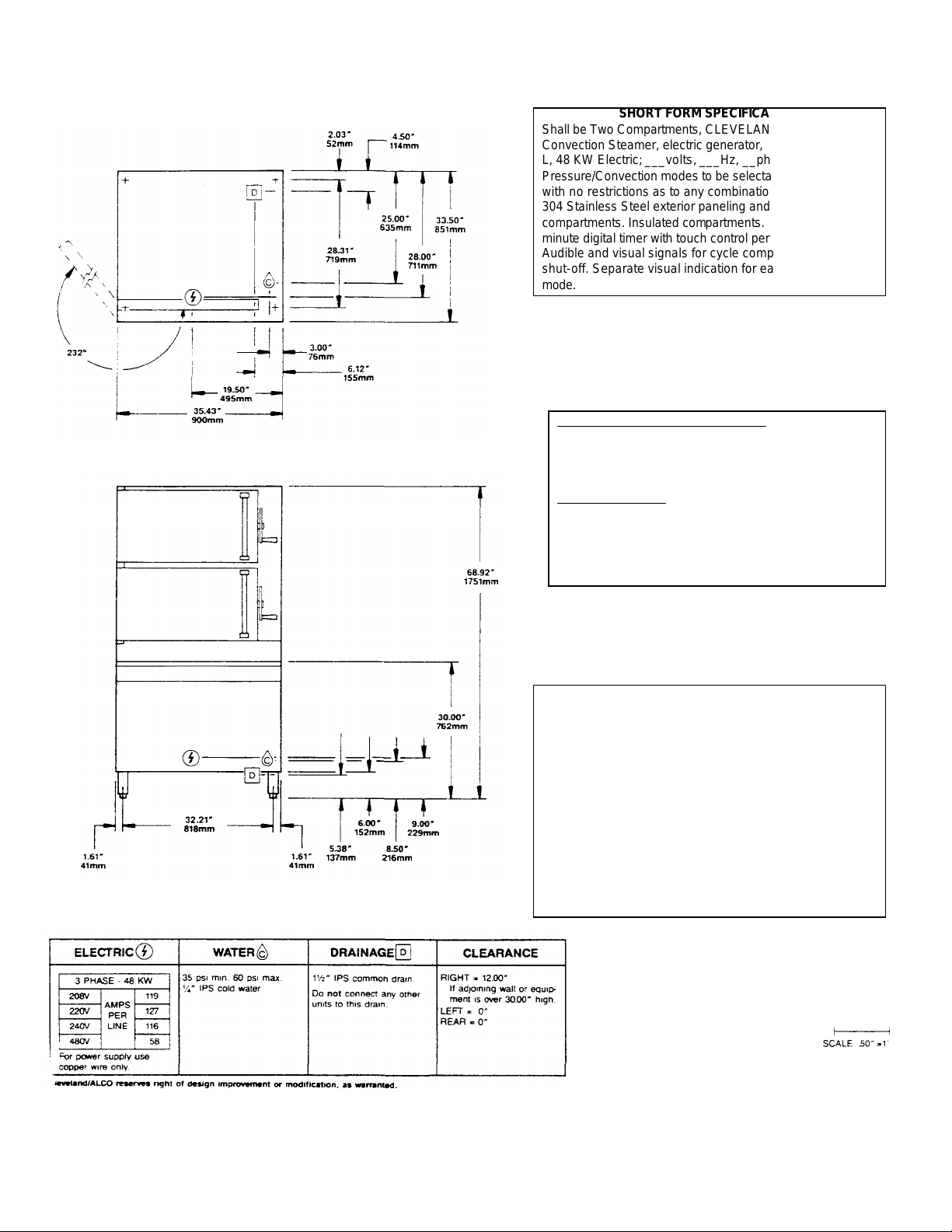

SHORT FORM SPECIFICATION

Shall be Two Compartments, CLEVELAND Pressure/

Convection Steamer, electric generator, Model 9-PCEM-48L, 48 KW Electric; ___volts, ___Hz, __phase, 3 wire.

Pressure/Convection modes to be selectable at user's option

with no restrictions as to any combination of modes. Type

304 Stainless Steel exterior paneling and cooking

compartments. Insulated compartments. One solid state, 99

minute digital timer with touch control per compartment.

Audible and visual signals for cycle completion and steam

shut-off. Separate visual indication for each operational

mode.

•Each compartment has capacity for:

Eight, 12" x 20" x 2 1/2" pans. Can accommodate

18" x 26" bun pans.

• Many local codes exist and it is the responsibility of the

owner and installer to comply with those codes.

•Cleveland/ALCO equipment is built to comply with

applicable standards for manufacturers. Included among

those approval agencies are: UL, A.G.A., NSF,

ASME/N.Bd., CSA, CGA, ETL, and others.

The recommended minimum water quality standards

whether untreated or pre-treated, based upon 10 hours of

use per day, and a Daily Slowdown, are as follows:

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than13 parts per million

pH FACTOR greater than 75

Consult a local water treatment specialist for an on site

water analysis for recommendations concerning steam

generator feed water treatment (if required), in order to

remove or reduce harmful concentrations of minerals. The

use of highly mineralized water will mean that more frequent

servicing of the steam generator will be necessary. The fact

that a water supply is potable is not proof that it will be

suitable for the generator.

WATER QUALITY REQUIREMENT

4.

Page 6

SteamPro® XVI

PRESSURE/CONVECTION STEAMER

• TWO LARGE COMPARTMENTS

• GAS STEAM GENERATOR

250 or 300M BTU

• 900mm CABINET BASE

General Specifications:

• Pressure or Convection steam cooking. Each compartment

independently operational in Pressure or Convection mode,

user selectable

• In Convection mode. cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for safety

• Solid state, digital timer with wipe clean touch control panel,

one per compartment, each wit h 99 minute capacity plus

selectable "Repeat Cycle" feature

• Automatic temperature compensated timing action for

consistent product results

• Alternate manual operation mode (Convection only)

• "Clean Cove" corners in cooking compartments — easy to clean

• Solid state controls for boiler and steam flow

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors, table top

• Exterior sheathing is type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, all boiler controls and components, compartment drain lines and steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

• Single cold water connection

• Boiler empties under pressure (blows down) automatically

upon each shut -down, automatic water fill upon start-up —

single button control.'

• Standard control panel languages are English, French and

Spanish

• Electronic spark ignition

MODELS: 9-PCGM-250-L

9-PCGM-300-L

ITEM NUMBER___________________________

JOB NAME / NUMBER______________________

Options and Accessories:

* "California Code" boiler controls compliance kit factory

installed. Single button control replaced by two button

controls

Gas other than natural

Cooking pans

8", 10" or 12" adjustable legs

Stainless Steel base frame (FSS)

5.

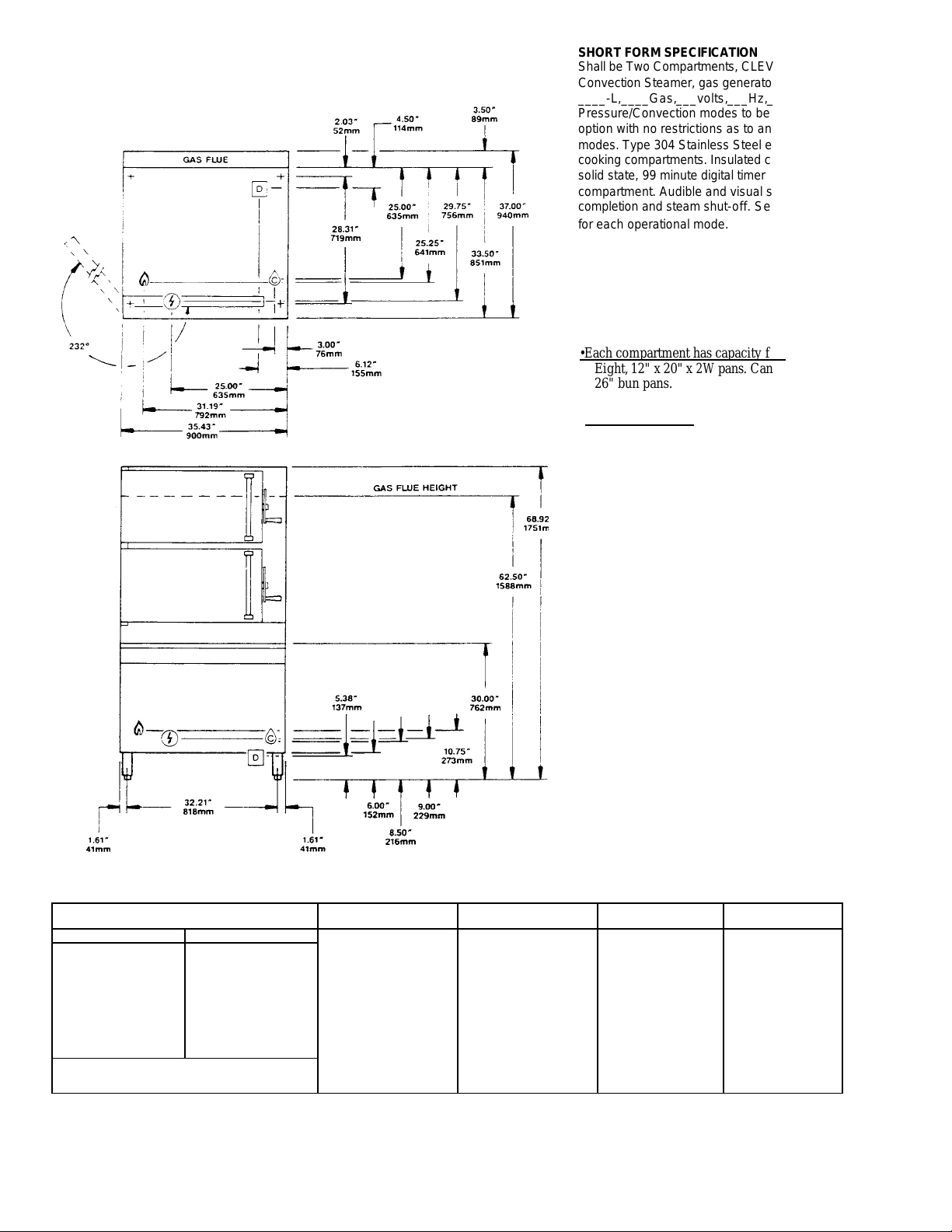

Page 7

NATURAL

PROPANE

1” IPS for

Used above 2,000 ft. altitude.

SHORT FORM SPECIFICATION

•Each compartment has capacity for:

Shall be Two Compartments, CLEVELAND Pressure/

Convection Steamer, gas generator, Model 9-PCGM ____-L,____Gas,___volts,___Hz,___phase.

Pressure/Convection modes to be selectable at user's

option with no restrictions as to any combination of

modes. Type 304 Stainless Steel exterior paneling and

cooking compartments. Insulated compartments. One

solid state, 99 minute digital timer with touch control per

compartment. Audible and visual signals for cycle

completion and steam shut-off. Separate visual indication

for each operational mode.

Eight, 12" x 20" x 2W pans. Can accommodate 18" x

26" bun pans.

•Many local codes exist and it is the responsibility of the

owner and installer to comply with those codes.

•Cleveland/ALCO equipment is built to comply with

applicable standards for manufacturers. Included among

those approval agencies are UL, A.G.A., NSF,

ASME/N.Bd., CSA, CGA, ETL, and others.

WATER QUALITY REQUIREMENT

The recommended minimum water quality standards

whether untreated or pre-treated, based upon 10

hours of use per day, and a Daily Blowdown, are as

follows:

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

pH FACTOR greater than 7.5

Consult a local water treatment specialist for an onsite

water analysis for recommendations concerning

steam generator feed water treatment (if required),

in order to remove or reduce harmful concentrations of

minerals. The use of highly mineralized water will mean

that more frequent servicing of the steam generator will be

necessary. The fact that a water supply is potable is not

proof that it will be suitable for the generator.

GAS ELECTRIC WATER DRAINAGE CLEARANCE

Piping-1” IPS for

240,000 BTU or more.

Supply pressure

4.00” W.C. Min.

14.00” W.C. Max.

Manufacturer must be notified if unit is to be

Cleveland/ALCO reserves right of design improvement or modification as warranted.

Piping-

Supply pressure

12.00” W.C. Min.

14.00” W.C. Max

240,000 BTU

or more.

115V-1 PH 25

watts per Compartment.

50 watts boiler control.

35 psi min. 60 psi max.

'/4” - IPS cold water

6.

1 1/2" IPS common

drain.

Do not connect any

other units to this

drain.

RIGHT = 12"

If adjoining wall or

equipment is over

30.00" high.

LEFT = 0"

REAR = 0"

For use only in

non-combustible

locations

Page 8

SteamPro™

XVI

PRESSURE/CONVECTION STEAMER

DIRECT STEAM

TWO LARGE COMPARTMENTS

900mm CABINET BASE

General Specifications:

• Pressure or Convection cooking, selected by the user, can be

in any combination at the same time, no restrictions

• In Convection mode, cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for sa fety

• Solid state, digital timer with wipe clean touch control panel,

one per compartment, each with 99 minute capacity plus

selectable "Repeat Cycle" feature

• High speed cooking with 10 psi operating pressure

• Automatic temperature compensated timing action for

consistent product results

• Alternate manual operation mode (Convection only)

• "Clean Cove" corners in cooking compartments — easy to

clean

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors, table

top

• Exterior sheathing is Type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, compartment drain lines and

steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

(none furnished standard)

• Single cold water connection

• Standard control panel languages are English, French, and

Spanish

A Clean, non-toxic, uncontaminated steam is required at the

steamed

MODEL: 9-PCDM-L

Options and Accessories:

Reversed door opening: hinges at right, controls on

left

Cooking pans

8", 10" or 12" adjustable legs

Stainless steel base frame (FSS)

7.

Page 9

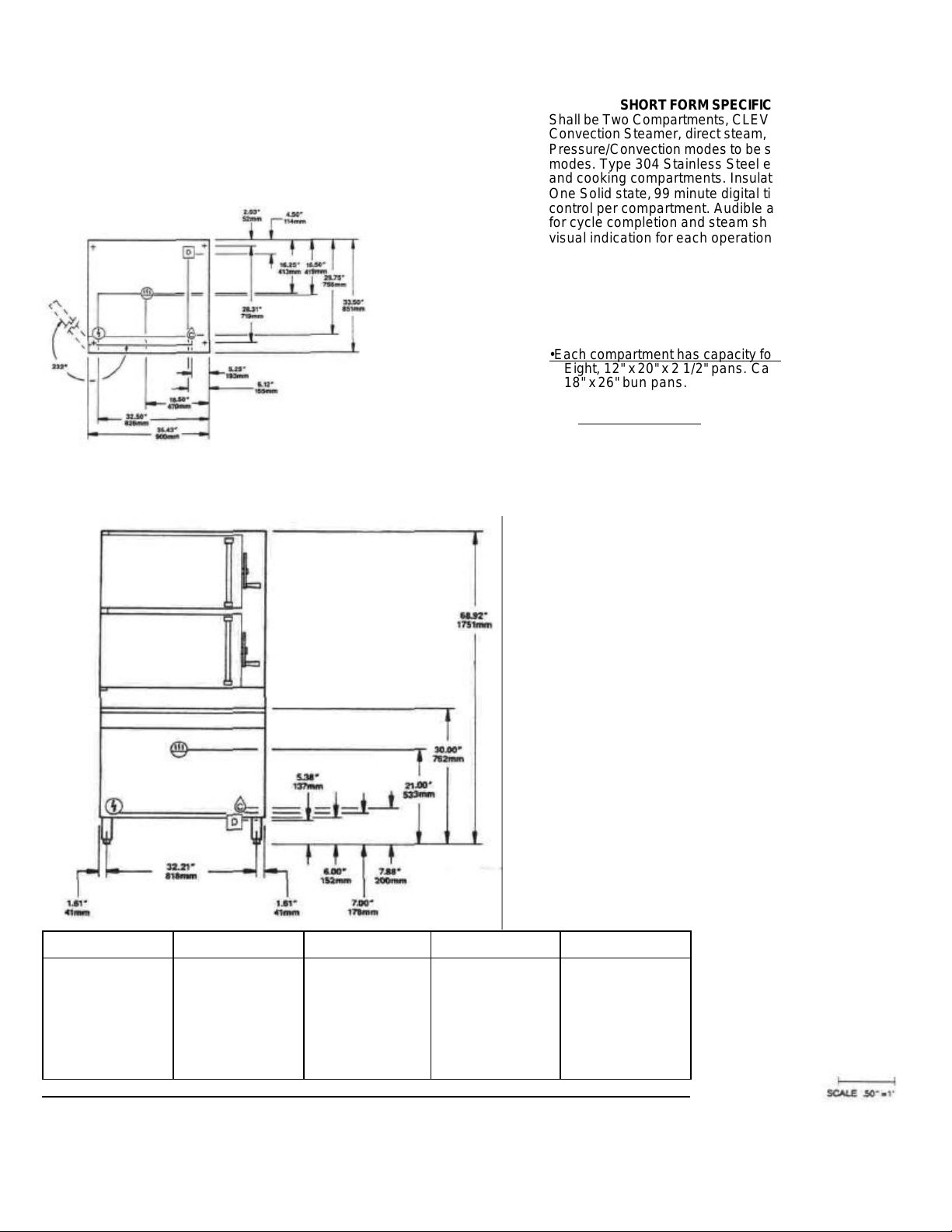

Shall be Two Compartments, CLEVELAND, Pressure/

SHORT FORM SPECIFICATION

Convection Steamer, direct steam, Model 9-PCDM-L,

Pressure/Convection modes to be selectable at user's

modes. Type 304 Stainless Steel exterior paneling

and cooking compartments. Insulated compartments.

One Solid state, 99 minute digital timer with touch

control per compartment. Audible and visual signals

for cycle completion and steam shut -off. Separate

visual indication for each operational mode.

•Each compartment has capacity for:

Eight, 12" x 20" x 2 1/2" pans. Can accommodate

18" x 26" bun pans.

•Many local codes exist and it is the responsibility of

the owner and installer to comply with those codes.

•Cleveland/ALCO equipment is built to comply with

applicable standards for ma nufacturers. Included

among those approval agencies are: UL, A.G.A.,

NSF, ASME/N.Bd., CSA, CGA, ETL, and others.

DIRECT STEAM WATER (C) DRAINAGE (D) ELECTRIC® CLEARANCE

Steam Supply:

Furnish 3/4" IPS mm.

line. 40 psi mm. SO psi

max. required, for

pressures above 50 psi.

an additional pressure

reducing valve must be

specified.

Cleveland/ALCO reserves right of design improvement Of modification — warranted

40 psi min. 60 psi max.

3/8 IPS cold water

1 1/2" IPS common

drain.

Do not connect any

other units to this drain.

115V-1PH 25 watts per

compartment

RIGHT - 12.00"

If adjoining wall or equipment is over 30.00" high.

LEFT = 0"

REAR = 0"

8.

Page 10

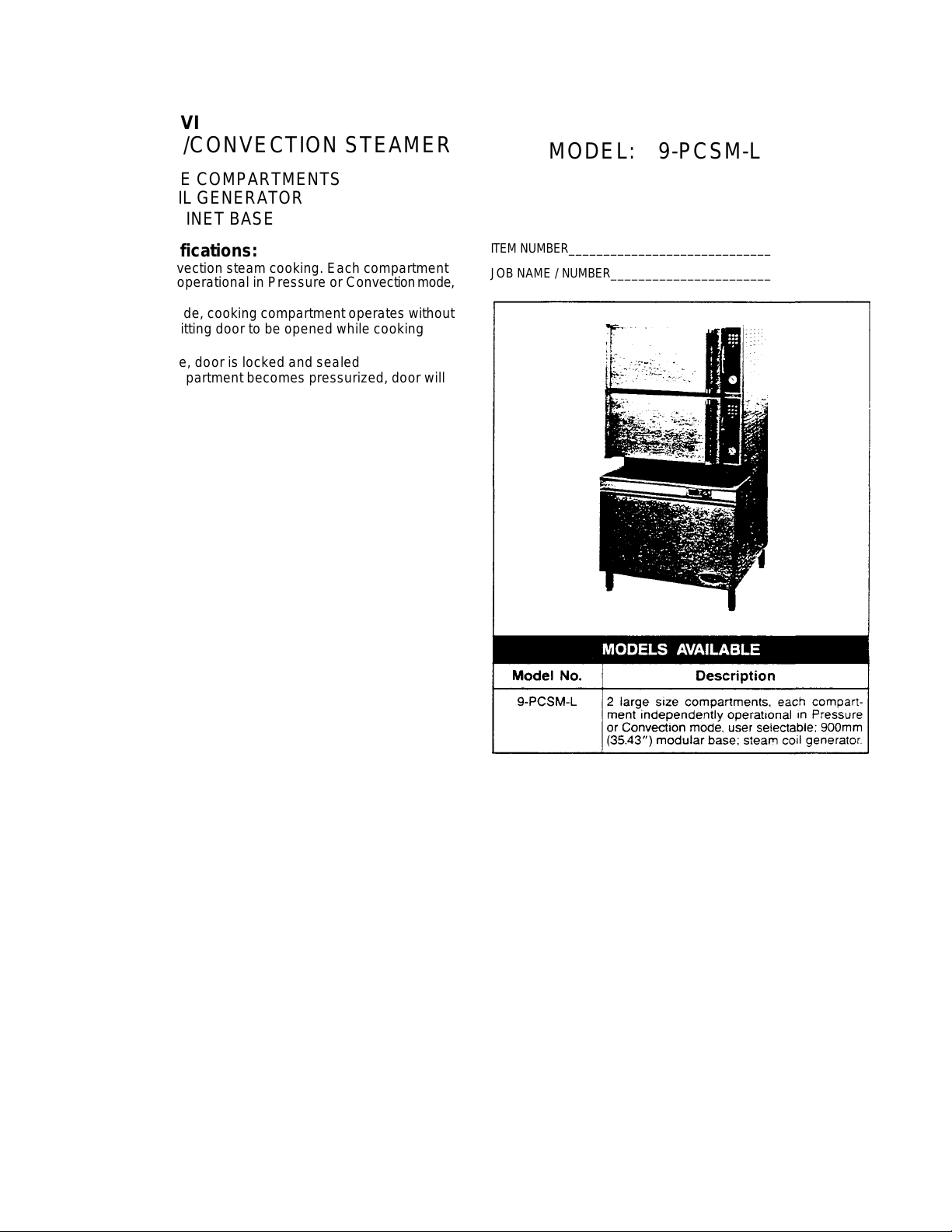

SteamPro® XVI

PRESSURE/CONVECTION STEAMER

• TWO LARGE COMPARTMENTS

• STEAM COIL GENERATOR

• 900mm CABINET BASE

General Specifications:

• Pressure or Convection steam cooking. Each compartment

independently operational in Pressure or Convection mode,

user selectable

• In Convection mode, cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for safety

• 10 psi operating pressure in Pressure mode

• Solid state, digital timer with wipe clean touch control panel,

one per compartment, each with 99 minute capacity plus

selectable "Repeat Cycle" feature

• Automatic temperat ure compensated timing action for

consistent product results

• "Clean Cove" corners in cooking compartments — easy to

clean

• Solid state controls for boiler and steam flow

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors, table top

• Exterior sheathing is type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, all boiler controls and components, compartment drain lines and steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

• Single cold water connection

• Boiler empties under pressure (blows down) automatically

upon each shut -down, automatic water fill upon start-up

• Standard control panel languages are English, French, and

Spanish

MODEL: 9-PCSM-L

ITEM NUMBER________________________________________

JOB NAME / NUMBER__________________________________

Options and Accessories:

"California Code" boiler controls compliance kit factory

installed.

Voltages other than standard (115V)

Cooking pans

Stainless steel base frame (FSS)

8", 10" or 12" adjustable legs

9.

Page 11

ing

Cleveland/ALCO reserves right of design improvement or modification, as warranted.

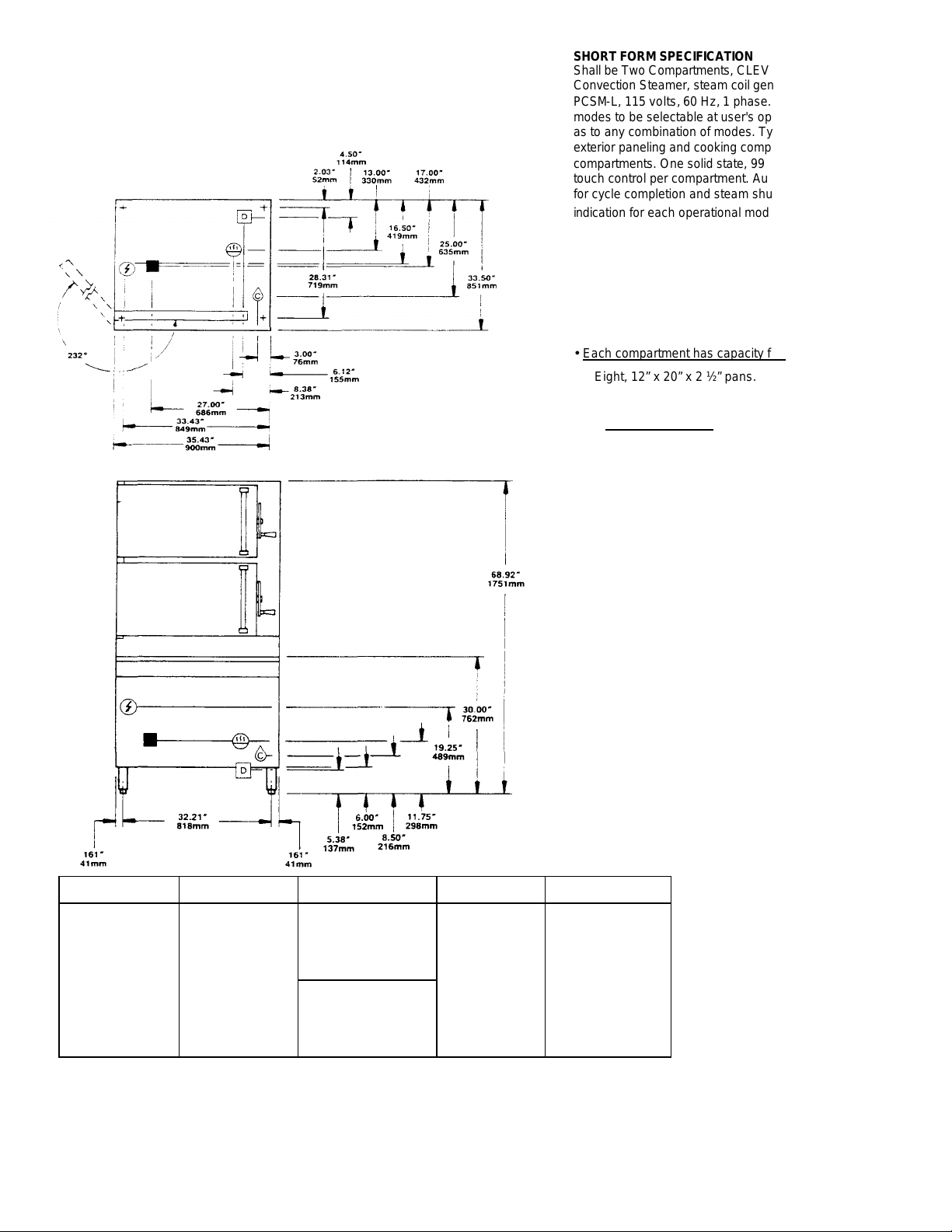

SHORT FORM SPECIFICATION

Scale .

50

"=1’

Shall be Two Compartments, CLEVELAND Pressure/

Convection Steamer, steam coil generator, Model 9PCSM -L, 115 volts, 60 Hz, 1 phase. Pressure/Convection

modes to be selectable at user's option with no restrictions

as to any combination of modes. Type 304 Stainless Steel

exterior paneling and cooking compartments. Insulated

compartments. One solid state, 99 minute digital timer with

touch control per compartment. Audible and visual signals

for cycle completion and steam shut-off. Separate visual

indication for each operational mode.

• Each compartment has capacity for:

Eight, 12” x 20” x 2 ½” pans.

• Many local codes exist and it is the responsibility of

the owner and installer to comply with those codes.

• Cleveland/ALCO equipment is built to comply with

applicable standards for manufactures. Included

among those approval agencies are: UL, A.G.A.,

NSF, ASME/N.Bd., CSA, ETL, and others.

WATER QUALITY REQUIREMENT

The recommended minimum water quality standards whether

untreated or pre-treated, based upon 10 hours of use per day,

and a Daily Slowdown, are as follows:

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

pH FACTOR greater than 7.5

Consult a local water treatment specialist for an onsite

water analysis for recommendations concerning steam

generator feed water treatment (if required), in order to

remove or reduce harmful concentrations of minerals. The use

of highly mineralized water will mean that more

frequent servicing of the steam generator will be necessary.

the fact that a water supply is potable is not proof that it will be

suitable for the generator.

STEAM COIL WATER DRAINAGE ELECTRIC CLEARANCE

Steam Supply

Piping: • ¾” IPS

min. for 35 to 50 psi.

• For pressure

above 50 psi, a

pressure reduc

valve must be

specified.

35 psi. min. 60 psi ©

max. 3/8" IPS cold

water.

1 ½” IPS common

drain.

Do not connect any

other units to this drain.

Steam Cold Drain

•3/4” IPS. Do not

connect to common

drain.

115V-1 PH

25 watts per

compartment.

RIGHT - 12.00"

If adjoining wall or

equipment is over

30.00" high.

LEFT = 0”

REAR =0”

10.

Page 12

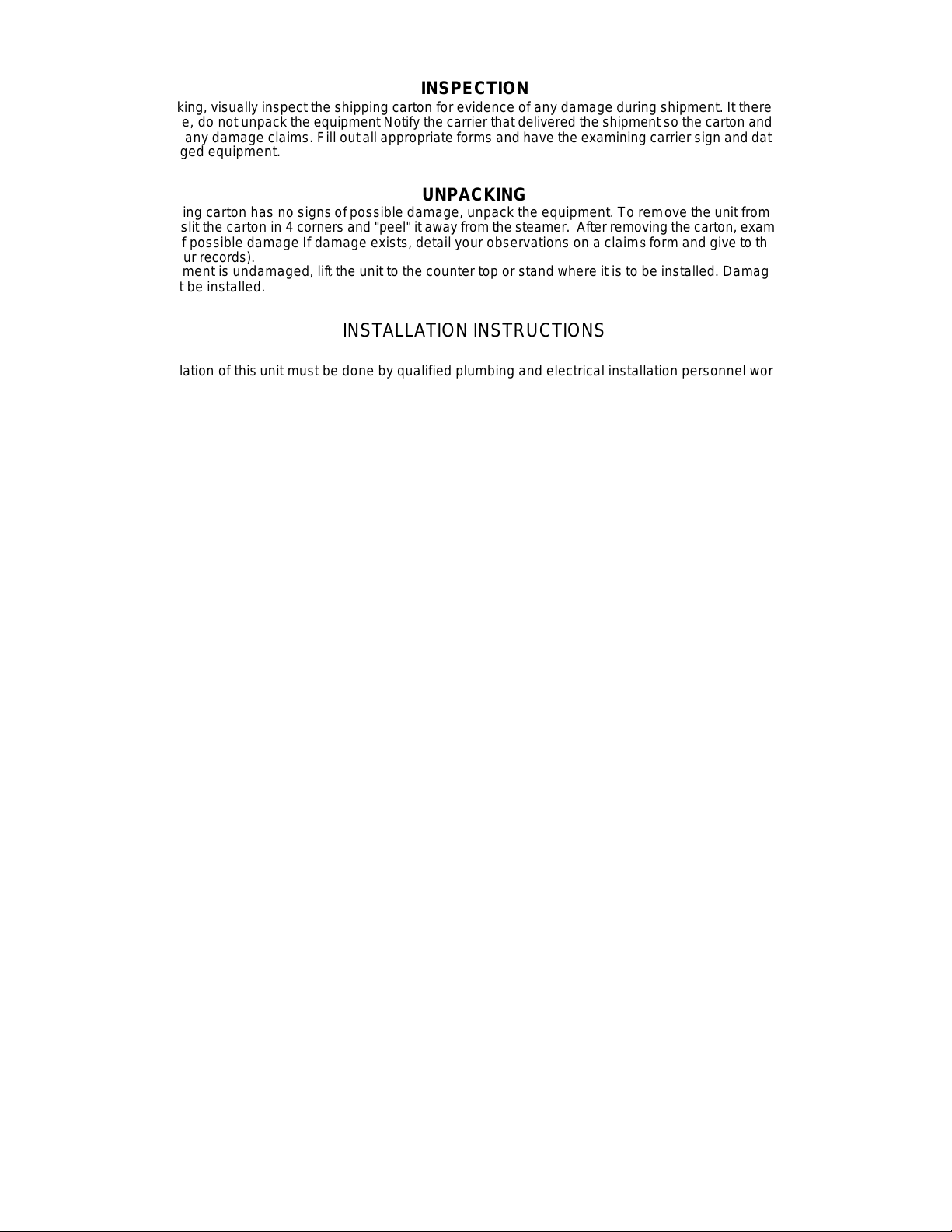

INSPECTION

Before unpacking, visually inspect the shipping carton for evidence of any damage during shipment. It there are signs of

possible damage, do not unpack the equipment Notify the carrier that delivered the shipment so the carton and its contents can

be examined for any damage claims. Fill out all appropriate forms and have the examining carrier sign and date each form. Do

not install damaged equipment.

UNPACKING

1. If the shipping carton has no signs of possible damage, unpack the equipment. To remove the unit from the carton. it is

easiest to slit the carton in 4 corners and "peel" it away from the steamer. After removing the carton, examine the steamer

for signs of possible damage If damage exists, detail your observations on a claims form and give to the shipper (keep a

copy for your records).

2. If the equipment is undamaged, lif t the unit to the counter top or stand where it is to be installed. Damaged equipment

should not be installed.

INSTALLATION INSTRUCTIONS

Warning: Installation of this unit must be done by qualified plumbing and electrical installation personnel working to all

applicable local and national codes. Improper installation of this product could cause injury or damage and void customer

warranty.

INSTALLATION POLICIES:

• Cleveland/ALCO equipment is designed and manufactured to comply with applicable standards for manufacturers. Included

among those certification agencies which have approved the safety of the equipment design and construction are:

UL NSF, CSA, and others.

• Cleveland/ALCO equipment is designed and certified for safe operation only when permanently installed in accordance with

local and/or national codes. Many local codes exist, and it is the responsibility of the owner and installer to comply with these

codes.

• In no event shall Cleveland/ALCO assume any liability for damage or injury resulting from installations which are not in strict

compliance with our Installation Instructions. Specifically, Cleveland/ALCO will not assume any liability for damage or injury

resulting from improper installation of equipment, including, but not limited to, temporary or mobile installations.

INSTALLATION INSTRUCTIONS FOR ALL MODELS:

WARNING INSTALLER: ALL SteamPro XVI units MUST BE securely anchored to the floor at all times.

1. These instructions must be retained by the owner/user for future reference. Gas-fired boilers are only to be

installed in noncombustible areas that have provisions for adequate air supply. The term "boiler" will be used

synonymously with "steam generator".

2. Position: For proper operation and drainage, the equipment must be level. It should be placed next to an open floor

drain. DO NOT POSITION THE UNIT DIRECTLY ABOVE THE FLOOR DRAIN. Observe all clearance

requirements to provide air supply for proper operation, as well as sufficient clearance for servicing. The

surrounding area must be free and dear or combustibles. Dimensions and clearance specifications for each model

are shown on the specification sheets enclosed.

3. Inst all in accordance with local codes and/or the National Electrical Code ANS1/NFPA No. 70-1984. Installation in

Canada must be in accordance with the Canadian Electrical Code CSA Standard C22-1. Equipment that Is

connected to electricity must be grounded by the installer A wiring diagram Is provided inside the base cabinet.

4. Attach drain extension piping to the drain connection to carry steam condensate and boiler drain water away from

the cabinet, to the floor drain. The drain extension piping must be 1 1/ 2" diameter minimum (ips), and not exceed

6 feet in length, with no more than two elbows, before draining. The drain extension termination MUST vent freely

to the air (not plumbed solidly into the floor drain). Each unit requires its own 1 1/2" diameter drain extension. Do

not interconnect any other drains to this units drain extension. Ensure that the boiler's manual drain valve is

closed.

11.

Page 13

5. Connect COLD water supply plumbing to the line strainer. (Never connect hot water to the boiler's water fill line

strainer). Constant flow pressure must be maintained between 40 and 60 psi. and not experience a pressure drop

below 35 psi when other appliances are used. If the water pressure exceeds 60 psi, a pressure reducing valve must

be installed in the water supply plumbing to reduce the water pressure to less than 60 psi. Locations and pressure

data are shown on the specification sheet. 3/8" ips plumbing is required for water supply lines regardless of length.

Rush water supply lines thoroughly before connecting them to the unit Use water which Is low in total dissolved

solids content and low in gas content to prevent Internal scaling, pitting and corrosion of the steam generator and

carry-over of minerals into the steam. (Water which is fit to drink can still contain highly detrimental impurities.)

6. Turn on the cold water supply to the unit. Ensure that the manual water valve, inside the base cabinet, is open.

7. Connect the primary fuel supply in accordance with the following instructions. Location and other data are shown on

the specification sheet.

For Gas-Fired Steam Generators:

Post, in a prominent location. Instructions to be followed In the event the user smells gas. This information shall be

obtained by consulting the local gas supplier. Install as a sediment trap (drip leg) in the gas supply line, then connect

gas supply piping to the boiler's gas valve piping. GAS-FIRED EQUIPMENT IS DESIGNED FOR INSTALLATION

ONLY IN NON-COMBUSTIBLE LOCATIONS. Location, plumbing size, and pressure data Is shown on the specification

sheet. Boilers rated at less than 225.000 BTU require 3/4" ips gas supply piping, and boilers rated at 225,000 BTU

or more require 1" gas supply piping. Natural gas supply pressure must be between 4"-14" water column and LP gas

supply pressure must be between 12" -14" water column. NEVER EXCEED 14" WATER COLUMN (1/2 psi) GAS

PRESSURE. If the gas supply pressure ex ceeds 14" water column a pressure regulating valve must be installed in

the gas supply plumbing to reduce the gas pressure to less than 14" water column. Installation must be In accordance with

local codes or in the absence of local codes, with the National Fuel Gas Code, ANSlZ223.1-1984. Installation in

Canada must be in accordance with Installation Codes for Gas Burning Appliances and equipment B149.1 and

Bl49.2-Use a gas pipe Joint compound which is resistant to LP gas. Turn the gas valve's control knob to "on" (the

word "on" on the knob will be opposite the Index on the valve's body). Test all pipe joints for leaks with soap and

water solution. New obstruct the flow or combustion and ventilation air. Observe clearance requirements to provide

adequate air openings into the combustion chamber. The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during any pressure testing of that system at test pressures in

excess of 1/2 pri (14" water column or 3.45 kPa). The appliance must be isolated from the gas supply piping system

at test pressures equal to or less than 1/2 psi (14" water column or 3.45 kPa). A permanent 115 volt electrical

connection is required at the Junction box. Location shown on the specification sheet. The unit must be electrically

grounded by the installer.

For Electric Powered Steam Generator's

Connect electric power location and data are shown on the specification sheet Provide connection as required

by your unit; either directly to the single contactor, or to the terminal block (when equipped with mutiple contactors).

Electric supply must match power requirements specified on the data plate inside the base cabinet. The copper

wiring must be adequate to carry the required current at the rated voltage. A separate fused disconnect switch must

be supplied and Installed. The unit must be electrically grounded by the installer.

For Direct-Steam-Connected Steamers:

Connect steam supply piping to the input side or the line strainer. Location and pressure data are shown on the

specification sheet Flush the steam line thoroughly before connecting it to the steamer ensure an adequate volume

or steam, the branch steam supply line must be 3/4" ips minimum. A permanent 115 volt electrical connection is

required at the junction box. The junction box location is shown on the specification sheet. The unit must be

electrically grounded by the installer.

8. Press the "power" on-off rocker switch. The red indicator light in the switch will come on and the boiler will begin to fill

with water. Direct-Steam-Connected steamers are not equipped with self -generating, boilers or "steam" switches.

Therefore, these models do not require the 5 minute boiler water fill time, nor is it necessary to push a "steam"

switch to produce steam, as Indicated In step #9. As soon as the pressure gauge on the control panel registers 10

psi (5 psi for pressure steamers), preheating may begin. (If you are operating a direct steam-connected steamer,

steps #9 and #10 do not apply. Refer directly to step #11.)

9. After about five minutes the amber light in the "steam" switch will glow indicating the water has reached a safe

operating level in the boiler. The "steam" switch can now be pressed (momentarily) in order to produce steam in the

boiler. This will activate the energy source (electric heaters, gas burners, or steam solenoid valve), and

12.

Page 14

Connect (To “House

Steam Supply

With or Without Kettles

to be connected to the “house” steam supply.

the amber light will go out The energy source cannot be activated until the boiler contains sufficient water indicated

by the amber light. The "steam" switch must be pushed to re-start the steamer after it is shut off for any reason

(including a momentary power interruption). Do not attempt to start or operate this appliance during a power failure.

Whenever the amber light is illuminated, the heater, steam supply, or burners are off, and no steam is being

generated.

NOTE FOR UNITS CONTAINING GAS-FIRED BOILERS ONLY: If the burners fail to ignite in four seconds,. a

safety circuit will de-energize the system. In this event, momentarily press the power switch to the "off"

position, then back to the "on" position. (The "steam" switch amber light should be on. Wait 5 minutes, then

press the "steam" switch to start the burner ignition cycle once again.)

10. Check to ensure that the water in the boiler's sight gauge glass stays at about 2/3 full when the boiler is started up

and operated.

11. Check to ensure that the steam pressure gauge registers 10 psi. The steam pressure is factory adjusted to provide

the proper pressure in some cases, however the factory setting may shift due to shaking in transit, and resetting

will be required after installation. Proper adjustments and maintenance procedures should be made only by

qualified service personnel. The factory pressure settings shown in the accompanying chart should never be

exceeded.

12. When the installation is complete and free of leaks, refer to the OPERATIONAL FUNCTIONS section, in order to

understand proper operation of the unit.

GUAGE PRESSURE READING WITH NO STEAM FLOW (STATIC PRESSURE)

Self-Contained Steam Generator Gas or Electric Self-Contained Steam Coil Generator Direct-

Steamer’s

Pressure

Equipment

Steam Generator Only 5 psi N/A 5 psi 10 psi 5 psi 10 psi 30-45 psi N/A N/A

Pressure Steamer N/A 5 psi 10 psi 5 psi 10 psi 30-45 psi 5 psi 12-45 psi

Pressure Steamer

With Any Kettle

Steam Generator Only

10 psi

Kettle Only N/A 10 psi 15 psi N/A N/A N/A N/A 5-45 psi

Convection Steamer

Reducing

Valve

5 psi 10 psi 15 psi 5 psi 10 psi 30-45 psi 5 psi 12-45 psi

N/A 10 psi 15 psi 10 psi 15 psi 30-45 psi N/A N/A

N/A 10 psi 15 psi 10 psi 15 psi 35-45 psi 10 psi 15-45 psi

Operating

Pressure

Switch

High Limit

Safety

Pressure

Switch

Operating

Pressure

Switch

High Limit

Safety

Pressure

Switch

Kettles are

Steam

Supply

Pressure

Range

Steam Supply)

Steamer’s

Pressure

Reducing

Valve

Pressure

Range

INSTALLATION CHECK

Proper operation of the Cleveland SteamPTO XVl Steamer is dependant upon proper installation. After the steamer has

been installed, a few quick checks could save unnecessary service calls.

1. The SteamPro'" XVI Steamer requires a cold water connection for proper, efficient operation. DO NOT USE HOT

WATER. The cold water must be connected to the line strainer located at the front lower-right of the steamer base.

Ensure that the manual water su pply valve is open.

The cold water feed One must maintain 40 to 60 psi constant flow pressure, and not experience a pressure drop

when other appliances are used. Both the hot and cold water lines should maintain 35 to 60 psi flow pressure.

2. The unit must be level.

3. On electric units, the supply voltage must agree with the voltage Indicated on the rating plate inside the base cabinet,

and with the voltage shown on the packing slip. The unit must be protected with a separate fused disconnect and be

properly grounded, in accordance with the National Electric Code.

Page 15

4. On Gas Steam Coil and Direct-Steam-Connected units. there is a 115 volt connection required at the junction box

located in the base ax the bottom front.

5. The drain extension termination must vent freely to the air (not plumbed solidly into the floor drain). The drain extension

piping must have a gravity flow, be 1 1/2" diameter minimum (IPS), and not exceed 6 feet in length with no more than

two elbows before draining. Each steamer requires its own 1 1/2" diameter drain extension. Do not interconnect any

other drains to this steamers' drain extension. Ensure that the manual drain valve is dosed.

REMEMBER: D0 NOT POSITION THE UNIT DIRECTLY ABOVE THE FLOOR DRAIN. AS RISING CLOUDS OF STEAM

CONDENSATE DAMAGE ELECTRONC COMPONENTS.

CAUTION Failure to comp ly with these drain instructions could result in the accumulation of hot water in the

cooking compartment .

6. On Direct-Connect units the incoming steam pressure must be 35 to 50 psi. and anything less than 35 psi will not

effectively operate this unit.

7. Gas-fired steam generators should never exceed a 14" water column or 1/2 psi gas pressure. Gas equipment is

designed for installation only in non-combustible locations.

Installer: Please complete and mail the Installer's Checklist.

INTRODUCTION TO SteamPr o XVI OWNERSHIP

To get the full advantage of steam cooking, Cleveland/ALCO SteamPro XVI must be properly installed. A steamer which

is improperly installed, improperly used, improperly maintained or improperly repaired will create a dangerous condition

and may cause injury to personnel.

OPERATIONAL SAFETY:

Your Cleveland/ALCO SteamPro XVI will require minimum servicing provided it is operated according to instructions and

given the care recommended.

Make sure that responsible personnel understand how your steam cooking equipment should be operated and cared for.

Proper use and maintenance pay handsome dividends in long life and satisfactory performance.

Safe steam cooking equipment operation dictates that every owner of steam cooking equipment should follow these rules

for operational safety:

1) Begin a comprehensive continuous program of intend and external steam cooking equipment inspection.

2) Never allow untrained personnel to operate or experiment with a steamer.

3) At the end of each days operation -

• Remove any spoiled food, then wash the racks and compartment interiors thoroughly with mild detergent in warm

water.

• Rinse thoroughly with clean warm water.

WARNING — Let rinse water drain through compartment drain opening. If water does not drain freely, drain lines must

be cleaned out before cooking again. Clogged or slow drains are dangerous because hot water may collect and spill out

when compartment doors are opened after a cooking cycle.

• When cleaning the steamer's exterior, BE SURE THAT POWER TO THE UNIT IS OFF. Never apply water to

controls on the console. Use a damp cloth for cleaning.

4) Always leave the compartment door ajar when the compartment is not in use.

14.

Page 16

• On boiler equipped steamers, blow down the boiler. Then refill the boiler with water, and shut off the power

switch.

• On direct connected steamers, cut off the main steam supply with a valve ahead of the steamer's pressure

reducing valve

6) Read and follow the Cleveland/ALCO Instructions on steamer and steam generator maintenance in the Owners

Manual,

7) Only allow the use of replacement parts which are factory authorized as equivalent to the parts being replaced, to

preserve the certification of Underwriters Laboratories, American Gas Association, Canadian Standards Association or Canadian Gas Association (as applicable).

8) Never allow unqualified personnel to tamper with the steamer or steam generator controls, or to replace worn out

parts.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other appliance

9) For gas fired steam generators (boilers): Post In a prominent location Instructions to be followed in the event

the user smells gas. This Information shall be obtained by consulting the local gas supplier.

For additional information on steamer safety, refer to the steamer operating procedure on page

Instructions for the occasional servicing that will be needed are given on pages 18-19 Servicing beyond these in-

structions should not be attempted without specialized skills and experience. Such attempts may void the warranty on

the equipment.

OPERATIONAL FUNCTIONS

Operation of the Cleveland SteamPro XVI Is very easy. Each operator should become familiar the following operation

functions and procedures to effectively start, operate and shut down the steamer.

CONTROL PANEL OVERVIEW: ————————————————————————————————————

CAUTION The touch pad controls are designed to be pressed with finger tips only. Be careful not to use fingernails,

kitchen utensils or anything that could cause damage.

"DIGITAL TIME DISPLAY" - Time programmed In the Pressure or Convection mode will be displayed here In red

numbers. A maximum of "99" minutes can be programmed. During operation, time displayed will countdown to "00".

"00" will blink until the compartment door is opened. (When using the Manual mode, time displayed will stay at "00".

The Timer is not used in this mode.)

"TIMER TOUCH PANEL” - "Number" touch pads are used to program the desired cooking time for Pressure or

Convection mode. The Time entered will be shown in the DIGITAL TIME DISPLAY

"START/CANCEL" - Press this touch pad once to START the compartment operational mode process. The green

indicator light (LED 1) will come on and stay on until the touch pad is pressed again to CANCEL. When the

compartment temperature reaches 194%F (in either Pressure or Convection mode) the green indicator light (LED 2)

will come on and start flashing until countdown is completed. START/CANCEL is not used when in "Manual

Operation" mode or TIMER BYPASS function.

"PRESSURE OPERATION" -Press this touch pad to change from the Convection mode to the Pressure mode. The

red indicator light (LED 3) will come on and stay on until the steaming cycle is completed, the compartment is depressurized (the "LOCKED" symbol will go out) and the compartment door is unlatched.

WARNING: At the end of a Pressure mode steaming cycle, wait at least 2 minutes for the compartment to depressurize and drain before opening the compartment door. Premature opening can result in steam or hot water

bums.

15.

Page 17

"MANUAL OPERATION" - Press the touch pad to operate the compartment in the Convection mode but without the

use of the START/CANCEL touch pad, the TIMER TOUCH PANEL or the DIGITAL TIME DISPLAY. The green

indicator light (LED 4) will come on and stay on until the touch pad is pressed again. "COMPARTMENT PRESSURE" Use this gauge to monitor the compartment pressure.

WARNING Open the compartment door only when the Pressure Gauge returns to "0" PSI. If the gauge does not indicate “0” PSI,

do not attempt to pull up on the compartment latch handle or to open the compartment door. The Unit must be serviced by qualified

personnel.

TIMER INFORMATION

Each cooking compartment is equipped with an independent electronic digital timer, which has maximum programming capability of

99 minutes. Each timer is connected to a temperature sensing device the cooking compartment. This sensor will allow the timer to

count down only when the internal compartment{s} reaches proper cooking temperature. This assures uniformity In the final

product as the timer automatically compensates for the amount and temperature of the in the compartment.

16.

Page 18

TIMER SETTINGS (programming)

Press the "Start/Cancel" touch pad once to ensure that no time remains in the timer. Program the desired cooking time. by

pressing the appropriate number pads. The time programmed will be displayed above the "Number" touch pads. Ex ample,

pressing the "1" pad, then the "2" pad programs 12 minutes.

Press the "Start/Cancel" pad to start the timer. This starts the flow of steam into the cooking compartment - Remember the timer

will begin to count down only after the compartment reaches proper cooking temperatures. After the programmed time has

counted down to zero, an alarm will sound for 5 seconds and steam flow (into the cooking compartment) will stop in "Manual

Operation" mode, the steamer operates as a Convection steamer only.

The timer must be programmed and started before steam will begin to flow into the selected steaming compartment,

whether in Pressure or Convection mode.

In either Pressure or Convection mode, the desired cooking time must be programmed Into the timer and the

"Start/Cancel" touch pad must be pressed (to begin the flow of steam). The timer will delay its' countdown, automatically

compensating for defrosting and/or food product heat -up time. Example: If you have programmed the timer at 10

minutes. It may in fact take 11 or 12 minutes for the programmed time to expire and the signal to sound. This is normal.

The additional time was used to heat the compartment and to remove the air. When the timer counts down to zero, the

Digital Timer Display will flash, a signal will sound and the steam flow to the cooking compartment will shut-off. To stop

the Digital Timer Display from flashing, press "Start/Cancel" touch pad once. (The signal will also sound when the

compartment is heated to announce the beginning of the timer count down.)

COMPARTMENT DOOR LATCH/LOCK INFORMATION

Latching:

The door handle/latch are positive and offer some resistance to movement. This is normal. Also note that

latching the door is a two (2) step movement. Be sure to latch completely into the second step, otherwise the

unit will not operate.

Unlatching:

In the Convection mode, the door is never "Locked" and can be unlatched and opened at anytime. If the door Is

opened during the cooking cycle for food seasoning or inspection, keep your hands out of the steaming

compartment to prevent burning them. Use hot pads when removing pans from compartment Steam will still

flow into the compartment when the handle is in the down, latched position, regardless of whether the door Is

closed or open. Steam flow stops when the handle is unlatched.

To open the compartment door, partially unlatch the door. If some water comes out of the compartment, or off

the door, allow it to finish dripping before completely unlatching and opening the door.

Locking/Unlocking:

In the Pressure mode, the "Locked" symbol will be illuminated, indicating that the door latch is locked and cannot be

opened. Only when the "Locked" symbol is no longer illustrated and the steaming compartment de-pressurized can

the door be unlatched and opened.

BASIC SEQUENCE OF OPERATION

CONVECTION STEAMING MODE ———————————————————————————————

1. User programs desired steaming time (0 to 99 minutes) via numeric keypad-

2. Compartment door is dosed and latched.

3. Cycle is started by pressing "Start/Cancel"" touch pad.

4. Steam is introduced into compartment via steam distribution tubes.

5. Steaming begins.

6. Compartment temperature rises to 194°F.

17.

Page 19

7. Countdown timing begins. Audio signal sounds for 1 second. Countdown indicator (LED2) begins flashing.

8. "Timer" counts down to zero. Alarm sounds for 4 seconds.

9. User presses "Start/Cancel" touch pad. Digital Time Display stops flashing.

10. End of Cycle.

PRESSURE STEAMING MODE ————————————————————————————————————

1. User programs desired steaming time (0 to 99 minutes) via numeric keypad. Pressure mode is selected by

pressing "Pressure Operation" touch pad. Mode indicator (LED2) lights.

2. Compartment door is closed, latched and automatically locked.

3. Steaming cycle is initiated by pressing "Start/Cancel" touch pad. Indicator (LED1) rights.

4. Steam is introduced into compartment via steam distribution tubes.

5. Steaming begins.

6. Compartment temperature rises to 194 F.

7. Countdown timing begins. Audio signal sounds for 1 second. Countdown indicator (LED2) begins flashing.

8. Pressure begins to build in compartment

9. Steaming continues at 10 psi pressure. Timer counts to zero.

10. Digital Timer Display begins to flash. Touch pad panel indicators (LED's 1.2 and 3) turn off.

11. Steam flow stops.

12. Compartment releases pressure.

13. Compartment door is automatically unlocked.

14. User presses "Start/Cancel" touch pad to cancel mode.

15. End of Cycle.

START-UP AND PREHEAT

CAUTION Do not attempt to start or operate this appliance during a power failure.

1. Check the cooking compartments to ensure that the steam tubes and drain screens are in place and secure. On

steamers equipped wit h self-contained boilers, check inside the steamers' base cabinet to ensure that the manual

drain valve is dosed and the manual water supply valve is open.

18.

Page 20

2. Press the red "power on-off" rocker switch located near the steam pressure gauge, at the right side of the base

cabinet console. The red indicator light in the switch will come on and the boiler will begin to fill with water.

Direct-steam -connected steamers are not equipped with self-generating boilers or "steam" switches. Therefore,

these models do not require the 5 minute boiler water fill time, nor is it necessary to push a "steam switch" to

produce steam, as indicated in step #3 below. As soon as the pressure gauge on the control panel register,

10 psi, preheating may begin. (If you are operating a direct-steam -connected steamer, "skip* step #3, and refer

directly to step #4.)

3. After three to five minutes, the amber light in the "STEAM" switch will glow. Indicating the water has reached a safe

operating level in the boiler. The "STEAM" switch can now be pressed (momentarily) in order to produce steam in

the boiler. This will activate the energy source electric heaters, gas burners, or steam solenoid valve), and the

amber light will go out. The energy source cannot be activated until the boiler contains sufficient water, indicated by

the amber light The "STEAM" switch must be pressed to re-start the steamer after it is shut off for any reason

(including a momentary power Interruption). No attempt should be made to operate the equipment during a power

failure. Whenever the amber right is illuminated, the heaters, steam supply, or burners are OFF and no steam Is

being generated.

NOTE FOR STEAMERS CONTAINING GAS-FIRED BOILERS ONLY: If the burners fail to ignite in four seconds,

a safety circuit will de-energize the system. In this event, momentarily press the power switch to the "off" position,

then back to the "on" position. The "STEAM" switch amber light should be on. Wait 5 minutes, then press the

"STEAM" switch to start the burner Ignition cycle once again. In about 20 minutes she steam pressure gauge on

the control panel should register 10 psi.

4. You can now preheat the cooking compartment(s). Cooking compartments should always be preheated before

cooking.

5. To preheat, dose and latch the compartment door securely. Set the Digital Timer Display for one minute. It

will be several minutes before the time display counts down. When the preheating is completed, the steam will

automatically shut off and a five second signal will sound.

6. Your steamer is now ready to begin a Steaming Operation.

19.

Page 21

PREVENTATIVE MAINTENANCE

BOILER SHUTDOWN: (Applies only to steamers which have a self -contained boiler).

The red-lighted power switch must be shut off for 3 minutes every 8 hours to automatically drain highly mineralized

water from the boiler (which reduces the formation of scale). See step 1 below.

DAILY CLEAN-UP:

Your Cleveland SteamPro XVI Steamer, must be cleaned regularly to maintain its fast, efficient cooking per-formance,

and to ensure its continued safe, reliable operation.

1. The boiler must be drained (blowdown) daily. or after maximum of 8 hours of use. If the boiler's feed water contains

more than 300 parts per million to total dissolved solids, the boiler must have a blowdown two or three times daily.

"Blowdown" means draining the boiler while under pressure.

The boiler "BLOWDOWN" is performed by simply shutting off the steamers' red-lighted "POWER" switch while the

boiler's at normal 10 psi operating pressure. When the bottom of the "POWER" rocker switch is pushed, its' red light

goes out, and the drain valve automatically opens, draining the boiler. An automatically timed drain water condenser

will flush the drain for 3 minutes, then shut off. The steamer is then again ready for use.

When steam is produced, the water in the boiler to being distilled. During this process, the minerals that come into the

boiler with the water remain in the boiler as the water boils away as steam- When allowed to accumulate, the water

becomes nightly mineralized, which results In erratic operation, lime build-up corrosion, and premature failures. In some

cases complete boiler replacement becomes necessary, which is extremely expensive. By draining the boiler under

pressure, most sediment present will be flushed down the drain.

2. The steamer is equipped with a drain screen in the back of each cooking compartment. No compartment should be

operated without its' drain screen in place. This screen prevents large food parades from entering and possibly

plugging the drain line. Any restriction of the drain line will cause an accumulation of hot water in the cooking

compartment, which could cause injury when the door is opened. It also may adversely affect the convection action

of the steam in the compartment, which is critical to optimum performance. Pouring USDA approv ed drain cleaner

through the compartment drains once a week will help to ensure an open drain. A manual (hand crank) drain auger,

or "snake", may be safely used to clear obstructions in the compartment drains. Do not use a power auger, as

damage to the plastic drain system may result.

CAUTION With steamer off, open the cooking compartment door (s)) and allow the steamer to cool before cleaning

the cooking compartments) and their components.

3. At the end or each day's operation, wash the pan slide racks, drain screens, door gaskets, and compartment interiors

with mild detergent and warm water, either by hand or in a dishwasher. Rinse water should drain free ty through the

compartment drain openings. If it does not, the drain must be cleaned before using the steamer.

4. Always leave compartment door opened a little when not in use to prolong gasket life.

WEEKLY CLEAN-UP:

1. Once a week, remove the steam tubes and dean the orifices. First remove the pan slide racks by lifting upward and

toward the center of the compartment. Pressing backward on the steam tube will allow its front eyelet to dear the

compartment stud. The tube is then angled toward the center or the compartment just enough to dear the stud and

be pulled forward, out or its socket. The orifices can be cleaned easily with a paper clip. Then, thoroughly wash and

rinse all steam tubes. This can be done in a dishwasher. Lubricate each tube's open end with cooking oil before

replacing in the steamer's compartment. Be sure ail the steam tubes are securely in place before activating the

compartment. The tubes are interchangeable and may be placed in any spot In either compartment.

EXTERIOR CLEAN-UP:

WARNING Always turn off power to equipment before using water to wash equipment.

1. Allow steamer to cool before washing. Use the same cleaners and cleaning procedures as for other kitchen surfaces

of stainless steel or aluminum. Mild soapy water, with a dear water rinses, is recommended. Do not allow water to

run into electrical controls.

20.

Page 22

EXTENDED MAINTENANCE:

A qualified serviceman should be contacted for routine Preventative Maintenance.

1. Periodic boiler inspections should be made by a qualified serviceman.

2. Once every three months the cold water line strainer should be cleaned,

3. The "blowdown" procedure will not completely remove the mineral deposits that adhere to the top of the boiler. A

chemical descaling should be done by a boiler treatment specialist. This should be done once a year in average

water conditions, but in poor-water areas it may be needed two or three times a year.

Cleveland/ALCO supports a worldwide network of Maintenance and Repair Centers, which are regional distributors of

pans and service. Contact your nearest Maintenance and Repair Center for the name of an authorized service agency

In your area, or for replacement parts, or information regarding the proper maintenance and repair of your equipment In

order to preserve the various agency safety certifications (UL, A.G.A., CGA, NSF, ASME/NU. Bd., etc.), only factory supplied replacement parts should be used. The use of other than factory -supplied replacement parts will void the

warranty.

21 .

Page 23

CLEVELAND RANGE COMPANY

MINUTES

Beans, gr

een

2"

cut 6 5 French cut

4 5"

whole

6 4

Broccoli, spears

3 2-3

flowerettes

2-3 1-2

chopped

6-8 Brussels sprouts

4-5 4

Cabbage.

12-16 wedges/head

4 Cabbage.

whole

- to remove leaves

2

(or cabbage rolls

Carrots, baby whole

10 6

sliced, crinkle cut

7-8 3

diced 2

Cauliflower, flowerettes

4-5 3-4

whole

10 Celery, diagonal cut

1

1/2" 3

diced 2 1 minced

1 Corn. yellow whole kernel

2 on cob, cobbettes

6 12—

Mixed vegetables

3-4 Mushro

oms. whole

(1 1/2"

dia.) 3

sliced 1

Onions, diced, sliced

2-3 1

whole

4 2

Peas, green

2 Potatoes, whole

8

oz. 30-35

peeled. Quartered, fresh

12-19 peeled, diced

8-10 Potatoes, sweet whole

30-35 Spinach leaf

2 21— chopped

21—

Squa

sh, acorn halves

15 butternut, quartered

7 whipped*

20—

spaghetti squash, halves

15-18 Tomatoes, whole, sliced*

1 Turnips, whole

20-25 Zucchini. sliced

2-4 2-4

SEAFOODS:

Steam all seafoods on a perforated pan with catch pan.

Cod fillets,

5

oz. portions

3 4

Crab legs. king

4-6 Snow crab

2-4 Crab. live.

4

oz- 4 3/4 - 1 Ib. 12

Halibut.

6-8

oz. portions

4-6 6-8

Lobster, whole.

1 Ib. 7-9

Lobster tails,

8

oz. 8-10

defrosted, butterflied

4-6 Mussels in shell

2 Oysters in shell

2-4 Red snapper,

8

oz. 4-5 4-5

Salmon steak.

8

oz. 6 /

Shrimp.

10

ct per Ib. IQF

3 4-6 5 Ib. block, peeled

&

deveined

30

ct 6-

8**

potato salad

10-12

Soft cooked

3

Coddled

6 Poached in a cup

2-3

Blanch for peeling

Fresh: Avocado

1 Apple, cored

1 Grapefruit

1 Orange

1 Apricot

1 Pineapple, whole

2 Dried*: add water to re

-

hydrate

Apple

10 Apricot

10

Peach

10

Pear 10

Prune

10

THE CLEVELAND CONVECTION STEAMER™

TIMER SETTINGS

Timer settings are approximate due to the differences in food quality, age, shape and the degree of "doneness" desired. It is not necessary to add water.

Perforated pans are recommended. Starred items (*) must be cooked in solid pans or containers. Items marked with two stars (**) require handling in two steps.

First, steam for approximately 1/2 the time shown, remove from steamer. separate thawed portion, or stir, and return to the steamer for the time remaining. The

compensating feature of the timer allows the cooking compartment to reach cooking temperature before the preset time starts to count up.

VEGETABLES: Fresh Frozen

Artichoke 12

Asparagus, spears 4 6

Clams in shell 3-5

MINUTES

Fresh Frozen

Eggplant sliced, diced 1

22.

5 to. block. green. 26-30 ct (nested pan) 10**

EGGS: Medium Sized

Hard cooked (or egg salad.

Scrambled* 6-7 **

FRUITS: MINUTES

Page 24

CLEVELAND RANGE COMPANY

for gravy, sauces, beef stock

and soups. The size of portion.

thickness of cut grade, should be considered when selecting

POULTRY: Fresh Frozen

Chicken.

5-8

oz. breaded

pieces

18

-20 rnin. halves. 1 1/4

-

1 1/2 lb. per

Pork,

Chop,

4

count/lb.

10

Italian sausage.

4

oz. portion

10

Ribs. 3 lb. and down

20

-

26

Cubes. 1 1/2"

6

-

7 min./lb.

6

min./lb.

Ground

chuck for chill

4 min./lb.

4

-6 min./lb.

Pot roast, choice

8

-12 min./lb.

Rump roast, choice

boned, rolled, tied

12 min./lb.

Meat loaf.

4

lb. loaf 5

min./lb.

Liver baby beet.

8 oz. Slice

2-4 2

-

4 Corned beef. 6

-

8 lb. cut

Using a

1/4" to

1"

steak, the steaming tim

e

listed below pro

-

duces a "rare" steak. A "well done" steak is first ste

amed to the

"rare" stage, then broiled or grilled for

1 %

minute on each

side. This "well done" steak shrinks less. is more tender and

chopped

8

oz.

4

Rib eye.

8

oz.

4

Top butt steak

6

oz.

4

8

oz.

6

Filet Mignon. butterflied

—

4oz.

3

8oz.

3

-

4 8

oz.

4

10

oz.

5

16

oz. whole (Chateaubriand)

8

12

oz. 7 T-bone— 12

oz. 5 16

oz. 8 18

oz. 8

Cabbage rolls, stuffed*

25

20

cover with tomato

sauce & serve

Casserole

dishes*

beet Stew,

20-25 25-30 stroganoff

20

-

25 25-30 Lasagna*. freshly prepared

20

-

25 25-30

Potatoes*: 2 1/2 random sliced

4

cups cold water/lb.

17

Beans*, pre

-

soaked overnight

1

lb. beans

* 1%

qts. water

45

Beans*.unsoaked.

1

Ib. be

ans.

* 1

1/2 qts. water

2 1/2 hrs

Steam in nested pans. Place pasta on used as a

La

sagna noodles

10-12" Macaroni, shells, elbow

10-12

** Rigatoni

10** Spaghetti, vermicelli

8** Spaghetti, regular

10**

THE CLEVELAND CONVECTION STEAMER™ TIMER

MEATS & POULTRY:

Steam meats and poultry in nested pans. as juices can be used

a timer setting for doneness.

MINUTES

Turkey, whole 6-8 min./lb. 6-8 min./lb.

half 20-24 min. 20-24 min.

PORK. SAUSAGE. HOT DOGS:

Hot dogs. 8 count/lb. 2

BEEF:

SETTINGS

(Continued)

MINUTES

Strip steak — 10 oz. 5

22 oz. 10

MINUTES

PREPARED ENTREES: Fresh Frozen

Full size pans

reheat each serving 4" 6-8

DEHYDRATED FOODS;

plus 5 cups cold water/lb. 12

RICE* BEANS

Rice*, long grain

12

add 1/2 water to pan 20-23 min./lb.

STEAKS

juicy: and. when served, is the same size as the "rare" steak.

MINUTES

Sirloins patties.

Refried beans*. 2 #10 cans 15-17

PASTA:

liner in a solid 2 1/2" pan. Cover |

Egg noodle*. 1/2" wide 4-6 **

2 1/2" perforated pan

pasta with cold water.

MINUTES

23.

Page 25

Electrical Box Assembly For Two

Probe Gas Generator

1. 20478 Timer, Solid State Interval - 3 Minute

2. 20528 Transformer - Spark Ignition Supply

3. 23198 Control Water Level

4. 03524 Relay, 120 V, 50/60 HZ, AL, DPDT

5. 03525 Socket, Relay

6. 44163 Box -Electric Assembly - For Gas Two Probe

24.

Page 26

Power Supply

100766 - Power Supply Board

25.

Page 27

Timer Panel Assembly

Panel Assembly, Instrument

Timer Assembly, Complete

Nut, 6-32, Plastic

Gauge, Pressure-30" Vac., 30 psi

26.

Page 28

1. 44169

Cable Ignition Asm.

2. 03546 Control Module, Direct Spark Ignition, 4 Second

3. 02361 Box, Handi-Box Electrical, 4 1/8" x 1 13/16" #180-1/2

4. 66037 Cover, Elect, Box Generator, 2 Probe

5. 44164 Terminal Block Assembly - 4 Pole Gas Units

6. 44163 Box - Electric Assembly - For Gas 2-Probe

Electrical Box Assembly For

Two Probe Gas Generator

Page 29

Latch Assembly

1. 450821 Plate, Weldment - Latch Mount PCL/PCS HL

2. 44148 Pawl Assembly - PCS/PCL – HL

3. 100771 Solenoid, 120 Vac., 60 HZ, Continuous Duty, Class F Insul.

4. 100768 Cylinder, Pressure Lock

5. 19972 Switch, Thermal Close 193+5 Deg. F, Open 173+5 Deg. F,

6. 100710 Sprint, Cam Arm Return

7. 46020 Handle Assembly

8. 101524 Cam/Arm Assembly - PCL/PCS - HL

9. 45084 Latch Assembly, Door-PCL/PCS - HL

28

Page 30

1. 20005 Switch, Rocker - Red

29.

Page 31

1. 19972 Switch, Thermal Close 193+5 Deg. F, Open 173+5 Deg. F, PCI

30.

Page 32

1. 101233 Water Regulator Assembly. (Wilkins)

2. 100218 Regulator, Water Pressure - 3/4" x 3/4" (PCL)

31.

Page 33

32.

Water Valve Assembly

1. 07169 Gauge 0-100 PSI, 2-1/2", 1/4" Bottom Mount, Brass Movement

2. 03606 Coupling, Full, Brass, 1/2"

3. 100976 Manifold, Water Valve Support PCL/PCS

4. 22241 Valve, Solenoid 2-Way NC 1/4 NPT, Orifice 5/32 1200/60

5. 22236 Valve, Solenoid, 3-Way, 120 V/60 HZ

6. 14304 Nipple, Yellow Brass, 1/4" x Close

7. 101061 Manifold, Water Assembly. PCL/PCS

Page 34

Plumbing Assembly

1. 565191 Fitting - Hose Drain Manifold

2. 15462 Orifice, Flow Regulator 1/8" GPM

3. 20211 Tee-Black 1"

4. 22238 Valve, Pinch 1"NPT

5. 100223 Tee 1"x 1/2" x 1" Black

6. 14553 Nozzle, Spray Drain Manifold GP1 - 1/8 GG Full Jet, Brass

Page 35

Steam Outlet Assembly

1. 101035 Valve, Safety, 3/4", 12 PSI

2. 101207 Trap, Thermostatic w/POL Seat

3. 100307 Piping, Steam Outlet -PCL, Rev. B End Gen., Gas 34.

Page 36

Steam Valve Assembly

1. 22193

Value, Solenoid

3/4 x 3/4,

2NC 120V, 60HZ

2. 05295 Elbow, Union 1/2" x 1/2", Female to Female Brass

3. 101794 Steam Value Assembly (PCL)

Page 37

Water Feed Assembly

1. 03276 Value Ball 1/4" Brass, Full Port

2. 22102 Value, Swing Check, 1/4" Brass, 36" Leads

3. 22223 Value, Solenoid, 1/4" NPT, Conduit 130-120 V

4. 100303 Clamp, Mounting - 3/8 Tee Elbow, Tube Fitting

5. 100339 Angle, Top Front -1200 MM Oyster Kettle Base

6. 100304 Piping, Water Feed Assembly 3/8", Rev. Bend Gen.

36.

Page 38

Heater Assembly

08165 Heater 12KW, 208-220V, 3" Square Flange, 3 Phase

08166 Heater, 12KW, 230-240V, 3" Square Flange, 3 Phase

8167 Heater, 12KW, 440-480V, 3" Square Flange, 3 Phase

07128 Heater Gasket

37.

Page 39

Drain Manifold Assembly

1. 1008983 Drain Manifold Assembly

2. 13252 Manifold-1.500" Dia., 8 1/2" Length-Black

Page 40

39.

Page 41

40.

Loading...

Loading...