Page 1

INSTALLATION

& OPERATING

INSTRUCTIONS

GAS & ELECTRIC XPRESS GRILLS

FOR SONIC

MODEL NUMBERS:

XG36S, XG362S-L, XE36S, XE362S-L

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS OR

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

APPLIANCE

PLEASE READ ALL SECTIONS OF THIS MANUAL AND

RETAIN FOR FUTURE REFERENCE.

THIS PRODUCT HAS BEEN CERTIFIED AS COMMERCIAL

COOKING EQUIPMENT AND MUST BE INSTALLED BY

PROFESSIONAL PERSONNEL AS SPECIFIED.

WARNING:

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY, OR DEATH.

READ THE INSTALLATION,

OPERATING AND MAINTENANCE

INSTRUCTIONS THOROUGHLY

BEFORE INSTALLING OR

SERVICING THIS EQUIPMENT

Users are cautioned that maintenance and repairs must be performed by a Garland authorized service agent

using genuine Garland replacement parts. Garland will have no obligation with respect to any product that has been

improperly installed, adjusted, operated or not maintained in accordance with national and local codes or installation

instructions provided with the product, or any product that has its serial number defaced, obliterated or removed,

or which has been modified or repaired using unauthorized parts or by unauthorized service agents.

For a list of authorized service agents, please refer to the Garland web site at http://www.garland-group.com.

The information contained herein, (including design and parts specifications), may be superseded and is subject

to change without notice.

IN THE COMMONWEALTH OF MASSACHUSETTS

THIS PRODUCT MUST BE INSTALLED BY A LICENSED

PLUMBER OR GAS FITTER.

For Your Safety:

Post in a prominent location, instructions to be

followed in the event the user smells gas. This

information shall be obtained by consulting your local

gas supplier.

GARLAND COMMERCIAL RANGES, LTD.

1177 Kamato Road, Mississauga, Ontario L4W 1X4

CANADA

Phone: 905-624-0260

Fax: 905-624-5669

Part # 4526884 Rev. 6 (06/06/13)

© 2009 Garland Commercial Industries, Inc.

Page 2

IMPORTANT INFORMATION

WARNING:

This product contains chemicals known to the State of California to cause cancer and/or birth

defects or other reproductive harm. Installation and servicing of this product could expose you

to airborne particles of glass wool/ceramic fibers. Inhalation of airborne particles of glass wool/

ceramic fibers is known to the State of California to cause cancer. Operation of this product could

expose you to carbon monoxide if not adjusted properly. Inhalation of carbon monoxide is known

to the State of California to cause birth defects or other reproductive harm.

Part # 4526884 Rev. 6 (06/06/13)Page 2

Page 3

PRODUCT INFORMATION

The Garland Xpress Grill provides a method for ecient two-sided cooking, while accommodating a variety of products. The

unit will also serve as a at grill, and meets all standards for safety, eciency, and cleanliness.

Standard Features:

• Stainlesssteelfront,top&sides

• 33,000BTU/Hrinputforeachtwelve-inchsection

of griddle

• Builtinpressureregulator,(onepertwelveinch

section of griddle), and gas shut-o valve

• 3/4"thick,Carbonsteelgriddleplate,machineground,

highly polished

• Swivelcasterscompletewithfrontbrakes(4)

• Diecastaluminumelectrictopheatingelements

rated 208V or 240V

• Automaticliftingandloweringtopheaters

• Towelbarwithbunpanlip

• Two, 1.5 gal. (5.68 L), stainless steel grease containers

with utensil holders

• Separateprogrammablecontrollerforeach

twelve-inch section

• Multi-coloredLEDindicatorlightstoidentify

operational mode

• Cordandplugpowersupply

• Oneyearlimitedpartsandlaborwarranty

(USA&Canada)

Model XG362S-L

Part # 4526884 Rev. 6 (06/06/13) Page 3

Page 4

TABLE OF CONTENTS

IMPORTANT INFORMATION...................................................2

PRODUCT INFORMATION .....................................................3

Standard Features: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

DIMENSIONS AND SPECIFICATIONS ...........................................6

INTRODUCTION..............................................................7

Warranty .........................................................................................7

Shipping Damage Claim Procedure................................................................ 7

SAFETY PRECAUTIONS .......................................................8

INSTALLATION...............................................................9

Rating Plate Location .............................................................................9

General Information .............................................................................. 9

National Codes Requirements: ....................................................................9

Gas Connections, and Pipe Sizing: ................................................................. 9

Accessory Kit – Main Gas Inlet:....................................................................10

Accessory Kit – Electrical Supply Lines:............................................................11

Electrical Connection Terminal Block Connection .................................................12

Grease Bucket: ...................................................................................12

Appliances Equipped with Casters: ...............................................................12

Ventilation and Clearance:........................................................................13

Changing to a dierent type of gas ...............................................................13

GRILL CONTROLS ...........................................................14

Master Power Switch: ............................................................................14

LED Indicators:...................................................................................14

Display: .........................................................................................14

Product Buttons (0-9):............................................................................14

Power Button: ...................................................................................14

Program Button: .................................................................................14

Temperature Button: .............................................................................15

Up/Down Arrow Buttons; 2 Functions: ...........................................................15

Enter Button: ....................................................................................15

Cancel/Raise Platen Button, (Green): .............................................................15

Black Button: ....................................................................................15

Main Pre-Programed Product Items...............................................................15

OPERATION.................................................................16

Installing Release Material: .......................................................................16

Lighting Instructions: ............................................................................16

Simplied Cook Cycle Instructions: ...............................................................17

To Cook in Two-Sided Mode: .....................................................................17

To Cook in Flat Grill Mode:........................................................................18

Enter Standby Mode:.............................................................................18

Exit Standby Mode: ..............................................................................18

To Display the Current Temperatures: .............................................................18

To View Settings for a Menu Item:.................................................................18

To Clean the Grill: ................................................................................18

CLEANING AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Cleaning During Operation: ......................................................................19

Daily Cleaning:...................................................................................19

PLATEN ZEROING ...........................................................21

ACCESSORIES...............................................................22

Part # 4526884 Rev. 6 (06/06/13)Page 4

Page 5

TABLE OF CONTENTS continued

PROGRAMMING ............................................................25

Programming Modes/Menu Sequence: ...........................................................25

Menu Items...

To Change the Cook Time of a Product: ...........................................................27

To Turn Platen, (2-Sided), Cooking On/O: ........................................................27

To Change Upper Platen Set Temperature: ........................................................27

To Change Grill Set Temperature: .................................................................27

To Change Product Gap Setting:..................................................................27

To Change Product Button, “Key” Assignment .....................................................28

To Change a Product Name: ......................................................................28

System Info...

To View Recovery Time - Upper Platen:............................................................28

To View Recovery Time - Grill:.....................................................................28

To View the Garland Part Number: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

To View the Flash Number: .......................................................................29

To View the Software Number:....................................................................29

To View the Download Number: ..................................................................29

System Setup

To Change temperature Units, (°F or °C): ..........................................................29

To Change Gap Setting Display Units:.............................................................29

To Change the Alarm Volume: ....................................................................30

To Change the Key Chirp:.........................................................................30

To Select Upper Set Temperature:.................................................................30

To Select Grill Set Temperature: ...................................................................30

To Change Probe Calibration - Upper:.............................................................30

To Change Probe Calibration - Grill: ...............................................................31

To Change Platen Set: ............................................................................31

To Change Instant-On Time:......................................................................31

To Change Control Type: .........................................................................31

To Turn Extended Time On/O: ...................................................................32

To Change the Grill Function:.....................................................................32

To Change the Start Delay: .......................................................................32

To Change the Alarm Mode: ......................................................................32

To Turn Clean Mode On/O: ......................................................................33

To Add a Product Name in Library:................................................................33

To Modify a Product Name in Library: .............................................................33

Service Mode

To Change SCK Address:..........................................................................33

To Perform Limit Switch Test: .....................................................................34

CALIBRATION ...............................................................34

Bi-Weekly Calibration:............................................................................34

Probe Locations: .................................................................................35

TROUBLESHOOTING ........................................................36

ERROR MESSAGES:

Probe Error:......................................................................................36

Heating Error:....................................................................................36

Platen Down Error: ...............................................................................37

Platen Up Error: ..................................................................................37

Gas Ignition Error:................................................................................37

COMM Error:.....................................................................................37

Motor Over Current Error: ........................................................................37

Motor Error:......................................................................................37

Motor Error2: ....................................................................................38

Lower Switch Error: ..............................................................................38

Upper Switch Error: ..............................................................................38

WIRING DIAGRAMS .........................................................39

Part # 4526884 Rev. 6 (06/06/13) Page 5

Page 6

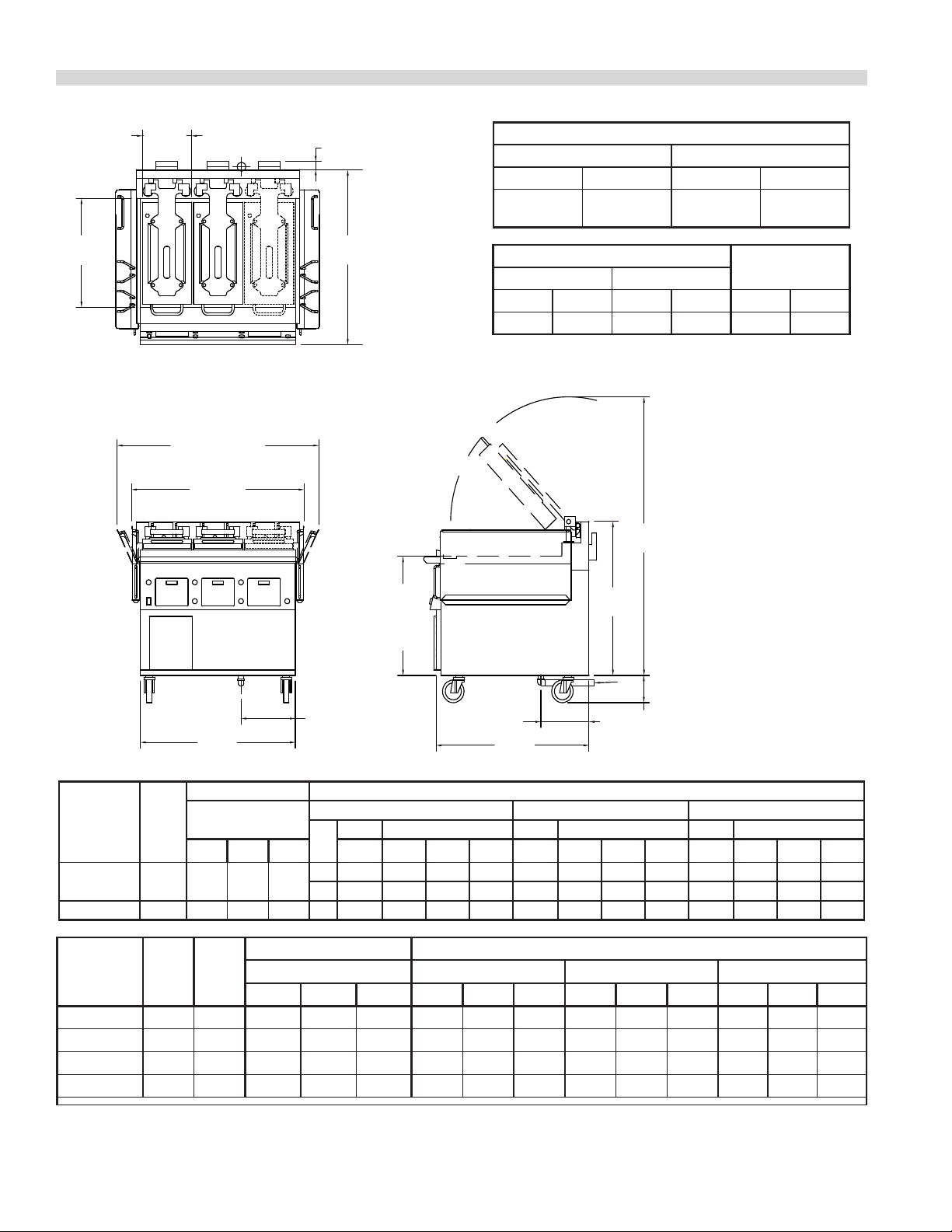

DIMENSIONS AND SPECIFICATIONS

G*

MIN: 6"

[152mm]

MAX: 9"

[229mm]

TOP

HEATER

11-1/2"

[292mm]

GRILL PLATE 24" X 36"

[610mm X 914mm]

24"

[610mm]

12-5/8"

[321mm]

GAS INLET*

47"

[1192mm]

FLARED BUCKETS

40-3/16"

[1021mm]

STRAIGHT BUCKETS

1-3/4"

[44mm]

FLUE OUTLETS*

TOP VIEW

FRONT VIEW

RIGHT SIDE VIEW

61-1/4"

[1556mm]

3/4"

GAS INLET*

35-5/8"

[905mm]

36-1/8"

[918mm]

26-3/16"

[665mm]

GRILL

PLATE

HEIGHT

TOLERANCE

+/- 1/8"

[3mm]

33-7/8"

[860mm]

11-3/16"

[284mm]

GAS INLET*

38 1/2"

[978mm]

Clearances (all models)

Entry Installation

Crated Uncrated Sides Rear

47-1/2"

(1207mm)

40-3/4"

(1035mm)

6"

(152mm)

(76mm)

3"

* GAS MODELS ONLY

Gas Pressure (XG models)

Supply (min.) Operating

NAT PRO NAT PRO BTU/Hr kW

7.0"WC 7.0” WC 3.5"WC 3.5” WC 99,000 29.1

Total Gas Input

(XG models)

Garland products are not

approved or authorized

for home or residential

use, but are intended for

commercial applications

only. Garland will not

provide service, warranty,

maintenance or support

of any kind other than in

commercial applications

Gas input ratings shown

here are for installations

up to 2,000 Ft. (610m)

above sea level. Specify

altitudes over 2,000 Ft.

Loading kW/Phase Nominal Amps Per Line

Total

Model

XG36S 12.99 4.00 4.99 4.00

XG362S-L/R 8.66 2.66 3.33 2.66 1 41.63 24.93 22.14 24.93 39.36 23.57 20.94 23.57 36.08 21.61 19.19 21.61

3-Phase

Models

XE36S TB1 17.30 6.07 5.97 5.27 50.10 47.22 46.80 47.36 44.65 44.24 43.42 40.92 40.56

XE362S-L TB1 13.12 4.73 4.45 3.93 38.25 36.13 34.94 36.17 34.16 33.03 33.15 31.32 30.28

208/220/240V 3ph

kW

Load

X-Y X-Z Y-Z L1-L2 X Y Z L1-L2 X Y Z L1-L2 X Y Z

Total

LINE

TB2 8.30 3.03 2.63 2.63 23.61 23.61 21.93 22.32 22.32 20.73 20.46 20.46 19.00

TB2 8.30 3.03 2.63 2.63 23.61 23.61 21.93 22.32 22.32 20.73 20.46 20.46 19.00

kW

Load

Loading kW Per Phase Nominal Amps Per Line

208/220/240V 3ph 208V 3-Phase Delta 220V 3-Phase Delta 240V 3-Phase Delta

X-Y X-Z Y-Z L1 (X) L2 (Y) L3 (Z) L1 (X) L2 (Y) L3 (Z) L1 (X) L2 (Y) L3 (Z)

1-Ph 3-Phase Delta 1-Ph 3-Phase Delta 1-Ph 3-Phase Delta

TB

1 41.63 37.43 33.30 37.43 39.36 35.38 31.49 35.38 36.08 32.43 28.90 32.43

2 20.82 – – – 19.68 – – – 18.04 – – –

208V 220V 240V

Part # 4526884 Rev. 6 (06/06/13)Page 6

Page 7

INTRODUCTION

The Garland Xpress grill, for Sonic provides a method for

ecient two-sided cooking, while accommodating a variety

of products. The unit will also serve as a at grill, and meets

all of Sonic’s standards for safety, eciency, and cleanliness.

Warranty

This warranty covers defects in material and workmanship

under normal use providing that:

a) The equipment has not been accidentally or intentionally

damaged, altered or misused.

b) The equipment is properly installed, adjusted, operated

and maintained in accordance with national and local

codes and in accordance with the installation instructions

provided with this product.

c) The warranty serial number axed to the appliance by

Garland has not been defaced, obliterated or removed.

d) An acceptable report for any claim under this warranty is

supplied to Garland.

The equipment warranty coverage remains in force for one

(1) year (parts and labor) from the date the equipment is put

into operation.

The Garland Group agrees to repair or replace, at it’s

option, any part that proves to be defective in material or

workmanship at no charge for the part or normal labor.

We assume no responsibility for installation, adjustments,

diagnosis, or normal maintenance such as: lubrication of

springs or valves. We exclude failures caused by erratic

voltage or gas supplies. We assume no responsibility for

travel costs beyond 100 miles round trip, travel other

than overland, and overtime costs of repair. We exclude

broken glass, paint and porcelain nish, surface rust, gasket

material, ceramic material , light bulbs and fuses from normal

coverage. We exclude damage or dysfunction caused by re,

ood, and like “Acts of God” that are beyond the control of

The Garland Group.

The Garland Group’s liability on a claim of warranty shall

not exceed the price of the material and/or service , which

caused the claim. This warranty is limited and is in lieu of all

other warranties, expressed or implied. The Garland Group,

our employees, or our agents shall not be held liable for any

claims of personal injury or consequential damage or loss.

This warranty gives you specic legal rights, and you may

have other rights which vary from state to state.

Shipping Damage Claim Procedure

Please note that the Garland equipment was carefully

inspected and packed by skilled personnel before leaving

the factory. The transportation company assumes full

responsibility for safe delivery upon acceptance of the

equipment.

What to do if the equipment arrives damaged:

1. File a claim immediately regardless of the extent of

damage.

2. Besuretonote,"visiblelossordamage,"onthefreight

bill or express receipt and have the person making the

delivery sign it.

3. Concealed loss or damage: if damage is unnoticed until

the equipment is unpacked, notify the freight company

immediately, (within 15 days), and le a concealed

damage claim.

Part # 4526884 Rev. 6 (06/06/13) Page 7

Page 8

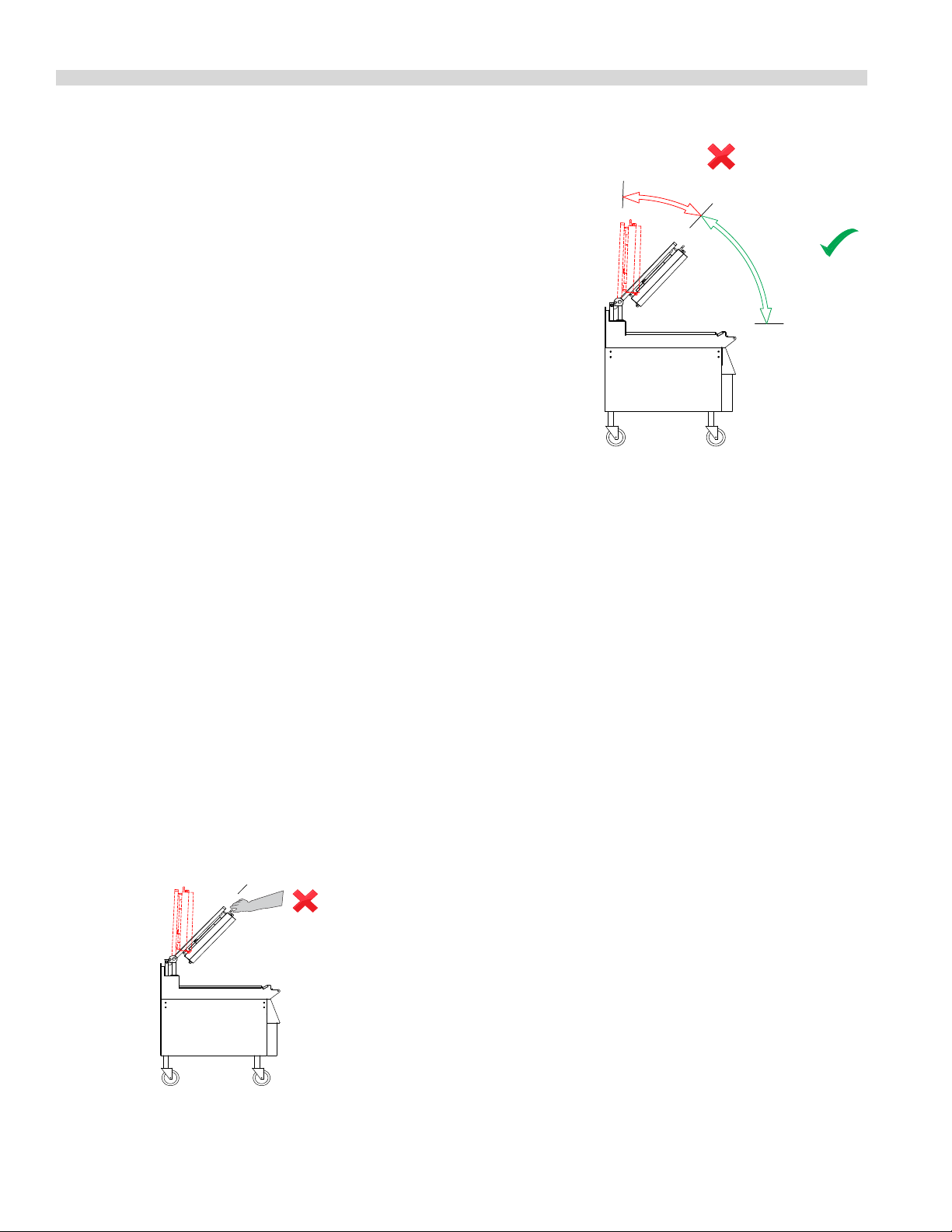

SAFETY PRECAUTIONS

Do Not

Push

Platen

Normal

Platen

Position

Close

Open 45

0

Wrong

Platen

Position

Do Not

Push

Platen

Always follow these safety precautions when operating the

Xpress Grill.

• THISGRILLMUST be operated by persons who have

been given adequate training.

• THISEQUIPMENTMUSTONLYBEOPERATEDUNDER

AN APPROVED HOOD SYSTEM.

• DONOT operate the grill without reading this operation

manual.

• DONOT operate the Xpress grill unless all service and

access panels are in place and fastened properly.

The Garland Xpress Grill is a semi-automatic cooking

appliance. The upper platen is lowered automatically,

following the manual, two-handed initiation of the cooking

cycle, and the upper platen is raised automatically upon

completion of the cooking cycle.

When two sided cooking, the area between the upper platen

and the griddle plate should be regarded as a “danger zone.”

During two sided cooking the operator must not be within

this danger zone. When used as a at grill, then this area is no

longer a danger zone, the platens do not move.

For whatever reason, be it cleaning, maintenance, or normal

operation, any exposed person must use extreme caution if

within this danger zone.

In two side cooking the upper platen remains in the lowered

position by nature of its own weight. It is not locked down. It

can be raised by lifting up on the handle on the front of the

platen.

Be aware that lifting the platen manually over the open

position at 450, is very dangerous and leads to a premature

failure of the electrical ex steel conduit, and lifting

mechanism. Under no circumstances, other than safety,

should the platen be manually opened more than the

position at 450. For cleaning procedure please follow the

instructions in the Installation and Operating Instructions

Manual delivered with the grill.

The Xpress Grill may during its operation emit airborne noise

equivalent to a continuous A weighted sound pressure level

of 73dB(A).

WARNING: To avoid serious personal injury:

• DONOT attempt to repair or replace any part of the

Xpress Grill unless all main power supplies to the grill

have been disconnected.

• USEEXTREMECAUTION in setting up, operating and

cleaning the Xpress Grill to avoid coming in contact

with hot grill surfaces or hot grease. Suitable protective

clothing should be worn to prevent the risk of burns.

• DONOT clean this appliance with a water jet.

• DONOT apply ICE or COLD WATER to a HOT grill surface.

• NOTE all warning labels and markings axed to the grill.

WARNING: After turning the master power switch to the

START position, the grill will go through initialization. If

the upper platens are in the lowered position they will

return to their raised upper position. This movement takes

approximately 8 seconds.

Part # 4526884 Rev. 6 (06/06/13)Page 8

Page 9

INSTALLATION

Installation shall be made with the gas connector that has

been supplied loose with the grill. The quick disconnect

tting and gas shut o valve must be installed in the

direction indicated on their outer body.

NOTE: When checking gas pressure, be sure that all other

equipment on the same gas line is on.

The appliance and its individual shut-o valve must be

disconnected from the gas supply piping system during any

pressure testing of that system pressures in excess of ½ PSIG

(3.45kPa, 14” WC).

Adequate clearance must be provided for servicing and

proper operation.

National Codes Requirements:

The type of gas for which the grill is equipped is stamped on

the data plate on the inside rear of the unit and on the lower

front panel. Connect a grill stamped for Natural Gas only to

Natural Gas.

The installation must conform to the National Fuel Gas Code

ANSI Z223.1-1998 or latest edition, NFPA No. 54 – latest

edition and National Electrical Code ANSI/NFPA 70-1990 or

latest edition and/or local code to assure safe and ecient

operation. In Canada, the installation must comply with CSA

B149.1 and local codes where applicable.

In Canada, electrical connection must comply with

applicable sections of the Canadian Electrical Code, C22.1

- 1990, latest edition, “Safety Standard for Installation,

Part 1” and C22.2- No. O-M 1982 latest edition , “General

Requirements, Part 2”.

Gas Connections, and Pipe Sizing:

The size of the gas line is very important. If the line is too

small, the gas pressure at the burner manifold will be low.

This will cause slow recovery and delayed ignition. The

incominggaspressurelineshouldbeaminimumof1-1/2".

Allgrillsrequirea3/4"connection.

when pressure testing of that system at pressures in excess of

1/2 psi (3.45 kPa).

Check the data plate to determine the proper type of gas

before connecting the quick disconnect or piping from the

building gas supply.

An incoming gas pressure test nipple is provided on the

incoming gas manifold for pressure checks.

MinimumincominggaspressureforNaturalGasis6"W.C.

MaximumincominggaspressureforNaturalGasis13"W.C.

MinimumincominggaspressureforPropaneis10"W.C.

MaximumincominggaspressureforPropaneis13"W.C.

Burner operating gas pressure can be checked at the outlet

side of the gas valve at the pressure test point.

BurnermanifoldpressureforNaturalGasmustbe3.2"W.C.;

BurnerpressureforPropanemustbe3.5"W.C.

To adjust the burner pressure, remove the sealing screw

from the pressure test nipple, connect a manometer, remove

the sealing cap on the gas valve regulator, turn on the grill,

adjust the screw in the regulator to give the correct pressure,

turn o the grill, ret the regulator sealing cap, remove the

manometer, replace the seal screw in the test nipple and test

for gas leaks.

Gas pressures should be checked by the local Gas Company

or an authorized service agency only.

Test all piping and connections for gas leaks. A rich soap

solution should be used for this purpose. Never use a ame.

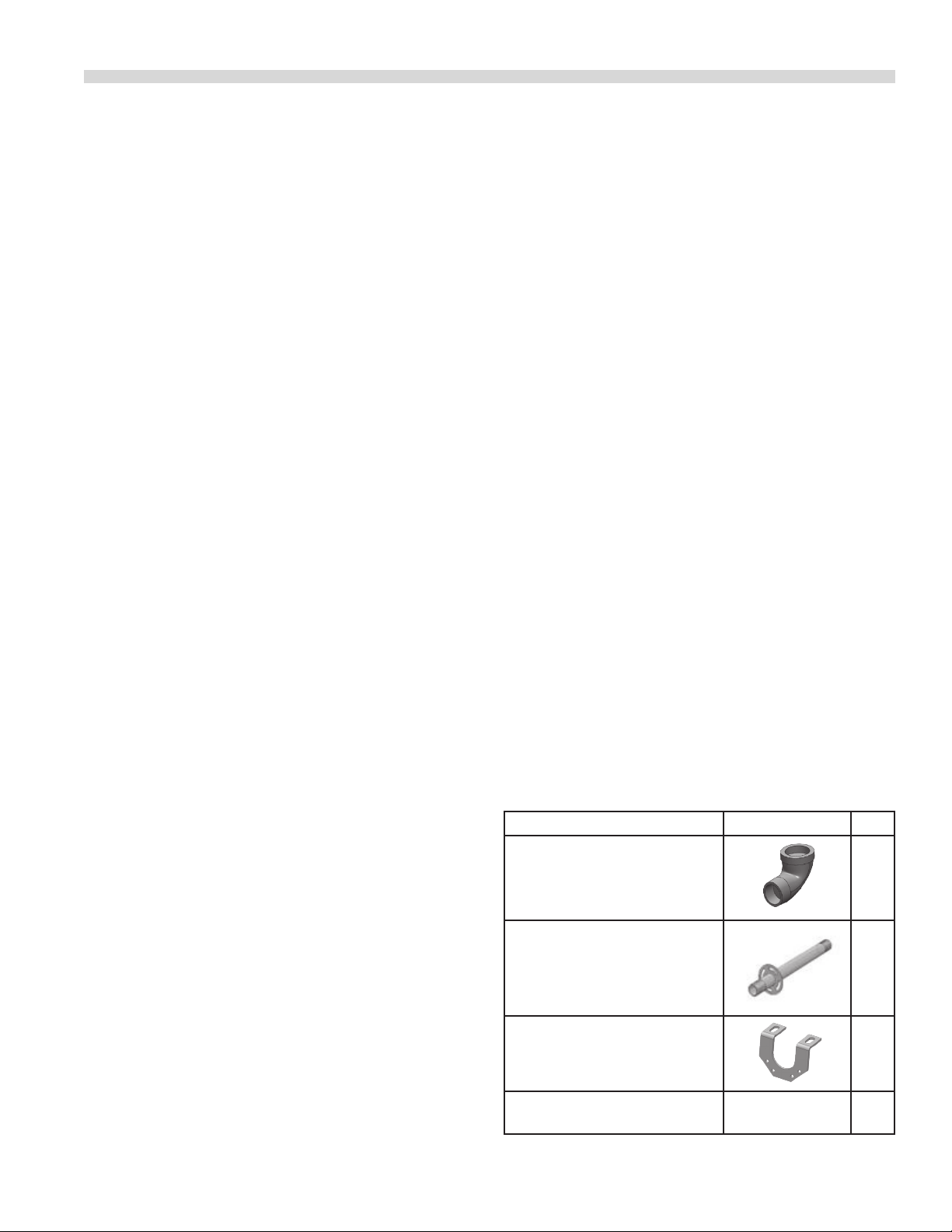

Accessory Kit – Main Gas Inlet:

(Accessory kit part numbers 4524785 or 4525509 and

also includes electrical supply lines, see next section).

Each griddle is supplied with an extended rear gas manifold

kit., with the following parts.

DESCRIPTION PART DRAWING QT Y.

Before connecting new pipe the pipe must be blown out to

dispose of any foreign particles. These particles will cause

improper operation.

When using thread compound, use small amounts on male

threads only. Use a compound that is not aected by the

chemical action of LP gases. Avoid applying compound

to the rst two threads to prevent clogging of the burner

orices and control valve.

Have the installer check all gas plumbing with a soap

solution for leaks. DO NOT USE matches, candles or other

ignition sources in checking for leaks.

The grill must be disconnected from the gas supply system

Part # 4526884 Rev. 6 (06/06/13) Page 9

3/4”x 3/4” 90 Degree Elbow

Nipple Assembly

Manifold Support Bracket

8-32x0.375” PH PAN HD T/C

(self-tapping screws)

1

1

1

4

Page 10

INSTALLATION continued

Installation of Kit:

1. Install the nipple assembly in the reduction elbow

(3/4” NPT) connected to the manifold. (Figure A)

Figure A

2. Install the manifold support bracket over the nipple and

leave the two screws loose. (Figure B)

Installation of Cord And Plug With Strain Relief:

1. Remove the left grease bucket support attached by two

metal screws and the stainless steel left side body panel

attached by ve metal screws.

2. Removethecord&plugandstrainreliefassemblyfrom

the accessory kit. Refer to photo D.

Figure B

3. Adjust the manifold support bracket ush with the rear

gas support bracket. (Figure C)

Figure C

4. Tighten the two loose screws of the manifold support

bracket onto the frame U-channel.

5. Lock the two brackets together using two screws.

(Figure C)

6. ¾” 90 degree elbow is supplied, to be installed if required.

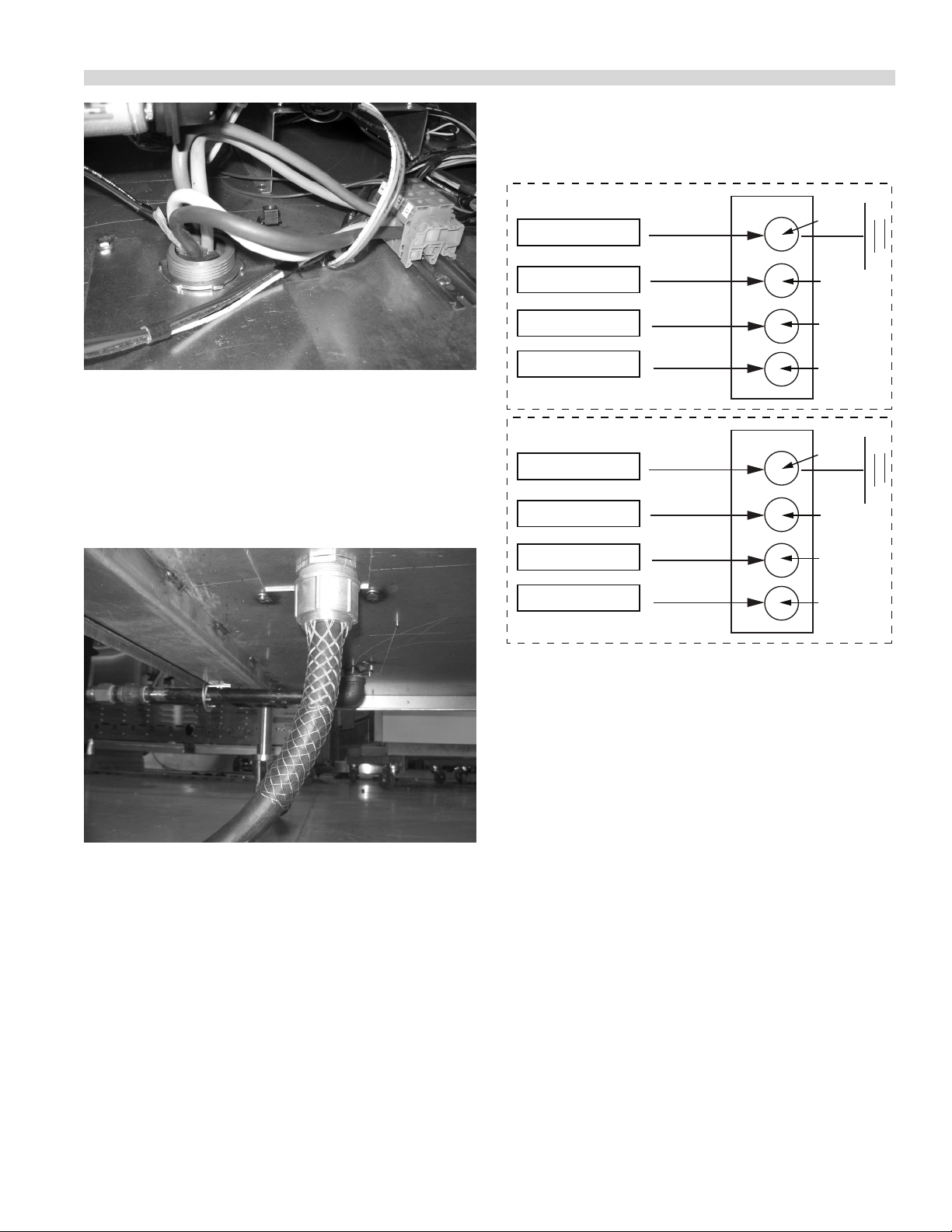

Accessory Kit – Electrical Supply Lines:

Photo D

3. Remove the locknut from at the end of the cord. Refer to

photo E.

Photo E

4. Insert loose wires and strain relief cord end through the

hole at the bottom of the unit Refer to photo F and secure

with locknut. Refer to photo E.

The accessory kit also contains electric power cord and

plug and has a stain relief suited for each unit. See Plug

Conguration in SPECIFICATIONS and Photo D

Part # 4526884 Rev. 6 (06/06/13)Page 10

Page 11

INSTALLATION continued

Wire leads from

Main Terminal

Note: see diagram below for connections to terminal block.

Photo F

5. Attached wire ends to terminal block as shown in next

section and referenced in wiring diagrams at back of this

manual.

6. Reinstall the side panel and grease bucket support with

metal screws. The external electrical connection should

appear as in photo G.

Cord and Plug

3-PHASE

Green-Ground

White - Z

Black - Y

Red - X

SINGLE PHASE

Green-Ground

Black - Z

White - Y

Red - X

Block of Grill

G

Z

Y

X

G

L1

N

L2

Photo G

Electrical Connection

Terminal Block Connection

All electrically operated appliances must be electrically

grounded in accordance with local codes; or in the absence

of local codes, with the latest edition of National Wiring

Regulations. A wiring diagram is located behind the rear

panel of the grill. For proper voltages, see rating plate in the

circuit breaker box, or on the right-rear frame upright.

Grease Bucket:

The griddle is supplied with two stainless steel side grease

buckets that must be installed before the unit is used. Each

bucket slides into position along stainless steel supports.

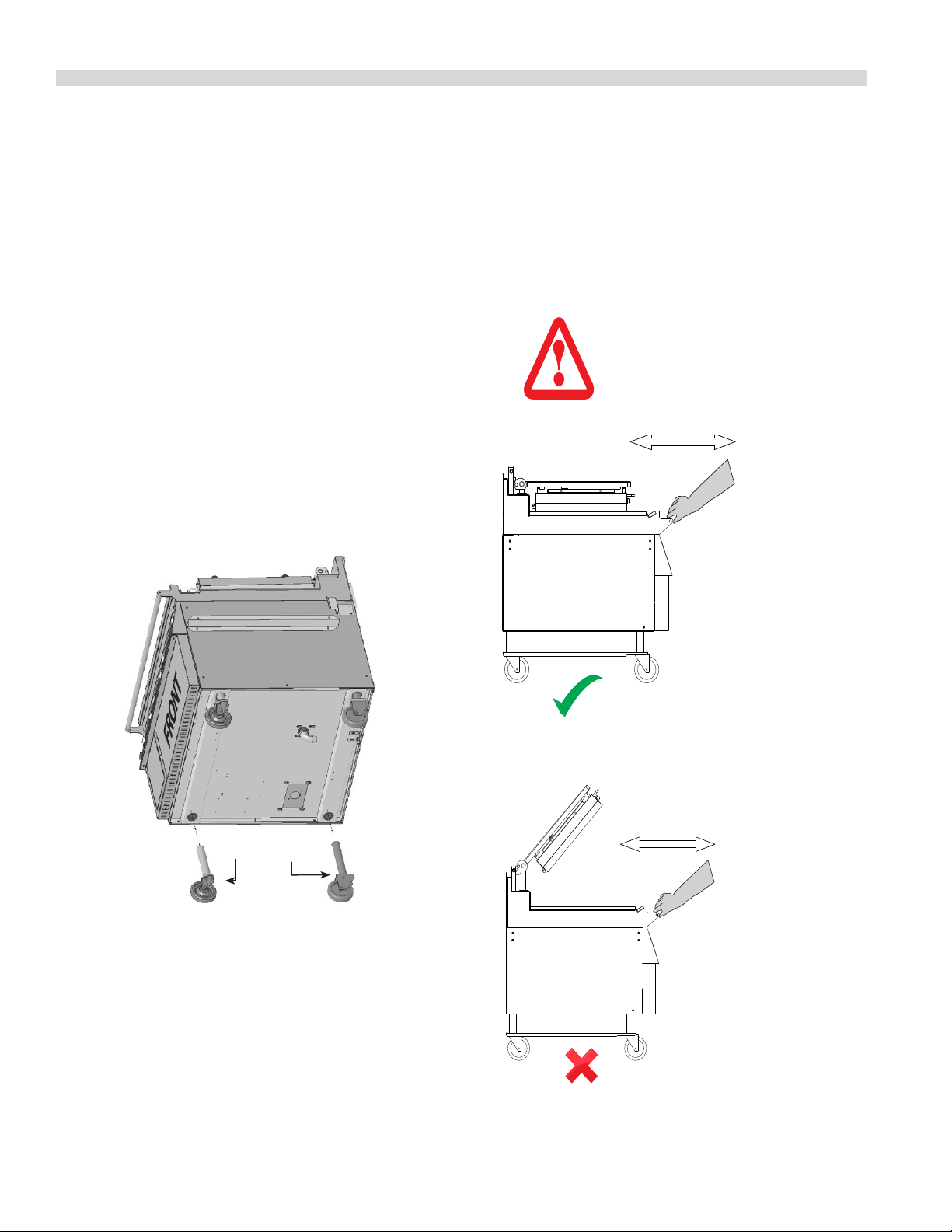

Appliances Equipped with Casters:

1. The installation shall be made with a connector that

complies with the Standard for Connectors for Moveable

Gas Appliances, ANSI Z21.69 or latest edition, addenda

Z21.69a-1989, and a quick-disconnect device that

complies with the Standard for Quick Disconnects for Use

with Gas Fuel. ANSI Z21.41 or latest edition.

2. The front casters on the appliance are equipped with

brakes to limit the movement of the appliance without

placing any strain on the connector or quick-disconnect

device or its associated piping.

3. Please be aware; required restraint is attached to a

bracket (which is located on the rear caster closest to the

gas connection), and if disconnection of the restraint

is necessary; be sure to reconnect the device after the

appliance has been returned to its original position.

Part # 4526884 Rev. 6 (06/06/13) Page 11

Page 12

INSTALLATION continued

1. Turn main switch ON.

2. Press green button to lower platen(s).

3. Turn main switch OFF.

4. Unplug power cord and proceed with

pull/push.

WARNING,

Avoiding procedure may cause

damage or loss of calibration on

the platen and potential of error

message can occur.

PASS – Gently pull or push

FAIL – Potential to damage

platen adjustment

FAIL – Potential to damage

platen adjustment

Swivel Caster Installation

Prior to installation, the four casters, supplied loose with the

grill, must be securely located on the underside of the base.

The casters tted with a brake must be located at the front of

the grill.

1. Carefully remove the top and side packaging leaving the

grill on shipping pallet.

DO NOT REMOVE THE TIES SECURING THE PLATEN ARMS

TO THE GRILL TOWEL BAR.

2. Raise the grill vertically o the pallet to a comfortable

working height and install the casters. DO NOT TIP THE

GRILL ON ITS BACK OR SIDE. If a truck lift is used, be

careful when inserting the lifting arms under the grill as

the gas inlet elbow is protruding in the center of the base.

WARNING - GRILL WEIGHT IS APPROXIMATELY 800 LBS –

USE CAUTION

3. Install the casters as shown below. The two casters with

brakes go on the front, and the two without on the rear.

4. Make sure platens are down, in close position, when

moving grill around or during transportation.

WITH

BRAKE

WITHOUT

BRAKE

Part # 4526884 Rev. 6 (06/06/13)Page 12

Page 13

NOTE: CASTERS MUST BE THREADED INTO GRILL BASE

LEAVING APPROXIMATELY ONE INCH OF EXPOSED

THREAD. THIS IS THE STARTING POINT FOR LEVELLING

THE GRILL AFTER IT IS IN POSITION.

Ventilation and Clearance:

One of the most important considerations for ecient grill

operation is proper ventilation and air supply. Insure the

grill is installed so the products of combustion are removed

eciently and the ventilation system does not produce

drafts that interfere with proper burner operation.

Proper operation of exhaust fans (speed, rotation and

adjustment) is essential. In addition to the exhaust system

the make-up air system, (HVAC), for the kitchen is the

air supply for the combustion air for the burners. Proper

incoming air is essential for all gas operated equipment. Poor

incoming make-up will cause inecient burner operation,

delayed ignition and possible burner failure.

Any ventilation system will break down if improperly

maintained. The duct system, the hood, and the lters must

be cleaned on a regular basis and kept grease free.

The room containing the grill is required to have a

permanent air vent. The minimum eective area of the vent

shall be 0.7 in.² per kW. Air vents shall be of such a size to

compensate for the eects of any extract fan in the premises.

Changing to a dierent type of gas

Changing from one gas type to another must only be

done by a Qualied Gas Engineer and according to local

regulations.

Part # 4526884 Rev. 6 (06/06/13) Page 13

Page 14

BUTTON

BUTTON

GRILL CONTROLS

CANCEL/

RAISE PLATEN

BUTTON

MASTER

POWER

SWITCH

POWER

BUTTON

PROGRAM

"START COOK TIME COUNTDOWN" (flat grill cooking)

BUTTON

TEMPERATURE

WHEN PUSHED SIMULTANEOUSLY:

OR "LOWER PLATEN" (two-sided cooking)

LED

INDICATORS

UP ARROW

16-CHARACTER

2-LINE DISPLAY

ENTER

BUTTON

DOWN ARROW

BUTTON

PRODUCT

BUTTONS

Master Power Switch:

Controls power to the grill and must be turned “ON” to start

operation. The controller display will be active when the

switch is “ON”.

LED Indicators:

There are two, (2), indicator lights, indicating the

temperature status of each control’s heat zones; one, (1), on

the upper platen, (top light), and one, (1), on the grill surface.

Each light can display three, (3), dierent colors, indicating

temperature status for the corresponding zone.

Red: The zone is too hot, (more than 79°F/45°C over the set

temperature), or heat zone failure.

Amber: The zone is calling for heat.

Green: The zone is at or above the set temperature.

Display:

The controller display will contain information relevant to

each operation in both cook and program modes.

Product Buttons (1-8):

Buttons 9 and 0 are used for standby and clean. They also

can be used in programming to move the cursor left or right

when creating or modifying product names in “PROD NAME

LIB” program mode.

Power Button:

After the main power switch is turned on, this button will put

the control into cook mode. If pressed again, the control will

go back to displaying “OFF.”

Program Button:

The primary function is to access Programming and

Calibration of the grill. Push and hold for ve (5) seconds.

Display will ask for the code. After entering code, ve

programming features will be accessible “MENU ITEMS,”

“SYSTEM INFO,” “SYSTEM SETUP,” “SERVICE MODE,” and

“PRODUCT NAME LIB.”

Part # 4526884 Rev. 6 (06/06/13)Page 14

Page 15

GRILL CONTROLS continued

Temperature Button:

In the Cook mode, each time the button is pressed the

current temperature for one zone is displayed. The grill

temperature is displayed rst followed by the platen

temperature. After ve (5) seconds, the display will return

to the menu item selected. Pressing and holding the

temperature button for 5 seconds will display both the grill

and platen temperatures. To exit press the temperature

button.

Up/Down Arrow Buttons; 2 Functions:

1. In the cook mode, the Up/Down Arrow Buttons will cycle

through the dierent menu items.

2. In the program mode, the Up/Down Arrow Buttons will

change the value of the current setting.

Enter Button:

Function is to accept programming steps.

Cancel/Raise Platen Button, (Green):

During the cooking cycle, pressing this button will cancel the

cooking timer and return the grill to the “IDLE” mode. This

button will also bring the grill out of STANDBY.

Black Button:

When both Black and Green “CANCEL/RAISE” buttons are

pressed simultaneously, the upper platen will lower to the

griddle surface.

Main Pre-Programed Product Items

Abbrev Cook Time Upper Platen Upper Temp Grill Temp Gap

BIG PAT 2:00 YES 425°F 350°F 0.420 1

JR Pat 1:10 YES 425°F 350°F 0.310 2

Gr. Chk. 1:45 YES 425°F 350°F 0.460 3

Sausg 1:30 YES 425°F 350°F 0.320 4

Egg :50 YES 425°F 350°F 0.310 5

Bcn 1:15 YES 425°F 350°F 0.100 6

LTO 1:20 YES 425°F 350°F 0.320 7

LTO 1:20 YES 425°F 350°F 0.320 8

STDBY N/A YES 425°F 350°F 0.400 STDBY

CLEAN N/A YES 220°F 220°F 0.400 CLEAN

Key

Assingment

Part # 4526884 Rev. 6 (06/06/13) Page 15

Page 16

OPERATION

Installing Release Material:

A release material sheet must be replaced when:

• Productstickstoreleasematerial.

• Carbonbuild-upruinstasteorappearance.

• Tearingoccursinthesheet’scookingarea.

• Releasematerialcoatingiswornosheet.

Slide release material rod through hemmed end of the

release material sheet.

Hook release material rod on brackets located at the rear of

the upper plate

Holding the bottom of the release material sheet in place,

gently pull the sheet toward the front of the platen.

RELEASE

MA TERIAL

BAR

RELEASE

MA TERIAL

UPPER PLATEN (side view )

FR ONT OF GRILL

RELEASE

MA TERIAL

LOCKIN G

CLIP (1)

NOTE: Make sure release material ts smoothly over upper

platen. Installing release material sheets too tight may cause

premature failure of the sheet.

Release sheets are reversible and should be ipped over

and reattached on a daily basis. For instructions on cleaning

release sheets, see Step 17., under Daily Cleaning in Cleaning

and Maintenance section

Lighting Instructions:

UPPER PLATEN (side viw)

RELEASE MA TERIAL HOOK

RELEASE

MA TERIAL RO D

RELEASE MA TERIAL SHEET

REAR OF GRILL

Thread the front edge of the release material sheet behind

the release material bar on the front of the platen, then

around the top and down over the front of the bar as shown.

Place locking clips over release material sheet and press into

place over release material bar.

1. Ensure that the exible gas hose is connected to the grill

and the power cord is plugged into the receptacles.

2. Turn the main power switch ON and allow the controls

to go through the power-up self-check. Once the control

panel displays the word “OFF” the unit is ready to begin

the heating process.

3. Press . The control will automatically initiate the

heating cycle. The burner will ignite and heat until the

temperature specied by the menu item has been

obtained.

If ignition of the burner does not occur on the rst trial, the

bottom indicator light will ash amber. If the burner(s) do

not light within four trials for ignition, the control will display

a ashing warning, “IGNITION ERROR.” The ashing amber

light will turn to solid red and an audible alarm will sound. If

this occurs, turn the main power switch o, wait 5 minutes,

and then repeat steps 2 and 3.

Check alignment and tightness of release material against

upper platen.

Part # 4526884 Rev. 6 (06/06/13)Page 16

Page 17

- - - - - - -

*** *

START

STOP

EMERGENCY

- - - - - - -

*** *

START

STOP

EMERGENCY

Clam Grill Operating Instructions

2

- - - - - - -

*** *

START

STOP

EMERGENCY

- - - - - - -

*** *

START

STOP

EMERGENCY

- - - - - - -

*** *

START

STOP

EMERGENCY

Press button to turn on main

power to grill.

Press button to turn zone power on.

Clam Grill Operating Instructions

2

3.6 PATT Y

*** *

START

STOP

EMERGENCY

3.6 PATT Y

*** *

START

STOP

EMERGENCY

4

- - - - - - -

*** *

START

STOP

EMERGENCY

Press button to turn zone power on.

3.6 PATT Y

*** *

START

STOP

EMERGENCY

OPERATION continued

- - - - - - -

*** *

START

STOP

EMERGENCY

Press both green and black buttons

to lower clam and begin cooking

product.

Press button to turn zone power on.

Clam Grill Operating Instructions

2

3.6 PATT Y

*** *

START

STOP

EMERGENCY

4

- - - - - - -

*** *

START

STOP

EMERGENCY

Simplied Cook Cycle Instructions:

1. Press button to turn on mainpower to grill.

2. Press to turn zone power on.

3. Load product on grill surface and select the

corresponding product key.

5. Press green button to cancel any time during cook cycle.

To Cook in Two-Sided Mode:

1. To start a cook cycle select a product recipe by using the

product keys (1 through 9) or by using the UP/DOWN

keys or to select a product recipe.

The display alternately blinks the recipe and the word

SELECTED 2 times then the recipe displays continuously.

2. The controller regulates the platen and grill temperatures

to the set temperatures of the product selected and

reads “TOO COOL” or “TOO HOT” with “MENU ITEM”, until

the grill attains the set temperature range for the item.

NOTE: If the display reads either “TOO COOL” or “TOO HOT”

the upper platen will not lower and initiate a cooking

sequence.

3 After loading the product onto the grill, press the green

CANCEL/RAISE PLATEN BUTTON and BLACK button

simultaneously. A cook cycle starts and the upper platen

lowers if the product selected is clamshell recipe.

4. Press both green and black buttons to lower clam and

begin cooking product.

Part # 4526884 Rev. 6 (06/06/13) Page 17

4 To cancel a cook cycle at anytime press the green

CANCEL/RAISE PLATEN BUTTON and the upper platen

will rise if the product recipe selected is clamshell recipe.

5. During a cook cycle, the display shows the product recipe

name in the rst line and the remaining cook time count

down in the second line.

6 When the cook timer reaches one, (1), second remaining

a pre-time-out alarm sounds alerting the operator.

7 When the cooking time has been completed the platen

raises automatically. On the controller the “PRODUCT

NAME” and the word “REMOVE” will be displayed and an

audible alert will sound.

8. Pressing the green CANCEL/RAISE PLATEN BUTTON stops

the audible alert and the unit will revert back to IDLE

mode.

Page 18

OPERATION continued

To Cook in Flat Grill Mode:

1. To start a cook cycle select a product recipe by using the

product keys (1 through 9) or by using the UP/DOWN

keys or to select a product recipe.

The display alternately blinks the recipe and the word

SELECTED 2 times then the recipe will be displayed

continuously.

2. The controller regulates the grill temperature to the set

temperature of the product selected and reads “TOO

COOL” or “TOO HOT” with “MENU ITEM”, until the grill

attains the set temperature range for the item.

NOTE: If the display reads either “TOO COOL” or “TOO HOT” it

will not initiate a cooking sequence.

3 After loading the product onto the grill, press the green

CANCEL/RAISE PLATEN BUTTON and BLACK button

simultaneously. That will start a cook cycle if the product

selected is clamshell recipe.

4 To cancel a cook cycle at anytime the press the green

CANCEL/RAISE PLATEN BUTTON .

Enter Standby Mode:

Stand by mode is used during slow periods to conserve

energy with out a complete shut down of the unit. When

cooking temperatures are again required, pre-heat cook

temperature/time is reduced. Stand by mode temperatures

can be adjusted, see the PROGRAMING section.

1. Select Standby Mode by pressing or until

“STANDBY” is displayed.

2. Press the GREEN (‘CANCEL/RAISE’) and the BLACK buttons

at the same time. As soon as the upper platen moves

down, the display will read “STANDBY MODE.” (Note: The

rst time Standby Mode is entered, the display prompts

the operator to press ENTER after pressing the GREEN

and BLACK buttons.)

Exit Standby Mode:

1. Press the GREEN (‘CANCEL/RAISE’) button. The upper

platen will raise and the display will read “CANCEL” with

an audible alarm.

To Display the Current Temperatures:

5. During a cook cycle, the display shows the product recipe

name in the rst line and the remaining cook time count

down in the second line.

6. The display shows the “SEAR” or “FLIP” alarm message

with ashing in the second line if the current cooking

product is at recipe and the sear time or ip time is not

zero.

7. A cook alarm sounds with a repeating beep pattern.

Pressing the black RAISE button acknowledges the “SEAR”

or “FLIP” alarm message if the alarm eld in system setup

is set to MANUAL.

8. The “SEAR” or “FLIP” alarm message stops after 5 seconds

if the alarm eld in system setup is set to AUTO.

9. When a cook is complete, the display shows the product

recipe name in the rst line and a ashing “REMOVE”

message in the second line. A repeating beeping alarm

also sounds.

10. Pressing the black RAISE button cancels the cook done

alarm.

11. The unit revertes back to IDLE mode.

1. Press the button and repeat for each zone to be

displayed...

1st press - LOWER GRILL ZONE

2nd press - UPPER PLATEN

3rd Pressing and holding the button for 5 seconds

will display both the grill and platen temperatures (preset

and actual). Press again ) to exit.

NOTE: The temperatures may be displayed at any time,

including during a cooking cycle.

To View Settings for a Menu Item:

1. Enter Programming; Menu Items, (see Programming)

2. Press to enter “PROGRAMMING MODE MENU ITEMS”

3. Use and to choose the desired Menu Item.

4. Press to scroll through settings for the chosen item.

To Clean the Grill:

1. To start a CLEAN MODE select the clean mode recipe by

pressing product key 10 or by using the UP/DOWN keys

or to select the clean mode recipe.

2. The controller regulates the platen and grill temperatures

to the set temperatures of the clean mode recipe. The

display shows the message “CLEAN MODE” in the rst line

and the actual grill temperature in the second line.

Part # 4526884 Rev. 6 (06/06/13)Page 18

Page 19

OPERATION continued

3. Press the ENTER key to initiate the clean mode.

4. The display SHOWS the message “READY TO CLEAN” with

ashing in the second line when the actual temperature

is reached (or greater than the set temperatures of clean

mode recipe (default 220°F for both the platen and grill).

A 5 second repeating beep pattern is sounded.

5. Press the ENTER key again, the heater’s control for the

platen and grill are turned o and the display shows the

message “CLEANING” with ashing in the second line.

6. Press the ENTER key again to exit the CLEAN MODE. The

display shows the message “STANDBY” in the rst line.

The control transitions to “STANDBY MODE” and preheats

to idle condition.

PLATEN SET:

This function allows the platen to be moved up or down

once it is parallel to the grill surface. Values range from –160

to +160.

EXTENDED TIME:

This option will add 6, 4 and 2 seconds to the time of the next

three cooks respectively if the grill has had no activity for

5 minutes. Provided the temperature is not 25°F above set

temperature for either the grill or the platen.

INSTANT ON TIME:

This can be set in the range of 00:00 to 00:40. Instant on will

turn on the heat zone(s) as soon as a cook cycle starts.

START DELAY:

This number is how long the operator must hold the GREEN

(‘CANCEL/RAISE’) and BLACK buttons to start a cooking cycle

for 2-sided recipes only. There will be one beep when the

cook is started and another beep when the START DELAY

time is reached. If the GREEN (‘CANCEL/RAISE’) and BLACK

buttons are released before that time the cook will be

canceled. If Yes is toggled press enter to allow the user to

pick from 1 to 5 seconds in 0.5 second increments using

and .

CLEANING AND MAINTENANCE

Cleaning During Operation:

1. After each product load is removed, Use a grill scraper to

scrape grease on lower grill plate from front to back only.

Do not scrape left to right across the lower grill plate with

the grill scraper.

2. Use a grill squeegee to clean release material sheet on

upper platen in a downward motion. Do not press hard

against the release material sheet to prevent scratching

or tearing.

Daily Cleaning:

Warning: The upper platen surface and edges are very hot! To prevent burn injuries, use extreme caution when wiping

down release sheets and platen edges.

3. Push the grease to the rear of the grill, or pull it to the

front trough. Then, squeegee the grease into the buckets

on either side. Do not use the scraper for this step.

4. Use a clean, damp cloth to clean back splash and

bullnose areas as needed during operation.

Note: To increase life of release material sheets, wipe

them down with a folded clean, damp cloth at least four

times during each hour of operation.

High-Temperature

Grill Cleaner

Part # 4526884 Rev. 6 (06/06/13) Page 19

Grill Cleaning Pad & Handle Grill Scraper

Heat-Resistant Gloves Clean, Sanitizer-Soaked

Grill Cloths

Grill Squeegee

Page 20

CLEANING AND MAINTENANCE continued

01

01

• Select Clean Mode

When Clean Mode has

been reached, the LED

indicators will turn GREEN.

05

• Remove the grease trough

from each side. Empty and

replace.

02

• Wipe the Release

Material sheets with a

clean,sanitizer-soaked

grill cloth.

06

• Apply the grill cleaner

to front side of platens

starting from right platen

to left platen.

• DONOTSCRUB.

03

• Remove the locking clips,

bars, and release sheets.

Wash, rinse, and set aside

to dry.

• Set release sheets aside

on a at surface.

07

• Apply the grill cleaner to

platen surfaces starting

from right platen to left

platen.

• DONOTSCRUB

04

• Scrape the lower grill

surface with the scraper.

• Usethegrillsqueegeeto

push residual grease into

trough.

• Washandrinsethe

squeegee and scraper.

08

• Apply the grill cleaner to

back side of platens from

right platen to left platen.

• DONOTSCRUB

09

• Apply the grill cleaner to

outer edges of right and

left platens.

• DONOTSCRUB

• Pressgreen&black

buttons to lower the

center platen.

10

• Apply grill cleaner to

inner edges of the right

and left platens, and

the edges of the center

platen.

• DONOTSCRUB

• Pressgreenbuttonto

raise center platen..

11

• Apply grill cleaner to

bottom grill surface.

• Spreadthecleanerover

the entire lower grill

surface from front to back

using even strokes.

• DONOTSCRUB

12

• Rinse platen surfaces with

a clean, sanitizer-soaked

grill cloth, starting from

right to left platens.

• Pressgreen&black

buttons to lower the

center platen.

Part # 4526884 Rev. 6 (06/06/13)Page 20

Page 21

CLEANING AND MAINTENANCE continued

14

15

17

19

13

• Rinse the edges of all three

platens.

• Pressgreenbuttontoraise

center platen.

• Wipe lower grill with a

clean,sanitizer-soaked

grill cloth. Repeat until no

visible soil remains.

• Pour a small amount of

lukewarm water on a

clean, sanitizer-soaked

grill cloth over the

bottom grill surface and

wipe o residue.

18

• Empty, wash, rinse,

and replace the grease

troughs.

• Place upper platen

release material sheets

at on the lower grill

surface.

• Gentlycleanbothsides

of the release material

sheets with the grill

cleaning pad

• Wipe remaining grill

surfaces with a clean,

sanitizer-soaked grill

cloth.

16

• Rinse both sides of

the release material

sheets with a clean,

sanitizersoaked grill cloth.

• Reinstalltherelease

material sheets. Secure in

place with bars and clips

20

• Apply a thin coat of fresh

shortening to the lower

grill surface only..

PLATEN ZEROING

Turn Master power switch “ON”, wait for controllers to display

“OFF”.

Note: Release sheets should not be installed during this

procedure.

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

Part # 4526884 Rev. 6 (06/06/13) Page 21

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times in succession to display

“PROGRAMMING MODE SYSTEM SETUP.”

5. Press eight, (8) times. “PLATEN SET +/- XX” is displayed.

(XX=numbers that will vary from grill to grill.)

6. Allow time for grill to heat and turn ready. Press

both the Cancel (Green) and Standby (Black) buttons

simultaneously to lower the upper platen. Press the

Page 22

PLATEN ZEROING

Cancel (Green) button to raise the platen. Now, press

both the Cancel (Green) and (Black) Buttons to re-lower

the platen.

7. Remove platen adjuster caps from all four adjustment

points on each platen. Remove the four locking caps from

the adjustment points.

8. Using the adjusting tool lower platen until adjusting tool

touches the arm assembly.

9. With gapping tool, adjust right rear of platen until the

gapping tool ts snugly between the upper platen and

grill surface.

10. Move next to the left front adjuster and raise the platen

until the gapping tool ts snugly between the upper

platen and grill surface.

ACCESSORIES

11. Next go to the left rear adjuster and raise the platen until

the gapping tool ts snugly between the upper platen

and grill surface.

12. Move next to the right front adjustment and raise the

platen until the gapping tool ts snugly between the

upper platen and grill surface.

13. Repeat steps 9-12 one or more times until gapping tool

ts snugly between the upper platen and grill surface at

all four adjustment points without further adjustment.

(See diagram below.)

14. Replace the platen adjuster locking caps “hollow side

down” and tighten snugly. Replace platen adjuster caps.

15. Repeat steps 9-14 for each platen.

Teflon Release Material Sheet - 1799303

(one per platen)

Teflon Release Material Rod - 4517008

(one per platen; 3 shown)

Teflon Release Material Clip - 1851301

(one per platen; 3 shown)

Part # 4526884 Rev. 6 (06/06/13)Page 22

Page 23

ACCESSORIES

Grill Squeegee - 1868201

Platen Gapping Tool -1838701

“No-Go”

“Go”

Insert gap tool directly below platen adjusters.

Part # 4526884 Rev. 6 (06/06/13) Page 23

Page 24

PLATEN ZEROING continued

Lower

Front

Left

Raise

Back

Right

Platen leveling should be done from one corner

to the opposite corner. The adjuster nuts should

be turned opposite of one another.

Platen Adjusting Tool - 4523323

Platen Adjuster Cap - 1859102

Platen Adj Lock Nut - 1859103

Shoulder Bolt - 8005401

Platen Adjuster Nut - 1859101

Use this end to turn all slotted

adjuster caps and nuts

Part # 4526884 Rev. 6 (06/06/13)Page 24

Page 25

PROGRAMMING

Programming Modes/Menu Sequence:

System Information

28

28

28

27

27

27

27

27

28

29

29

29

28

Part # 4526884 Rev. 6 (06/06/13) Page 25

Page 26

PROGRAMMING continued

System Set-up

UPPER SET TEMP

GRILL SET TEMP

PLATEN GAP SET

29

29

30

30

30

30

30

31

31

31

31

33

33

33

Service Mode

33

34

31

32

32

32

33

Part # 4526884 Rev. 6 (06/06/13)Page 26

Page 27

PROGRAMMING continued

Menu Items...

To Change the Cook Time of a Product:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter Programming Mode. “PROGRAMMING

MODE MENU ITEMS” is displayed.

4. Press

Use and to choose the desired Menu Item.

5.

6. Press to display “(MENU ITEM) COOK TIME XX:XX”

7. Use and to adjust the cook time.

8. Press to save the changes.

9. Press twice to exit.

To Turn Platen, (2-Sided), Cooking On/O:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

. “MENU ITEMS STANDBY” is displayed.

5. Use and to choose the desired Menu Item.

6 Press three, (3) times to display “(MENU ITEM) UPPER

TEMP XXX” displayed in °F or °C.

7. Use and to change the set temperature to the

desired value.

8. Press to save the changes.

9. Press twice to exit.

To Change Grill Set Temperature:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4.

Press . “MENU ITEMS STANADBY” or” MENU ASSIGNED

TO BUTTON 1” is displayed.

Use and to choose the desired Menu Item.

5.

6. Press four, (4) times to display “(MENU ITEM) GRILL

TEMP XXX” displayed in °F or °C.

7. Use and to change the set temperature to the

desired value.

8. Press to save the changes.

4.

Press . “MENU ITEMS STANADBY” or” MENU ASSIGNED

TO BUTTON 1” is displayed.

Use and to choose the desired Menu Item.

5.

6. Press twice to display “(MENU ITEM) UPPER PLATEN

YES/NO “.

7. Use and to turn upper platen on or o.

8. Press to save the changes.

9. Press twice to exit.

To Change Upper Platen Set Temperature:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4.

Press . “MENU ITEMS STANADBY” or” MENU ASSIGNED

TO BUTTON 1” is displayed.

9. Press twice to exit.

To Change Product Gap Setting:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4.

Press . “MENU ITEMS STANADBY” or” MENU ASSIGNED

TO BUTTON 1” is displayed.

Use and to choose the desired Menu Item.

5.

6. Press ve, (5) times to display “GAP XXX” displayed in

inches or mm.

7. Use and to change the gap setting to the desired

value.

8. Press to save the changes.

9. Press twice to exit.

Part # 4526884 Rev. 6 (06/06/13) Page 27

Page 28

PROGRAMMING continued

To Change Product Button, “Key” Assignment

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press

button 1 is displayed.

Use and to select any unused item from the Menu

5.

Item.

6. Press six, (6) times to display “ASSIGN TO KEY (1-8 or

NONE)” - Make sure you have assigned desired values to

time, gap and temperatures.

NOTE: If time is left with zero value, the key assignment will

not go into eect.(you will hear double beep when choosing

key in cooking mode)

7. Use and to change the key, (Product Button),

assignment, and replace any previous assignments to

that key.

8. Press to save the changes.

9. Press twice to exit.

. “MENU ITEMS STANDBY” or menu assigned to

To Change a Product Name:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press one, (1) time to display “PROGRAMMING MODE

SYSTEM INFO.”

5. Press to view the upper recovery time. “RECOVERY

UPPER XXXX” is displayed.

6. Press to return to “PROGRAMMING MODE SYSTEM

INFO”.

7. Press to exit.

To View Recovery Time - Grill:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press one, (1) time to display “PROGRAMMING MODE

SYSTEM INFO.”

5. Press two, (2), times to view the grill recovery time.

“RECOVERY GRILL XXXX” is displayed.

6. Press to return to “PROGRAMMING MODE SYSTEM

INFO”.

7. Press to exit.

To View the Garland Part Number:

4. Press

button 1 is displayed.

Use and to choose the desired Menu Item.

5.

6. Press seven, (7) times to display “PRODUCT NAME

(CHOSEN ITEM)” – Make sure you have assigned desired

values to time, gap and temperatures.

7. Use and to cycle through the available product

names until the desired name is achieved.

8. Press to save the changes. You will automatically

return to “PROGRAMMING MODE MENU ITEMS”.

9. Press to exit.

. “MENU ITEMS STANDBY” or menu assigned to

System Info...

To View Recovery Time - Upper Platen:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press one, (1) time to display “PROGRAMMING MODE

SYSTEM INFO.”

5. Press three, (3), times to view the Garland Part Number

for the grill. “GARLAND PART # X…X” is displayed.

(number varies by grill).

6. Press to return to “PROGRAMMING MODE SYSTEM

INFO”.

7. Press to exit.

Part # 4526884 Rev. 6 (06/06/13)Page 28

Page 29

PROGRAMMING continued

.To View the Flash Number:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press one, (1) time to display “PROGRAMMING MODE

SYSTEM INFO.”

5. Press four, (4), times to view the Flash Number. “FLASH

NUMBER X…X” is displayed. (Flash number varies by grill).

6. Press to return to “PROGRAMMING MODE SYSTEM

INFO”.

7. Press to exit.

To View the Software Number:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press one, (1) time to display “PROGRAMMING MODE

SYSTEM INFO.”

5. Press five, (5), times to view the Software Number.

“SOFTWARE NUMBER X…X” is displayed. (number varies

by grill).

6. Press to return to “PROGRAMMING MODE SYSTEM

INFO”.

7. Press to exit.

To View the Download Number:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press one, (1) time to display “PROGRAMMING MODE

SYSTEM INFO.”

5. Press six, (6), times to view the Download Number.

“DOWNLOAD NUMBER X…X” is displayed. (Download

number varies by grill).

6. Press to return to “PROGRAMMING MODE SYSTEM

INFO”.

7. Press to exit.

System Setup

To Change temperature Units, (°F or °C):

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

Press to enter system setup. “TEMP DISPLAY

5.

FAHRENHEIT (or CELSIUS)” is displayed.

6. Press to change the temperature units to either

Fahrenheit or Celsius.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

To Change Gap Setting Display Units:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

Press two, (2), times. “GAP SETTING DISPLAY INCHES

5.

(or MILLIMETERS)” is displayed.

6. Press to change the Gap Setting Display units to either

Inches or Millimeters.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

Part # 4526884 Rev. 6 (06/06/13) Page 29

Page 30

PROGRAMMING continued

To Change the Alarm Volume:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

Press three, (3), times. “ALARM VOLUME LOW (or

5.

HIGH)” is displayed.

6. Use or to change the Alarm Volume to either Low

or High.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

To Change the Key Chirp:

To turn key chirp on or o in programing mode only.

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

Press four, (4), times. “KEY CHIRP ON (or OFF” is

5.

displayed.

6. Use or to change the key chirp to either ON or OFF.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

To Change Upper Set Temperature:

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

Press five, (5), times to display “UPPER SET TEMP”. The

5.

default temperature value is 425F (218C).

6. Press or use and to change the key to a desired

temperature value (typically the most used in cooking).

The temp range is 300 – 425F.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

To Change Grill Set Temperature:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

Press six, (6), times to display “GRILL SET TEMP”. The

5.

default temperature value is 350F (177C).

6. Press to accept or use and to change the key to

a desired temperature value (typically the most used in

cooking). The temp range is 275 – 375F.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

To Change Probe Calibration - Upper:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

Part # 4526884 Rev. 6 (06/06/13)Page 30

Page 31

PROGRAMMING continued

Press seven (7) times. “PROBE CAL-UPPER XXXF” is

5.

displayed. The temp value from “UPPER SET TEMP” is

displayed.

6. Use or to change the Probe Calibration to the

correct temperature measured with a pyrometer.* SEE

CALIBRATION REQUIREMENTS and CALIBRATION section.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

To Change Probe Calibration - Grill:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

5. Press eight (8) times. “PROBE CAL-GRILL XXXF” is

displayed. The temp value from “GRILL SET TEMP” is

displayed.

6. Use or to change the Probe Calibration to the

correct temperature measured with a pyrometer.* SEE

CALIBRATION REQUIREMENTS and CALIBRATION Section.

To Change Platen Gap Set:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

5. Press nine, (9) times. “PLATEN GAP SET +/- XX” is

displayed. (numbers will vary by grill)

6. Use and to change the Platen Gap Set to the

correct value.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE MENU

ITEMS”

9. Press again to exit.

To Change Instant-On Time:

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE SYSTEM

SETUP”

9. Press again to exit.

*CALIBRATION REQUIREMENTS

The control software will beep to the user when it

is appropriate to calibrate. The control will allow

calibration provided the following conditions are met:

• Temperatureiscurrentlyfallingfromadetectedpeak

of 360°F or higher.

• Temperatureisfallingandhasfallen2°Ffroma

detected peak that is within the 350-360°F range. (i.e.

calibration would be allowed at 355°F if the achieved

peak temperature was 357°F)

• Temperatureisrisingthroughthe350-360°Frangeas

a result of a heat on pulse of less than 30 seconds.

Part # 4526884 Rev. 6 (06/06/13) Page 31

4. Press two, (2) times. “PROGRAMMING MODE SYSTEM

SETUP” is displayed.

5. Press ten, (10) times. “INSTANT ON TIME XX:XX” is

displayed. (numbers will vary by grill).

6. Use and to change the Instant on Time to the

desired value.

7. Press to save the changes.

8. Press to return to “PROGRAMMING MODE MENU

ITEMS”

9. Press again to exit.

To Change Control Type:

Note: this must be veried if the control is changed, match

the new control to the grill.

1. Press and hold for three, (3) seconds. “ENTER CODE” is

displayed.

Page 32

PROGRAMMING continued

2. Using the Product buttons, 0-9 enter the code, (1251).

“ENTER CODE **** ” is displayed.

3. Press to enter the Programming Mode.

“PROGRAMMING MODE MENU ITEMS” is displayed.