Cleveland WT-300 Service Manual

SteamerGard™

WT-300, WT-600 and WT-900

WATER TREATMENT SYSTEM

INSTALLATION,

OPERATION AND

MAINTENANCE

MANUAL

Pan Number 98-0800

WTS-04

Contents

Installation

Installation Requirements 1

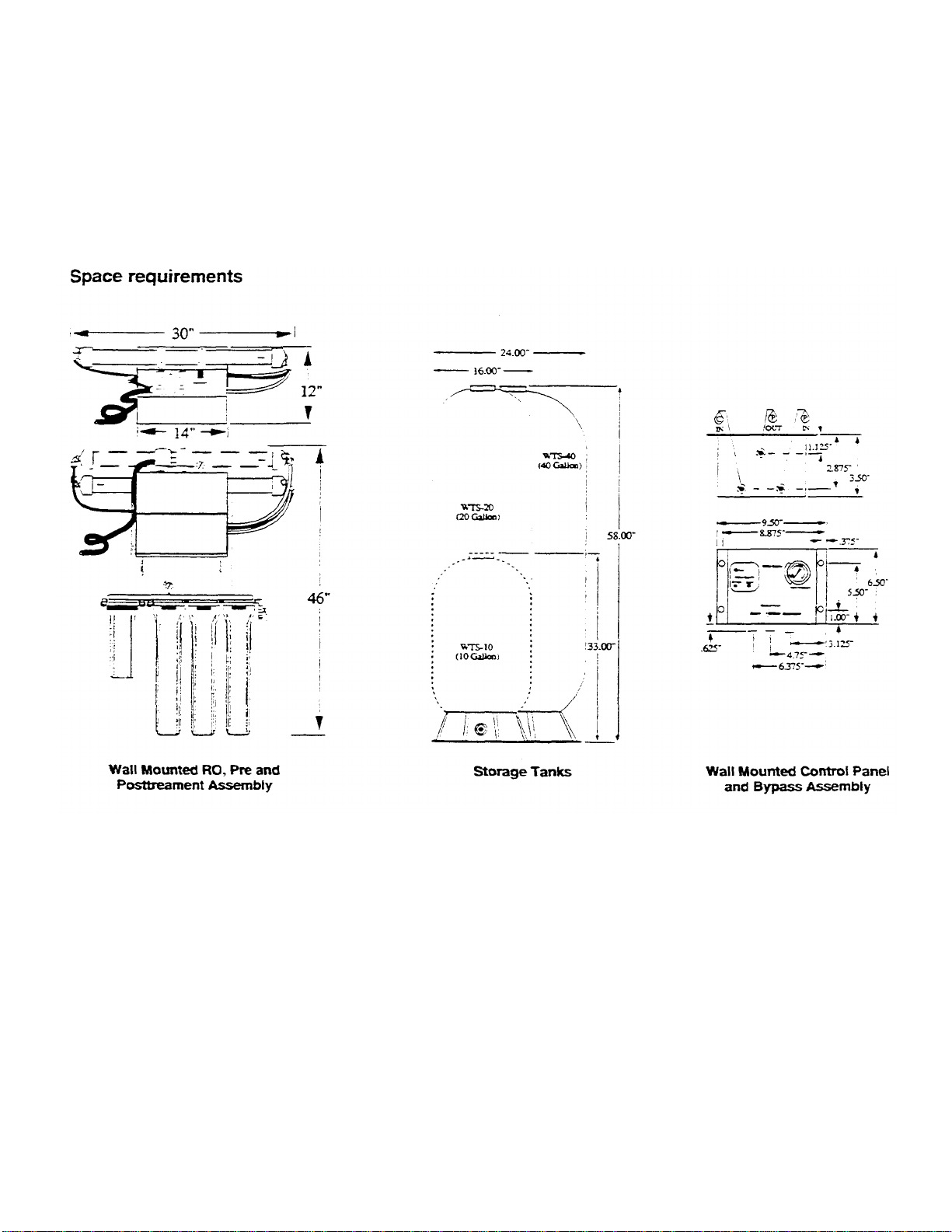

Space Requirements 1

Operating Parameters 1

Feedwater Chemistry 2

Electrical 2

Installation Drawings

Space Requirements, Figure 1. 1

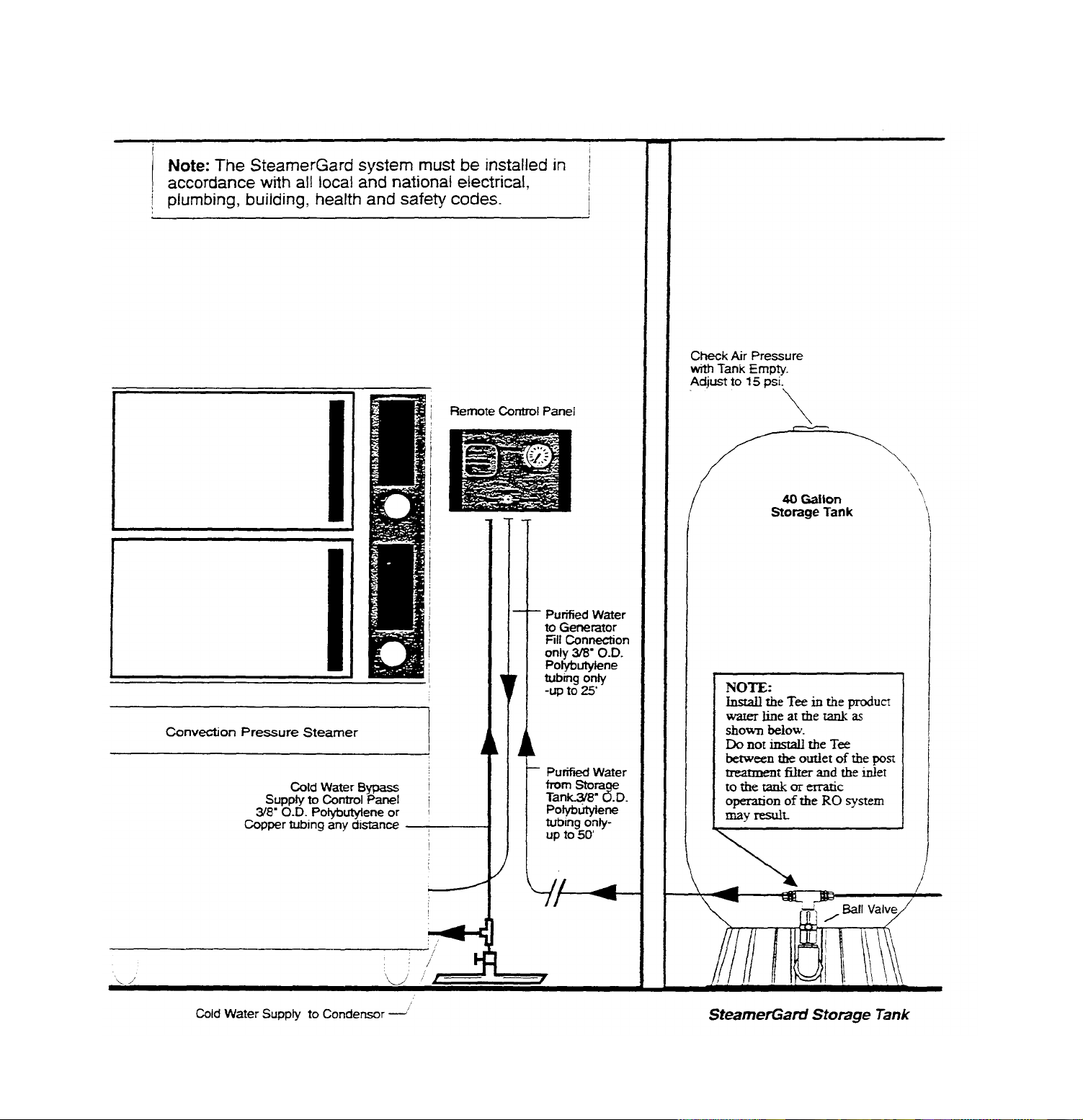

Typical Installation, Figure 2 4-5

SteamerGard Detail, Figure 3 6-7

Installation Procedure

Positioning equipment. 8

Wall Mounting RO. 8

Wall Mounting Filter Assy. 9

Feedwater Connection. 9

Drain Connection 10

Product Water Connection 10

Electrical Connection 10

Storage Tank Installation Procedure 11

Contol-Bypass Panel Installation Procedure 12

Final Connection to Steamer 12

Start-UP Procedure

Start-up Procedure 13

Final Inspection. 13

Routine Maintenance

Depressurization Procedure 14

Sediment Filter Replacement 14

Carbon Filter Replacement 15

Post Treatment Filter Replacement 15

Final Inspection 15

Restarting and Purging the RO 15

Wiring Diagram 16

Installation Requirements

Before beginning the installation, review the criteria below to make sure that the requirements have been or will be met when the

installation is complete. Also,confirm that the feed water falls within the limits shown below. If you're not sure if this has been done,

check with your SteamerGard distributor or the factory before installing the system. This is important because failures caused by

water related problems are not covered under the system warranty.

Operating paramet ers:

Model

Operating pressure 175 psi

Typical TDS rejection >96%

Feed Temperature 40- 100° F (4-38° C)

Feed pressure 25 - 85 psi (1.4 - 5.9 bar) at 3 gpm

Production* WT-300, WT -600, WT-900

*Model number equals nominal production in gallons per day @ 77°F (25°C) @ 500 ppm based on 24 hr day. Actual output may vary

according to local water conditions and membrane variations.

1

Installation Requirements, Cont'd

2

Feedwater chemistry:

Parameter

Feed TDS Up to 2000 ppm Feed pH 5-11

Hardness 20 grains or less Free chlorine <2mg/l

Iron (Fe) . 1 mg/I maximum Manganese .05 mg/1 maximum

Hydrogen sulfide none allowable Turbidity <5NTU

If your water analysis indicates that any of these parameters are not in range, additional pretreatment or higher frequency

of maintenance may be required. Contact your SteamerGard distributor or the factory for assistance. NOTE: The presence

of silica or flocculants (e.g. alum or cationic polymers) in the feedwater can cause membrane fouling and may require

special chemical pretreatment or periodic membrane cleaning.

Electrical requirements:

Model

Electrical 115 VAC, 60 Hz, 6.2 Amp. 115 VAC, 60 Hz, 7.5 Amp.

Motor 1/3 HP 1/2 HP

Pump Rotary vane type Rotary vane type

WT-300, WT-600

WT-900

Drain

Drain must allow a minimum flow of 5 gallons per minute.

Follow local plumbing codes for connection of drain line. Most plumbing codes require the installation of an

approved air gap in the drain line.

Getting to Know the SteamerGard System

3

Before beginning the installation, take a few minutes to familiarize yourself with the SteamerGard system by studying the

drawings on the following pages. Figure 2 shows a typical SteamerGard installation. Figure 3 shows a detailed view of the

SteamerGard RO, pretreatment and post treatment system.

Loading...

Loading...