Page 1

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 1-216-481-4900 Fx: 1-216-481-3782 Web Site: www.clevelandrange.com

Cleveland Range, LLC

SINCE 1922

INNOVATIVE STEAM COOKING SOLUTIONS

MIXER KETTLES

TWIN MIXER KETTLE, ELECTRIC

LEG MOUNTED, CONSOLE TYPE

2/3 JACKETED, TILTING

MODELS: TMKEL-40-T TMKEL-80-T

TMKEL-60-T

ITEM NUMBER __________________________________________

JOB NAME / NUMBER __________________________________

Cleveland Standard Features

■ Solid State Temperature Control (±1°F) for perfect

simmering

■ Solid State Low Water Safety Control

■ Steam Jacket permanently filled with distilled water,

corrosion inhibitor and antifreeze

■ 50 psi Safety Valve and Steam Jacket Rating

■ No Water Gauge required

■ Rear mounted Pressure/Vacuum Gauge and Pressure Relief

Valve protected by Stainless Steel Bracket

■ Infinitely Variable Scraper Speed Control from 0-40 rpm

■ Infinitely Variable Ratio between Scraper And Agitator:

Agitator rotates from 0-8 times the speed of the Scraper

■ Removable (without tools) Nylon Blades scrape entire

Jacketed surface

■ 3 Horsepower Hydraulic powered Agitator, Scraper and

Bridge Lift

■ Safety Device prevents high speed starts

■ Mixer stops when Bridge is lifted

■ Agitator and Scraper are bayonet mounted for easy removal

■ Tilt mechanism of Roller Bearings and case hardened self-

Locking worm and segment gear

■ Hot and Cold Water Faucets

■ 2" diameter Tangent Draw-Off Valve with Drain Strainer

■ All Plumbing, Electrical and Hydraulics enclosed in Stainless

Steel Consoles

■ Enclosed, Balanced, 10 Gauge Stainless Steel Hydraulically

operated Mixer Bridge

■ Kettle and all Exterior surfaces are Stainless Steel

■ Level adjustable feet (flanged for bolting)

■ Large Pouring Lip

■ Gallon Markings on Scraper Shaft

■ Standard 120/208-240 volts, 60 Hz, 3 phase, 4 wire

Options & Accessories

❐ Covers (MPT)

❐ Product Time/Temperature Controls and Indicators

❐ Food Strainer (FS-20)

❐ Flow Diverter (FD)

❐ Pan Carrier (PCK)

❐ Swing Funnels (SF-1 or SF-2)

❐ Alternate Mounting Systems (wall, bulkhead)

❐ Power Tilt (PT)

Shall Be CLEVELAND, Model TMKEL - _____ - T, console / leg mounted,

Electric Twin Mixer Kettle with permanently filled Steam Jacket: _____ p si

Steam Jacket Rating and Safety Valve; Solid State Temperature (±1F°) and

Low Water Safety Controls; 3 H.P. Hydraulic Powered Agitator, Scraper and

Bridge Lift; Infinitely Variable Scraper Speed; Infinitely Variable Ratio

between Scraper and Agitator; enclosed Mixer Bridge; all plumbing, electrical, and hydraulics contained in Consoles; Gallon Markings on Scraper

Shaft; Safety Device prevents high speed starts; Mixer stops when Bridge

is lifted. Bayonet Mounted Agitator and Scraper; 2" Tangent Draw-Off Valves,

Hot and Cold Water Faucet; Kettles and all exterior surfaces Stainless Steel.

❐ Kettle Accessory Kit (KAK) includes:

❐ Clean-up Brush (CB) ❐ 36˝ Kettle Paddle (KP)

❐ 36˝ Kettle Whip (KW) ❐ 36˝ Kettle Brush (KB)

❐ Draw-off Brush (DB) ❐ 24 oz.Ladle (KL)

❐ Type 316 Stainless Steel Interior for high acid food

products (316-20G)

❐ Water Meter (GMF or LMF) Wall Mount or on Stand (SWM)

❐ Leg Extensions (ELTMK)

❐ Voltages (VOS) other than standard

Short Form Specifications

SECT. XI PAGE 7

1003

Shown with optional Power Tilt

Page 2

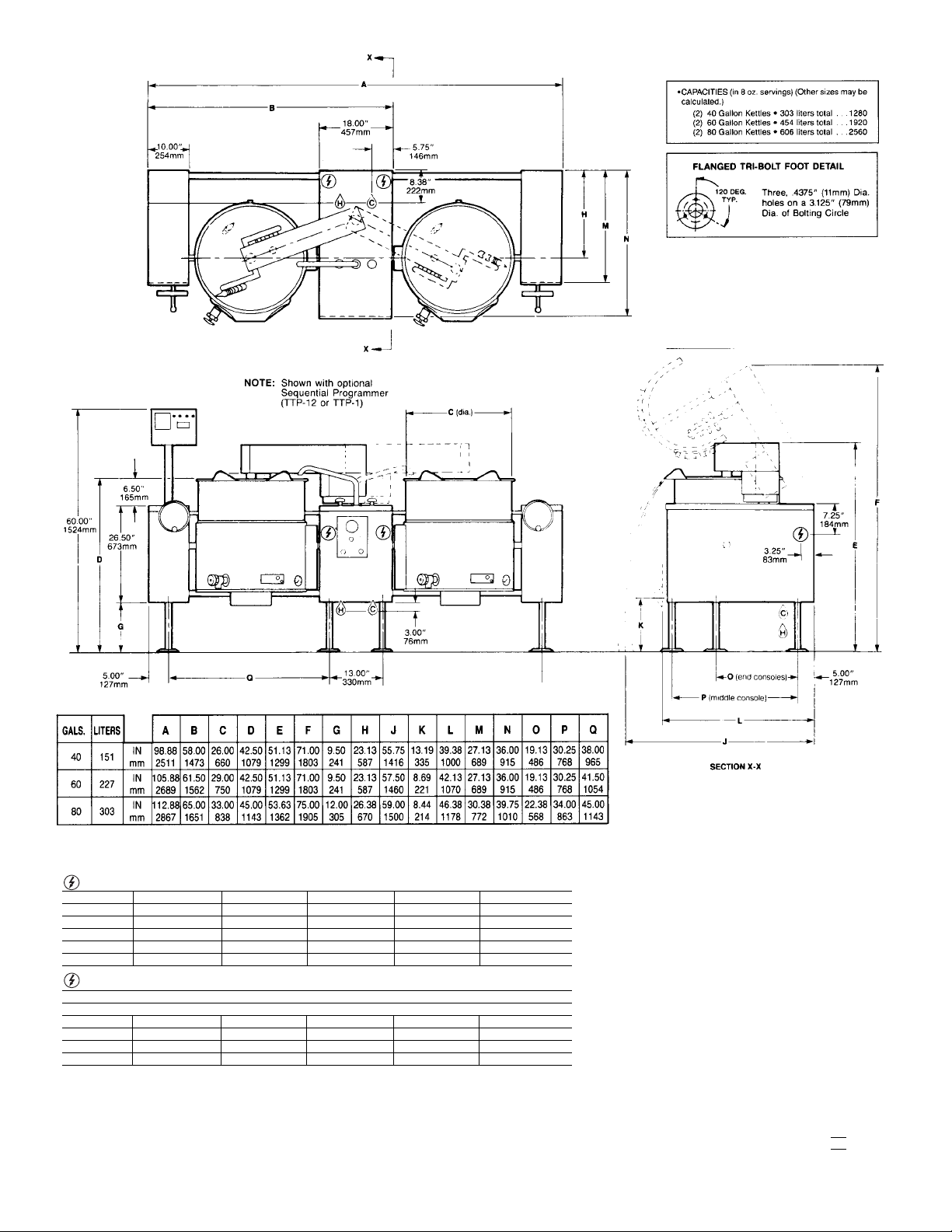

ST ANDARD W A TT A GE

208V 240V 480V 380V 415V

AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS

GALS. LITERS KW 1PH 3PH KW 1PH 3PH KW 1PH 3PH KW 1 PH 3PH KW 1 PH 3PH

40 150 14.7 70.8 40.9 19.5 81.7 47.1 19.6 40.8 23.6 15.1 39.7 22.9 18 43.4 25

60 225 14.7 70.8 40.9 19.5 81.7 47.1 19.6 40.8 23.6 15.1 39.7 22.9 18 43.4 25

80 300 14.7 70.8 40.9 19.5 81.7 47.1 19.6 40.8 23.6 15.1 39.7 22.9 18 43.4 25

HIGH WA TTA GE

208V 240V 480V 380V 415V

AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS AMPS

GALS. LITERS KW 1PH 3PH KW 1PH 3PH KW 1PH 3PH KW 1 PH 3PH KW 1 PH 3PH

40 150 24.5 N/A 68.1 30 N/A 75.3 32.6 68.1 39.3 25.1 66.2 38.2 30 72.3 41.7

60 225 29.4 N/A 81.7 39.2 N/A 94.3 39.2 81.7 47.1 30.2 79.4 45.9 36 86.7 50.1

80 300 29.4 N/A 81.7 39.2 N/A 94.3 39.2 81.7 47.1 30.2 79.4 45.9 36 86.7 50.1

SECT. XIPAGE 8

0402

Litho in USA

(NOT TO SCALE)

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

Loading...

Loading...