Cleveland TMKEL-100-T User Manual

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

MIXER KETTLES

TWIN MIXER KETTLE, ELECTRIC

LEG MOUNTED, CONSOLE TYPE

2/3 JACKETED, TILTING

Cleveland Standard Features

II

olid State Temperature Control (±1°F) for perfect

S

simmering

II

Solid State Low Water Safety Control

II

Steam Jacket filled with treated water, venting and/or refilling

not required

II

50 psi Safety Valve and Steam Jacket Rating

II

No Water Gauge required

II

Rear mounted Pressure/Vacuum Gauge and Pressure Relief

Valve

II

Infinitely Variable Scraper Speed Control from 0-40 rpm

II

Infinitely Variable Ratio between Scraper And Agitator:

Agitator rotates from 0-8 times the speed of the Scraper

II

Removable (without tools) Nylon Blades scrape entire

Jacketed surface

II

3 Horsepower Hydraulic powered Agitator, Scraper and

Bridge Lift

II

Safety Device prevents high speed starts

II

Mixer stops when Bridge is lifted

II

Agitator and Scraper are bayonet mounted for easy removal

II

Tilt mechanism of Roller Bearings and case hardened selfLocking worm and segment gear

II

Hot and Cold Water Faucets

II

2" diameter Tangent Draw-Off Valve with Drain Strainer

II

All Plumbing, Electrical and Hydraulics enclosed in Stainless

Steel Consoles

II

Enclosed, 10 Gauge Stainless Steel hydraulically operated

Mixer Bridge

II

Kettle and all Exterior surfaces are Stainless Steel

II

Level adjustable feet (flanged for bolting)

II

Large Pouring Lip

II

Gallon Markings stamped into Scraper Shaft

II

Standard 208-240 volts, 60 Hz, 3 phase, 4 wire, high wattage

II

Typical approvals include UL., CSA, CE, NSF and ASME

Options & Accessories

Ë Covers (MPT)

Ë Product Time/Temperature Controls and Indicators

Ë Food Strainer (FS-20)

Ë Flow Diverter (FD)

Ë Pan Carrier (PCK)

Ë Swing Funnels (SF-1 or SF-2)

Ë Alternate Mounting Systems (wall)

MODELS: TMKEL-40-T TMKEL-80-T

TMKEL-60-T TMKEL-100-T

Shown with optional Power Tilt

Short Form Specifications

Shall be CLEVELAND, Model TMKEL- _____ -T, console/Leg mounted,

Electric Mixer KettleS with permanently filled Steam Jackets; 50 psi Kettle

Jacket Ratings and Safety Valves, High Wattage standard, Solid State

Temperature (±1°F) and Low Water Safety Controls.

ered Scraper/Agitator and Bridge Lift. 0-40 rpm Scraper Speed with Variable

Scraper to Agitator Ratio from 1-1 to 8-1. Stainless Steel enclosed Mixer

Bridge. All Plumbing, Electrical and Hydraulics enclosed in Consoles. Gallon

Markings. Safety Device prevent high speed starts.

high speed starts; Mixer stops when Bridge is lifted.

Agitator and Scraper. 2" Tangent Draw-0ff Valve. Hot and Cold Water Faucet.

Kettle and all exterior surfaces are Stainless Steel.

Ë Power Tilt (PT)

Ë Kettle Accessory Kit (KAK) includes:

Ë Clean-up Brush (CB) Ë 36˝ Kettle Paddle (KP)

Ë 36˝ Kettle Whip (KW) Ë 36˝ Kettle Brush (KB)

Ë Draw-off Brush (DB) Ë 24 oz. Ladle (KL)

Ë Type 316 Stainless Steel Interior for high acid food

products (316-20G)

Ë Water Meter (GMF or LMF) Wall Mount or on Stand (SWM)

Ë Leg Extensions (ELTMK)

Ë Voltages (VOS) other than standard

3 H.P. H

ydraulic pow-

Safety Device prevents

Bayonet Mounted

SECT. XI PAGE 7

0609

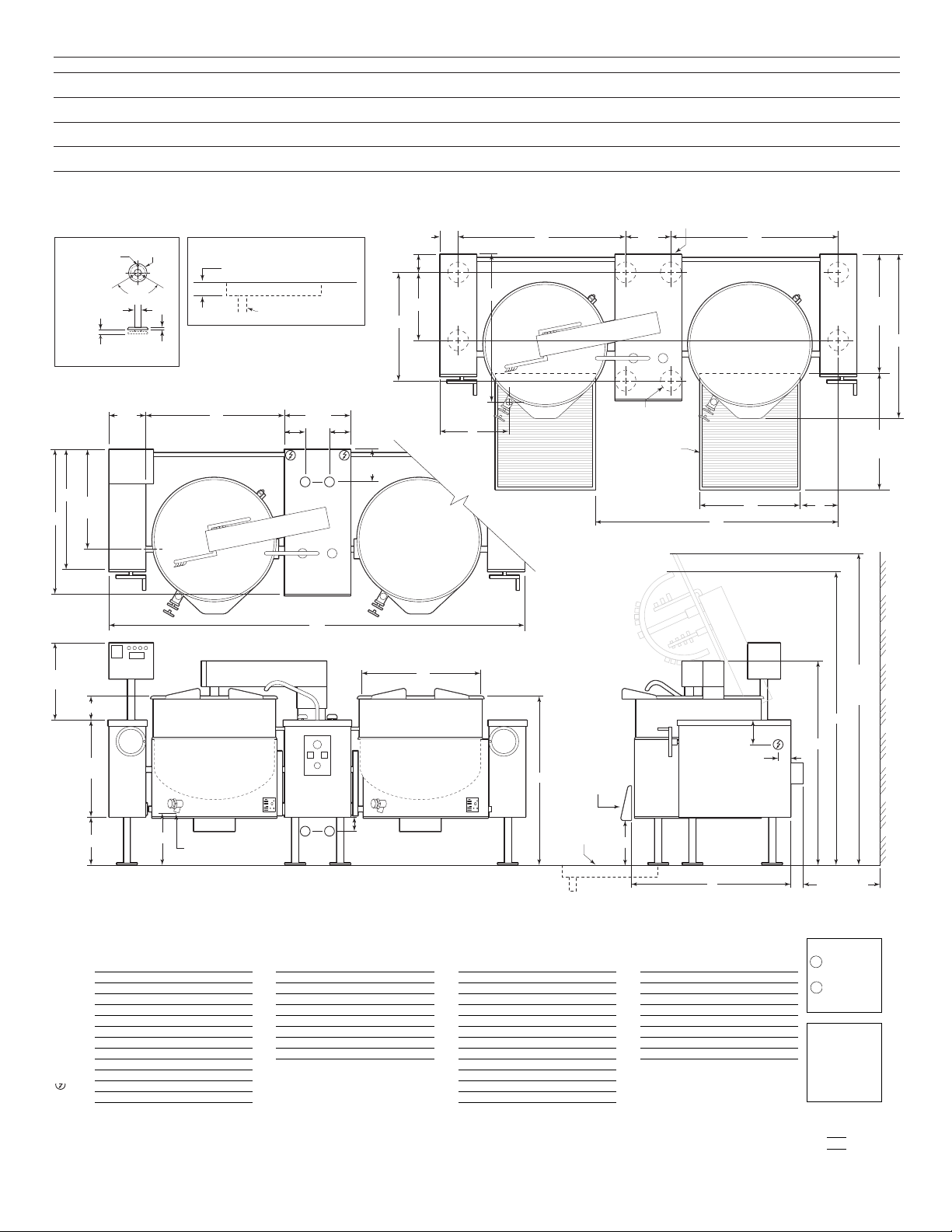

C

W

(I.D.)

H

(TRUNNION)

G

D

K

X

26.50"

673mm

2" (51mm) TANGENT

DRAW OFF VALVE

KETTLE

LIP IN

TILTED

POSITION

6.50" (165mm)

21.00"

533mm

3.00"

76mm

8.75"

222mm

E

F

Y

C

OVER

FULLY

OPEN

7.25"

184mm

3.25"

83mm

H C

H C

SEE

RECOMMENDED

FLOOR SLOPE

M

N

A

+ 0.125 (3.18mm), - 0

18"

475mm

10"

254mm

5.75"

146mm

5.75"

146mm

L

REAR OF CONSOLE

O

S

EE FLANGED

FOOT DETAIL

FLOOR

DRAIN

GRATES

R

P

5" (127mm)

Q Q

13"

3

30mm

5.00"

1

27mm

S

T

U

(DRAIN

GRATE)

V

(DRAIN

GRATE)

0.56"

1

4mm

120º

TYP

1.00" (25mm)

MAX. ADJUSTMENT

1.625" (42mm)

Ø

FLANGED FOOT DETAIL

0.44" ( 11mm)

Ø

3 HOLES ON

3

.125" (80MM)

Ø

B.C.D.

4 7/8"

124

Ø mm

FLOOR SLOPE = 1.00" (26mm) per 4' (1220mm)

RECOMMENDED FLOOR SLOPE

PIPE DRAIN RECOMMENDED

min. valve size plus 1.00" (26mm)

6.00" (153mm) RECOMMENDED

4.00" (102mm) MINIMUM

40/150 99.00

2511

26.00

660

43.25

1099

52.75

1340

72.00

1829

10.25

260

23.13

587

55.75

1416

11.00

279

27.38

695

39.88

1013

36.00

915

18.38

467

28.00

711

38.00

965

5.63

143

27.00

686

30.00

762

44.00

1118

18.25

464

76.00

1930

GAL/LIT A C D E F G H J K ML N0PQRST UVWX Y

60/225 106.00

2689

29.50

750

43.25

1099

52.75

1340

73.00

1854

10.25

260

23.13

587

57.50

1460

6.63

168

27.38

695

42.13

1070

36.00

915

18.38

467

28.00

711

41.50

1054

6.50

165

9.50

749

31.00

787

45.00

1143

14.75

375

79.00

2007

80/300 113.00

2867

33.00

838

45.75

1162

55.25

1403

79.00

2007

12.75

324

26.38

670

59.00

1500

6.63

168

32.63

778

46.38

1178

39.25

997

21.63

549

31.25

794

45.00

1143

7.38

187

31.38

797

35.00

889

46.00

1168

15.00

381

84.00

2134

100/375 35.50

902

47.75

1213

57.25

1454

82.00

2083

14.75

375

26.38

670

61.00

1550

6.00

152

32.63

778

47.63

1210

39.25

997

21.63

549

31.25

794

47.50

1207

8.00

203

33.00

838

36.00

914

47.00

1194

15.00

381

54.38

1381

30.50

775

58.50

1486

34.00

864

63.00

1600

37.50

953

66.00

1676

40.00

1016

89.00

2261

117.88

2994

DIMENSIONS ("/mm)

3.00"

76mm

18" (457mm)

Recomended

0 = Minimum

Z

A2

A

1

16.00

406

Z

18.25

464

19.13

486

20.75

527

35.75

980

A1

37.50

953

42.75

1086

43.75

1111

39.00

991

A2

40.75

1035

46.00

1168

47.00

1194

ELECTRICAL - HIGH WATTAGE

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

Kettle

L 200 3360 22684 81.6 3

R 200 3360 22684 65.5 4

L 208 3360 24535 83.8 3

R 208 3360 24535 68.1 4

L 220 3360 27448 87.1 2

TMKEL-40-T

R 220 3360 27448 72.0 3

L 230 3360 30000 90.0 2

R 230 3360 30000 75.3 3

L 240 3360 32665 92.8 2

R 240 3360 32665 78.6 3

L 380 3360 25153 47.1 6

R 380 3360 25153 38.2 6

(Left/Right)

Supply

Voltage

Phase

WiresHZTotal

Wattage

Supply

Amps

Kettle

Wire Size

L 400 3360 27871 48.8 6

R 400 3360 27871 40.2 6

L 415 3360 30000 50.1 6

R 415 3360 30000 41.7 6

L 440 3360 27448 44.1 6

TMKEL-40-T

R 440 3360 27448 36.0 8

L 480 3360 32665 46.9 6

R 480 3360 32665 39.3 6

WATER

Kettle

(Left/Right)

Supply

Voltage

Phase

Wires

HZ

Total

Wattage

Supply

(Left/Right)

Supply

Voltage

Phase

WiresHZTotal

Wattage

Supply

Amps

Wire Size

L 200 3360 27221 94.7 2

R 200 3360 27221 78.6 3

L 208 3360 29442 97.4 1

R 208 3360 29442 81.7 3

L 220 3360 32938 101.5 1

R 220 3360 32938 86.4 2

L 230 3360 36000 105.0 1

R 230 3360 36000 90.4 2

L 240 3360 39198 108.5 1

R 240 3360 39198 94.3 2

L 380 3360 30184 54.7 6

TMKEL-60-T, TMKEL-80-T, TMKEL-100-T

R 380 3360 30184 45.9 6

Amps

Kettle

(Left/Right)

Supply

Voltage

Phase

Wires

Wire Size

L 400 3360 33445 56.8 4

R 400 3360 33445 48.3 6

L 415 3360 36000 58.4 4

R 415 3360 36000 50.1 6

L 440 3360 32938 51.3 6

R 440 3360 32938 43.2 6

L 480 3360 39198 54.8 6

R 480 3360 39198 47.1 6

TMKEL-60-T, TMKEL-80-T, TMKEL-100-T

HZ

Total

Wattage

Supply

Amps

Wire Size

Hot Water 3/4 NPT

Cold Water 3/4 NPT

CLEARANCE

Right - 0, Left - 0

Rear -

18" (457mm)

Recommended

0 - Minimum

(NOT TO SCALE)

SECT. XI PAGE 8

H

C

Litho in USA

0609

Loading...

Loading...