Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COOK CHILL SYSTEMS

Cook/Chill Systems

TM

COMBINATION COOK TANK, CHILLER

& SOUS VIDE PRODUCTION UNIT

Cleveland General Specifications

The capacity of the TurboJet is up to 100 gal. for pumpable

(kettle produced) products and up to 1000 lbs. of meat in the

cook tank mode. The TurboJet functions as a cook tank, a

product chiller and a sous vide production unit. Most pumpable

food products packaged in pouches or casings can be cooled

from 170°F to 40°F in an average of less than one hour.

Cleveland Standard Features

I Microprocessor operating controls mounted in

housing

G Power on/off switch

G Time and temperature set-point controls

G Two pen chart recorder

G Stainless steel bag unloading tool

G Three operating mode selection

Chill Cycle

Cooking/Heating cycle to time and temperature

Automatic cooking cycle with core temperature probe

I Low 40" loading rim height

I Tank equipped with two powerful turbo jets for water and

product agitation

I All stainless steel type 304 construction

I Rounded internal tank corners for efficient cooling and

easy cleaning

I Powerful 7.5 HP water circulation pump with high and low

pre-set flow-rates

I 1 HP water circulation pump for even water bath

temperature distribution

I High efficiency plate type heat exchanger for

product cooling

I 100 PSI steam jacket for product/tank heating

I Stainless steel spring assisted hinged rear cover

I 4 legs with adjustable flanged feet for floor bolting

I Core-temperature meat probe for recording internal

product temperature

I

Built in chart recorder for time / temperature recording

I 20 HP remote condensing unit (specify air or water cooled)

I 190 gal. capacity heat exchange tank with automatic tem-

perature control and 5 HP glycol circulation pump for cooling.

I Accepted for use in U.S.D.A. Inspected Facilities

Type 4X

MODEL:TJ-100-CC

Short Form Specifications

Shall be CLEVELAND Model: TJ-100-CC Combination Cook Tank,

Product Chiller and Sous Vide Production Unit with 20 HP Remote

Condensing Unit and Heat Exchange Tank, capacities; 100 gal. of

casing packaged pumpable product or 700 lbs. of meat.

Temperature reduction of 170°F to 40°F in less than one hour for

most products, 40" loading rim height, all stainless steel type 304

construction, 7.5 HP Water Circulation Pump with high/low preset

flow rates, 1 HP Water Circulation Pump with tank mounted

Microprocessor Operating Controls and Chart Recorder.

Options & Accessories

Ë One set of wire baskets with carrier for meat cooking

Ë Dolly for wire basket set

Ë

Ice-builder Package(in lieu of glycol heat exchange package)

Ë

Electric Chain Hoists for product loading of cook tank items

Ë Steam Boiler

Ë Spare Meat Probe

Ë Product Lifting Rack

Ë Flow Meter for chilled water loop

Ë Air Power Vacuum Clipper

SECT. XIV PAGE 33

0609

Page 2

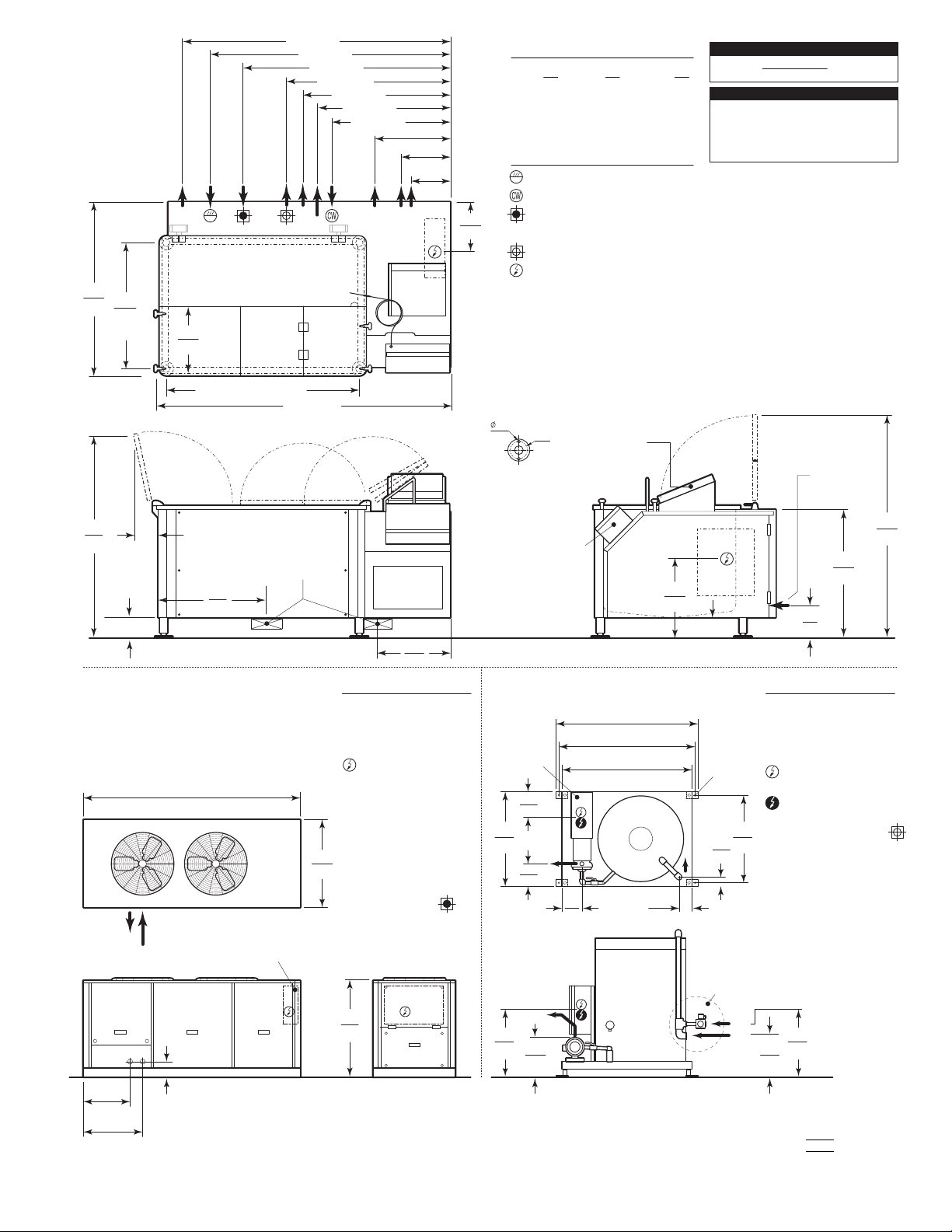

24.0"

610

5.5" / 140

9.0"

229

68.9"

1750

40.5"

1029

PLUMBING

C

ONNECTIONS

HEIGHT

C

HART

RECORDER

6

8.2"

1731

52.0"

1321

33.0"

839

22.3"

565

(MINIMUM CLEARANCE)

LIFTING AREA

FOR FORK TRUCK

CONTROL BOX

CONTROL CENTER

& JUNCTION BOX

PLUMBING LINES

SHOWN ROTATED

FOR CLARITY

0.8" / 19

HOLE IN

EACH FOOT

D1DC

S

F

CR

3 PIECE HINGED

FRONT COVER

12.0"

3

05

BF

2

BF

1

1

5.0"

381

2

3.0"

584

37.0"/ 940

4

5.0"/ 1143

4

3.0"/ 1092

4

8.0"/ 1219

6

3.0"/ 1600

7

3.0"/ 1854

82.0"/ 2083

57.5"/ 1461 (LEG CENTERS)

57.0"

1

448

1

5.0"

3

81

4

1.8"

1061

(LEG CENTERS)

3

PIECE HINGED

FRONT COVER

8

8.5"/ 2248

BF

1

B

F

2

D1

DC

CR

SF

Utility Connections

1" NPT STEAM IN (420 lbs./191 kg. per hour required, 60-80 PSI steam pressure recommended)

1

" NPT COLD POTABLE WATER IN (30 gal./114 litres per minute)

1

1/2" NPT COOLING WATER OR GLYCOL IN (flow rate is 40 gal./152 litres per minute)

3/4" NPT CONDENSATE RETURN

1 1/2" NPT COOLING WATER OR GLYCOL RETURN

MAIN POWER IN (208V/3PH/60hz - FLRA 45 Amps)

1

1/2" NPT TANK DRAIN TO FLOOR DRAIN

1

/2" NPT COOLING DRAIN WATER TO FLOOR DRAIN

1

" NPT STRAINER FLUSH TO FLOOR DRAIN

1

" NPT BACKFLUSH WATER IN (25 gal./95 litres per minute, 165°F/75°C hot water min.)

1" NPT BACKFLUSH WATER OUT TO FLOOR DRAIN

FLANGED FOOT

D

ETAIL

0

.6"

16

4.0"

102

N

OTE: OPTIONAL HOIST AVAILABLE (HIGHLY

RECOMMENDED) FOR LOADING

COOK TANK BASKETS

N

OTE: The pressure drop is 12 to 15 PSI for steam and chilled water passing through the TurboJet.

M

inimum Clearance

BACK -

12.0"

LEFT -

6.0"

RIGHT -

36.0"

305 153 914

DIMENSIONS

INCHES"

M

ILLIMETERS

SHIPPING WEIGHTS

TurboJet Chiller : 1,700 lbs. (772 kg.)

Condensing Unit : 1,600 lbs. (726 kg.)

Heat Exchange Package : 450 lbs. (205 kg.)

TurboJet

Tank

AC

1

AC

2

2

3.4"

594

42.0"

1067

Air Cooled

Condensing Unit

20 HP air cooled condensing unit (13 ton cooling

capacity) for outdoor installation

Note: optional water cooled condensing unit for indoor

installation available

1 1/2" NPT GLYCOL OUT TO

AC2

ON CONDENSING UNIT

GLYCOL SOLUTION NOT

SUPPLIED BY

CLEVELAND RANGE

1 1/2" NPT GLYCOL FROM

AC1

ON CONDENSING UNIT

1 1/2" NPT GLYCOL FROM

ON TURBOJET

PUMP MOTOR POWER IN

(208V/3PH/60hz, 18 Amps)

FACTORY RECOMMENDATION: INSTALL CONDENSING UNIT AND HEAT EXCHANGE TANK NEXT TO EACH OTHER

NOTE: G LYCOL SOLUTION NOT SUPPLIED BY CLEVELAND RANGE

27.3

"

693

32.3

"

820

6.0"

153

108.0"

2744

JUNCTION

BOX

AC1AC

2

Heat Exchange Tank

CONDENSING UNIT POWER

208/3/60 - Min. Circuit

Amps (MOC) - 95A with

Maximum Over Current

Protection (MOCP) 125 Amp

Fused Disconnect

460/3/60 - Minimum Circuit

Amps (MOC) - 45A with

Maximum Over Current

Protection (MOCP) 60 Amp

Fused Disconnect

CR3

CR2

CR1

CR2

CR1

CR3

NOTE:

CONTROL POWER IN

(120V/1PH/60hz, 3 Amps)

2" NPT GLYCOL FROM

CR3

ON HEAT EXCHANGE TANK

2" NPT GLYCOL TO

ON TURBOJET AND

CR2

ON HEAT EXCHANGE TANK

AC

1

AC

2

Minimum Clearance

BACK -

42.0"/ 1067

FRONT -

24.0"/ 610

LEFT -

24.0"/ 610

RIGHT -

36.0"/ 915

10.0"

254

16.0"

407

28.0"

712

Minimum Clearance

(for cooling)

BACK -

6.0"/ 153

FRONT -

20.0"/ 508

LEFT -

20.0"/ 508

RIGHT -

6.0"/ 153

18.0"

558

22.0"

559

37.7"

958

41.0"

1042

4.7

"

118

10.5"

267

CR3

8.0

"

202

53.5"

1359

56.0"

1447

58.0"

1472

CR1

CR2

5.7

"

143

Cleveland Range reserves right of design improvement or modification, as warranted.

SECT. XIV PAGE 34

(NOT TO SCALE)

0609

Litho in USA

Loading...

Loading...