Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

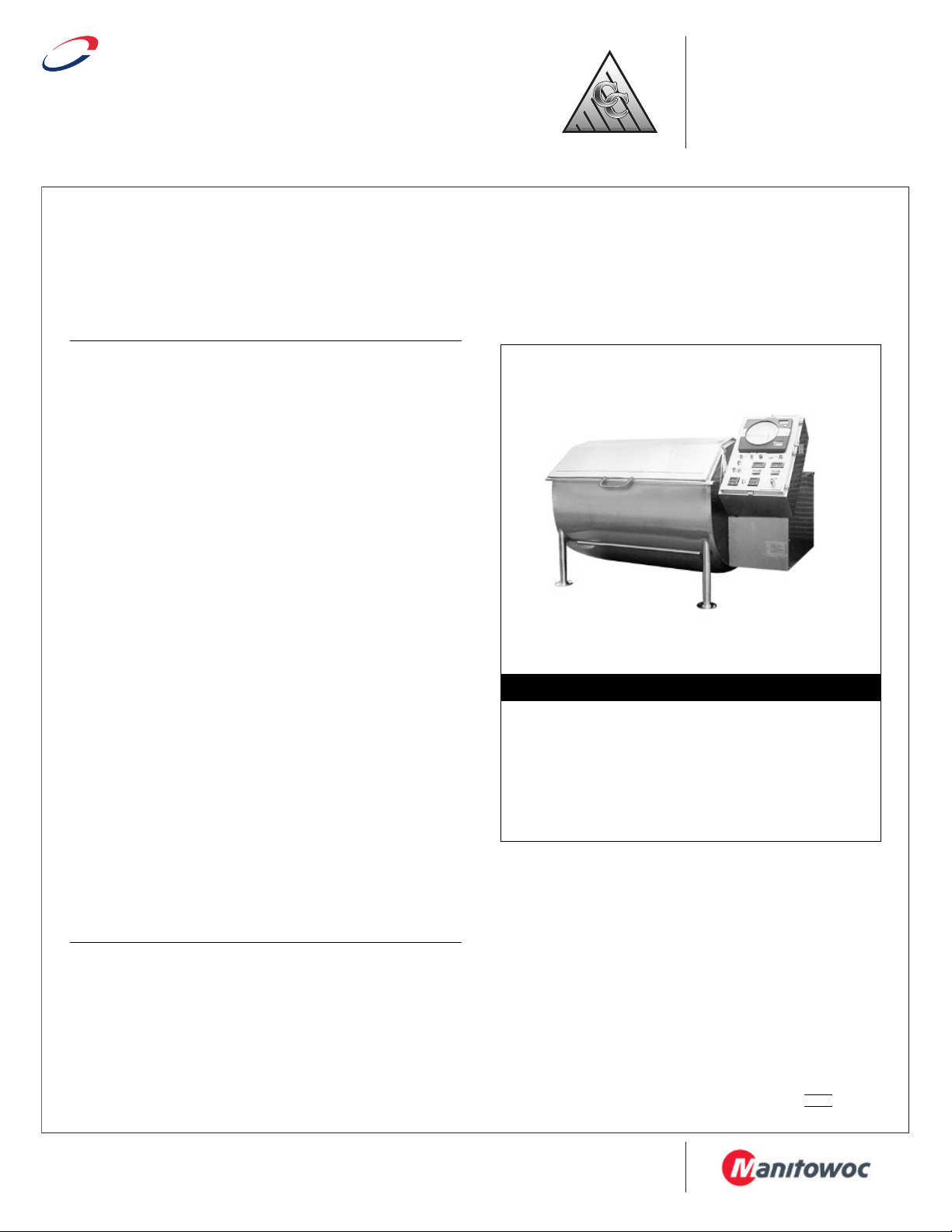

COOK CHILL SYSTEMS

Cook/Chill Systems

COMBINATION

TUMBLE CHILLER/

COOK TANK

Cleveland Standard Features

I Load capacity for up to; 60 gallons of pumpable product,

300 lbs. of meat

I Combination System greatly reduces valuable kitchen floor

space used

I Two pen Chart Recorder for permanent record of time and

temperature for both Water Bath and Product

I Selector Switch for Timed or Meat Probe operation

I Programmable Time/Temperature Controls

I Digital Temperature Displays

I Thaw Timer for thawing frozen products before cooking

I Preprogrammed Power Failure Controls for Food Safety

I Steam heated Tank with 50 psi Steam Jacket pressure

rating

I Electric driven, perforated, Product Cylinder

I Spring assist, hinged Cover totally encloses Rotating Inner

Cylinder

I Safety Interlock Switch stops cylinder rotation when cover is

even slightly lifted

I Two Wire Divider Shelves and one Top Hold-down Rack to

keep product in place

I Preset water levels for cooking and cooling

I Shell and Tube Heat Exchanger for fast cooling of products

I Integrated water conservation system to allow use of chilled

water throughout the production day

I Meat Probe for automatic cooking and cooling

I Water Circulating Pump for even Water Bath Temperature

I Manual Override “start/stop” Button

I All electrical and plumbing enclosed in a Stainless Steel

Housing

I Accepted for use in U.S.D.A. Inspected Facilities

MODEL:TCCT-60-CC

Short Form Specifications

Shall be CLEVELAND, Model: TCCT-60-CC, Combination

TUMBLE CHILLER/COOK TANK; 300 lbs. or 60 gallons

of product capacity; electric driven perforated Product

Cylinder; preset water levels; Meat Probe; Water Circulating

Pump; two pen Chart Recorder; programmable

Time/Temperature Controls; Digital Temperature Displays;

All electrical and plumbing enclosed in a Stainless Steel

Housing.

Options & Accessories

Ë Vacuum Packaging unit (Clipper Vac)

Ë Ice Builders

Ë Condensing units for Ice Builders

Ë Ice Water Control Panel

Ë Steam Boilers

Ë Spare Meat Probe

Ë Flow Meter for chilled water loop

Air Power Vacuum Clipper.

Ë

SECT. XIV PAGE 35

0609

Page 2

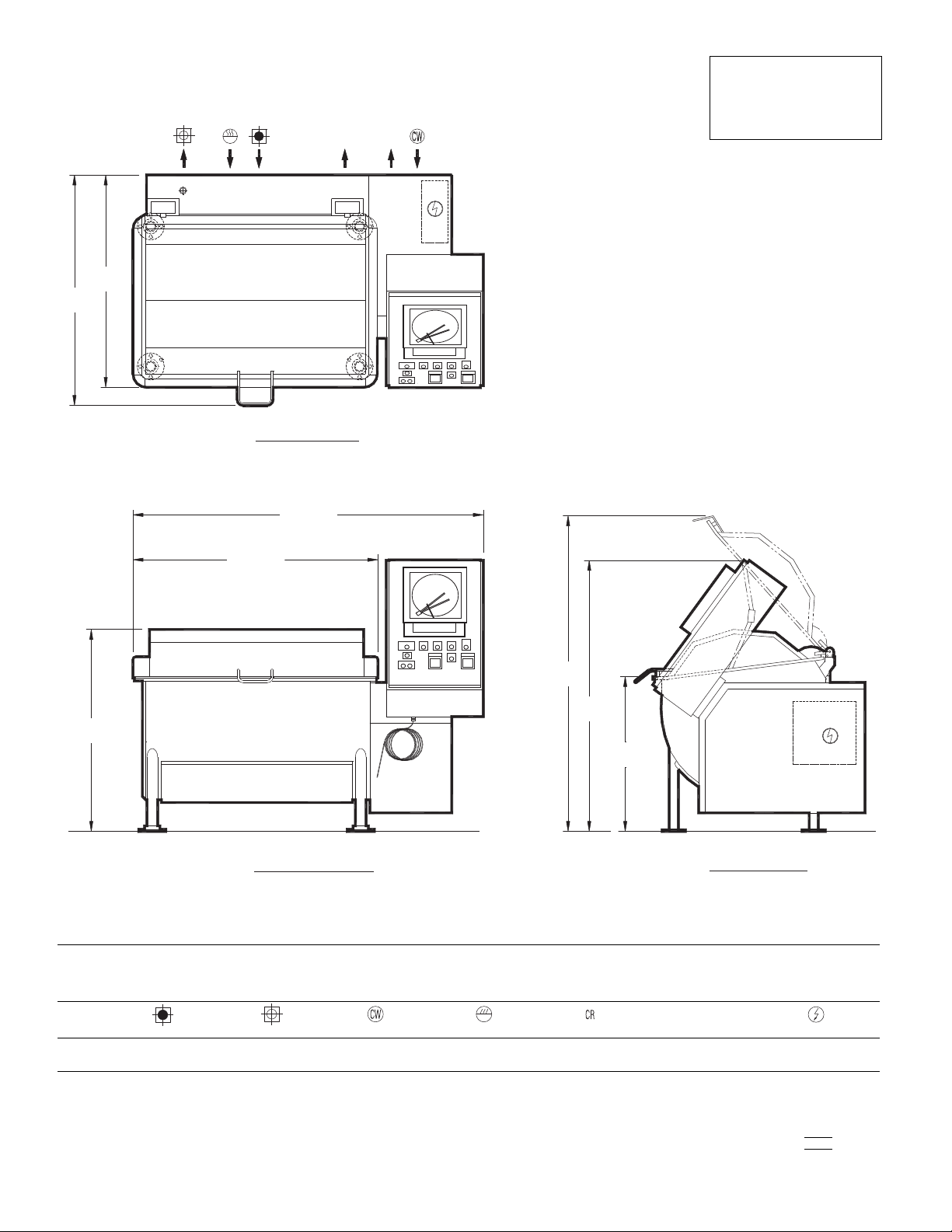

77 5/8"

54 1/4"

FRONT VIEW

PLAN VIEW

44 11/16"

47"

SIDE VIEW

60"

70"

34 1/2"

51"

DCR

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

D

1 D 2

B

MINIMUM CLEARANCE

FRONT 36"

SIDE 12"

REAR 18"

UTILITY CONNECTIONS

MODEL INLET RETURN WATER STEAM RETURN DRAIN 208/3PH

TCCT-60 1 1/4" NPT 1 1/4" NPT 1" NPT 3/4", 50 PSI 3/4" 1 1/2" NPT 9 AMPS

NOTE: The pressure drop is 12 to 15 PSI for steam and chilled water passing through

the combination tumble chiller - cook tank.

Cleveland Range reserves right of design improvement or modification, as warranted.

CHILLED CHILLED CONDEN

WATER WATER COLD -SATE TANK ELECTRICAL

D

50 GPM 30 GPM 250 lbs/hr

(NOT TO SCALE)

SECT. XIV PAGE 36

Litho in USA

0609

Loading...

Loading...