Page 1

FOR MODELS BUILT

ECO 000646 ECN 6731

MAJOR CHANGE DUE TO GEARBOX

REPLACEMENT.

27 turns for

manual to tilt,

AFTER MAY 2006:

POUR DES MODÈLES

ÉTABLIS APRÈS MAI 2006:

SGL-30-T1

SGL-40-T1

Sevice Manual

Le service Manual

T1 Gas Braising Pan

T1 Casserole de braisage de gaz

™

Cleveland

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Ph: 216.481.4900 Fx: 216.481.3782

www.clevelandrange.com

SE95050 Rev. 8

February 2010

Page 2

FOR THE USER

FOR YOUR SAFETY

Do not store or use gasoline or

any other flammable liquids

and vapours in the vicinity of

this or any other appliance.

IMPORTANT

This information shall be obtained by consulting your local gas supplier.

The following points are to insure the safe installation and operation of this equipment:

• Insure all gas and electrical supplies match rating plate and electrical stickers.

• Keep appliance area free and clear from combustibles.

• Observe all clearance requirements.

• All service must be performed by a qualified Cleveland Range Technician.

• Do not obstruct the flow of combustion and ventilation air.

NOTICE: When this appliance is installed with casters, it must be installed with the casters supplied, a connector

complying with either ANSI Z21.69 • CSA 6.16 and a quickdisconnect device complying with ANSI Z21.41 • CSA

6.9. It must also be installed with restraining means to guard against transmission of strain to the connector, as

specified in the appliance manufacturer's instructions.

: Post in a prominent location, instructions to be followed in the event the user smells gas.

WARNING: Improper installation, adjustment,

alteration, service or maintenance can cause

property damage, injury or death. Read the

installation and operating instructions thoroughly

before installing or servicing this equipment.

RETAIN THIS MANUAL FOR YOUR REFERENCE

POUR L’UTILISATEUR

POUR VOTRE SÉCURITÉ

Ne pas stocker ni utiliser de

l’essence ou tout autre vapeur

ou liquide inflammable à

proximité de cet appareil ou de

tout autre dispositif.

IMPORTANT

respirerait du gaz. Ces informations peuvent être obtenues en contactant votre fournisseur de gaz local.

Les points ci-dessous permettent de s’assurer que ce matériel a été installé et fonctionne en toute sécurité:

• Assurez-vous que toutes les alimentations en gaz et en électricité correspondent à la plaque signalétique et aux

étiquettes des propriétés électriques.

• Conservez la zone de l'appareil libre et sans matériaux combustibles.

• Respectez toutes les conditions en terme d’espacement.

• Tous les travaux d’entretien doivent être réalisés par un technicien qualifié sur la gamme de Cleveland.

• N’obstruez pas le flux de combustion ni l’air de ventilation.

AVIS: Si cet appareil doit être installé avec des roulettes, vous devez utiliser les roulettes fournies, ainsi qu’un

connecteur se conformant à ANSI Z21.69 ou CSA 6.16 et un dispositif à débranchement rapide conforme à ANSI

Z21.41 • CSA 6.9. Il doit également être installé avec des éléments de retenue pour prévenir la transmission de

tension au connecteur, comme spécifié dans les instructions du fabricant de l’appareil.

: Dans un lieu bien en vue, placez les instructions à suivre dans l'éventualité où l'utilisateur

AVERTISSEMENT: Une installation, un réglage,

une modification, un entretien ou une

maintenance incorrect peut provoquer des dégâts

matériels, des blessures voire la mort. Veuillez lire

soigneusement les instructions d’installation et

de fonctionnement avant d’installer ou d’effectuer

l’entretien de cet équipement.

CONSERVEZ CE MANUEL POUR VOTRE RÉFÉRENCE

Page 3

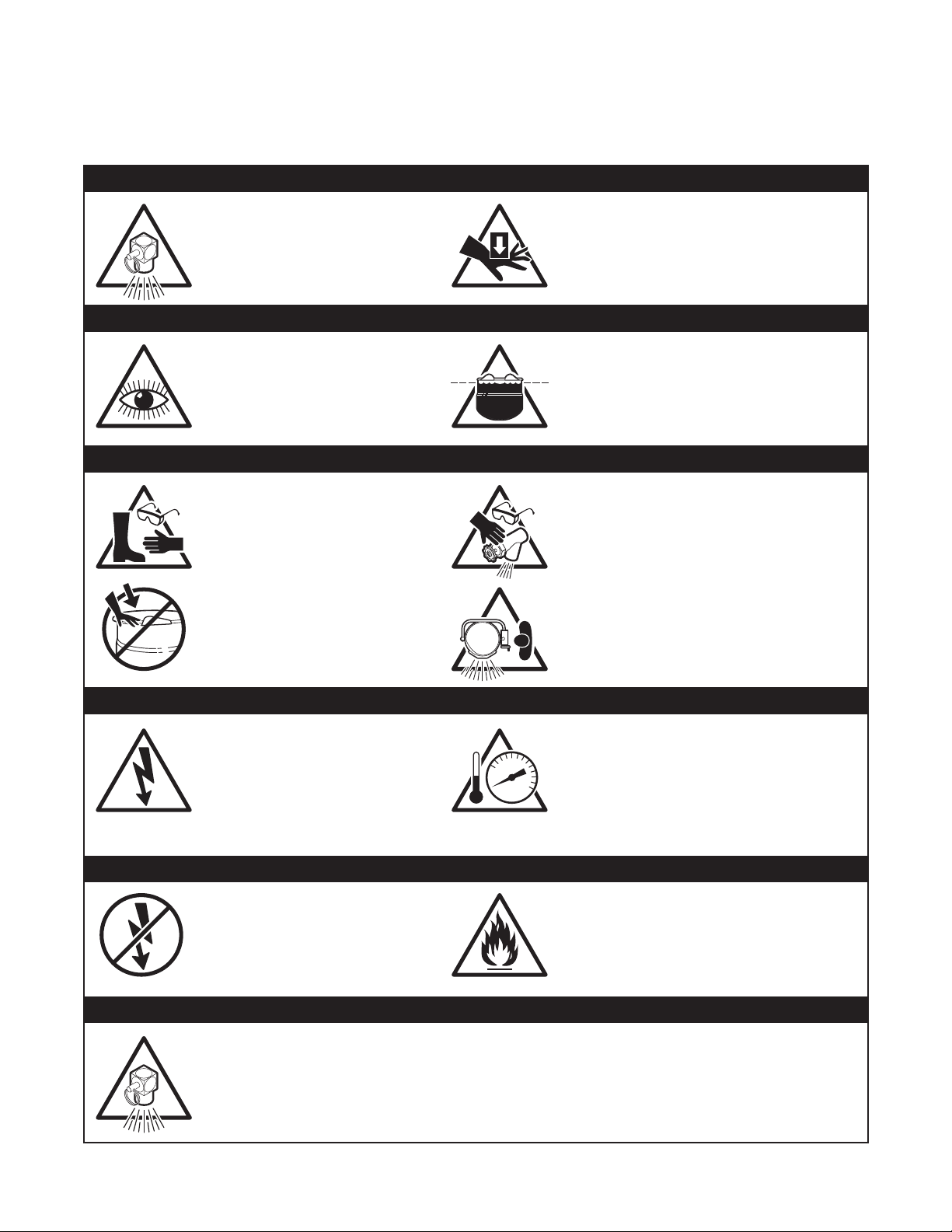

DANGER / DANGER / PELIGRO / GEFAHR

MAINTENANCE / ENTRETIEN / MANTENIMIENTO / WARTUNG

SERVICING / ENTRETIEN / SERVICIO / WARTUNG

IMPORTANT / IMPORTANT / IMPORTANTE / WICHTIG

CAUTION / ATTENTION / PRECAUCIÓN / VORSICHT

GAS APPLIANCES / APPAREILS À GAZ / APARATOS A GAS / GASGERÄTE

0

For your safety / Pour votre sécurité /

Para su seguridad / Für Ihre Sicherheit

Shut off power at main fuse disconnect

prior to servicing. / Couper l’alimentation

sur le principal fusible sectionneur avant

l‘entretien. / Apague la alimentación

eléctrica en el fusible desconectador

principal antes de darle servicio. /

Vor der Wartung den Strom am

Haupttrennschalter abschalten.

Ensure kettle is at room temperature and pressure gauge

is showing zero or less prior to removing any fittings. /

S’assurer que le chaudron se trouve dans une

température ambiante et que le manomètre affiche zéro

ou moins avant de déposer les raccords. / Asegúrese de

que la marmita está a temperatura ambiente y el

manómetro está mostrando cero o menos antes de quitar

cualquier accesorio. / Vergewissern, dass der Topf bei

Raumtemperatur ist und das Druckmessgerät Null oder weniger anzeigt.

Inspect unit daily for proper operation.

/ Inspecter le bloc quotidiennement

pour garantir le fonctionnement

normal. / Inspeccione diariamente

el funcionamiento correcto de la

unidad. / Die Einheit täglich auf

richtige Funktion untersuchen.

Do not fill kettle above recommended level marked

on outside of kettle. / Ne pas remplir le chaudron

au-delà du niveau indiqué à l’extérieur. / No llene la

marmita por encima del nivel recomendado

marcado en la parte exterior de la marmita. / Den

Topf nicht über das empfohlene, an der Aussenseite

markierte Niveau füllen.

Surfaces may be extremely hot! Use protective

equipment. / Les surfaces peuvent être

extrêmement chaudes ! Utiliser des

équipements de protection. / ¡Las superficies

pueden estar muy calientes! Utilice equipo

protector. / Die Oberflächen können sehr

heiß werden! Schutzausrüstung tragen.

Keep appliance and area free and clear of

combustibles. / Garder l’appareil et la zone libres et

exempts de combustibles. / Mantenga el aparato y

el área siempre libres de combustibles. / Das Gerät

und Umgebung von brennbaren Stoffen freihalten.

Stand clear of product discharge path when

discharging hot product. / Se tenir loin du chemin de

purge des produits lors de la purge des produits

chauds. / Manténgase alejado de la trayectoria de

descarga del producto al descargar producto

caliente. / Nicht im Produktauslasspfad stehen

während das heiße Produkt entleert wird.

Wear protective equipment when discharging hot

product. / Porter des équipements de protection

lors de la purge des produits chauds. / Utilice

equipo protector al descargar producto caliente. /

Beim entleeren des heißen Produkts

Schutzausrüstung tragen.

Do not lean on or place objects on kettle

lip. / Ne pas adosser ou placer des

objets contre le bord de chaudron. /

No se apoye en la tapa de la marmita

ni coloque objetos sobre ella / Nicht

auf den Topfrand lehnen und dort

keine Gegenstände absetzen.

Do not attempt to operate this appliance during a

power failure. / Ne pas essayer de manœuvrer

cet appareil pendant une panne d’alimentation.

/ No intente poner en marcha este aparato

durante un fallo de alimentación eléctrica. /

Dieses Gerät nicht während eines

Stromausfalls betreiben.

Keep clear of pressure relief discharge. /

Se tenir hors de portée de la purge des

soupapes de surpression. /

Manténgase alejado de la descarga

de presión. / Den Druckablasspfad

v

ermeiden.

Keep hands away from moving parts and pinch

points. / Tenir les mains à l’abri des pièces mobiles

et des angles. / Mantenga las manos lejos de las

piezas movibles y los puntos de presión. / Die

Hände von bewegenden Teilen und Klemmstellen

fernhalten.

The pressure relief valve must be inspected every six months. / La soupape de décharge doit être inspectée à

tous les six mois. / La válvula de descarga de presión debe ser inspeccionada cada seis meses. / Das

Druckablassventil muss alle 6 Monate überprüft werden.

Have an qualified service technician inspect your unit yearly. / L'unité doit être inspectée annuellement par un

technicien de service qualifié. / Haga que un técnico de servicio calificado inspeccione su unidad anualmente.

/ Ein qualifizierter Techniker sollte Ihre Anlage einmal jährlich überprüfen.

Page 4

INSTALLATION

INSPECTION

1. Before unpacking visually inspect the unit for evidence

of damage during shipping.

2. If damage is noticed, do not unpack the unit, follow

shipping damage instructions.

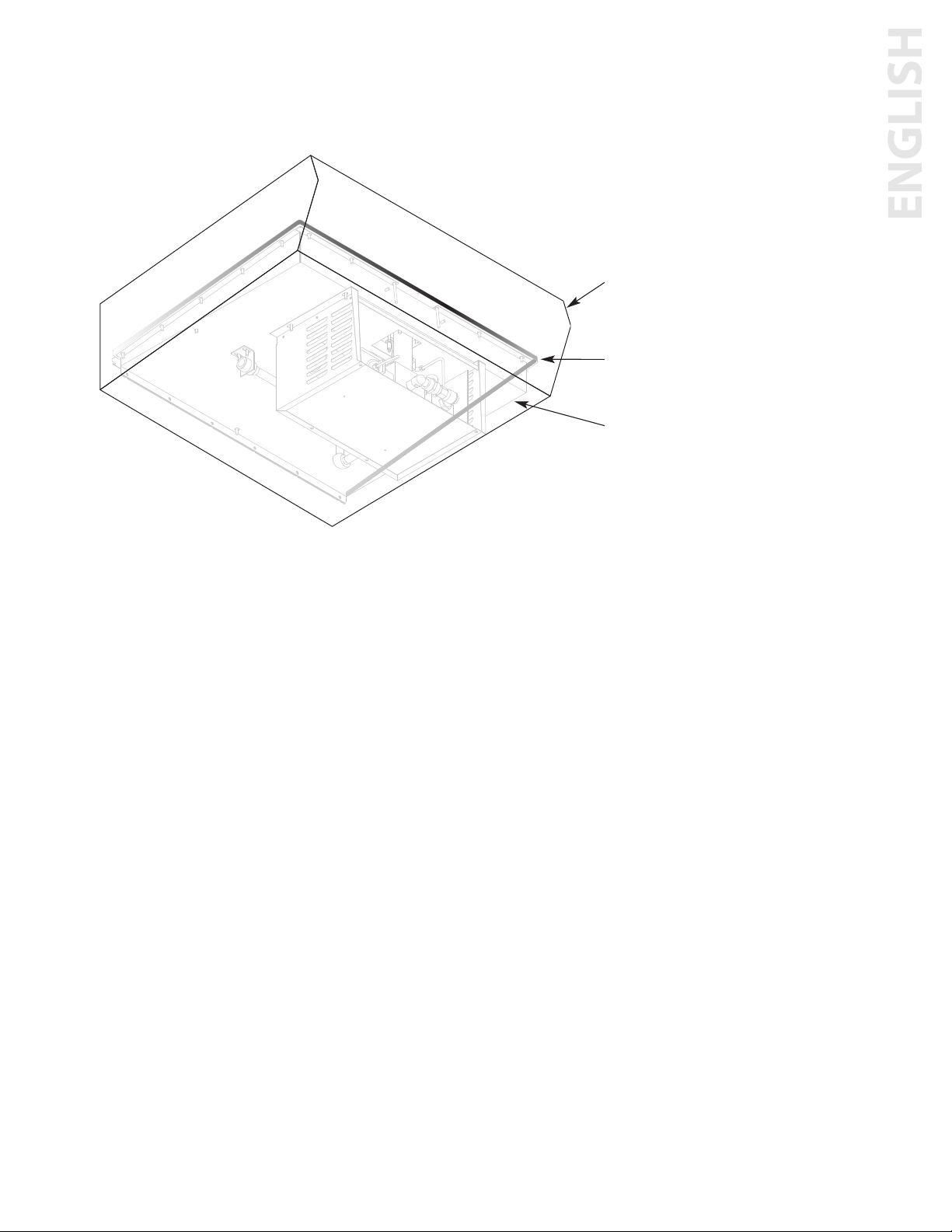

3. Carefully remove unit from shipping carton. Remove

any packing material from unit. After carefully

unpacking check for "concealed" damage. If damage is

noticed, follow "SHIPPING DAMAGE INSTRUCTIONS"

shown below.

4. A protective material has been applied to the stainless

steel panels. This material must be removed

immediately after installation, as heat will melt the

material and make it more difficult to remove.

SHIPPING DAMAGE INSTRUCTIONS

If shipping damage to the unit is discovered or suspected,

observe the following guidelines in preparing a shipping

damage claim.

1. Write down a description of the damage or the reason

for suspecting damage as soon as it is discovered.

This will help in filling out the claim forms later.

2. As soon as damage is discovered or suspected, notify

the carrier that delivered the shipment.

3. Arrange for the carrier's representative to examine the

damage.

4. Fill out all carrier claims forms and have the examining

carrier sign and date each form.

GENERAL

Installation of the kettle must be accomplished by qualified

installation personnel working to all applicable local and

national codes. Improper installation of product could

cause injury or damage.

This equipment is built to comply with applicable standards

for manufacturers. Included among those approval

agencies are: UL, A.G.A., NSF, ASME/N.Bd., CSA, CGA,

ETL, and others. Many local codes exist, and it is the

responsibility of the owner/installer to comply with these

codes.

Observe all clearance requirements to provide proper

make-up air flow. Do not obstruct the flow of combustion

and ventilation air. Check rating plate to ensure that kettle

has been equipped to operate with the type of gas

available at the installation.

Dimensions and clearance requirements are shown on the

Specification Sheet.

CLEARANCE REQUIREMENTS

This unit must be installed in accordance with the

clearances shown on the rating label which is adhered to

the unit.

RIGHT LEFT REAR

Manual Tilt 4” 0 0*

Power Tilt 1” 0 0*

*Allow 3.5” at rear for combustable walls.

FOR YOUR SAFETY. Keep the appliance area free and

clear of combustible materials.

INSTALLATION

1. Position the unit in it's permanent location, and level the

unit by turning the adjustable feet.

2. Once positioned and leveled, permanently secure the

unit's flanged feet to the floor using 5/16" lag bolts and

floor anchors (supplied by the installer). Three bolts are

required to secure each of the flanged feet.

3. Seal joints of flanged feet with a silicone sealant.

GAS

ENSURE THE GAS SUPPLY MATCHES THE KETTLE'S

REQUIREMENTS AS STATED ON THE RATING PLATE.

Installation must conform, with local codes or in the

absence of local codes, with the National Fuel Gas Code

ANSI Z223.1/NFPA 54, or the Natural Gas and Propane

Installation Code, CSA B149.1.

The appliance and its individual shut-off valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psi (3.45 kPa).

The appliance must be isolated from the gas supply piping

system by closing its individual manual shut-off valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psi (3.45

kPa).

It is recommended that a sediment trap (drip leg) be

installed in the gas supply line. If the gas pressure exceeds

14” water column, a pressure regulator must be installed, to

provide a maximum of 14” water column gas pressure to

the gas control valve.

Connect the gas line to the manual valve located at the

rear of the control box.

Use a gas pipe joint compound which is resistant to L.P.

gas. Test all pipe joints for leaks with soap and water

solution. Ensure that the gas pressure regulator is set for

the manifold pressure indicated on the gas rating plate.

Page 5

ELECTRICAL

NOTE: Wiring diagram is located on the underside of the

unit's control panel.

ENSURE THE ELECTRICAL SUPPLY MATCHES THE

UNIT'S REQUIREMENTS AS STATED ON THE RATING

LABEL.

INSTALLATION CHECKS

Although the unit has been thoroughly tested before leaving

the factory, the installer is responsible for ensuring the

proper operation of unit once installed.

DO NOT ATTEMPT TO OPERATE THIS UNIT DURING A

POWER FAILURE.

A cord and plug are supplied with the 115 volt unit. Simply

plug the unit into any grounded outlet rated for a minimum

of 10 amps. The wiring diagram is located on the back of

the console access panel.

When a unit is ordered and built for 208/240 volt, the supply

line must be connected to the wiring terminations located

inside the console. A wiring diagram is attached to the

underside of the control panel.

WARNING: Electrical Grounding Instructions.

This unit is equipped with a three-prong (grounding) plug

for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong

receptacle. Do not cut or remove the grounding prong from

this plug.

Standard supply voltage is 115 volts A.C., however, optional

A.C. voltages can be supplied on special order. A separate

fused disconnect switch must be supplied and installed in

the high voltage electrical supply line. The unit when

installed, must be electrically installed and grounded in

accordance with local codes, or in the absence of local

codes, with National Electrical Code, ANSI/NFPA 70-1990

(USA) or the Canadian Electrical Code, CSA C22.2, Part 1

(Canada).

VENTILATION

Gas fired units are only to be installed under a ventilation

hood in a room which has provisions for adequate make up

air. Further information can be obtained by referring to the

U.S.A. National Fire Protection Associations NFPA96

regulations. These standards have also been adopted by

the National Building Code in Canada..

KEEP APPLIANCE AND AREA FREE AND CLEAR OF

COMBUSTIBLES.

1. Supply power to the unit by placing the fused

disconnect switch to the "ON" position.

2. Turn on main gas supply to unit. Open the unit's shut-off

valve (located at lower rear left).

3. Toggle HI / OFF / LO Switch to the "HI" or "LO" position.

4. For your safety the unit is equipped with a power

interrupter which automatically shuts off the gas supply

to the burners whenever the unit is raised more than 8°.

IMPORTANT: Before commencing to cook, ensure the

pan is in the lowered position. Also ensure the cover is

raised.

5. Turn temperature control to maximum. Tilt pan until heat

indicator light turns off and heating system shuts down.

The pan should be on a 5-10° angle.

6. Lower pan. Heat indicator light will re-light and heating

system will re-energize.

7. Unit will continue to heat, heat indicator light will remain

on until temperature is reached. Then the heat indicator

light will cycle OFF indicating the heating system has

shut off. The heat indicator light will continue to cycle

ON and OFF as the heating system cycles ON and OFF

maintaining the desired temperature.

8. Toggle HI / OFF / LO Switch to the "OFF" position.

CLEANING

After installation the unit must be thoroughly cleaned and

sanitized prior to cooking.

WATER CONNECTION

(OPTIONAL)

A 1/2" NPT cold water line and/or a 1/2" NPT hot water line

are required if unit is equipped with a single or double

pantry faucet.

Page 6

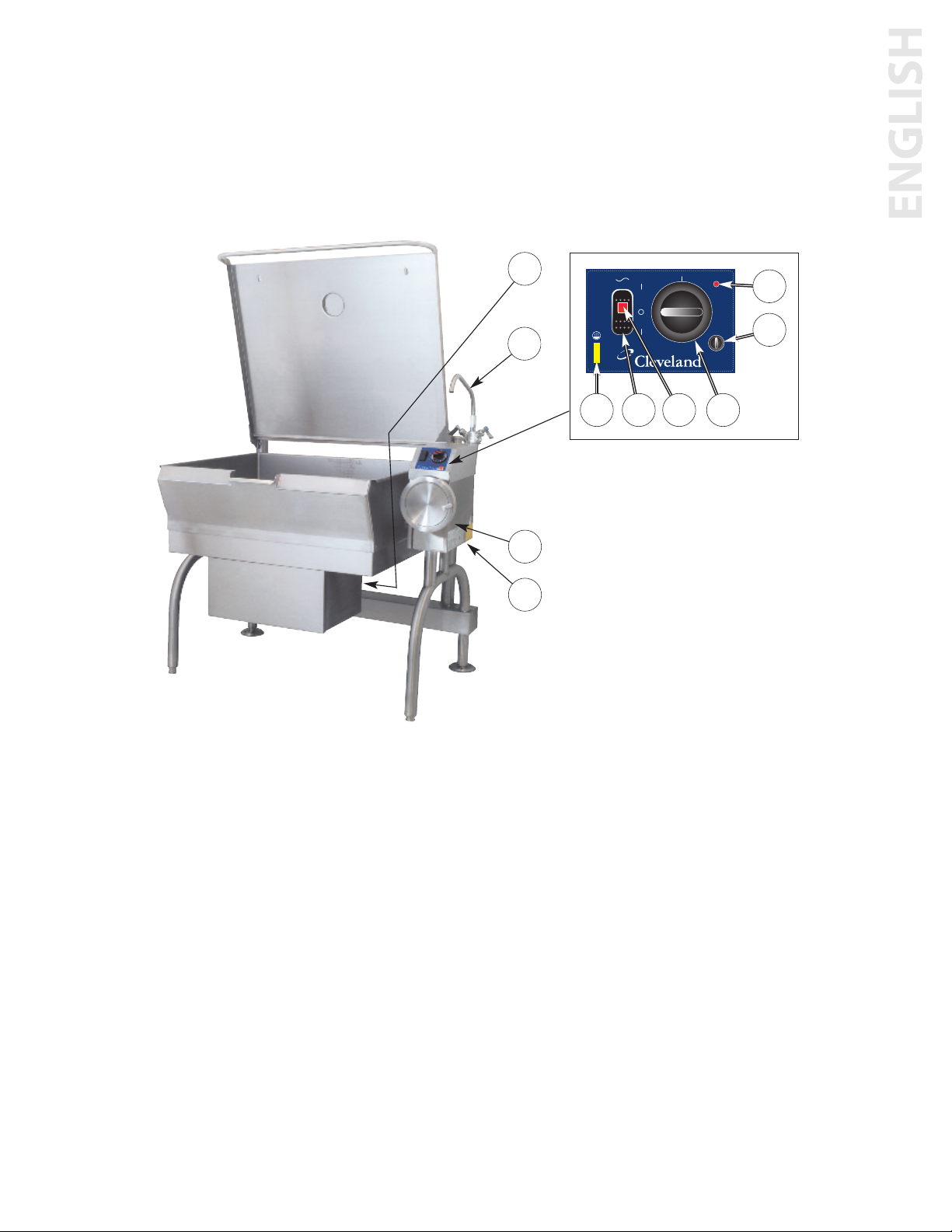

HI

L

O

OPERATING

INSTRUCTIONS

9

10

4 1 2 3

5

7

6

ITEM # DESCRIPTION

1. HI / OFF / LO Switch

2. Power Indicator Light (red)

3. Temperature Dial

4. Heat Indicator Light (yellow)

5. Hand Tilt Wheel

6. Power Tilt Switch (location may vary)

7. Reset Button (location may vary)

8. Manual Tilt Override

9. Gas Shut Off Valve

10. Faucet

11. Tangent Draw-Off Valve

8

Page 7

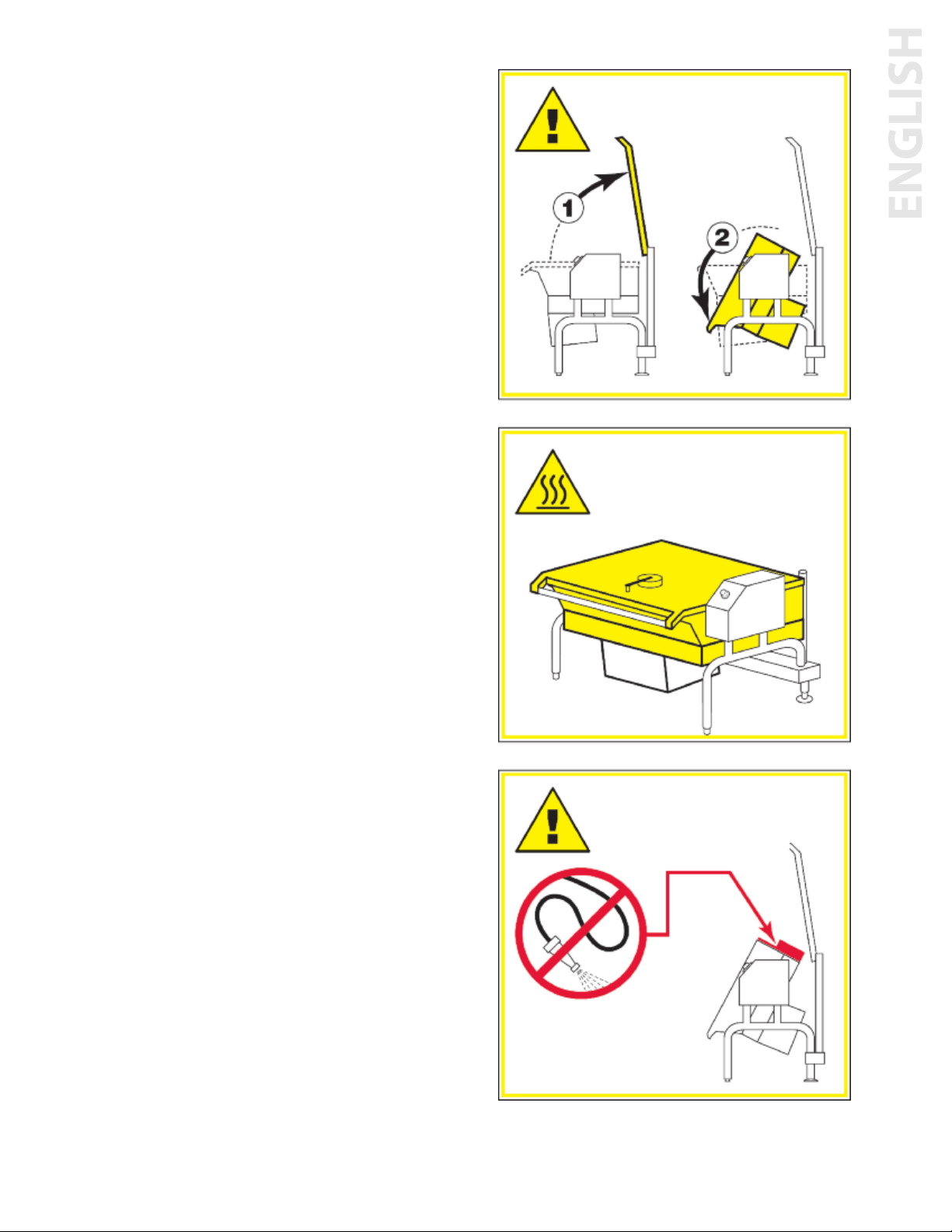

OPERATING THE UNIT

1. Ensure the gas and electrical supply to the unit are

in the ON position.

FOR YOUR SAFETY:

This unit will automatically shut off the gas supply when

pan is raised more than 8°.

Before commencing to cook, ensure pan is in the

lowered position.

2. MANUAL TILT: Cleveland braising pans are

equipped with a manual tilt mechanism for raising

and lowering the pan. To raise pan, raise the cover

and turn the crank clockwise. To lower pan, turn

counterclockwise.

POWER TILT: Cleveland braising pans can also

be equipped with an optional electric power tilt

mechanism for raising and lowering the pan. To

raise pan, raise the cover and press up on the tilt

switch. To lower pan, press down on the tilt switch.

3. Toggle HI / OFF / LO Switch to the "HI" or "LO"

position. The red Power Indicator Light indicates

power is on. The yellow Heat Indicator Light

indicates burners are on.

4. To preheat, set Temperature Dial to desired

cooking temperature. Unit is preheated when the

yellow light goes out.

INSERT LID BEFORE

TILTING PAN

HOT

5. Insert product in pan.

6. If desired, once product has cooked, it can be held

prior to serving at a lower temperature setting.

7. When cooking is completed, set Temperature Dial

and HI / OFF / LO Switch to the OFF position.

8. The best time to clean the unit is immediately after

use, once unit has cooled down. Refer to section

titled "CLEANING INSTRUCTIONS" for details.

OPERATING SUGGESTIONS

1. Turn power switch to the "OFF" position when unit is

not in use.

2. Allow unit to preheat before adding product.

3. Always lift the spring assist cover before activating

the tilt mechanism.

4. During an electrical power interruption, turn Power

Switch to the OFF position. This unit cannot be

made to operate without electrical power.

DO NOT HOSE DOWN

THIS AREA

Page 8

CLEANING INSTRUCTIONS

CAUTION

SURFACES MAY BE

EXTREMELY HOT!

CARE AND CLEANING

Cooking equipment must be cleaned

regularly to maintain its fast, efficient

cooking performance and to ensure its

continued safe, reliable operation. The

best time to clean is shortly after each

use (allow unit to cool to a safe

temperature).

WARNINGS

Do not use

detergents or

cleansers that are

chloride based or

contain quaternary

salt.

Chloride Cleaners

Do not use a metal

bristle brush or

scraper.

Wire Brush &

Scrapers

CLEANING INSTRUCTIONS

1. Turn unit off.

2. Remove drain screen (if applicable). Thoroughly wash and rinse the screen

either in a sink or a dishwasher.

3. Prepare a warm water and mild detergent solution in the unit.

4. Remove food soil using a nylon brush.

5. Loosen food which is stuck by allowing it to soak at a low temperature

setting.

6. Drain unit.

7. Rinse interior thoroughly.

8. If the unit is equipped with a

a) Disassemble the draw-off valve first by turning the valve knob counter-

clockwise, then turning the large hex nut counter-clockwise until the

valve stem is free of the valve body.

b) In a sink, wash and rinse the inside of the valve body using a nylon

brush.

Use a nylon brush to clean tangent draw-off tube.

c)

d) Rinse with fresh water.

e) Reassemble the draw-off valve by reversing the procedure for

disassembly. The valve's hex nut should be hand tight only.

9. Using mild soapy water and a damp sponge, wash the exterior, rinse, and

dry.

NOTES

➩ For more difficult cleaning applications one of the following can be used:

alcohol, baking soda, vinegar, or a solution of ammonia in water.

➩ Leave the cover off when the kettle is not in use.

➩ For more detailed instructions refer to Stainless Steel Equipment Care and

Cleaning (www.nafem.org/resources/stainlesssteelfinal.doc) on Nafem’s

website (www.nafem.org).

TTaannggeenntt DDrraaww--OOffff VVaallvve

e

, clean as follows:

Steel Pads

High Pressure

Spray Hose

Stagnant

Water

Steel wool should

never be used for

cleaning the stainless

steel.

Unit should never be

cleaned with a high

pressure spray hose.

Do not leave water

sitting in unit when

not in use.

Page 9

MAINTENANCE

correct to match

with pg 26

WARNING:

Any maintenance or service involving disassembly of components

!

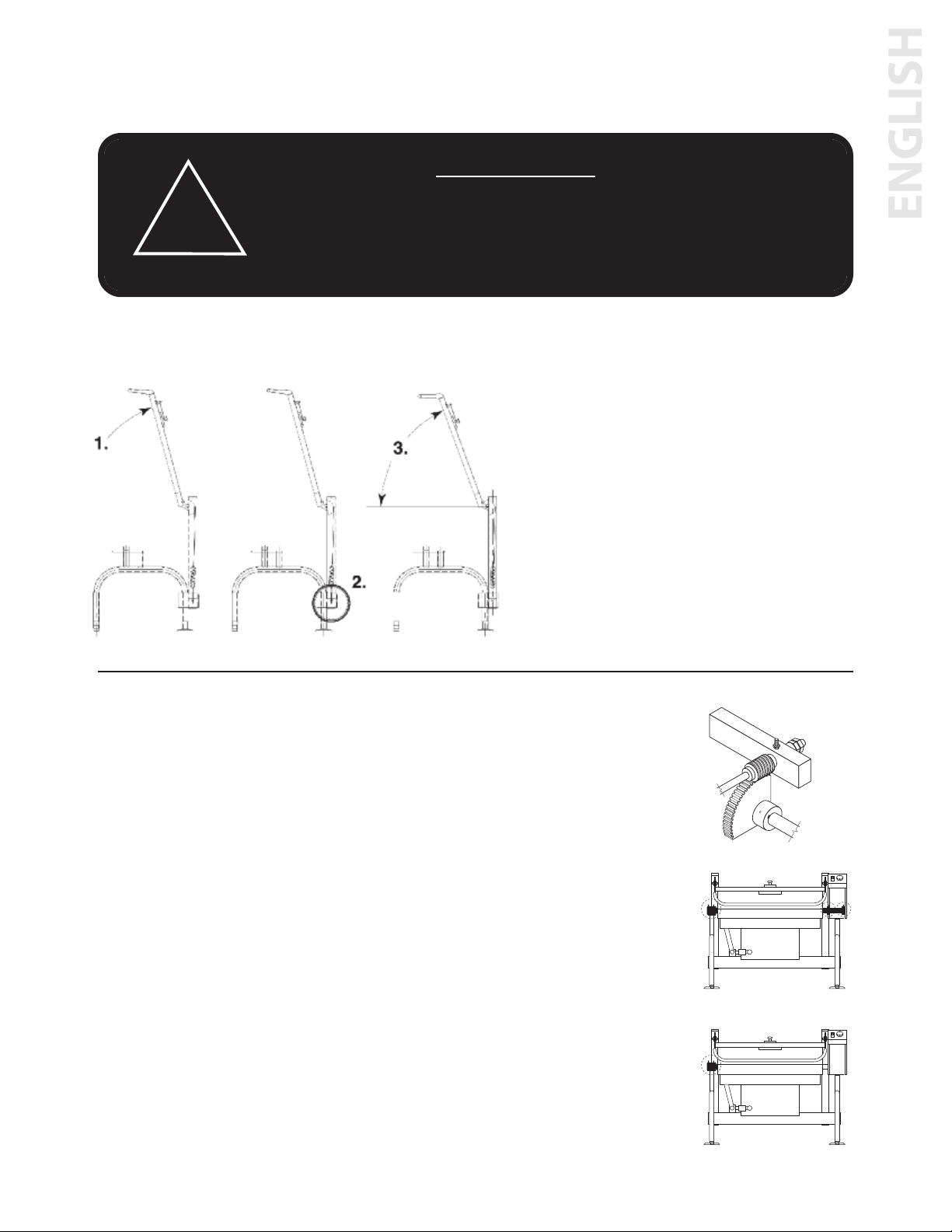

HINGE ADJUSTMENT INSTRUCTIONS

should be made by a qualified service technician. Ensure gas,

electrical and water supply (if applicable) to the unit are shut off.

1. Fully lift cover to

release spring tension.

2. Using a 7/16” deep

socket adjust left and

right bolts evenly.

3. When properly

adjusted, cover should

rest at 70°.

LUBRICATION PROCEDURE

Lubricate the following parts every three months to insure smooth operation and

reduce wear.

TRUNNION HOUSING, WORM SCREW AND TILT GEAR (prior

to May 2006)

These parts are accessed throught the top cover of the console.

Apply grease to gear teeth. Check for excessive play and adjust with adjusting screw

located on top of cross bar.

TRUNNIONS (prior to May 2006)

These parts are accessed throught the top cover of the console.

Apply grease to gear teeth. Check for excessive play and adjust with adjusting screw

located on top of cross bar.

TRUNNION2 (after May 2006)

On the left hand side of the skillet there are two grease nipples on the top back

portion of the trunnion housing.

Page 10

BURNER ASSEMBLY GASKET

EXAMINATION PROCEDURE

SKILLET PAN

GASKET

BURNER PAN ASSEMBLY

NOTE: It is imperative that this procedure be completed at least twice yearly.

1. Turn unit to ON. The burner must be firing during this procedure.

2. Using a stainless steel extension mirror, inspect gasket between burner

pan assembly and skillet pan (sides and front only).

3. Replace gasket if:

- gasket shows signs of deterioration

- a flame can be seen coming through the gasket

- condensation forms on the extension mirror (indicating escaping heat)

GASKET PART #s

30 GALLON 40 GALLON

SIDES SK2472402 SK2472402

FRONT SK2472400 SK2472401

Page 11

SEQUENCE OF OPERATIONS

When using these instructions refer to the SGL-TI wiring

schematic.

1. 115 VAC is sent through the 3 amp fuse to

■ The primary of the 24 VAC transformer

24 VAC is sent from the secondary of the

24VAC transformer to the Hi/Off/Low Switch.

■ Contacts of the RI Blower Relay

■ The optional Power Tilt Circuit

2. With the Hi/Off/Low switch in the Low position.

■ 24 VAC is sent through the normally closed high

limit switch to the mercury switch.

■ If the unit is in the down position then 24 VAC is

sent through mercury switch to pin 9 on the

thermostat.

3. With the Hi/Off/Low Switch in the Hi position 24

VAC is also sent to the Hi terminal on the gas

valve.

■ Gas will not leave the valve until the main gas

valve opens (see step 7).

4. If the steamer is calling for heat the 24 VAC is sent

from pin number 10 to R1 Blower Relay.

■ The normally open contacts of the blower relay

close sending 115 VAC to the blower.

■ The blower turns closing the air switch.

■ 24 VAC is sent through the now closed air switch

to the ignition module.

5. Ignition module sends spark from terminal SP to

the igniter.

6. Ignition module also sends 24 VAC from pins PV

and MV/PV to the pilot coil of the gas valve pins P

and C.

■ Pilot valve opens sending gas to the Pilot

assembly.

■ Spark and gas meet and pilot is ignited.

■ AC current is passed through the flame and

rectified then sent back to the ignition module.

7. If the ignition module reads a minimum of 1.0

micro-amps through the burner ground then 24

VAC is sent from pins MV and MV/PV of the ignition

module to pins M and C on the Gas valve.

■ The main (low) gas valve opens and gas (3.0"

W.C. natural gas or 8.0" W.C. LP) is sent to the

burner.

■ If the unit is in the Hi position (see step 3) 24VAC

will be at the HI terminal and the gas pressure will

be 3.5" W.C. natural or 10.0" W.C. LP.

■ Burner ignites until thermostat is satisfied.

8. When thermostat is satisfied, 24 VAC is removed

from pin 10 on the thermostat and the heat circuit

is de-energized

9. If the unit has the optional Power Tilt option and is

in the down position, 115 VAC is sent from the

customer connect through the circuit breaker and

the up limit switch to the tilt switch.

10. With the tilt switch in switch in the Up position

■ 115 VAC is sent to the Bridge Rectifier

115 VDC is sent from the rectifier through the

30-ohm resistor to the normally open RY10

and RY11 relay contacts.

■ 115 VAC is sent to the RY 10 relay coil.

■ The normally open RY10 contact close and 90

VDC is sent to the DC motor

■ The DC motor is energized and the unit tilts until

the switch is released or the up limit switch opens.

11. With the Tilt switch in the Down position

■ 115 VAC is sent to the Bridge Rectifier

115 DC is sent from the rectifier through the

30-ohm resistor to the normally open RY10

and RY11 relay contacts.

■ 115 VAC is sent to the RY 11 relay coil.

■ The normally open RY 11 contact close and the

polarity of the 90 VDC is reversed.

■ The DC motor is energized and the unit lowers

until the switch is released or the Down limit switch

opens.

Page 12

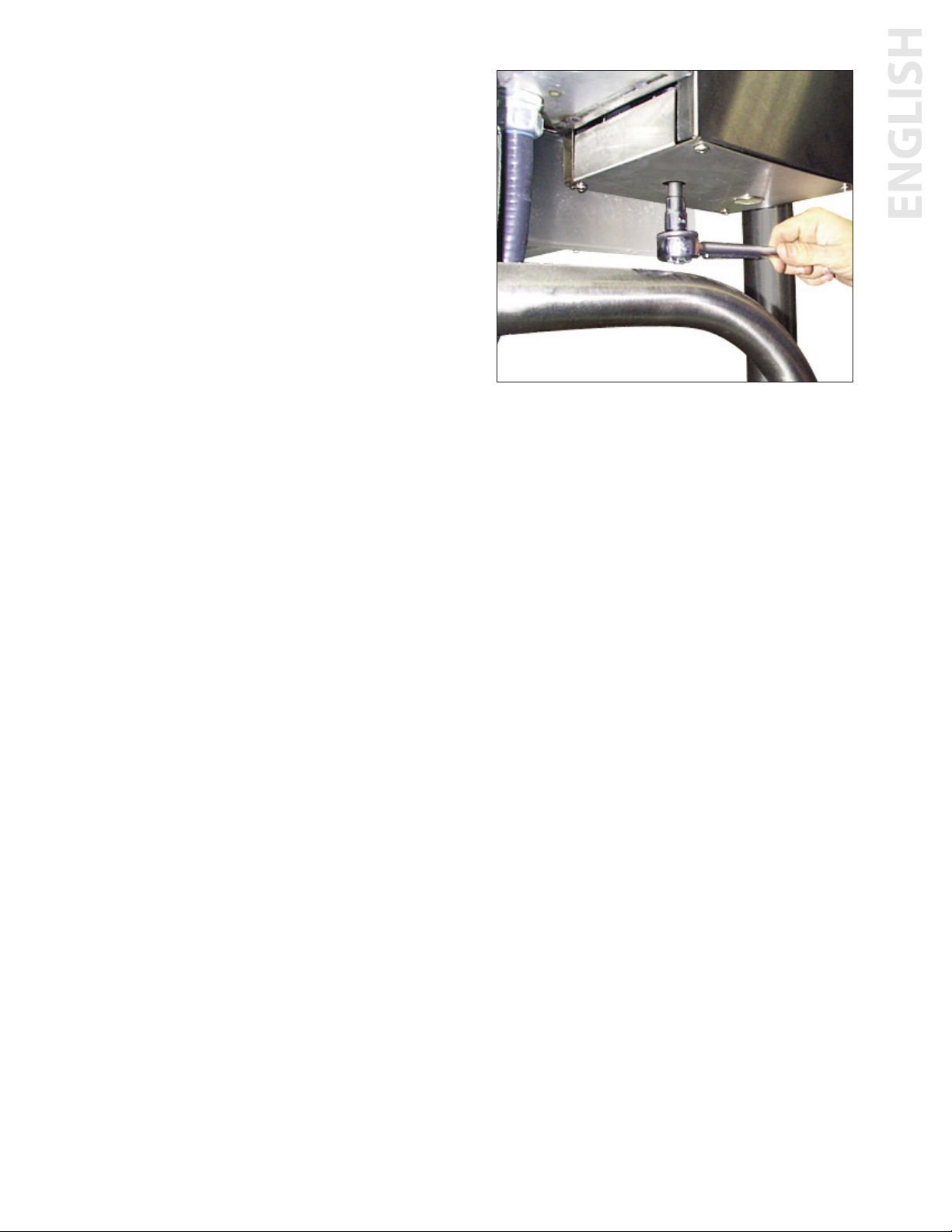

POWER TILT MANUAL

OVERRIDE

In case of power failure or malfunction the skillet pan

can be tilted manually following these instructions.

1. (prior to May 2006) - Fit a 10mm SIX point socket

over the Manual Tilt Shaft as shown above.

(after May 2006) - Fit a 1/2” SIX point socket

over the Manual Tilt Shaft as shown above.

2. Turn socket wrench clockwise to empty contents.

Page 13

INSTALLATION

INSPECTION

1. Avant de déballer, inspectez visuellement l'unité pour détecter

tout dommage occasionné pendant le transport.

2. Si vous remarquez un dommage, ne déballez pas l'unité et

suivez les instructions sur les dommages liés au transport.

3. Retirez soigneusement l’unité de l’emballage d’expédition.

Enlevez tout matériel d'emballage de l'unité. Après avoir fini le

déballage méticuleux, confirmez l’absence de tout dommage

"non apparent". Lorsqu’un dommage est constaté, suivez les

"Instructions concernant les dommages liés au transport"

présentées ci-dessous.

4. Les panneaux en acier inoxydable ont été traités avec un

matériau protecteur. Ce matériau doit être retiré

immédiatement après l’installation de l’unité puisque la chaleur

va fondre ce matériau et le rendra plus difficile à éliminer.

INSTRUCTIONS CONCERNANT LES

DOMMAGES LIÉS AU TRANSPORT

If shipping damage to the unit is discovered or suspected,

observe the following guidelines in preparing a shipping damage

claim.

1. Faites une description du dommage ou de la raison pour

laquelle vous soupçonnez un dommage dès que vous vous en

rendez compte. Cela permettra de remplir les formulaires de

réclamation par la suite.

2. Dès lors que vous découvrez ou soupçonnez un dommage,

informez le transporteur qui vous a fourni le matériel.

3. Prenez les arrangements nécessaires pour que le

représentant du transporteur examine le dommage.

4. Remplissez tous les formulaires du transporteur et demandez

à son représentant de signer et de dater chaque formulaire.

GÉNÉRAL

L'installation de la chaudière doit être effectuée par du personnel

qualifié pour l'installation et travaillant conformément à tous les

codes locaux et nationaux en vigueur. Une installation incorrecte

du produit peut provoquer des blessures ou des dommages.

Ce matériel a été conçu pour respecter les normes applicables

aux fabricants. Parmi ces organismes d'approbation se trouvent :

UL, A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL, et autres. Il existe

de nombreux codes locaux, et il est de la responsabilité du

propriétaire/installateur de se conformer à ces codes.

Respectez toutes les conditions d'espacement pour permettre un

débit d'air correct. N’obstruez pas le flux de combustion ni l’air de

ventilation. Vérifiez la plaque signalétique pour vous assurer que la

chaudière a été équipée pour fonctionner avec le type de gaz

disponible dans l'installation.

Les dimensions et les exigences d’espacement sont indiquées

dans la notice technique.

CONDITIONS EN TERMES

D'ESPACEMENT

Cette unité doit être installée conformément aux espacements

indiqués sur la fiche signalétique collée sur l'unité.

DROIT GAUCHE ARRIÈRE

Inclinaison manuelle 4” 0 0*

Inclinaison électrique 1” 0 0*

*Prévoyez 3,5” à l’arrière pour les murs à constitution combustible.

POUR VOTRE SÉCURITÉ. Conservez la zone de l'appareil libre et

sans matériaux combustibles.

INSTALLATION

1. Placez l'unité dans son emplacement définitif, et mettez-la à

niveau en faisant pivoter les pieds réglables.

2. Une fois positionnée et à plat, serrez définitivement les pieds

bridés de l'unité au sol avec des tire-fonds de 5/16" (7,94

mm) et des ancrages pour plancher (fournis par l'installateur).

Ces boulons sont nécessaires pour serrer chaque pied bridé.

3. Scellez les joints des pieds bridés avec un enduit de silicone.

GAZ

ASSUREZ-VOUS QUE L’ALIMENTATION EN GAZ EST

CONFORME AUX EXIGENCES DE LA CHAUDIÈRE, TEL

QU’INDIQUÉ SUR LA PLAQUE SIGNALÉTIQUE.

L'installation doit être conforme aux codes locaux et/ou à la

dernière édition du code national du gaz combustible ANSI Z223.1

(États-Unis) ou à la dernière version des codes d'installation pour

les appareils et le matériel à gaz combustible CAN/CSA B149.1.

L’appareil et son robinet doivent être débranchés des tuyauteries

d’alimentation de gaz pendant tous les tests de pression effectués

sur ce système à des pressions d’essai dépassant 1/2 psi (3,45

kPa).

L’appareil doit être isolé des tuyauteries d’alimentation en gaz en

fermant son robinet individuel pendant les tests de pression

effectués sur ce système à des pressions d’essais équivalentes ou

inférieures à 1/2 psi (3,45 kPa).

Il est recommandé d'installer un piège de sédiments (collecteur de

condensats) dans le conduit d’alimentation en gaz. Si la pression

du gaz dépasse la colonne d'eau de 14" (35,56 cm), un régulateur

de pression doit être installé pour offrir une pression de la colonne

d'eau de 14" (35,56 cm) au maximum à la vanne de commande du

gaz.

Reliez le conduit du gaz à la vanne manuelle située à l'arrière de

l'armoire de commande.

Pour les conduits de gaz, utilisez un produit pour joints résistant au

gaz de pétrole liquéfié. Testez tous les raccords du tuyau pour

détecter les fuites avec une solution d'eau savoneuse. Assurezvous que le régulateur de pression de gaz est réglé à la pression

du manifold, tel qu'indiqué sur la plaque signalétique du gaz.

Page 14

ÉLECTRIQUE

NOTE: Le schéma de câblage se trouve sur le dessous

du tableau de commande de l'appareil.

ASSUREZ-VOUS QUE L’ALIMENTATION ÉLECTRIQUE

CORRESPOND AUX EXIGENCES DE L'UNITÉ, TEL

QU’INDIQUÉ SUR LA PLAQUE SIGNALÉTIQUE.

VÉRIFICATIONS DE L‘INSTALLATION

Bien que l'unité ait été testée minutieusement avant son

expédition de l'usine, l'installateur est chargé de veiller au

fonctionnement adéquat de l'unité dès son installation.

N’ESSAYEZ PAS D’EXPLOITER CETTE UNITÉ LORS

D’UNE COUPURE DE COURANT.

Un cordon et une prise de courant sont fournis avec l'unité

de 115 volts. Il vous suffit de brancher l'unité à une prise à

contact de mise à terre ayant une valeur nominale minimale

de 10 ampères. Le schéma de câblage se trouve à l'arrière

de la console du panneau de service.

Lorsqu'une unité est commandée et construite pour une

tension de 208/240 volts, la ligne d'alimentation doit être

branchée aux raccordements de câblage situés à l'intérieur

de la console. Un schéma de câblage est attaché au

dessous du tableau de commande

AVERTISSEMENT: Instructions concernant la mise à la

terre électrique.

Cet appareil est équipé d'une fiche tripolaire (à terre) pour

garantir votre protection contre tout risque de choc

électrique et doit être branché directement sur une prise

tripolaire convenablement mise à terre. Ne coupez et ne

retirez pas la broche de mise à terre de cette fiche.

La tension d'alimentation standard est de 115 volts CA.

Cependant, d’autres tensions optionnelles en C.A. peuvent

être fournies sur commande spéciale. Un sectionneur à

fusibles distinct doit être fourni et installé sur la ligne

d’alimentation électrique de haute tension. Une fois installé,

l’appareil doit être calibré électriquement et mis à terre

conformément aux codes locaux ou, en l'absence de

codes locaux, selon le Code national de l'électricité,

ANSI/NFPA 70-1990 (États-Unis) ou le Code canadien de

l'électricité, CSA C22.2, Partie 1 (Canada).

VENTILATION

Les unités à gaz doivent être installées uniquement sous

une hotte de ventilation dans un lieu pouvant fournir de l'air

d’appoint adéquat. D'autres informations sont disponibles

en se référant aux règlementations NFPA96 de la «

National Fire Protection Association » contre le feu aux

États-Unis. Ces normes ont également été adoptées par le

« National Building Code » (Code national du bâtiment) au

Canada..

CONSERVEZ L’APPAREIL ET SON ENTOURAGE

LIBRES ET SANS MATÉRIAUX COMBUSTIBLES.

1. Mettez l'appareil sous tension en positionnant le

sectionneur à fusibles sur «ON».

2. Activez l'alimentation principale en gaz de l'unité.

Ouvrez le robinet de sectionnement de l’appareil (situé

à l’arrière, en bas à gauche).

3. Basculez le commutateur HI / OFF / LO à la position

"HI" ou "LO".

4. Pour votre sécurité, l'appareil est équipé d'un

interrupteur de puissance qui coupe automatiquement

l'alimentation en gaz des brûleurs dès que l'unité est

soulevée de plus de 8°.

IMPORTANT: Avant de commencer la cuisson, vérifiez

que la casserole est en position abaissée. Assurez-vous

aussi que le couvercle est soulevé.

5. Mettez le régulateur de température au maximum.

Inclinez la casserole jusqu'à voir le voyant de

l’indicateur thermique éteint et le système de chauffage

arrêté. La casserole doit avoir un angle d’inclinaison de

5-10°.

6. Abaissez la casserole. Le voyant de l’indicateur

thermique se rallumera et le système de chauffage

redémarrera.

7. La température de l’appareil continuera de monter et le

voyant de l’indicateur thermique restera allumé jusqu'à

atteindre la température voulue. Le voyant de

l’indicateur thermique passera, ensuite, au cycle OFF

indiquant que le système de chauffage s’est arrêté. Le

voyant de l’indicateur thermique ainsi que le système

de chauffage continueront de basculer entre les cycles

ON et OFF pour maintenir la température souhaitée.

8. Basculez le commutateur HI / OFF / LO à la position

"OFF".

RACCORDEMENT D‘EAU

(EN OPTION)

Une conduite d'eau froide NPT d’1/2" et/ou une conduite

d’eau chaude NPT d’1/2" est requise si l'appareil est

équipé d'un robinet d'évier simple ou double.

NETTOYAGE

Après l'installation, la chaudière doit être entièrement

nettoyée et aseptisée avant la cuisson.

Page 15

HI

L

O

INSTRUCTIONS

D’OPÉRATION

9

10

4 1 2 3

5

7

6

8

# D’ARTICLE DESCRIPTION

1. Interrupteur HI / OFF / LO

2. Lampe d’indication d’alimentation électrique (rouge)

3. Cadran de la température

4. Témoin de chaleur (jaune)

5. Roue à basculement manuel

6. Interrupteur de basculement électrique (l’emplacement peut varier)

7. Bouton de remise à zéro (l’emplacement peut varier)

8. Annulation du basculement manuel

9. Robinet d’arrêt du gaz

10. Robinet

11. Soupape de soutirage tangentiel

Page 16

OPÉRER L’UNITÉ

1. Assurez-vous que l’alimentation de gaz et électrique

de l’unité sont dans la position ON.

POUR VOTRE PROTECTION :

Cette poêle va arrêter l’alimentation de gaz

automatiquement si la cuvette augmente de plus de 8°.

Avant de commencer la cuisson, assurez-vous que la

cuvette est dans la position abaissée.

2. BASCULEMENT MANUEL : Les poêles Cleveland

sont équipées d’un mécanisme de basculement

manuel pour soulever et baisser la cuvette. Pour

soulever la cuvette, soulevez le couvercle et tournez

la manivelle dans le sens des aiguilles d’une

montre. Pour baisser la cuvette, tournez-la dans le

sens opposé des aiguilles d’une montre.

BASCULEMENT ÉLECTRIQUE : Les poêles

Cleveland peuvent aussi être équipées d’un

mécanisme de basculement électrique pour

soulever et baisser la cuvette. Pour soulever la

cuvette, soulevez le couvercle et appuyez sur

l’interrupteur de basculement. Pour baisser la

cuvette, appuyez sur l’interrupteur de basculement.

3. Basculez l’interrupteur HI / OFF / LO à la position «

HI » ou « LO ». La lampe d’indication d’alimentation

électrique indique que l’unité est allumée. Le témoin

de chaleur jaune indique que les brûleurs sont

allumés.

4. Pour le préchauffage, réglez le cadran de la

température à la température de cuisson désirée.

L’unité est préchauffée lorsque la lampe jaune

s’éteint.

5. Insérez le produit dans la cuvette.

6. Si désiré, une fois que le produit a fini de cuire, il

peut être gardé avant de servir à une température

plus basse.

7. Lorsque la cuisson est complétée, réglez le cadran

de la température et l’interrupteur HI / OFF / LO à la

position OFF.

8. Le meilleur moment pour nettoyer la poêle est

immédiatement après l’emploi, une fois que la poêle

a refroidi. Référez à la section intitulée « CLEANING

INSTRUCTIONS » pour obtenir plus de détails.

INSÉREZ LE COUVERCLE AVANT

LA CUVETTE BASCULANTE

CHAUD

N’ARROSEZ PAS CETTE

PARTIE

SUGGESTIONS D’OPÉRATION

1. Tournez l’interrupteur d’alimentation électrique à la

position « OFF » lorsque la poêle n’est pas utilisée.

2. Permettez à la poêle de préchauffer avant d’ajouter

le produit.

3. Soulevez toujours le couvercle assisté par ressort

avant d’activer le mécanisme de basculement.

4. Pendant une panne électrique, tournez l’interrupteur

d’alimentation électrique à la position OFF. Cette

unité ne peut pas opérer sans alimentation

électrique.

Page 17

INSTRUCTIONS DE NETTOYAGE

ATTENTION

LES SURFACES PEUVENT

ÊTRE EXTRÊMEMENT

CHAUDES !

ENTRETIEN ET NETTOYAGE

Le matériel de cuisson peut être nettoyé

régulièrement pour conserver ses

performances de cuisson rapides et efficaces

et assurer un fonctionnement sûr et fiable en

continu. Le meilleur moment pour le

nettoyage est peu de temps après chaque

utilisation (laissez l'unité refroidir à une

température sûre).

AVERTISSEMENTS

N'utilisez pas de

détergents ni de

nettoyant à base de

chlorure ou qui

contiennent du sel

quaternaire.

Nettoyants à base

de chlorure

N'utilisez pas de

brosse métallique ni

de raclette.

Brosse métallique

et raclettes

N'utilisez jamais de

laine d'acier pour

nettoyer l'acier

inoxydable.

INSTRUCTIONS DE NETTOYAGE

1. Éteignez l'unité.

2. Retirez l'écran de drainage (le cas échéant). Lavez et rincez entièrement l'écran

dans un évier ou un lave-vaisselle.

3. Préparez une solution avec de l'eau chaude et un détergent doux dans l'unité.

4. Enlevez le reste des aliments avec une brosse en nylon.

5. Décollez les aliments coincés en les laissant tremper à un réglage de basse

température.

6. Purgez l'unité

7. Rincez abondamment l'intérieur.

8. Si l'unité est équipée d'une

manière suivante :

a) Démontez la vanne à passage direct, d'abord en tournant le bouton de la

vanne dans le sens contraire des aiguilles d'une montre, puis en tournant le

grand écrou hexagonal dans le sens contraire des aiguilles d'une montre

jusqu'à ce que la tige de la vanne se détache du corps de la vanne.

b) Dans un évier, lavez et rincez l'intérieur du corps de la vanne à l'aide d'une

brosse en nylon.

c) Utilisez une brosse en nylon pour nettoyer le tube tangent de passage

direct.

d) Rincez avec de l'eau fraîche.

e) Remontez la vanne à passage direct en inversant la procédure de

démontage. L'écrou hexagonal de la vanne doit être serré à la main

uniquement.

9. Avec de l'eau douce savonneuse et une éponge humide, lavez l'intérieur, rincez

et séchez.

VVaannnnee ttaannggeennttee àà ppaassssaaggee ddiirreecct

REMARQUES

➩ Pour les procédés de nettoyage plus difficiles, vous pouvez utiliser l'un des

éléments suivants : alcool, hydrogénocarbonate de sodium, vinaigre ou une

solution d'ammoniac diluée dans de l'eau.

➩ Laissez le couvercle fermé lorsque la chaudière est sous tension.

➩ Pour obtenir des instructions plus détaillées, référez-vous au Nettoyage et entretien

du matériel en acier inoxydable (www.nafem.org/resources/stainlesssteelfinal.doc)

sur le site Internet de Nafem (www.nafem.org)

).

t

, nettoyez de la

Coussinets d'acier

Tuyau d'arrosage à

haute pression

Eau stagnante

L'unité ne doit jamais

être nettoyée avec un

tuyau d'arrosage à

haute pression.

Ne laissez pas d'eau

stagner au fond de

l'unité lorsqu'elle n'est

pas utilisée.

Page 18

ENTRETIEN

AVERTISSEMENT :

Tout entretien qui implique le démontage des composantes devrait être réalisé

!

INSTRUCTIONS POUR AJUSTER LES CHARNIÈRES

par un technicien d’entretien qualifié. Assurez-vous que les alimentations de

gaz, électrique et d’eau (si applicable) à l’unité sont éteintes.

1. Soulevez le couvercle

complètement pour détacher la

tension des ressorts.

2. En utilisant une douille longue de

7/16 pouces, ajustez les boulons

de gauche et de droite

uniformément.

3. Lorsque le couvercle est ajusté

LUBRICATION PROCEDURE

Lubricate the following parts every three months to insure smooth operation and

reduce wear.

COMPARTIMENT DU TOURILLON, VIS TANGENTE ET

EMBRAYAGE DE BASCULEMENT

Vous pouvez obtenir l’accès à ces pièces par le couvercle supérieur de la console.

Appliquez de la graisse aux dents de l’embrayage. Vérifiez s’il y a trop de jeu et

faites l’ajustement avec la vis d’ajustement située sur la traverse.

TOURILLONS (avant mai 2006)

Sur le côté gauche de la poêle, il y a deux mamelons de graisse sur la portion

arrière du haut du compartiment de tourillons.

Sur le côté droit du chaudron, vous devez retirer le couvercle de la console pour

obtenir l’accès aux deux mamelons de graisse.

(avant mai 2006)

correctement, il devrait rester à un

angle de 70°.

TOURILLONS

(après mai 2006) Sur le côté gauche de la poêle, il y a deux mamelons de graisse

sur la portion arrière du haut du compartiment de tourillons.

Page 19

BURNER ASSEMBLY GASKET

EXAMINATION PROCEDURE

CUVETTE DE LA POÊLE

JOINT D’ÉTANCHÉITÉ

ASSEMBLÉE DE LA

CUVETTE DU BRÛLEUR

NOTE: Il est essentiel que cette procédure soit complétée au moins deux fois par an.

1. Allumez la poêle. Le brûleur doit être allumé pendant cette procédure.

2. En utilisant un miroir de fouille en acier inoxydable, examinez le joint d’étanchéité entre

l’assemblée du brûleur de la cuvette et la cuvette de la poêle (uniquement les côtés et l’avant).

3. Remplacez la douille d’étanchéité si :

- le joint d’étanchéité montre des signes de détérioration

- vous voyez une flamme à travers le joint d’étanchéité

- il y a une formation de condensation sur le miroir de fouille (ceci indique que la chaleur

s’échappe)

# DE PIÈCES DU JOINT D’ÉTANCHÉITÉ

30 GALLON 40 GALLON

CÔTÉS SK2472402 SK2472402

AVANT SK2472400 SK2472401

Page 20

ENCHAÎNEMENT DES

OPÉRATIONS

Référez-vous au schéma de branchement lorsque vous

suivez ces instructions.

1. Un courant de 115 VCA est passé à travers le

fusible de 3 ampères

■ au primaire du transformateur 24 VCA

Le 24 VCA est envoyé du secondaire du

transformateur 24VAC au commutateur

Hi/Off/Lo.

■ aux contacts du relais du ventilateur R1

■ au circuit de l’option d’inclinaison electrique

2. Tout en ayant le commutateur Hi/Off/Low

(Haut/Arrêt/Bas) en position Low (Bas).

■ Le courant de 24 VCA est passé à travers

l'interrupteur de fin de course supérieur,

normalement fermé, à l’interrupteur à mercure.

■ Si l'appareil est en position abaissée, le 24 VCA

est passé alors à travers l’interrupteur à mercure

vers la broche 9 du thermostat.

3. Tout en ayant le commutateur Hi/Off/Low en

position Hi (Haut), un 24 VCA est aussi passé à la

borne Hi (Haut) de la soupape à gaz.

■ Le gaz ne sortira pas de la soupape jusqu’à

ouvrir la soupape à gaz principale (voir l’étape 7).

4. Si le four à vapeur demande un chauffage, du 24

VCA est passé de la broche numéro 10 au relais

R1 du ventilateur.

■ Les contacts du relais du ventilateur

normalement ouverts se ferment et envoient une

charge de 115 VCA au ventilateur.

■ Le ventilateur pivote et ferme le commutateur de

débit d'air.

■ Un courant de 24 VCA est passé à travers le

commutateur de débit d'air fermé au module

d'allumage

5. Le module d'allumage envoie une étincelle de la

borne SP à l'allumeur.

6. Le module d'allumage envoie également 24 VCA

des broches PV et MV/PV à la bobine pilote des

broches P et C de la soupape à gaz.

■ La soupape pilote s’ouvre et alimente

l’assemblage pilote en gaz.

■ Le gaz et l’étincelle se croisent et le pilote

s’allume.

■ Le courant alternatif est passé à travers la

flamme et est rectifié, puis renvoyé vers le module

d'allumage.

7. Si le module d'allumage détecte un minimum de

1,0 microampères à travers la prise terre du

brûleur, un courant de 24 VCA est alors passé des

broches MV et MV/PV du module d'allumage aux

broches M et C de la soupape à gaz.

■ La soupape à gaz principale (low - Bas) s’ouvre

et du gaz (3,0" W.C. gaz naturel ou 8,0" W.C. LP)

est acheminé au brûleur.

■ Si l'appareil est en position Hi (voir l’étape 3), un

courant de 24 VCA sera envoyé à la borne HI et la

pression du gaz sera de 3.5" WC naturel ou 10,0"

WC LP.

■ Le brûleur s'allumera et se maintiendra jusqu'à

aboutir au niveau de température du thermostat

8. Lorsque la température du thermostat arrive au

niveau voulu, le courant de 24 VCA est retiré de la

broche 10 du thermostat et le circuit thermique est

mis hors tension.

9. Si l'appareil, en position abaissée, est doté de

l’option d’inclinaison électrique, un courant de 115

VCA est envoyé de la prise client à travers le

disjoncteur et l'interrupteur de fin de course

supérieur vers le commutateur d'inclinaison.

10. Tout en ayant le commutateur d’inclinaison en

position Haut.

■ Le 115 VCA est envoyé au redresseur en pont.

■ Le 115 VDC est envoyé du redresseur à travers

la résistance de 30-ohm aux relais de contacts

RY10 et RY11 normalement ouverts.

■ Le 115 VCA est passé à la bobine du relais

RY10.

■ Le contact RY10, normalement ouvert, se ferme

et un courant de 90 VCC est envoyé au moteur à

courant continu.

■ Le moteur à courant continu est mis sous tension

et l'appareil s'incline jusqu'au relâchement du

commutateur ou jusqu’à l’ouverture de l'interrupteur

de fin de course supérieur.

11. Tout en ayant le commutateur d’inclinaison en

position Bas

■ Le 115 VCA est envoyé au redresseur en pont.

■ Le 115 VDC est envoyé du redresseur à travers

la résistance de 30-ohm aux relais de contacts

RY10 et RY11 normalement ouverts.

■ Le 115 VCA est passé à la bobine du relais

RY11.

■ Le contact RY11, normalement ouvert, se ferme

et la polarité du courant 90 VCC est inversée.

■ Le moteur à courant continu est mis sous tension

et l'appareil s'incline jusqu'au relâchement du

commutateur ou jusqu’à l’ouverture de l'interrupteur

de fin de course inférieur.

Page 21

ANNULATION MANUELLE DU

BASCULEMENT ÉLECTRIQUE

S’il y a une défaillance ou une panne électrique, la

cuvette de la poêle peut être basculée manuellement

en suivant les instructions suivantes.

1. (avant mai 2006) – Cadrez une douille à SIX points

de 10 mm au-dessus du levier de basculement

manuel, tel qu’indiqué ci-dessus.

(après mai 2006) – Cadrez une douille à SIX points

de ½ pouces au-dessus du levier de basculement

manuel, tel qu’indiqué ci-dessus.

2. Tournez la clé à douilles dans le sens des aiguilles

d’une montre pour vider les contenus.

Page 22

WIRING

up / haut

o / arrêt

down / bas

up / haut

o / arrêt

down / bas

up limit switch

interrupteur limiteur haut

down limit switch

interrupteur limiteur bas

tilt switch

position

position de

interrupteur

d'inclinaison

closed contact

contact fermé

open contact

ouvrez le contact

b

lower

v

entilateur souant

air switch

commutateur d'air

gas valve

robinet

de gaz

on

sur

o

marche

fuse, 3 Amp

fusible, 3 ampère

relay 1

relais 1

relay 1

relais 1

fuse,

1.25 Amp

fusible,

1.25 ampère

circuit breaker

disjoncteur

power tilt option

option d'inclinaison de puissance

heat indicator

indicateur de la chaleur

operation thermostat

thermostat d'opération

high limit

limite supérieure

on/o/on switch

i

nterrupteur d'on/o/on

tilt switch

interrupteur d'inclinaison

thermostat

thermostat

operating

thermostat

thermostat

d'opération

DC

motor

moteur

de C.C.

bridge rectier

pont redresseur

Description - (English / Français)

bk - (black / noir), red - (red / rouge), bl - (blue / bleu), yl - (yellow / jaune), or - (orange / orange),

pk - (pink / rose), wh - (white / blanc), gr - (green / vert), gy - (gray / gris), br - (brown / brun), pr - (purple / pourpre)

pilot ignitor

Igniteur pilote

gas control

module

module de

commande

d

e gaz

DIAGRAM /

Schéma

électrique

Page 23

1

1

2

2

3

3

4

4

5

9

10

10

13

8

12

11

13

14

12

11

7

6

6

SERVICE PARTS

WARRANTY

Our Company supports a worldwide network of Maintenance and Repair Centers. Contact your nearest

Maintenance and Repair Centre for replacement parts, service, or information regarding the proper

maintenance and repair of your cooking equipment

In order to preserve the various agency safety certification (UL, NSF, ASME/Ntl. Bd., etc.), only factorysupplied replacement parts should be used. The use of other than factory supplied replacement parts will

void warranty.

FAUCET ASSEMBLY

ITEM PART DESCRIPTION QTY.

NO. NO.

1. KE50825-7 3/4" SPOUT . . . . . . . . . . . . . . . . . . . . . . . .1

2. FA95022 RETAINING RING . . . . . . . . . . . . . . . . . . . .1

3. FA05002-19 "O" RING . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE51736 LONG FAUCET NUT . . . . . . . . . . . . . . . . .1

5. SE50020 HOT WATER STEM ASSEMBLY . . . . . . . . .1

6. SE50021 COLD WATER STEM ASSEMBLY . . . . . . . .1

7. KE51401 SINGLE PANTRY BODY . . . . . . . . . . . . . . .1

8. KE50335 ADAPTER WASHER . . . . . . . . . . . . . . . . . .1

9. KE51403 DOUBLE PANTRY BODY . . . . . . . . . . . . . .1

(DOUBLE PANTRY ONLY)

(C/W ITEM NO. 6)

(SINGLE PANTRY ONLY)

(C/W ITEM NO. 5&6)

10. SK00395-1 FAUCET MOUNTING BRACKET . . . . . . . .1

11. FA11258 HEX CAP SCREW . . . . . . . . . . . . . . . . . . .2

12. FA30505-1 WASHER . . . . . . . . . . . . . . . . . . . . . . . . . .2

13. FA21008 HEX NUT . . . . . . . . . . . . . . . . . . . . . . . . . .2

14. SE50447 WASHER HORSESHOE . . . . . . . . . . . . . . .1

Page 24

FRAME / LID ASSEMBLY

9

19 120 21 22

23

2

13 12

24 25 26

10

11

17

4 18

6

7

8

27

5

OPEN END OF

SPRING TO BE

L

OCATED ON TOP

APPLY

REMOVABLE

LOCKTITE

KE530683 Caster

KE530684 Locking Caster.

ITEM NO. PART NO. DESCRIPTION QTY.

1. SK00392-1 FRAME WELDMENT (30 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK00392-2 FRAME WELDMENT (40 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. SK2457192 LID ASSEMBLY (30 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2457193 LID ASSEMBLY (40 GALLON) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE50187-1 CAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

5. SK00394-1 HOOK WELDMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

6. SK2452300 SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

7. FA95087-1 EYE BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. FA20008 HEX NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

9. KE53573-1 BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

10. FA15019-4 SHOULDER BOLT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

11. FA21501-2 ACORN NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

12. KE00099 ADJUSTABLE FOOT (FLANGED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

13. KE50249-1 FOOT ADJUSTOR (W/O FLANGE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

17. FA31029 LOCKWASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

18. FA11054 SCREW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

19. SK2459299 COUPLING ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

20. FA21024 HEX NUT (5/16-18) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

21. FA31030 LOCKWASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

22. FA30055 FLAT WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

23. SK00054 VENT COVER ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

24. SK2211200 SPACER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

25. FA95081-1 BOLT, MODIFIED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

26. SK50179 WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

27. FA30504 WASHER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Page 25

1

2

3

4

5

6

7

2" TANGENT DRAW-OFF VALVE

ITEM NO. PART NO. DESCRIPTION QTY.

1. - 7. KE50972-B DRAW-OFF ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1. FA95049 WING NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. KE527551 KNOB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE52754 HEX NUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. KE52753 RETAINER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. KE52752 PISTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

6. FA00111 "O" RING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

7. KE52751 VALVE BODY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Page 26

CORRECTIONAL

PACKAGE OPTIONS

GENERAL ASSEMBLY

COMPONENTS

Page 27

GENERAL ASSEMBLY COMPONENTS

ITEM NO. PART NO. DESCRIPTION QTY.

4400 GGaall..

3300 GGaall..

22 FA21008 HEX. NUT 1/4-20 4 4

23 FA31029 SPLIT LOCKWASHER 1/4 44

46 KE51084-2 WASHER 11

65 KE002486-1 FLUE DEFLECTOR ASSEMBLY 1-

KE002486-2 FLUE DEFLECTOR ASSEMBLY - 1

67 FA21501-2 ACORN NUT 1/4-20, S.S. 5 5

68 SK50942-1 FRONT COVER 1 -

SK50942-2 FRONT COVER -1

69 SK50943-1 SIDE COVER, R.H. 11

70 SK50943-2 SIDE COVER, L. H. 11

71 SK50946-1 FRONT BOX COVER ASSEMBLY 1 1

75 FA11511-20 SECURITY HEX SOCKET SCREW 3/8-16 X1 (CP OPTION) 4 4

KE55443 CAP SCREW, 3/8-16 X1 HIGH STRENGTH (NO CP OPTION) 4 4

80 KE53068-3 SWIVEL CASTER W/O BRAKE 2 2

81 KE53068-4 SWIVEL CASTER WITH BRAKE 2 2

82 KE53046-1 CASTER SLEEVE 4 4

83 KE95447 LABEL TO COVER FAUCET MTG. HOLES 1 1

85 KE003160 HANDLE WELDMENT 11

88 SK2473800 SPRING CUP 22

89 F10 SCREW: PAN QUAD 8-32 X 3/8 22

90 FA11511-101 SHORT ARM SECURITY HEX KEY 1 1

91 SK2495600 STRIP FILL 1-

SK2474400 STRIP FILL - 1

92 KE55445 WASHER, HIGH STRENGTH ULTRA-COATED 4 4

93 FA31031 SPLIT LOCK WASHER, S.S., 3/8 DIA. 4 4

94 FA95007-12 RETAINING RING, 1 DIA. 3/16 1 1

95 KE55440 WIPER SEAL 1 1

96 FA05002-47 0-RING, 2 DIA. X 2 DIA. 3/16 1 1

97 KE55446 PLATE, BEARING RETAINING 1 1

98 FA11511-2 10-32 X 3/8 PAN HEAD TORX SCREW (CP OPTION) 4 4

F182 10-32 X 1/2 SLOTTED HEAD S.S. SCREW (NO CP OPTION) 4 4

99 KE02383 HOUSING ASSEMBLY, TRUNNION 1 1

100 FA30505-1 FLAT WASHER 1/4 44

101 FA11258 1/4-20 X 3/4 BOLT, 18-8 S.S. 44

102 F01518-1 SHUT SET VALVE 1 1

103 N0640C1.5 NIPPLE 1 1

104 SK2472702 SWIVEL CONNECTOR 1 1

105 KE95497 RISK OF ELECTRIC SYMBOL 1 1

106 KE95552-2 LABEL, GAS RATING 1 1

107 KE95533-9 TAG 1 1

108 KE51258-1 CONDUIT CONNECTOR 1 1

110 KE54907-16 PLUG BUTTON 1 1

111 KE55356 EXTRUDEC WASHER 4 4

113 KE55407 EQUIPMENT INSTALLATION LABEL 1 1

114 FAL1511-2 10-32 X 3/8 PAN HEAD TORX SCREW (CP OPTION) 8 8

114 FL 82 10-32 X 1/2 S.S. SLOTTED HEAD SCREW (NO CP OPTION) 8 8

120 FAL1511-11 1/4-20 X 3/4 PAN HEAD TORX SCREW (CP OPTION) 2 2

FA11258 1/4-20 X 3/4 PAN HEAD CAP SCREW (NO CP OPTION) 2 2

Page 28

F

F

MANUAL TILT

POWER TILT

POWER TILT

SECTION F-F

Common Parts

Gearbox cover Assembly Option

KE602239: STOP ARM (for

units built prior to August

2006)

KE6022391: STOP ARM (for

units built from August 2006

to July 2011)

KE6022393: STOP ARM (for

units built from July 2011 to

October 2013).

KE6022394: STOP ARM (for

units built after October

2013).

TILT ASSEMBLY COMPONENTS

Page 29

Common Parts

Gearbox cover Assembly Option

Power Tilt Option

Manual Tilt Option

TILT ASSEMBLY

COMPONENTS

Page 30

1 2

11

9

12

15

10

14

13

3 4

5 6

7

8

8

9

9

16

SECTION

A - A

SECTION

B - B

SECTION

C - C

BA

ABCC

W

ARNING: Improper installation,

a

djustment, alteration, service or

m

aintenance can cause property

d

amage, injury or de ath. Read the

i

nstallation, operating and maintenance

instructions thoroughly before installing

o

r servicing this equipment.

A

VERTISSEMENT: Une mauvaise

i

nstallation, un réglage inadapté ou

u

n manque d'entretien peuvent

o

ccasionner des dommages

matériels ou corporels. Il est donc

i

ndispensable de lire attentivement

l

es notices avant l'installation ou

l'entretien.

WARNUNG: Unsachgemäßer Einbau,

E

instellung, Veränderung, Bedienung oder

W

artung können Sachschaden,

Verletzungen oder Tod verursachen. Lesen

S

ie bitte die Einbau-, Bedienungs- und

W

artungsanleitungen genau durch, ehe Sie

d

ieses Gerät einbauen oder bedienen.

A

DVERTENCIA: La in stalación, ajuste,

a

lteración, servicio o mantenimiento

i

ncorrectos pueden causar daños a la

p

ropiedad, lesiones o muerte. Lea

d

etenidamente las instrucciones de

i

nstalación, operación y mantenimiento antes

d

e instalar o dar servicio a este equipo.

A

TTENZIONE: Installazione, regolazione,

modifiche, riparazioni o manutenzione

e

rronee possono causare danni, infortuni o

m

orte. Leggere attentamente le istruzioni per

l

'installazione, il funzionamento e la

m

anutenzione prima di installare o riparare

q

uesto macchinario

.

H

OT

C

HAUD

1

2

!

SK95063

17

18

CONTROL BOX ASSEMBLY

SE00119

KE00320911

(for units built prior to December 2008)

ITEM NO. PART NO. DESCRIPTION QTY.

1. SK2138700 KNOB ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. SK2360700 DIAL INSERT °F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2360701 DIAL INSERT °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE51005 RUBBER BOOT. #N9030 X 1/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. SK2498399 POTENTIOMETER SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2166800 POTENTIOMETER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2167000 TENSION PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INCLUDES

SK2167100 WASHER, BOWED/SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2167200 RETAINING RING, SP-NR #R1000-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

{

SK2167300 PANEL BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2382800 RETAINING RING CLIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. FA21006 NUT, S.S. F#10-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

6. FA32022 TOOTH LOCK WASHER #10 S.S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

7. FA40000-6 #10-24 X 3/8 S.S. WELD STUD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. SK50903-1 BRACKET, INDICATOR LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. SK50905-1 HEAT INDICATOR, 28V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. SK2142002 THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. SK2159300 THERMOSTAT INSULATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. SK2491500 STOP PLATE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. SK95063 CAUTION LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. SK90125-3 WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. KE95604-5 CONTROLS LABEL, MANUAL TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE95604-6 CONTROLS LABEL, POWER TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. SK2474102 SWITCH, ON/OFF/ON, DUAL FIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. KE53137-3 TILT SWITCH, ON/OFF/ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE53184 CONTACT SECTION HOLDER (LATCH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE53138-1 CONTACT BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

18. KE50579-2 CIRCUIT BREAKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

FA05002-34 "O" RING, CIRCUIT BREAKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50580 WATER RESISTANT BOOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Page 31

1 2

11

9

12

15

10

14

13

3 4

5 6

7

8

8

9

9

16

SECTION

A - A

SECTION

B - B

SECTION

C - C

B

A

ABCC

W

ARNING: Improper installation,

a

djustment, alteration, service or

m

aintenance can cause property

d

amage, in jury or death. Read the

i

nstallation, ope rating and maintena nce

instructions thoroughly before installi ng

o

r servicing this equipment.

A

VERTISSEMENT: Une mauvaise

i

nstallation, un réglage inadapté ou

u

n manque d'entretien pe uvent

o

ccasionner des dommages

matériels ou corporels. Il est donc

i

ndispensable de lire attentivement

l

es notices avant l'installatio n ou

l'entretien.

WARNUNG: Unsachgem äßer Einbau,

E

instellung, Veränderung, Bedienung oder

W

artung können Sach schaden,

Verletzungen oder Tod verursachen. Lesen

S

ie bitte die Einbau- , Bedienung s- und

W

artungsanleitungen genau durch, ehe Sie

d

ieses Gerät einbauen oder bedienen.

A

DVERTENCIA: La instalación, ajuste,

a

lteración, servicio o manten imiento

i

ncorrectos puede n c ausar daños a la

p

ropiedad, lesiones o muerte. Lea

d

etenidamente las instr ucciones de

i

nstalación, operación y mantenimiento antes

d

e instalar o dar servicio a este equipo.

A

TTENZIONE: Installazione, regolazione,

modifiche, ripar azioni o manutenzion e

e

rronee possono causare danni, infortuni o

m

orte. Leggere attentamente le istruzioni per

l

'installazione, il fu nzionamento e la

m

anutenzione prima di installare o riparare

q

uesto macchinario

.

H

OT

C

HAUD

1

2

!

SK95063

18

17

19

CONTROL BOX ASSEMBLY

.63 amp

SE00119

(for units built after December 2008)

ITEM NO. PART NO. DESCRIPTION QTY.

1. SK2138700 KNOB ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2. SK2360700 DIAL INSERT °F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3. KE51005 RUBBER BOOT. #N9030 X 1/4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

4. SK2498399 POTENTIOMETER SHAFT ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

5. FA21006 NUT, S.S. F#10-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

6. FA32022 TOOTH LOCK WASHER #10 S.S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

7. FA40000-6 #10-24 X 3/8 S.S. WELD STUD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

8. SK50903-1 BRACKET, INDICATOR LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

9. SK50905-1 HEAT INDICATOR, 28V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

10. SK2142002 THERMOSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

11. SK2159300 THERMOSTAT INSULATOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

12. SK2491500 STOP PLATE ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

13. SK95063 CAUTION LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

14. SK90125-3 WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

15. KE95604-5 CONTROLS LABEL, MANUAL TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

16. SK2474102 SWITCH, ON/OFF/ON, DUAL FIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

17. SE003687 SWITCH ASSEMBLY REPLACEMENT KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

18. KE50579-2 CIRCUIT BREAKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

INCLUDES

INCLUDES

SK2360701 DIAL INSERT °C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2166800 POTENTIOMETER SHAFT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2167000 TENSION PIN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2167100 WASHER, BOWED/SPRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2167200 RETAINING RING, SP-NR #R1000-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

{

SK2167300 PANEL BEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

SK2382800 RETAINING RING CLIP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE95604-6 CONTROLS LABEL, POWER TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE603208-4 SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE603208-7 LATCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE603208-9 CONTACT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

{

KE603747 LABEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

FA05002-34 "O" RING, CIRCUIT BREAKER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

KE50580 WATER RESISTANT BOOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Page 32

15 10

19

11 12 9 12

1

15

16

13

18

13

17

12

7 8 14 20 16 15 6 13 5 13 18

SUPPORT PLATE ASSEMBLY

(for units built between August 2006 & June 2009)

ITEM NO. PART NO. DESCRIPTION QTY.

SUB-ASSEMBLIES -

KE002907-5 SUPPORT PLATE ASSEMBLY; MT, SGL-T1, 110-120V

KE002907-6 SUPPORT PLATE ASSEMBLY; PT, SGL-T1, 110-120V

KE002907-7 SUPPORT PLATE ASSEMBLY, MT, SGL-T1, 220-240V

KE002907-8 SUPPORT PLATE ASSEMBLY, PT, SGL-T1, 220-240V

COMPONENT PARTS -

1 KE602587 SUPPORT PLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

6 KE53444 BRACKET, TRANSFORMER MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

7 KE51139 FUSE HOLDER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

8 KE52936-8 FUSE 1.25 AMP, 250V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

11 KE602598 BRACKET, SWITCH MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

12 SK2474500 SWITCH, TILT LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1