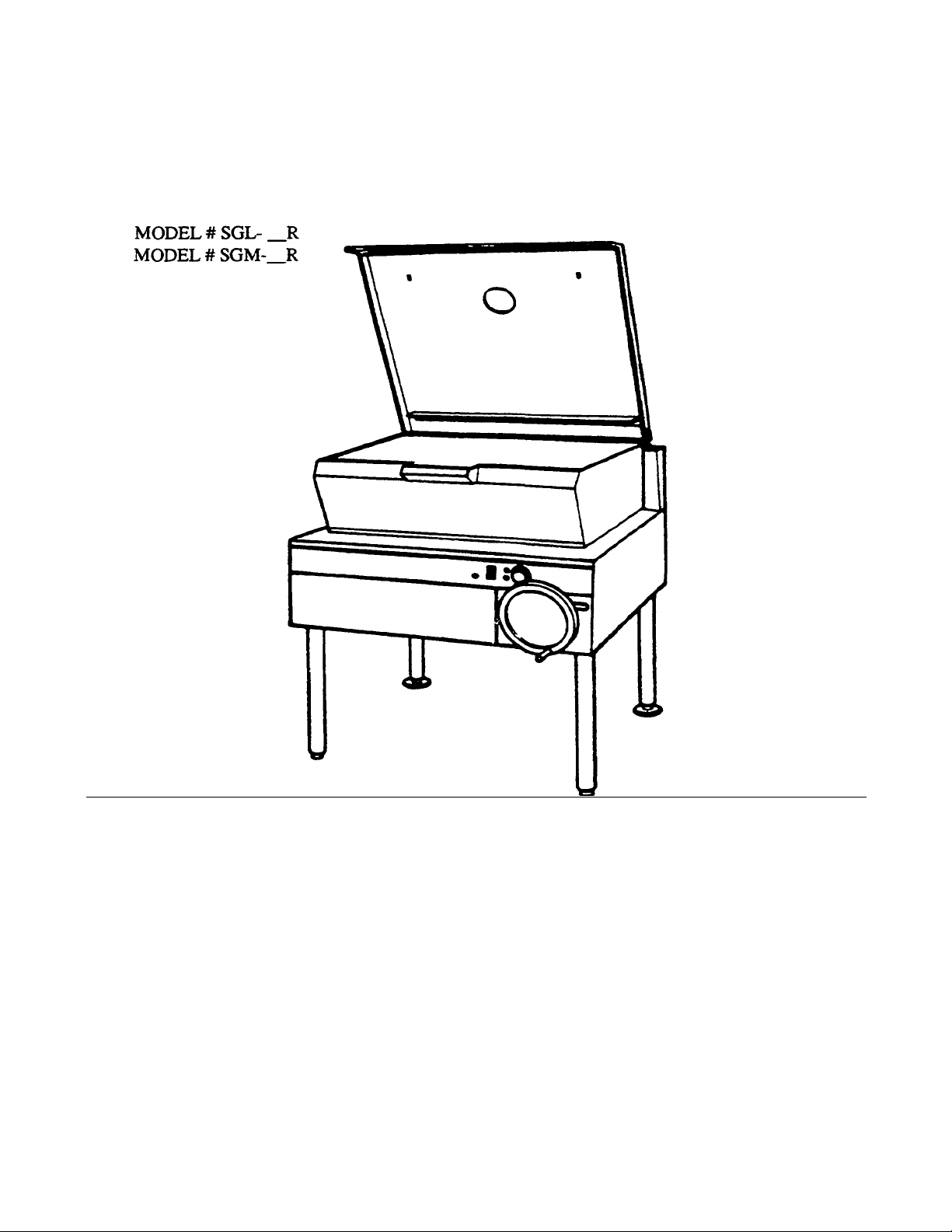

Page 1

INSTALLATION, OPERATION AND REPAIR MANUAL

SKI

-09

CLEVELAND RANGE COMPANY

1177 Kamato Rd.

Mississauga, Ontario

L4W1X4

Telephone: (905) 624-0260 Toll

Free Fax: 1-800-316-7745

P114-(Rev. 9/93)

CLEVELAND RANGE COMPANY

1333 East 179th St. Cleveland, Ohio

U.S.A. 44110

Telephone: (216) 481-4900

FAX: (216) 481-3782

Page 2

DON'T BE FOOLED BY

GENERIC PARTS

Short term savings could create a major expense.

Please read the following points:

* The use of generic parts will void existing warranties.

* Agency certifications such as CSA, ASME/Bd., CGA, AGA, etc. are based on equipment

using certified parts. The use of generic parts may conflict with certified specifications.

* The use of other than original manufacturer's authorized parts could invalidate possible

insurance claims.

* Cleveland Range cannot stand behind equipment that has been modified with generic

parts.

To ensure safe and dependable equipment, use only original manufacturer's authorized parts.

Please contact your AUTHORIZED SERVICE COMPANY for parts and service.

Use genuine CLEVELAND replacement parts.

Page 3

FOR YOUR SAFETY

WARNING

IMPROPER INSTALLATION, AD-

DO NOT STORE OR USE GASO LINE OR OTHER FLAMMABLE

VAPOURS OF LIQUIDS IN THE

JUSTMENT, ALTERATION, SERVICE OR MAINTENANCE CAN

CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE INSTALLATION, OPERATION AND

VICINITY OF THIS OR ANY

MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE IN-

OTHER APPLIANCE.

STALLING OR SERVICING THIS

EQUIPMENT.

IMPORTANT

THE FOLLOWING POINTS ARE TO ENSURE THE SAFE INSTALLATION AND OPERATION OF THIS

EQUIPMENT:

ENSURE ALL GAS AND ELECTRICAL SUPPLIES MARCH RATING PLATE

AND ELECTRICAL STICKERS.

OBSERVE ALL CLEARANCE REQUIREMENTS.

DISCONNECT THE ELECTRICAL POWER SUPPLY TO THE APPLIANCE BEFORE

CLEANING OR SERVICING UNIT.

ONLY QUALIFIED SERVICE TECHNICIANS SHOULD REPAIR THIS UNIT.

THE INSTALLATION AND CONNECTION MUST COMPLY WITH LOCAL CODES, OR IN THE ABSENCE

OF LOCAL CODES, WITH CAN/CGA-B149 INSTALLATION CODE OR WITH THE NATIONAL FUEL GAS

CODE, ANSI Z223.1 - LATEST EDITION.

POST IN A PROMINENT LOCATION, INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE USER

SMELLS GAS. THIS INFORMATION SHALL BE OBTAINED BY CONSULTING YOUR LOCAL GAS

SUPPLIER.

THE APPLIANCE AND ITS INDIVIDUAL SHUT OFF VALVE MUST BE DISCONNECTED FROM THE

GAS SUPPLY PIPING SYSTEM DURING ANY PRESSURE TESTING OF THAT SYSTEM AT TEST

PRESSURES IN EXCESS OF 1/2 PSIG. (3.45 KPA).

THE APPLIANCE MUST BE ISOLATED FROM THE GAS SUPPLY PIPING SYSTEM BY CLOSING ITS

INDIVIDUAL MANUAL SHUT OFF VALVE DURING ANY PRESSURE TESTING OF THE GAS SUPPLY

PIPING SYSTEM AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG. (3.45 KPA).

RETAIN THIS MANUAL FOR FUTURE REFERENCE.

-1 -

Page 4

GENERAL INFORMATION

The serial plate is located directly behind the upper

front panel (right side). For easy access, remove the 2

screws securing the upper front panel and hinge the

lower front panel downwards. Gas type, burner

ratings and electrical requirements are stated on the

Plate.

1. Damage Check: Check carton or crate for possible

damage incurred in shipping. After carefully

uncrating, check for 'concealed' damage. Report any

damage immediately to your carrier.

equipment on the same gas line is turned to the

'ON' position.

6. Make certain that new piping, joints and

connections have been made in a clean manner

and have been purged, so that piping compound,

chips, etc.. will not clog valves and/ or controls.

Use pipe joint sealant that is approved for use

with liquefied petroleum gas.

7. WARNING: Always check gas connections for

leaks using soap solution or similar means. DO

NOT CHECK WITH AN OPEN FLAME.

2. All units are protected with fuses which are located

inside the service box. For easy access, hinge front

panel downwards.

3. The correct type of gas for which the unit was

manufactured is noted on the rating plate, and this

type of gas must be used.

4. A pressure tap is supplied with each unit and is

installed on the manifold. The gas pressure must

be checked when unit is installed, to ensure unit

gas pressure is the same as specified on the rating

plate. For access to the pressure tap, remove front

panel, turn power switch to the 'OFF' position as a

precaution and hinge front panel downwards. The

pressure tap is located behind the front shield. If

necessary, pressure adjustments can be made at the

pressure regulator which is installed on the

manifold. For easy access to the pressure

regulator, view along left side of unit from

underneath. Once pressure test is completed, turn

power switch and thermostat to the 'OFF' position.

Raise lower front panel back into positio n.

5. Have a qualified gas technician check the gas

pressure to make certain that existing gas facilities

(meter, piping, etc.) will deliver the BTU's of gas

required at the unit with no more than 1/2" water

column pressure drop. When checking pressure, be

certain that all the

INSTALLATION CLEARANCES

This unit must be installed in accordance with the

following clearances in order to provide proper

operation and servicing of the appliance. Also. it is

recommended that unit be installed with sufficient

clearances to provide for proper cleaning and

maintenance. Minimum clearances are 0" for the sides

and 6" (152mm) from back to adjacent combustible

walls. Zero clearance is required from noncombustible surfaces. Certified for installation on

combustible floor.

INSTALLATION INSTRUCTIONS

1. Carefully remove unit from carton or crate. Remove

any packing material from unit.

2. A protective material has been applied to the

stainless steel panels.

NOTE: This material must be removed

immediately after installation, as heat will melt the

material and make it difficult to remove.

3. These units must be installed under an adequate

ventilation system. Refer to the sections titled

VENTILATION and AIR SUPPLY for further

instructions.

4. Comply with clearances stated on the specification

sheet. Ensure there is sufficient

-2-

Page 5

clearance between skillet and back wall. Check

for overhead clearance to accommodate for

hinged cover when in the raised position.

5. Level skillet by means of adjustable stainless steel

feet. Use a spirit level and level unit four ways;

across front and back and down left and right

edges. Securely anchor the adjustable feet to the

floor and seal joints with a silicone sealant.

6. FOR YOUR SAFETY: Keep the appliance area

free and clear of combustible materials.

ELECTRICAL CONNECTION

A cord and plug is supplied on each unit, 120 volts,

single phase, 1.0 amps.

WARNING Electrical Grounding

Instructions

This appliance is equipped with a three prong

(grounding) plug for your protection against shock

hazard and should be plugged directly into a properly

grounded three prong receptacle. Do not cut or

remove the grounding prong from this plug.

IMPORTANT: This appliance must be electrically

grounded in full accordance with local codes, or in

the absence of local codes, wit h the Canadian

Electrical Code C22. 1 or with the National Electrical

Code, ANSI/NFPA No. 70-latest edition (whichever

is applicable).

GAS CONNECTION

A 3/4" NPT gas connection is required along the left

side of the unit.

It is recommended the a sediment trap (drip leg) be

installed in the gas supply line. If the gas pressure

exceeds 14" water column, a pressure regulator must

be installed, to provid e a maximum of 14" water

column gas pressure to the gas control valve.

Connect the gas supply piping to the input side of the

gas control valve. Location and pressure data are

shown on the specification sheet. Installation must be

in accordance with local codes and/or the National

Fuel Gas Code ANSI Z233.1 -latest edition (USA) or

Installation Codes for Gas Burning Appliances and

Equipment CAN/CGA -B 149.1 and B 149.2

(Canada). Use a gas pipe joint compound which is

resistant to L.P. gas. Test all pipe joints for leaks with

soap and water solution. Ensure that the gas pressure

regulator is set for the manifold pressure indicated on

the gas rating plate.

A separate 15 amp service must be provided. For

120V usage, each skillet is electrically equipped with

a cord set with a three prong plug which fits any

standard 120 volt three prong grounded receptacle.

When a unit is ordered and built for 208/240 volt, the

supply line must be connected to the wiring

terminations located inside the terminal box. For ease

in attaching the supply line , there is a removable

cover on the terminal box. A wiring diagram is

attached to the rear panel of each unit

-3-

WATER CONNECTIONS (OPTIONAL)

A 3/8" NPT cold wate r line and a 3/8" NPT hot water

line are required for the fill faucet.

VENTILATION

A gas skillet must be installed in a location in which

the facilities for ventilation permit satisfactorycombustion of gas and proper venting. Proper ven-

Page 6

tilation is imperative for good operation of the appliance. The ideal method of ventilating a gas skillet is

the use of a properly designed ventilating canopy,

which should extend at least 6" (152mm) beyond all

sides of the appliance (except against a wall, if the

canopy is a wall installation). This is usually part of a

mechanical exhaust system.

1. Turn the main manual gas valve to the 'ON'

position.

2. Turn power switch to the 'ON' position.

3. Set thermostat to desired temperature.

Further information can be obtained by referring to the

U.S.A. National Fire Protection Association's NFPA96

regulations. These standards have also been adopte d

by the National Building Code in Canada.

AIR SUPPLY

1. Appliances shall be located so as not to interfere

with proper circulation of air within the confined

space. All gas burners require sufficient air to

operate.

2. Large objects should not be placed in front of the

appliance which might obstruct the air flow

through the front. Do not obstruct the flow of

combustion and ventilation air.

3. Do not permit fans to blow directly at the appliance

and wherever possible avoid open windows

adjacent to the appliance sides and back; also wall

type fans which create air cross-currents within the

room.

START UP PROCEDURE

This appliance has been factory tested and adjusted

under ideal conditions but, rough handling, low gas

pressure, altitude or variations in gas cha racteristics

may require fine adjustment.

All units are equipped with fixed orifices and do not

require primary air adjustment.

LIGHTING INSTRUCTIONS

4. If ignition fails and/or the control system goes into

lockout set pow er switch to the 'OFF" position.

5. Wait 5 minutes then repeat steps 1 through 3. If the

problem persists, have a qualified serviceman

check the system.

6. To shutdown system, turn power switch and main

manual gas valve to the 'OFF position.

OPERATING INSTRUCTIONS

1. Ensure gas and electrical supply to the appliance are

in the 'ON' position.

2. Turn power switch to the 'ON' position. The green

pilot light will indicate power is on. Wait one

minute to allow flame sensor to heat up.

3. PowerTilt

Cleveland skillets are equipped with an electric

power tilt mechanism for raising and lowering the

frypan. To raise frypan, raise the cover and press

up on the tilt switch. To lower frypan, press down

on the tilt switch.

Manual Tilt

Cleveland skillets can also be equip ped with the

optional manual tilt mechanism for raising and

lowering the frypan. To raise frypan, raise the

cover and turn the wheel clockwise. To lower

frypan, push in on the lever located behind the

wheel.

NOTE: This appliance is equipped with a direct spark

ignition system. Ensure gas and electrical supply to the

appliance, are in the 'ON' position.

4. FOR YOUR SAFETY, this skillet is also equippe d

with a power interrupter which automatically

shuts off the gas supply to the

-4-

Page 7

burners whenever the skillet is raised more than

1/2" (13mm).

MAINTENANCE INSTRUCTIONS

IMPORTANT: Before commencing to cook,

ensure frypan is in the lowered position by

pressing down on the tilt switch. Ensure cover is

raised first.

5. To preheat, set thermostat to desired cooking

temperature. The amber pilot light will cycle on

and off with the thermostat.

6. Allow skillet to preheat for approximately 15-30

minutes.

7. Once preheated, insert product in skillet and adjust

thermostat to required cooking temperature.

8. If desired, once product has cooked, it can be held

prior to serving at a lower temperature setting.

9. When cooking is completed, set thermostat and

power switch to the 'OFF position.

10. The best time to clean the skillet is immediately

after use, once skillet has cooled down. Refer to

section titled CLEANING INSTRUCTIONS.

NOTE: ANY MAINTENANCE OR SERVICE INVOLVING DISSASSEMBLY OF COMPONENTS

SHOULD BE MADE BY A QUALIFIED SERVICE

TECHNICIAN. ENSURE GAS, ELECTRICAL AND

WATER SUPPLY (IF APPLICABLE) TO THE

APPLIANCE ARE SHUT OFF.

You have purchased the finest commercial cooking

equipment available anywhere. Like any other fine,

precision built piece of equipment it should be given

regular care and maintenance.

Periodic inspections by your dealer or a qualified

service agency are recommended to check temperatures, adjustments and ensure moving parts are

operative. Whenever possible, avoid overheating idle

equipment as this us the primary cause for increased

service costs.

When corresponding with the factory or your

equipment dealer regarding service problems or

replacement parts, be sure to refer to the particular

unit by the correct model number (including prefix

and suffix letters and numbers) and the serial or code

number. The rating plate affixed to the unit contains

this information.

OPERATING SUGGESTIONS

1. Turn power switch to the 'OFF' position when

skillet is not in use.

2. Clean skillet as soon as possible after cooking.

3. Allow skillet to preheat before adding product.

4. Always lift the spring assist cover before activating

the tilt mechanism.

5. During an electrical power interruption, turn power

switch to the ‘Off’ position. This unit cannot be made

to operate without electrical power.

"REGULAR MAINTENANCE ENSURES PEAK

PERFORMANCE".

CLEANING INSTRUCTIONS

A regular daily cleaning program should be followed

to maintain your skillet's efficient perfor mance and

minimize service calls. At the end of each day's

operation, the following steps are recommended:

1. Turn power switch to the 'OFF' position.

2. Skillet should be cleaned after each use, as soon as

possible after cooking. CAUTION: Ensure skillet

has cooled down.

-5-

Page 8

For general purpose cleaning, use a soft cloth

with mild detergent and warm water. A sponge,

non-abrasive scouring pad or a fibre brush can

also be used for this purpose.

steel finish of the frypan. After cooking of such

products, clean frypan interior with a baking soda

and water solution. Use one tablespoon of baking

soda per one gallon of water.

To remove grease that has baked on, apply a nonabrasive cleanser to a damp cloth or sponge and

rub cleanser on the metal in the direction of the

polishing lines of the metal. NEVER RUB IN A

CIRCULAR MOTION. Soil or burnt deposits

which do not respond can usually be removed by

rubbing the surface with Scotch-Brite scouring

pads or stainless scouring pads. DO NOT USE

ORDINARY STEEL WOOL.

Do not use grill stones. Heat tint can be removed

by a vigorous scouring in the direction of the

polish lines using Scotch-Brite scouring pads or a

stainless scouring pad in combination with a nonabrasive cleanser.

Tomato and vinegar based products have a high

acid content which could attack the stainless

7. After cleaning, the skillet should be thoroughly

rinsed with clean water and dried.

TILT MECHANISM LUBRICATION

The linear actuator (power tilt models), the hydraulic

cylinder (manual tilt) and the bronze bushings are all

self-lubricating and require no lubrication.

CALIBRATION INSTRUCTIONS

IMPORTANT: DO NOT ATTEMPT TO CALIBRATE THE THERMOSTAT.

The electronic thermostat supplied with this skillet

has been precisely calibrated at the factory and should

not require field calib ration.

-6-

Page 9

ACTUATOR

Item Part No. Description Qty.

1 2346100 Actuator 1

2 2337499 Actuator Mounting Bracket Assy 1

3 2357500 Sleeve Bearing 1

4 2376500 Actuator Pin (Front) 1

5 2376502 Retaining Ring 4

6 2376501 Actuator Pin (Rear) 1

7 2357400 Flange Bearing 2

Page 10

Page 11

BURNER BOX ASSEMBLY

Item Part No. Description Qty.

1 2359300 Back Top Mounting Bracket 2

2 2360101 Rear Combustion Seal - 40 Gal. 1

2360100 Rear Combustion Seal - 30 Gal. 1

3 2342400 Burner Rest - 40 Gal. 1

2342300 Burner Rest - 30 Gal. 1

4 071497-1-9 Inside Hinge Cover 2

5 2342602 Burner Tie Down - 40 Gal. 2

2342600 Burner Tie Down R/H - 30 Gal. 1

2342601 Burner Tie Down L/H - 30 Gal. 1

6 2360001 Secondary Burner Rest R/H - 40 Gal. 1

2360000 Secondary Burner Rest L/H - 40 Gal. 1

2359900 Secondary Burner Rest R/H - 30 Gal. 1

2359800 Secondary Burner Rest L/ H - 30 Gal. 1

7 2347800 Front Shield - 40 Gal. 1

2347900 Front Shield - 30 Gal. 1

8 2342200 Burner Pan - 40 Gal. 1

2342100 Burner Pan - 30 Gal- 1

9 2346900 Ignitor Mounting Bracket 1

10 2346500 Radiation Shield A - 40 Gal. 1

2346600 Radiation Shield B - 40 Gal. 1

2346700 Radiation Shield C - 30 Gal. 1

2346800 Radiation Shield D - 30 Gal. 1

Page 12

Page 13

COMPONENT BOX

Item

2 1427305 Capacitor 1

3 2282100 Capicitor Clamp 1

4 1426600 Resistor 1

5 077145-2 Rectifier 1

6 2320702 Fuse Holder 1

7 2346300 Fuse 2.5A MDL 115V Power Tilt 1

8 2346302 Fuse 15A MDA Power Tilt Only 1

9 2346301 Fuse 1.25A AGC 1

10 2147403 Liquid-Tight Fitting 1

11 2147400 Liquid-Tight Fitting 2

12 2147401 Liquid-Tight Fitting 1

13 2361500 Liquid-Tight Fitting 1

14 2329100 Ignition Module 1

15 050069 Terminal Block - Junction 8

16 050070 Terminal End 1

17 2361700 Liquid-Tight Conduit 1

18 2348100 Sealed Switch 1

19 2383300 Cover Gasket 1

Part No. Description Qty.

2075700 Transformer - Power Tilt - 240V Dom. 1

077190-2 Transformer - Power Tilt - 208V Exp. 1

077190-4 Transformer - Power Tilt - 220V Exp. 1

077190-2 Transformer - Power Tilt - 240V Exp. 1

G03559-1 Transformer - Hand Tilt - 115V 1

2283700 Transformer - Hand Tilt - 208/240V 1

2346303 Fuse 1 -5A MDL 208/240V Power Tilt 1

2346304 Fuse .5A AGC 115V Hand Tilt 1

2346305 Fuse .25A AGC 208/240V Hand Tilt 1

Terminal Block - Line 2

Page 14

HAND TILT

Item Part No. Description Qty.

*1 2381000 Hydraulic Cylinder 1

*2 2388400 "0" Ring 1

*3 2388300 "U" Cup 3

*4 2388500 Top Bearing 1

5 2376502 Retaining Ring 4

6 2376500 Actuator Pin (Front) 1

7 2357500 Sleeve Bearing 1

8 2376501 Actuator Pin (Rear) 1

9 2357400 Flange Bearing 2

* - Part No.'s 1, 2, 3, 4 purhased as assembly 2381000

Page 15

Item Part No. Description Qty.

1 F424 Lock Nut 1/2-13 S.S. 2

2 F257 Lock Washer 1/2-13 S.S. 2

3 078248-1 Spacer 2

4 G02925-2 Bushing 2

5 F59 Bolt 1/2-13 x 3/4" 2

6 F183 Truss Head Screw 8-32 x 1 S.S. 1

7 F237 Hex Nut 8-32 S.S. 1

8 2354199 Striker Plate Assy 1

9 F359 Set Screw 1/2-13x1-3/4 1

10 F358 Hex Jam Nut 1/2-13 1

11 F246 Hex Nut 1/2-13 S.S. 1

PAN HINGE

Page 16

Page 17

HYDRAULIC TILT ASSEMBLY

Item Part No. Description Qty.

1 2379100 Hydraulic Adaptor 2

2 2379600 Hydraulic Hose Assy 1

3

2379501 Hydraulic Hose Assy 30 Gal. 1

4 2379500 Hydraulic Hose Assy 1

5 2379000 Hydraulic Adaptor 1

6 2379001 Hydraulic Adaptor 1

7 2378901 Tee F/M/M 1

8 2379400 Check Valve 1

9 2379300 Ball Valve c/w Handle and Nut 1

10 2382700 Valve Return Spring 1

11 2378900 Tee M/F/M 1

12 2375699 Oil Tank Assy 1

13 2250700 Plug (Drilled) 1

14 2376200 Link Rod 1

15 078279-1 Ball Knob 1

16 F430 Hitch Pin 1

17 2379201 "0" Ring Boss 90° 1

18 2379203 "0" Ring .644" 1

19 2379200 "0" Ring Boss 1

20 2379202 "0" Ring .468" 1

21 2378800 Hydraulic Pump 1

22 078072-6P Handwheel 1

23 078108-1P Revolving H andle 1

24 F212 Hex Screw 1

25 02973-4 Heyco Plug 1

Page 18

Page 19

MANIFOLD ASSY

Item Part No. Description Qty.

1 076129-1 Burner - 40 Gal. 10

2 03056 Orifice Fitting (Specify Gas) - 40 Gal. 10

3 1415200 Spark Electrode 1

4 2363599 Nipple Plate Assy 1

5 G01518-1 Shut-Off Valve 1

6 G01738-14 Nipple 3/4" NPT 2

7 2127502 Gas Regulator - Natural 1

8 G01918-5 NPT Bushing 3/4" x 1/2" 1

9 1004642 Nipple 1/2" NPT x 2" 2

10 2361500 Liquid-Tight Fitting 1

11 2345700 Gas Solenoid 1

12 G01474-9 Elbow 90° 3/4" x 1/2" 1

13 1026905 Union 3/4" NPT 1

14 2339799 Manifold - 40 Gal. 1

2127500 Gas Regulator - LP 1

Burner - 30 Gal. 7

Orifice Fitting (Specify Gas) - 30 Gal. 7

Page 20

Page 21

CONTROL PANEL

Item Part No. Description Qty.

1 2343500 Power Switch 1

2 2343501 Tilt Switch (Power Tilt Only) 1

3 2138700 Dial 1

4 2360701 Dial Insert °C 1

5 23480 Graphic Overlay (Specify Model) 1

6 23561 Indicator Light - Green (Specify Voltage) 1

7 2356102 Indicator Light - Amber 1

8 2142002 Electronic Thermostat 1

9 050069 Terminal Block 8

10 F419 Sealer Washer 4

11 2147403 Liquid-Tight Fitting 5/8" 1

12 2147402 Liquid-Tight Fitting 3/8" 1

13 2147401 Liquid-Tight Fitting 5/16" (Power Tilt Only) 1

14 2147400 Liquid-Tight Fitting 3/16" 1

15 2352899 Control Box Assy - Power Tilt 1

16 2353100 Control Box Cover 1

17 2383200 Control Cover Gasket 1

18 2357900 Neoprene Gasket 1

19 2300600 High Limit 1

2360700 Dial Insert °F 1

050070 Terminal End 1

2352898 Control Box Assy - Hand Tilt 1

Page 22

SPRING ASSY

Item

2 2381700 Tumbuckle Body 2

3 2374900 Connecting Rod R/H Thread 1

4 2372799 Bell Crank Assy R/H 1

5 F299 Bolt 1/4-20 x 1/2" Shoulder 2

6 F112 Flat Washer 3/8" I.D. 4

7 F255 Lock Washer 1/4" I.D. 2

8 F239 Nut 1/4-20 S.S. 2

9 2372400 Bell Crank Hook 2

Part No. Description Qty.

2374901 Connecting Rod L/H Thread 1

2372798 Bell Crank Assy L/H 1

Page 23

SHAFT ASSY

Item Part No. Description Qty.

1 2142002 Electronic Thermostat 1

2 2159300 Insulator - Thermostat 1

3 2167000 Spring Tension Pin 1

4 2166800 Potentiometer Shaft 1

5 2167200 Retaining Ring 1

6 2167100 Bowed Spring Washer 1

7 2167300 Panel Bearing Assy 1

8 2382800 Retaining Spring 1

9 2166900 Stop Plate 1

10 2358600 Stop Plate Spacer 1

11 2358200 Rotary Shaft Seal 1

12 F419 Sealer Washer 2

13 F163 Screw 6-32 x 3/8 2

Page 24

PLATE

Item Part No. Description Qty.

1 2300600 Hi-Limit 1

2 2353900 Bulb Clamp 1

3 2354099 Bulb Shield Assy 1

4 F95 Nut 1

5 2345100 RTD Sensor 1

6 2344900 Shield Liner 1

7 2345000 Shield 1

Page 25

LOADING

NOMINAL AMPS PER LINE

TOTAL

LOADING

- HT(L,M)R

24

.21 .12 .11 .10 -

40HTR

24 ,21 .12 .11 .10

SERIAL N

O

. TO

WATTS

- HT(L,M)R 24

X-Y Y-Z X-Z 115 208 220 240

.21 .12 .11 .10

1 PHASE

- 30HTR 24

DESCRIPTION DR. DATE REV. #

REVISIONS

CABLE 16 SO90 C X

34 18 TEW X ORANGE 12 1

33 18 TEW X BLUE 12 1

32 18 TEW X BLUE 9 1

31

30

29

28

27 18 TEW X BLAC

26 18 TEW X WHIT

25 16 TEW X RED 10 1

24 16 TEW X RED 10 1

No GA.

TEW X BLUE • 11 1 220-240V EXP.

TEW X BLAC

TYPE SOLID

STRAND

DATE

COLOR LENGTH QTY

.21 .12 .11 .10

23

45,5

11 1

11 1 208-240V DOM.

11 1 115V 2 16 TEW X WHITE 18 1

8 18 TEW- -X ORANGE .26 1

NOTE: ALL WIRES ARE STRANDED TYPE

USE FROM

MODEL NO: F30, 40G-HTL,MR SGHTL,M-30,40R 115/208/220/240V

22 20 TFE X OR(IGN.) 30 1

21 16 TGS • X WHT/BLK 30 1

20

18A

18 16 TEW X GREEN 38 1

17

16

15

14 18 TILT ITERUPTER CABLE WHITE

13

12

11 16 TEW X BLACK 26 1

10

9 18 TEW X GREEN 9 1

7 18 TILT IITERUPTER CABLE BLACK

6 18 TEW X BROWN 26 1

5

4

3 16 TEW X BLACK 18 1

2A 16 TEW X WHITE 18 1

1A 16 TEW X RED 18 1

1 16 TEW X RED 18 1

NO GA, TYPE SOLID

TEW X BLACK 18 1

TEW X BLUE 18 1

TEW X BLUE 18 1

TEW X BLACK 18 1

STRAND

COLOR TG3/TG4

LENGTH

208-240V DOM.

220-240V EXP,

115V

220-240V EXP.

208-240V DOM.

115V

ON

2374401

DR:

Page 26

2574401

MODEL: F30,40 G-HTL, MR

SGL.M-30, 40HTR

Loading...

Loading...