Cleveland SD-1200-K612 Installation Manual

SE95008 Rev. 6

Operators Manual

Table-Top Direct

Steam Kettles

MODELS: KDT- 1- T

KDT- 3- T

KDT- 6- T

KDT-12- T

KDT-20- T

SD Stands

MODELS: SD- 450

SD- 650

SD- 760

SD-1050

SD-1200

SD-1600

SD-1800

Kettles on

SD Stands

MODELS: SD-450 - K 6

SD-650 - K12

SD-760 - K12

SD-760 - K20

SD-1050- K 6 6

SD-1200- K 6 12

SD-1600- K 6 20

SD-1600- K 12 12

SD-1600- K 12 20

SD-1600- K 20 20

1333 East 179th St., Cleveland, Ohio, U.S.A. 44110

Phone: (216) 481-4900 Fax: (216) 481-3782

Visit our web site at www.clevelandrange.com

d

Enodis

For a complete Service Manual

refer to www.clevelandrange.com

Direct Steam Table Top Kettles

Installation & Operation

™

Clev elan

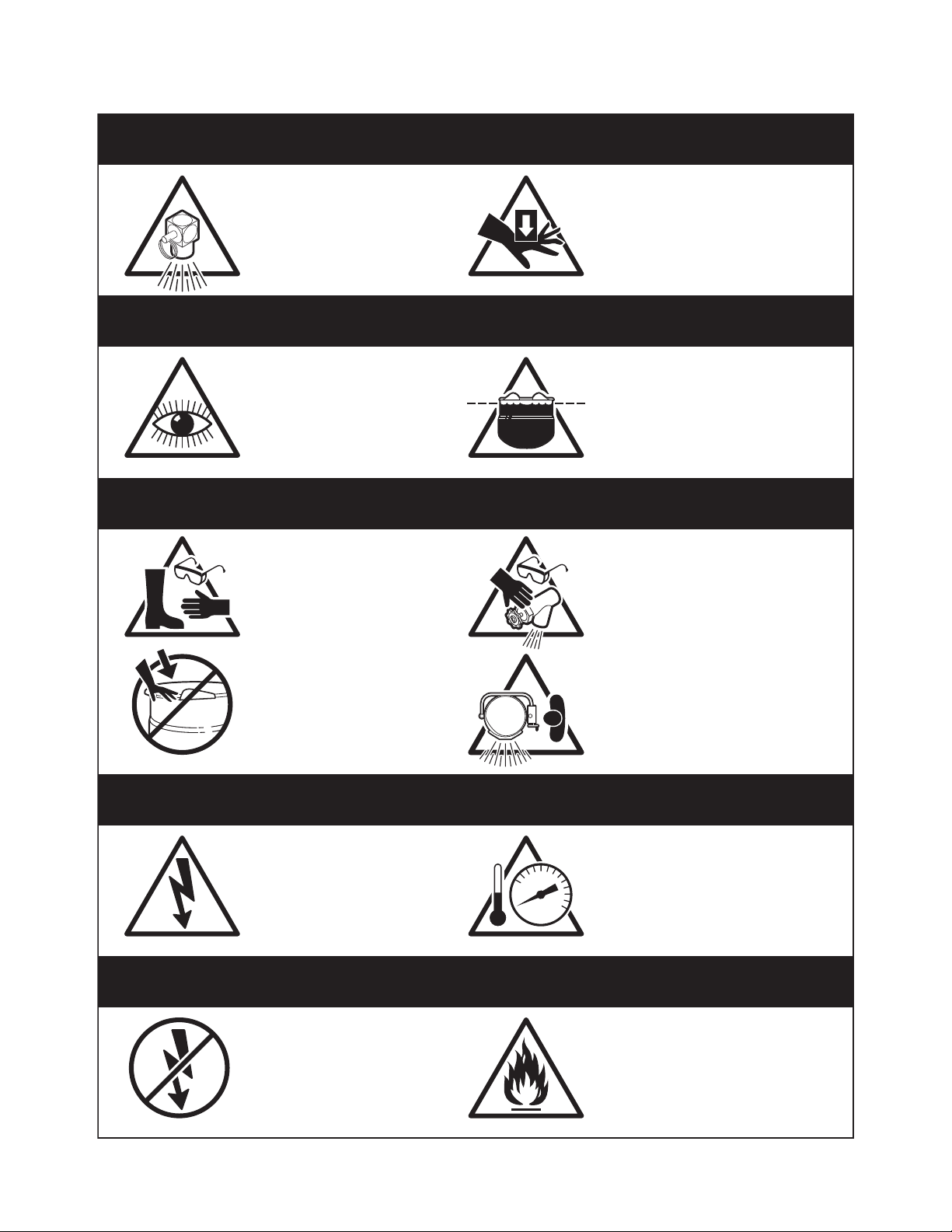

For your safety

DANGER

Keep clear of pressure

relief discharge.

IMPORTANT

Inspect unit daily for

proper operation.

CAUTION

Surfaces may be

extremely hot! Use

protective equipment.

Keep hands away from

moving parts and pinch points.

Do not fill kettle above

recommended level

marked on outside of kettle.

Wear protective equipment

when discharging hot product.

Do not lean on or place

objects on kettle lip.

SERVICING

Shut off power at main

fuse disconnect prior

to servicing.

GAS APPLIANCES

Do not attempt to operate

this appliance during a

power failure.

Stand clear of product

discharge path when

discharging hot product.

Ensure kettle is at room

0

temperature and pressure

gauge is showing zero or less

prior to removing any fittings.

Keep appliance and area free

and clear of combustibles.

GENERAL

Installation of the unit must be accomplished by

qualified installation personnel working to all

applicable local and national codes. Improper

installation of product could cause injury or damage.

This unit is built to comply with applicable

standards for manufacturers. Included among

those approval agencies are: UL, NSF,

ASME/Ntl.Bd., CSA, ETL, CE, and others. Many

local codes exist, and it is the responsibility of the

owner/installer to comply with these codes.

INSPECTION

Before uncrating, visually inspect the unit for

evidence of damage during shipping. If damage

is noticed, do not unpack the unit, follow shipping

damage instructions.

SHIPPING DAMAGE

INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or the

reason for suspecting damage as soon as it is

discovered. This will help in filling out the claim

forms later. If possible, take a polaroid picture.

2. As soon as damage is discovered or suspected,

notify the carrier that delivered the shipment.

3. Arrange for the carrier's representative to

examine the damage.

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

CLEARANCE REQUIREMENTS

The first installation step is to refer to the

SPECIFICATION DRAWINGS at the back of this manual

in order to determine the exact location of the kettle.

CLEARANCE REQUIREMENTS TO

COMBUSTIBLE AND NONCOMBUSTIBLE

SURFACES:

RIGHT LEFT BACK

KDT-1-T 4" 0" 0"

KDT-3-T & KDT-6-T 4" 4" 1"

KDT-12-T & KDT-20-T 4" 4" 1.75"

Note: For SD Stands (with or without kettles) zero

clearance is required on the sides and back.

KETTLES

Table-top models must be positioned on a firm stand

or existing counter top and secured in place. An

optional modular cabinet base (SD Stand), with

level-adjustable legs is available .

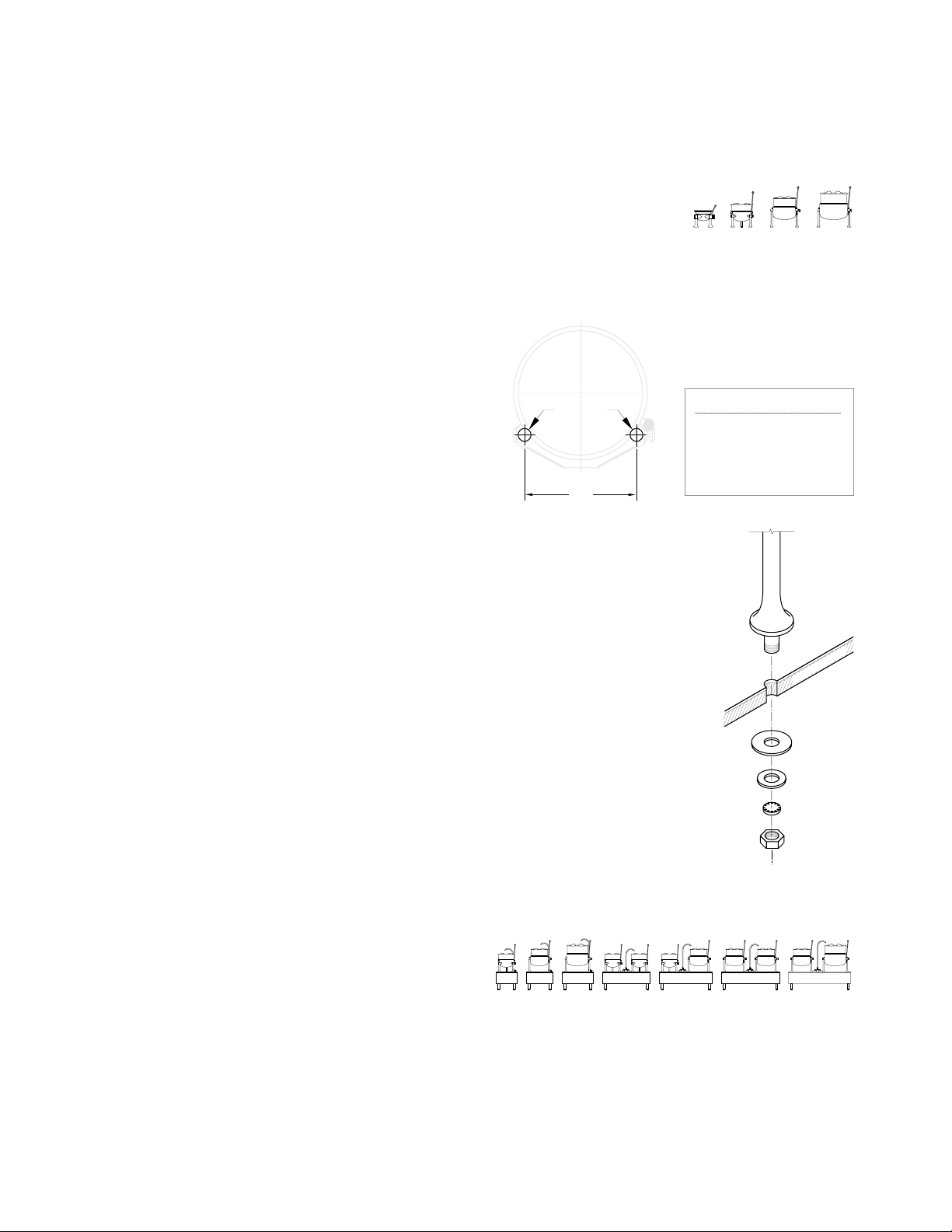

1. Make two 1" holes for

the kettle legs.

2. Remove the leg mounting

locknuts and washers from

the kettle's legs.

3. Install the legs into the two

1" holes.

4. Position washers as

illustrated and secure

the kettle to its' base by

refastening the locknut

from underneath the

cabinet or countertop.

5. Once the kettle is secure,

screw the tilt handle into

the mounting block welded

to the side of the kettle.

6. Install service requirements

as required.

KETTLES c/w SD STAND

1. Place unit in desired location.

2. Place a carpenter's level on the kettle rim and

level the stand using the level adjustable feet.

3. Install service requirements as required.

INSTALLATION

A

KDT-1-T 8 1/8"

KDT-3-T 10"

KDT-6-T 12"

KDT-12-T 19 1/2"

KDT-20-T 23 3/4"

DRILL TWO

1" HOLES

A

COUNTERTOP

STEAM

All steam plumbing to and from the kettle and

steam boiler should be thoroughly cleaned and

inspected for dirt and debris before final

connection to the kettle are made.

Generally, kettles require 1/2" i.p.s. pipe, 10-45 psi

steam pressure. If the steam supply pressure

exceeds 45 psi, a pressure reducing valve is

required. The steam inlet is at the right side of the

kettle, as n from the front.

A pressure reducing valve is required on the

incoming line as shown below. The relief valve

should have a capacity of 300 lb/hr (136 kg/hr).

CONDENSATE (Kettles without SD Stands)

Maximum pressure rating on table-top kettles is

50psi. It is highly recommended that a pressure relief

valve equal to or less than this pressure be installed

on the incoming steam line close to the kettle.

A steam condensate trap must be plumbed to a drain,

using minimum 1/2" NPT plumbing. The condensate line

is limited to a maximum rise of 10 feet in order for the

steam pressure to adequately force the condensate

through the plumbing. Any higher rise requires a pump.

If the steam boiler to which this kettle is installed has a

condensate return (closed loop system), a 1/2" steam

strainer, a 1/2" steam trap, and a 1/2" check valve must

be installed on the output (condensate) side of the kettle.

CONDENSATE (Kettles c/w SD Stands)

The stand comes factory plumbed so the condensate

is connected to the stands drain manifold.

POTABLE WATER

The water faucet (optional on kettles purchased

without SD stands) with swing spout, requires 1/2

inch O.D. copper tube plumbing for hot or cold water

supplies to the faucet (SPK - cold water connection

only, DPK - hot and cold water connection).

FINAL INSTALLATION CHECK

1. Partially fill the kettle with water.

2. Slowly turn the steam supply valve's knob to

the open position.

3. Release the safety valve, ensuring that the

steam escapes freely. Stay clear of steam

exhaust when releasing the safety valve.

4.

Observe that the water in the kettle comes to a boil.

5. Close the steam supply valve.

6. Drain off the water by tilting the kettle.

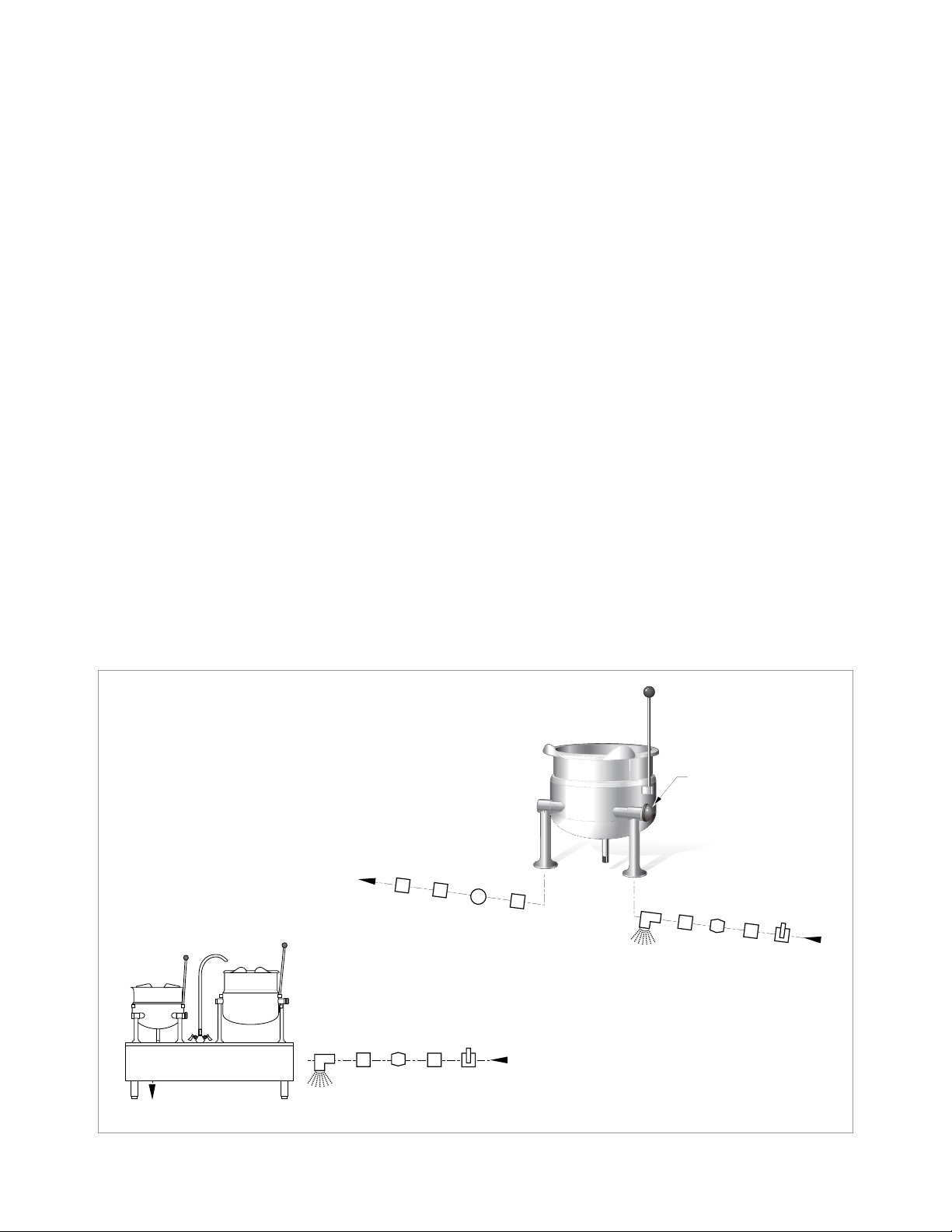

KETTLES

RECOMMENDED PIPING

SCHEMATICS

(all service connections shown supplied by others)

KETTLES c/w

SD STANDS

TO DRAIN OR BOILER

CONDENSATE LINE

RELIEF

VALVE

STRAINER

TO DRAIN (CONDENSATE RETURN PLUMBED TO 1 1/2" DRAIN MANIFOLD)

CONDENSATE RETURN

UNION

CHECK

PRESSURE

REDUCING

VALVE

UNION

VALVE

STEAM

TRAP

SHUT OFF

VALVE

STRAINER

STEAM

MANUAL

STEAM

VALVE

STRAINER

RELIEF

VALVE

IN

PRESSURE

REDUCING

VALVE

UNION

STEAM

SHUT OFF

VALVE

IN

Loading...

Loading...