Cleveland PDM Owner’s Manual

Installation,Operation&MaintenanceManual

PRESSURESTEAMERS

SERIES:PGM,PEM,PSM,PDM,PDL-2/3

260APC-A

Operator’s Manual P/N-260APC-A

Table of Contents

INSTALLATION 3

Correct Installation 3

Water Quality 3

Drain Line Connection 4

Installation Safety 4

Installation Instructions 5

Installation checks 5

Gauge Pressure Reading with No Steam Flow* (Static Pressure) 7

OPERATION 7

Controls and Controls Panels 7

Steam Generator Controls 7

Start-up and Preheat 8

Cooking Operations 8

Startup and Preheat 9

Cooking Operation 9

Boiler Shutdown 9

Care and Cleaning 9

MAINTENANCE 10

Preventative Maintenance-Descaling Instructions 11

TROUBLESHOOTING 15

Operators Troubleshooting Guide 16

Troubleshooting Notes 16

PRESSURE STEAMER COOKING INFORMATION 17

______________________________________________________________________________

2

Operator’s Manual P/N-260APC-A

Installation

CORRECT INSTALLATION

You have purchased the finest Steam Cooking Equipment

made. The following information we know will increase the

productivity and life span of the equipment.

Every product needs proper installation and with a

steamer it is critical. The following is some important

information you should check on before and during

installation of the equipment.

Water

The quality of water you put into the steam generator is

important. Poor quality water will create generator problems.

Water is no longer just plain and simple. Water has many

natural ingredients in it. These are called Total Dissolved

Solids, or TDS. This includes calcium, iron, and other

minerals in the water that collect in the steam generator

Because of the droughts in many areas, water and TDS's

are being pumped up from the bottom of the water

systems. If these TDS are not pre-filtered out or cleaned

out with a regular preventive maintenance program, your

steam generator could deteriorate and develop holes.

CHLORIDE is another chemical in our water creating

many problems with all steam generators. When the generator creates steam from the water it also carries the

chloride gas with it. These chlorides begin to eat away the

inside of the generator and follow the steam into the

compartments causing a rusting action (oxidation) as it

goes along.

A CARBON OR CHARCOAL FILTER must be installed on

the incoming water line to the steamer if the chlorine is

over 30 parts per million. These filters will remove the

chloride.

The WATER QUALITY REQUIREMENTS for your

STEAMER are as follows:

Total Dissolved Solids less than 60 parts per million

Total Alkalinity less than 20 parts per million

Silica less than 13 parts per million

Chlorides less than 30 parts per million

pH Factor greater than 7.5

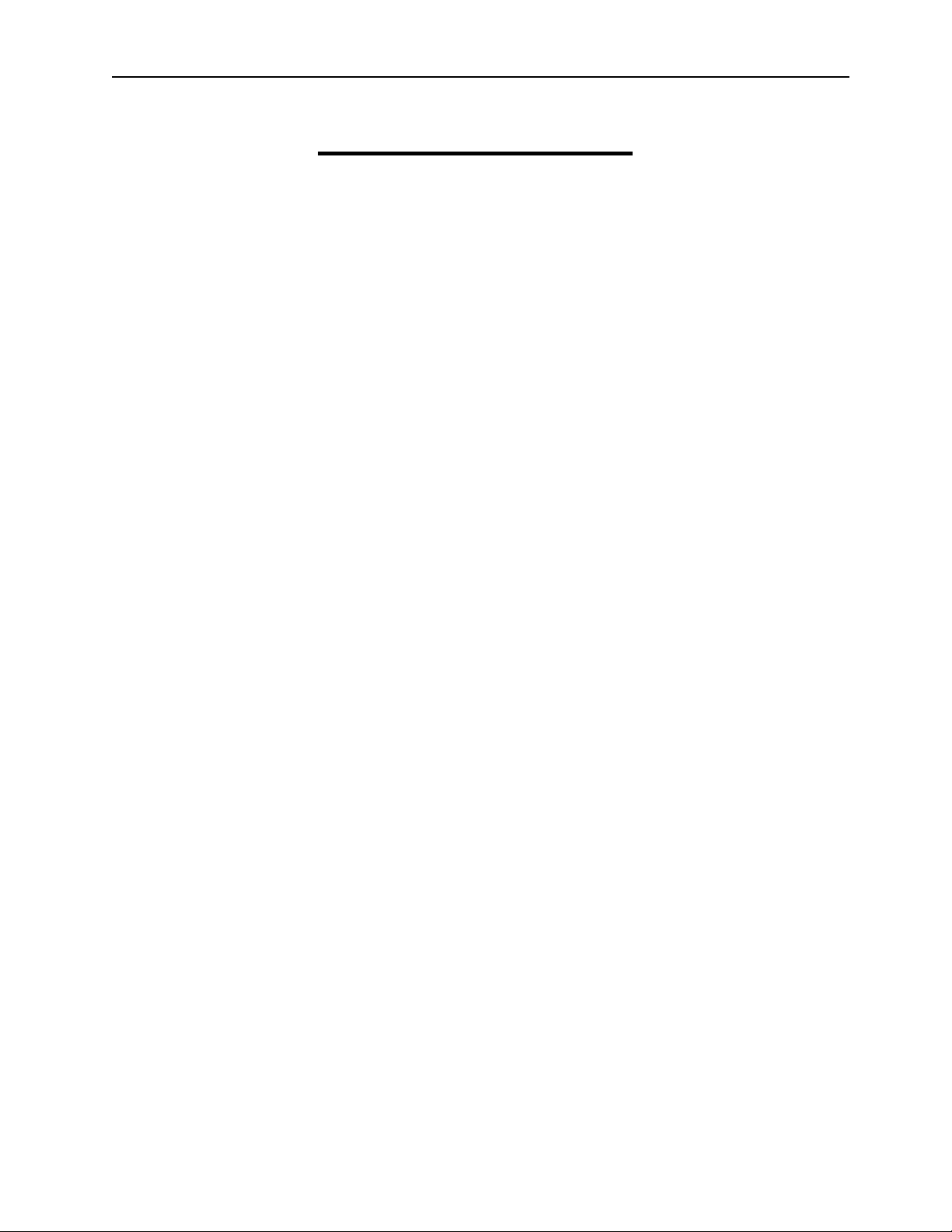

Figure 1. Drain Connections

If the drain line is not large enough, not open at the end,

or does not have a gravity flow; pressure and hot water

will back up into the compartments. If any of these conditions exist and hot water does back up into the compartment someone could be seriously burned and injured.

This can happen even with a correct installation if a drain

cleaner is not used on a regular basis.

An open and free flowing drain line IS REQUIRED for the

proper cooking performance of a CONVECTION

STEAMER. It helps create a swirling action around the

products being cooked. This movement of hot steam

around the product is your CONVECTION STEAM

COOKING.

DO NOT INSTALL UNIT OVER A FLOOR DRAIN. If it

becomes an absolute must, using an 18.' stainless steel

or aluminum pan turn it over and cut a notch in the side

wall to fit over the drain line. Place the pan directly over

the drain opening- DO NOT SEAL TO THE FLOOR. The

steam from the drain line will collect on the under side and

condense into the drain opening.

DO NOT INSTALL GAS UNITS ON

FLAMMABLEFLOORS OR NEAR WALLS. A flammable

floor or wall is any material such as wood, linoleum, or

vinyl that is easily ignitable and bums rapidly.

The intent of these instructions is to provide meaningful

information, which will help you obtain many years of

Drain Line Connection

A proper drain line connection is important. If the drain

line is clogged it can create a back up of pressure causing

extreme and costly repairs.

production. Before installing the steamer, please read

those instructions carefully to maintain your safety and

warranty.

______________________________________________________________________________

3

Operator’s Manual P/N-260APC-A

INSTALLATION SAFETY

WARNING

Qualified installation personnel, working to all applicable

local and national codes must accomplish installation of

this equipment. Improper installation of this product could

cause or damage.

Do not store or use gasoline or other flammable Vapors

and liquids in the vicinity of this or any other appliance.

The flooring that will be directly under the boiler must also

be made of a noncombustible material.

Cleveland Range equipment is designed and built to comply with applicable standards for manufacturers. Included

among those certification agencies which have approved

the safety of the equipment design and construction:

UL, A.G.A., NSF ASME, CSA, CGA, and others.

Cleveland Range equipment is designed and certified for

safe operation only when permanently installed in accordance with local and I or national codes. Many local codes

exist and it is the responsibility of the owner and installer

to comply with these codes

In no event shall Cleveland Range assume any liability for

consequential damage or injury resulting from installations

which is not in strict compliance with our installation

instructions. Specifically, Cleveland Range will not

assume any liability for damage resulting from improper

installation of equipment including, but not limited to,

temporary or mobile installations

INSTALLATION INSTRUCTIONS

1. These instructions must be retained by the owner/user

for future reference. Gas-fired boilers are only to be installed in noncombustible areas that have provisions for

adequate air supply. The term "boiler’

onymously with "steam generator".

2. Position: For proper operation and drainage, the equipment must be level. It should be placed next to an open

floor drain. DO NOT POSITION THE UNIT DIRECTLY

ABOVE WE FLOOR DRAIN. Observe all clearance requirements to provide air supply for proper operation,

as well as sufficient clearance for servicing. The

surrounding area must be free and clear of

combustibles. Dimensions and clearance specifications

are shown on the specification sheet.

3. Install in accordance with local codes and/or the National Electric Code ANSI/NFPA No.70-1987.

Installation in Canada must be in accordance with

Canadian Electrical Code CSA Standard C22.1. The

installer A wiring diagram is provided inside the

base cabinet must ground equipment that is

connected to electricity.

s

will be used syn-

WARNING

INJURY TO PERSONNEL AND EQUIPMENT DAMAGE

May result from an improper drain connection. No

connection lines are to be under the unit

4. Drain Line. The drain line outlet discharges exhaust

steam and hot condensate. Connect 1-1/2-inch IPS

piping (or larger) to extend the drain line to a nearby

open floor drain. Up to two elbows and six feet of 1-1/2inch IFS (or larger) extension pipe should be connected

to the drain termination. No more than two pieces of

Cleveland Range Equipment should be connected to

one common drain line. The extension piping must have

a gravity flow and vent freely to the air. This drain outlet

must be free-vented to avoid the creation of

backpressure in the steamer cooking compartments. To

ensure a vented drain line, DO NOT UNDER ANY

CIRCUMSTANCES, CONNECT THE DRAIN OUTLET

DIRECTLY TO THE FLOOR DRAIN OR SEWER LINE.

Do not run the drain line discharge into PVC drain

piping or any other drain piping material not capable of

sustaining 180' F operation.

5. Water Supply. Connect COLD water plumbing to the

line strainer (Never conned hot water to the condensate

water fill line strainer) Constant flow pressure must be

maintained between 35 and 60 psi, and not experience

a pressure drop below 35 psi when other appliances

are used. If the water pressure exceeds 60 psi, a

pressure-reducing valve must be installed in the water

supply plumbing to reduce the water pressure to less

than 60 psi. Locations and pressure data are shown on

the specification sheet. 3/S-inch IPS plumbing is

sufficient for water supply lines up to 20 feet in length,

but water supply lines longer than 20 feet should be at

least 1/2-inch IPS. Flush water supply lines thoroughly

before connecting them to the unit. Use water, which is

low in total dissolved solids content and low in gas

content to prevent internal scaling, pitting and corrosion

of the steam generator, and carry-over of minerals into

the steam. Water, which is fit to drink, can still contain

highly detrimental impurities.

NOTE: If equipped with a kettle and kettle water fill

swing spout, 3/8-inch (10 mm) hot and/or

cold-water connection(s) will be required at

the swing spout valve.

6. Turn on the cold water supply to the unit Ensure that

the manual water valve, inside the base cabinet is

open.

7. Fuel Supply. Connect the primary fuel supply in accordance with the following instructions. Location and other

data are shown on the specification sheet.

For Gas-Fired Steam Generators: Post in a prominent

location, instructions to be followed in the event the user

smells gas. This information shall be obtained by the

consulting the local gas supplier.

______________________________________________________________________________

4

Operator’s Manual P/N-260APC-A

Install a sediment trap (drip leg) in the gas supply line,

and then connect gas supply piping to the boiler gas valve

piping. GAS-FIRED EQUIPMENT IS DESIGNED FOR

INSTALLATION ONLY IN NONCOMBUSJJBLE

LOCATIONS. THIS INCLUDES THE FLOOR-INC THAT

WILL BE DIRECTLY UNDER THE EQUIPMENT Location,

plumbing size, and pressure data are shown on the

specification sheet. Boilers rated at less than 225,000 Btu

require 3/4-inch 'PS gas supply piping, and boilers rated

at 225,000 Btu or more require 1-inch II'S gas supply

piping. Natural gas pressure must be between 4" -14"

water column and LP gas supply pressure must be

between 12" - 14" water column. NEVER EXCEED 14"

WATER COLUMN (1/2 psi) GAS PRESSURE. If the gas

supply pressure exceeds 14" water column, a pressureregulating valve must be installed in the gas plumbing to

reduce the gas pressure to less than 14" water column.

Installation must be in accordance with local codes, or in

the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-1984. Installation in Canada must be

in accordance with Installation codes for Gas Burning

Appliances and Equipment B149.1 and B149.2. Use a gas

pipe joint compound, which is resistant to LP gas. Turn

the gas valve control knob to ON (the word "on" the knob

will be opposite the index on the valve's body). Test all

pipe joints for leaks with soap and water solutions. Never

obstruct the flow of combustion and ventilation air

Observe all clearance requirements to provide adequate

air openings into the combustion chamber. The appliance

and it's individual shutoff valve must be disconnected from

the gas supply piping system during any pressure testing

of that system at test pressures in excess of 14" water

column (1/2 psi or 3.45 k}'a). The appliance must be

isolated from the gas supply piping system at test

pressures equal to or less than 14" water column (1/2 psi

or 3.45 kpa). A permanent 115-volt electrical connection is

required at the junction box. The junction box location is

shown on the specification sheet. The installer must

electrically ground the unit.

For Electric-Powered Steam Generators: Connect

electric power: location and data are shown on the

specification sheet. Provide connection as required by the

unit, either directly to the single contactor, or to the

terminal block (when equipped with multiple contactors).

Electric supply must match power requirements specified

on the data plate inside the base cabinet. The copper

wiring size must be adequate to carry the required current

at the rated voltage. A separate fused disconnect switch

must be supplied and installed. The installer must

electrically ground the unit

For Steam Coil Steam Generators: Connect steam

supply piping to the input side of the steam coil. Location

and pressure data are shown on the specification sheet.

Incoming steam pressure must be regulated between 35

and 45 psi. A 3 /4inch strainer, equipped with a 20 mesh

stainless steel screen, must be supplied and installed at

the incoming steam connection

point. Flush the steam

line thoroughly before connecting it to the boiler. To

ensure an adequate volume of steam, the branch steam

supply line must be 3/~inch 'PS minimum. Connect the

inverted bucket trap to the outlet end of the steam coil. Pill

the trap with water before installing it. A permanent 115volt electrical connection is required at the junction box.

The junction box location is shown on the specification

sheet. The installer must electrically ground the unit.

For Direct-Steam Connected Steamers and Kettles:

Connect steam supply piping to the input side of the line

strainer. Location and pressure data are shown on the

specification sheet. Flush the steam line thoroughly

before connecting it to the steamer. To ensure an

adequate volume of steam, the branch steam supply line

must be 3/4 inch 'PSI 'minimum. Direct-steam-connected

kettles require 1 /2-inch 'PS pipe if the kettle total capacity

is 20 gallons or less, and 3/4-inch 'PS pipe if the total

capacity exceeds 20 gallons.) A permanent 115-volt

electrical connection is required at the junction box. The

junction box location is shown on the specification sheet.

The installer must electrically ground the unit

INSTALLATION CHECKS

Proper operation of the Cleveland Convection Steamer is

dependent upon proper installation. After the steamer has

been installed, a few quick checks could save

unnecessary service calls.

1. The unit must be level.

2. The Convection Steamer requires a cold water

connection for proper efficient operation. DO NOT

USE HOT WATER. The cold water must be

connected to the line strainer, located at the front

lower right of the steamer base.

3. Check that the manual water supply valve is open.

4. Check all water supply lines and valves for leaks.

5. Check that the water supply pressure and water

quality meets the requirements of installation

paragraphs.

6. On electrical units, verify that the supply voltage

meets the voltage requirements on the rating plate

inside the base cabinet and the voltage shown on the

packing slip. Verify that the unit is protected with a

separate fused disconnect and is properly grounded

in accordance with the National Electric Code.

On gas, steam coil and dir'cct4team-connected units

7. On all gas, steam-coil, and direct steam connected

units, verify that there is a 115-Volt connection at the

handy-box located on the left side of the base.

______________________________________________________________________________

5

Operator’s Manual P/N-260APC-A

8. On all steamcoil units, the incoming steam pressure

must be 35-50 psi. Less than 35 will not effectively

operate the unit. Pressure in excess of 50 psi must be

reduced (with a pressure-reducing valve) to 35-50 psi.

9. Check that the drain lines meet installation

requirements specified in installation paragraph 4

WARNING

INJURY TP PERSONNEL AND EQUIPMENT DAMAGE

may result from an improper installation.

10. After completing checks 1 through 9, correct any

deficiencies refer to the Start-Up and Pre heat

instructions in the Operation section. Verify that the unit

operates properly, make checks 11 and 12.

11.Check to ensure that the water in the boiler sight

gauge glass automatically stays about 1/3 full when

boiler is started up and operated.

12. Check to ensure that the steam pressure gauge

registers 10 psi. The steam pressure is factory-adjusted

to 10 psi

Factory setting may shift due to shaking in transit and

resetting will be required after installation. Proper adjustments and maintenance procedures am detailed on a

separate data sheet entitled "Steam Pressure Adjustments." Adjustments should be made only by qualified

service personnel- the factory pressure settings shown in

the accompanying chart should never be exceeded.

GAUGE PRESSURE READING WITH

NO STEAM FLOW* (STATIC PRESSURE)

Self-Contained Steam Generator; Gas or Electric

Operating Pressure Switch 10 psi

High Limit Safety Pressure Switch 15 psi

Self-Contained Steam Coil Generator

Operating Pressure Switch 10 psi

High Limit Safety Pressure Switch 15psi

Steam Supply Pressure Range 35-45 psi

Direct-Connect (to House Steam Supply)

Steamer Pressure Reducing Valve 10 psi

Steam Supply Pressure Range 1545 psi

** With or without kettle

______________________________________________________________________________

6

Loading...

Loading...