Page 1

SERVICE AND

PARTS MANUAL

Mini Combi with Easy Touch

Series: OES6.10 and 3.10 MINI COMBI

1333 East 179

Cleveland, Ohio 44110

7/11

Phone: (216) 481-4900

1-800-338-2204

Fax: (216) 481-3782

www.clevelandrange.com

th

Street

Page 2

equipment damage, and property damage.

FOR YOUR SAFETY

Do not store or use gasoline or

other flammable vapors or liquids

in the vicinity of this or any other

appliance.

Improper installation, adjustment, alteration, service or

maintenance can cause property damage, injury or death.

Read the installation, operating and maintenance instructions

thoroughly before installing or servicing this equipment.

Disconnect power at the main external power switch before servicing or repairing a MINI.

Failure to disconnect power can result in death, injury, and property damage.

ALL SERVICE MUST BE PERFORMED BY A QUALIFIED

CLEVELAND RANGE AUTHORIZED TECHNICIAN.

Do not connect the MINI Oven-Steamer drain connection to any drain material

that cannot sustain 140o Fahrenheit.

Using drain material that cannot withstand 140o Fahrenheit can result in injury,

This Operation Manual is a part of your new MINI. You must keep and maintain it for

entire life span of your MINI and pass it on to the next owner of the MINI.

the

This manual may be subject to new technical developments, modifications, and unforeseen errors.

KEEP THIS MANUAL FOR REFERENCE

The MINI Convotherm by Cleveland Combi/Oven-Steamers are intended for other than household use.

For caster equipped MINIs: If the Restraining Device must be disconnected,

it must be reconnected after the MINI has been returned to its originally

installed position BEFORE restarting the MINI.

Page 3

CONVOTHERM by Cleveland STATEMENT OF POLICIES

L I M I T E D W A R R A N T Y

CONVOTHERM by Cleveland products are warranted to the original purchaser to be free from defects in materials and

work-manship under normal use and service for the standard warranty period of one year from date of installation or 18 moths

from date of shipment, which ever comes first.

CONVOTHERM by Cleveland agrees to repair or replace, at its option, f.o.b. factory, any part which proves to be defective

due to defects in material or workmanship during the warranty period, providing the equipment has been unaltered, and has

been PROPERLY INSTALLED, MAINTAINED, AND OPERATED IN ACCORDANCE WITH THE CONVOTHERM by

Cleveland OWNER’S MANUAL.

CONVOTHERM by Cleveland agrees to pay any FACTORY AUTHORIZED EQUIPMENT SERVICE AGENCY (within the

continental United States, and Hawaii) for reasonable labor required to repair or replace, at our option, f.o.b. factory, any part

which proves to be defective due to defects in material or workmanship, during the labor warranty period. This warranty

includes travel time not to exceed two hours and mileage not to exceed 50 miles (100 miles round-trip), BUT DOES NOT

INCLUDE POST START-UP, TIGHTING LOOSE FITTINGS, MINOR ADJUSTMENTS, MAINTENANCE, CLEANING OR

DESCALING.

The standard labor warranty allows factory payment of reasonable labor required to repair or replace such defective parts.

CONVOTHERM by Cleveland will not reimburse the expense of labor required for the repair or replacement of parts after the

standard warranty period, unless an Extended Labor Warranty Contract has been purchased to cover the equipment for the

balance of the warranty period from the date of equipment installation, start-up, or demonstration.

PROPER INSTALLATION IS THE RESPONSIBILITY OF THE DEALER, THE OWNER-USER, OR INSTALLING

CONTRACTOR, AND IS NOT COVERED BE THIS WARRANTY. Many local codes exist, and it is the responsibility of the

owner and installer to comply with these codes. Cleveland Range equipment is built to comply with applicable standards for

manufacturers, including UL, AGA, NSF, ASNE/Ntl. Bd, CSA, CGA, ETL and others.

BOILER (Steam Generator) MAINTENANCE IS THE RESPONSIBILITY OF THE OWNER-USER AND IS NOT COVERED

BY THIS WARRANTY. The use of good quality feed water is the responsibility of the Owner-User (see Water Quality

Recommendations below). THE USE OF POOR QUALITY FEED WATER WILL VOID EQUIPMENT WARRANTIES. Boiler

maintenance supplies, including boiler hand gaskets, are not warranted beyond the first 90 days after the date the equipment

is placed into service. Preventive maintenance records must be available showing descaling per applicable Cleveland

Operator Manual for Boiler Proration Program considerations.

WATER QUALITY RECOMMENDATIONS (NEW)

TDS………………………50-125 ppm pH Factor…………..7.0-8.5

Total Alkalinity………….50-100 ppm Free Chlorine………< 0.1 ppm

Silica……………………..<13 ppm Hardness……………50-100 ppm (3,6gpg)

Chloride………………….< 25ppm Dynamic Water Pressure 35-80 psi

The foregoing shall constitute the sole and exclusive remedy of original purchaser and the full liability of CONVOTHERM by

Cleveland for any breach of warranty. THE FOREGOING IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

WHETHER WRITTEN, ORAL. OR IMPLIED, INCLUDING ANY WARRANTY OF PERFORMANCE, MERCHANTABILITY, OR

FITNESS FOR PURPOSE, AND SUPERSEDES AND EXCLUDES ANY ORAL WARRANTIES OR REPRESENTATIONS, OR

WRIT-TEN WARRANTIES OR REPRESENTATIONS, NOT EXPRESSLY DESIGNATED IN WRITING AS A “WARRANTY”

OR “GUARANTEE” OF CLEVELAND RANGE MADE OR IMPLIED IN ANY MANUAL, LITERATURE, ADVERTISING

BROCHURE OR OTHER MATERIALS.

CONVOTHERM by Cleveland liability on any claim of any kind, including negligence, with respect to the goods or services

covered hereunder, shall in no case exceed the price of the goods or services, or part thereof, which gives rise to the claim.

IN NO EVENT SHALL CONVOTHERM by Cleveland BE LIABLE FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, OR ANY DAMAGES IN THE NATURE OF PENALTIES.

LIMITED EXTENDED WARRANTY COVERAGE

The purchase of a Limited Extended Warranty Contract extends the standard warranty coverage to the purchased period of time (one to two

years) from the date of installation, start-up, or demonstration, whichever is sooner.

*An additional two years Parts and Labor Warranty can be purchased with each piece of Cleveland equipment for an additional

3.5% of the List Price per year. The 3.5% of list price charge will be the net invoice amount for each year of extended warranty

purchased.

- Extended warranty must be purchased at the same time the equipment is purchased.

- Extended Warranty has the same exclusions as stated in our standard warranty.

Page 4

Page 5

INTRODUCTION

For safe use of MINIs, each operator must read, understand, and follow the instructions, and heed and

obey the warnings of the Installation Manual and Operators Manual, and the labels on the MINI,

accessories, and supporting products.

The owner(s) and operator(s) of this equipment must keep these instructions in an easily accessible

location for reference and training.

The owner(s) and operators(s) of this equipment must be aware that steam can cause s

and equ

various NOTICES, CAUTIONS, WARNINGS, and DANGERS displayed in this manual and on the

equipment.

ipment damage. Pay particular attention to the Operational Safety section of this chapter and the

A. OPERATIONAL SAFETY

The safe and eective operation of one or more MINIs depends upon proper installation, use,

maintenance, and repair. Operational Safety must encompass all of these factors. This section outlines

the minimum safety policies that must be considered

Safety Program must be tailored to the specic site and use of the equipment. To help avoid injuries,

accidents and damage to the MINI Oven-Steamer, the owner / operator must instruct and train employees

on a regular basis.

Burn hazards are present in any professional food service operation. When using the MINI, observe the

following precautions to help reduce the risk of burns and other

NOT

E: Cooking is interrupted whenever the MINI door is opened.

1. AIR SUPPLY Use the MINI Oven-Steamer in a draft-free and well vented environment. Proper air

supply for ventilation is REQUIRED for and CRITICAL to safe, ecient operation of a MINI.

when using one or more MINIs. Any Operational

injuries.

erious injuries

2. STEAM –Remember at all times that steam can cause severe burns.

3. HEAT – The MINI, cooking containers, shelves, and inner door and anything else inside the cooking

compartment are HOT, as are m

4. HEAT – During operation the temperature of the glass panel in the door and the outer door casing

can rise above 140°F.

5. Never breathe steam, condensate, or hot air.

6. SCALDS – Do not place containers with liquid contents or contents that become liquid on oven racks

higher than you can see into the containers.

7. SCALDS – Cover containers (individual or on trolleys) containing hot or hot l

pre

vent spills during transport.

8. EXHAUST VENTS – The top of the MINI, and the steam exhaust vents are very hot during operation

and remain hot for some time.

a. Never breathe gas or steam from the exhaust vents.

b. Use extreme caution when working on or near the exhaust vents, surrounding area and component parts.

9. HAND SHOWER: GREASE SPATTER – Hot grease will spatter and cause burns if sprayed with

water. Locate fryers and similar

HAND SHOWER: ELECTRIC SHOCK – Use the optional hand shower only on the inside of the oven.

10.

Use of the hand shower, hoses, power cleaners, or pressure washers on the outside of the MINI can

cause electric shock and / or damage electrical and electronic components.

11. Optional HAND SHOWER – Do NOT spray water in a hot cooking compartment.

12. Wear BOOTS appropriate to the work area to help protect feet,

13. Use non-slip, draining, anti-fatigue FLOOR MATS (not included) rated for use in wet, greasy, and dry

work areas to help prevent slipping and / or falling injuries.

• Obtain the best mats for your needs from your local supplier.

any of the component parts. Wear

appliances outside the range of the optional MINI hand shower.

DRY heatproof gloves or mitts.

iquid items to help

and to help prevent slips

and falls.

Page 6

B. CLEANING AND MAINTENANCE

1. CLEANING AND DAILY MAINTENANCE – Wait for the MINI to cool before cleaning and performing

daily maintenance.

2. CLEANING AND DAILY MAINTENANCE – Do NOT use hoses, power cleaners or pressure washers,

or harsh or abrasive cleaning agents inside OR outside the cooking compartment.

3. CLEANING AGENTS – Use only genuine Convotherm by Cleveland and Cleveland Range cleaning

and descaling products.

4. CLEANING AGENT

. CLEANING AGENTS – Products other than genuine Convotherm by Cleveland and Cleveland Range

5

cleaning and descaling products can damage the MINI, cause injury, or present heath hazards.

6. DRAIN – Inspect and clean the drain cover and drain before each use. Injury, equipment damage,

and/or reduced cooking performance can result from a blocked drain cover and drain at the bottom of

cooking compartment.

the

7.

GENERAL INSPECTION – Before each use of the MINI, Inspect the door glass, door gasket

assembly, shelves, racks, drain and accessories for proper installation and cleanliness.

S – Follow the instructions and heed and obey the warnings on the labels.

C. NEVER!

1. MINI must NEVER be started or operated at a temperature lower than 40°F, including after transport,

or storage outside, or in an unheated area.

2. The MINI must never be operated outside.

3. MINIs must never be used to cook foodstus in sealed containers other than those

purpos

e. (MINIs are excellent for “purpose built” containers such as sous-vide packages.)

4. MINIs must never be used to heat ammable items such as oils, fats, cloths, or similar items.

5. MINIs must never be used to heat non-food items (except suitable appliance accessories).

6. Never operate a MINI without the fan guard latched in place.

7. Never reach behind the fan guard during operation.

8. Never manually stop the fan.

Never operate a MINI without the drain cover in place.

9.

Never use anything but hands to operate the keys, switches, and controls on the MINI.

10.

11. Never push food, debris, or scale into the drain.

designed for this

D. SERVICE AND SERVICE RECORDS

1. Allow only qualied Cleveland Range authorized service representatives to service the MINI.

2. Use only Cleveland Range f actory authorized repair parts.

3. Maintain written records of maintenance, service, and repairs. Each

• The date and time of maintenance, service, or repair

• A description of the maintenance, service, or repair. Include part numbers if applicable.

• Copies of purchase orders and invoices for parts and labor.

• The name and signature of the person performing the maintenance, service, or repair.

record should include

at least:

E. OPERATOR TRAINING

Any Operational Safety Program must be tailored to the specic site and use of the equipment.

Operator training should include

1. Operation of the MINI and accessories.

2. Start-up procedures.

3. Normal and emergency shut-down procedures.

4. Interior and exterior cleaning procedures

5. How to recognize and report problems so that corrective action can be taken by trained personnel.

:

Page 7

MINI

GENERAL OPERATION

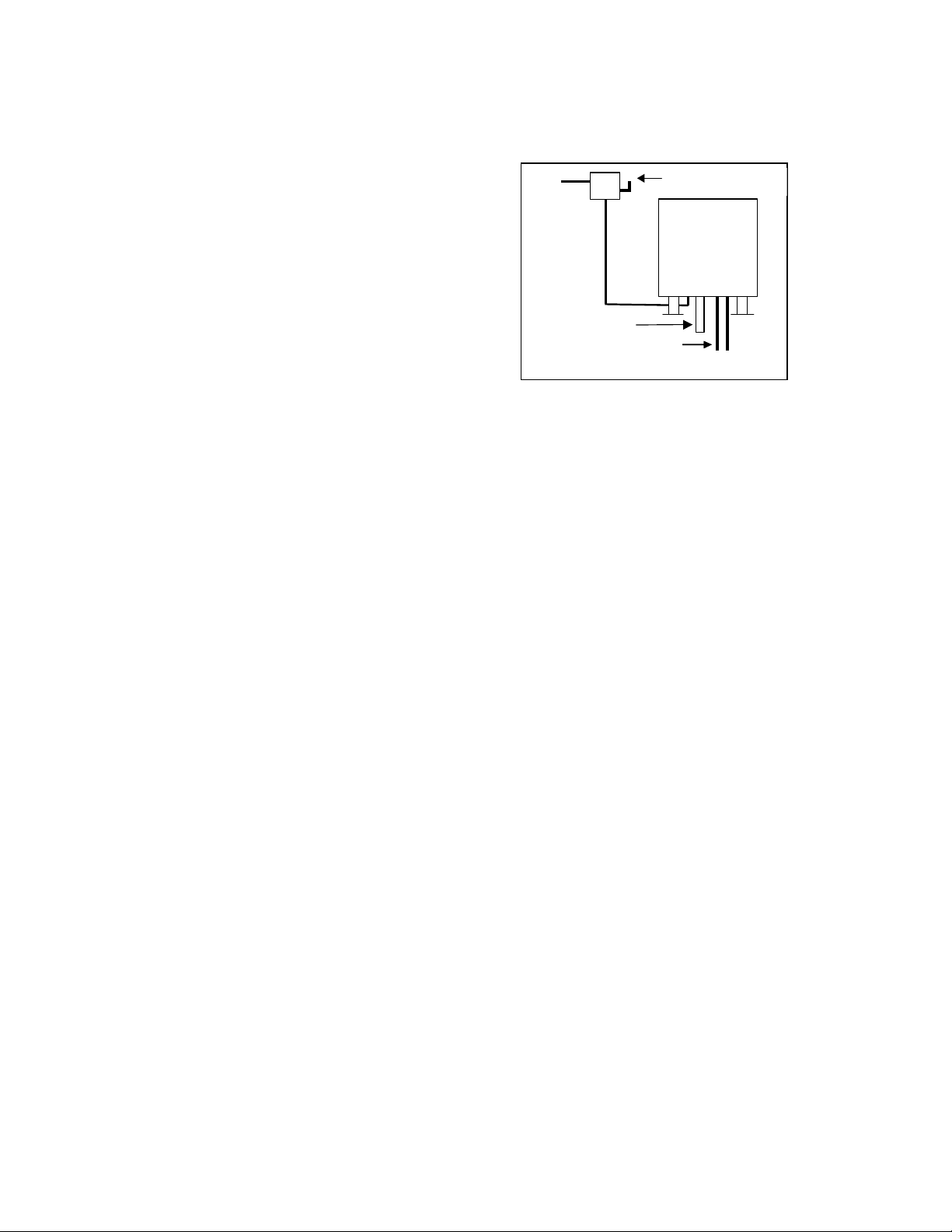

A. MAIN EXTERNAL POWER SWITCH

NOTE: To help protect electrical and electronic

components: Turn OFF the Control Power Service

Disconnect Switch BEFORE turning on the Main External

Power Switch.

The Main External Power Switch is usually left ON. If the

switch is o, turn it ON as follows:

1. Turn ON the water supply valve(s).

2. Turn ON the Main External Power Switch.

DRAIN LINE

COLD W ATER SUPPLY LINES

3. Turn ON the MINI with the ON/OFF key

NOTE: D

epending on the time the Main External Power Switch has been o, the date and ti

to be reset .

B. DOOR HANDLE and DOOR SWITCH

The door handle combines the door latch with a safety vent position and

a wear-free door switch. The MINI cannot start unless the door is closed and latched. Cooking functions

stop if the door handle is moved to the open position. The MINI Oven-Steamer can only work with a

functioning door switch. If a malfunction occurs, imm

autho

rized service representative.

The door handle operates as follows:

Handle Positions

• Vertical: closed. (The wear-free door switch is engaged and the MINI can operate.)

• Turn to the right or left to unlatch the door.

• The handle springs back to Vertical when let go.

To open the closed MINI door:

1. Stand to the hinge side and back from the door.

2. Turn the handle, open the door slightly and wait for steam

(The MINI cannot operate with the handle in the airing position.)

3. Open the door.

ediately contact your qualied Cleveland Range

, condensate and heat to dissipa

MAIN EXTERNAL

POWER SWITCH

me may need

te.

Page 8

C. START-UP AND SHUTDOWN INSTRUCTIONS

Do NOT attempt to operate a MINI during a power failure!

Death, injury, and equipment damage can result.

In the event of a power failure:

1. Turn OFF the Main External Power Switch.

2. Turn OFF Control Power Service Disconnect Switch.

3. If the power failure is prolonged: turn OFF the water supply.

4. When power is restored: restart a MINI with the Startup Procedure.

Start-up Instructions

1. Turn on the MINI by pressing the ON/OFF key.

2. Press the key for operating mode desired; steam or hot air:

a. Select time and temperature.

tart the MINI by pressing the Start/Stop Key.

b. S

3. To cook in other modes or use features: see the Operator’s Manual.

Shutdown Instructions

1. Press the ON/OFF key to turn o the MINI.

D. INSPECTING THE MINI BEFORE SWITCHING ON

Inspect the MINI before switching ON.

1. Check for assembly, operation, and cleanliness as follows:

a. Check regularly to ensure that the screws and hinges of the door are rmly in place and operating

properly

b. Inspect the glass door panels. If the glass door panels are nicked, scratched, or cracked: remove the

MINI from service and replace the glass immediately. Damaged glass panels may shatter during

operation.

c. Make sure the glass door panels are clean and latched into place.

d. Do not place or store anything on top of the MINI. The exhaust vent area and the top of the MINI

are hot.

e. Do not place or store anything underneath the MINI.

f. KEEP THE APP

g. Do not store or leave combustibles near the MINI.

h. Do not block or obstruct the area beneath the gas MINI with objects of any kind.

i. Make sure the air vents of the MINI are not blocked.

j. Check for water line leaks.

k. Check for clogged or slow cooking compartment drain, drainpipe, and oor drain.

l. Check for control malfunctions.

m. Check the door gasket for proper assembly, damage, wear, and se

.

LIANCE AREA FREE OF AND CLEA

R FROM COMBUSTIBLES.

al leaks.

Page 9

E. INSPECTING THE COOKING COMPARTMENT

Inspect the cooking compartment before starting a cooking operation with a MINI for proper assembly and

cleanliness as follows:

1. Inspect the Drain

The drain in the bottom of the cooking compartment has a removable cover. The cover prevents large

food particles, debris and scale from entering and blocking the drain line. Any blockage of the drain

line or drain cover can reduce reduced cooking performance, equipment d

A b

locked or slow drain may cause:

•

Hot water to collect in the compartment and spill out when the compartment door opens.

•

Steam leaks around the door gasket.

•

Reduced cooking performance.

amage, and injury.

CAUTION

Injury, equipment damage, and/or reduced cooking performance can result from a

blocked drain cover and drain at the bottom of the cooking compartment.

2. Inspect for proper latching and assembly of the cooking compartment.

The following features should be checked before every operation of the MINI for proper assembly.

a. Check that the fan guard is in position and secure.

b. Check that the han

bottom

c. Make sure that the inner door glass is properly latched into position. When properly latched, the

inner door is tight with the outer door and does not move by itself or rattle.

d. Open and close the door. All movements should be smooth.

NOTES:

• DO NOT USE the MINI if water stands in the drain opening. Immediately clean the drain. See

Chapter 9, “At the End of the Day or Shift”

• Re

move any food, debris, or scale blocking the drain or screen.

• Never push food, debris, or scale into the drain.

• Be sure the drain cover is properly installed into the bottom of the cooking compartment. The

drain cover prevents large pieces of food from entering and blocking the drain.

Inspect and clean the drain cover and drain before each use .

ging shelf racks are secured into their operating positions at both the top and

.

for instructions.

F. PRE-HEATING THE MINI

1. The pre-heating function heats the oven to the desired temperature before loading food and helps

ensure consistency and quality. Use pre-heating at the start of a shift, after long pauses in cooking,

and bet

NOTICE: Before pre-heating: inspect and clean the Oven Compartment. After pre-heating the Oven

Compartment is too hot to inspect and clean safely.

a. To pre-heat a MINI: Close the door and start the MINI in the desired mode (Steam, Hot Air, or

ween multiple cooking or rethermalizing batches.

MINI).

• Pre-heat temperatures should be 10-20% higher than cooking temperatures.

• Typical-pre-heat t

• See Chapter 3, for basic operating instructions.

imes are 10 to 15 minutes.

Page 10

• Repeat the preheat process as needed to maintain constant oven temperature and high food

quality.

b. To use pre-heating in a recipe: Pre-heating is also a programmable function.

c. To Pre-Heat or reheat between batches for Rethermalization:

Do not place containers with liquid contents or contents that become liquid on oven

racks higher than you can see into the containers.

Hot liquid can spill or splash causing death, injury, or equipment damage.

G. CORE TEMPERATURE SENSOR

• The Core Temperature Sensor is REQUIRED for PC-HACCP, Delta-T cooking, and Cook & Hold.

1. The Core Temperature Sensor may be HOT! Wear dry, heatproof gloves or mitts to handle it.

2. The

3. Hang the Core Temperature Sensor correctly in its rack when not in use.

4. Do not allow the Core Temperature Sensor to hang out of the oven.

5. Do not prick yourself or others with the Core Temperature Sensor tip(s).

6. Remove the Core Temperature Sensor from the food before removing dishes from the oven.

Core Temperature Sensor is a precision measuring device. Handle with care.

H. ERROR MESSAGES FUNCTION

NOTES:

• MINIs have a fully automatic error diagnosis system.

• Most e

• See “Troubleshooting” for a list of error codes and remedies.

rrors are indicated in the Multifunction Display by an error code and description.

Page 11

HOT!

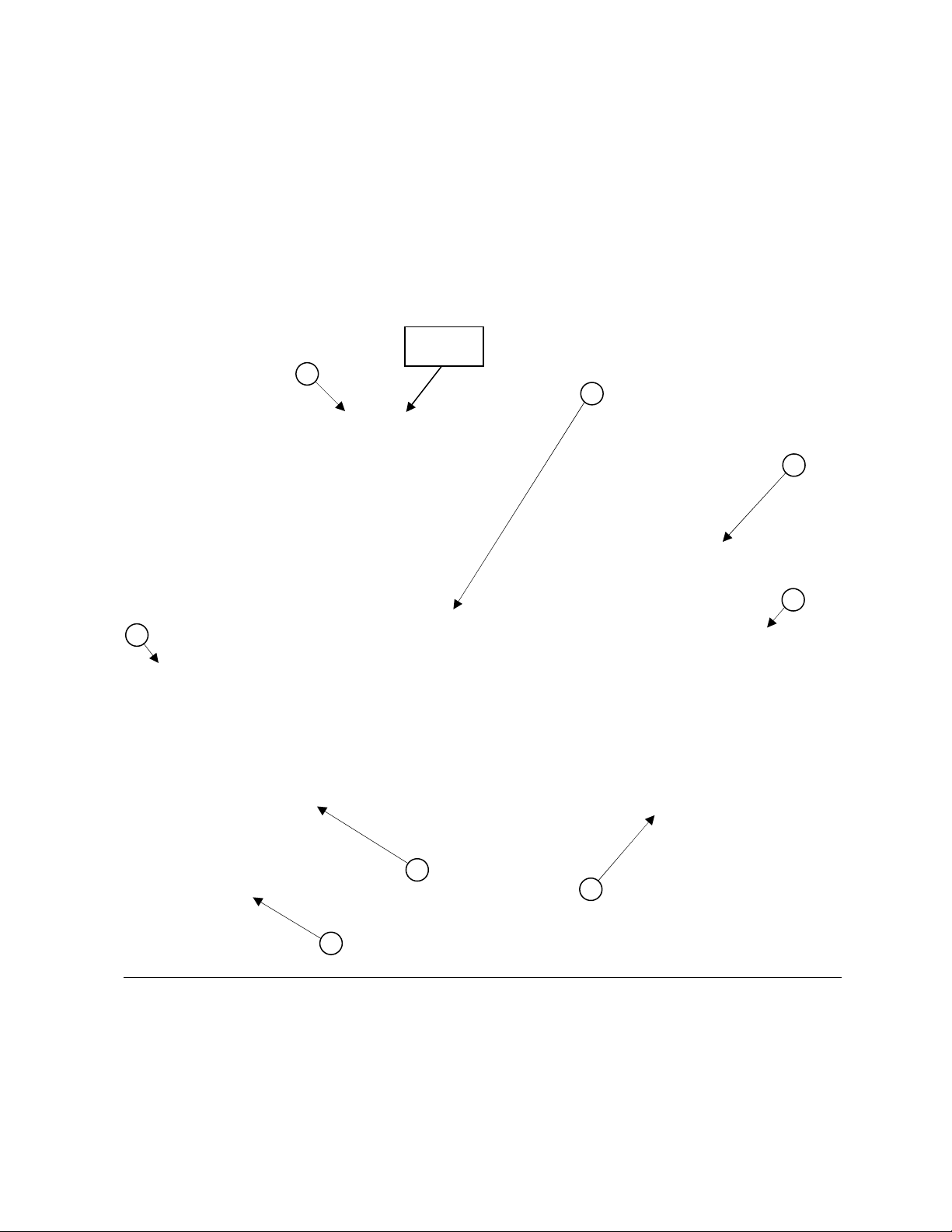

PRODUCT VIEWS AND OPERATION

A. EXTERIOR VIEWS

1.

Control Panel

2. Oven Light

3. Door with Double Glass Panel

4.

Door Handle

CAUTION

1

5. Door Drip Tray

6. Appliance Drip Tray

7. Legs (Required)

8. Rating Plate

2

3

8

Notes:

1. Magnetic Door Switch

• If the oven door is opened during operation, the magnetic door switch automatically interrupts the

recipe. The timer stops.

• After the door is closed, the MINI automatically continues the recipe.

• If the oven door is opened when the buzzer sounds at the end of a recipe, it automatically

switches the buzzer o.

2. Operate controls with hands only!

7

6

5

4

Page 12

B. QUICK START GUIDE CONTROL PANEL BASIC OPERATION

Operate Controls with HANDS Only!

ALWAYS PRE-HEAT!

1. Switch on with key (1).

2. Select cooking mode with keys (2-5).

3. Press key (10) to start.

OR

1. Press key (7) and rotate Selector Dial

(15) to set oven temperature.

2. Press key (8) and rotate Selector Dial

(15) to set cooking time.

OR

Press key (9) and rotate Selector Dial (15)

to set co

ALL

re temperature.

1. Press key (10) to start the MINI.

17

6

13

2. To change the settings while cooking:

press keys (7) OR (8) OR (9) and adjust

the settings with the Selector Dial (15).

3. When the buzzer sounds press key (11)

or open the door.

14 12

15

ON

OFF

STEAM COMBI RETHERMHOT AIR

COOKBOOK EDIT

START

STOP

TEMP PROBETIME

1 234

5 678

1

2

3

4

5

7

8

Figure 4-1

Control Panel

10

9

11

16

Page 13

C. CONTROL PANEL DETAIL VIEW

Item numbers correspond to numbers on the control panels in Figure 4-1

Operate controls with hands only!

1. ON/OFF

When the MINI is turned ON:

• Self-diagnosis is performed.

• Oven light turns on.

• Steam generator lls and heats (OEB and

OGB models).

2. Steam

• Oven temperature is continuously

variable between 86°F and 248°F.

3. Combi Hot Air and Steam

• Oven temperature is continuously

variable between 212°F and

Air

4. Hot

• Oven temperature is continuously

variable between 86°F and 482°F.

5. Retherm

• Oven temperature is continuously

variable between 248°F and 320°F.

6. Display

Display in normal mode :

• Date.

• Time.

• Oven Temperature.

• Cooking Time

• Core (Probe) Temperature.

Display in programming mode:

• Clear text.

• Memory.

• Symbols.

7. Oven Temperature

• Set the nominal oven temperature.

• View the actual or nominal oven

temperature.

See elapsed coo

•

Core Temperature mode.

8. Cooking Time

• Set the cooking time from 1 minute to 9

hours, 59 minutes using the Selector Dial.

• Set Continuous Mode

1. At 9:59 or 0:01, release the Selector

Dial.

2. Turn the Selector Dial again to the left

or right.

• See the actual or nominal cooking time.

• See elapsed cooking time when using

Core Temperature mode.

king time when using

482°F.

9. Core Temperature

• Set the nominal core temperature.

• See the actual or nom

tem

• See the actual core temperature during

cooking time mode.

• See elapsed cooking time when using

Core Temperature mode.

10. Start/Stop

• Start cooking modes and recipes.

• Stop the cooking activity.

• Escape or Exit Smart Key functions

11. Scroll Left and Scroll Right

• Page / Scroll one step forward or back

in programming mode.

12. Cookbook

• Call up, exit cookbook.

• View a list of stored recipes in the

display

13. S

mart Key

• Set Extra Functions.

• Set-Up the MINI.

• Enter Sub-Menus.

14. Edit

• Create, change, copy, and delete

recipes.

15. Selector Dial

• Set: Oven temperature, cooking time,

core temperature, recipe name, recipe

number.

• Select Smart Key functions, editing

functions and recipes in the cookbook.

16. Press & Go Keys

• Start saved recipes with one key.

• LED below key lights up when

corresponding recipe is started.

17. Function Ind

•

Light up when function or activity is

engaged:

Reduced Power

Burner or Electric Heating ON

Reduced Fan Speed

Cooking Mode Engaged

Button Lock

Crisp & Tasty Engaged

Program Protection

inal core

perature.

.

icators (left to right)

Page 14

AT THE END OF THE DAY OR SHIFT

A. Cleaning the Oven Chamber

1. Cleaning – General

a. Regular cleaning of the MINI after use, inside and out, helps guarantee many years of

b. Clean and maintain the MINI ONLY when the MINI is cold.

c. Use the hand shower only inside the oven chamber.

d. Clean the outside of the MINI only by hand.

e. Never use the hand shower, hose, pressure washer or similar device on the outside of the MINI.

f. NEVER spray anything on or into the air intakes or outlets of the MINI.

g. D

h. Do NOT spray water into a hot oven chamber.

i. Use only genuine Convotherm by Cleveland and Cleveland Range cleaning products. Follow the

j. Never use irr

k. Poor water quality can cause discoloration inside the oven chamber. Remove these

l. Damage

Clean the oven chamber at least once per day or more frequently as needed

Failure to clean the Combi properly and regularly can cause equipment damage.

Damage caused by improper cleaning will invalidate the Warranty!

INTERIOR CLEANING INSTRUCTION

To clean the cooking compartment, see the Operator’s Manual for complete

instructions. CONVOClean solution followed by CONVOCare solution, followed by a

thorough rinsing is the only authorized method of cleaning and the only cleaning

solutions to be used to clean this equipment.

Improper cleaning can cause equipment damage and will invalidate the Warranty.

satisfaction from your MINI.

o NOT use hoses, pressure washers, high-pressure cleaners, or water jets to clean inside the

MINI oven chamber.

instructions and heed and obey the warnings on the labels. Other products can cause injury,

present heath hazards, and damage the MINI.

itant, acidic, highly alkaline cleaners, high-alcohol, chlorine, chlorinated, or abrasive

cleaning agents, scrapers, or abrasive materials to clean the MINI.

discolorations with CONVOCare. Spray CONVOCare on the aected surfaces in a COLD oven

chamber, wait 10 minutes, wipe o with a soft cloth or sponge, rinse thoroughly with clean water

and begin cleaning as usua

caused as a result of improper cleaning voids the warranty.

l.

CAUTION

CAUTION

2. Semi-Automatic Cleaning - General

a. If the oven chamber is very heavily soiled, additional manual cleaning may be necessary.

b. Depending on the level of soiling of the oven chamber, the hanging pan racks may be left in the

oven during the automatic cleaning process.

c. Do NOT interrupt the semi-automatic cleaning process.

Page 15

When working with cleaning agents and spray bottles: Wear suitable clothing,

protective gloves and protective goggles to help protect from splashes and spills.

Failure to do so can result in chemical burns on skin and in eyes.

3. Manual Cleaning of the Oven Chamber

a. Use CONVOClean and CONVOCare to clean the oven chamber.

b. Clean the MINI daily to prevent discoloration and corrosion of the stainless steel.

c. Clean the fan guard and the fan area behind the fan guard at the same time.

Read, understand, and heed and obey all instructions and safety

information found on cleaning agent labels, Material Safety Data Sheets,

and related documents and sources. Failure to do so can result in death,

injury, and equipment damage.

1) Spray with CONVOClean and wait ve minutes.

2) Rinse thoroughly with the hand shower (or similar sprayer).

3) Spray with CONVOCare and wait ve minutes

4) Rinse thoroughly with the hand shower (or similar sprayer)..

1) Avoid scratching the oven chamber or fan guard.

2)

Scratches can collect soil and / or allow corrosion to begin.

3) Do NOT use harsh or abrasive cleaning agents, scouring pads, or scrapers.

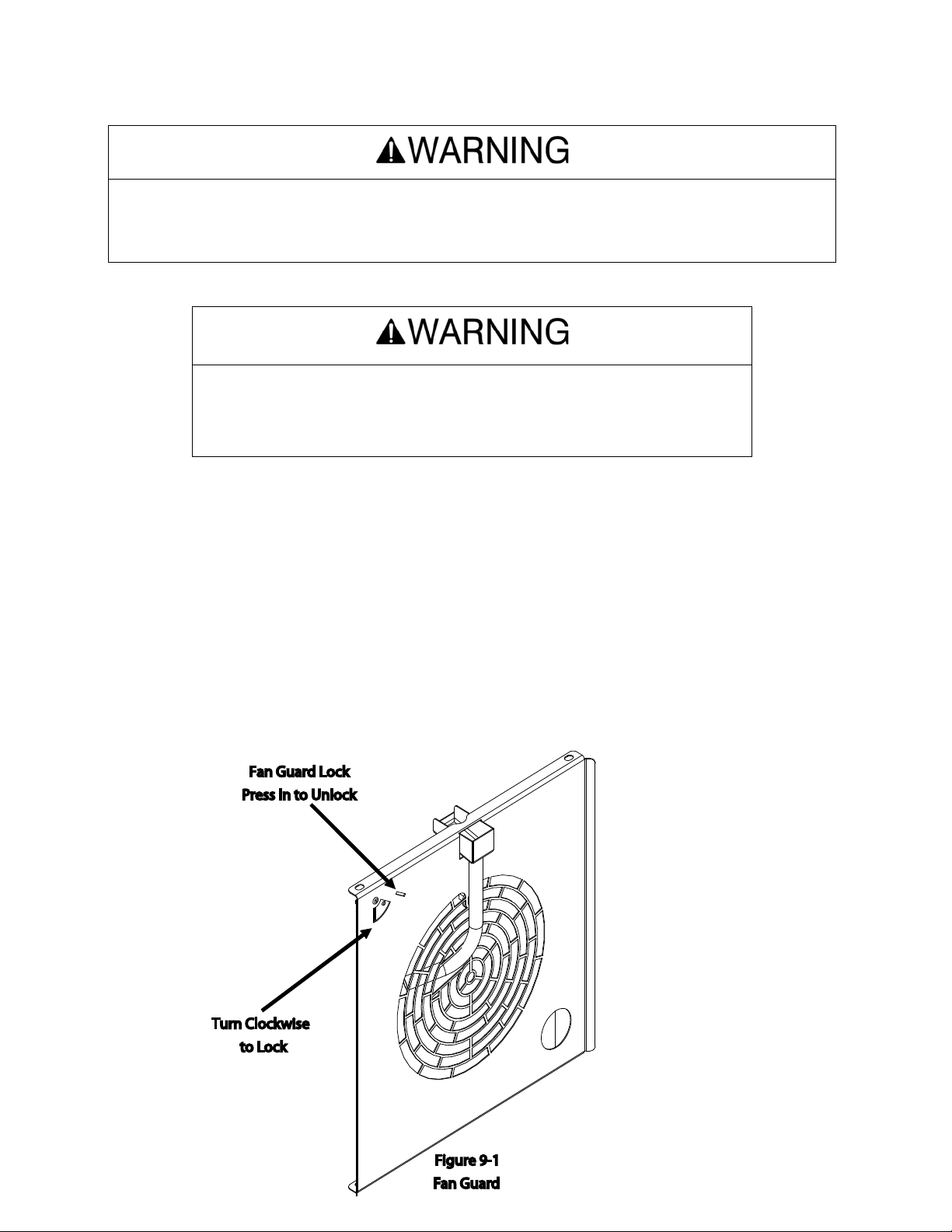

Fan Guard Lock

ress In to Unlock

P

urn Clockwise

T

ock

to L

Figure 9-1

F

an Guard

Page 16

1) Remove the fan guard. See Figure 9-1.

a. Push the fan guard lock in. Do NOT use the core temperature sensor (probe).

b. Lift up on the bottom of the f an guard while pushing in on the fan guard lock.

c. Pull the bottom of the fan guard towards you and remove it.

2) Clean the fan guard in a sink or dishwasher, and clean the oven chamber

3) Replace the fan guard. See Figure 9-1.

a. Insert the fan guard top edge rst into the oven chamber.

b. Place the bottom edge on the su

urn the fan guard lock back to its locked position. (It will click.)

c. T

pport pins.

CAUTION

4) Make sure that the hanging pan racks do not become bent; otherwise grills, racks,

d. Clean the interior of the of the double glass doors daily

1) Releas

2) Clean the glass with a non-abrasive cleaner and a soft cloth.

3) Do not use harsh or abrasive cleaning agents, scouring pads, or scrapers because they will

e. Regular cleaning of the hygienic plug-in gasket (door gasket) increases service life.

1) Wait for the gasket to cool.

2) Clean the gasket with mild, scent free dish detergent and a soft cloth.

3) Do not use harsh or abrasive agents, scouring pads or scrapers becau

4) Air dry the gasket.

f. Remove and clean the drain cover.

1) Clean food residue and drippings from the cover and drain in the oven chamber.

2) Spray with CONVOClean and wait ve minutes

3) Rinse thoroughly with the hand shower (or similar sprayer).

4) Spray with CONVOCare and wait ve minutes

5) Rinse thoroughly with the hand shower (or similar sprayer).

g. Clean the drain and make sure that it is not blocked.

h. C

NOTES:

• If a white deposit forms inside the oven chamber, the water treatment system is not correctly

Do NOT use hanging pan racks that are bent or otherwise damaged in

any way. Pans and accessories placed in damaged racks can tip and

spill, causing burns, injuries and/or equipment damage

containers and accessories will no longer be safely supported. If the hanging pan racks

become bent then remove the MINI from service and contact your qualied Cleveland

Range authorized service representative at once.

.

e the quick-action locks on the door glass.

damage the glass.

the gasket.

lean the door drip tray, appliance drip trays and accessory drip trays.

set, or the addition of a water treatment system is required. To remove this deposit, use ConvoCare full

strength or vinegar and a soft cloth.

se they will damage

Page 17

the oven chamber is above 158°F.

• Ask your qualied Cleveland Range authorized service representative about adding or

setting a water treatment system.

B. Semi-Automatic Cleaning of the Oven Chamber

NOTE: Do NOT press the Start/Stop key while using the Semi-automatic Cleaning process. This

stops the cleaning process.

Note: Semi-automatic cleaning uses cooking modes to assist the cleaning process. The display

shows the nominal values for the cooking modes.

The Semi-Automatic Cleaning process is designed to be started when the

oven chamber temperature is at or below 158°F. Death, injury, and equipment

damage can result from starting the Semi-Automatic Cleaning process when

Semi-automatic cleaning

e MINI has a semi-automatic oven chamber cleaning mode: “Cleaning.”

• Th

• See this instruction sheet (P/N 260AYM), “One-Hand Sprayer with Telescoping Wand,” for safety

information, detailed instructions for using the Sprayer (P/N 111598) and other information.

• Semi-automatic cleaning uses cooking modes to assist the cleaning process. The display shows the

nominal values for the cooking modes.

• Always wear appropriate protective clothing and equipment when using t

protective gloves and goggles.

1. Before starting the Semi-Automatic Cleaning process, make sure the oven chamber is below 158°F

by stopping all processes and pressing the Temperature key twice to view the actual temperature.

2. If the oven chamber is above 158°F then open the MINI door and wait 15 minutes.

3. Check the oven temperature again.

a) If the oven temperature is at or below 158°

If the oven temperature is still above 158°F then wait 15 more minutes and check the oven

b)

chamber temperature. Repeat this step as needed until the oven chamber temperature is at or

below 158°F and then go to Step 4.

4. Press the Smart Key. Various options appear in the display.

of oven chamber

his Sprayer, including

F then go to Step 4.

5. Use the Selector Dial to select “Cleaning”

6. Conrm by pressing the Smart Key.

7. Conrm “Yes” with the Smart Key.

8. The display shows the Time and Temperature for “Cleaning.”

9. Press the Smart Key The cleaning process will start.

10. The rst step is 158°F for 10 minutes in Hot Air mode.

11. After the rst step, the signal tone sounds.

12. Open the oven door and spray the oven chamber, and accessories. with original Convotherm by

Cleveland CONVOClean, using the Hand Sprayer, P/

13

. Close the door and allow the CONVOClean to take eect.

14. Do NOT press the Start / Stop key again.

15. The cleaning cooking mode will continue automatically.

16. The next step is 86°F for 10 minutes in Steam mode, followed by 212°F for 10 minutes in Steam

mode.

.

N 111598.

Page 18

17. After both steps have run, the second signal tone sounds.

18. Clean thoroughly behind the fan guard. Clean the fan guard in a sink or dishwasher.

Remove the fan guard. See Figure 9-1.

a. Push the fan guard lock in. Do NOT use the core temperature sensor (probe).

b. Lift up on the bottom of the fan guard while pushing in on the fan guard lock.

c. Pull the bottom of the fan guard towards you and remove it.

19. Remove the oven racks operating positions and pla

Run MINI mode with Crisp ‘n’ Tasty at level 3 (High) at 212°F for 10 minutes.

20.

ce them in the bottom of the oven chamber.

21. Turn OFF the MINI.

22. IMPORTANT: Rinse the oven chamber, accessories, and behind the fan guard thoroughly

with the hand shower (or similar sprayer).

23. Repeat “Cleaning” using CONVOCare in place of CONVOClean including Step 22, rinsing the

oven chamber, accessories, and behind the fan guard thoroughly with the hand shower

sprayer).

similar

(or

24. After cleaning, replace the oven racks and fan guard.

Replace the fan guard. See Figure 9-1.

a. Insert the fan guard top edge rst into the oven chamber.

b. Place the bottom edge on the support pins.

c. Turn the fan guard lock back to its locked position. (It will click.)

25. In the case of severe staining or soiling, repeat the cleaning process.

26. After use or after cleaning, leave the MINI door open.

C. Fully-Automatic Cleaning of the Oven Chamber

NOTE: Do NOT press the Start/Stop key while using the Fully-automatic Cleaning process. This

stops the cleaning process.

Check that the following requirements have been met:

No food has been left in the oven.

For 6.102in1 and 10.10, make sure the two drawers are lled correctly and contain enough cleaner.

For the 3.10 or 6.10, make sure the cleaning uid containers are connected correctly to the unit and

that the containers contain en

u are already conversant with the operating steps..

Yo

ough cleaning uid.

1. Turn the armature nozzle on the top of the over through one complete turn to ensure that it moves

freely.

2. Remove the larger items of burnt food residues from the oven.

3. Close the appliance door

4. Select the functions menu:

5. Use the selector switch to choose the "fully automatic cleaning" icon.

6. Press the "Functions menu" button to conrm and verify that the Conrm menu appears in the display..

7. Use the tilt selector switch to choose "YES".

8. Press the "Functions menu" button to conrm that A selection menu appears in the display.

9. Use the tilt selector switch to choose the soiling level.

a. Q = quick clean

b. 1 = light soiling

c. 2 = normal soiling

Page 19

d. 3 = heavy soiling

e. 4 = heavy soiling with Shine+

10. Press the "Functions menu" button to conrm that Fully automatic cleaning starts.

11. Open the appliance door when prompted by the system, ensure that the oven is empty and close the appliance

door so the the combi steamer starts the fully automatic cleaning program. Caution: Never interrupt this cycle.

Do not open the appliance door.

12. For very heavy soiling, we recommend following this cycle with semi-automatic cleaning when you

can target any remaining dirt.

13. The following table shows what faults might occur and the appropriate actions:

Fault Action

"Not enough water" appears in display Check the water supply.

"No cleaner pressure" appears in display Check which uid container or drawer is almost

empty and re-ll it. In an emergency use water.

Power failure or interruption of the fully automatic

cleaning cycle.

If cleaning solutions have been used, the combi

steamer will automatically rinse the oven before it

can be operated.

Page 20

MINI SETUP

NOTES:

The various setup options are described in detail below.

You can exit the menu at any time by pressing the Start/Stop key.

To use the Setup Menu:

1. Press the Smart Key.

2. Various options appear in the display.

3. Use the Selector Dial to select “Setup”

4. Conrm by pressing the Smart Key.

5. Conrm “yes” with the Smart Key.

6. Various options appear in the display.

A. Signal Tone

To select the Signal Tone from the Setup Menu:

1. Select “Signal Tone”

2. Conrm by pressing the Smart Key.

3. The display shows the selection of available Signal Tones.

4. To choose a Signal Tone, use the Selector Dial.

5. Pause on a Signal Tone to hear it sound.

6. Conrm the selection by pressing the Smart Key.

B. Volume

To select a Volume Level from the Setup Menu:

• When setting the volume, consider the noise level in your kitchen.

1. Select “Volume”

2. Conrm by pressing the Smart Key.

3. The display shows the volume options and a Signal Tone sounds.

4. Use the Selector Dial to select the desired volume.

5. Conrm the setting by pressing the Smart Key.

with the Selector Dial.

with the Selector Dial.

.

C. Time

To set the Time from the “Setup” menu:

• If the power is o for more than three days, the time must be re-entered

1. Select “Time”

2. Conrm by pressing the Smart Key.

3. The display shows the time format options available.

4. Select the desired format with the Selector Dial.

5. To enter the current time, use the Scroll (arrow) keys to switch between hours and minutes.

6. Set the correct time with the Selector Dial.

7. Conrm the setting by pressing the Smart Key.

with the Selector Dial.

Page 21

D. Date

To set the Date from the Setup Menu:

• If the power is o for more than three days, the date must be re-entered

1. Select “Date”

2. Conrm by pressing the Smart Key.

3. The display shows the date formats available.

4. Select the desired format with the Selector Dial.

5. To enter the current date, use the Scroll (arrow) keys to switch between day, month and year

6. Set the correct date with the Selector Dial.

7. Conrm by pressing the Smart Key.

E. Order of Cookbook Recipes

To organize recipes alphabetically or numerically in the Cookbook with the Setup Menu:

1. S

elect “cookbook alphabetic”

2. Conrm by pressing the Smart Key.

3. Use the Selector Dial to select “Yes” to sort alphabetically, OR select “No” to sort numerically.

4. Press the Smart Key to conrm the selection.

5. “Please wait” appears in the display. The sorting may take some time.

6. When the sorting is complete, the MINI returns to cooking mode.

with the Selector Dial.

with the Selector Dial.

F. Default and Memory Settings

NOTES:

• Select whether the default or the memory setting (i.e. the last setting used) for cooking time and

temper

• Using the default settings helps prevent mistakes by semi-skilled sta.

• Every time a cooking mode is selected, the settings are stored.

• Memory settings are suitable for cooking several batches one after the other. Time and

temperature are set and the cooking mode can be started immediately

• The factory default settings

To s

elect Default or Memory Settings from the Setup Menu:

1. Select “practical settings” with the Selector Dial.

2. Conrm by pressing the Smart Key.

3. To use default settings:

• The MINI uses default settings.

4. OR To change the default settings:

5. The display shows a list of the default settings set.

6. Select the default setting to change with the Selector Dial.

7. Use the Scroll RIGHT (arrow) key to space through to the desired number

8. Set the required default setting with the Selector Dial.

9. Use the Scroll LEFT (arrow) key to space back to accept the setting.

10. To change more settings, repeat the procedure above.

11. Press

ature appears in the display when a cooking mode (cooking mode) is selected.

are adjustable.

select “no” with the Selector Dial and press the Smart Key.

Select “yes” with the Selector Dial and press the Smart Key.

the Smart Key to conrm the new settings.

Page 22

Factory Default Settings

Cooking Mode Oven Temperature Core Temperature Cooking Time

212°F 158°F 25 min

302°F 158°F 70 min

338°F 158°F 30 min

275°F 158°F 5 min

Table 10-1

G. Temperature Display

To select temperature display in °C or °F for temperature in the Setup Menu:

1. Select “temperature in °C,”

2. Conrm by pressing the Smart Key.

3. Select “yes” for °C and “no” for °F

4. Conrm the selection with the Smart Key.

5. The temperature display is set as specied.

H. Network Address

NOTES:

• The Network Address is factory set to “1.”

• Select a dierent network address for each appliance.

• The network address is required for the use of PC Control, PC-HACCP and the Convotherm by

Cleveland Service System.

To set the Network Address from the Setup Menu:

1. U

se the Selector Dial to select “Network Address” .

2. Conrm by pressing the Smart Key.

3. The display shows the network address currently set.

4. Use the Selector Dial to select the desired network address (1 - 99)

5. Conrm by pressing the Smart Key.

I. Language

To select a language from the Setup Menu.

1. Choose, select “Language”

2. Conrm by pressing the Smart Key.

3. The languages available appear in the display.

4. Use the Selector Dial to select the desired language

5. Conrm by pressing the Smart Key.

with the Selector Dial

Page 23

TROUBLESHOOTING

A. Error Diagnosis System

• Convotherm by Cleveland MINI Oven-Steamers are equipped with an error diagnosis system.

1. If an error occurs, the system displays an error code and a description of the error.

2. To continue operating, emergency operation is available (see below).

3. The following tables help troubleshoot if errors or malfunctions occur while a MINI Oven-Steamer

is operating. The tables show possible causes and the

4

. If the instruction in the “Remedy” column is “Call for Service,” call your service agency or the

Service Department at Cleveland Range at 216-481-4900.

If the Burner or Electric Heating ON icon and the Cooking Mode Engaged

icon

then remove the MINI from service.

Use of the MINI with these two icons lit can cause injury or equipment damage.

Call your qualied Cleveland Range authorized service representative at once.

are lit, but the electric heater does not start and the fan does not start

If an error cannot be rectied with the aid of these tables,

contact your qualied Cleveland Range authorized service

representative at once; otherwise, injury or equipment

damage may result.

ir remedies.

Page 24

rror Messages and Remedies

B. E

Error Mess

E01 Not enough water Water valve closed Open water valve

age on display Possible cause Remedy

Solenoid valve dirt filter contaminated Remove and clean filter

Solenoid valve fault Call for Service

E02 Connection area temperature

too high

E04 Connection area fan

malfunction

E11/E32 Excess temperature in oven

or oven sensor failure

E15/E36 Excess temperature of

condenser or condenser

sensor failure

E33 Core Temperature Sensor

faulty

E29 Ground connection of sensor Temperature sensor fault

E80/E95/E96 ID error / software error /

connection fault

E82 Working parameter error Problems during switch between C and F Check settings in Cookbook or

Connection area ventilation fault

Air supply blocked

Auxiliary fan fault Call for Service

Excess oven temperature

Oven sensor fault

Water tap closed Open water tap

Excess temperature in condenser via hot

water connection

Solenoid valve dirt filter contaminated Remove and clean filter

Solenoid valve fault

Condenser sensor fault

Core Temperature Sensor faulty Set cooking mode with time, and

Control fault

Allow MINI to cool, or continue

cooking at a lower oven

temperature, and call Service

Call for Service

Call for Service

Connect appliance to cold water,

restart

Call for Service

Call for Service

call Service

Call for Service

Call for Service

check °C/F in settings

C. Operating Irregularities not having Error Messages

Error Possible cause Remedy

Uneven browning Fan guard not correctly locked Lock fan guard correctly

Nominal oven temperature too high Select lower temperature and increase

cooking time

Not pre-heated Always pre-heat MINIs

Bypass pipe greasy Clean bypass

Incorrect accessories, containers Use suitable accessories and containers

Control elements not illuminated and do

not react when switched on

Appliance does not react to information

entered

Appliance cannot be switched on or off ON/OFF has been locked for 3 seconds Try again after 3 seconds

Oven is not lit inside Oven light faulty Call for Service

Water sprays from air outlet when door is

closed

No power connection, external failsafe

triggered

Software has hung itself up Hold down the ON/OFF switch for 5

Steam measuring line blocked Clean steam measurement line; see

Appliance drain blocked Clean drain

Call for Service

seconds or disconnect appliance for 5

seconds

“Daily servicing and maintenance”

44

Page 25

Opera

ting Irregularities not having Error Messages (Continued)

Error Poss

Water inside the oven Drain blocked Descale

Steam or water running out of base of

appliance (condenser).

White or black marks inside oven Incorrect cleaning agent Use genuine CONVOClean and

Drain connection blocked or covered Remove object

Drain blocked Rinse condenser and drain thoroughly,

Water hardness too high See Water Quality Recommendations in

ible cause Remedy

clean/check own drain system

CONVOCare cleaning agents

Warranty

45

Page 26

CHAPTER 12 EMERGENCY OPERATION

• To continue to use your Convotherm by Cleveland MINI Oven-Steamer in the case of an error

which cannot be solved immediately, an “Emergency Operation” function is available.

• This allows you to use at least some of the appliance functions despite a malfunction.

• Call the Service Department at Cleveland Range at 216-481-4900 immediately.

S:

NOTE

• Cooking times can be longer.

• Monitor the cooking process and the status of the product carefully.

• Locked modes will not respond to keys being pressed.

If the MINI experiences an error:

• The Signal Tone sounds.

• An error number appears in the display, e.g. “E01.”

A. Instructions for Emergency Operation

1. Press the Start/Stop key to confirm the error.

2. The modes which can be selected are indicated by flashing.

3. Proceed as normal.

4. Select a mode by pressing the corresponding key

5. Set operating information as described under the individual modes.

6. Depending on the error, a limited range of functions (e.g. Temperature) will be available.

7. To start the MINI in Emergency Operation, press the Start/Stop key.

8. When the cooking time has elapsed, press the Start/Stop key.

9. When the error has been rectified, the appliance automatically switches back to normal operation:

a. The error number will no longer be displayed.

b. The back-lighting / function display of the mode keys will not flash.

c. Keys will react to being pressed as normal.

46

Page 27

X

mergency Operation Methods

B. E

Error Message on display OES Steam Combi Hot

E01 Not enough water X

E02 Connection area temp.

too high

E04 Connection area fan

malfunction

E11 Excess oven

temperature

E15 Excess temperature of

condenser

E33 Core temp. sensor

faulty

E36 Condenser sensor

failure

E 29 Error in ground

connection

E80 ID error

E81 Program memory error X X X X X X X

E82 Working parameter

error

E83 Algo. error X X X X X X X

E89 I2C error X X X X X X X

X: Operation possible

–: O

peration not possible

Retherm Cook

Air

-- --

X X up to 284°F up to

X X up to 284°F up to

-- -- -- -- -- -- --

X

X X X X X X X

X

-- -- -- -- -- --

-- -- -- -- -- -- --

X X X X X X X

-- --

up to 356°F

(2)

(2)

up to

356°F

284°F

284°F

up to

356°F

up to

356°F

(2)

--

up to

284°F

up to

284°F

--

up to

356°F

(2)

&

Hold

X X

up to

284°F

up to

284°F

X X

X

(2)

Delta-

T

up to

284°F

up to

284°F

X (2)

--

NOTES:

1) Cooking time will be much longer, dishes in upper levels will be ready first

2) Injection of water into condenser constantly activated (higher water consumption)

3) Errors E23 and E26 simultaneously, steam generator is not pre-heated

47

Page 28

CABINET ASSEMBLY

1

2

3

4

6

78910111213

14

17

5

18

19

20

21

22

23

24

Leg Assembly

C2619058

Leg Kit 113640

C8017012

8 m nut

113376

113374

112748

112747

C2016302

6mm ID hose

C7012302

C2618931

Cooling fan

baffle.

112138 Hose

Phillip screw 111111

1/420x1/2" SS

C7011060

Page 29

3

FKC2128695

CONTROL PANEL ASSEMBLY EASY TOUCH

Before S/N 1110230000900

Page 30

CONTROL PANEL ASSEMBLY EASY TOUCH

After S/N 1110230000900

FKC2128695

Page 31

STANDARD

CONTROL PANEL

ASSEMBLY

Page 32

C5118285

ELECTRICAL PANEL

ASSEMBLY

Page 33

5

WIRE INSERTION VIEW

A10:X16

6

CONTROL RELAY BOARD

Page 34

TRIM POTS ARE TO BE SET AS SHOWN

AC DRIVE

BOARD

Page 35

BACK PANEL

Part no. description

300689 CABLE,POWER,3PH,COMBI,MINI

300690 CABLE;POWER;OES;6.08; 1 PHASE

300971 ASSY, PLUG AND CORD, 1PH

10GA SO CORD, 650P PLUG

300972 ASSY, PLUG AND CORD, 3PH

10GA SO CORD, L1530P

Page 36

Part no. description

300689 CABLE,POWER,3PH,COMBI,MINI

300690 CABLE;POWER;OES;6.08; 1 PHASE

300971 ASSY, PLUG AND CORD, 1PH

10GA SO CORD, 650P PLUG

300972 ASSY, PLUG AND CORD, 3PH

10GA SO CORD, L1530P

Page 37

5

23

OES 3.10 DOOR

ASSEMBLY

Page 38

OES 6.10 Mini R H

Door Assembly

C2527089

C2529771

Page 39

OES 6.10 Mini L H

Door Assembly

C2529775

Page 40

FAN MOTOR

ASSEMBLY

123

4

5

6

7

8

9

10

11

12

13

14

15

17

16

18

motor wire

harness 300772

Page 41

CONDENSATE BOX

12346758910111213

Page 42

4

Water Valve Assembly

FK1132281

Page 43

REGULATOR ASSEMBLY

3.10 / 6.10 MINI

6.20/10.10/10.20

12.20

20.20

FK1132281

FK1132282

FK1132283

FK1132284

Set at 17

P.S.I.

Page 44

OES 3.10 MINI

LIGHT

ASSEMBLY

Page 45

OES 6.10 MINI

LIGHT

ASSEMBLY

Page 46

CLEANING PUMP

ASSEMBLY

S113158

Page 47

1

B6

B3

1

2

3

4

5

6

7

8

91011

121314

15161718192021

ITEM DESCRIPTION

1 SOLENOID

Y1 CONDENSATE

Y4 STEAM INJECTION

Y21 RINSE

2 INJECTION REGULATOR

3 INJECTION PRESSURE GUAGE

4 INJECTION PRESSURE SWITCH

5 FLOW REGULATOR

6 CONDENSATE SPRAY NOZZLE

7 HUMIDTY VALVE

8 INJECTION NOZZLE

9 OVEN PROBE B6

ITEM DESCRIPTION

10 OVEN FAN MOTOR

11 CONDENSATE OVERFLOW

12 DRAIN

13 CONDENSATE BOX

14 CONDENSATE BOX GASKET

15 ELEMENT

16 WASH SPRAY ARM

17 RINSE SPRAY HEAD

18 WASH PRESSURE SWITCH

19 RINSE PUMP

20 CLEAN PUMP

21 CONDENSATE PROBE

OES 3.10 W/WASH WATER FLOWCHART

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Loading...

Loading...