Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

MIXER KETTLES

MIXER KETTLES, GAS-FIRED

VERTICAL AGITATOR

TILTING, 2/3 STEAM JACKETED

Cleveland Standard Features

I

I

igh Efficiency (65%) Forced Air Double Pass Heating

H

System. 140M BTU on 40 gallons, 190M BTU on 60 and

80 gallons

II

Automatic Ignition System and 50 psi Steam Jacket Rating

I

I

Insulated Heat Exchanger

II

Type 304 Stainless Steel with #4 finish on kettle and supports

II

Enclosed, Balanced 10 gauge Stainless Steel hydraulically

operated mixer-bridge

II

Steam Jacket permanently filled with treated distilled water

II

Recessed, front-mounted Pressure/Vacuum Gauge

II

Solid-State, precise temperature controls with less than 1˚ C

temperature differences. LED indicator for Heat Cycle and Low

Water Indicator, Power On/Off Switch

II

Infinitely Variable Ratio Control between Scraper and Agitator.

Agitator rotates from 0 to 8 times the speed of the Scraper.

Infinitely Variable Scraper Speed Controls from

0 to 45 RPM

3-horsepower hydraulic powered Agitator, Scraper and Bridge

II

Lift. Nylon Scraper Blades removable without tools

II

3˝ diameter Quick Opening Butterfly Valve

II

Tilt Mechanism of roller bearings and case hardened

self-locking machined worm and segment gear

II

Standard for natural gas operation, standard voltage is

120/208-240, 3 phase

II

Level adjustable flanged feet, Gallon markings on

Scraper Shaft

II

Typical approvals include AGA, CSA, CE, NSF and ASME

Options & Accessories

Ë 316 Stainless Steel Interior Liner. (316G)

Ë 3˝ Air Operated Flush Piston Valve. (FPVA3)

(for use with a food pump, replaces 3˝ butterfly valve)

(requires air compressor)

Ë Hot & Cold Water Faucet. (DPK)

Ë Water Meters (GMC1 or LMC1)

Ë Two-Piece Lift-Off Covers. (MTP)

MODELS: MKGL-40-T MKGL-80-T

MKGL-60-T

Short Form Specifications

Cleveland Gas-Fired Tilting Vertical Mixer Kettle. MKGL-___T ___

gallons, 2/3 steam jacketed, 65% efficient forced air double pass

heating system, 50 psi steam jacket rating, automatic ignition,

solid-state splash-proof controls, 3˝ Diameter Butterfly Valve.

Ë Product Time / Temperature Controls & Indicator. (DTCI)

Ë Pan Carriers (PCK), Food Strainers. (FS)

Ë Kettle Accessory Kit (KAK) includes:

Ë Clean-up Brush (CB) Ë 36˝ Kettle Paddle (KP)

Ë 36˝ Kettle Whip (KW) Ë 36˝ Kettle Brush (KB)

Ë Draw-off Brush (DB) Ë 24 oz. Ladle (KL)

Ë Tri-Basket Strainer Support Systems. (TBS)

SECT. XI PAGE 21

0609

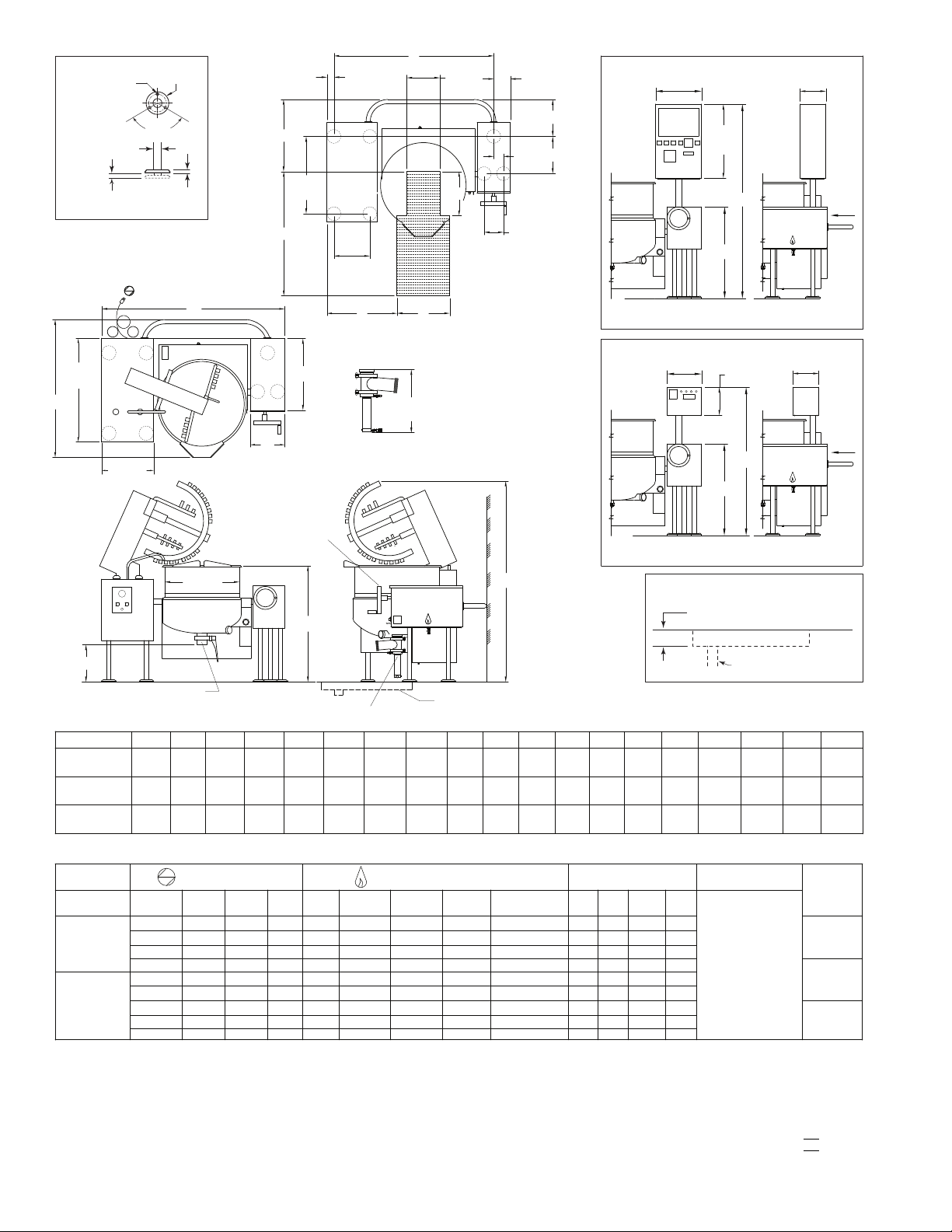

Page 2

925 LBSLBS

420 KGS

1000 4" TO 14" W.C.NAT 190,00060153208/240 3.5

Allow 6.00" (152mm)

space

Minimum from rear

and sides when

located near

combustible walls

3.5

3.5

3.5

3.5

1. MANUFA CTURER MUST BE NOTIFIED IF UNIT WILL BE OPERATING ABOVE 2,000 FOOT ALTITUDE.

3. ALL VERTICAL DIMENSIONS SHOWN ARE MINIMUM. FEET ARE ADJUSTABLE TO 1 INCH MAXIMUM.

2. CONSULT FACTORY FOR MANUFACTURED GAS.

MKGL-80-T

MKGL-60-T

NOTES:

415

208/240

480

480

9360

8

8

15

3

3

3

60

60

60

190,000NAT

190,000

190,000

190,000

LP

NAT

LP

1000 LBS

454 KGS

MKGL-80-T

4" TO 14" W.C.

4" TO 14" W.C.

4" TO 14" W.C.

4" TO 14" W.C.

1000

2500

1000

2500

**

4.00" (102mm)

clearance required if

adjoining equipment

is over 36" high

*

*

*

*

*

*

3.5

3.5

WATE R

COLUMN

3.5

3.5

MKGL-40-T

208/240

480

480

208/240

VOLTS

MODEL

SPECIFICATIONS:

DIMENSIONS:

8

15

8

3

3

3

60

60

60

15

AMPS

3

PHASE

60

FREQ

140,000

140,000

140,000

LP

LP

NAT

140,000

BTU

RATI NG

NAT

TYPE

WEIGHT

SHIPPING

850 LBS

386 KGS

MKGL-40-T

MKGL-60-T

CGA

APPROVALS

4" TO 14" W.C.

4" TO 14" W.C.

SUPPLY

PRESSURE

4" TO 14" W.C.

4" TO 14" W.C.

2500

2500

1000

1000

CU. FT.

BTU PER

**

**

**

AGA

CLEARANCE:

RIGHT: 0 LEFT: 0

REAR: 0

*

*

*

*

*

NSFCE

MARK

ELECTRICAL SUPPLY:

GAS SUPPLY: (PIPING 3/4 NPT)

63.75”

1619mm

66.63”

1692mm

70.38”

1788mm

25.00”

635mm

48.00”

1219mm

MKGL-40-T

MKGL-60-T

MKGL-80-T

50.50”

1283mm

54.00”

1372mm

25.50”

648mm

26.00”

660mm

MODEL NO. A B

48.00”

1219mm

70.00”

1778mm

40.50”

1029mm

13.50”

343mm

77.00”

1959mm

74.00”

1880mm

43.75”

1111mm

44.75”

1137mm

54.00”

1372mm

52.00”

1321mm

14.25”

362mm

15.75”

400mm

CD E F G

14.00”

356mm

23.00”

584mm

24.00”

61mm

25.00”

635mm

13.50”

343mm

14.50”

368mm

14.00”

356mm

27.00”

686mm

25.00”

635mm

30.00”

762mm

28.00”

711mm

28.00”

711mm

26.00”

660mm

14.00”

356mm

14.00”

356mm

HJ LK M

53.75”

1365mm

55.00”

1397mm

55.50”

1410mm

69.75”

1772mm

34.00”

864mm

21.00”

533mm

13.00”

330mm

11.75”

298mm

13.25”

337mm

20.50”

521mm

21.63”

549mm

70.00”

1778mm

71.50”

1816mm

35.75”

908mm

35.13”

892mm

NOPQ

55.25”

1403mm

26.00”

660mm

61.88”

1572mm

58.13”

1476mm

29.50”

749mm

33.00”

838mm

(I.D.)R ST

C

H

A

SHOWN WITH BUTTERFLY VALVE

SHOWN WITH OPTIONAL AIR VALVE

OPTIONAL

AIR VALVE

H

ANDLE REPLACED

BY SWITCH FOR

POWER TILT OPTION

SEE FLOOR DRAIN

DETAIL

WALL

REMOTE CONSOLE BOX MOUNTING DETAI L (DTCI OPTION)

REAR

O

F

UNIT

REAR

OF

UNIT

F

EET & FLOOR FEET & FLOOR

DRAIN LOCATION DRAIN LOCATION

DETAILDETAIL

CHART RECORDER BOX MOUNTING DETAIL (TCR OPTION)

C

B

O

J

T

G

H

K

F

L

E

D

P

P

Q

R

S (I.D.)

N

A

12.00”

305mm

12.00”

305mm

13.00”

330mm

28.00”

711mm

6.00”

152mm

2.50”

64mm

3.50”

89mm

3

.50”

178mm

12.00”

3

05mm

9.00”

2

29mm

16.00”

405mm

23.75”

603mm

9.00”

229mm

9.75”

248mm

1

5.00”

381mm

18.13”

460mm

36.00”

914mm

0

.56"

1

4mm

120º

T

YP

1.00" (25mm)

MAX. ADJUSTMENT

1.625" (42mm)

Ø

FLANGED FOOT DETAIL

0.44" (1 1mm) Ø

3 HOLES ON

3.125" (80MM)

Ø

B.C.D.

4

7/8"

1

24

Ø

m

m

F

LOOR SLOPE = 1.00" (26mm) per 4' (1220mm)

RECOMMENDED FLOOR SLOPE

PIPE DRAIN RECOMMENDED

min. valve size plus 1.00" (26mm)

6.00" (153mm) RECOMMENDED

4.00" (102mm) MINIMUM

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

SECT. XI PAGE 22

0609

Litho in U.S.A.

Loading...

Loading...