Cleveland KDL-80-SH, KDL-60-SH Specifications

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

DIRECT STEAM KETTLES

SHORT SERIES™ DIRECT STEAM KETTLES

RIM HEIGHTS - 32.1˝ (40 GALLON), 34.8˝ (60 & 80 GALLONS)

STATIONARY, FULL STEAM JACKETED

40, 60 or 80 GALLONS (150, 225 or 300 LITERS)

Cleveland Standard Features

n 50 psi Steam Jacket Rating and 50 psi chrome plated

Safety Valve

n Type 304 Stainless Steel with #4 finish on kettle and

supports

n Spring-assisted, hinged, rotatable, domed Stainless

Steel Cover

n 2˝ Tangent Draw-Off Valve with Drain Strainer

n Faucet Mounting Bracket (FBK)

n Steam Control Inlet Valve

n Condensate Drain Valve with insulated handle

n Level adjustable flanged feet for floor bolting

n Typical approvals include NSF and ASME

Options & Accessories

MODELS: c KDL-40-SH c KDL-80-SH

c KDL-60-SH

p 316 Stainless Steel Interior Liner (316G)

p Factory installed Steam Control Kit, consisting of a Steam

Trap, Condensate Strainer and Check Valve (SCK1)

p 3˝ Tangent Draw-off Valve (TD3)

p 3˝ Butterfly Valve (BV3)

p Hot & Cold Water Faucet (DPK)

p Pressure Reducing Valve for regulating incoming steam

pressure o

p Kettle Accessory Kit (KAK)

p Tri-Basket Strainer Support Systems (TBS)

p Kettles Markings (KM)

p Measuring Strips (MS)

p Correctional Packages

p Heat Deflector Shield (HS001)

p Isulated Out J

er 45 psi (PR

v

acket (IOJ)

VK)

Short Form Specifications

Cleveland Direct Steam Stationary Kettle, Model KDL-( )SH, 32 rim

height (40 gal), 34 rim height (60, 80 gal) fully steam jacketed, 50

psi Steam Jacket Rating, spring-assisted rotable Domed cover,

Faucet Bracket, 2 Tangent Draw-off Valve; heavy re-enforced

Rolled Rim.

SECT. X PAGE 23

0707

APACITIES: (in 8 oz. servings,

C

ther sizes may be calculated.)

o

0 Gallon / 150 liters . . . 640 servings

4

60 Gallon / 225 liters . . . 960 servings

80 Gallon / 300 liters . . . 1280 servings

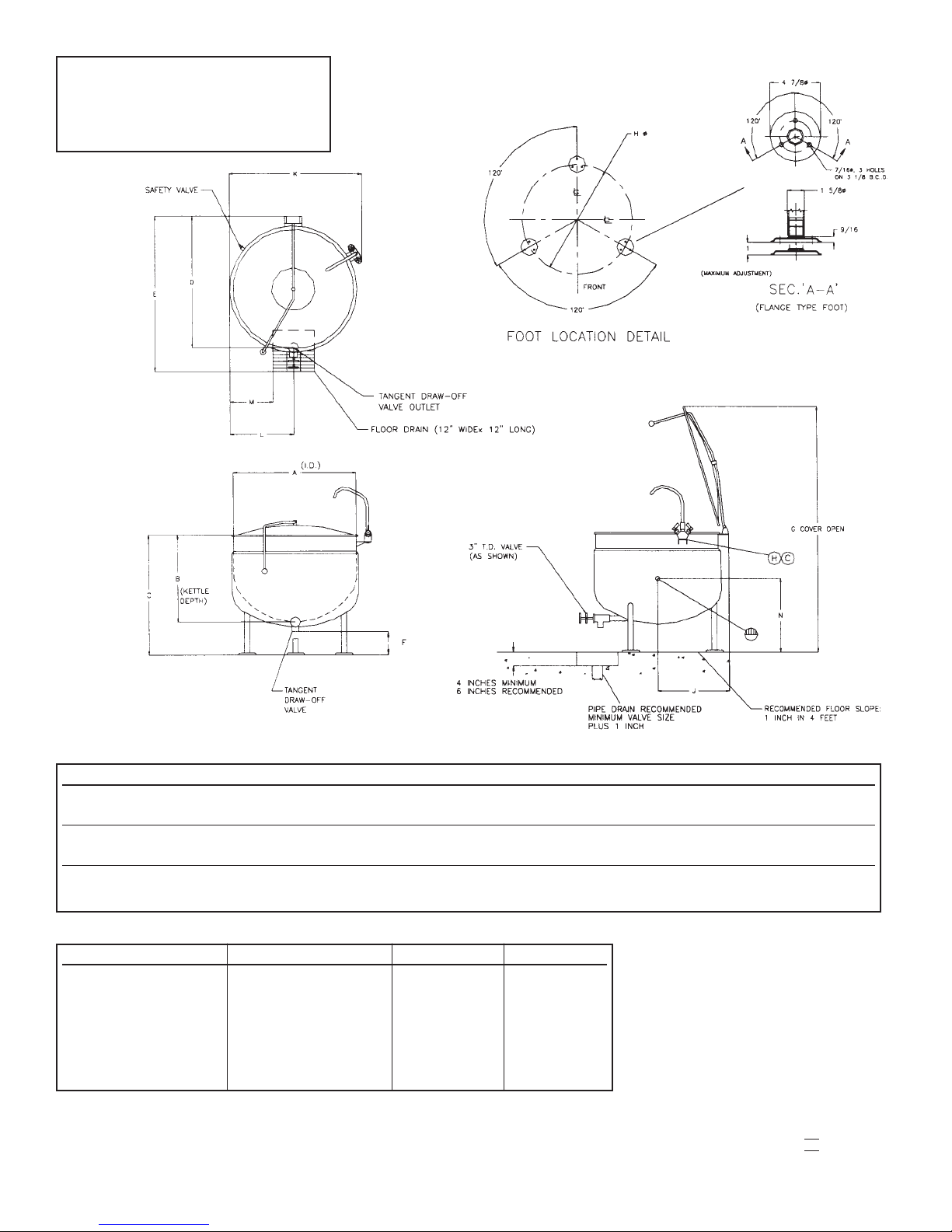

MODEL NO A B C D E F G H J K L M N

KDL-40SH IN 29.5 19.2 32.1 34.2 41.2 10.7 62.6 26.3 18.5 34.7 15.7 9.7 22.7

mm 749 488 815 869 1046 272 1590 668 470 881 399 246 577

KDL-60SH IN 33 22.6 34.8 36.6 43.6 9.7 68.8 29.8 20.2 38.2 17.5 11.5 23.8

mm 850 574 884 930 1107 246 1748 757 513 970 445 292 605

KDL-80SH IN 35.5 25.3 34.8 38.5 45.5 7.06 71.3 32.3 21.5 40.7 18.7 12.7 21.9

mm

902 643 884 978 1156 179 1811 820 546 1034 475 323 556

DIRECT STEAM DRAINAGE WATER CLEARANCE

Steam Supply

3

nish

* Fur

⁄4˝ IPS

1

⁄2˝ N.P.T. Condensate

n with Strainer Soft Copper LEFT = 0

Retur

minimum line and Trap Tubing each REAR = 0

* Operating Pressure When ordered

5-45 psi with a 50 psi

Safety Valve faucet

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Installation of backflow preventers, vacuum breakers and other specific coder requirements is the responsibility of the owner and installer.

Cleveland Range equipment is built to comply with applicable standards for manufacturers. Included among those approval agencies are U.L., A.G.A., NSF, ASME/N.Bd., CSA, CGA, ETL and others.

1

⁄2˝ diameter RIGHT = 0

with optional

SECT

(NO

.

O SCALE)

T

T

GE

A

X P

24

0707

Litho in U.S.A.

Loading...

Loading...