Cleveland KDL Installation Manual

CLEVELAND

MODEL KDL

- T

9209 REV:1

INSTALLATION, OPERATION AND REPAIR MANUAL

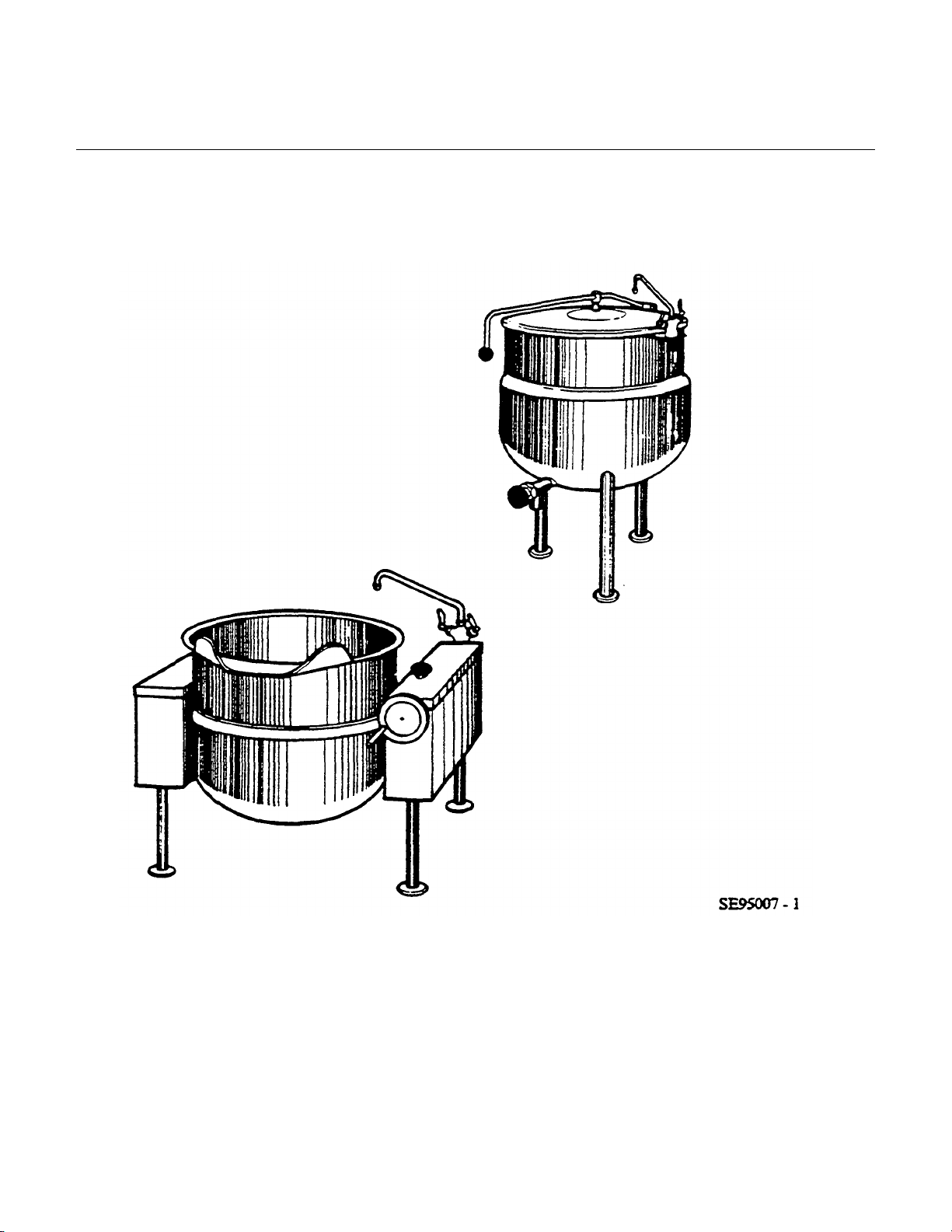

DIRECT STEAM KETTLES

KDL

KDP

CLEVELAND RANGE INC.

1333 East 179th St.

Cleveland, Ohio U.S.A- 44110

(216)481-4900

233-01CC

KET-09

INSTALLATION. OPERATION -AND MAINTENANCE INSTRUCTIONS

TILTING, STATIONARY, AND PEDESTAL MODELS

KDL-25-T

KDL-30-T

KDL-40-T

KDL-60-T

MODEL STYLE ____________________

FOR

DIRECT STEAM KETTLES

KDL-25

KDL-30

KDL-40

KDL-60

PRODUCT INFORMATION

KDP-25

KDP-30

KDP-40

KDP-60

MODEL NO. _____________ SERIAL NO. ___________

INSTALLATION DATE______ INSTALLER ___________

RETAIN THIS MANUAL FOR YOUR REFERENCE

9203 REV:0 1 233-01TE

INSTALLATION INSTRUCTIONS FOR

DIRECT STEAM KETTLES

4. Fill out all carrier claims forms and have the

examining carrier sign and date each form.

INSTALLATION

WARNING:Installauon of kettle must be

accomplished by qualified installation personnel,

working to all applicable local and national codes.

Improper installation of product could cause injury

or damage.

This equipment is built to comply with applicable

standards for manufacturers. Included among those

approval agencies are: UL, NSF, ASME/Ntl.Bd.,

CSA, ETL, and others. Many local codes exist, and it

is the responsibility of the owner and installer to

comply with these codes.

INSPECTION

Before unpacking visually inspect the unit for

evidence of damage during shipping. If damage is

noticed, do not unpack the unit, follow shipping

damage instructions.

SHIPPING DAMAGE INSTRUCTIONS

If shipping damage to the unit is discovered or

suspected, observe the following guidelines in

preparing a shipping damage claim.

1. Write down a description of the damage or

the reason for suspecting damage as soon as

it is discovered. This will help in filling out

the claim forms later.

2. As soon as damage is discovered or

suspected, notify the carrier that delivered

the shipment.

3. Arrange for the carrier's representative to

examine damage.

The first installation step is to refer to the

specification sheet for clearance requirements, in

order to determine the location of the kettle. Next,

carefully cut open the shipping carton for easy

removal of the kettle.

KDL SERIES (Tri-Leg Models)

Position the kettle in its permanent location, and level

the kettle by turning the adjustable flanged feet.

Once positioned and levelled, permanently secure the

kettle's flanged feet to the floor using 5/16" lag bolts

and floor anchors (to be supplied by the installer).

There are three bolts required to secure each of the

flanged feet.

KDP SERIES (Pedestal Models)

1. Position the kettle in its permanent location,

and mark the floor around the circumference

of the base collar or the base plate. Locate the

centre of this circle and mark the floor at this

centre point. This is the point at which the

kettle's base plate will be secured to the floor.

2- Lay kettle on its side (on a cushioned surface

to prevent scratching), and slide the base

collar up the pedestal, exposing the plate for

removal.

3. Remove the four cap screws securing the base

plate and slide it off the kettle.

2

4. Prepare the floor location, for mounting the

kettle, by installing a 3/4"(19mm) stud, cast

into the floor, at the base plate's centre point.

Note: a 3/4"(19mm) lag bolt and floor

anchor may be substituted for a cast-in stud.

The anchor is installed in the floor, and the

lag bolt is threaded down through the base

plate, into the anchor, after completion of step

6.

5. Thread the four 3/8"(10mm) levelling bolts

into plate from the top, and insert the plate

over stud.

6. Adjust bolts until the plate is level.

7. Install a nut on the 3/4" (19mm) bolt (or

insert a lag bolt if the alternate fastener

method is used) and secure base plate to the

floor.

8. Check for level "set" of the kettle by placing

the kettle on the base plate with the screw

holes aligned and applying a carpenter's level

at the kettle rim. If the kettle is level, it may

be fastened in place with the four cap screws.

If the kettle is not level, the kettle must be

removed from the base, the plate loosened,

and the levelling bolts re-adjusted until a

level installation is attained.

9. Slide the base collar down to the floor, and

draw a line around the circumference of the

pedestal at the top of the collar, using the top

of the collar as a guide. Slide the collar back

up the pedestal.

10. Apply a bead of silicone sealer to the

circumference of the pedestal, at the line, and

also to the bottom rim of the collar.

Slide the collar down the pedestal and press it

tightly to the floor. The silicone sealer will

create a seal where the collar meets the

pedestal, and where the collar meets the floor.

SERVICE CONNECTIONS

Install service connections as required. Locations and

other data are shown on the specification sheet.

STEAM

All steam plumbing to and from the kettle and steam

boiler should be thoroughly cleaned and inspected for

din and debris before the final connections to the

kettle are made.

Refer to the specification sheet for the minimum

allowable size of the branch steam supply plumbing

(from the steam "main" plumbing or a nearby boiler).

Generally, kettles require a minimum of 3/4" i.p.s.

pipe. Kettles require 100 psi steam pressure. Check

the rating plate for the maximum steam pressure that

your kettle is rated for. If the steam supply pressure

exceeds the rated pressure, a pressure reducing valve

is required. The steam inlet is at the right side of the

kettle, as seen from the front.

CONDENSATE

The steam condensate trap must be plumbed to an

open, free-venting drain -or a condensate return

system, using minimum 1/2" NPT plumbing. The

condensate line is limited to a maximum rise of 10

feet in order for the steam pressure to adequately

force the condensate through the plumbing. Any

higher rise requires a pump.

3

If the steam boiler to which this kettle is installed

has a condensate return, a 1/2" (13mm) steam

strainer, a 1/2" (13mm) steam trap, and a 1/2" (13

mm) check valve must be installed on the

output (condensate) side of the kettle.

FAUCET (OPTIONAL)

The water faucet, with swing spout, requires 1/2

inch O.D. copper tube plumbing for hot/or cold

water supplies to the faucet (if so equipped).

5. Observe that the water in the kettle comes to

a boil.

6. Close the steam supply valve.

7. Drain off the water by opening the draw-off

valve or tilting the kettle forward. Power

pour kettles ONLY: To raise the kettle,

press the top of the rocker switch. To lower

the kettle, press the bottom of the rocker

switch.

OPERATION

ELECTRICAL

Power pour kettles require a permanent 115 volt

electrical connection. Refer to the specification

sheet for precise location. A kettle that is

connected to electricity must be grounded by the

installer, and installed in accordance with local

codes and/or the National Electrical Code

ANSI/NFPA No. 70-1990. Installation in Canada

must be in accordance with the Canadian Electric

Code CSA Standard C22.1.

FINAL INSTALLATION CHECK

1. If the kettle is equipped with a tangent

draw-off valve, ensure that it is closed.

2. Partially fill the kettle with water.

3. Slowly turn the steam supply valve's

knob counter-clockwise, to the open

position.

4. Release the safety valve, ensuring that the

steam escapes freely. Stay clear of steam

exhaust when releasing the safety valve.

Ensure that there is an adequate steam

supply to the kettle.

For optimum performance on free-standing floor

model tilting kettles, open the drain petcock to drain

condensate from the kettle's jacket, then close the

drain petcock before applying steam to a cold kettle.

If the kettle is equipped with a tangent draw-off

valve, ensure that it is closed before filling the kettle.

To keep solid food particles out of the draw-off

valve, place either the solid or the perforated disc

(strainer) in the bottom of the kettle. Use the solid

disc if the liquid is to be retained, and the perforated

disc if the liquid is to be drained off.

Turn the steam control valve to the full open position

by turning the knob counter-clockwise, then allow

the kettle to preheat.

NOTE: When cooking egg and milk products, the

kettle should NOT be preheated, as products of this

nature adhere to hot cooking surfaces. These types of

foods should be placed in the kettle before heating is

begun.

4

Fill the kettle with product to the desired level.

CARE AND CLEANING

When the product has reached the desired

temperature, regulate the heat, as required, by

turning the steam control valve clockwise for less

steam, and therefore, a lower temperature.

When cooking is complete, close the steam

control valve by turning the knob clockwise until

it stops turning.

Power-pour kettles are provided with a rockertype center-off switch for raising and lowering

the kettle. To raise the kettle, press the top of the

switch. To lower the kettle, press the bottom of

the switch- Release the switch, allowing it to

return to the center "off' position when the

desired degree of tilt has been reached. Limit

switches are provided that automatically stop the

tilt motion at the maximum limit of movement in

either direction.

To raise and lower manual tilt, floor mounted

kettles, turn the handwheel counter-clockwise to

lower and clockwise to raise.

Your kettle must be cleaned regularly to maintain its

fast, efficient cooking performance, and to ensure

its continued safe, reliable operation.

WARNING: Do not use chlorine base

detergent.

1. Prepare a warm water and mild detergent

solution in the kettle.

2. Remove food soil inside the kettle using a

nylon brush. Do not use a metal bristle

brush, as this may permanently damage the

kettle's stainless steel surface.

3. Loosen food which is stuck to the kettle by

allowing it to soak at a low temperature

(simmer or low boil).

4. Open the draw-off valve or tilt kettle

forward to drain the wash water.

If the kettle is equipped with a draw-off valve, it

should be cleaned as follows:

For kettle/steamer combinations: If the boiler in a

steamer is supplying steam to a kettle, always

heat the kettle first. After the kettle contents are

heated, and the boiler's steam pressure returns to

normal, the steamer may be used- Pressure

steamer compartments should be sequentially

started, and preheated before cooking.

NOTE: As with cleaning food soil from any

cookware, an important part of kettle cleaning is

to prevent foods from drying on. For this reason,

cleaning should be completed immediately after

cooked foods are removed. Please refer to the

"Care and Cleaning" instructions for detailed

kettle washing procedures.

5

a. Remove the drain strainer from the bottom of

the kettle. Thoroughly wash and rinse the

strainer, either in a sink or a dishwasher, then

replace it into the kettle.

b. Disassemble the draw-off valve, first by

turning valve knob counter-clockwise, then

turning the large hex nut counter-clockwise,

until valve stem is free of the valve body.

c. In a sink, wash and rinse the valve stem, hex

nut, and knob. Wash and rinse the inside of

the valve body using a nylon brush. Kettle

brushes and other accessories are available

from your authorized dealer.

Loading...

Loading...