Page 1

6212011

SSeerrvviiccee BBuulllleettiinn ##EEQQUUIIPP00441111CCW

WTT--0066

TO: All Cleveland Range Maintenance & Repair Centers

FROM: Cleveland Range Service Department

DATE: 4-15-2011

SUBJECT: Water Treatment System Change.

For over 18 years Cleveland Range has offered a carbon block filter system for

the steamers. Carbon block filters will remove 5 micron particles and chlorine from the

water supply. This alone will increase the life of the steamer but does nothing for the

accumulation of scale.

The addition of the scale stick helped prevent the scale from adhering to the

steam generator. With regular maintenance this also extended the life of the steamer.

The scale stick however had a negative result in the new spritzers style combi--the

polyphosphate coated the cabinet and bonded with the oils from the food.

After testing several types of water treatment systems the Claris ion exchange

system accomplished mineral reduction without harming the equipment. Installation is

simple as well as cartridge replacement. In areas tested, the minerals in the water were

reduced enough to extend the time between maintenance descalings significantly. It is

important to note that maintenance is still needed.

Beginning March 1st, 2011 the Claris water treatment system, model number

CWT-06, will be available through Cleveland Range This will replace the previous filter

systems for the floor model steamers and Combi’s. *Claris Steam System w/ Pre-filter &

Meter Kit consists of:

-

• Claris 0 Bypass head

• Claris XL Cartridge

• Claris Hose 10CM, 3/8x1/2

(2 pieces)

Attached is a cut sheet for the product. Please note that the quality of the water is

very important to the life of the Claris XL cartridge and once the Claris test kit is used

the flowmeter must be set to determine when the cartridge is to be changed. The chart

included is used to determine the setting of the flow meter.

Any questions or concerns please contact Cleveland Range Technical Service at

800-338-2204.

• Claris Test Kit

• Prefilter

• Flow Meter.

Cleveland Range, Inc. 1333 East 179th St., Cleveland, Ohio 44110-2587 USA

Phone: (216) 481-4900 Fax: (216) 481-3782 Web Site: www.clevelandrange.com

Page 2

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COMBI OVEN-STEAMER

Options & Accessories

Claris Water Treatment System

for Convotherm by Cleveland Combi Ovens

MODEL: CWT-06 (includes complete system)

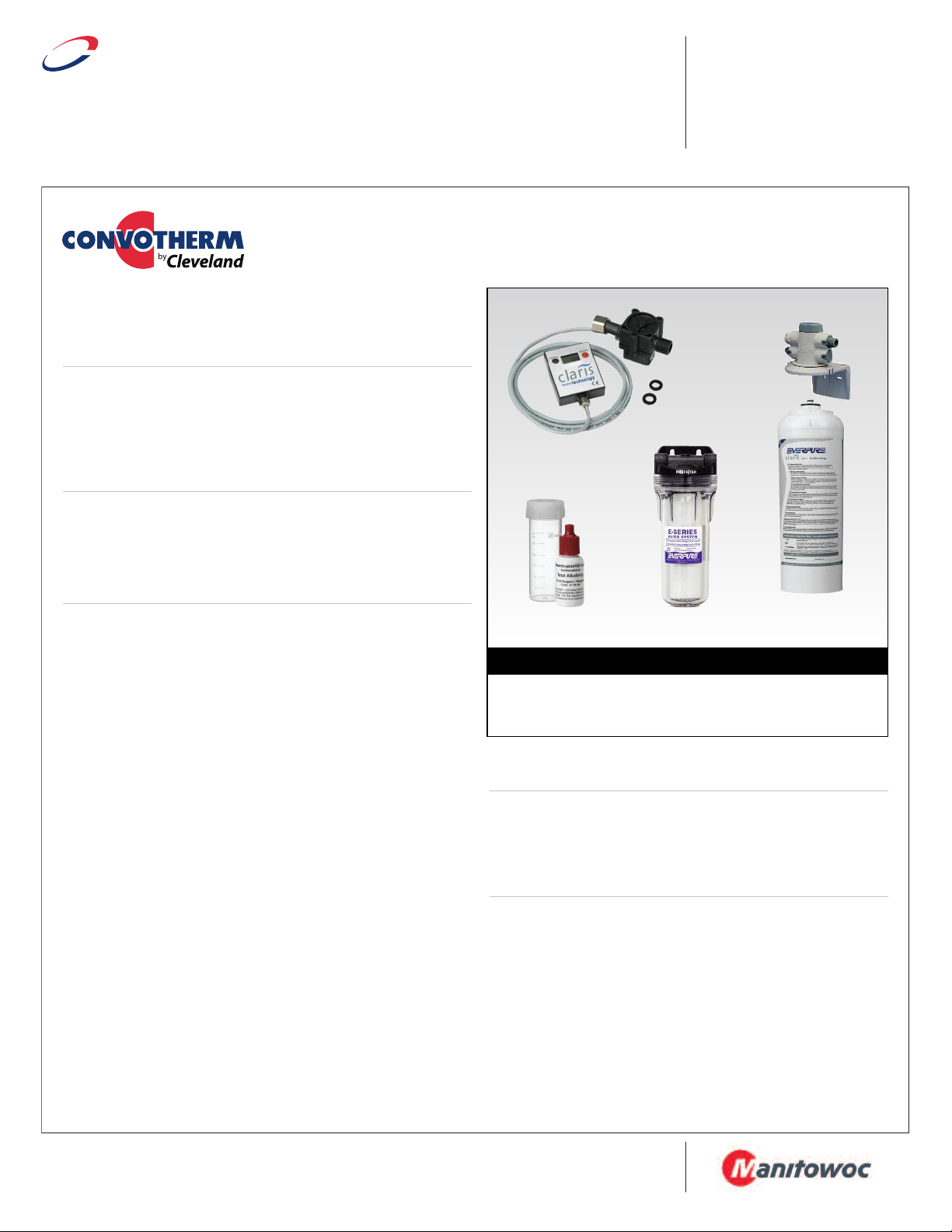

System Components , Includes:

I

I

one (1) Pre-filter

I

I

one (1) Claris X-Large Steam System

I

I

one (1) Claris Flow Meter

I

I

one (1) Water Test Kit

Accessories:

Ë Claris X-Large Filter Cartridge (CWT-XLC)

Ë EC-110 Cartridge - Prefilter Replacement Cartridge (EC-110)

Cleveland Standard Features:

E-10 Prefilter System

I

I

Filters out larger dirt and rust particles.

I

I

Extends the life of primary filter cartridges.

I

I

Tightly spun EC-110 sediment cartridge delivers 10 micron

nominal filtration.

I

I

Durable slim bowl design makes cartridge replacement easy.

I

I

Clear housing allowing visual inspection of trapped particles to

determine when to change the cartridge.

I

I

10” bowl design accepts most 10” drop in cartridges.

Claris Single Head with Zero Bypass

I

I

Commercial quality filter head designed exclusively for Claris filter

cartridges.

I

I

Engineered for durability, strength and longevity.

I

I

Corrosion resistant hardware.

I

I

The system can be operated horizontally or vertically, depending

on the available space.

Water Test Kit

I

I

Used to determine the scale causing hardness (mainly calcium and

magnesium).

I

I

Indicates water test completion when the color changes from bluegreen to orange-yellow.

Flow Meter

rogramer

P

& Display

Water Test Kit

Pre-Filter with Housing

Claris Flow Sensor

and Display

Short Form Specifications

Shall be Cleveland Model CWT-06 Claris Water Treatment System including

one (1) Pre-filter, one (1) Claris X-Large Steam System, one (1) Claris Flow

Meter & one (1) Water Test Kit.

Claris X-Large Filter Cartridge:

I

I

5-stage filtration process.

I

I

Operation in vertical or horizontal position.

I

I

NSF Certified under NSF/ANSI Standard 42.

Claris Flow Sensor and Display

I

I

Monitors water usage rate to determine cartridge replacement.

I

I

Display indicates cartridge replacement based on gallons of

water treated.

I

I

Display unit provides information about residual capacity of

installed cartridge, total filtrate volume since flow sensor was

installed, filtrate volume and operation time of last five (5)

installed cartridges.

SECT. IIB PAGE 12

0111

Page 3

5.35”

136mm

20.67”

5

27mm

5.16”

131mm

5.35”

136mm

12.44”

316mm

20.67”

527mm

INLET

3/4” FNPT

OUTLET

3/4” FNPT

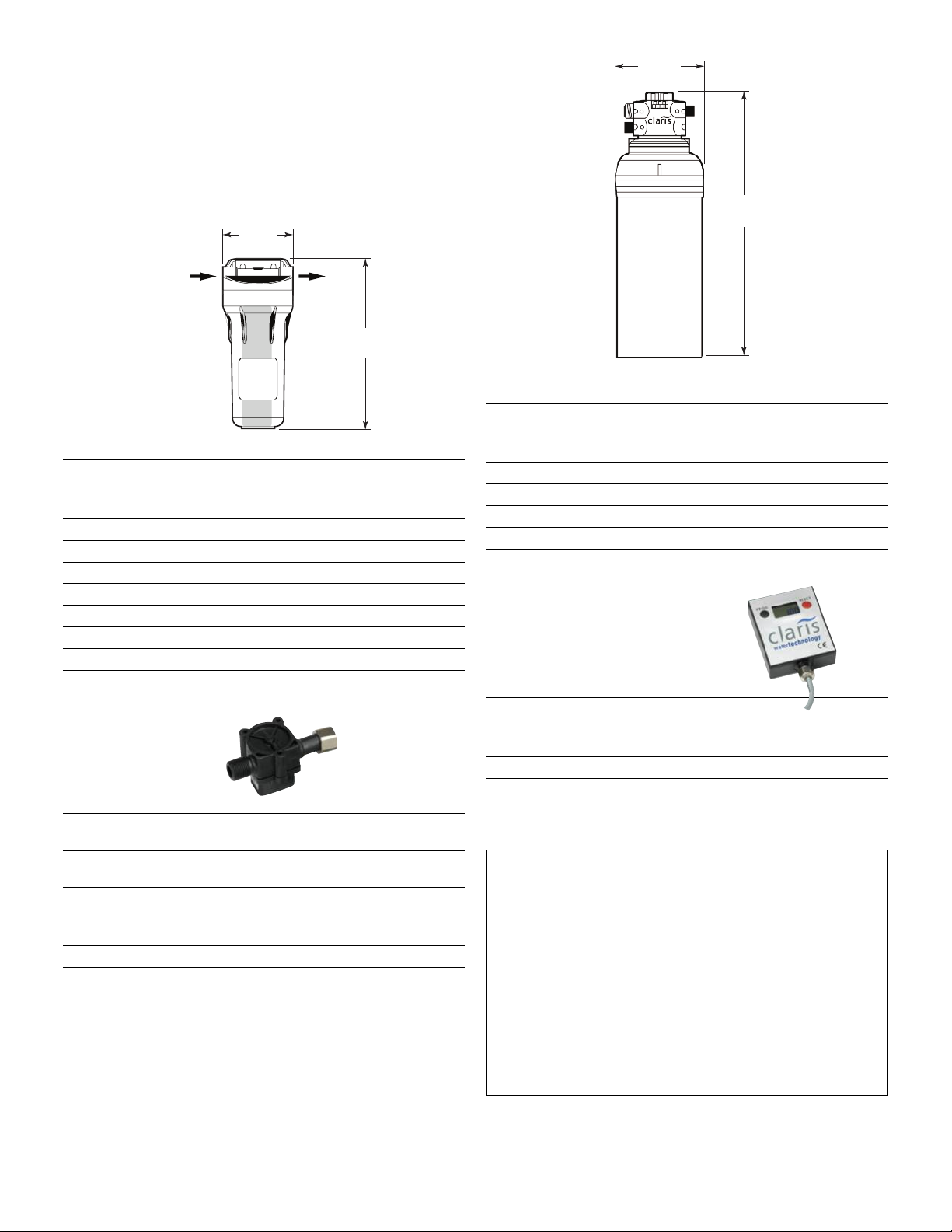

Technical Data:

Claris Water Treatment Components

Pre-Filter

Overall Dimensions:

Inlet Connection:

Outlet Connection:

Service Flow Rate:

Pressure Requirement:

Water Temperature Inlet Requirement: 39º - 86ºF (4º - 30ºC)

Electrical: No electrical connection required

Shipping Weight:

Operating Weight:

12.44" H x 5.16" W

(316mm

H x

131mmW)

3/4" FNPT

3/4" FNPT

Maximum 6.0 gpm (22.7 Lpm)

35 psi - 70 psi (2.4 – 4.8 bar) non-shock

4 lbs.

6 lbs.

Claris X-Large Filter Cartridge

Overall Dimensions:

Service Flow Rate:

Treatment Capacity*:

Pressure Requirement:

Water Temperature Inlet Requirement: 39º - 86ºF (4º - 30ºC)

Electrical: No electrical connection required

*Capacity is based on water hardness of 180 ppm.

20.67" H x 5.35" Dia.

(525 mm x 136 mm)

1.0 gpm (3.7 Lpm)

1,100 gal.

35 psi - 70 psi (2.4 – 4.8 bar) non-shock

Programmer & Display

Overall Dimensions:

Cable:

Electrical:

2.75" H x 2" W

(70mm

H x

51mmW)

59" (1.5 meters)

Lithium Coin Battery (type CR2032)

Flow Meter Sensor

Overall Dimensions:

Connection:

Service Flow Rate:

Pressure Loss:

Pressure Requirement: 35 psi - 70 psi (2.4 – 4.8 bar) non-shock

Ambient Temperature (min/max): 39 - 104 °F (+4 - +40 °C)

Installation Position:

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers.

3.25 W x 2" H x 2" D

(83mm

W x

Inlet: 3/8-inch BSP F nut

Outlet: 3/8-inch BSP M

0.44-3.08 gpm (100-700 LPH)

184 gph (up to 700 LPH flow rate)

3 PSI (0,2 bar)

Horizontal recommended

51mm

H x

51mmD)

WATER QUALITY REQUIREMENTS FOR CLEVELAND STEAMERS

TDS . . . . . . . . . . . . . . . . . < 6 0 ppm pH Fac tor . . . . . . . . . . 7.0 – 8.5

Total Al kalinity . . . . . . . < 20 ppm Free C hlorine . . . . . . . < 0.1 ppm

Silic a . . . . . . . . . . . . . . . < 13 ppm Conduc tivity . . . . . . . . min. 20 μS/cm (50 kOh ms)

Chlor ide . . . . . . . . . . . . . < 25 ppm

NOTES : Proper mainten ance of the ste am cooki ng equi pment an d water treatment system

is t he respo nsibilit y of th e owner /operator. I mproper installat ion or maintena nce

may v oid the warranty. Refer t o the O perators Manual for prop er inst ructions . A

water quality analysi s is re quired p rior to install ing the Claris water tre atment

syste m, since water c onditions vary througho ut the country.

Do n ot use the “Claris System” wit h water that is microbio logicall y unsafe or of

unkno wn quali ty, witho ut adeq uate disi nfectio n before or aft er the system.

SECT. IIC PAGE 12

0111

Page 4

Short installation guide

1

1

2

2

1

3

2

S/M min. > 5 l (1.5 US gal)

L/XL min. > 10 l (3.0 US gal)

XXL min. > 15 l (4.0 US gal)

3

4

Everpure, LLC, 1040 Muirfield Drive, Hanover Park, Illinois 60133, phone: +1-630-307-3000, www.everpure.com

5

70.900.973

Page 5

Capacities in US gallons

Combi Steamers

Direct Injection

°KH

< 6 6 107 11 0 400 660 1'230 1'760 2'910

10 10 179 18 0 240 400 740 1'060 1'740

11 11 196 20 0 220 360 670 960 1'580

12 12 214 21 0 200 330 620 880 1'450

13 14 232 23 0 180 300 570 810 1'340

14 15 250 25 0 170 280 530 760 1'240

15 16 268 27 0 160 260 490 700 1'160

16 17 286 29 0 150 250 460 660 1'090

17 18 304 30 0 140 230 440 620 1'020

19 20 339 34 0 120 210 390 560 920

21 22 375 38 0 110 190 350 500 830

23 24 411 41 0 100 170 320 460 760

26 27 464 46 0 90 150 280 410 670

29 30 518 52 0 80 140 250 370 600

33 34 589 59 0 70 120 230 320 530

38 40 679 68 0 60 100 190 280 460

Grains

(US)

7 7 125 13 0 340 560 1'060 1'510 2'490

8 8 143 14 0 300 500 930 1'320 2'180

9 9 161 16 0 260 440 820 1'170 1'940

PPM °FH

Bypass-

levels

S M L XL XXL

capacity in US gal

Capacities are intended as guidelines and can vary according the machine typ. Please contact us for recommendations.

Everpure, LLC, 1040 Muirfield Drive, Hanover Park, Illinois 60133, phone: +1-630-307-3000, www.everpure.com

Page 6

Step 2. Test water to determine filter capacity

- Thoroughly rinse the vial with

the same water to be tested

- Take 5 ml sample water

- Holding the reagent bottle

vertically, add drops to the

sample water and shake to mix

even

- Start counting the drops when

the water turns blue, record

the number of reagent drops

when sample water turns to

orange-yellow

- With the number of drops

recorded, look up on chart

and locate the number of

water gallon under XL column

(or the column corresponding

to filter size), record the

number as result

Example: for 10 reagent drops, the filter

capacity is 1060 US Gal.

Page 7

5. Programming

Programming the Flow Meter

5.1 Setting the fi lter capacity in gallon

Please follow the capacity instruction for the appropriate CLARIS filter cartridge (see CLARIS filter Guide).

Step Button Display

1. Press the „PROG“ button once - „PROG“ flashes

2. Press the „RESET“ button once – active digit flashes

3.

4.

5.

6. Repeat Steps 4 and 5 until all digits have been set

7.

5.2 Resetting the fi lter capacity (after replacement of fi lter cartridge)

Step Button Display

1.

2.

By pressing the „RESET“ button, set the desired value

- For the digit “2”, press “RESET” two times

Press the „PROG“ button once to confirm the desired digit and switch to

the next digit. - Active digit flashes

By pressing the „RESET“ button, set the desired value

- For the digit „6“, press „RESET“ six times

Press the „PROG“ button once

- Final filter capacity is set - the programmed value appears

- Display flashes

Programmed filter capacity exhausted or maximum operation time of 12

months exceeded

Press and hold the „RESET“ button for approx. 3 sec.

- „rESEt“ appears on the display

3. The filter capacity is reset and the last programmed value appears

5.3 Memory Access

There is a possibility to individually retrieve the operating data (volume in gallon) and operation time in month of the

last five filter cartridges installed.

Step Button Display

1.

2.

3.

4.

5.

Press and hold the „PROG“ button for approx. 5 sec.

- The digit „1“ appears

The display indicates the volume in gallons and the operation

time in months of the last cartridge in place

Press the „RESET“ button once

- The operating data of the next to last filter cartridge are

displayed

Repeat Step 3 to access to the memories of the prior installed

filter cartridges

Press the „PROG“ button once

- The current filter capacity is displayed

6

Page 8

113560

10”

113583 ¾ X ½ Bushing

113558 Hose

113556

Claris

Head

Prefilter

113557 Flow Meter

113559

Test Kit

113857 O-ring

113555 Claris XL

Cartridge

Page 9

113560

113562

Prefilter

Cartridge

113587 O-Ring

113583 3/4 X 1/2

Bushing

113589 Prefilter head

113588 10”

113586 Wrench

Clear Bowl

Loading...

Loading...