Page 1

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

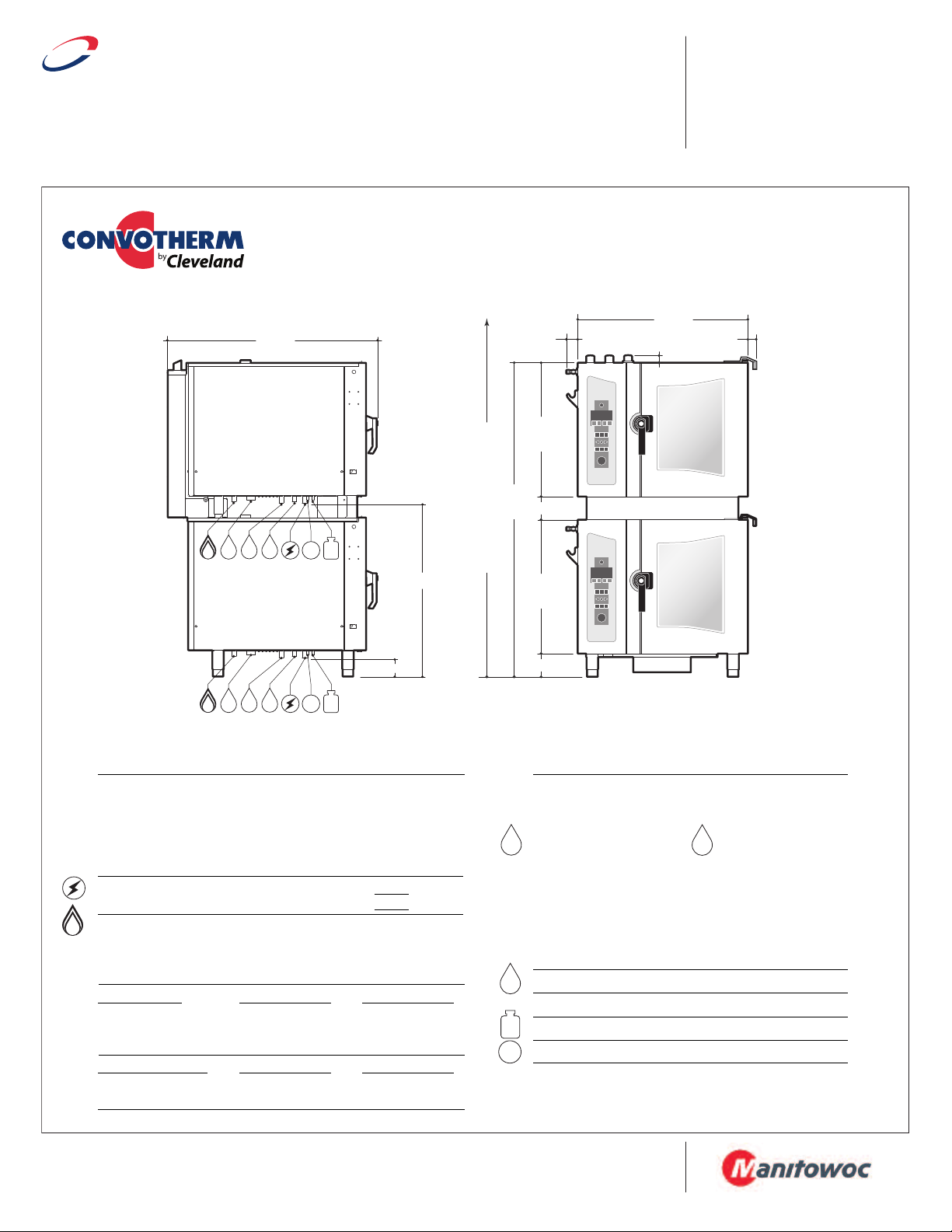

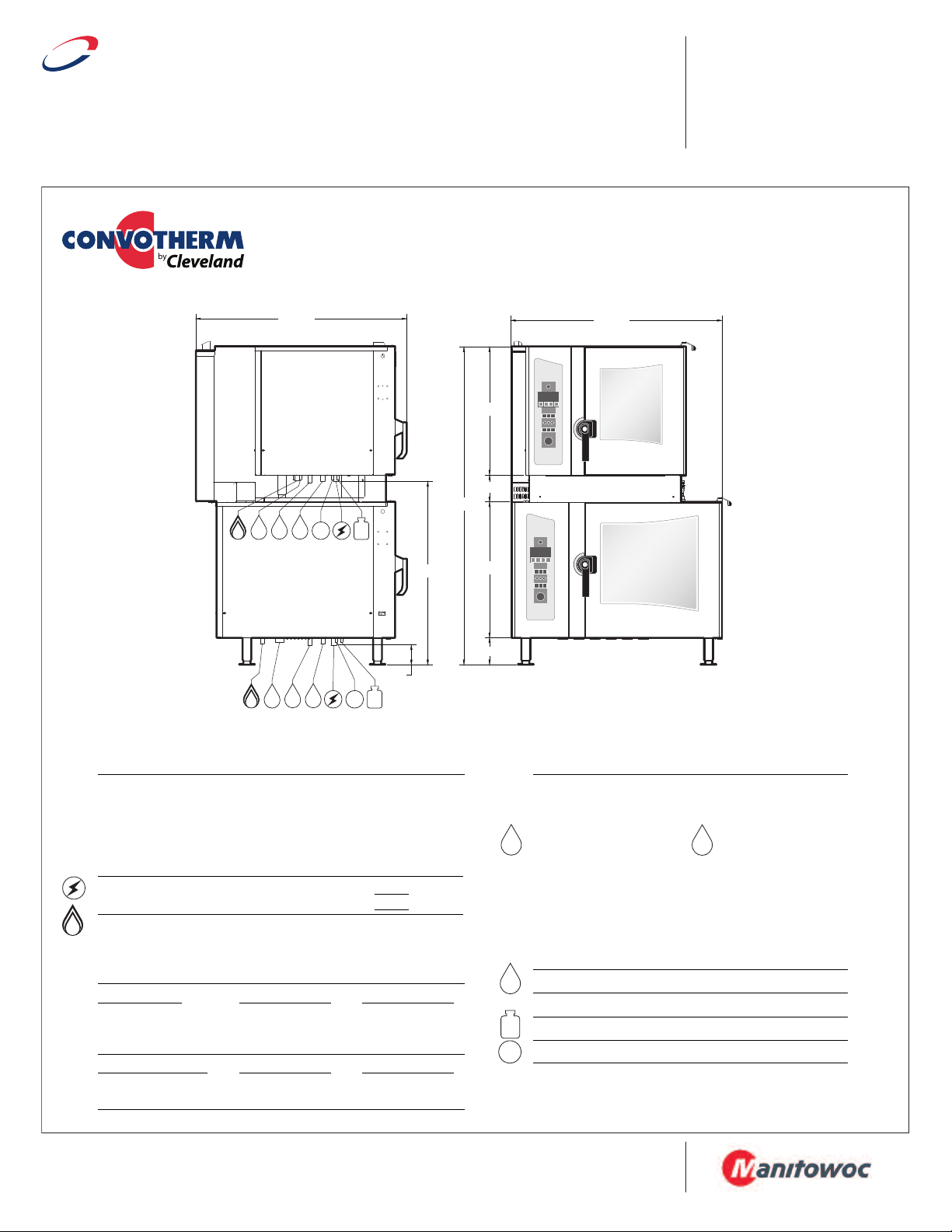

UNIT A

UNIT B

NOTE: Overall height of unit does not change for units with casters.

R

C

C

S

W1 W2

D

G

RC

CS

W1 W2

D

G

4.38"

38.08"

39.21"

L

EFT SIDE VIEW

UNIT A

UNIT B

36.70"

1.58"

28.43

5

.00"

1

.82"

67.8 5 "

28.43

6.00"

78.00” (MIN. HOOD REQUIREMENT)

2.52"

G

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.10 on OGB 6.10 or OGS 6.10 on OGS 6.10)

Model # Description

CSTK610 for mounting two 6.10 models

STK610CA for mounting two 6.10 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factory service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

Gas Type: Natural Gas (Propane optional)

Gas Flow Pressure: Natural Gas - Min. 5.5" WC / Max. 14" WC

BOILER MODELS

Total Connected Load: 45.400 BTU 45.400 BTU

Steam Generator: 45.400 BTU 45.400 BTU

Hot Air: 45.400 BTU 45.400 BTU

BOILERLESS MODELS

Total Connected Load: 45.400 BTU 45.400 BTU

Hot Air: 45.400 BTU 45.400 BTU

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

UNIT A UNIT B -

11.7 amps

11.7 amps

Propane Gas - Min. 11" WC / Max. 14" WC

UNIT A - OGB 6.10 UNIT B - OGB 6.10

UNIT A - OGS 6.10 UNIT B - OGS 6.10

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5A

0810

Page 2

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

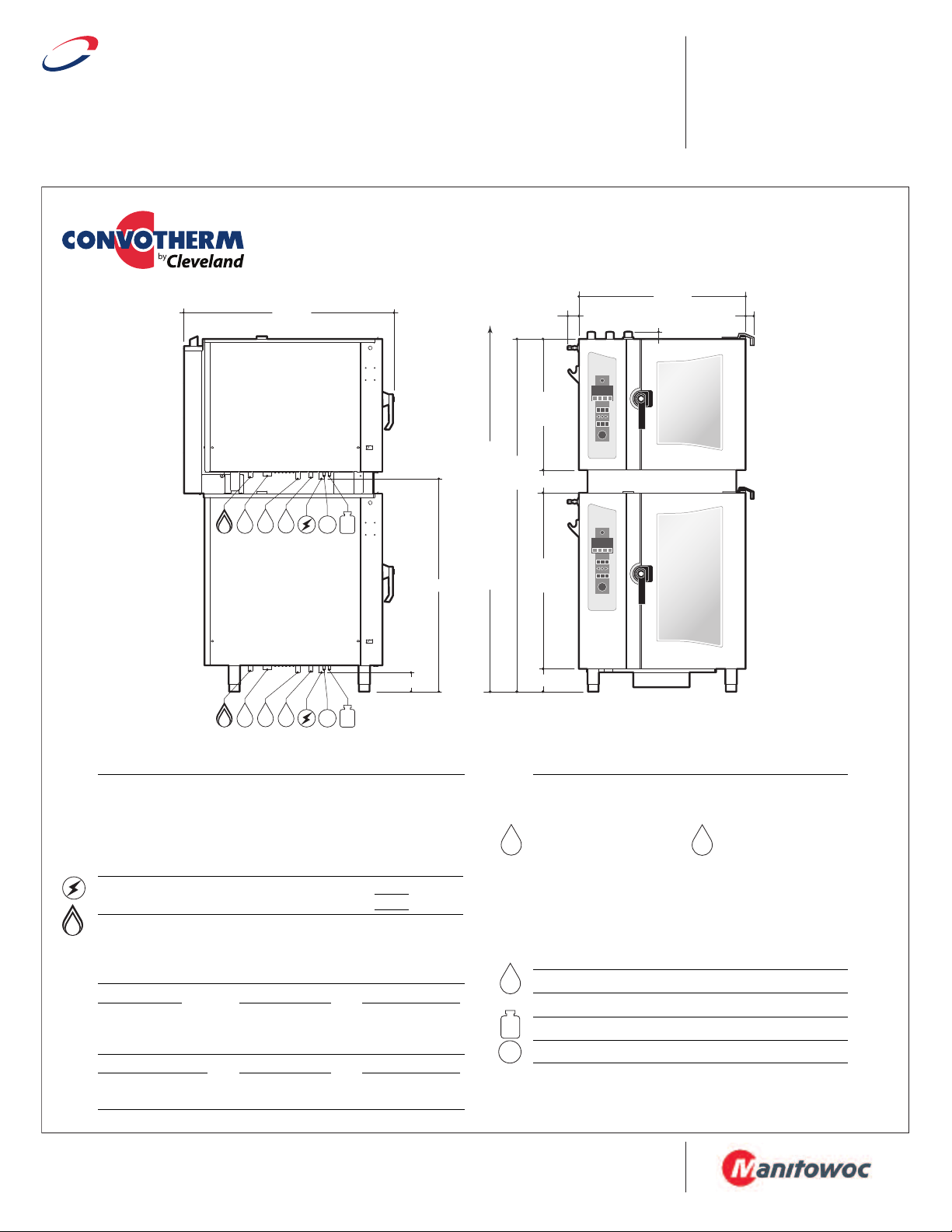

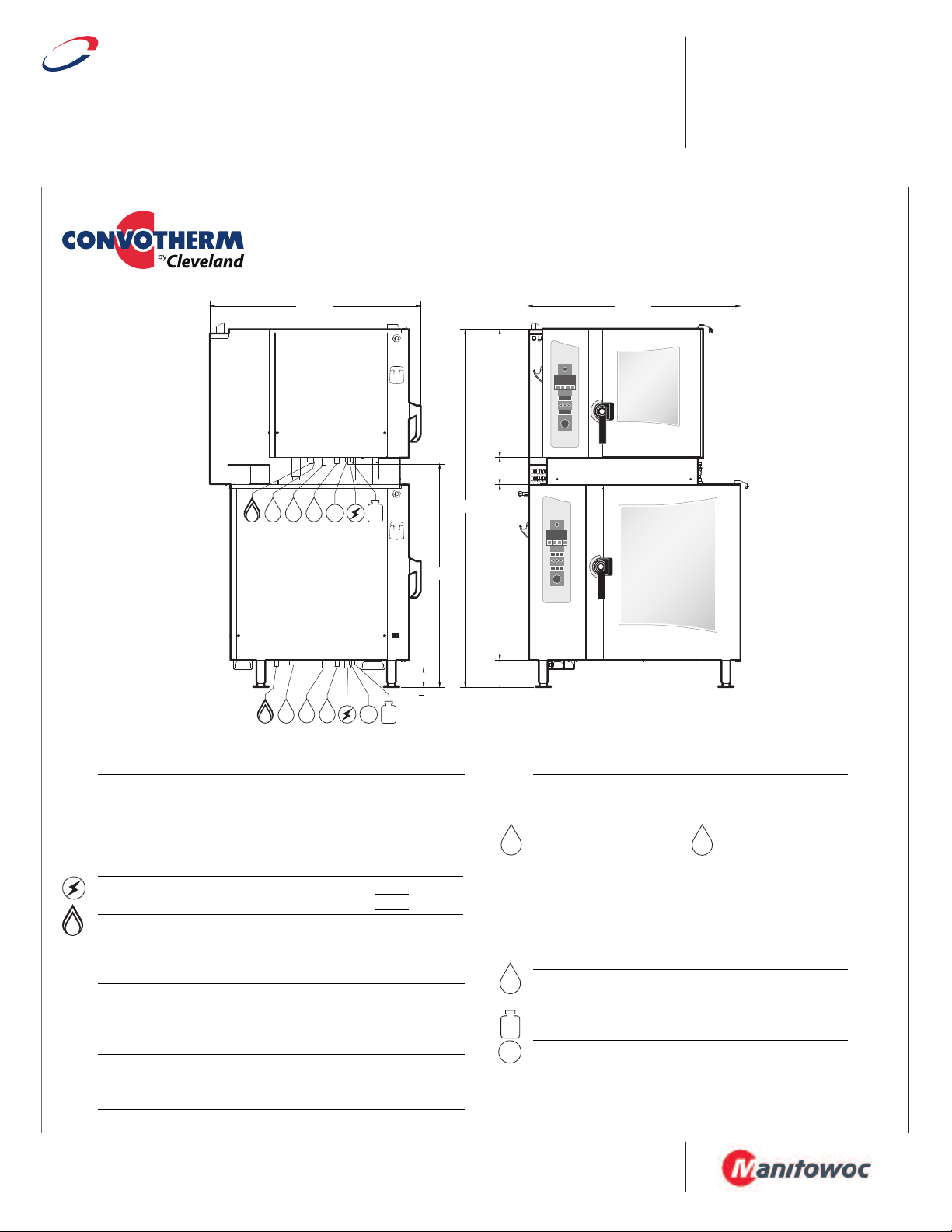

UNIT A

UNIT B

RC

CS

W1 W2

D

G

RC

C

S

W1 W2

D

G

4.38"

48.54”

39.21"

NOTE: Overall height of unit does not change for units with casters.

U

NIT A

UNIT B

L

EFT SIDE VIEW

78.41"

36.70"

1.58"

1.82"

28.43

5.00"

38.98"

6.00"

80.00” (MIN. HOOD REQUIREMENT)

2.52"

G

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.10 on OGB 10.10 or OGS 6.10 on OGS 10.10)

Model # Description

CSTK1010 for mounting one 6.10 model on top of one 10.10 model

CSTK1010CA for mounting one 6.10 model on top of one 10.10 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factory service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

Gas Type: Natural Gas (Propane optional)

Gas Flow Pressure: Natural Gas - Min. 5.5" WC / Max. 14" WC

BOILER MODELS

Total Connected Load: 45.400 BTU 75,700 BTU

Steam Generator: 45.400 BTU 68,200 BTU

Hot Air: 45.400 BTU 75,700 BTU

BOILERLESS MODELS

Total Connected Load: 45.400 BTU 75,700 BTU

Hot Air: 45.400 BTU 75,700 BTU

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

UNIT A UNIT B -

11.7 amps

11.7 amps

Propane Gas - Min. 11" WC / Max. 14" WC

UNIT A - OGB 6.10 UNIT B - OGB 10.10

UNIT A - OGS 6.10 UNIT B - OGS 10.10

3/4" GHT-F (Female Garden Hose Connection)

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

SECT. IIB PAGE 5B

0810

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

Page 3

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

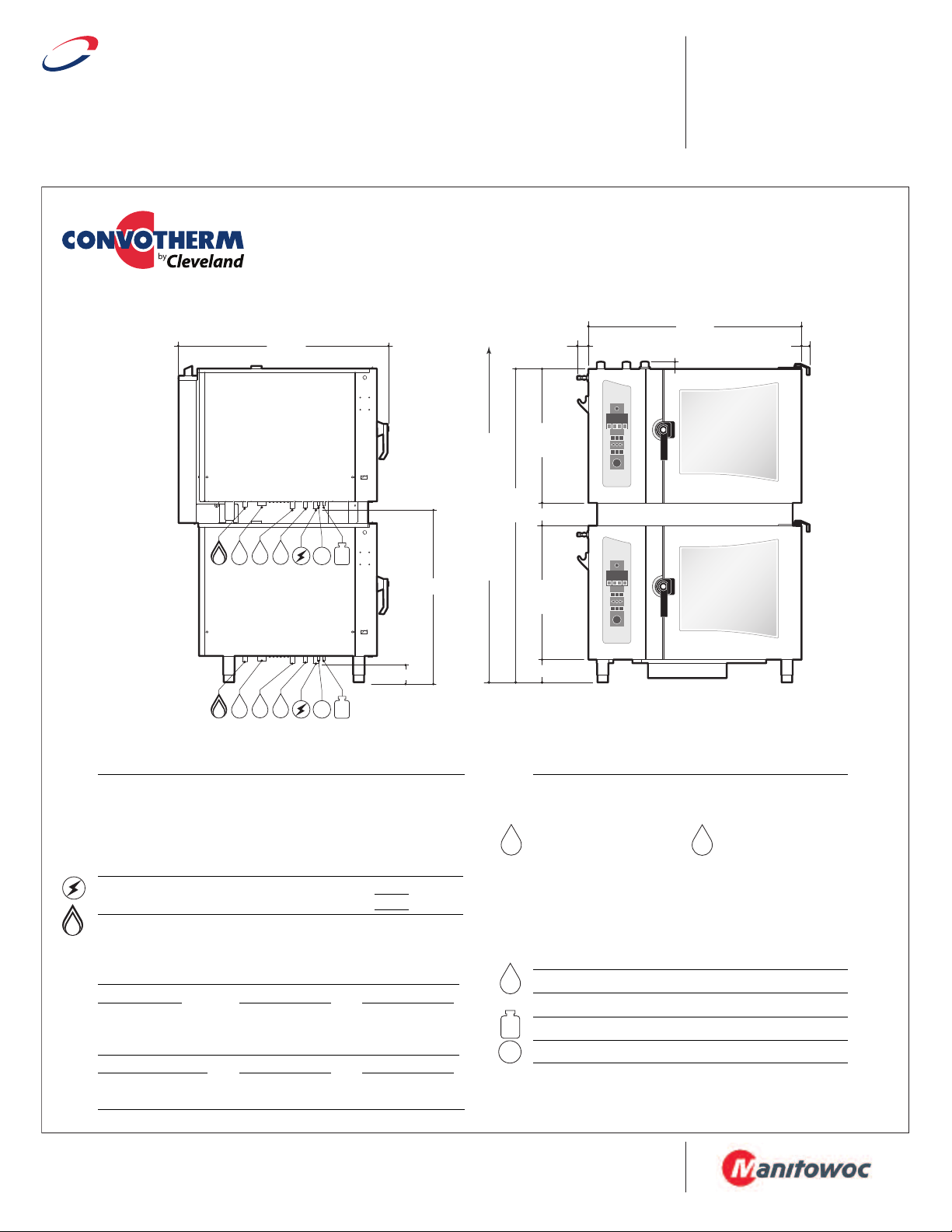

2.52"

30.12"

5.00"

30.12"

6.00"

47.92"

1.58"

1.82"

71.24"

NOTE: Overall height of unit does not change for units with casters.

78.00” (MIN. HOOD REQUIREMENT)

RC

CS

W1 W2

D

G

RC

CS

W1 W2

D

G

4.38"

39.50"

47.72"

U

NIT A UNIT A

UNIT B

UNIT B

LEFT SIDE VIEW

FRONT VIEW

G

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.20 on OGB 6.20 or OGS 6.20 on OGS 6.20)

Model # Description

CSTK620 for mounting two 6.20 models

STK620CA for mounting two 6.20 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factory service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

Gas Type: Natural Gas (Propane optional)

Gas Flow Pressure: Natural Gas - Min. 5.5" WC / Max. 14" WC

BOILER MODELS

Total Connected Load: 75,700 BTU 75,700 BTU

Steam Generator: 68,200 BTU 68,200 BTU

Hot Air: 75,700 BTU 75,700 BTU

BOILERLESS MODELS

Total Connected Load: 75,700 BTU 75,700 BTU

Hot Air: 75,700 BTU 75,700 BTU

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

Propane Gas - Min. 11" WC / Max. 14" WC

UNIT A - OGB 6.20 UNIT B - OGB 6.20

UNIT A - OGS 6.20 UNIT B - OGS 6.20

UNIT A -

11.7 amps

UNIT B -

11.7 amps

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5C

0810

Page 4

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

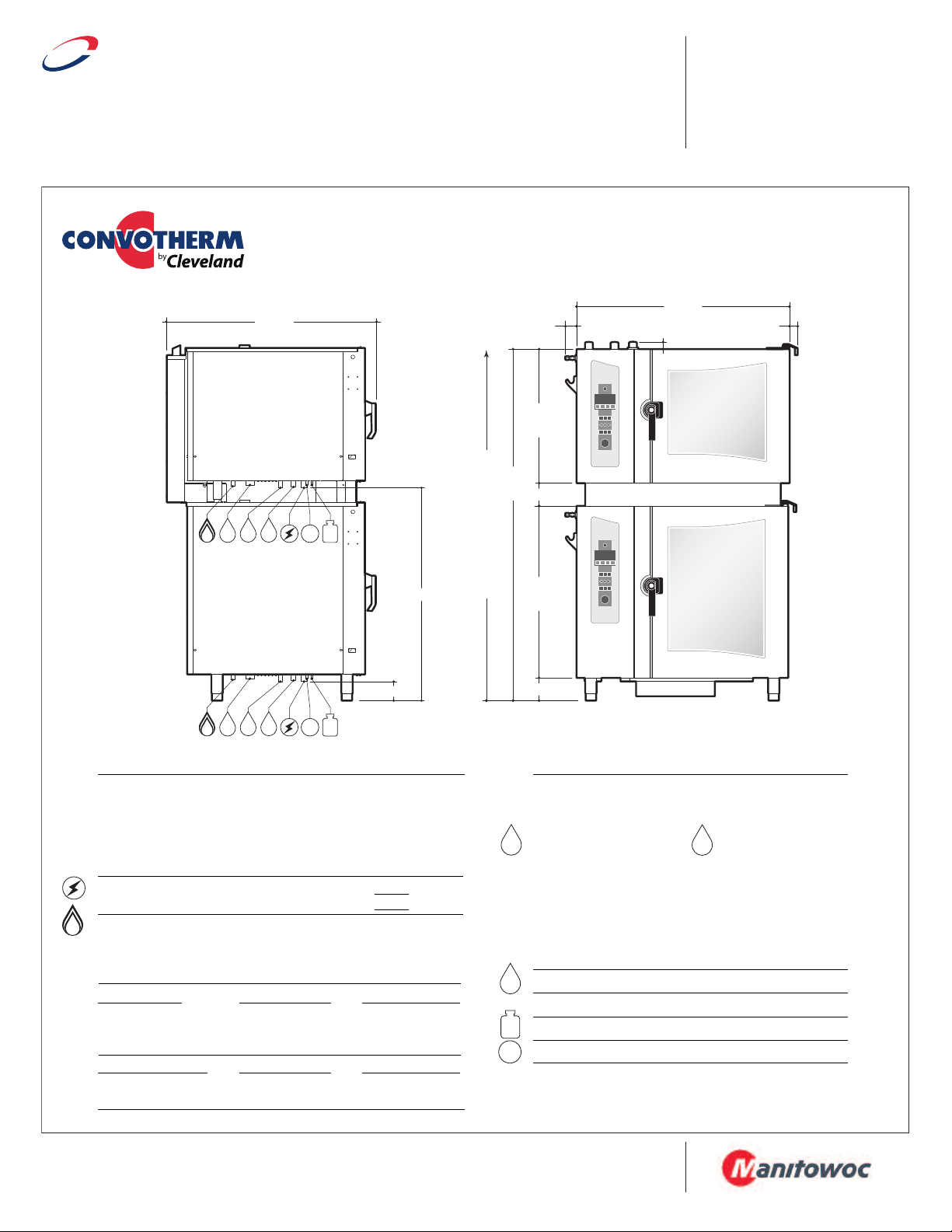

80.09"

47.92"

2.52"

1.58"

1.82"

30.12"

5.00"

38.98"

6.00"

81.00” (MIN. HOOD REQUIREMENT)

RC

CS

W1 W2

D

G

RC

CS

W1 W2

D

G

4.38"

48.32"

4

7.72"

NOTE: Overall height of unit does not change for units with casters.

UNIT A UNIT A

UNIT B

UNIT B

LEFT SIDE VIEW

FRONT VIEW

G

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.20 on OGB 10.20 or OGS 6.20 on OGS 10.20)

Model # Description

CSTK1020 for mounting one 6.20 model on top of one 10.20 model

CSTK1020CA for mounting one 6.20 model on top of one 10.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factory service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

Gas Type: Natural Gas (Propane optional)

Gas Flow Pressure: Natural Gas - Min. 5.5" WC / Max. 14" WC

BOILER MODELS

Total Connected Load: 75,700 BTU 132,700 BTU

Steam Generator: 68,200 BTU 113,600 BTU

Hot Air: 75,700 BTU 132,700 BTU

BOILERLESS MODELS

Total Connected Load: 75,700 BTU 132,700 BTU

Steam Generator: 75,700 BTU 132,700 BTU

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

Propane Gas - Min. 11" WC / Max. 14" WC

UNIT A UNIT B -

11.7 amps

15.9 amps

UNIT A - OGB 6.20 UNIT B - OGB 10.20

UNIT A - OGS 6.20 UNIT B - OGS 10.20

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

3/4" GHT-F (Female Garden Hose Connection)

SECT. IIB PAGE 5D

0810

Page 5

D

RC

CS

W1

W2

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

UNIT A

UNIT B

NOTE: Overall height of unit does not change for units with casters.

6.00"

30.19"

5.98"

28.46"

4.41"

40.73"

70.64"

4

7.82"

47.82"

R

C

C

S

W1 W2

D

RC

CS

W1 W2

D

G

G

G

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.10 on OGB 6.20 or OGS 6.10 on OGS 6.20)

Model # Description

CSTKG610620 for mounting one 6.10 model on top of one 6.20 model

CSTKG610620CA for mounting one 6.10 model on top of one 6.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factory service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

Gas Type: Natural Gas (Propane optional)

Gas Flow Pressure: Natural Gas - Min. 5.5" WC / Max. 14" WC

BOILER MODELS

Total Connected Load: 45.400 BTU 75,700 BTU

Steam Generator: 45.400 BTU 68,200 BTU

Hot Air: 45.400 BTU 75,700 BTU

BOILERLESS MODELS

Total Connected Load: 45.400 BTU 75,700 BTU

Hot Air: 45.400 BTU 75,700 BTU

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

Propane Gas - Min. 11" WC / Max. 14" WC

UNIT A - OGB 6.10 UNIT B - OGB 6.20

UNIT A - OGS 6.10 UNIT B - OGS 6.20

UNIT A -

11.7 amps

UNIT B -

11.7 amps

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5E

0810

Page 6

D

RC

CS

W1

W2

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

UNIT A

UNIT B

NOTE: Overall height of unit does not change for units with casters.

6.00"

3

9.04"

5.98"

28.46"

79.49"

4.33"

4

9.57"

4

7.82"

48.11"

R

C

CS

W1 W2

D

RC

CS

W1 W2

D

G

G

G

COMBI OVEN-STEAMER

Stacking Kits for Gas Table Type Models

(OGB 6.10 on OGB 10.20 or OGS 6.10 on OGS 10.20)

Model # Description

CSTKG6101020 for mounting one 6.10 model on top of one 10.20 model

CSTKG6101020CA for mounting one 6.10 model on top of one 10.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located

next to the unit.

• Allow for sufficient clearance on left side for service access (contact the

factory service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

Do not connect to a G.F.I. outlet.

Gas Connection: 3/4" NPT

Gas Type: Natural Gas (Propane optional)

Gas Flow Pressure: Natural Gas - Min. 5.5" WC / Max. 14" WC

BOILER MODELS

Total Connected Load: 45.400 BTU 132,700 BTU

Steam Generator: 45.400 BTU 113,600 BTU

Hot Air: 45.400 BTU 132,700 BTU

BOILERLESS MODELS

Total Connected Load: 45.400 BTU 132,700 BTU

Hot Air: 45.400 BTU 132,700 BTU

Rear - 2", Left Side - 4", Right Side - 2 1/2"

120 volt, 60 Hz, single phase,

Propane Gas - Min. 11" WC / Max. 14" WC

UNIT A - OGB 6.10 UNIT B - OGB 10.20

UNIT A - OGS 6.10 UNIT B - OGS 10.20

UNIT A UNIT B -

15.9 amps

15.9 amps

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5F

0810

Page 7

D

RC

CS

W1

W2

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

37.83"

L

EFT SIDE VIEW

36.70"

1.58"

1.82"

2.52"

R

C

CS

W1 W2

D

RC

CS

W1 W2

D

NOTE: Overall height of unit does not change for units with casters.

4.38"

38.08"

28.43

5.00"

67.8 5 "

28.43

6.00"

78.00” (MIN. HOOD REQUIREMENT)

UNIT A

UNIT B

UNIT A

UNIT B

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.10 on OEB 6.10 or OES 6.10 on OES 6.10)

Model # Description

CSTK610 for mounting two 6.10 models

STK610CA for mounting two 6.10 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB 6.10 UNIT B - OEB 6.10

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 9.9 KW 12.8 KW 11 KW 13.1 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 8.6 KW 11.4 KW 9.1 KW 10.2 KW

Steam Generator: 7.7 KW 10.2 KW 8.6 KW 10.2 KW 7.7 KW 10.2 KW 8.6 KW 10.2 KW

Amps per Phase: 27.3 30.8 15.2 16.3 27.3 30.8 15.2 16.3

BOILERLESS UNIT A - OES 6.10 UNIT B - OES 6.10

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 9.9 KW 12.8 KW 11 KW 13.1 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 8.6 KW 11.4 KW 9.1 KW 10.2 KW

Amps per Phase: 27.3 30.8 15.2 16.3 27.3 30.8 15.2 16.3

Rear - 2", Left Side - 4", Right Side - 2 1/2"

Do not connect to a G.F.I. outlet.

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec

sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5G

0810

Page 8

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

UNIT A

UNIT B

RC

CS

W1 W2

D

RC

CS

W1 W2

D

37.83"

NOTE: Overall height of unit does not change for units with casters.

L

EFT SIDE VIEW

U

NIT A

UNIT B

4.38"

4

8.54"

78.41"

36.70"

1

.58"

1.82"

28.43

5.00"

38.98"

6.00"

80.00” (MIN. HOOD REQUIREMENT)

2.52"

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.10 on OEB 10.10 or OES 6.10 on OES 10.10)

Model # Description

CSTK1010 for mounting one 6.10 model on top of one 10.10 model

CSTK1010CA for mounting one 6.10 model on top of one 10.10 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB 6.10 UNIT B - OEB 10.10

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Steam Generator: 7.7 KW 10.2 KW 8.6 KW 10.2 KW 12.8 KW 17.1 KW 14.3 KW 17.1 KW

Amps per Phase: 27.3 30.8 15.2 16.3 45.5 51.8 24.2 26.4

BOILERLESS UNIT A - OES 6.10 UNIT B - OES 10.10

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Amps per Phase: 27.3 30.8 15.2 16.3 45.5 51.8 24.2 26.4

Do not connect to a G.F.I. outlet.

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5H

0810

Page 9

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

71.20"

47.92"

2.52"

1.58"

1.82"

30.12"

5.00"

30.12"

6.00"

78.00” (MIN. HOOD REQUIREMENT)

RC

CS

W1 W2

D

RC

CS

W1 W2

D

4.38"

39.50"

46.34"

NOTE: Overall height of unit does not change for units with casters.

UNIT A UNIT A

UNIT B

UNIT B

LEFT SIDE VIEW

FRONT VIEW

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.20 on OEB 6.20 or OES 6.20 on OES 6.20)

Model # Description

CSTK620 for mounting two 6.20 models

STK620CA for mounting two 6.20 models (with casters)

C

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB 6.20 UNIT B - OEB 6.20

MODELS

Total Connected Load: 16.4 KW 21.6 KW 18.5 KW 22 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Steam Generator: 12.8 KW 17.1 KW 14.3 KW 17.1 KW 12.8 KW 17.1 KW 14.3 KW 17.1 KW

Amps per Phase: 45.5 51.8 24.2 26.4 45.5 51.8 24.2 26.4

BOILERLESS UNIT A - OES 6.20 UNIT B - OES 6.20

MODELS

Total Connected Load: 16.4 KW 21.6 KW 18.5 KW 22 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Amps per Phase: 45.5 51.8 24.2 26.4 45.5 51.8 24.2 26.4

Rear - 2", Left Side - 4", Right Side - 2 1/2"

Do not connect to a G.F.I. outlet.

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5J

0810

Page 10

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

80.09"

47.92"

2

.52"

1.58"

1

.82"

30.12"

5.00"

38.98"

6.00"

81.00” (MIN. HOOD REQUIREMENT)

RC

CS

W1 W2

D

RC

CS

W1 W2

D

4.38"

48.32"

46.34"

NOTE: Overall height of unit does not change for units with casters.

UNIT A UNIT A

UNIT B

UNIT B

LEFT SIDE VIEW

FRONT VIEW

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.20 on OEB 10.20 or OES 6.20 on OES 10.20)

Model # Description

CSTK1020 for mounting one 6.20 model on top of one 10.20 model

CSTK1020CA for mounting one 6.20 model on top of one 10.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB 6.20 UNIT B - OEB 10.20

MODELS

Total Connected Load: 16.4 KW 21.6 KW 18.5 KW 22 KW 26.3 KW 34.9 KW 29.4 KW 34.9 KW

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 25.8 KW 34.3 KW 28.8 KW 34.3 KW

Steam Generator: 12.8 KW 17.1 KW 14.3 KW 17.1 KW 20.5 KW 27.3 KW 22.9 KW 27.3 KW

Amps per Phase: 45.5 51.8 24.2 26.4 77.8 88.8 41.4 44.9

BOILERLESS UNIT A - OES 6.20 UNIT B - OES 10.20

MODELS

Total Connected Load: 16.4 KW 21.6 KW 18.5 KW 22 KW 26.3 KW 34.9 KW 29.4 KW 34.9 KW

Hot Air: 14.7 KW 19.6 KW 16.5 KW 19.6 KW 25.8 KW 34.3 KW 28.8 KW 34.3 KW

Amps per Phase: 45.5 51.8 24.2 26.4 77.8 88.8 41.4 44.9

Do not connect to a G.F.I. outlet.

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5K

0810

Page 11

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

UNIT A

UNIT B

NOTE: Overall height of unit does not change for units with casters.

6.00"

4.37"

30.16"

5.98"

28.46"

43.38"

40.51"

4

7.79"

70.61"

R

C

C

S

W1 W2

D

RC

CS

W1 W2

D

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.10 on OEB 6.20 or OES 6.10 on OES 6.20)

Model # Description

CSTKE610620 for mounting one 6.10 model on top of one 6.20 model

CSTKE610620CA for mounting one 6.10 model on top of one 6.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB 6.10 UNIT B - OEB 6.20

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Steam Generator: 7.7 KW 10.2 KW 8.6 KW 10.2 KW 12.8 KW 17.1 KW 14.3 KW 17.1 KW

Amps per Phase: 27.3 30.8 15.2 16.3 45.5 51.8 24.2 26.4

BOILERLESS UNIT A - OES 6.10 UNIT B - OES 6.20

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 16.4 KW 21.6 KW 18.5 KW 22 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 14.7 KW 19.6 KW 16.5 KW 19.6 KW

Amps per Phase: 27.3 30.8 15.2 16.3 45.5 51.8 24.2 26.4

Rear - 2", Left Side - 4", Right Side - 2 1/2"

Do not connect to a G.F.I. outlet.

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5L

0810

Page 12

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

UNIT A

UNIT B

NOTE: Overall height of unit does not change for units with casters.

4.37"

49.36"

6.00"

39.02"

5.98"

28.46"

79.46"

43.38"

47.79"

RC

CS

W1 W2

D

RC

CS

W1 W2

D

D

RC

CS

W1

W2

COMBI OVEN-STEAMER

Stacking Kits for Electric Table Type Models

(OEB 6.10 on OEB 10.20 or OES 6.10 on OES 10.20)

Model # Description

CSTKE6101020 for mounting one 6.10 model on top of one 10.20 model

CSTKE6101020CA for mounting one 6.10 model on top of one 10.20 model (with casters)

UTILITIES (Utility connection shown below are listed per unit)

Required Clearances:

Rear - 2", Left Side - 4", Right Side - 2 1/2"

• Allow for sufficient distance if a "high heat source" (i.e. Broiler) is located next to

the unit.

• Allow for sufficient clearance on left side for service access (contact the factory

service department for recommendations).

• Installation must comply with all local fire and health codes.

Electrical Requirements:

BOILER UNIT A - OEB 6.10 UNIT B - OEB 10.20

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 26.3 KW 34.9 KW 29.4 KW 34.9 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 25.8 KW 34.3 KW 28.8 KW 34.3 KW

Steam Generator: 7.7 KW 10.2 KW 8.6 KW 10.2 KW 20.5 KW 27.3 KW 22.9 KW 27.3 KW

Amps per Phase: 27.3 30.8 15.2 16.3 77.8 88.8 41.4 44.9

BOILERLESS UNIT A - OES 6.10 UNIT B - OES 10.20

MODELS

Total Connected Load: 9.9 KW 12.8 KW 11 KW 13.1 KW 26.3 KW 34.9 KW 29.4 KW 34.9 KW

Hot Air: 8.6 KW 11.4 KW 9.1 KW 10.2 KW 25.8 KW 34.3 KW 28.8 KW 34.3 KW

Amps per Phase: 27.3 30.8 15.2 16.3 77.8 88.8 41.4 44.9

Do not connect to a G.F.I. outlet.

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

208/3/60 240/3/60 440/3/60 480/3/60 208/3/60 240/3/60 440/3/60 480/3/60

Water Connections: Cold Water (drinking water quality)

Flow Pressure: 35 - 60 PSI

Water Inlets:

Treated Water for Steam Generator Untreated Water for Condenser

NOTE: The owner / operator / purchaser must ensure that the Water Quality

Requirements are met. Not meeting the water quality requirements will void the

original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

3/4" GHT-F (Female Garden Hose Connection)

Drain Connection: 2" Tube

Venting: Exhaust Hood required

Connection for Cleaning Solution (Available as an option)

Connection for Rinse Cycle (Available as an option)

Note: For additional connection details, see spec sheet

for each individual combi model to be stacked.

SECT. IIB PAGE 5M

0810

Page 13

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

25.50”

20.28”

27.72”

24.00”

39.31”

72.77”

43.57”

71.25”

6.01”

35.41”

38.56”

35.06”

31.26”

THE "mini" COMBI OVEN-STEAMER

Stacking Kit for Electric Table Type Models

(OES 3.10 mini on OES 3.10 mini)

Model # Description

CST2310OB for mounting two OES 3.10 mini models

UTILITIES (Utility connection shown below are listed per unit)

ELECTRICAL CONNECTIONS

The 3 phase 208-240 volt units will be supplied with a 10 AWG,SOOW, 4

conductor 6 foot long cord. The customer will have to provide the NEMA plug

(NEMA # 15-30P or L15-30P). Unit current rating 24 amps.

The 1 phase 208-220 volt units will be supplied with a 10 AWG, SOOW, 3

conductor 6 foot long cord. The customer will have to provide the NEMA plug

(NEMA # 6-30P or L6-30P). Unit current rating 24 amps.

The 1 phase 240 volt units will be supplied with a 10 AWG, SOOW, 3

conductor 6 foot long cord. The customer will have to provide the NEMA plug

(NEMA # 6-50P or L6-50P). Unit current rating 25.5 amps.

These units cannot be hard wired to the circuit box. They must have a NEMA

plug to be connected to a mating NEMA receptacle (customer supplied) to

comply with the U.L. and NEC electrical standards.

OPTIONS & ACCESSORIES

CSH2310 Smooth action spray hose for stacked units

COLD WATER CONNECTION

One 3/4" GHT (Garden Thread Hose) connection. Use NSF approved hose.

35 PSI minimum, 60 PSI maximum.

NOTE: The owner / operator / purchaser must ensure that the Water Quality Requirements are met.

Not meeting the water quality requirements will void the original equipment warranty.

Water Quality Requirements:

TDS . . . . . . . . . . . . < 60 ppm pH Factor . . . . . 7.0 – 8.5

Total Alkalinity . . . . < 20 ppm Free Chlorine. . . < 0.1 ppm

Silica . . . . . . . . . . . < 13 ppm Conductivity . . . min. 20 µS/cm (50 kOhms)

Chloride . . . . . . . . < 25 ppm

DRAIN CONNECTION

1 1/2" tube.

Do not connect other units to this drain.

Drain line must be vented.

SERVICE CLEARANCES

3" left, 3" right, 3" rear, allow 20" on top for service.

SECT. IIB PAGE 5N

0810

Page 14

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COMBI OVEN-STEAMER

Options & Accessories

Stacking Stand for one Cleveland 6.20 Combi

and one Convection Oven

Cleveland Standard Features:

I

I

Stand frame constructed of 1 1/2" thick wall, square tubing

I

I

Solid top for directing heat away from Combi

I

I

Crossbar supported on three sides

I

I

Corner gussets for additional rigidity

I

I

16 gauge stainless steel table top

I

I

Four, one (1) inch high locator pins for mounting 6.20 combi on

stand

I

I

Stand restraining device (CBST62042CA only)

I

I

Four level adjustable flanged feet (CBST62042 only)

I

I

Four heavy duty 3" diameter swivel casters,

two with brakes (CBST62042CA only)

I

I

Service friendly and easy to clean

I

I

UL Sanitation approved, according to NSF2 standards

MODEL: CBST62042 (PN 112433) (with legs)

CBST62042CA (PN 112421) (with casters)

ITEM NUMBER __________________________________________

JOB NAME / NUMBER __________________________________

Notes:

Ë The stands are designed to accommodate full or half size gas or

electric Convection Ovens

Ë The stands are built to support all Cleveland 6.20 Combi models

Ë The Convection Oven must always be installed on the bottom

Short Form Specifications

Shall be Cleveland Model: CBST62042___ Stacking Stand for one Cleveland

6.20 Combi and one full or half size Convection Oven. Stand frame

constructed of 1 1/2" thick wall, square tubing. Crossbar supported on three

sides. 16 gauge stainless steel table top. Four, one (1) inch high locator pins

for mounting 6.20 combi on stand. Stand restraining device (for

CBST62042CA only). Four level adjustable flanged feet (CBST62042) or four

heavy duty 3" diameter swivel casters, two with brakes (CBST62042CA).

SECT. IIB PAGE 5P

0810

Page 15

4

5.00”

42.00”

6

.50”

42.00”

6

.50”

47.92” 40.44”

3.18”

38.26”

42.00”

78.90”

5

0.00”

45.00”

50.00”

80.50”

4

42.00”

CST62042 (with feet) CST62042CA (with casters)

The Convection Oven manufacturer and installers are responsible

for proper venting and if needed installing a flue diverter for the

Convection Oven (not supplied by Cleveland Range).

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers.

SECT. IIB PAGE 5Q

0810

Page 16

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COMBI OVEN-STEAMER

Options & Accessories

Stacking Stand for one Cleveland 6.10 Combi

and one Convection Oven

Cleveland Standard Features:

I

I

Stand frame constructed of 1 1/2" thick wall, square tubing

I

I

Solid top for directing heat away from Combi

I

I

Crossbar supported on three sides

I

I

Corner gussets for additional rigidity

I

I

16 gauge stainless steel table top

I

I

Four, one (1) inch high locator pins for mounting 6.10 combi on

stand

I

I

Stand restraining device (CBST61042CA only)

I

I

Four level adjustable flanged feet (CBST61042 only)

I

I

Four heavy duty 3" diameter swivel casters,

two with brakes (CBST61042CA only)

I

I

Service friendly and easy to clean

I

I

UL Sanitation approved, according to NSF2 standards

MODEL: CBST61042 (PN 113313) (with legs)

CBST61042CA (PN 113314) (with casters)

ITEM NUMBER __________________________________________

JOB NAME / NUMBER __________________________________

Notes:

Ë The stands are designed to accommodate full or half size gas or

electric Convection Ovens

Ë The stands are built to support all Cleveland 6.10 Combi models

Ë The Convection Oven must always be installed on the bottom

Short Form Specifications

Shall be Cleveland Model: CBST61042___ Stacking Stand for one Cleveland

6.10 Combi and one full or half size Convection Oven. Stand frame

constructed of 1 1/2" thick wall, square tubing. Crossbar supported on three

sides. 16 gauge stainless steel table top. Four, one (1) inch high locator pins

for mounting 6.10 combi on stand. Stand restraining device (for

CBST61042CA only). Four level adjustable flanged feet (CBST61042) or four

heavy duty 3" diameter swivel casters, two with brakes (CBST61042CA).

SECT. IIB PAGE 5R

0810

Page 17

45.00”

42.00”

6

.50”

42.00”

6.50”

36.70”

30.17”

3.18”

38.26”

42.00”

76.43”

50.00”

45.00”

50.00”

78.01”

CBST61042 (with feet) CBST61042CA (with casters)

The Convection Oven manufacturer and installers are responsible

for proper venting and if needed installing a flue diverter for the

Convection Oven (not supplied by Cleveland Range).

NOTES:

Cleveland Range reserves right of design improvement or modification, as warranted.

Many regional, state and local codes exist and it is the responsibility of the owner and installer to comply with the codes.

Cleveland Range equipment is built to comply with applicable standards for manufacturers.

SECT. IIB PAGE 5S

0810

Page 18

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

71.80”

38.28”

43.09”

38.33”

5.00”

CONVOTHERM

Stacking Kit

Garland

Stacking Kit

COMBI OVEN-STEAMER

Options & Accessories

Stacking Kits for stacking:

• one CONVOTHERM Combi Oven

(models OES & OEB 6.10)

on top of

• one Garland Convection Oven

(models MCO-ES-10-S & MCO-ED-10-S)

Models:

• From Cleveland:

Order CONVOTHERM Combi Oven with Stacking Kit

(PN 112256)

• From Garland:

Order Convection Oven with Stacking Kit

(PN 1951221-feet or 1951225-casters)

NOTE: Both Cleveland and Garland Stacking Kits are required.

SECT. IIB PAGE 5T

0810

Loading...

Loading...