Page 1

Cleveland

™

P

roject ________________________________

I

tem __________________________________

Quantity _______________________________

FCSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COOK CHILL SYSTEMS

CYCLE-MATIC

VERTICAL FORM-FILL-SEAL MACHINE

Cleveland Standard Features

n

Small footprint, compact, mobile design mounted on 5" locking casters

n

Fill speeds of up to 30 cycles per minute (speeds depend on

pouch size and length)

n

User friendly, menu driven, multi color touch screen controls

for selecting:

•

Pouch length

•

Film speed

•

Pouch count

•

Time and temperature heat-seal functions

•

Manual and automatic fill operation

•

Jog for film transport

•

Fill cycle start

•

Operation of the food transfer pump (AFF-950-FTP)

n

Main power on/off switch with two emergency safety stops

n

Standard pouch width of 9.5 inches with a selectable pouch

length of up to 30"

n

Feature to make a continuous tube for ease of cleaning

n

Base frame, shafts and bearings are constructed of stainless

steel

n

Stainless steel, teflon coated heating bars

n

Pneumatically operated sealing bars and ser

knife

n

Durable, hinged Lexan safety guards with cut off safety

switches

n

Motorized film unwinding to eleminate drag and minimize belt

wearing

n

Air contr

n

Factory mounted air regulator, filter and lubricator

n Accepted for use in U.S.D.A. Inspected Facilities

olled dispensing valve with a drip pr

rated cutting

oof seal

C

ook/Chill Systems

MODEL:cAFF-950

Short Form Specifications

Shall be CLEVELAND Model AFF-950 Cycle-Matic, VERTICAL

FORM-FILL-SEAL MACHINE; small footprint, compact, mobile design;

Fill speeds of up to 30 cycles per minute; User friendly, menu driven,

multi color touch screen controls; Standard pouch width of 9.5 inches

with a selectable pouch length of up to 30"; Base frame, shafts, bearings and heating bars ar

steel serrated cutting knife; Hinged Lexan safety guards with cut off

safety switches; Motorized film unwinding; Air controlled dispensing

valve with a drip proof seal.

ucted of stainless steel; Stainless

e constr

Options & Accessories

p Food transfer pump (AFF-950-FTP) (required to operate

Cycle-Matic)

p Exiting conveyor for pouches (AFF-950-EC)

p In-line thermal transfer printer (AFF-950-TTP)

p Film transfer/loading car

p 3” diameter food transfer hoses (specify 3, 6 or 9 foot long)

t (AFF-950-FTC)

SECT

.

XIV P

AGE

27

0707

Page 2

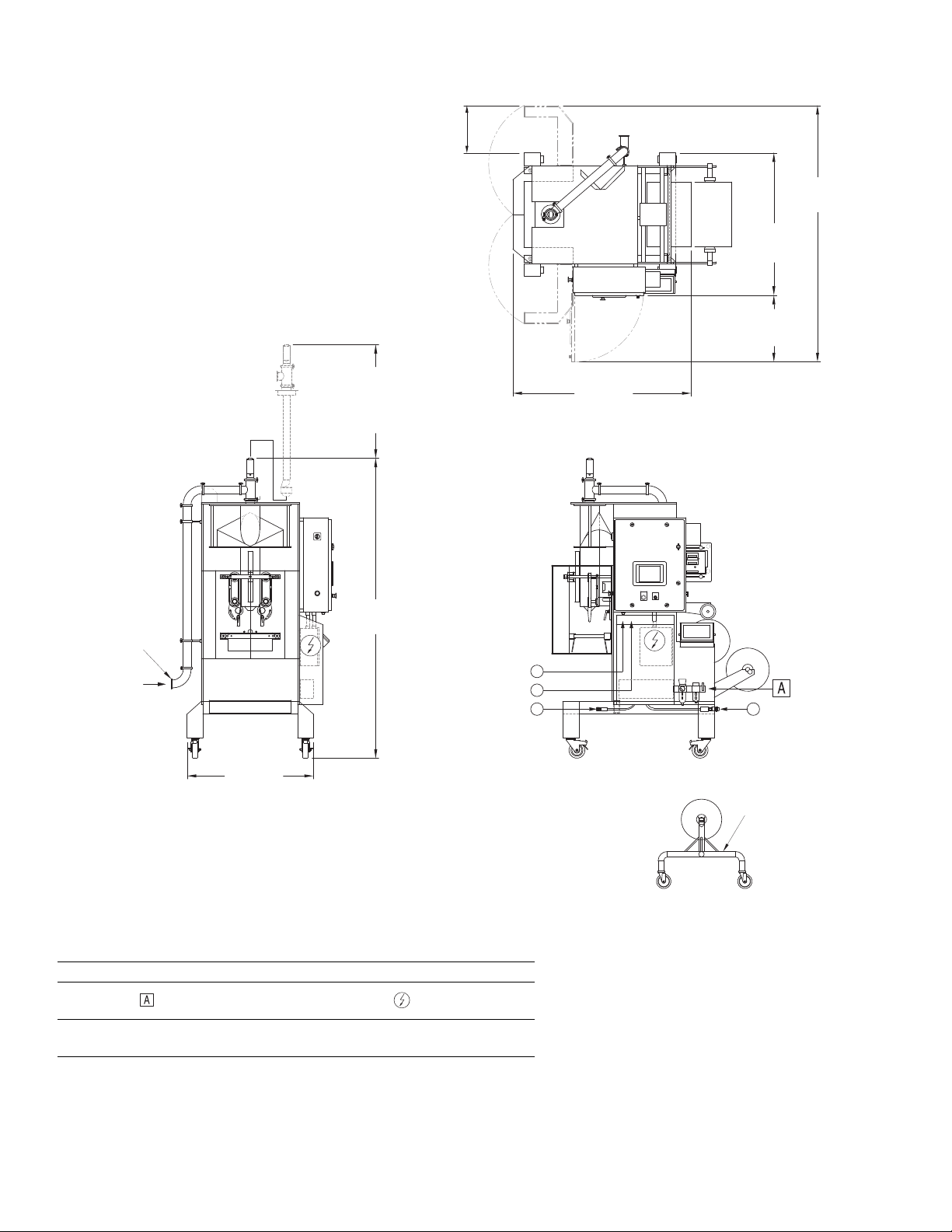

56.50"

1435mm

21.06"

535mm

45.13"

1146mm

95.50"

2426mm

40.00"

1016mm

35.63"

905mm

C

LEARANCE

TO REMOVE

V

ALVE ASSY.

15.00"

3

81mm

8

1.19"

2062mm

PRODUCT

FROM FOOD

TRANSFER

PUMP

2"

TRI-CLAMP

CONN.

OFFOFF

29.75"

(756 mm)

FILM CART

WITH STOCK

FILM ROLL

MUST BE PULLEDMUST BE PULLED

OUT TO RUNOUT TO RUN

PUSH TO STOPPUSH TO STOP

C

ONTROLCONTROL

P

OWERPOWER

OFF ONOFF ON

43

2

1

D

1

D

2

B

D

1 D 2

B

Utilities

MAIN AIR SUPPLY ELECTRICAL

1/2" NPT, 18 CFM AT 85 PSI 208/220V-1PH-60HZ, 25 AMP

OR 30

AMP WITH EXITING CONVEYOR

NOTE: AIR MUST BE DRY, CLEAN AND FREE OF OIL

Cleveland Range reserves right of design improvement or modification, as warranted.

O SCALE)

T

(NOT

SECT. XIV PAGE 28

0707

Litho in USA

Loading...

Loading...