Cleveland AFF-1150-EC Specifications

Cleveland

™

P

roject ________________________________

Item __________________________________

Quantity _______________________________

F

CSI Section ____________________________

A

pproval _______________________________

D

ate __________________________________

1333 East 179 St.,

Cleveland, Ohio, U.S.A. 44110

Tel: 1-216-481-4900

Fax: 1-216-481-3782

Web Site: www.ClevelandRange.com

Email: Steam@ClevelandRange.com

COOK CHILL SYSTEMS

Cook/Chill Systems

EXITING CONVEYOR

FOR USE WITH CYCLE-MATIC VERTICAL

FORM-FILL-SEAL MACHINE

Cleveland Standard Features

I Electrically powered belt Exiting Conveyor with quick

disconnects for the Air and Electrical hookups for use

with the Cycle-Matic Form-Fill-Seal Machine

I Air operated raise and lower, loading end of Exiting

Conveyor for various pouch lengths

I No additional Air or Electric required if used with

Cycle-Matic Form-Fill-Seal Machine

I All stainless steel construction

I Frame mounted on (4) 3" diameter lockable swivel

casters

I 18" wide USDA approved polypropylene belt with rub-

ber inserts

I 1/3 Horse power TEFC motor with drive gearbox

I Variable belt speed controlled from Cycle-Matic Form-

Fill-Seal Machine touch screen

I Exiting Conveyor can operate in either Constant Run or

Timed Run

I Operator start/stop controlled from Cycle-Matic Form-

Fill-Seal Machine touch screen

I Emergency stop at Cycle-Matic Form-Fill-Seal Machine

control panel

I Accepted for use in U.S.D.A. Inspected Facilities

MODEL:AFF-1150-EC

Short Form Specifications

Shall be CLEVELAND Model AFF-1150-EC EXITING CONVEYOR

with; Air operated raise and lower, loading end of Exiting

Conveyor for various bag lengths; All stainless steel construction; Frame mounted on (4) 3" diameter lockable swivel casters;

18" wide USDA approved polypropylene belt with rubber inserts;

1/3 Horse power TEFC motor with drive gearbox; Variable belt

speed and Operator start/stop controlled from Cycle-Matic FormFill-Seal Machine touch screen; Exiting Conveyor can operate in

either Constant Run or Timed Run; Emergency stop at CycleMatic Form-Fill-Seal Machine control panel.

SECT. XIV PAGE 33

0907

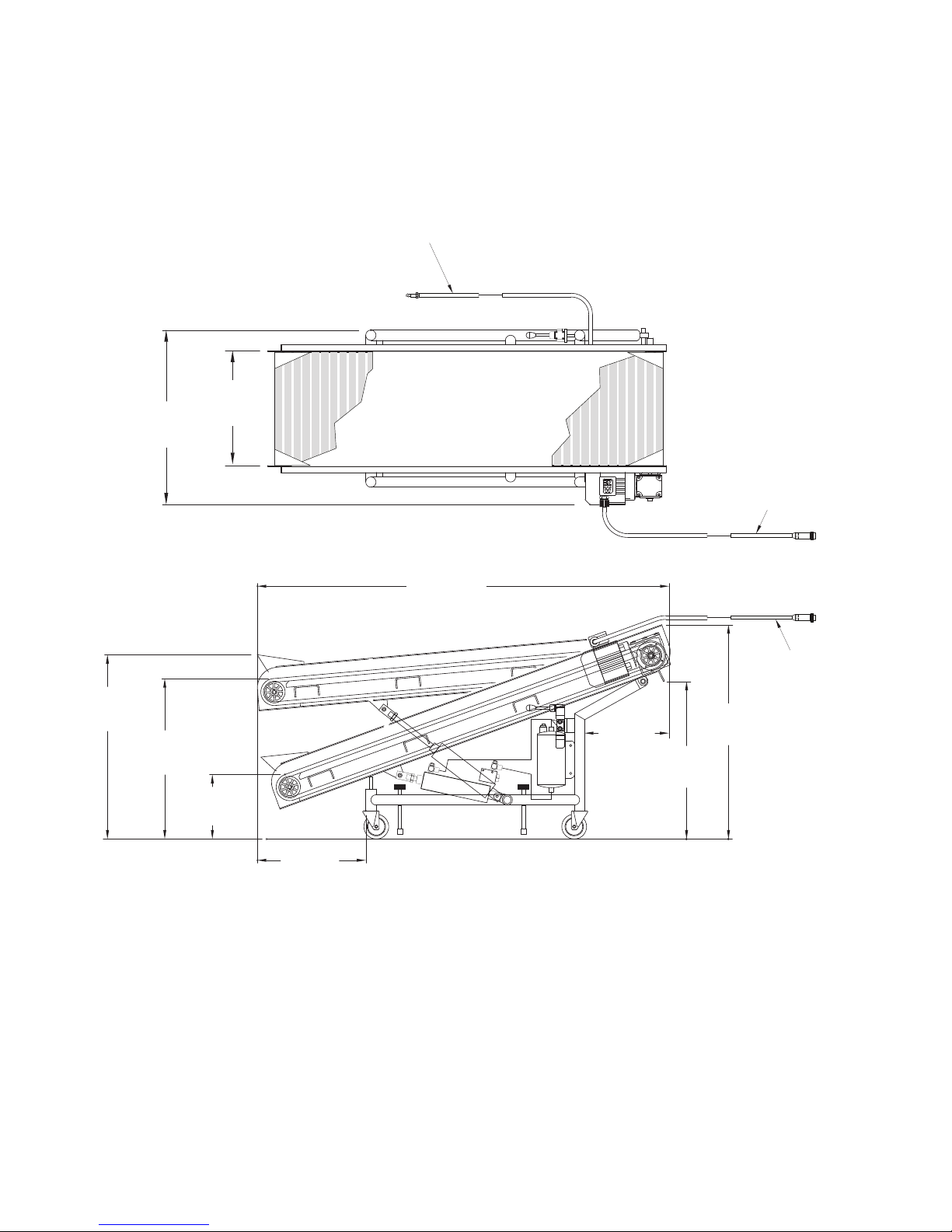

28.00"

711mm

18.00"

457mm

MOTOR POWER

CABLE TO

AFF-1150 CONTROL PANEL

NO EXTRA POWER

REQUIRED

MOTOR POWER

CABLE TO

AFF-1150

CONTROL BOX

NO EXTRA AIR

REQUIRED

AIR SUPPLY HOSE

TO AFF-1150

85 PSI MAX

A

IR SUPPLIED FROM CYCLEMATIC

NO EXTRA AIR REQUIRED

8.25" MIN.

(210mm)

25.50" MAX.

(648 mm)

29.75"

(756 mm)

66.25"

1683mm

25.25"

641mm

13.25"

337mm

17.50"

438mm

33.75"

857mm

Cleveland Range reserves right of design improvement or modification, as warranted.

(NOT TO SCALE)

SECT. XIV PAGE 34

0907

Litho in USA

Loading...

Loading...