Cleveland 9-PCDM-L Service Manual

CLEVELAND

SteamPro™ XVI

PRESSURE / CONVECTION

STEAMER

OWNERS

MANUAL

Models: 9-PCEM -48-L

9-PCGM -250-L

9-PCGM -300-L

9-PCDM -L

9-PCSM -L

R

e

v

.

1

P

{

r

Printed 01/90

PCS-02

Cleveland ALCO

PUBLICATION IMPROVEMENT RECOMMENDATION

Users of this publication are encouraged to report errors, omissions and

their recommendations for improving the publication. This sheet is

provided for that purpose. To file a Publication Improvement

Recommendation, fill in the information requested below, fold, tape and

mail this prepaid business reply form.

This Publication Improve ment

Recommendation pertains to manual __________________________ _____________

__________________________ Publication Date

of Manual

The following information Installation

was discovered during: (check one) Other (specify)__________________

Recommendation:_____________________________________________

(Be specific by referencing your remarks to page numbers, step numbers, etc.)

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

__________________________________________________________________________________________

(Continue on back if needed)

Your name _____________________________________

(Please print)

Service office ___________________________________

(City) (State)

Telephone _____________________________________

(Area code) (Number)

TABLE OF CONTENTS

Specification Information Page

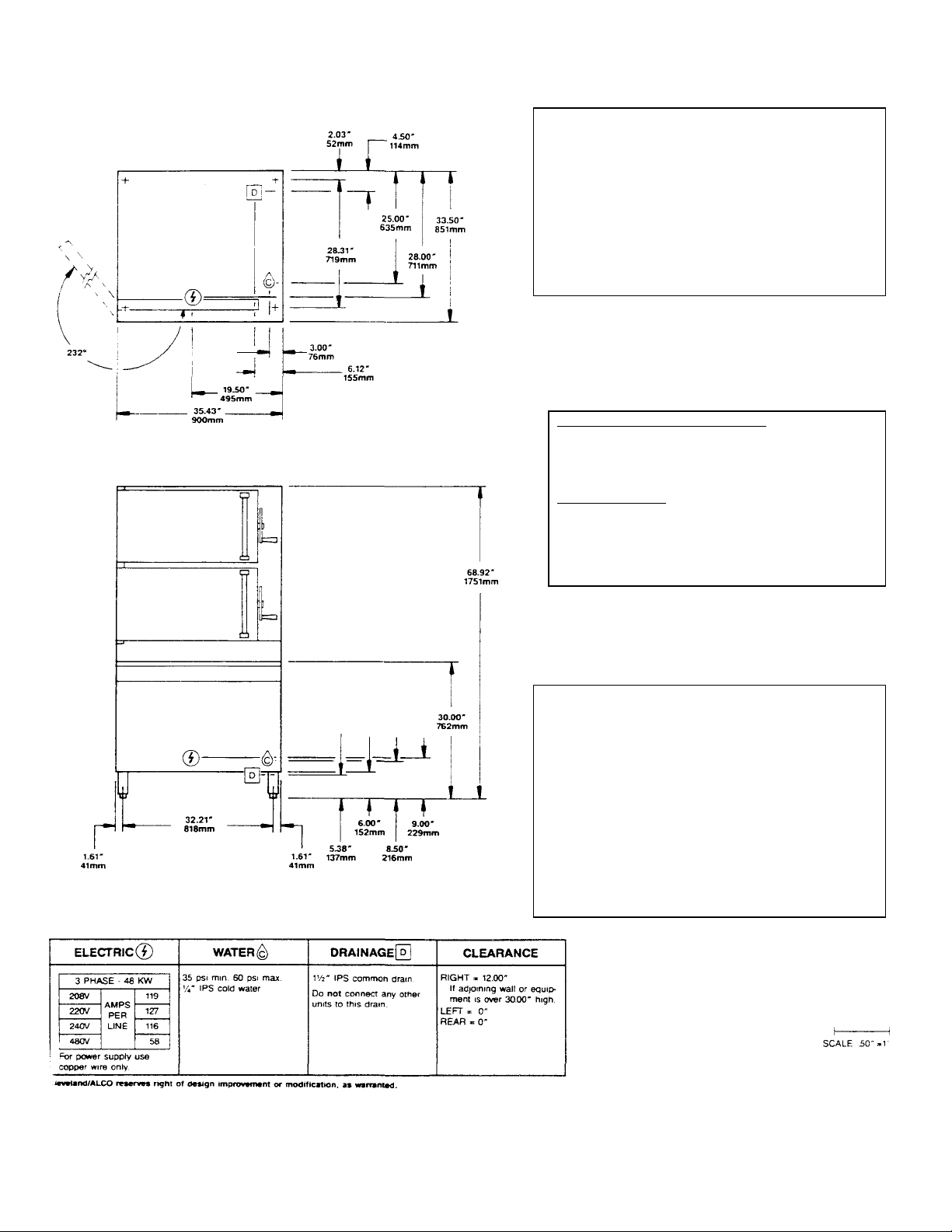

9-PCEM-L (Electric) 3-4

9-PCGM-L (Gas) 5-6

9-PCDM-L (Direct Steam) 7-8

9-PCSM-L (Steam Coil) 9-10

Inspection and Unpacking 11

Installation Instructions 11

Installation Policies 11

Installation Ins tructions for all models 11-13

Installation Check 13

Introduction to SteamPro XVI Ownership 14

Operational Safety 14-15

Operational Functions 15-17

Control Panel Overview 16-17

Timer Information 16-17

Timer Programming 17

Timer Bypass

Operating Mode Selection

Basic Sequence of Operation 17-18

Start-Up and Preheat 18-19

Steaming Operation 19

Preventative Maintenance 20-21

Steamer Timer Programming Guide 22-23

Parts Breakdown 24-38

Electrical Wiring Diagram 39-40

Maintenance and Repair Center Information 41

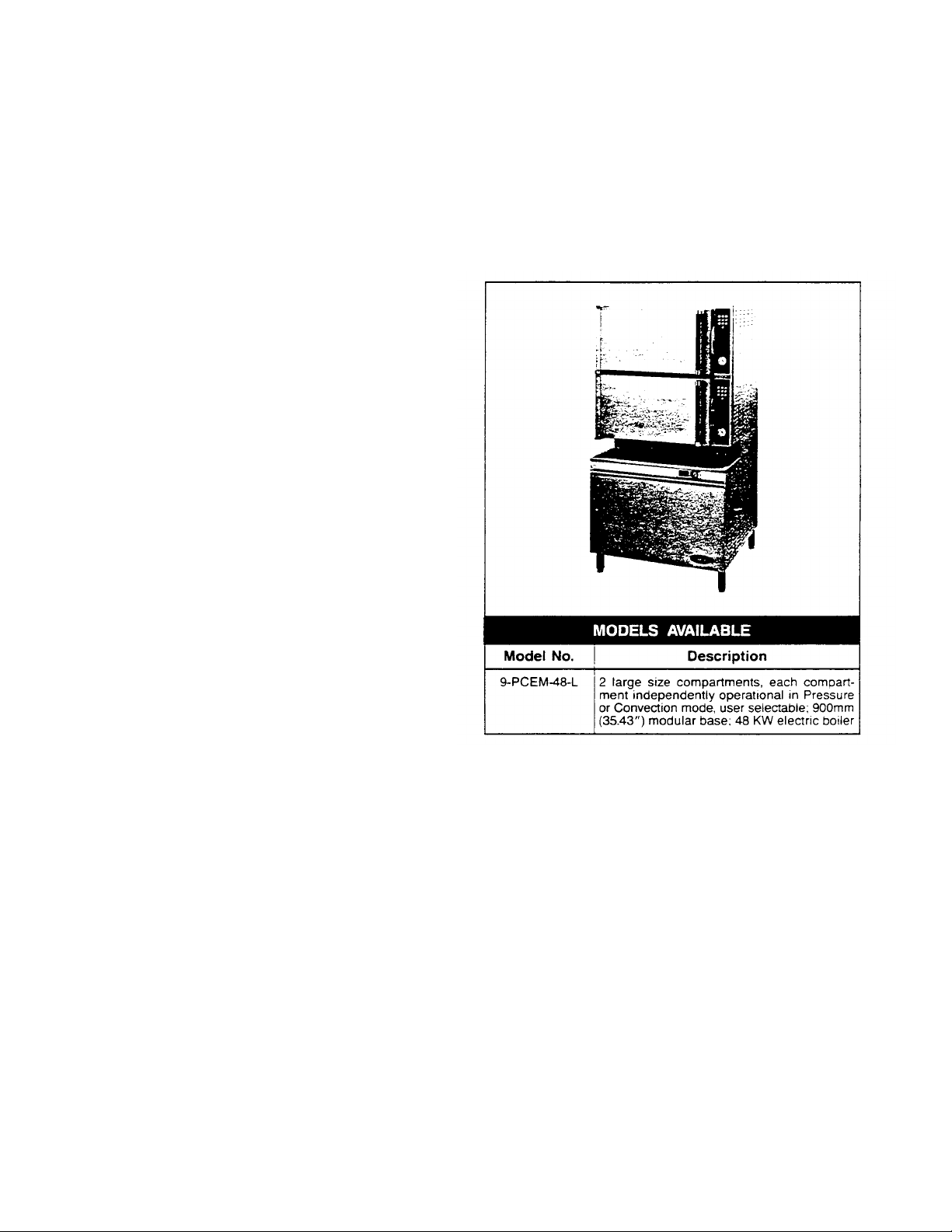

SteamPro® XVI

PRESSURE/CONVECTION STEAMER MODEL: 9-PCEM -48-L

• TWO LARGE COMPARTMENTS

• ELECTRIC STEAM GENERATOR

48 KW

• 900mm CABINET BASE

General Specifications:

• Pressure or Convection steam cooking. Each compartment

independently operational in Pressure or Convection mode,

user selectable

• In Convection mode, cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for safety

• Solid state, digital timer with wipe clean touch control panel:

one per compartment, each with 99 minute capacity plus

selectable "Repeat Cycle" feature

• High speed cooking with 10 psi operating pressure

• Standard voltage is 208V, 60 Hz, 3 phase, 3 wire

• Automatic temperature compensated timing action for

consistent product results

• Alternate manual operation mode (Convection only)

• "Clean Cove" corners in cooking compartments — easy to

clean

• Solid state controls for boiler and steam flow

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors,

table top

• Exterior sheathing is type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, all boiler controls and components, compartment drain lines and steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

(none furnished standard)

• Single cold water connection

• Boiler empties under pressure (blows down) automatically

upon each shut -down, automatic water fill upon start-up —

single button control*

• Standard control panel languages are English, French and

Spanish

ITEM NUMBER

JOB NAME / NUMBER__________________________________

———————————————

Options and Accessories:

"California Code" boiler controls compliance kit factory

installed. Single button control replaced by two button

controls

Voltages other than standard a

Cooking pans

8", 10" or 12" adjustable legs

Stainless Steel base frame (FSS)

3.

SHORT FORM SPECIFICATION

Shall be Two Compartments, CLEVELAND Pressure/

Convection Steamer, electric generator, Model 9-PCEM-48L, 48 KW Electric; ___volts, ___Hz, __phase, 3 wire.

Pressure/Convection modes to be selectable at user's option

with no restrictions as to any combination of modes. Type

304 Stainless Steel exterior paneling and cooking

compartments. Insulated compartments. One solid state, 99

minute digital timer with touch control per compartment.

Audible and visual signals for cycle completion and steam

shut-off. Separate visual indication for each operational

mode.

•Each compartment has capacity for:

Eight, 12" x 20" x 2 1/2" pans. Can accommodate

18" x 26" bun pans.

• Many local codes exist and it is the responsibility of the

owner and installer to comply with those codes.

•Cleveland/ALCO equipment is built to comply with

applicable standards for manufacturers. Included among

those approval agencies are: UL, A.G.A., NSF,

ASME/N.Bd., CSA, CGA, ETL, and others.

The recommended minimum water quality standards

whether untreated or pre-treated, based upon 10 hours of

use per day, and a Daily Slowdown, are as follows:

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than13 parts per million

pH FACTOR greater than 75

Consult a local water treatment specialist for an on site

water analysis for recommendations concerning steam

generator feed water treatment (if required), in order to

remove or reduce harmful concentrations of minerals. The

use of highly mineralized water will mean that more frequent

servicing of the steam generator will be necessary. The fact

that a water supply is potable is not proof that it will be

suitable for the generator.

WATER QUALITY REQUIREMENT

4.

SteamPro® XVI

PRESSURE/CONVECTION STEAMER

• TWO LARGE COMPARTMENTS

• GAS STEAM GENERATOR

250 or 300M BTU

• 900mm CABINET BASE

General Specifications:

• Pressure or Convection steam cooking. Each compartment

independently operational in Pressure or Convection mode,

user selectable

• In Convection mode. cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for safety

• Solid state, digital timer with wipe clean touch control panel,

one per compartment, each wit h 99 minute capacity plus

selectable "Repeat Cycle" feature

• Automatic temperature compensated timing action for

consistent product results

• Alternate manual operation mode (Convection only)

• "Clean Cove" corners in cooking compartments — easy to clean

• Solid state controls for boiler and steam flow

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors, table top

• Exterior sheathing is type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, all boiler controls and components, compartment drain lines and steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

• Single cold water connection

• Boiler empties under pressure (blows down) automatically

upon each shut -down, automatic water fill upon start-up —

single button control.'

• Standard control panel languages are English, French and

Spanish

• Electronic spark ignition

MODELS: 9-PCGM-250-L

9-PCGM-300-L

ITEM NUMBER___________________________

JOB NAME / NUMBER______________________

Options and Accessories:

* "California Code" boiler controls compliance kit factory

installed. Single button control replaced by two button

controls

Gas other than natural

Cooking pans

8", 10" or 12" adjustable legs

Stainless Steel base frame (FSS)

5.

NATURAL

PROPANE

1” IPS for

Used above 2,000 ft. altitude.

SHORT FORM SPECIFICATION

•Each compartment has capacity for:

Shall be Two Compartments, CLEVELAND Pressure/

Convection Steamer, gas generator, Model 9-PCGM ____-L,____Gas,___volts,___Hz,___phase.

Pressure/Convection modes to be selectable at user's

option with no restrictions as to any combination of

modes. Type 304 Stainless Steel exterior paneling and

cooking compartments. Insulated compartments. One

solid state, 99 minute digital timer with touch control per

compartment. Audible and visual signals for cycle

completion and steam shut-off. Separate visual indication

for each operational mode.

Eight, 12" x 20" x 2W pans. Can accommodate 18" x

26" bun pans.

•Many local codes exist and it is the responsibility of the

owner and installer to comply with those codes.

•Cleveland/ALCO equipment is built to comply with

applicable standards for manufacturers. Included among

those approval agencies are UL, A.G.A., NSF,

ASME/N.Bd., CSA, CGA, ETL, and others.

WATER QUALITY REQUIREMENT

The recommended minimum water quality standards

whether untreated or pre-treated, based upon 10

hours of use per day, and a Daily Blowdown, are as

follows:

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

pH FACTOR greater than 7.5

Consult a local water treatment specialist for an onsite

water analysis for recommendations concerning

steam generator feed water treatment (if required),

in order to remove or reduce harmful concentrations of

minerals. The use of highly mineralized water will mean

that more frequent servicing of the steam generator will be

necessary. The fact that a water supply is potable is not

proof that it will be suitable for the generator.

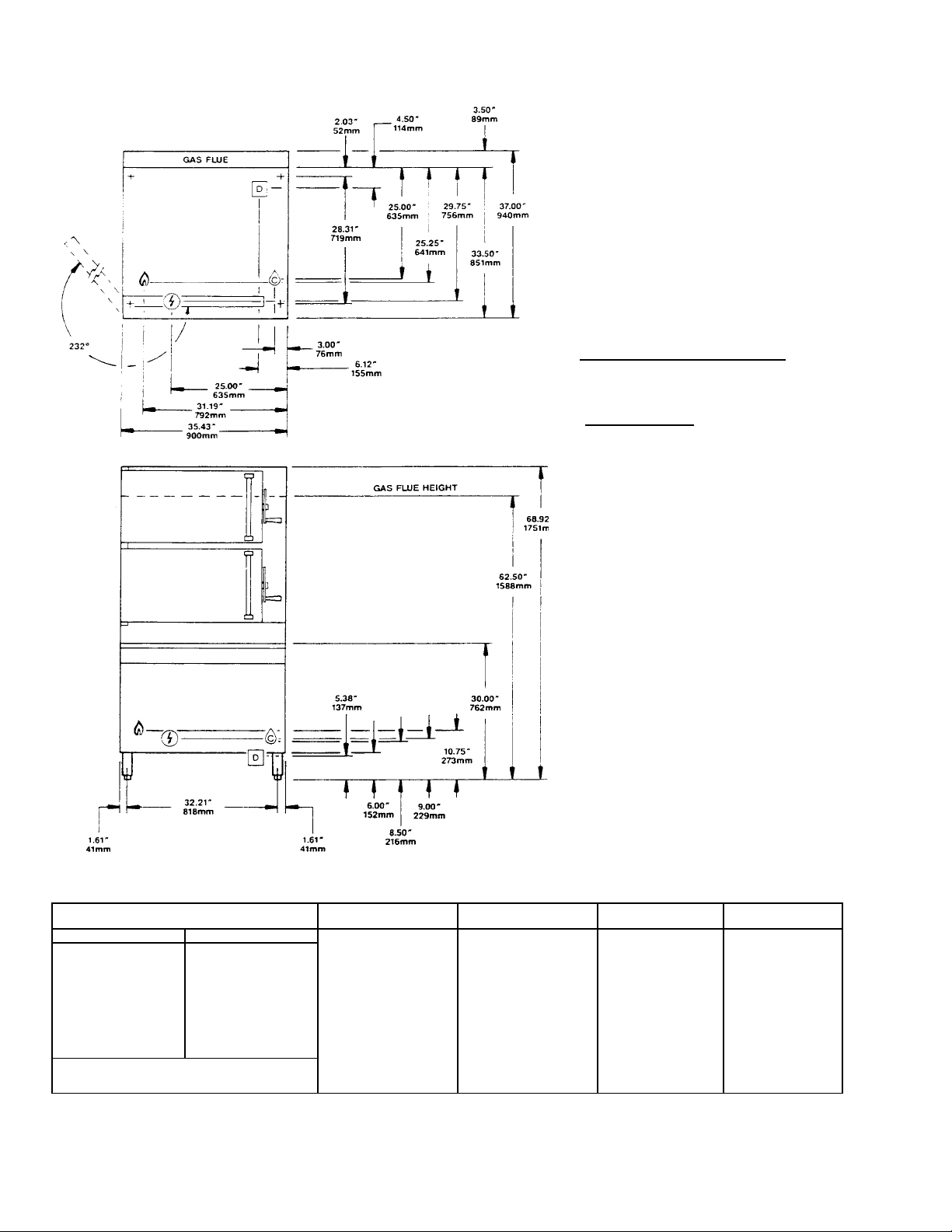

GAS ELECTRIC WATER DRAINAGE CLEARANCE

Piping-1” IPS for

240,000 BTU or more.

Supply pressure

4.00” W.C. Min.

14.00” W.C. Max.

Manufacturer must be notified if unit is to be

Cleveland/ALCO reserves right of design improvement or modification as warranted.

Piping-

Supply pressure

12.00” W.C. Min.

14.00” W.C. Max

240,000 BTU

or more.

115V-1 PH 25

watts per Compartment.

50 watts boiler control.

35 psi min. 60 psi max.

'/4” - IPS cold water

6.

1 1/2" IPS common

drain.

Do not connect any

other units to this

drain.

RIGHT = 12"

If adjoining wall or

equipment is over

30.00" high.

LEFT = 0"

REAR = 0"

For use only in

non-combustible

locations

SteamPro™

XVI

PRESSURE/CONVECTION STEAMER

DIRECT STEAM

TWO LARGE COMPARTMENTS

900mm CABINET BASE

General Specifications:

• Pressure or Convection cooking, selected by the user, can be

in any combination at the same time, no restrictions

• In Convection mode, cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for sa fety

• Solid state, digital timer with wipe clean touch control panel,

one per compartment, each with 99 minute capacity plus

selectable "Repeat Cycle" feature

• High speed cooking with 10 psi operating pressure

• Automatic temperature compensated timing action for

consistent product results

• Alternate manual operation mode (Convection only)

• "Clean Cove" corners in cooking compartments — easy to

clean

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors, table

top

• Exterior sheathing is Type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, compartment drain lines and

steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

(none furnished standard)

• Single cold water connection

• Standard control panel languages are English, French, and

Spanish

A Clean, non-toxic, uncontaminated steam is required at the

steamed

MODEL: 9-PCDM-L

Options and Accessories:

Reversed door opening: hinges at right, controls on

left

Cooking pans

8", 10" or 12" adjustable legs

Stainless steel base frame (FSS)

7.

Shall be Two Compartments, CLEVELAND, Pressure/

SHORT FORM SPECIFICATION

Convection Steamer, direct steam, Model 9-PCDM-L,

Pressure/Convection modes to be selectable at user's

modes. Type 304 Stainless Steel exterior paneling

and cooking compartments. Insulated compartments.

One Solid state, 99 minute digital timer with touch

control per compartment. Audible and visual signals

for cycle completion and steam shut -off. Separate

visual indication for each operational mode.

•Each compartment has capacity for:

Eight, 12" x 20" x 2 1/2" pans. Can accommodate

18" x 26" bun pans.

•Many local codes exist and it is the responsibility of

the owner and installer to comply with those codes.

•Cleveland/ALCO equipment is built to comply with

applicable standards for ma nufacturers. Included

among those approval agencies are: UL, A.G.A.,

NSF, ASME/N.Bd., CSA, CGA, ETL, and others.

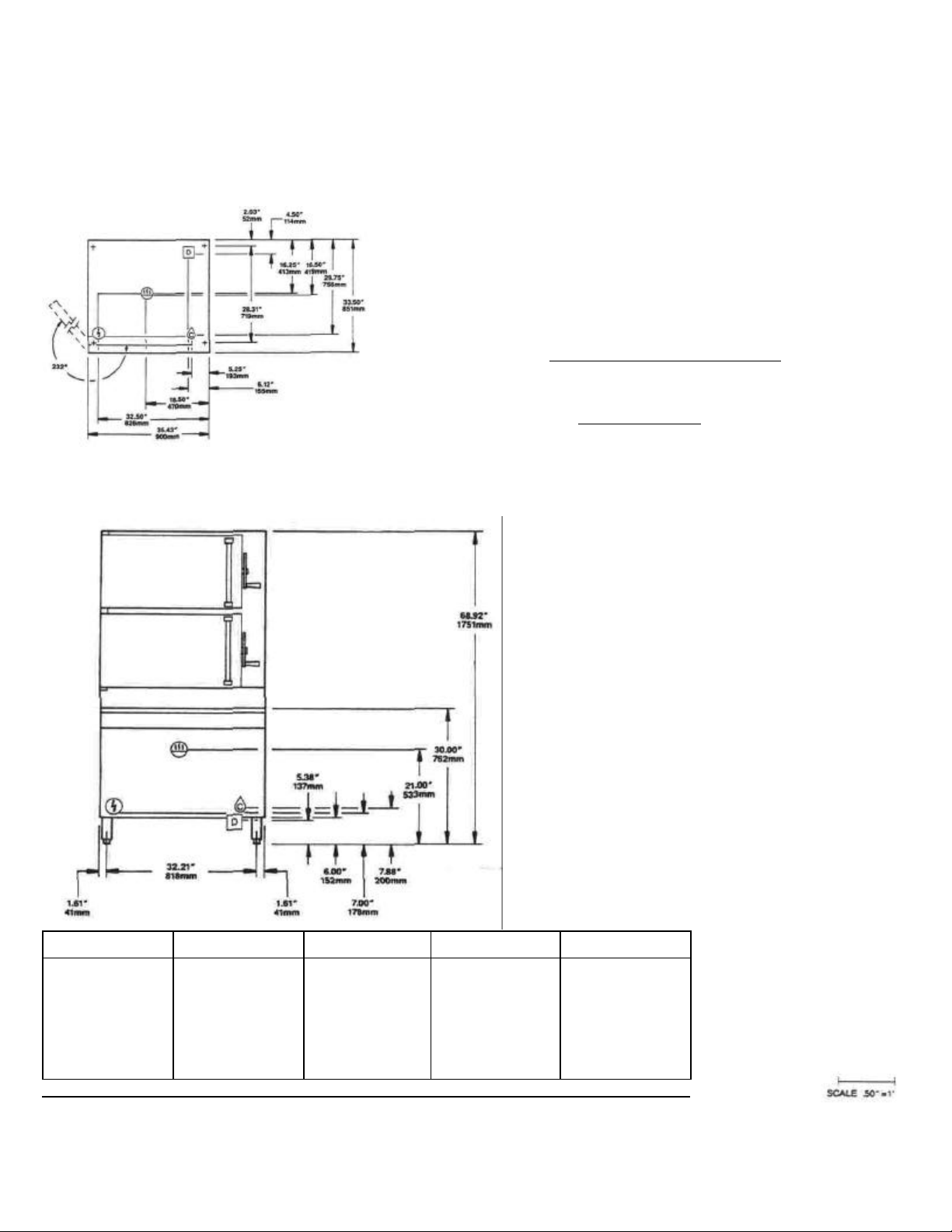

DIRECT STEAM WATER (C) DRAINAGE (D) ELECTRIC® CLEARANCE

Steam Supply:

Furnish 3/4" IPS mm.

line. 40 psi mm. SO psi

max. required, for

pressures above 50 psi.

an additional pressure

reducing valve must be

specified.

Cleveland/ALCO reserves right of design improvement Of modification — warranted

40 psi min. 60 psi max.

3/8 IPS cold water

1 1/2" IPS common

drain.

Do not connect any

other units to this drain.

115V-1PH 25 watts per

compartment

RIGHT - 12.00"

If adjoining wall or equipment is over 30.00" high.

LEFT = 0"

REAR = 0"

8.

SteamPro® XVI

PRESSURE/CONVECTION STEAMER

• TWO LARGE COMPARTMENTS

• STEAM COIL GENERATOR

• 900mm CABINET BASE

General Specifications:

• Pressure or Convection steam cooking. Each compartment

independently operational in Pressure or Convection mode,

user selectable

• In Convection mode, cooking compartment operates without

pressure, permitting door to be opened while cooking

continues

• In Pressure mode, door is locked and sealed

• At any time a compartment becomes pressurized, door will

automatically lock for safety

• 10 psi operating pressure in Pressure mode

• Solid state, digital timer with wipe clean touch control panel,

one per compartment, each with 99 minute capacity plus

selectable "Repeat Cycle" feature

• Automatic temperat ure compensated timing action for

consistent product results

• "Clean Cove" corners in cooking compartments — easy to

clean

• Solid state controls for boiler and steam flow

• 15 psi safety valve

• Insulated cooking compartments

• Type 304 Stainless Steel: cooking compartments, doors, table top

• Exterior sheathing is type 304 Stainless Steel, #4 finish

• Four Stainless Steel legs with level adjustment

• Serviceable from the front: solid state timers, electrical

controls and components, all boiler controls and components, compartment drain lines and steam injection tubes

• Capacity for either 12" x 20" pans or 18" x 26" bun pans

• Single cold water connection

• Boiler empties under pressure (blows down) automatically

upon each shut -down, automatic water fill upon start-up

• Standard control panel languages are English, French, and

Spanish

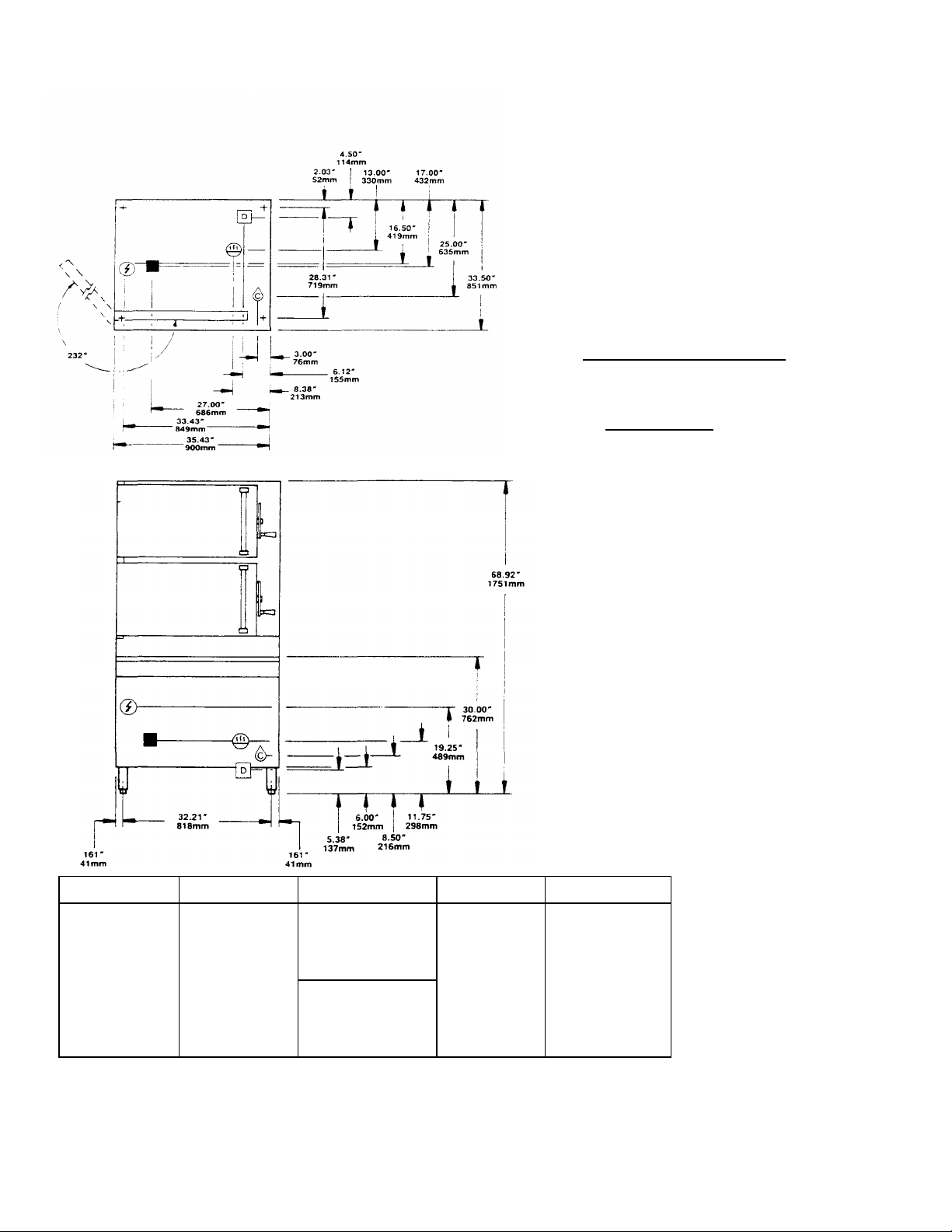

MODEL: 9-PCSM-L

ITEM NUMBER________________________________________

JOB NAME / NUMBER__________________________________

Options and Accessories:

"California Code" boiler controls compliance kit factory

installed.

Voltages other than standard (115V)

Cooking pans

Stainless steel base frame (FSS)

8", 10" or 12" adjustable legs

9.

ing

Cleveland/ALCO reserves right of design improvement or modification, as warranted.

SHORT FORM SPECIFICATION

Scale .

50

"=1’

Shall be Two Compartments, CLEVELAND Pressure/

Convection Steamer, steam coil generator, Model 9PCSM -L, 115 volts, 60 Hz, 1 phase. Pressure/Convection

modes to be selectable at user's option with no restrictions

as to any combination of modes. Type 304 Stainless Steel

exterior paneling and cooking compartments. Insulated

compartments. One solid state, 99 minute digital timer with

touch control per compartment. Audible and visual signals

for cycle completion and steam shut-off. Separate visual

indication for each operational mode.

• Each compartment has capacity for:

Eight, 12” x 20” x 2 ½” pans.

• Many local codes exist and it is the responsibility of

the owner and installer to comply with those codes.

• Cleveland/ALCO equipment is built to comply with

applicable standards for manufactures. Included

among those approval agencies are: UL, A.G.A.,

NSF, ASME/N.Bd., CSA, ETL, and others.

WATER QUALITY REQUIREMENT

The recommended minimum water quality standards whether

untreated or pre-treated, based upon 10 hours of use per day,

and a Daily Slowdown, are as follows:

TOTAL DISSOLVED SOLIDS less than 60 parts per million

TOTAL ALKALINITY less than 20 parts per million

SILICA less than 13 parts per million

pH FACTOR greater than 7.5

Consult a local water treatment specialist for an onsite

water analysis for recommendations concerning steam

generator feed water treatment (if required), in order to

remove or reduce harmful concentrations of minerals. The use

of highly mineralized water will mean that more

frequent servicing of the steam generator will be necessary.

the fact that a water supply is potable is not proof that it will be

suitable for the generator.

STEAM COIL WATER DRAINAGE ELECTRIC CLEARANCE

Steam Supply

Piping: • ¾” IPS

min. for 35 to 50 psi.

• For pressure

above 50 psi, a

pressure reduc

valve must be

specified.

35 psi. min. 60 psi ©

max. 3/8" IPS cold

water.

1 ½” IPS common

drain.

Do not connect any

other units to this drain.

Steam Cold Drain

•3/4” IPS. Do not

connect to common

drain.

115V-1 PH

25 watts per

compartment.

RIGHT - 12.00"

If adjoining wall or

equipment is over

30.00" high.

LEFT = 0”

REAR =0”

10.

INSPECTION

Before unpacking, visually inspect the shipping carton for evidence of any damage during shipment. It there are signs of

possible damage, do not unpack the equipment Notify the carrier that delivered the shipment so the carton and its contents can

be examined for any damage claims. Fill out all appropriate forms and have the examining carrier sign and date each form. Do

not install damaged equipment.

UNPACKING

1. If the shipping carton has no signs of possible damage, unpack the equipment. To remove the unit from the carton. it is

easiest to slit the carton in 4 corners and "peel" it away from the steamer. After removing the carton, examine the steamer

for signs of possible damage If damage exists, detail your observations on a claims form and give to the shipper (keep a

copy for your records).

2. If the equipment is undamaged, lif t the unit to the counter top or stand where it is to be installed. Damaged equipment

should not be installed.

INSTALLATION INSTRUCTIONS

Warning: Installation of this unit must be done by qualified plumbing and electrical installation personnel working to all

applicable local and national codes. Improper installation of this product could cause injury or damage and void customer

warranty.

INSTALLATION POLICIES:

• Cleveland/ALCO equipment is designed and manufactured to comply with applicable standards for manufacturers. Included

among those certification agencies which have approved the safety of the equipment design and construction are:

UL NSF, CSA, and others.

• Cleveland/ALCO equipment is designed and certified for safe operation only when permanently installed in accordance with

local and/or national codes. Many local codes exist, and it is the responsibility of the owner and installer to comply with these

codes.

• In no event shall Cleveland/ALCO assume any liability for damage or injury resulting from installations which are not in strict

compliance with our Installation Instructions. Specifically, Cleveland/ALCO will not assume any liability for damage or injury

resulting from improper installation of equipment, including, but not limited to, temporary or mobile installations.

INSTALLATION INSTRUCTIONS FOR ALL MODELS:

WARNING INSTALLER: ALL SteamPro XVI units MUST BE securely anchored to the floor at all times.

1. These instructions must be retained by the owner/user for future reference. Gas-fired boilers are only to be

installed in noncombustible areas that have provisions for adequate air supply. The term "boiler" will be used

synonymously with "steam generator".

2. Position: For proper operation and drainage, the equipment must be level. It should be placed next to an open floor

drain. DO NOT POSITION THE UNIT DIRECTLY ABOVE THE FLOOR DRAIN. Observe all clearance

requirements to provide air supply for proper operation, as well as sufficient clearance for servicing. The

surrounding area must be free and dear or combustibles. Dimensions and clearance specifications for each model

are shown on the specification sheets enclosed.

3. Inst all in accordance with local codes and/or the National Electrical Code ANS1/NFPA No. 70-1984. Installation in

Canada must be in accordance with the Canadian Electrical Code CSA Standard C22-1. Equipment that Is

connected to electricity must be grounded by the installer A wiring diagram Is provided inside the base cabinet.

4. Attach drain extension piping to the drain connection to carry steam condensate and boiler drain water away from

the cabinet, to the floor drain. The drain extension piping must be 1 1/ 2" diameter minimum (ips), and not exceed

6 feet in length, with no more than two elbows, before draining. The drain extension termination MUST vent freely

to the air (not plumbed solidly into the floor drain). Each unit requires its own 1 1/2" diameter drain extension. Do

not interconnect any other drains to this units drain extension. Ensure that the boiler's manual drain valve is

closed.

11.

5. Connect COLD water supply plumbing to the line strainer. (Never connect hot water to the boiler's water fill line

strainer). Constant flow pressure must be maintained between 40 and 60 psi. and not experience a pressure drop

below 35 psi when other appliances are used. If the water pressure exceeds 60 psi, a pressure reducing valve must

be installed in the water supply plumbing to reduce the water pressure to less than 60 psi. Locations and pressure

data are shown on the specification sheet. 3/8" ips plumbing is required for water supply lines regardless of length.

Rush water supply lines thoroughly before connecting them to the unit Use water which Is low in total dissolved

solids content and low in gas content to prevent Internal scaling, pitting and corrosion of the steam generator and

carry-over of minerals into the steam. (Water which is fit to drink can still contain highly detrimental impurities.)

6. Turn on the cold water supply to the unit. Ensure that the manual water valve, inside the base cabinet, is open.

7. Connect the primary fuel supply in accordance with the following instructions. Location and other data are shown on

the specification sheet.

For Gas-Fired Steam Generators:

Post, in a prominent location. Instructions to be followed In the event the user smells gas. This information shall be

obtained by consulting the local gas supplier. Install as a sediment trap (drip leg) in the gas supply line, then connect

gas supply piping to the boiler's gas valve piping. GAS-FIRED EQUIPMENT IS DESIGNED FOR INSTALLATION

ONLY IN NON-COMBUSTIBLE LOCATIONS. Location, plumbing size, and pressure data Is shown on the specification

sheet. Boilers rated at less than 225.000 BTU require 3/4" ips gas supply piping, and boilers rated at 225,000 BTU

or more require 1" gas supply piping. Natural gas supply pressure must be between 4"-14" water column and LP gas

supply pressure must be between 12" -14" water column. NEVER EXCEED 14" WATER COLUMN (1/2 psi) GAS

PRESSURE. If the gas supply pressure ex ceeds 14" water column a pressure regulating valve must be installed in

the gas supply plumbing to reduce the gas pressure to less than 14" water column. Installation must be In accordance with

local codes or in the absence of local codes, with the National Fuel Gas Code, ANSlZ223.1-1984. Installation in

Canada must be in accordance with Installation Codes for Gas Burning Appliances and equipment B149.1 and

Bl49.2-Use a gas pipe Joint compound which is resistant to LP gas. Turn the gas valve's control knob to "on" (the

word "on" on the knob will be opposite the Index on the valve's body). Test all pipe joints for leaks with soap and

water solution. New obstruct the flow or combustion and ventilation air. Observe clearance requirements to provide

adequate air openings into the combustion chamber. The appliance and its individual shut off valve must be

disconnected from the gas supply piping system during any pressure testing of that system at test pressures in

excess of 1/2 pri (14" water column or 3.45 kPa). The appliance must be isolated from the gas supply piping system

at test pressures equal to or less than 1/2 psi (14" water column or 3.45 kPa). A permanent 115 volt electrical

connection is required at the Junction box. Location shown on the specification sheet. The unit must be electrically

grounded by the installer.

For Electric Powered Steam Generator's

Connect electric power location and data are shown on the specification sheet Provide connection as required

by your unit; either directly to the single contactor, or to the terminal block (when equipped with mutiple contactors).

Electric supply must match power requirements specified on the data plate inside the base cabinet. The copper

wiring must be adequate to carry the required current at the rated voltage. A separate fused disconnect switch must

be supplied and Installed. The unit must be electrically grounded by the installer.

For Direct-Steam-Connected Steamers:

Connect steam supply piping to the input side or the line strainer. Location and pressure data are shown on the

specification sheet Flush the steam line thoroughly before connecting it to the steamer ensure an adequate volume

or steam, the branch steam supply line must be 3/4" ips minimum. A permanent 115 volt electrical connection is

required at the junction box. The junction box location is shown on the specification sheet. The unit must be

electrically grounded by the installer.

8. Press the "power" on-off rocker switch. The red indicator light in the switch will come on and the boiler will begin to fill

with water. Direct-Steam-Connected steamers are not equipped with self -generating, boilers or "steam" switches.

Therefore, these models do not require the 5 minute boiler water fill time, nor is it necessary to push a "steam"

switch to produce steam, as Indicated In step #9. As soon as the pressure gauge on the control panel registers 10

psi (5 psi for pressure steamers), preheating may begin. (If you are operating a direct steam-connected steamer,

steps #9 and #10 do not apply. Refer directly to step #11.)

9. After about five minutes the amber light in the "steam" switch will glow indicating the water has reached a safe

operating level in the boiler. The "steam" switch can now be pressed (momentarily) in order to produce steam in the

boiler. This will activate the energy source (electric heaters, gas burners, or steam solenoid valve), and

12.